DAEWOO LACETTI 2004 Service Repair Manual

Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1051 of 2643

FRONT DISC BRAKES 4D – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

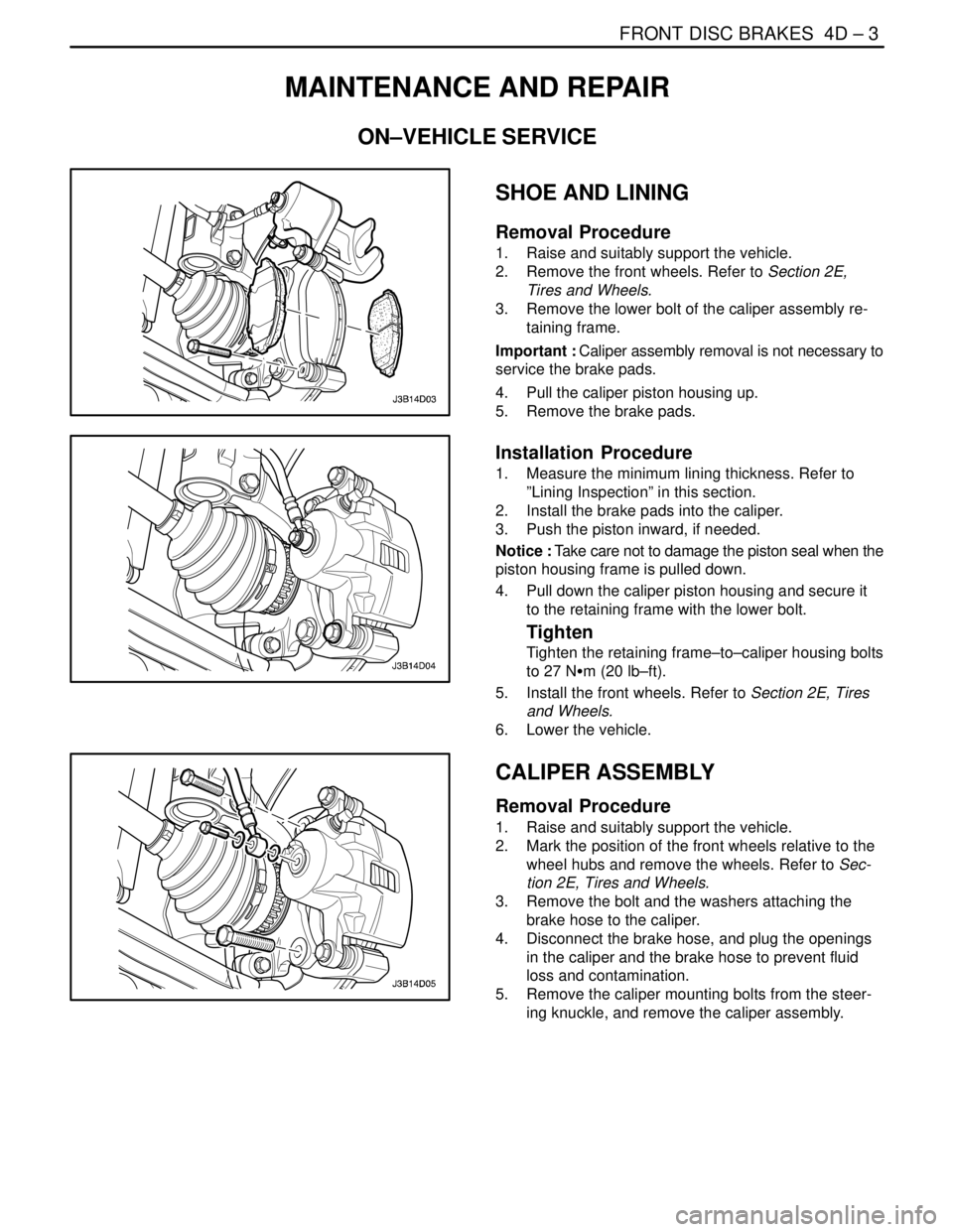

SHOE AND LINING

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the front wheels. Refer to Section 2E,

Tires and Wheels.

3. Remove the lower bolt of the caliper assembly re-

taining frame.

Important : Caliper assembly removal is not necessary to

service the brake pads.

