speed DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 909 of 2643

2B – 2IWHEEL ALIGNMENT

DAEWOO V–121 BL4

DIAGNOSIS

TIRE DIAGNOSIS

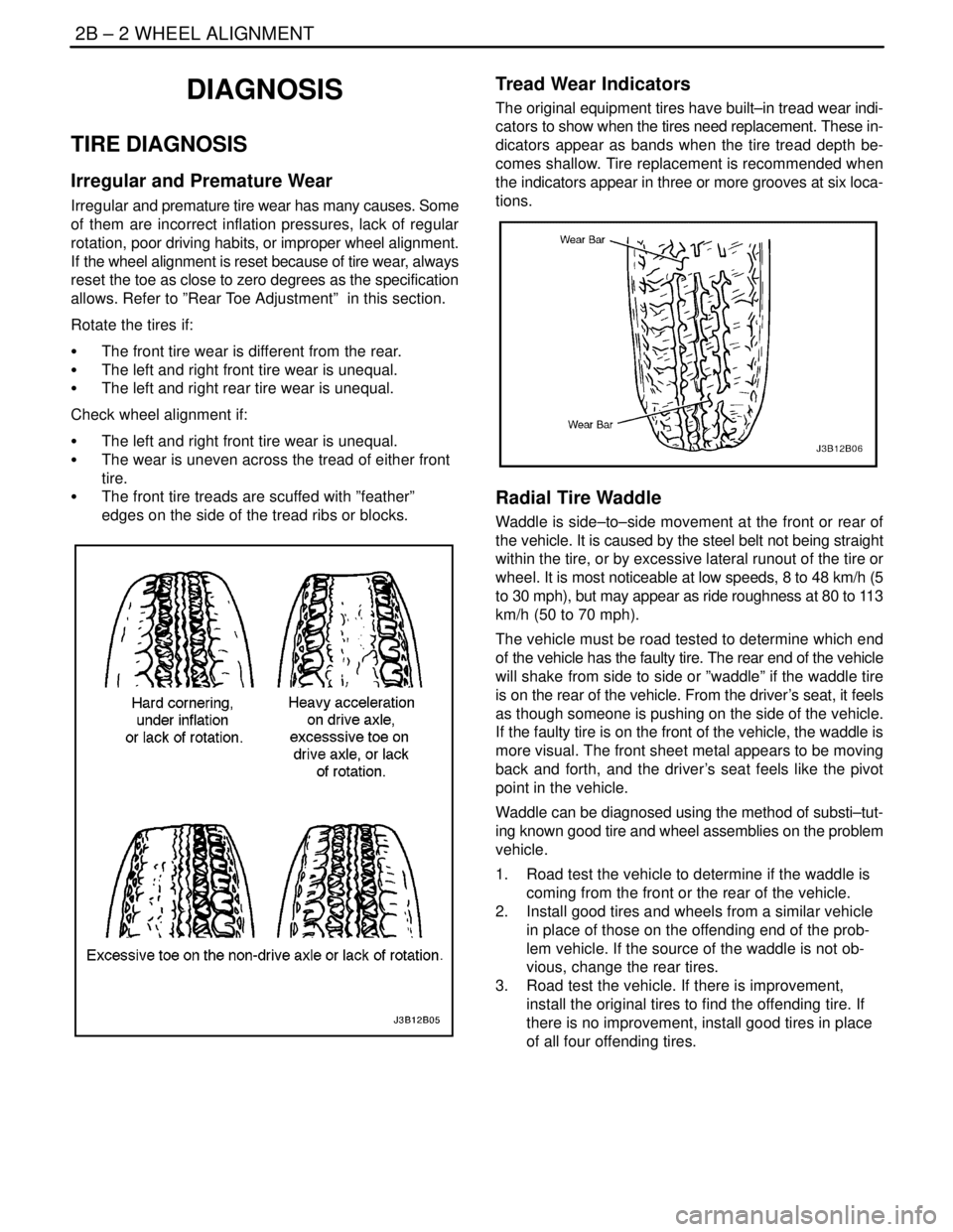

Irregular and Premature Wear

Irregular and premature tire wear has many causes. Some

of them are incorrect inflation pressures, lack of regular

rotation, poor driving habits, or improper wheel alignment.

If the wheel alignment is reset because of tire wear, always

reset the toe as close to zero degrees as the specification

allows. Refer to ”Rear Toe Adjustment” in this section.

Rotate the tires if:

S The front tire wear is different from the rear.

S The left and right front tire wear is unequal.

S The left and right rear tire wear is unequal.

Check wheel alignment if:

S The left and right front tire wear is unequal.

S The wear is uneven across the tread of either front

tire.

S The front tire treads are scuffed with ”feather”

edges on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built–in tread wear indi-

cators to show when the tires need replacement. These in-

dicators appear as bands when the tire tread depth be-

comes shallow. Tire replacement is recommended when

the indicators appear in three or more grooves at six loca-

tions.

Radial Tire Waddle

Waddle is side–to–side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire or

wheel. It is most noticeable at low speeds, 8 to 48 km/h (5

to 30 mph), but may appear as ride roughness at 80 to 113

km/h (50 to 70 mph).

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the vehicle

will shake from side to side or ”waddle” if the waddle tire

is on the rear of the vehicle. From the driver’s seat, it feels

as though someone is pushing on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle is

more visual. The front sheet metal appears to be moving

back and forth, and the driver’s seat feels like the pivot

point in the vehicle.

Waddle can be diagnosed using the method of substi–tut-

ing known good tire and wheel assemblies on the problem

vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the prob-

lem vehicle. If the source of the waddle is not ob-

vious, change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no improvement, install good tires in place

of all four offending tires.

