acc DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 964 of 2643

2E – 2ITIRES AND WHEELS

DAEWOO V–121 BL4

INFLATION PRESSURE CONVERSION SPECIFICATIONS

kPaPsikPaPsikPaPsi

140201852723534

145211902824035

155222002925036

160232053027540

165242153131045

170252203234550

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Wheel Bolt (Alloy Wheel)10074–

Wheel Bolt (Steel Wheel)10074–

DIAGNOSIS

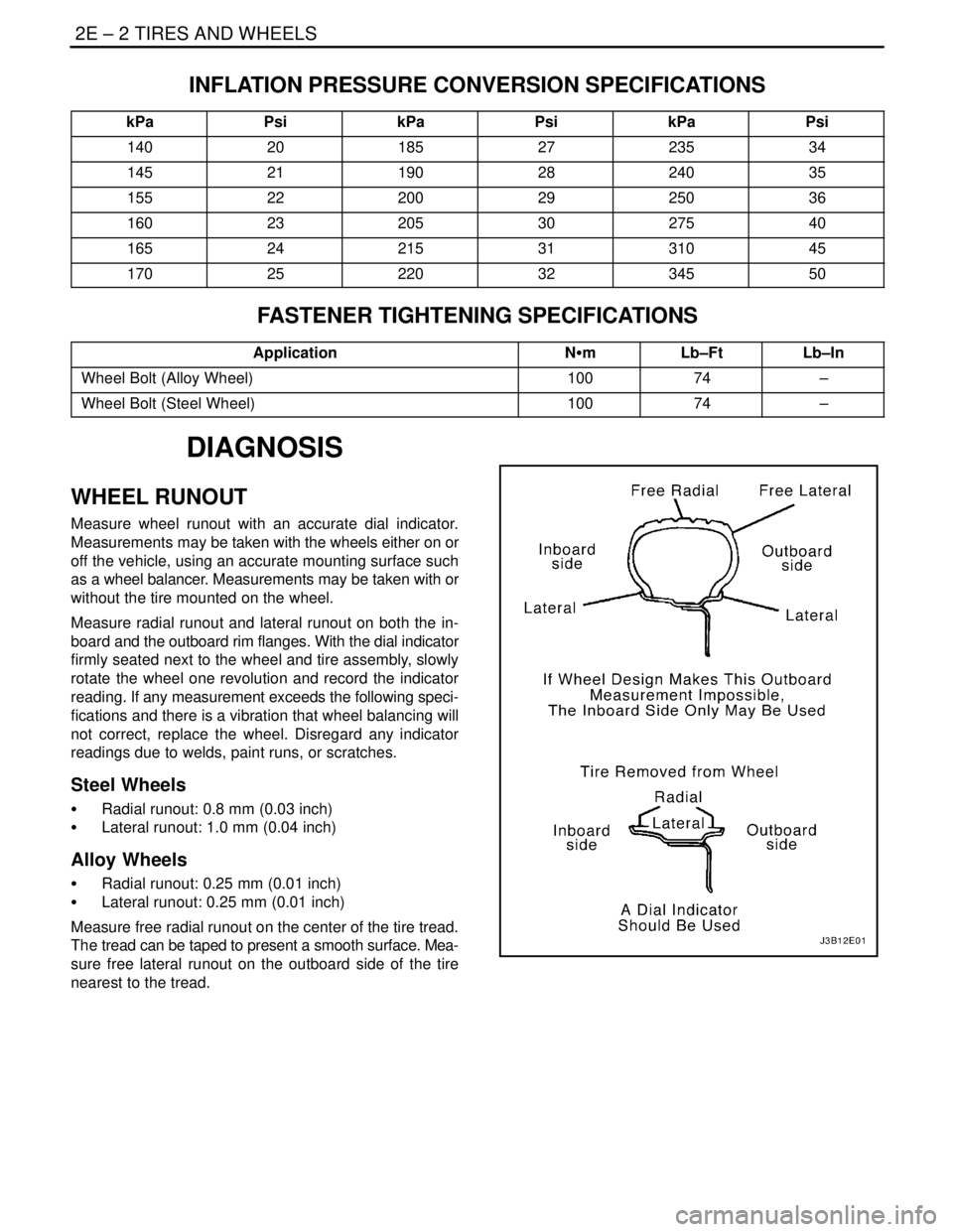

WHEEL RUNOUT

Measure wheel runout with an accurate dial indicator.

Measurements may be taken with the wheels either on or

off the vehicle, using an accurate mounting surface such

as a wheel balancer. Measurements may be taken with or

without the tire mounted on the wheel.

Measure radial runout and lateral runout on both the in-

board and the outboard rim flanges. With the dial indicator

firmly seated next to the wheel and tire assembly, slowly

rotate the wheel one revolution and record the indicator

reading. If any measurement exceeds the following speci-

fications and there is a vibration that wheel balancing will

not correct, replace the wheel. Disregard any indicator

readings due to welds, paint runs, or scratches.

Steel Wheels

S Radial runout: 0.8 mm (0.03 inch)

S Lateral runout: 1.0 mm (0.04 inch)

Alloy Wheels

S Radial runout: 0.25 mm (0.01 inch)

S Lateral runout: 0.25 mm (0.01 inch)

Measure free radial runout on the center of the tire tread.