4. Pull the caliper piston housing up.

5. Remove the brake pads.

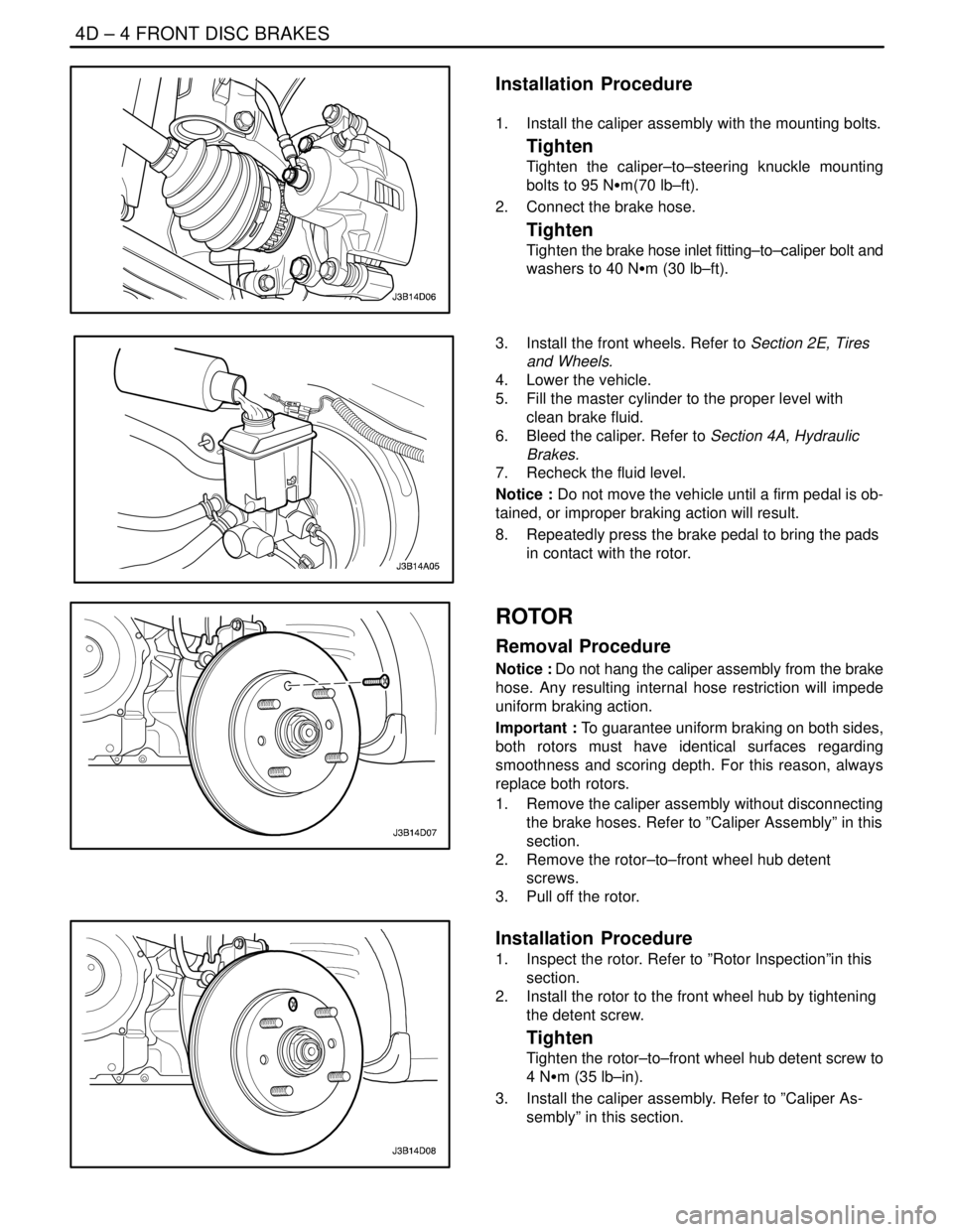

Installation Procedure

1. Measure the minimum lining thickness. Refer to

”Lining Inspection” in this section.

2. Install the brake pads into the caliper.

3. Push the piston inward, if needed.

Notice : Take care not to damage the piston seal when the

piston housing frame is pulled down.

4. Pull down the caliper piston housing and secure it

to the retaining frame with the lower bolt.

Tighten

Tighten the retaining frame–to–caliper housing bolts

to 27 NSm (20 lb–ft).

5. Install the front wheels. Refer to Section 2E, Tires

and Wheels.

6. Lower the vehicle.

CALIPER ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Mark the position of the front wheels relative to the

wheel hubs and remove the wheels. Refer to Sec-

tion 2E, Tires and Wheels.

3. Remove the bolt and the washers attaching the

brake hose to the caliper.

4. Disconnect the brake hose, and plug the openings

in the caliper and the brake hose to prevent fluid

loss and contamination.

5. Remove the caliper mounting bolts from the steer-

ing knuckle, and remove the caliper assembly.

Page 1052 of 2643

4D – 4IFRONT DISC BRAKES

DAEWOO V–121 BL4

Installation Procedure

1. Install the caliper assembly with the mounting bolts.

Tighten

Tighten the caliper–to–steering knuckle mounting

bolts to 95 NSm(70 lb–ft).

2. Connect the brake hose.

Tighten

Tighten the brake hose inlet fitting–to–caliper bolt and

washers to 40 NSm (30 lb–ft).

3. Install the front wheels. Refer to Section 2E, Tires

and Wheels.

4. Lower the vehicle.

5. Fill the master cylinder to the proper level with

clean brake fluid.

6. Bleed the caliper. Refer to Section 4A, Hydraulic

Brakes.

7. Recheck the fluid level.

Notice : Do not move the vehicle until a firm pedal is ob-

tained, or improper braking action will result.

8. Repeatedly press the brake pedal to bring the pads

in contact with the rotor.