Page 912 of 2643

WHEEL ALIGNMENT 2B – 5

DAEWOO V–121 BL4

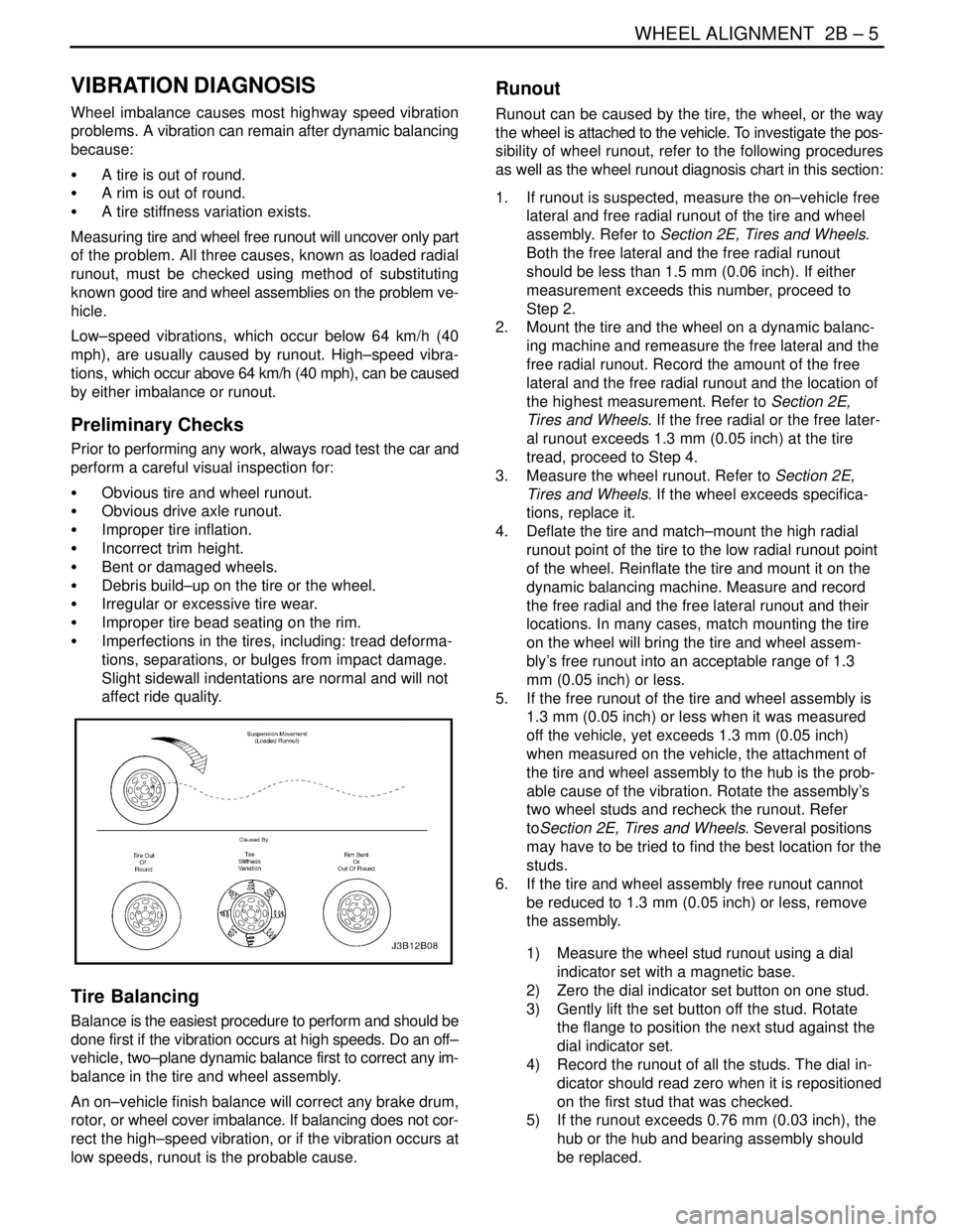

VIBRATION DIAGNOSIS

Wheel imbalance causes most highway speed vibration

problems. A vibration can remain after dynamic balancing

because:

S A tire is out of round.

S A rim is out of round.

S A tire stiffness variation exists.

Measuring tire and wheel free runout will uncover only part

of the problem. All three causes, known as loaded radial

runout, must be checked using method of substituting

known good tire and wheel assemblies on the problem ve-

hicle.

Low–speed vibrations, which occur below 64 km/h (40

mph), are usually caused by runout. High–speed vibra-

tions, which occur above 64 km/h (40 mph), can be caused

by either imbalance or runout.

Preliminary Checks

Prior to performing any work, always road test the car and

perform a careful visual inspection for:

S Obvious tire and wheel runout.

S Obvious drive axle runout.

S Improper tire inflation.

S Incorrect trim height.

S Bent or damaged wheels.

S Debris build–up on the tire or the wheel.

S Irregular or excessive tire wear.

S Improper tire bead seating on the rim.

S Imperfections in the tires, including: tread deforma-

tions, separations, or bulges from impact damage.

Slight sidewall indentations are normal and will not

affect ride quality.

Tire Balancing

Balance is the easiest procedure to perform and should be

done first if the vibration occurs at high speeds. Do an off–

vehicle, two–plane dynamic balance first to correct any im-

balance in the tire and wheel assembly.

An on–vehicle finish balance will correct any brake drum,

rotor, or wheel cover imbalance. If balancing does not cor-

rect the high–speed vibration, or if the vibration occurs at

low speeds, runout is the probable cause.