The tread can be taped to present a smooth surface. Mea-

sure free lateral runout on the outboard side of the tire

nearest to the tread.

Page 965 of 2643

TIRES AND WHEELS 2E – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

WHEEL

Removal Procedure

1. Loosen the wheel bolts.

2. Raise and suitably support the vehicle.

3. Remove the wheel bolts.

Notice : Never use heat to loosen a tight wheel. It can

shorten the life of the wheel, the wheel nuts and the wheel

bearings. Excessive force, such as hammering the wheel

or tire, can also cause damage and is not recommended.

Slight tapping of the wheel sidewall with one’s hand or with

a rubber mallet is acceptable.

4. Remove the wheel.

Difficulty in removing the wheels from the vehicle can be

due to foreign material or to a tight fit between the wheel

centerhole and the hub or the rotor. These wheels can be

removed by

5. Retightening the wheel bolts on the affected wheel

and then loosening the wheel bolts by two turns.

6. Lowering the vehicle and rocking it from side to side

as hard as possible, using one or more person’s

body weight to loosen the wheel.

7. Raising the vehicle and removing the wheel.

CAUTION : Do not allow the penetrating oil to get on

the vertical surfaces between the wheel and the drum

(or rotor) because penetrating oil in this area could

cause the wheel to work loose as the vehicle is driven,

resulting in loss of control and an injury accident.

Penetrating oil is not effective in removing tight wheels. If

it is used, however, apply it sparingly and only to the

wheel’s centerhole area.

Installation Procedure

Notice : Before installing the wheels, remove any buildup

of corrosion on the wheel mounting surface and the brake

drum or the rotor mounting surface by scraping and brush-

ing them with a wire brush. Installing the wheels without

good metal–to–metal contact at the mounting surfaces

can cause the wheel nuts to loosen, which can later allow

a wheel to come off while the vehicle is moving. Wheel

bolts must be tightened in sequence and to the proper

torque to avoid bending the wheel, the brake drum or the

rotor.

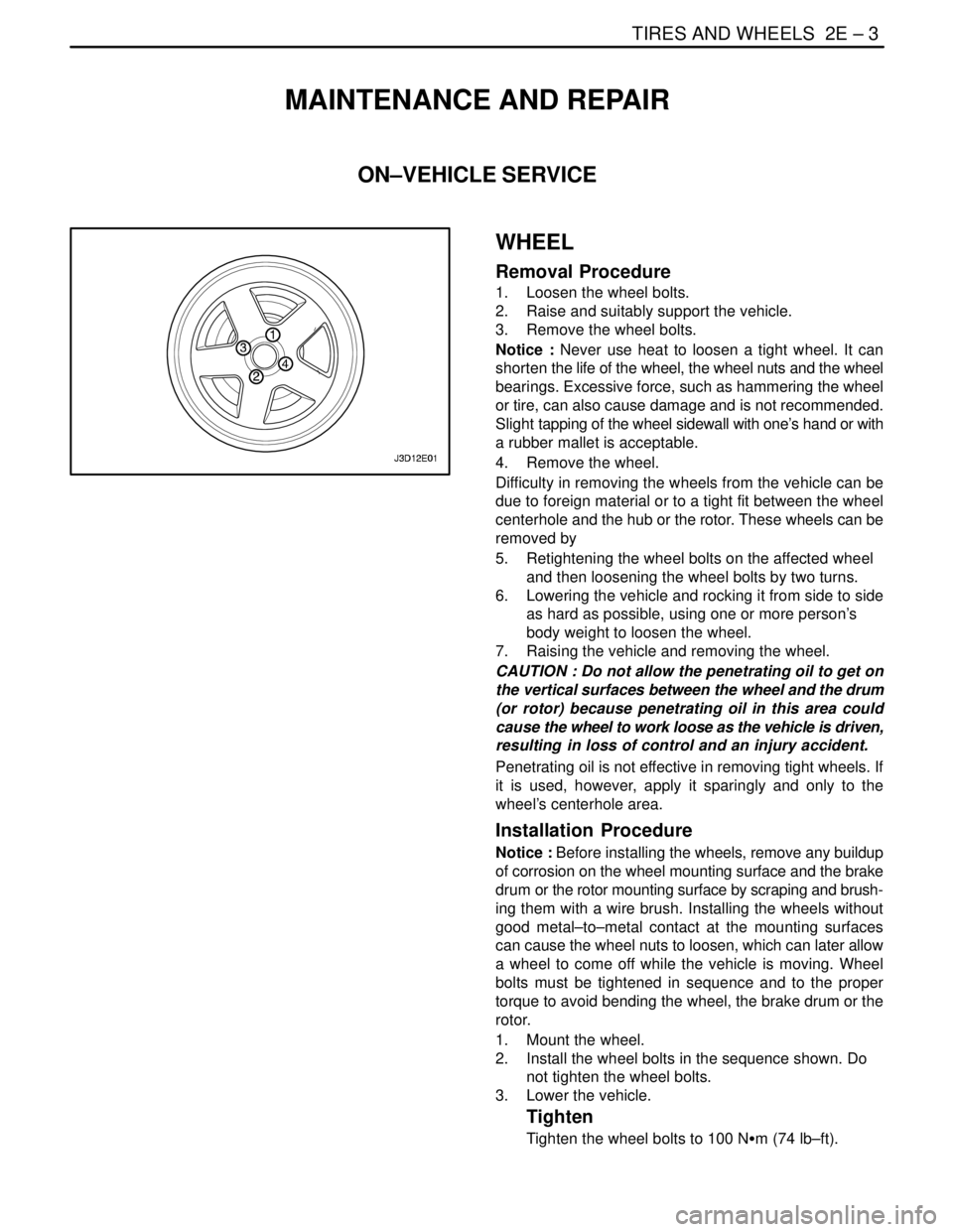

1. Mount the wheel.

2. Install the wheel bolts in the sequence shown. Do

not tighten the wheel bolts.

