speed DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 809 of 2643

ENGINE CONTROLS 1F – 563

DAEWOO V–121 BL4

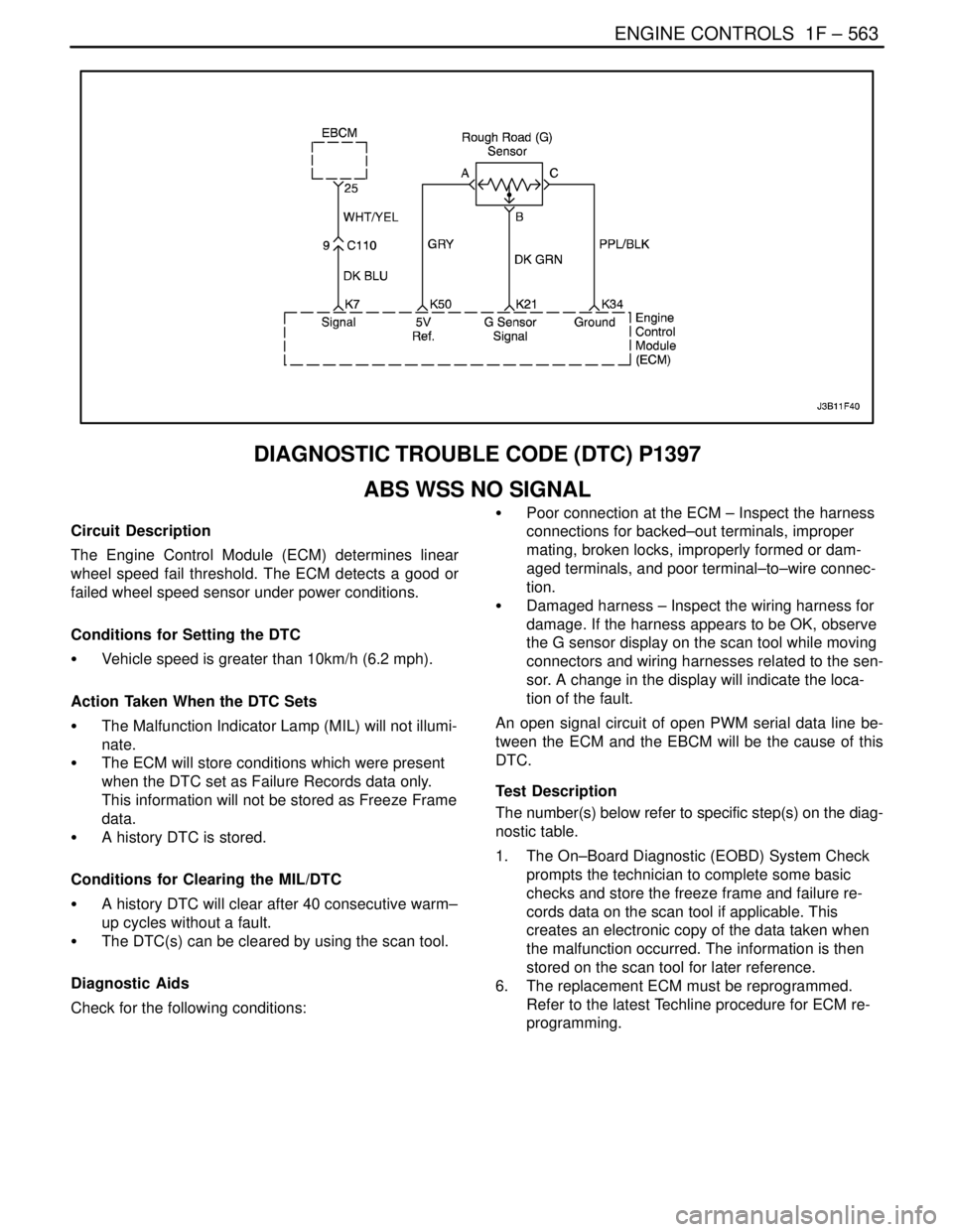

DIAGNOSTIC TROUBLE CODE (DTC) P1397

ABS WSS NO SIGNAL

Circuit Description

The Engine Control Module (ECM) determines linear

wheel speed fail threshold. The ECM detects a good or

failed wheel speed sensor under power conditions.