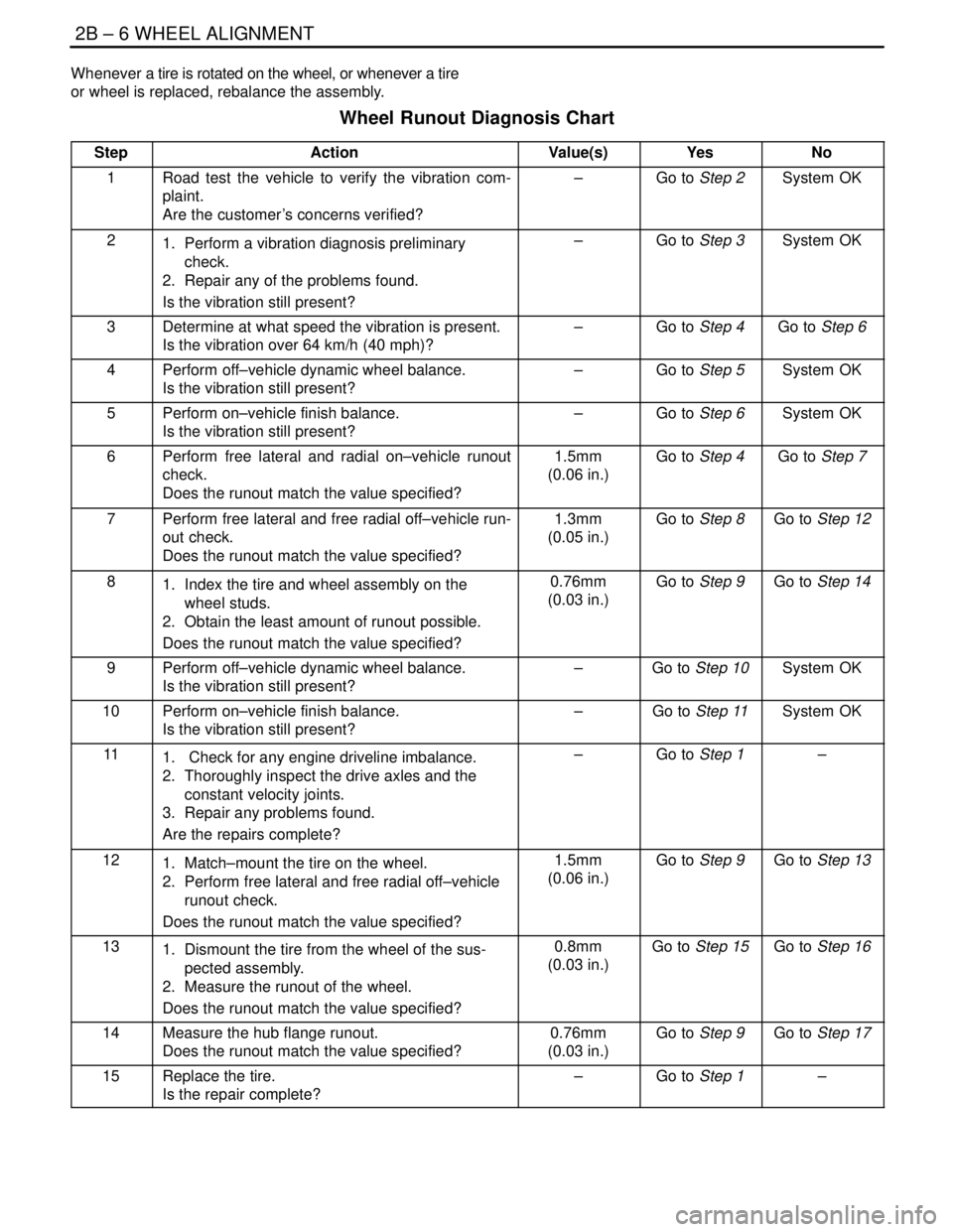

Runout

Runout can be caused by the tire, the wheel, or the way

the wheel is attached to the vehicle. To investigate the pos-

sibility of wheel runout, refer to the following procedures

as well as the wheel runout diagnosis chart in this section:

1. If runout is suspected, measure the on–vehicle free

lateral and free radial runout of the tire and wheel

assembly. Refer to Section 2E, Tires and Wheels.

Both the free lateral and the free radial runout

should be less than 1.5 mm (0.06 inch). If either

measurement exceeds this number, proceed to

Step 2.

2. Mount the tire and the wheel on a dynamic balanc-

ing machine and remeasure the free lateral and the

free radial runout. Record the amount of the free

lateral and the free radial runout and the location of

the highest measurement. Refer to Section 2E,

Tires and Wheels. If the free radial or the free later-

al runout exceeds 1.3 mm (0.05 inch) at the tire

tread, proceed to Step 4.

3. Measure the wheel runout. Refer to Section 2E,

Tires and Wheels. If the wheel exceeds specifica-

tions, replace it.

4. Deflate the tire and match–mount the high radial

runout point of the tire to the low radial runout point

of the wheel. Reinflate the tire and mount it on the

dynamic balancing machine. Measure and record

the free radial and the free lateral runout and their

locations. In many cases, match mounting the tire

on the wheel will bring the tire and wheel assem-

bly’s free runout into an acceptable range of 1.3

mm (0.05 inch) or less.

5. If the free runout of the tire and wheel assembly is

1.3 mm (0.05 inch) or less when it was measured

off the vehicle, yet exceeds 1.3 mm (0.05 inch)

when measured on the vehicle, the attachment of

the tire and wheel assembly to the hub is the prob-

able cause of the vibration. Rotate the assembly’s

two wheel studs and recheck the runout. Refer

toSection 2E, Tires and Wheels. Several positions

may have to be tried to find the best location for the

studs.

6. If the tire and wheel assembly free runout cannot

be reduced to 1.3 mm (0.05 inch) or less, remove

the assembly.

1) Measure the wheel stud runout using a dial

indicator set with a magnetic base.

2) Zero the dial indicator set button on one stud.

3) Gently lift the set button off the stud. Rotate

the flange to position the next stud against the

dial indicator set.

4) Record the runout of all the studs. The dial in-

dicator should read zero when it is repositioned

on the first stud that was checked.

5) If the runout exceeds 0.76 mm (0.03 inch), the

hub or the hub and bearing assembly should

be replaced.

Page 913 of 2643

2B – 6IWHEEL ALIGNMENT

DAEWOO V–121 BL4

Whenever a tire is rotated on the wheel, or whenever a tire

or wheel is replaced, rebalance the assembly.

Wheel Runout Diagnosis Chart

StepActionValue(s)YesNo

1Road test the vehicle to verify the vibration com-

plaint.

Are the customer’s concerns verified?–Go to Step 2System OK

21. Perform a vibration diagnosis preliminary

check.

2. Repair any of the problems found.

Is the vibration still present?–Go to Step 3System OK

3Determine at what speed the vibration is present.

Is the vibration over 64 km/h (40 mph)?–Go to Step 4Go to Step 6

4Perform off–vehicle dynamic wheel balance.

Is the vibration still present?–Go to Step 5System OK

5Perform on–vehicle finish balance.

Is the vibration still present?–Go to Step 6System OK

6Perform free lateral and radial on–vehicle runout

check.

Does the runout match the value specified?1.5mm

(0.06 in.)Go to Step 4Go to Step 7

7Perform free lateral and free radial off–vehicle run-

out check.

Does the runout match the value specified?1.3mm

(0.05 in.)Go to Step 8Go to Step 12

81. Index the tire and wheel assembly on the

wheel studs.

2. Obtain the least amount of runout possible.

Does the runout match the value specified?0.76mm

(0.03 in.)Go to Step 9Go to Step 14

9Perform off–vehicle dynamic wheel balance.

Is the vibration still present?–Go to Step 10System OK

10Perform on–vehicle finish balance.

Is the vibration still present?–Go to Step 11System OK

111. Check for any engine driveline imbalance.

2. Thoroughly inspect the drive axles and the

constant velocity joints.

3. Repair any problems found.

Are the repairs complete?–Go to Step 1–

121. Match–mount the tire on the wheel.

2. Perform free lateral and free radial off–vehicle

runout check.

Does the runout match the value specified?1.5mm

(0.06 in.)Go to Step 9Go to Step 13

131. Dismount the tire from the wheel of the sus-

pected assembly.

2. Measure the runout of the wheel.

Does the runout match the value specified?0.8mm

(0.03 in.)Go to Step 15Go to Step 16

14Measure the hub flange runout.

Does the runout match the value specified?0.76mm

(0.03 in.)Go to Step 9Go to Step 17

15Replace the tire.