3. Lower the vehicle.

Tighten

Tighten the wheel bolts to 100 NSm (74 lb–ft).

Page 968 of 2643

2E – 6ITIRES AND WHEELS

DAEWOO V–121 BL4

S Amchem Alodine No. 1001. Stock No. DX50T or

equivalent coating chemical for alloys.

S Ditzler Delclear Acrylic Urethane Clear, Stock No.

DAU–75 or equivalent.

S Ditzler Delthane Ultra–Urethane Additive, Stock No.

DXR–80 or equivalent.

Before repairing the alloy damage or the clear coat dam-

age, prepare the wheels and the tires.

1. Remove the wheel from the vehicle.

2. Mark the location of the outboard weights and re-

move them.

3. Wash the wheel inside and out with a water–based,

all–purpose cleaner. Remove the grease and oil

with a solvent cleaner.

4. Mask the tire prior to painting.

5. Using a 400–grit wet or dry sandpaper, sand over

the painted areas that will not require recoloring.

Sanding will promote the adhesion of the clear coat.

Alloy Damage on Wheel Surface

1. Mount the wheel on a brake lathe and spin the as-

sembly slowly.

2. Sand the wheel with a backing block or pad. Hold

the backing block or pad flat to the surface of the

wheel and sand slowly back and forth from the cen-

ter to the outer edge of the tire to remove the dam-

age. Use the following sandpaper grits in the order

listed:

1) 80 grit.

2) 150 grit.

3) 240 grit.

Clear Coat Damage on Unpainted Wheels

1. Apply the chemical stripper Amchem Alumi Prep

No. 33. Use a small 1/4–inch detail brush to apply

the stripper around the perimeter and spoke–like

areas.

2. Remove the stripper according to the manufactur-

er’s recommendations.

CAUTION : To avoid serious personal injury, do not

use engine power to rotate the wheel while sanding.

3. Sand the wheel with 240–grit sandpaper by rotating

the wheel on a slow–spinning brake lathe or by

mounting the wheel on the car and spinning it by

hand. Sanding restores the machined appearance

and promotes adhesion.

After repairing the alloy or clear coat damage, the wheels

must be recoated.

Page 969 of 2643

TIRES AND WHEELS 2E – 7

DAEWOO V–121 BL4

Recoating Procedure

CAUTION : To avoid serious personal injury when ap-

plying any two–part component paint system, follow

the specific precautions provided by the paint

manufacturer. Failure to follow these precautions

may cause lung irritation and an allergic respiratory

reaction.

1. Clean the surface.

2. Soak the wheel with Amchem Alumi Prep No. 33 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

3. Soak the wheel with Amchem Alodine No. 1001 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

4. Finish with Ditzler Delclear Urethane and Ditzler

Ultra–Urethane Additive or equivalent, using three

coats.

1st coat – spray on a light mist coat; let dry.

2nd coat – spray or paint on a light coat; let dry.

3rd coat – spray or paint on a heavy double wet

coat; let dry.

5. Let the urethane dry for 24 hours or flash for 30

minutes and force dry at 60°C (140°F) for 30 min-

utes. Allow the urethane to cool for 5 minutes be-

fore mounting the wheel on the vehicle.

OFF–VEHICLE BALANCING

Perform wheel balancing with an electronic off–vehicle ba-

lancer. The balancer is easy to use and gives both a static

and a dynamic balance. Unlike on–vehicle balancing, the

off–vehicle balancer does not correct for drum or rotor im-

balance. This drawback is overcome by its accuracy (usu-

ally to within 1/8 ounce). Secure the wheel on the balancer

with a cone through the back side of the centerhole, not

through the wheel bolt holes.

CORRECTING NON–UNIFORM TIRES

There are two ways to correct properly balanced tires

which still vibrate. One method uses an automatic ma-

chine which loads the tire and buffs small amounts of rub-

ber from high spots on the outer two tread rows. Correction

by this method is usually permanent and, if it is done prop-

erly, does not significantly affect the appearance or the

tread life of the tire. Tire truing with a blade–type machine

is not recommended because it substantially reduces the

tread life and often does not correct the problem perma-

nently.

Another method is to dismount the tire and rotate it 180 de-

grees on the rim. Do this only on the tire and wheel assem-

blies which are known to be causing a vibration because

this method is just as likely to cause good assemblies to

vibrate.