Conditions for Setting the DTC

S Vehicle speed is greater than 10km/h (6.2 mph).

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored as Freeze Frame

data.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

Diagnostic Aids

Check for the following conditions:S Poor connection at the ECM – Inspect the harness

connections for backed–out terminals, improper

mating, broken locks, improperly formed or dam-

aged terminals, and poor terminal–to–wire connec-

tion.

S Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the G sensor display on the scan tool while moving

connectors and wiring harnesses related to the sen-

sor. A change in the display will indicate the loca-

tion of the fault.

An open signal circuit of open PWM serial data line be-

tween the ECM and the EBCM will be the cause of this

DTC.

Test Description

The number(s) below refer to specific step(s) on the diag-

nostic table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 825 of 2643

ENGINE CONTROLS 1F – 579

DAEWOO V–121 BL4

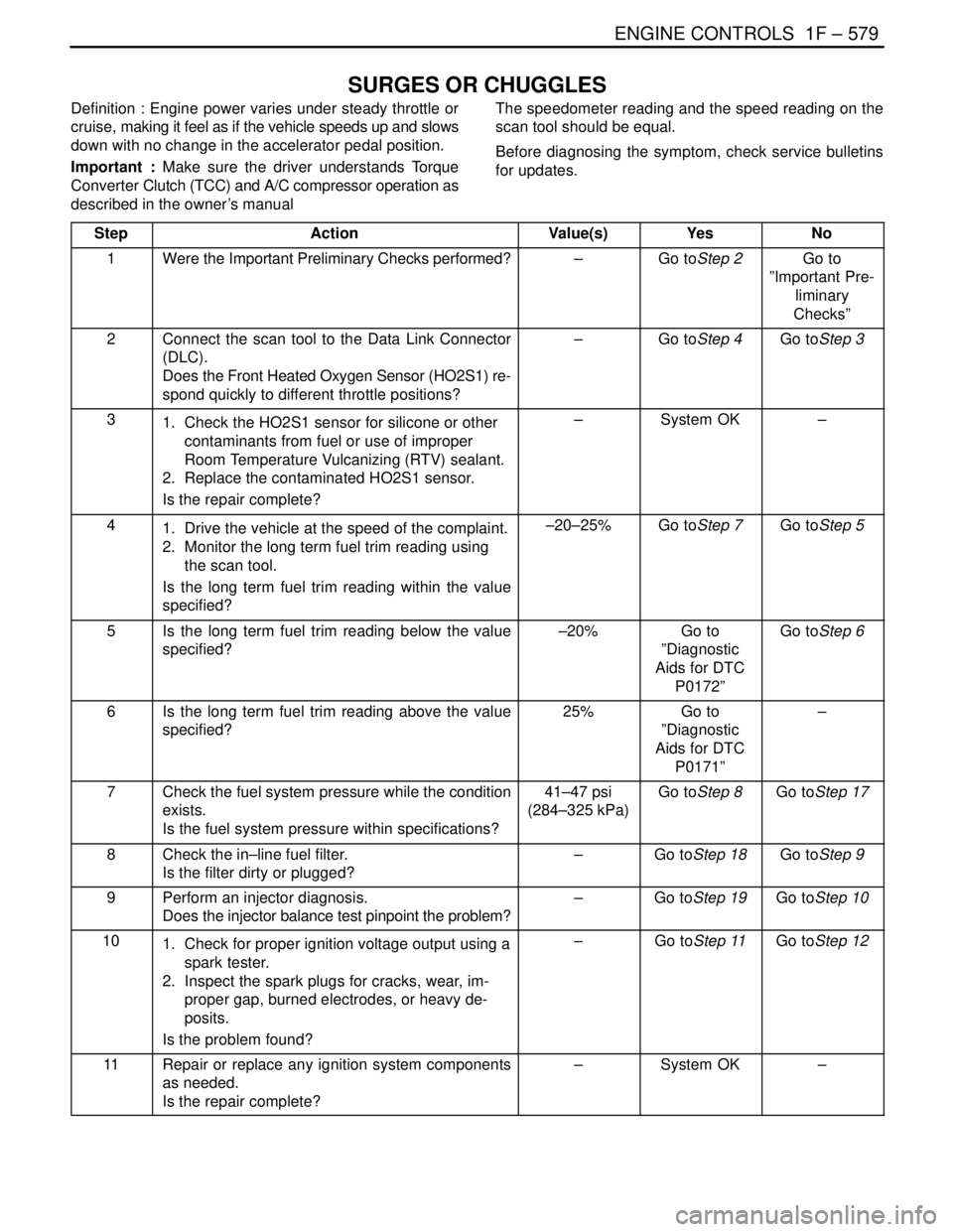

SURGES OR CHUGGLES

Definition : Engine power varies under steady throttle or

cruise, making it feel as if the vehicle speeds up and slows

down with no change in the accelerator pedal position.

Important : Make sure the driver understands Torque

Converter Clutch (TCC) and A/C compressor operation as

described in the owner’s manualThe speedometer reading and the speed reading on the

scan tool should be equal.

Before diagnosing the symptom, check service bulletins

for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Connect the scan tool to the Data Link Connector

(DLC).

Does the Front Heated Oxygen Sensor (HO2S1) re-

spond quickly to different throttle positions?–Go toStep 4Go toStep 3

31. Check the HO2S1 sensor for silicone or other

contaminants from fuel or use of improper

Room Temperature Vulcanizing (RTV) sealant.

2. Replace the contaminated HO2S1 sensor.

Is the repair complete?–System OK–

41. Drive the vehicle at the speed of the complaint.

2. Monitor the long term fuel trim reading using

the scan tool.

Is the long term fuel trim reading within the value

specified?–20–25%Go toStep 7Go toStep 5

5Is the long term fuel trim reading below the value

specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 6

6Is the long term fuel trim reading above the value

specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

7Check the fuel system pressure while the condition

exists.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 8Go toStep 17

8Check the in–line fuel filter.

Is the filter dirty or plugged?–Go toStep 18Go toStep 9

9Perform an injector diagnosis.

Does the injector balance test pinpoint the problem?–Go toStep 19Go toStep 10

101. Check for proper ignition voltage output using a

spark tester.