Is the repair complete?–Go to Step 1–

Page 928 of 2643

FRONT SUSPENSION 2C – 11

DAEWOO V–121 BL4

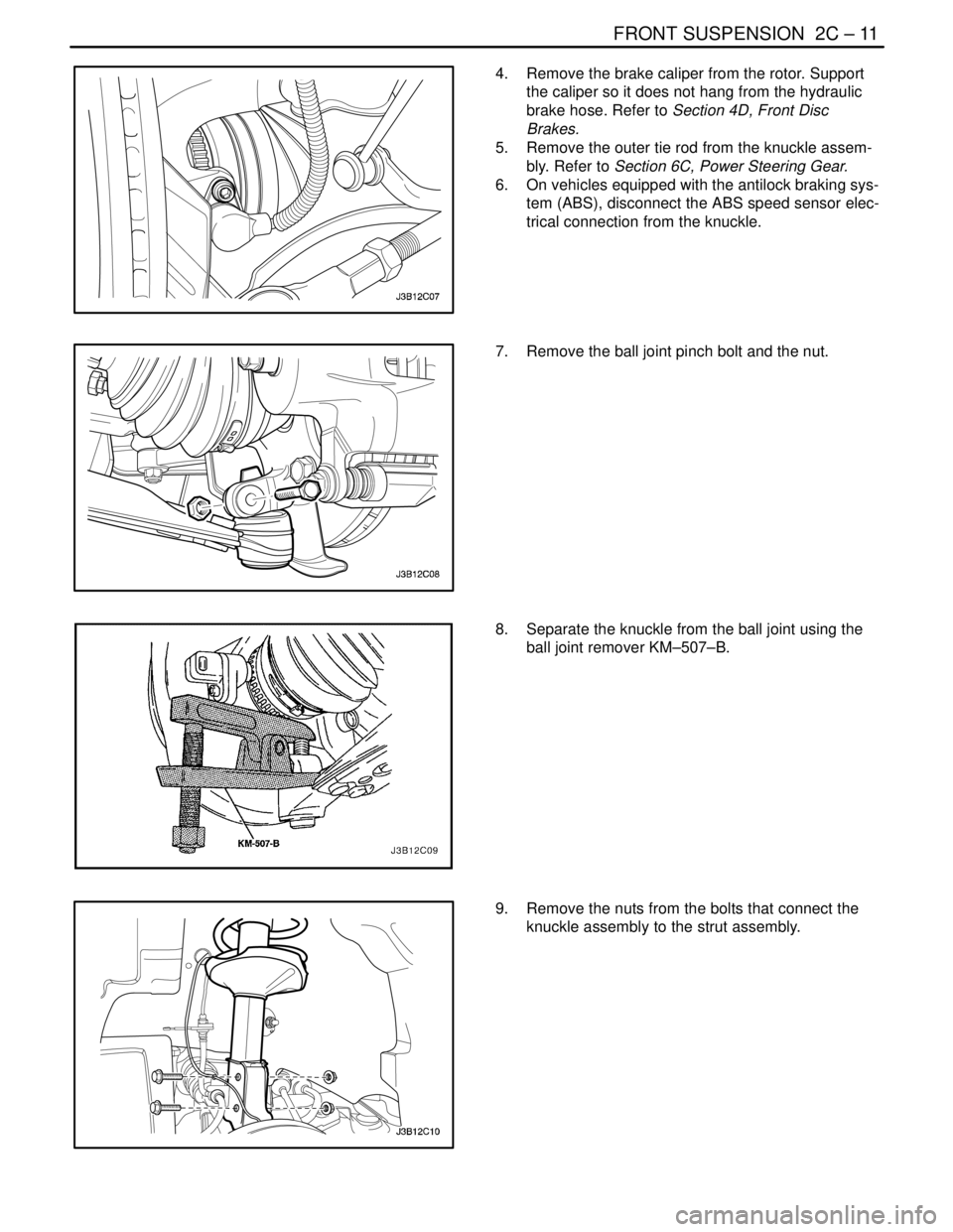

4. Remove the brake caliper from the rotor. Support

the caliper so it does not hang from the hydraulic

brake hose. Refer to Section 4D, Front Disc

Brakes.

5. Remove the outer tie rod from the knuckle assem-

bly. Refer to Section 6C, Power Steering Gear.

6. On vehicles equipped with the antilock braking sys-

tem (ABS), disconnect the ABS speed sensor elec-

trical connection from the knuckle.

7. Remove the ball joint pinch bolt and the nut.

8. Separate the knuckle from the ball joint using the

ball joint remover KM–507–B.

9. Remove the nuts from the bolts that connect the

knuckle assembly to the strut assembly.