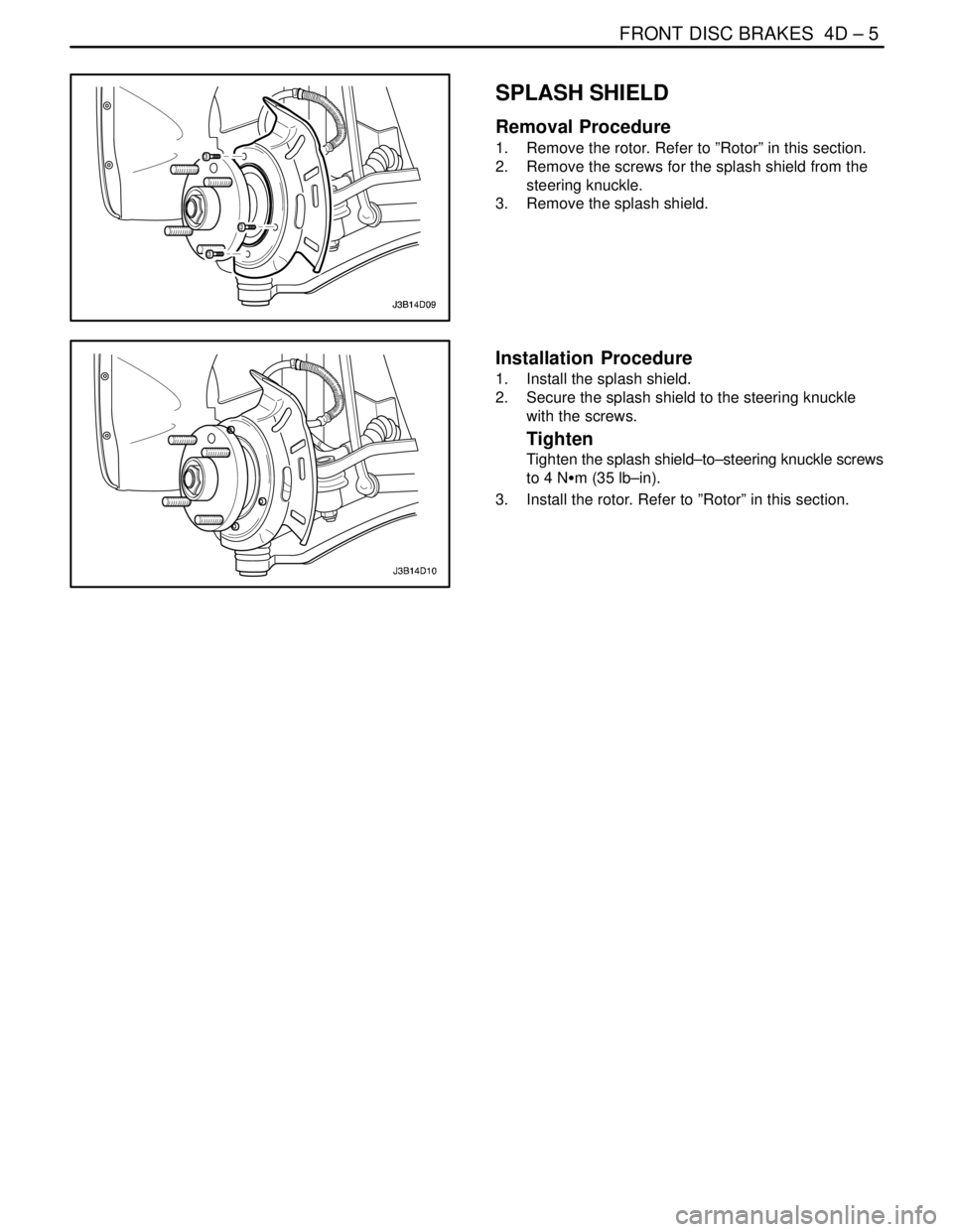

ROTOR

Removal Procedure

Notice : Do not hang the caliper assembly from the brake

hose. Any resulting internal hose restriction will impede

uniform braking action.

Important : To guarantee uniform braking on both sides,

both rotors must have identical surfaces regarding

smoothness and scoring depth. For this reason, always

replace both rotors.

1. Remove the caliper assembly without disconnecting

the brake hoses. Refer to ”Caliper Assembly” in this

section.

2. Remove the rotor–to–front wheel hub detent

screws.

3. Pull off the rotor.

Installation Procedure

1. Inspect the rotor. Refer to ”Rotor Inspection”in this

section.

2. Install the rotor to the front wheel hub by tightening

the detent screw.

Tighten

Tighten the rotor–to–front wheel hub detent screw to

4 NSm (35 lb–in).

3. Install the caliper assembly. Refer to ”Caliper As-

sembly” in this section.

Page 1053 of 2643

FRONT DISC BRAKES 4D – 5

DAEWOO V–121 BL4

SPLASH SHIELD

Removal Procedure

1. Remove the rotor. Refer to ”Rotor” in this section.

2. Remove the screws for the splash shield from the

steering knuckle.

3. Remove the splash shield.

Installation Procedure

1. Install the splash shield.

2. Secure the splash shield to the steering knuckle

with the screws.

Tighten

Tighten the splash shield–to–steering knuckle screws

to 4 NSm (35 lb–in).

3. Install the rotor. Refer to ”Rotor” in this section.

Page 1054 of 2643

4D – 6IFRONT DISC BRAKES

DAEWOO V–121 BL4

UNIT REPAIR

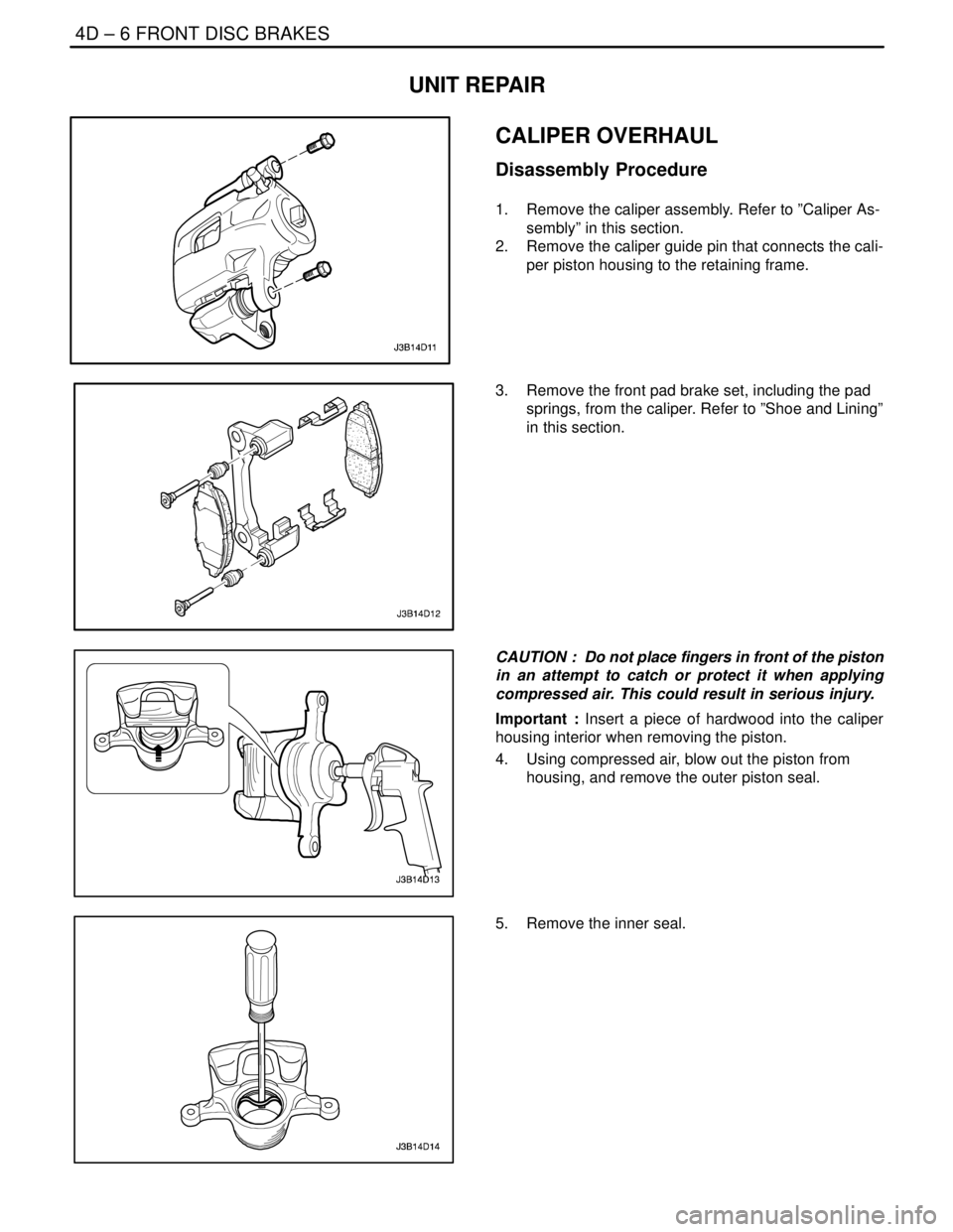

CALIPER OVERHAUL

Disassembly Procedure

1. Remove the caliper assembly. Refer to ”Caliper As-

sembly” in this section.