2. Inspect the spark plugs for cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

Is the problem found?–Go toStep 11Go toStep 12

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

Page 827 of 2643

ENGINE CONTROLS 1F – 581

DAEWOO V–121 BL4

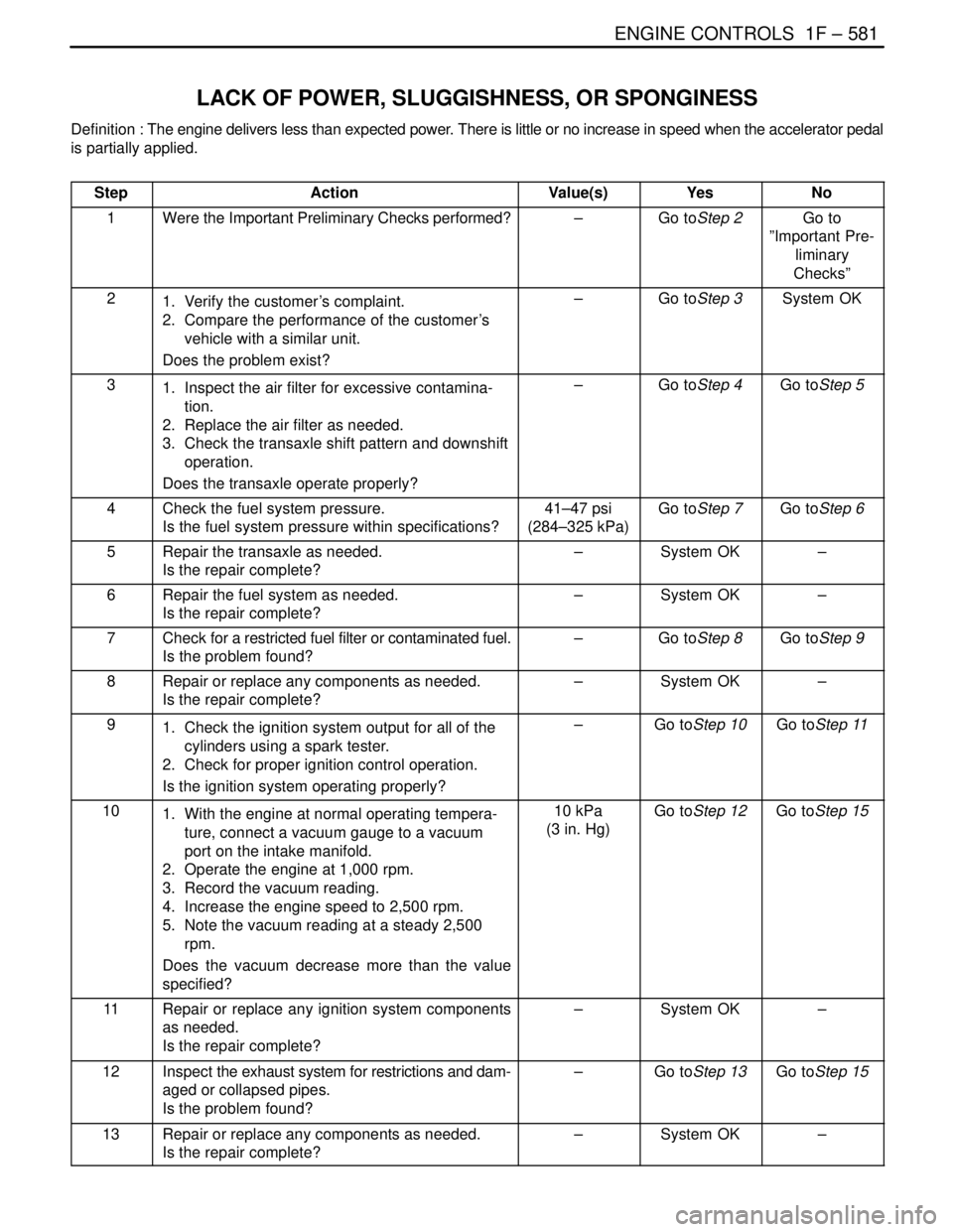

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Definition : The engine delivers less than expected power. There is little or no increase in speed when the accelerator pedal

is partially applied.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Verify the customer’s complaint.

2. Compare the performance of the customer’s

vehicle with a similar unit.

Does the problem exist?–Go toStep 3System OK

31. Inspect the air filter for excessive contamina-

tion.

2. Replace the air filter as needed.

3. Check the transaxle shift pattern and downshift

operation.

Does the transaxle operate properly?–Go toStep 4Go toStep 5

4Check the fuel system pressure.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 7Go toStep 6

5Repair the transaxle as needed.

Is the repair complete?–System OK–

6Repair the fuel system as needed.

Is the repair complete?–System OK–

7Check for a restricted fuel filter or contaminated fuel.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the ignition system output for all of the

cylinders using a spark tester.

2. Check for proper ignition control operation.

Is the ignition system operating properly?–Go toStep 10Go toStep 11

101. With the engine at normal operating tempera-

ture, connect a vacuum gauge to a vacuum

port on the intake manifold.

2. Operate the engine at 1,000 rpm.

3. Record the vacuum reading.

4. Increase the engine speed to 2,500 rpm.

5. Note the vacuum reading at a steady 2,500

rpm.