Page 929 of 2643

2C – 12IFRONT SUSPENSION

DAEWOO V–121 BL4

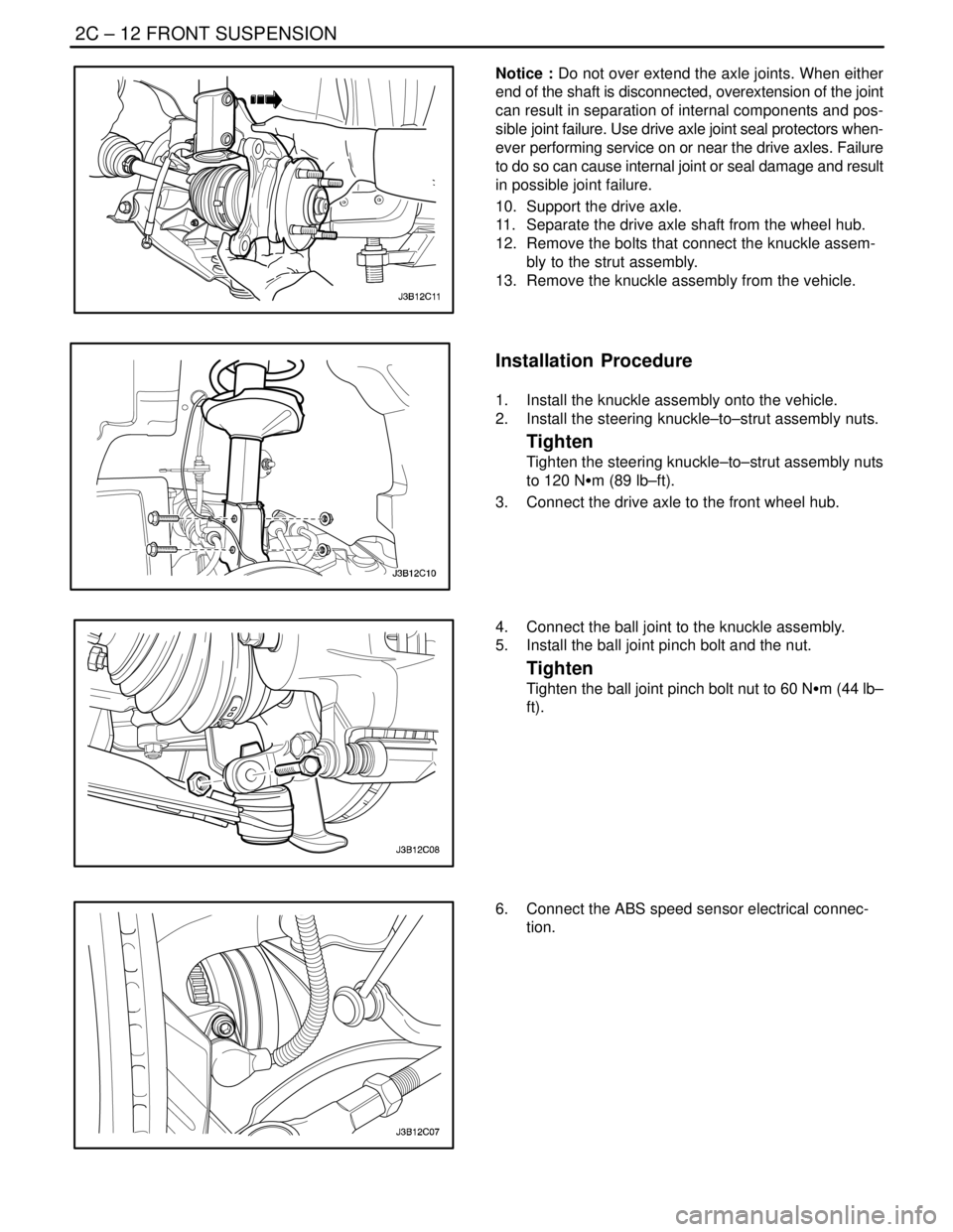

Notice : Do not over extend the axle joints. When either

end of the shaft is disconnected, overextension of the joint

can result in separation of internal components and pos-

sible joint failure. Use drive axle joint seal protectors when-

ever performing service on or near the drive axles. Failure

to do so can cause internal joint or seal damage and result

in possible joint failure.

10. Support the drive axle.

11. Separate the drive axle shaft from the wheel hub.

12. Remove the bolts that connect the knuckle assem-

bly to the strut assembly.

13. Remove the knuckle assembly from the vehicle.

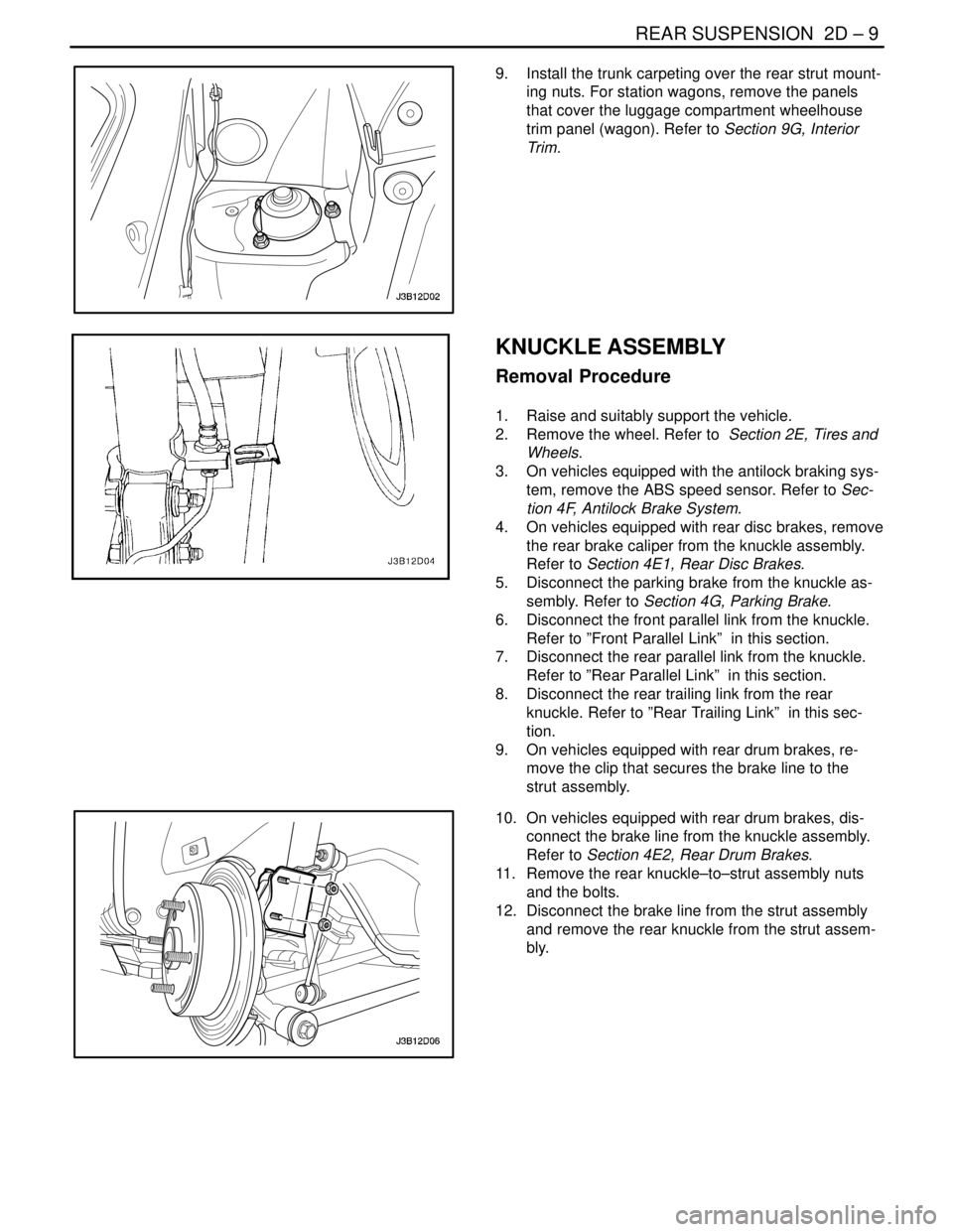

Installation Procedure

1. Install the knuckle assembly onto the vehicle.

2. Install the steering knuckle–to–strut assembly nuts.

Tighten

Tighten the steering knuckle–to–strut assembly nuts

to 120 NSm (89 lb–ft).

3. Connect the drive axle to the front wheel hub.

4. Connect the ball joint to the knuckle assembly.

5. Install the ball joint pinch bolt and the nut.

Tighten

Tighten the ball joint pinch bolt nut to 60 NSm (44 lb–

ft).

6. Connect the ABS speed sensor electrical connec-

tion.

Page 951 of 2643

REAR SUSPENSION 2D – 9

DAEWOO V–121 BL4

9. Install the trunk carpeting over the rear strut mount-

ing nuts. For station wagons, remove the panels

that cover the luggage compartment wheelhouse

trim panel (wagon). Refer to Section 9G, Interior

Trim.