2. Remove the caliper guide pin that connects the cali-

per piston housing to the retaining frame.

3. Remove the front pad brake set, including the pad

springs, from the caliper. Refer to ”Shoe and Lining”

in this section.

CAUTION : Do not place fingers in front of the piston

in an attempt to catch or protect it when applying

compressed air. This could result in serious injury.

Important : Insert a piece of hardwood into the caliper

housing interior when removing the piston.

4. Using compressed air, blow out the piston from

housing, and remove the outer piston seal.

5. Remove the inner seal.

Page 1055 of 2643

FRONT DISC BRAKES 4D – 7

DAEWOO V–121 BL4

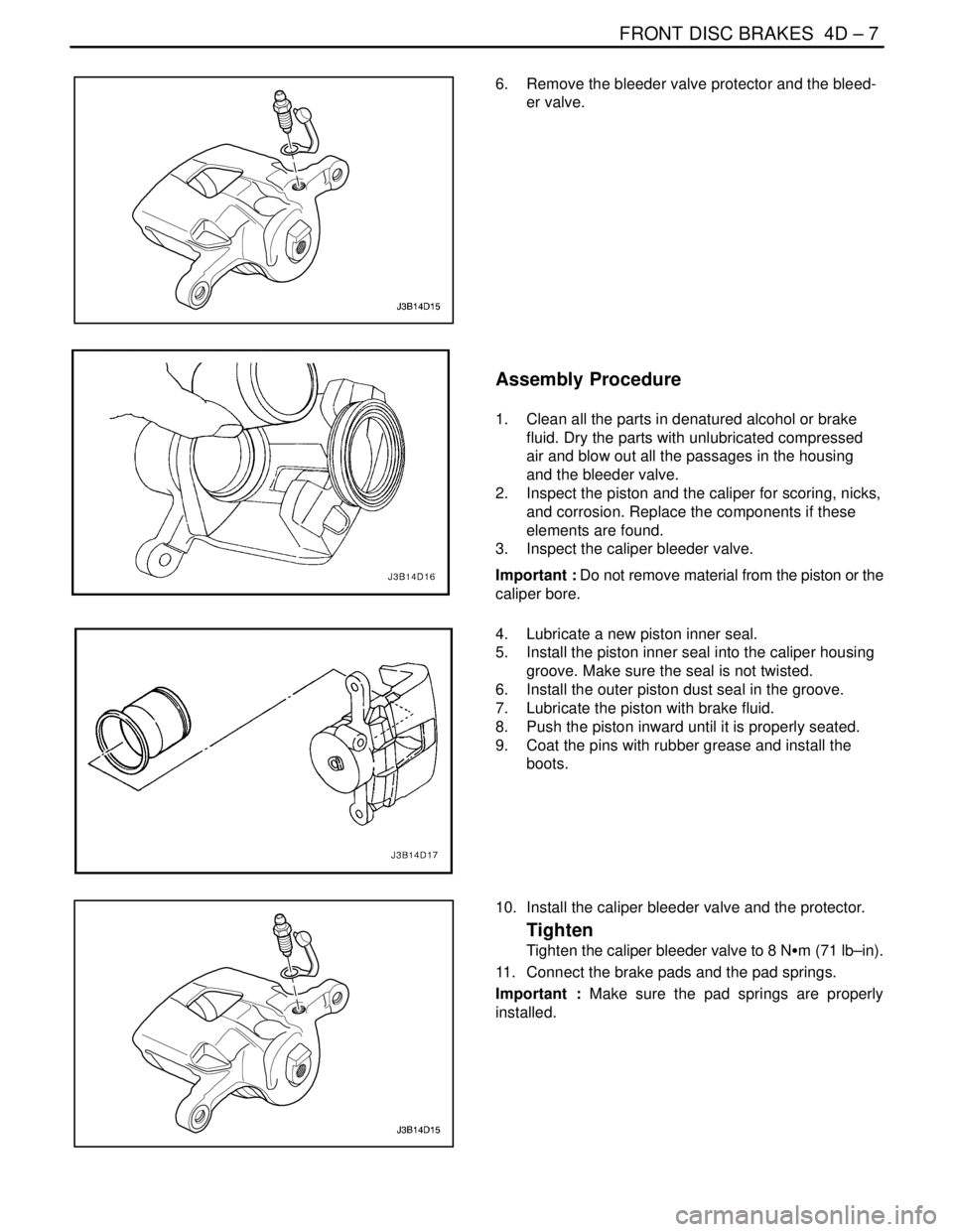

6. Remove the bleeder valve protector and the bleed-

er valve.