Page 971 of 2643

TIRES AND WHEELS 2E – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

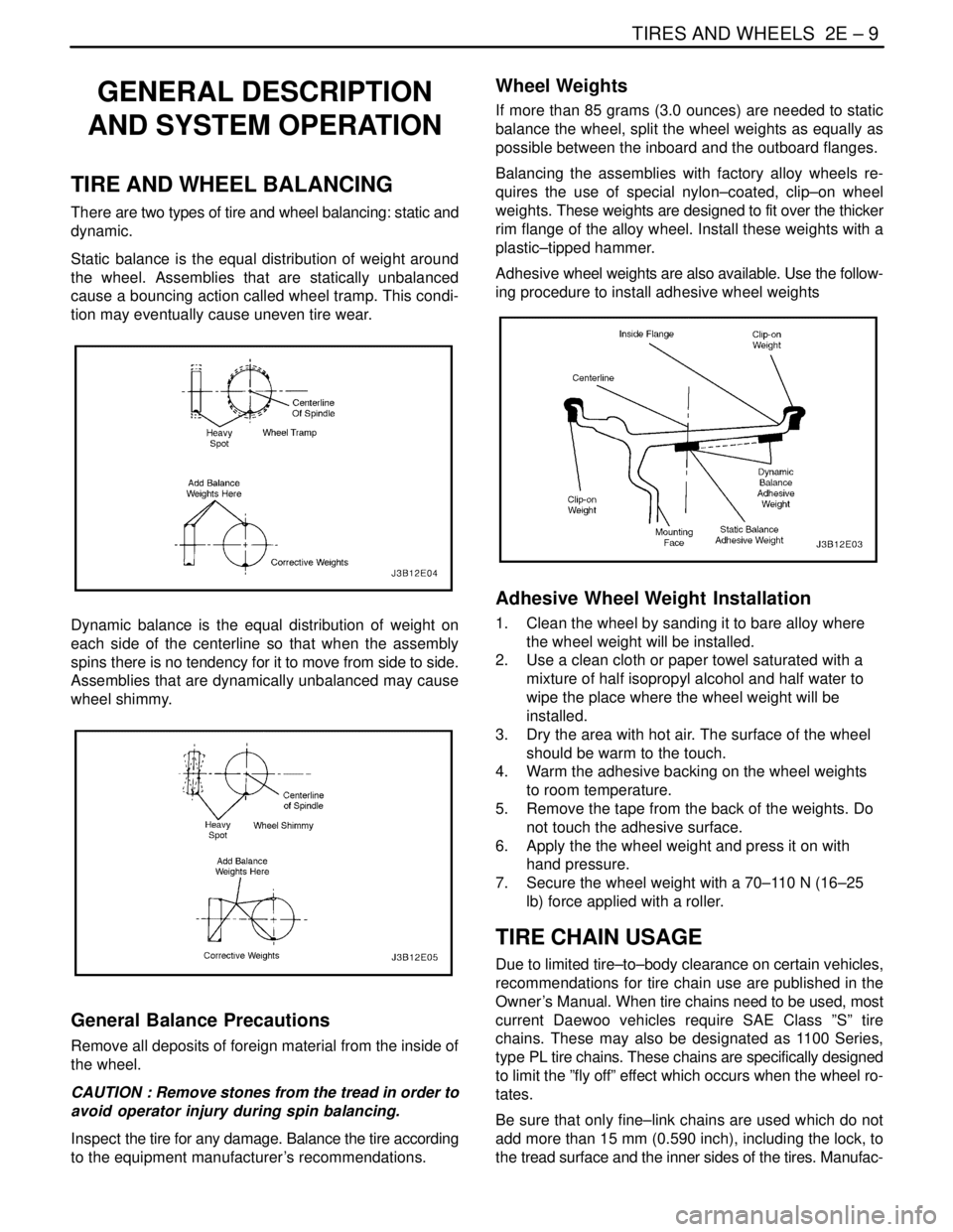

TIRE AND WHEEL BALANCING

There are two types of tire and wheel balancing: static and

dynamic.

Static balance is the equal distribution of weight around

the wheel. Assemblies that are statically unbalanced

cause a bouncing action called wheel tramp. This condi-

tion may eventually cause uneven tire wear.

Dynamic balance is the equal distribution of weight on

each side of the centerline so that when the assembly

spins there is no tendency for it to move from side to side.

Assemblies that are dynamically unbalanced may cause

wheel shimmy.

General Balance Precautions

Remove all deposits of foreign material from the inside of

the wheel.

CAUTION : Remove stones from the tread in order to

avoid operator injury during spin balancing.

Inspect the tire for any damage. Balance the tire according

to the equipment manufacturer’s recommendations.