Does the vacuum decrease more than the value

specified?10 kPa

(3 in. Hg)Go toStep 12Go toStep 15

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

12Inspect the exhaust system for restrictions and dam-

aged or collapsed pipes.

Is the problem found?–Go toStep 13Go toStep 15

13Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 829 of 2643

ENGINE CONTROLS 1F – 583

DAEWOO V–121 BL4

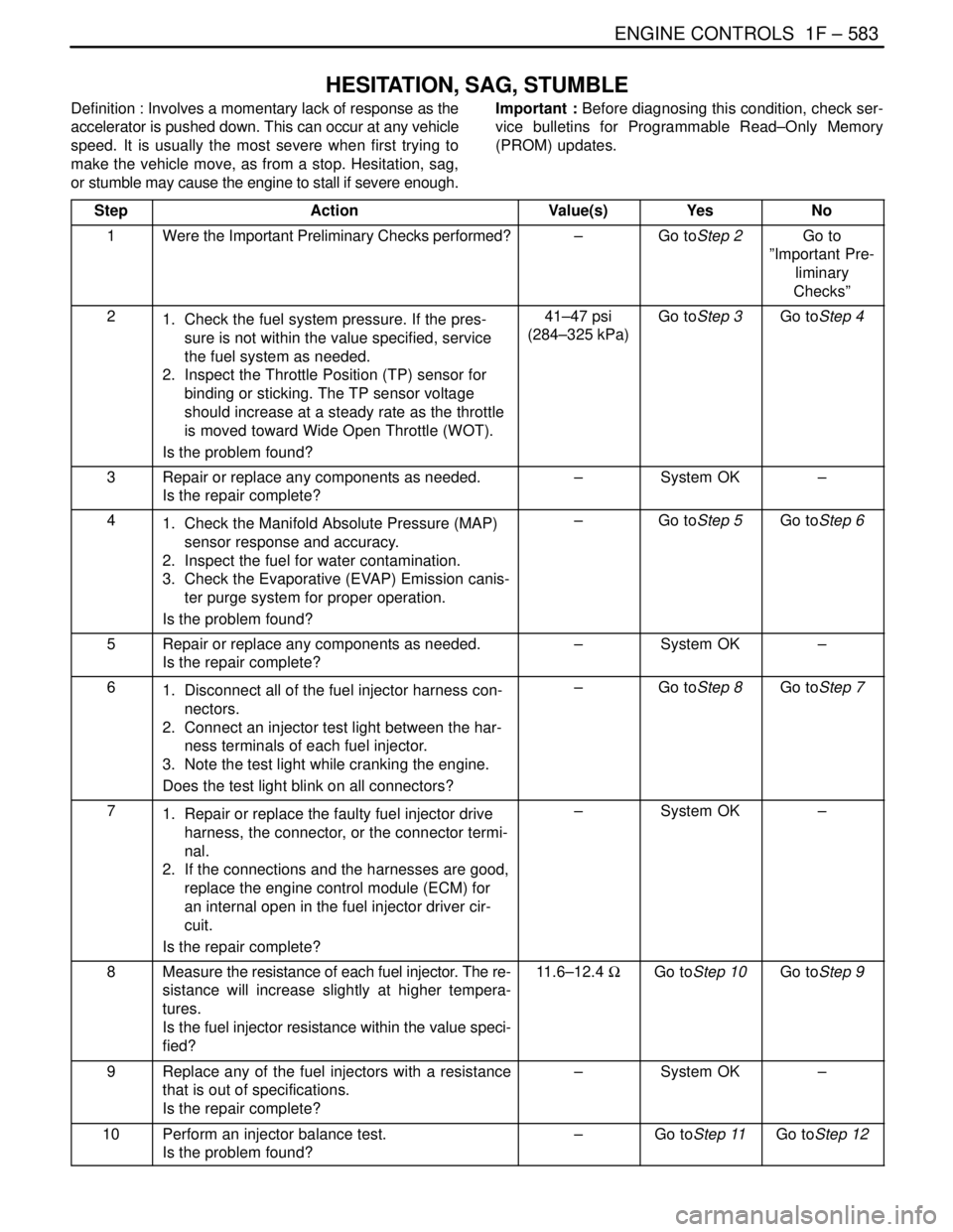

HESITATION, SAG, STUMBLE

Definition : Involves a momentary lack of response as the

accelerator is pushed down. This can occur at any vehicle

speed. It is usually the most severe when first trying to

make the vehicle move, as from a stop. Hesitation, sag,

or stumble may cause the engine to stall if severe enough.Important : Before diagnosing this condition, check ser-