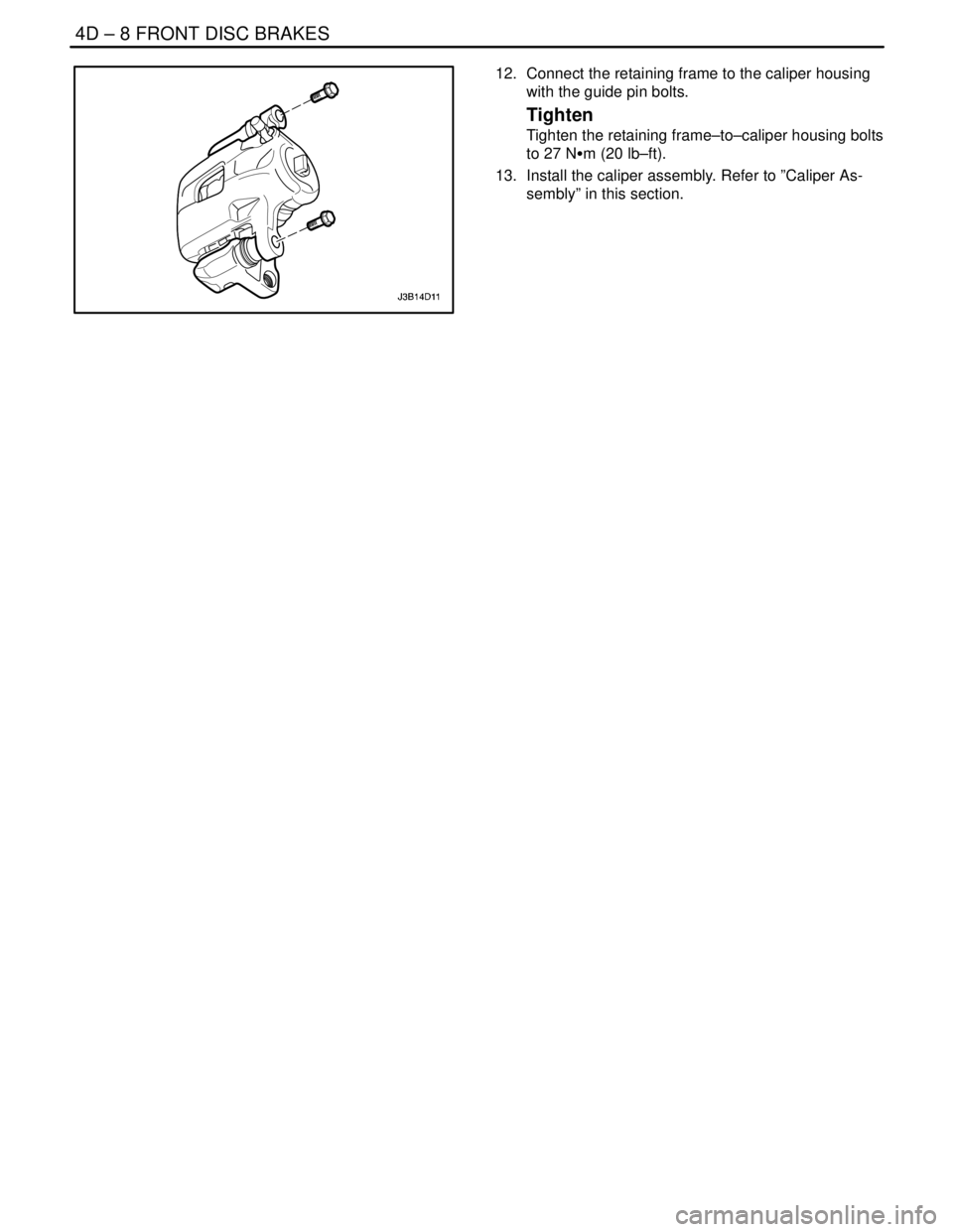

Assembly Procedure

1. Clean all the parts in denatured alcohol or brake

fluid. Dry the parts with unlubricated compressed

air and blow out all the passages in the housing

and the bleeder valve.

2. Inspect the piston and the caliper for scoring, nicks,

and corrosion. Replace the components if these

elements are found.

3. Inspect the caliper bleeder valve.

Important : Do not remove material from the piston or the

caliper bore.