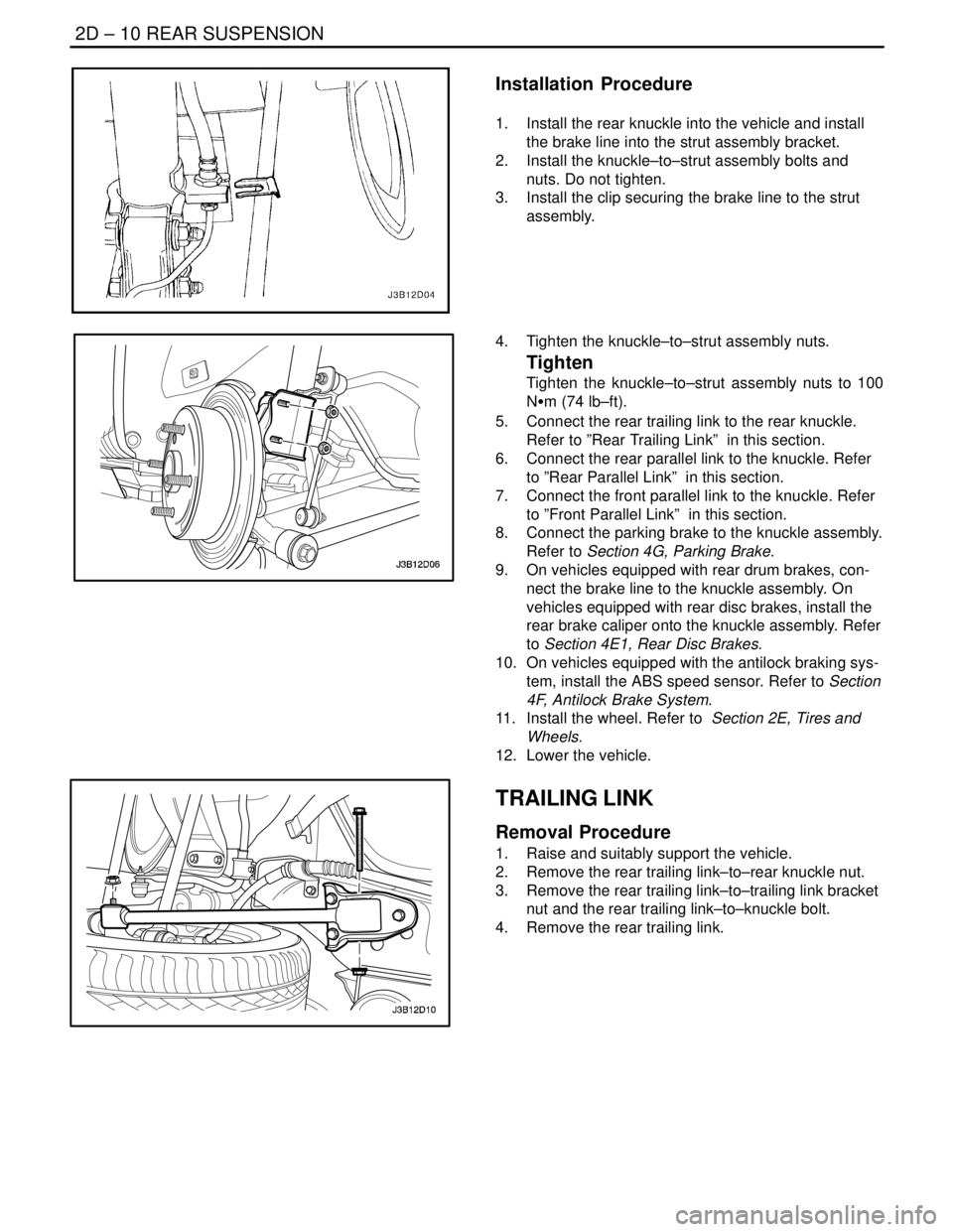

KNUCKLE ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. On vehicles equipped with the antilock braking sys-

tem, remove the ABS speed sensor. Refer to Sec-

tion 4F, Antilock Brake System.

4. On vehicles equipped with rear disc brakes, remove

the rear brake caliper from the knuckle assembly.

Refer to Section 4E1, Rear Disc Brakes.

5. Disconnect the parking brake from the knuckle as-

sembly. Refer to Section 4G, Parking Brake.

6. Disconnect the front parallel link from the knuckle.

Refer to ”Front Parallel Link” in this section.

7. Disconnect the rear parallel link from the knuckle.

Refer to ”Rear Parallel Link” in this section.

8. Disconnect the rear trailing link from the rear

knuckle. Refer to ”Rear Trailing Link” in this sec-

tion.

9. On vehicles equipped with rear drum brakes, re-

move the clip that secures the brake line to the

strut assembly.

10. On vehicles equipped with rear drum brakes, dis-

connect the brake line from the knuckle assembly.

Refer to Section 4E2, Rear Drum Brakes.

11. Remove the rear knuckle–to–strut assembly nuts

and the bolts.

12. Disconnect the brake line from the strut assembly

and remove the rear knuckle from the strut assem-

bly.

Page 952 of 2643

2D – 10IREAR SUSPENSION

DAEWOO V–121 BL4

Installation Procedure

1. Install the rear knuckle into the vehicle and install

the brake line into the strut assembly bracket.

2. Install the knuckle–to–strut assembly bolts and

nuts. Do not tighten.

3. Install the clip securing the brake line to the strut

assembly.

4. Tighten the knuckle–to–strut assembly nuts.

Tighten

Tighten the knuckle–to–strut assembly nuts to 100

NSm (74 lb–ft).

5. Connect the rear trailing link to the rear knuckle.

Refer to ”Rear Trailing Link” in this section.

6. Connect the rear parallel link to the knuckle. Refer

to ”Rear Parallel Link” in this section.

7. Connect the front parallel link to the knuckle. Refer

to ”Front Parallel Link” in this section.

8. Connect the parking brake to the knuckle assembly.

Refer to Section 4G, Parking Brake.

9. On vehicles equipped with rear drum brakes, con-

nect the brake line to the knuckle assembly. On

vehicles equipped with rear disc brakes, install the

rear brake caliper onto the knuckle assembly. Refer

to Section 4E1, Rear Disc Brakes.

10. On vehicles equipped with the antilock braking sys-

tem, install the ABS speed sensor. Refer to Section

4F, Antilock Brake System.

11. Install the wheel. Refer to Section 2E, Tires and

Wheels.

12. Lower the vehicle.

TRAILING LINK

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear trailing link–to–rear knuckle nut.

3. Remove the rear trailing link–to–trailing link bracket

nut and the rear trailing link–to–knuckle bolt.