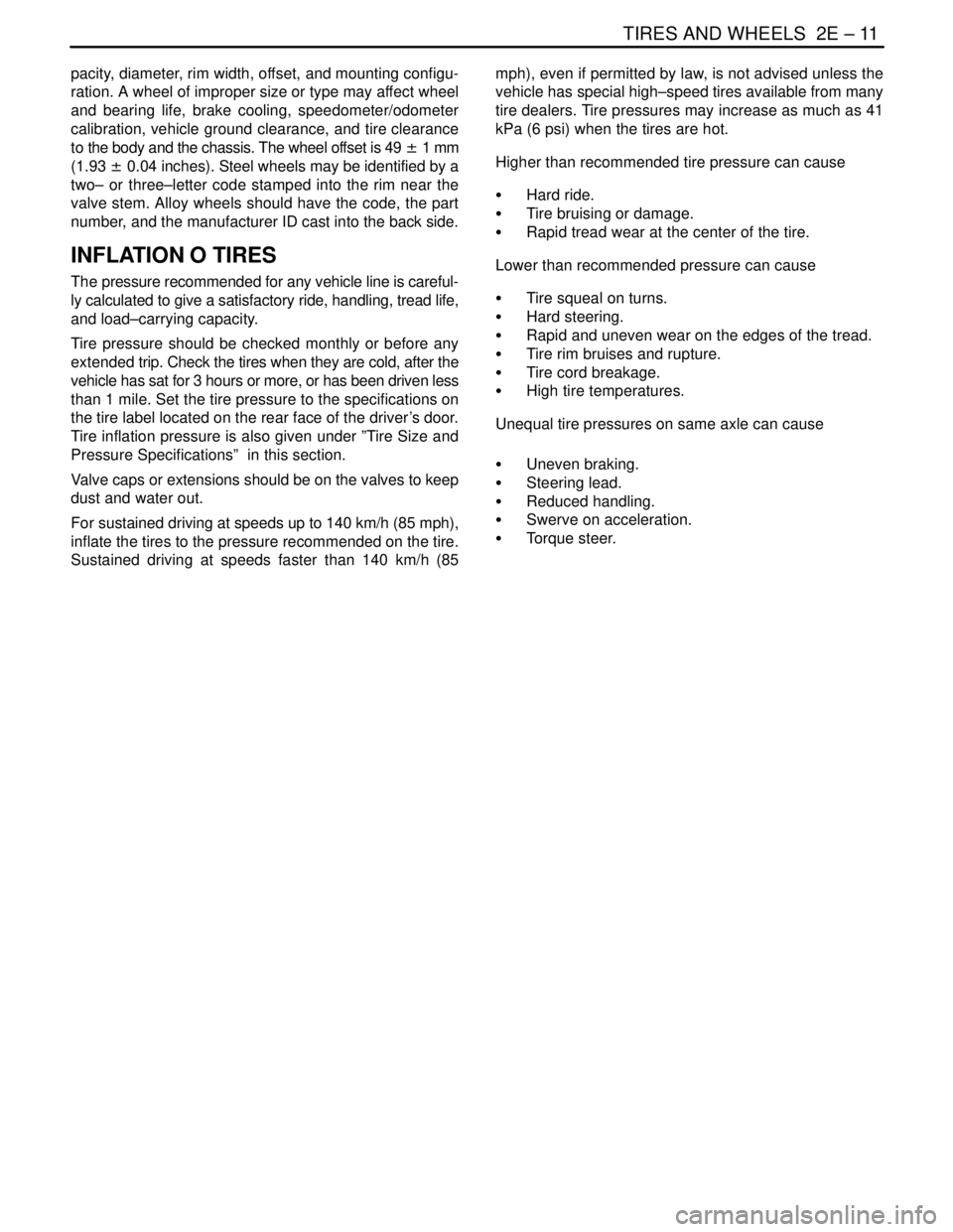

Wheel Weights

If more than 85 grams (3.0 ounces) are needed to static

balance the wheel, split the wheel weights as equally as

possible between the inboard and the outboard flanges.

Balancing the assemblies with factory alloy wheels re-

quires the use of special nylon–coated, clip–on wheel

weights. These weights are designed to fit over the thicker

rim flange of the alloy wheel. Install these weights with a

plastic–tipped hammer.

Adhesive wheel weights are also available. Use the follow-

ing procedure to install adhesive wheel weights

Adhesive Wheel Weight Installation

1. Clean the wheel by sanding it to bare alloy where

the wheel weight will be installed.

2. Use a clean cloth or paper towel saturated with a

mixture of half isopropyl alcohol and half water to

wipe the place where the wheel weight will be

installed.

3. Dry the area with hot air. The surface of the wheel

should be warm to the touch.

4. Warm the adhesive backing on the wheel weights

to room temperature.

5. Remove the tape from the back of the weights. Do

not touch the adhesive surface.

6. Apply the the wheel weight and press it on with

hand pressure.

7. Secure the wheel weight with a 70–110 N (16–25

lb) force applied with a roller.

TIRE CHAIN USAGE

Due to limited tire–to–body clearance on certain vehicles,

recommendations for tire chain use are published in the

Owner ’s Manual. When tire chains need to be used, most

current Daewoo vehicles require SAE Class ”S” tire

chains. These may also be designated as 1100 Series,

type PL tire chains. These chains are specifically designed

to limit the ”fly off” effect which occurs when the wheel ro-

tates.

Be sure that only fine–link chains are used which do not

add more than 15 mm (0.590 inch), including the lock, to

the tread surface and the inner sides of the tires. Manufac-

Page 973 of 2643

TIRES AND WHEELS 2E – 11

DAEWOO V–121 BL4

pacity, diameter, rim width, offset, and mounting configu-

ration. A wheel of improper size or type may affect wheel

and bearing life, brake cooling, speedometer/odometer

calibration, vehicle ground clearance, and tire clearance

to the body and the chassis. The wheel offset is 49 ± 1 mm

(1.93 ± 0.04 inches). Steel wheels may be identified by a

two– or three–letter code stamped into the rim near the

valve stem. Alloy wheels should have the code, the part

number, and the manufacturer ID cast into the back side.