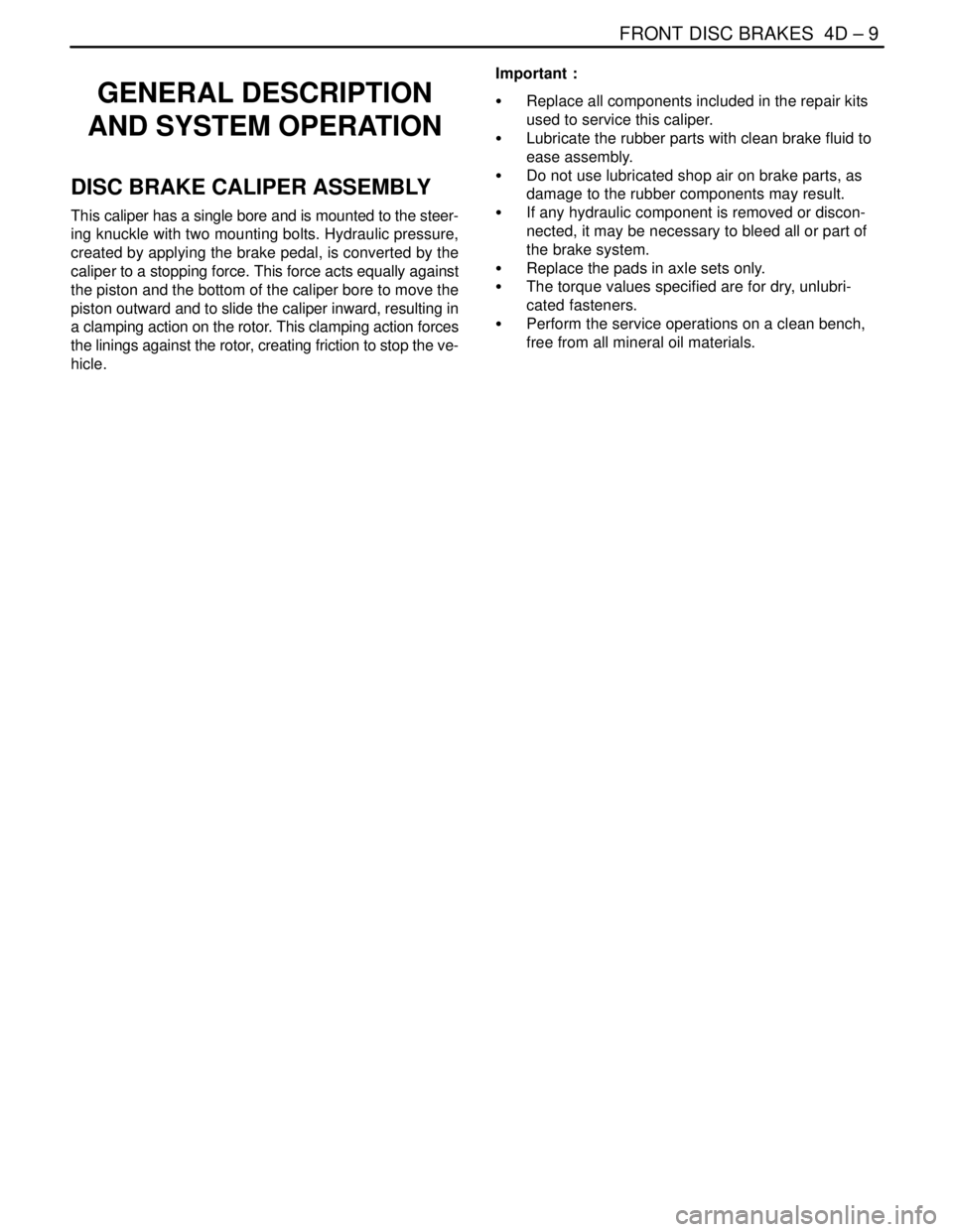

4. Lubricate a new piston inner seal.

5. Install the piston inner seal into the caliper housing

groove. Make sure the seal is not twisted.

6. Install the outer piston dust seal in the groove.

7. Lubricate the piston with brake fluid.

8. Push the piston inward until it is properly seated.

9. Coat the pins with rubber grease and install the

boots.

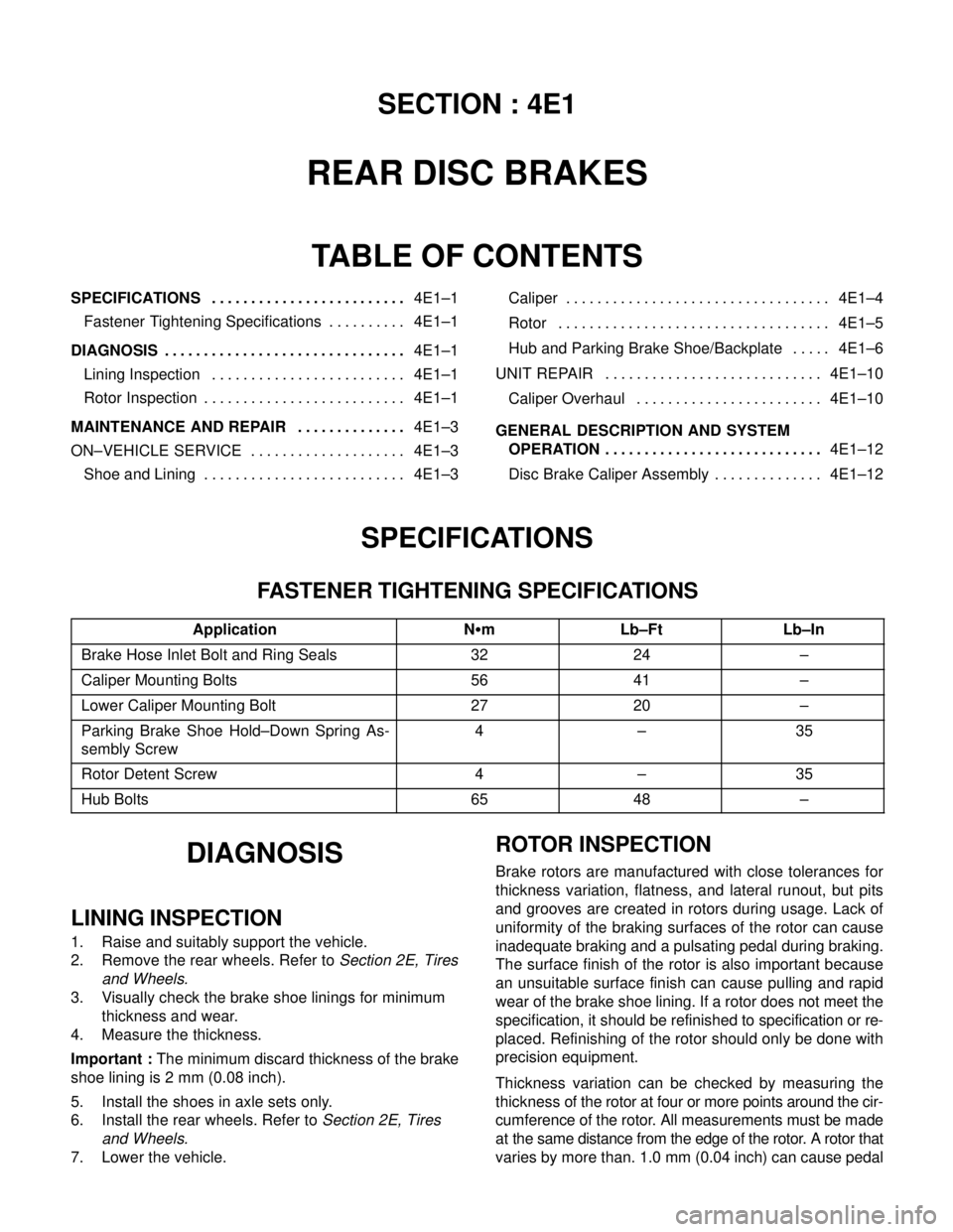

10. Install the caliper bleeder valve and the protector.

Tighten

Tighten the caliper bleeder valve to 8 NSm (71 lb–in).

11. Connect the brake pads and the pad springs.

Important : Make sure the pad springs are properly

installed.

Page 1056 of 2643

4D – 8IFRONT DISC BRAKES

DAEWOO V–121 BL4

12. Connect the retaining frame to the caliper housing

with the guide pin bolts.

Tighten

Tighten the retaining frame–to–caliper housing bolts

to 27 NSm (20 lb–ft).

13. Install the caliper assembly. Refer to ”Caliper As-

sembly” in this section.

Page 1057 of 2643

FRONT DISC BRAKES 4D – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DISC BRAKE CALIPER ASSEMBLY

This caliper has a single bore and is mounted to the steer-

ing knuckle with two mounting bolts. Hydraulic pressure,

created by applying the brake pedal, is converted by the

caliper to a stopping force. This force acts equally against

the piston and the bottom of the caliper bore to move the

piston outward and to slide the caliper inward, resulting in

a clamping action on the rotor. This clamping action forces

the linings against the rotor, creating friction to stop the ve-

hicle.Important :

S Replace all components included in the repair kits

used to service this caliper.