4. Remove the rear trailing link.

Page 956 of 2643

2D – 14IREAR SUSPENSION

DAEWOO V–121 BL4

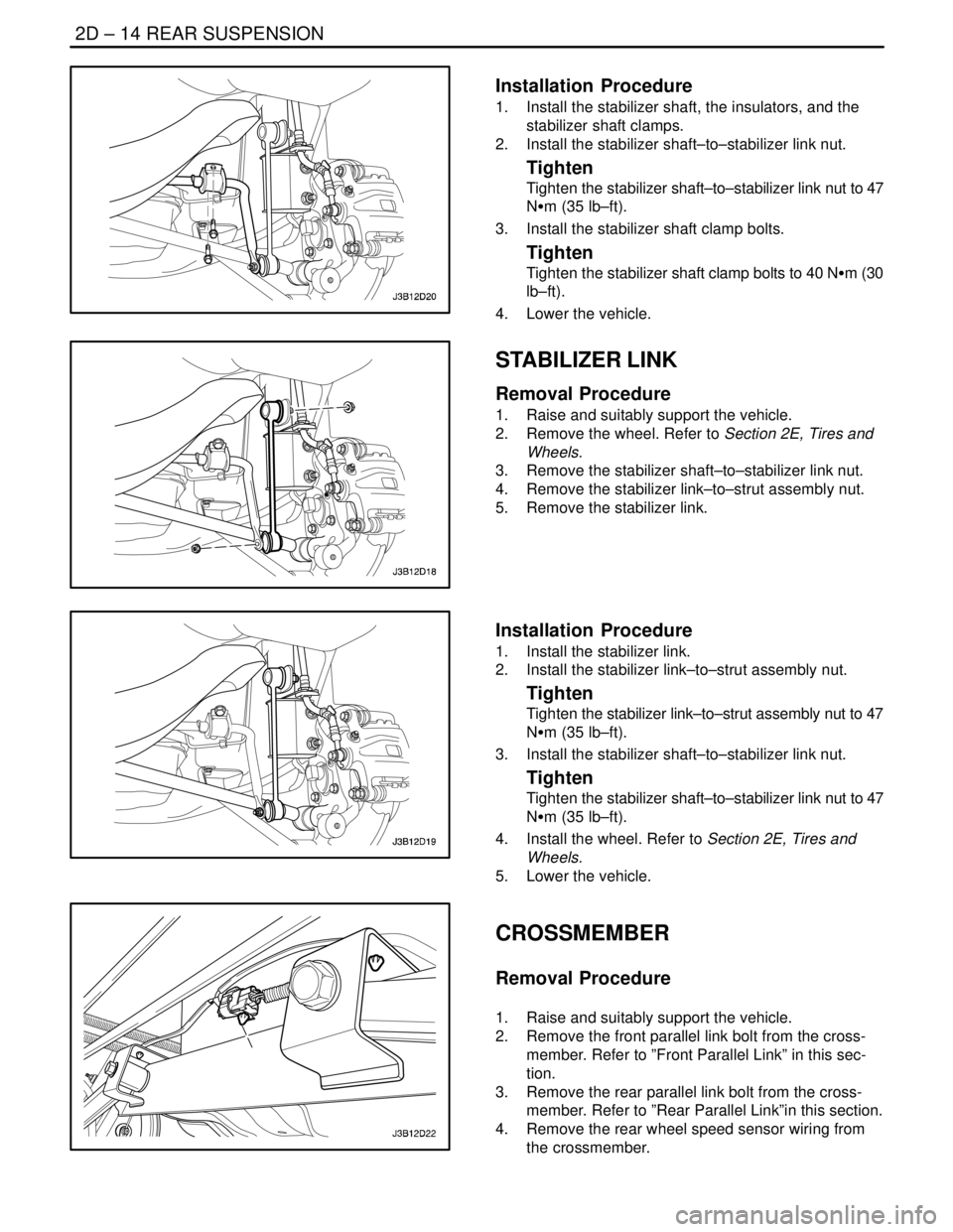

Installation Procedure

1. Install the stabilizer shaft, the insulators, and the

stabilizer shaft clamps.

2. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft clamp bolts.

Tighten

Tighten the stabilizer shaft clamp bolts to 40 NSm (30

lb–ft).

4. Lower the vehicle.

STABILIZER LINK

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the stabilizer shaft–to–stabilizer link nut.

4. Remove the stabilizer link–to–strut assembly nut.

5. Remove the stabilizer link.

Installation Procedure

1. Install the stabilizer link.

2. Install the stabilizer link–to–strut assembly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

4. Install the wheel. Refer to Section 2E, Tires and

Wheels.

5. Lower the vehicle.

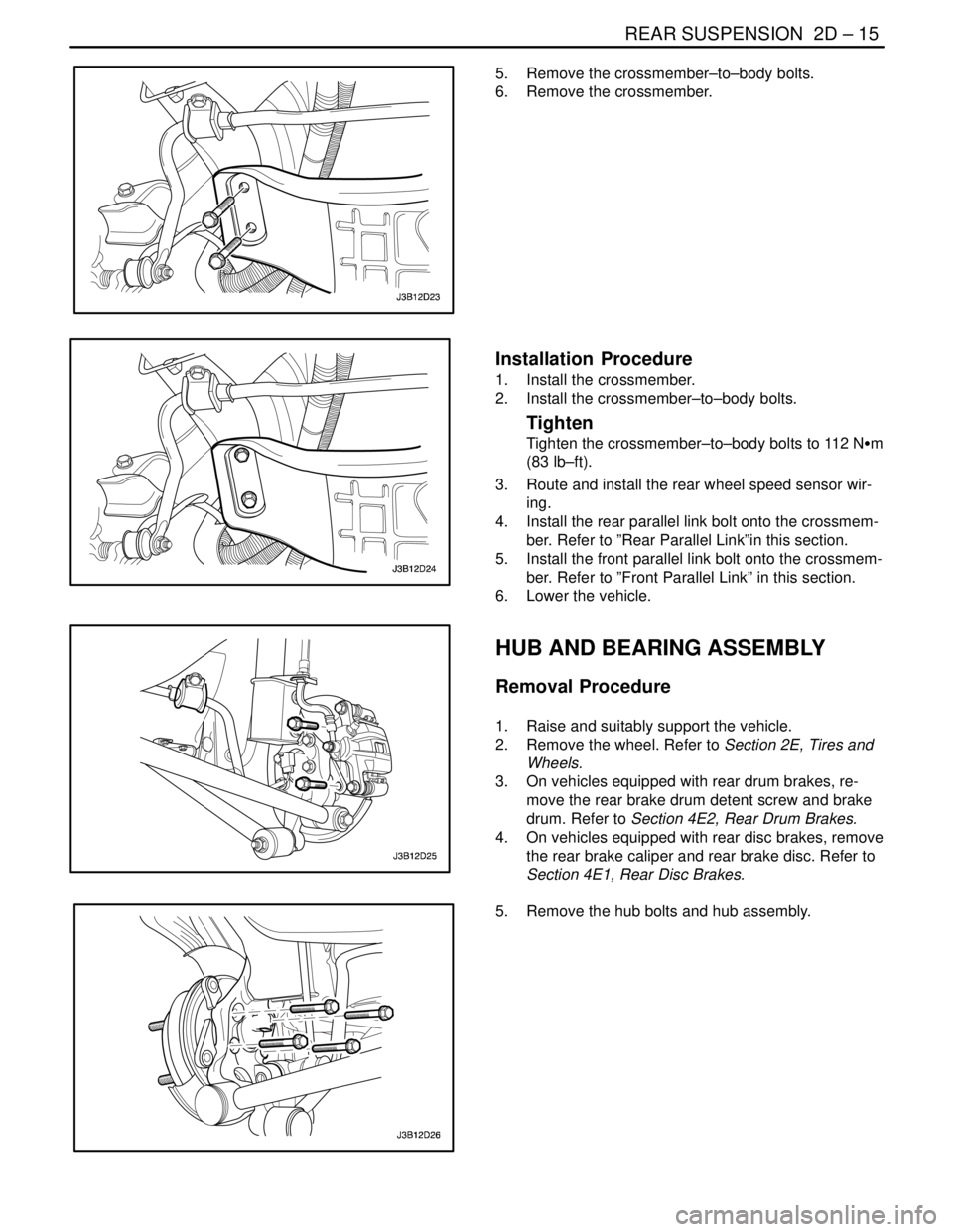

CROSSMEMBER

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the front parallel link bolt from the cross-

member. Refer to ”Front Parallel Link” in this sec-

tion.