INFLATION O TIRES

The pressure recommended for any vehicle line is careful-

ly calculated to give a satisfactory ride, handling, tread life,

and load–carrying capacity.

Tire pressure should be checked monthly or before any

extended trip. Check the tires when they are cold, after the

vehicle has sat for 3 hours or more, or has been driven less

than 1 mile. Set the tire pressure to the specifications on

the tire label located on the rear face of the driver’s door.

Tire inflation pressure is also given under ”Tire Size and

Pressure Specifications” in this section.

Valve caps or extensions should be on the valves to keep

dust and water out.

For sustained driving at speeds up to 140 km/h (85 mph),

inflate the tires to the pressure recommended on the tire.

Sustained driving at speeds faster than 140 km/h (85mph), even if permitted by law, is not advised unless the

vehicle has special high–speed tires available from many

tire dealers. Tire pressures may increase as much as 41

kPa (6 psi) when the tires are hot.

Higher than recommended tire pressure can cause

S Hard ride.

S Tire bruising or damage.

S Rapid tread wear at the center of the tire.

Lower than recommended pressure can cause

S Tire squeal on turns.

S Hard steering.

S Rapid and uneven wear on the edges of the tread.

S Tire rim bruises and rupture.

S Tire cord breakage.

S High tire temperatures.

Unequal tire pressures on same axle can cause

S Uneven braking.

S Steering lead.

S Reduced handling.

S Swerve on acceleration.

S Torque steer.

Page 974 of 2643

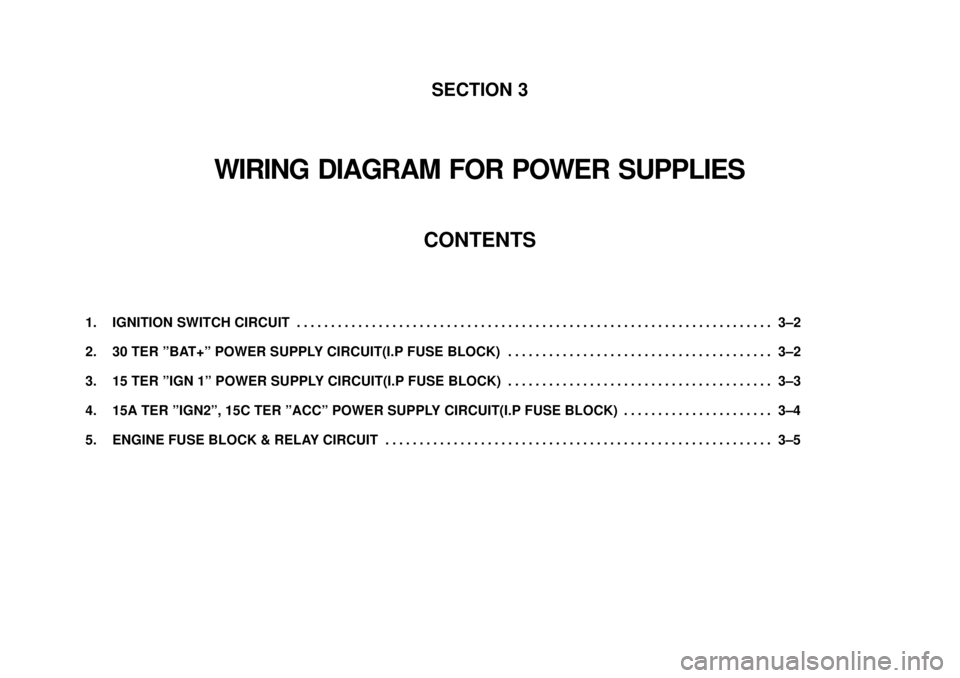

SECTION 3

WIRING DIAGRAM FOR POWER SUPPLIES

CONTENTS

1. IGNITION SWITCH CIRCUIT3–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. 30 TER ”BAT+” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. 15 TER ”IGN 1” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. 15A TER ”IGN2”, 15C TER ”ACC” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–4. . . . . . . . . . . . . . . . . . . . . .