vice bulletins for Programmable Read–Only Memory

(PROM) updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Check the fuel system pressure. If the pres-

sure is not within the value specified, service

the fuel system as needed.

2. Inspect the Throttle Position (TP) sensor for

binding or sticking. The TP sensor voltage

should increase at a steady rate as the throttle

is moved toward Wide Open Throttle (WOT).

Is the problem found?41–47 psi

(284–325 kPa)Go toStep 3Go toStep 4

3Repair or replace any components as needed.

Is the repair complete?–System OK–

41. Check the Manifold Absolute Pressure (MAP)

sensor response and accuracy.

2. Inspect the fuel for water contamination.

3. Check the Evaporative (EVAP) Emission canis-

ter purge system for proper operation.

Is the problem found?–Go toStep 5Go toStep 6

5Repair or replace any components as needed.

Is the repair complete?–System OK–

61. Disconnect all of the fuel injector harness con-

nectors.

2. Connect an injector test light between the har-

ness terminals of each fuel injector.

3. Note the test light while cranking the engine.

Does the test light blink on all connectors?–Go toStep 8Go toStep 7

71. Repair or replace the faulty fuel injector drive

harness, the connector, or the connector termi-

nal.

2. If the connections and the harnesses are good,

replace the engine control module (ECM) for

an internal open in the fuel injector driver cir-

cuit.

Is the repair complete?–System OK–

8Measure the resistance of each fuel injector. The re-

sistance will increase slightly at higher tempera-

tures.

Is the fuel injector resistance within the value speci-

fied?11.6–12.4 ΩGo toStep 10Go toStep 9

9Replace any of the fuel injectors with a resistance

that is out of specifications.

Is the repair complete?–System OK–

10Perform an injector balance test.