3. Remove the rear parallel link bolt from the cross-

member. Refer to ”Rear Parallel Link”in this section.

4. Remove the rear wheel speed sensor wiring from

the crossmember.

Page 957 of 2643

REAR SUSPENSION 2D – 15

DAEWOO V–121 BL4

5. Remove the crossmember–to–body bolts.

6. Remove the crossmember.

Installation Procedure

1. Install the crossmember.

2. Install the crossmember–to–body bolts.

Tighten

Tighten the crossmember–to–body bolts to 112 NSm

(83 lb–ft).

3. Route and install the rear wheel speed sensor wir-

ing.

4. Install the rear parallel link bolt onto the crossmem-

ber. Refer to ”Rear Parallel Link”in this section.

5. Install the front parallel link bolt onto the crossmem-

ber. Refer to ”Front Parallel Link” in this section.

6. Lower the vehicle.

HUB AND BEARING ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. On vehicles equipped with rear drum brakes, re-

move the rear brake drum detent screw and brake

drum. Refer to Section 4E2, Rear Drum Brakes.

4. On vehicles equipped with rear disc brakes, remove

the rear brake caliper and rear brake disc. Refer to

Section 4E1, Rear Disc Brakes.

5. Remove the hub bolts and hub assembly.

Page 966 of 2643

2E – 4ITIRES AND WHEELS

DAEWOO V–121 BL4

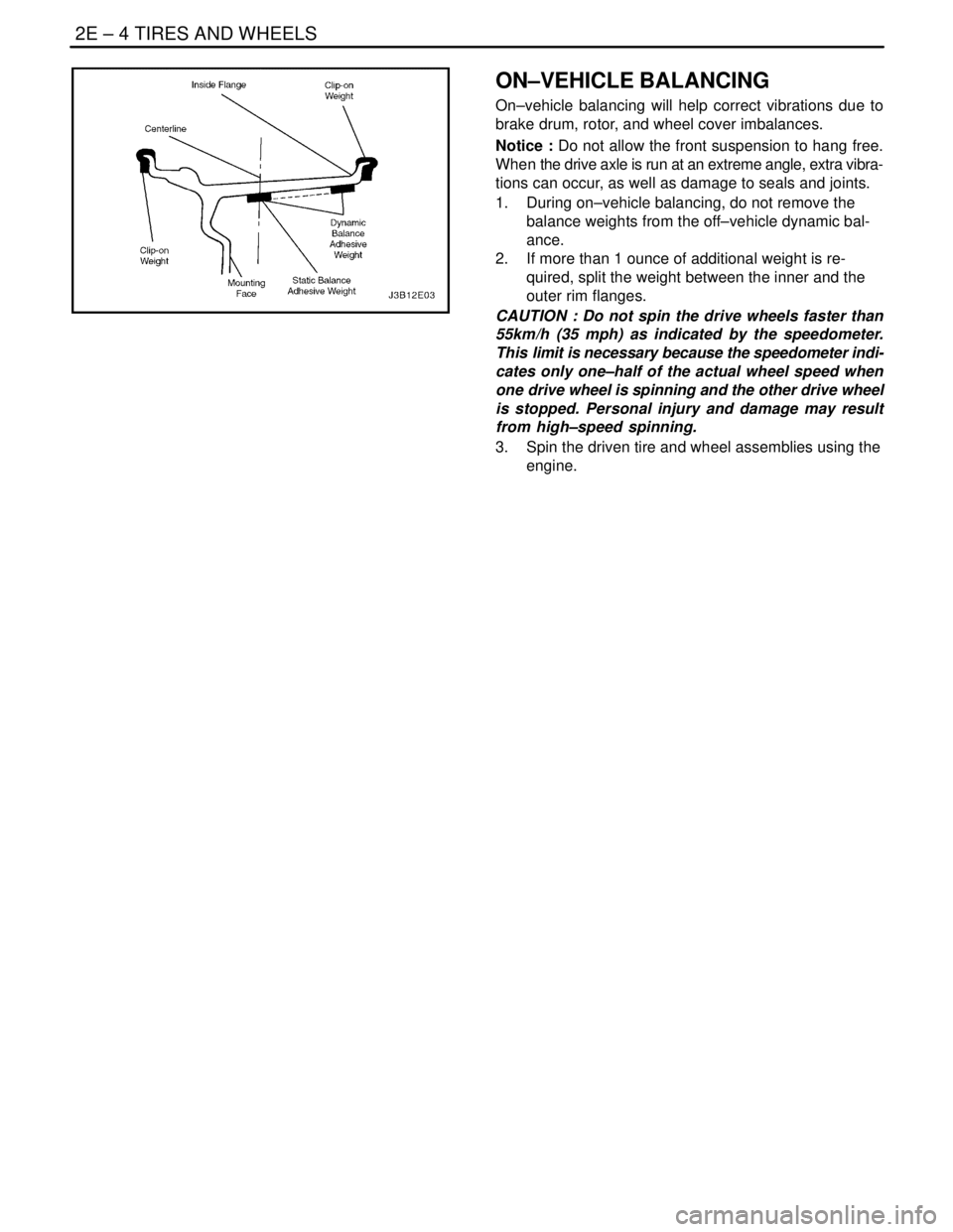

ON–VEHICLE BALANCING

On–vehicle balancing will help correct vibrations due to

brake drum, rotor, and wheel cover imbalances.

Notice : Do not allow the front suspension to hang free.

When the drive axle is run at an extreme angle, extra vibra-

tions can occur, as well as damage to seals and joints.

1. During on–vehicle balancing, do not remove the

balance weights from the off–vehicle dynamic bal-

ance.

2. If more than 1 ounce of additional weight is re-

quired, split the weight between the inner and the

outer rim flanges.

CAUTION : Do not spin the drive wheels faster than

55km/h (35 mph) as indicated by the speedometer.

This limit is necessary because the speedometer indi-

cates only one–half of the actual wheel speed when

one drive wheel is spinning and the other drive wheel

is stopped. Personal injury and damage may result

from high–speed spinning.

3. Spin the driven tire and wheel assemblies using the

engine.