S Lubricate the rubber parts with clean brake fluid to

ease assembly.

S Do not use lubricated shop air on brake parts, as

damage to the rubber components may result.

S If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system.

S Replace the pads in axle sets only.

S The torque values specified are for dry, unlubri-

cated fasteners.

S Perform the service operations on a clean bench,

free from all mineral oil materials.

Page 1058 of 2643

SECTION : 4E1

REAR DISC BRAKES

TABLE OF CONTENTS

SPECIFICATIONS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4E1–1. . . . . . . . . .

DIAGNOSIS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lining Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Rotor Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4E1–3 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4E1–3. . . . . . . . . . . . . . . . . . . .

Shoe and Lining 4E1–3. . . . . . . . . . . . . . . . . . . . . . . . . . Caliper 4E1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotor 4E1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub and Parking Brake Shoe/Backplate 4E1–6. . . . .

UNIT REPAIR 4E1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caliper Overhaul 4E1–10. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4E1–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disc Brake Caliper Assembly 4E1–12. . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Hose Inlet Bolt and Ring Seals3224–

Caliper Mounting Bolts5641–

Lower Caliper Mounting Bolt2720–

Parking Brake Shoe Hold–Down Spring As-

sembly Screw4–35

Rotor Detent Screw4–35

Hub Bolts6548–

DIAGNOSIS

LINING INSPECTION

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Visually check the brake shoe linings for minimum

thickness and wear.

4. Measure the thickness.

Important : The minimum discard thickness of the brake

shoe lining is 2 mm (0.08 inch).

5. Install the shoes in axle sets only.

6. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

7. Lower the vehicle.

ROTOR INSPECTION

Brake rotors are manufactured with close tolerances for

thickness variation, flatness, and lateral runout, but pits

and grooves are created in rotors during usage. Lack of

uniformity of the braking surfaces of the rotor can cause

inadequate braking and a pulsating pedal during braking.

The surface finish of the rotor is also important because

an unsuitable surface finish can cause pulling and rapid

wear of the brake shoe lining. If a rotor does not meet the

specification, it should be refinished to specification or re-

placed. Refinishing of the rotor should only be done with

precision equipment.

Thickness variation can be checked by measuring the

thickness of the rotor at four or more points around the cir-

cumference of the rotor. All measurements must be made

at the same distance from the edge of the rotor. A rotor that

varies by more than. 1.0 mm (0.04 inch) can cause pedal

Page 1059 of 2643

4E1 – 2IREAR DISC BRAKES

DAEWOO V–121 BL4

pulsation and/or front end vibration during braking. Thick-

ness can be measured with a commercially available mi-

crometer and should be 10 mm(0.39 inch) or over.

Light scoring of the rotor surfaces is acceptable if it does

not exceed 0.40 mm (0.016 inch) in depth. Scoring mea-

surements can be made with a commercially available

brake micrometer.