5. ENGINE FUSE BLOCK & RELAY CIRCUIT 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 977 of 2643

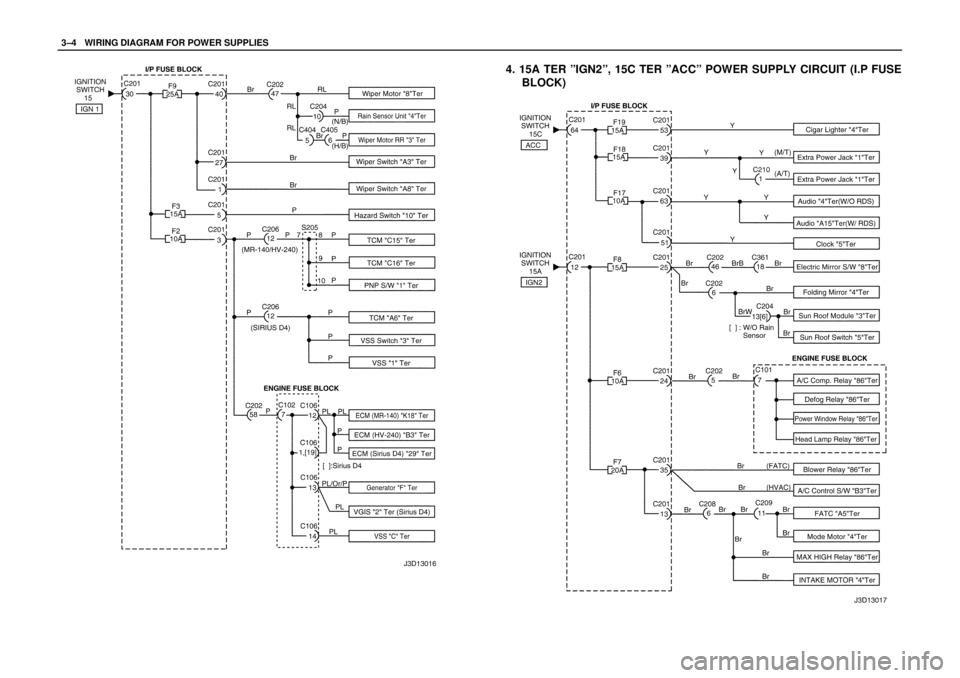

3–4WWIRING DIAGRAM FOR POWER SUPPLIES

4. 15A TER ”IGN2”, 15C TER ”ACC” POWER SUPPLY CIRCUIT (I.P FUSE

BLOCK)

Page 1015 of 2643

USAGE AND CAPACITY OF FUSES IN FUSE BLOCKW4–3

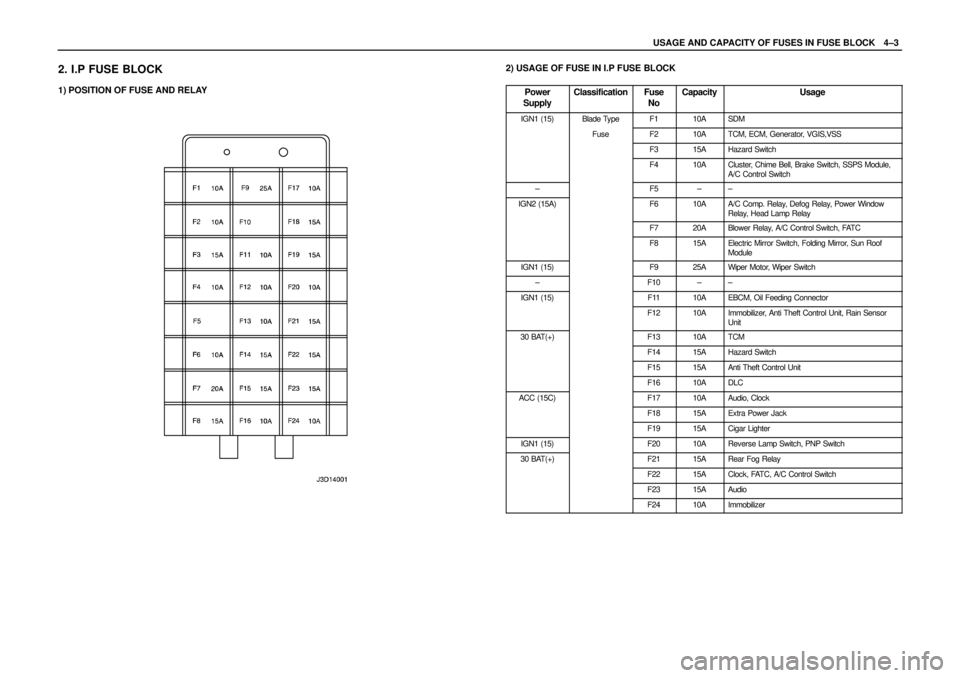

2. I.P FUSE BLOCK

1) POSITION OF FUSE AND RELAY

2) USAGE OF FUSE IN I.P FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

IGN1 (15)Blade TypeF110ASDM

FuseF210ATCM, ECM, Generator, VGIS,VSS

F315AHazard Switch

F410ACluster, Chime Bell, Brake Switch, SSPS Module,

A/C Control Switch

–F5––

IGN2 (15A)F610AA/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720ABlower Relay, A/C Control Switch, FATC