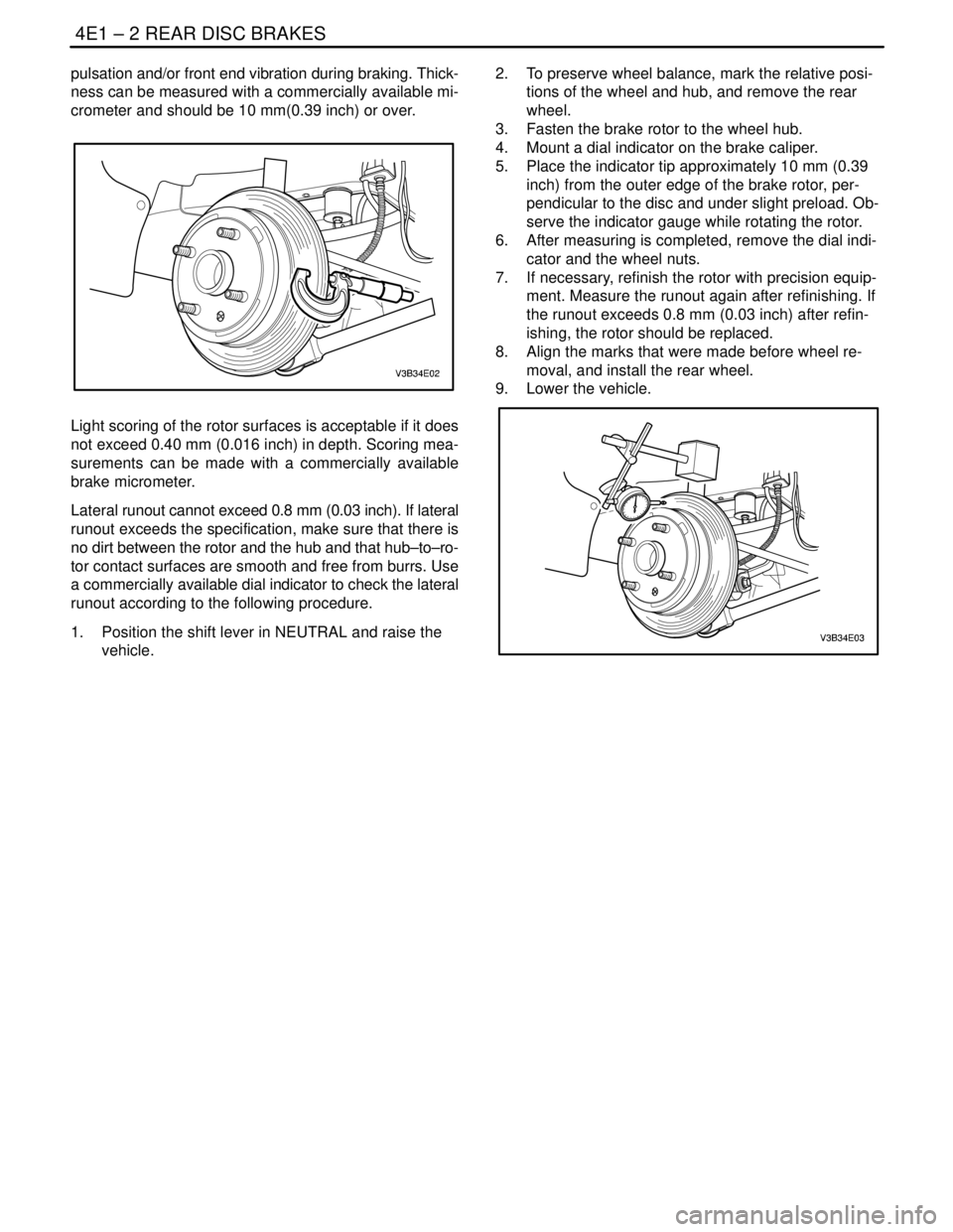

Lateral runout cannot exceed 0.8 mm (0.03 inch). If lateral

runout exceeds the specification, make sure that there is

no dirt between the rotor and the hub and that hub–to–ro-

tor contact surfaces are smooth and free from burrs. Use

a commercially available dial indicator to check the lateral

runout according to the following procedure.

1. Position the shift lever in NEUTRAL and raise the

vehicle.2. To preserve wheel balance, mark the relative posi-

tions of the wheel and hub, and remove the rear

wheel.

3. Fasten the brake rotor to the wheel hub.

4. Mount a dial indicator on the brake caliper.

5. Place the indicator tip approximately 10 mm (0.39

inch) from the outer edge of the brake rotor, per-

pendicular to the disc and under slight preload. Ob-

serve the indicator gauge while rotating the rotor.

6. After measuring is completed, remove the dial indi-

cator and the wheel nuts.

7. If necessary, refinish the rotor with precision equip-

ment. Measure the runout again after refinishing. If

the runout exceeds 0.8 mm (0.03 inch) after refin-

ishing, the rotor should be replaced.

8. Align the marks that were made before wheel re-

moval, and install the rear wheel.

9. Lower the vehicle.

Page 1060 of 2643

REAR DISC BRAKES 4E1 – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

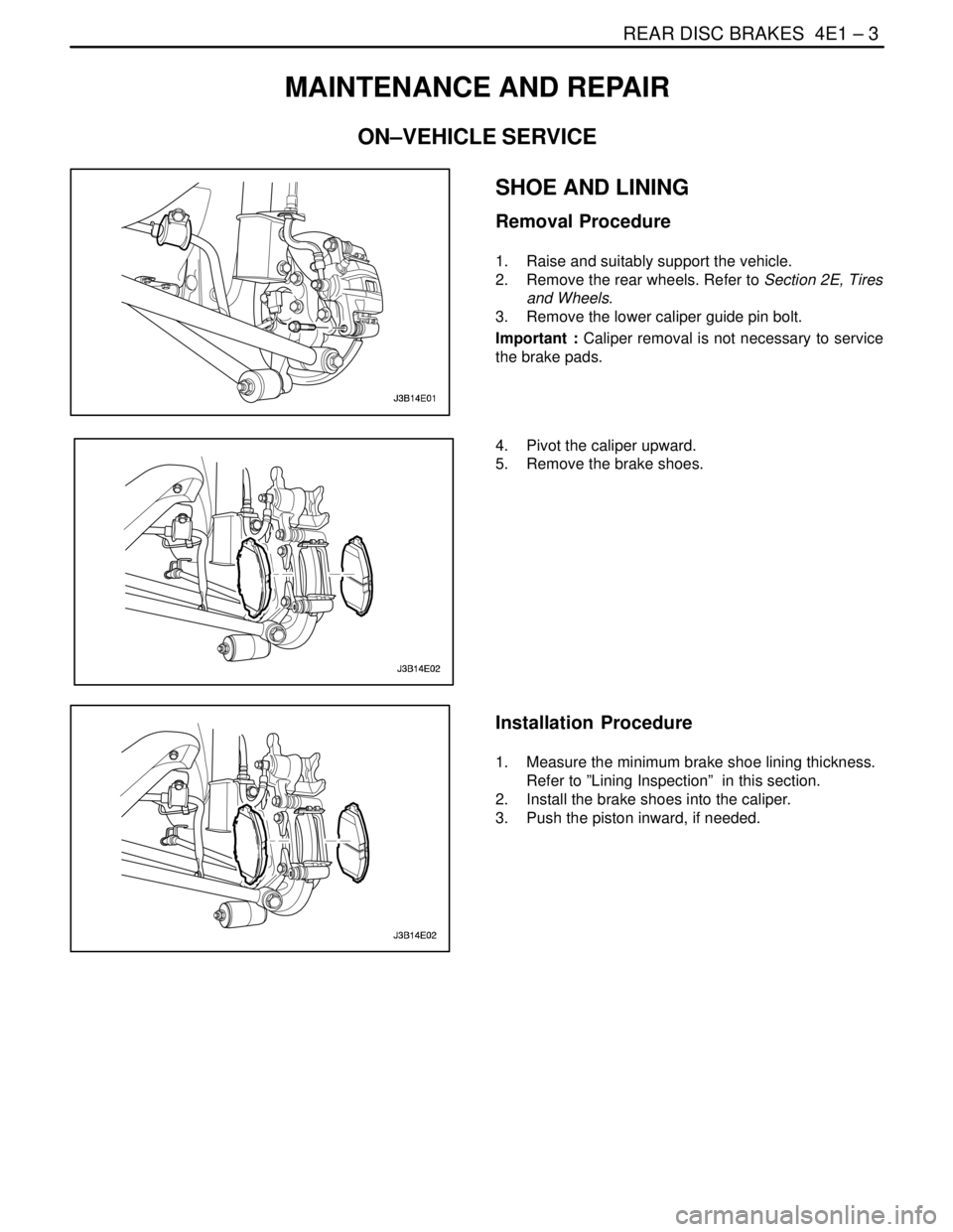

SHOE AND LINING

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Remove the lower caliper guide pin bolt.

Important : Caliper removal is not necessary to service

the brake pads.

4. Pivot the caliper upward.

5. Remove the brake shoes.

Installation Procedure

1. Measure the minimum brake shoe lining thickness.

Refer to ”Lining Inspection” in this section.

2. Install the brake shoes into the caliper.

3. Push the piston inward, if needed.