F815AElectric Mirror Switch, Folding Mirror, Sun Roof

Module

IGN1 (15)F925AWiper Motor, Wiper Switch

–F10––

IGN1 (15)F1110AEBCM, Oil Feeding Connector

F1210AImmobilizer, Anti Theft Control Unit, Rain Sensor

Unit

30 BAT(+)F1310ATCM

F1415AHazard Switch

F1515AAnti Theft Control Unit

F1610ADLC

ACC (15C)F1710AAudio, Clock

F1815AExtra Power Jack

F1915ACigar Lighter

IGN1 (15)F2010AReverse Lamp Switch, PNP Switch

30 BAT(+)F2115ARear Fog Relay

F2215AClock, FATC, A/C Control Switch

F2315AAudio

F2410AImmobilizer

Page 1050 of 2643

4D – 2IFRONT DISC BRAKES

DAEWOO V–121 BL4

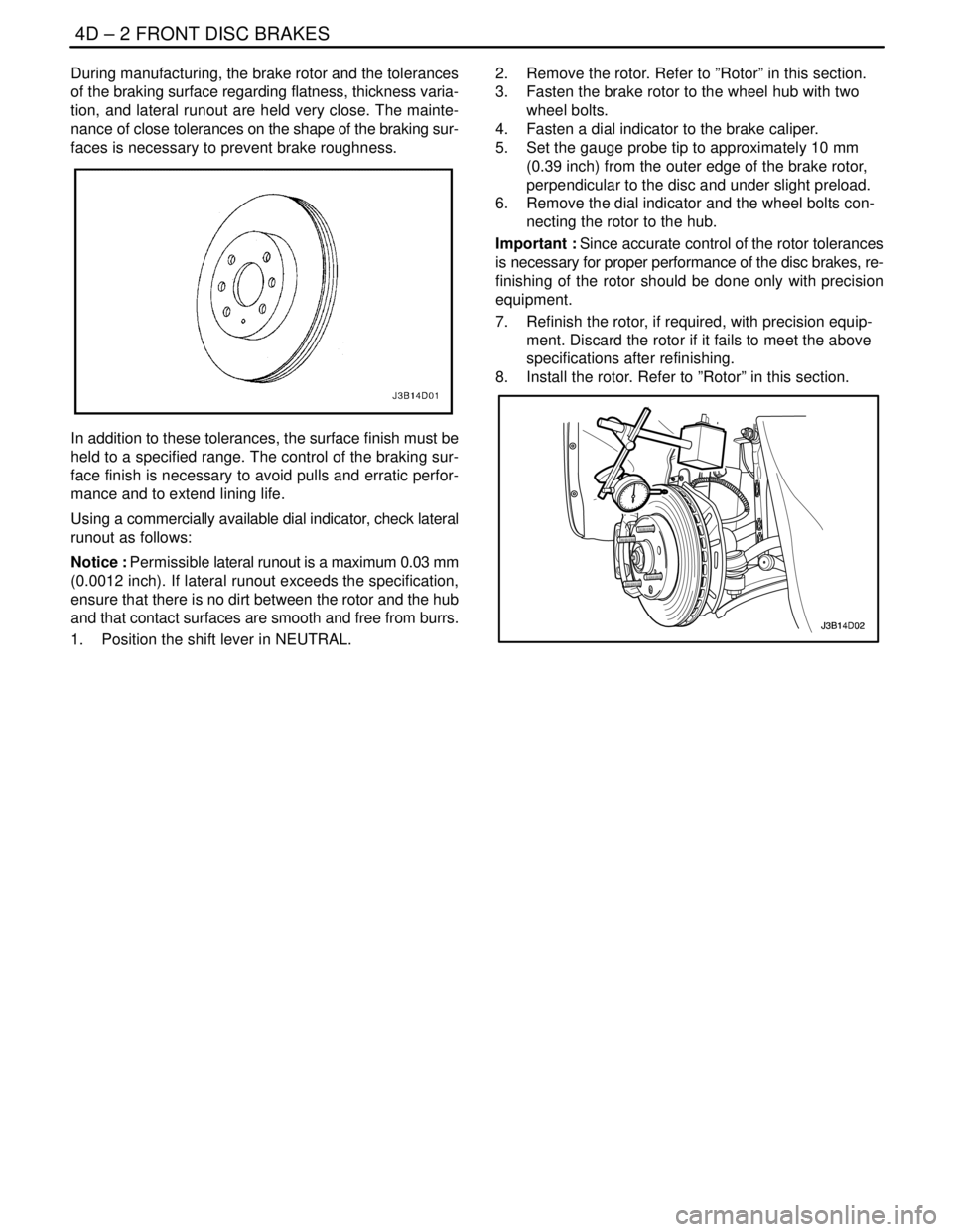

During manufacturing, the brake rotor and the tolerances

of the braking surface regarding flatness, thickness varia-

tion, and lateral runout are held very close. The mainte-

nance of close tolerances on the shape of the braking sur-

faces is necessary to prevent brake roughness.

In addition to these tolerances, the surface finish must be

held to a specified range. The control of the braking sur-

face finish is necessary to avoid pulls and erratic perfor-

mance and to extend lining life.

Using a commercially available dial indicator, check lateral

runout as follows:

Notice : Permissible lateral runout is a maximum 0.03 mm

(0.0012 inch). If lateral runout exceeds the specification,

ensure that there is no dirt between the rotor and the hub

and that contact surfaces are smooth and free from burrs.

1. Position the shift lever in NEUTRAL.2. Remove the rotor. Refer to ”Rotor” in this section.

3. Fasten the brake rotor to the wheel hub with two

wheel bolts.

4. Fasten a dial indicator to the brake caliper.

5. Set the gauge probe tip to approximately 10 mm

(0.39 inch) from the outer edge of the brake rotor,

perpendicular to the disc and under slight preload.

6. Remove the dial indicator and the wheel bolts con-

necting the rotor to the hub.

Important : Since accurate control of the rotor tolerances

is necessary for proper performance of the disc brakes, re-

finishing of the rotor should be done only with precision

equipment.

7. Refinish the rotor, if required, with precision equip-

ment. Discard the rotor if it fails to meet the above

specifications after refinishing.

8. Install the rotor. Refer to ”Rotor” in this section.