Is the problem found?–Go toStep 11Go toStep 12

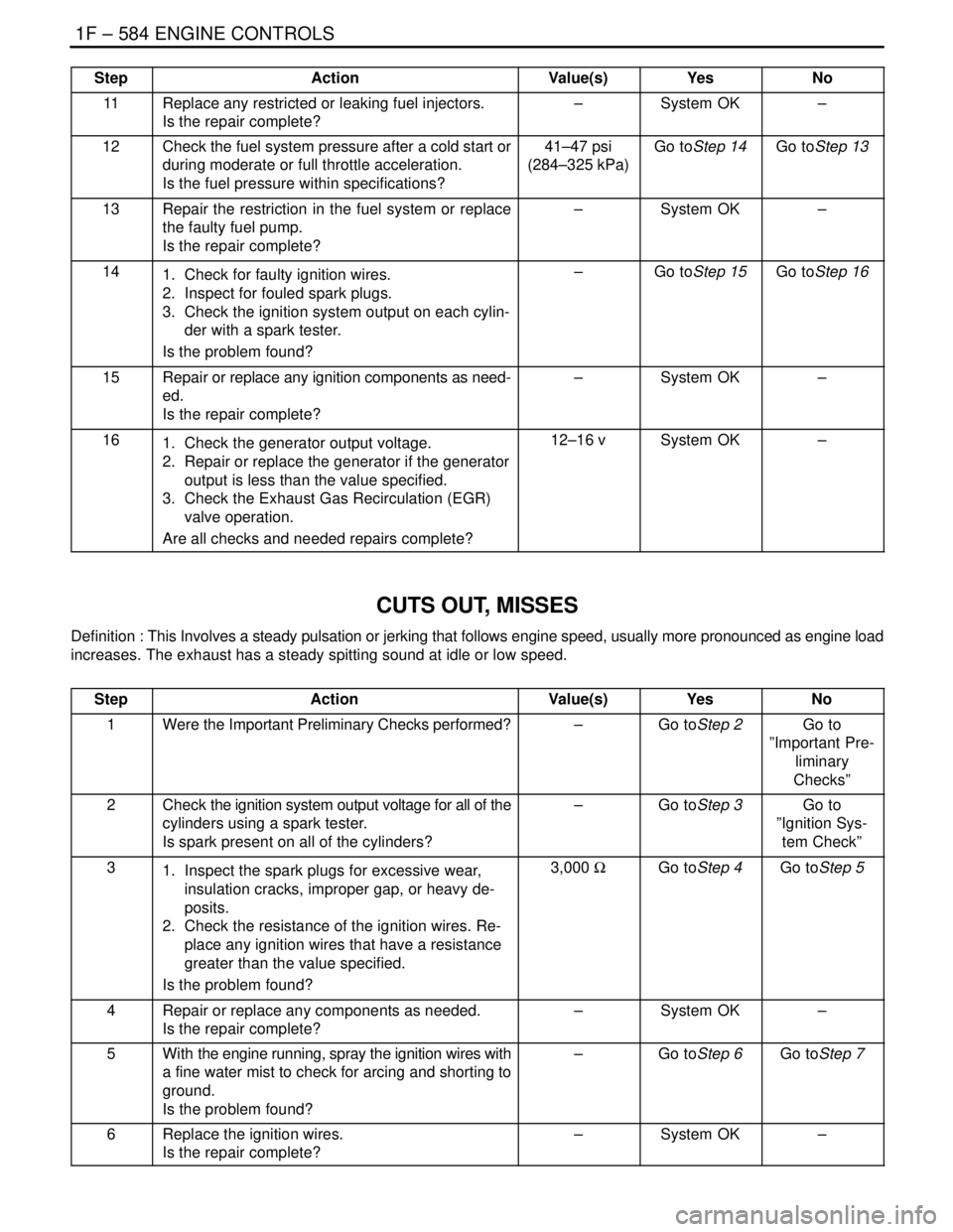

Page 830 of 2643

1F – 584IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

11Replace any restricted or leaking fuel injectors.

Is the repair complete?–System OK–

12Check the fuel system pressure after a cold start or

during moderate or full throttle acceleration.

Is the fuel pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 14Go toStep 13

13Repair the restriction in the fuel system or replace

the faulty fuel pump.

Is the repair complete?–System OK–

141. Check for faulty ignition wires.

2. Inspect for fouled spark plugs.

3. Check the ignition system output on each cylin-

der with a spark tester.

Is the problem found?–Go toStep 15Go toStep 16

15Repair or replace any ignition components as need-

ed.

Is the repair complete?–System OK–

161. Check the generator output voltage.

2. Repair or replace the generator if the generator

output is less than the value specified.

3. Check the Exhaust Gas Recirculation (EGR)

valve operation.

Are all checks and needed repairs complete?12–16 vSystem OK–

CUTS OUT, MISSES

Definition : This Involves a steady pulsation or jerking that follows engine speed, usually more pronounced as engine load

increases. The exhaust has a steady spitting sound at idle or low speed.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Check the ignition system output voltage for all of the

cylinders using a spark tester.

Is spark present on all of the cylinders?–Go toStep 3Go to

”Ignition Sys-

tem Check”

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Check the resistance of the ignition wires. Re-

place any ignition wires that have a resistance

greater than the value specified.

Is the problem found?3,000 ΩGo toStep 4Go toStep 5

4Repair or replace any components as needed.

Is the repair complete?–System OK–

5With the engine running, spray the ignition wires with

a fine water mist to check for arcing and shorting to

ground.

Is the problem found?–Go toStep 6Go toStep 7

6Replace the ignition wires.

Is the repair complete?–System OK–

Page 833 of 2643

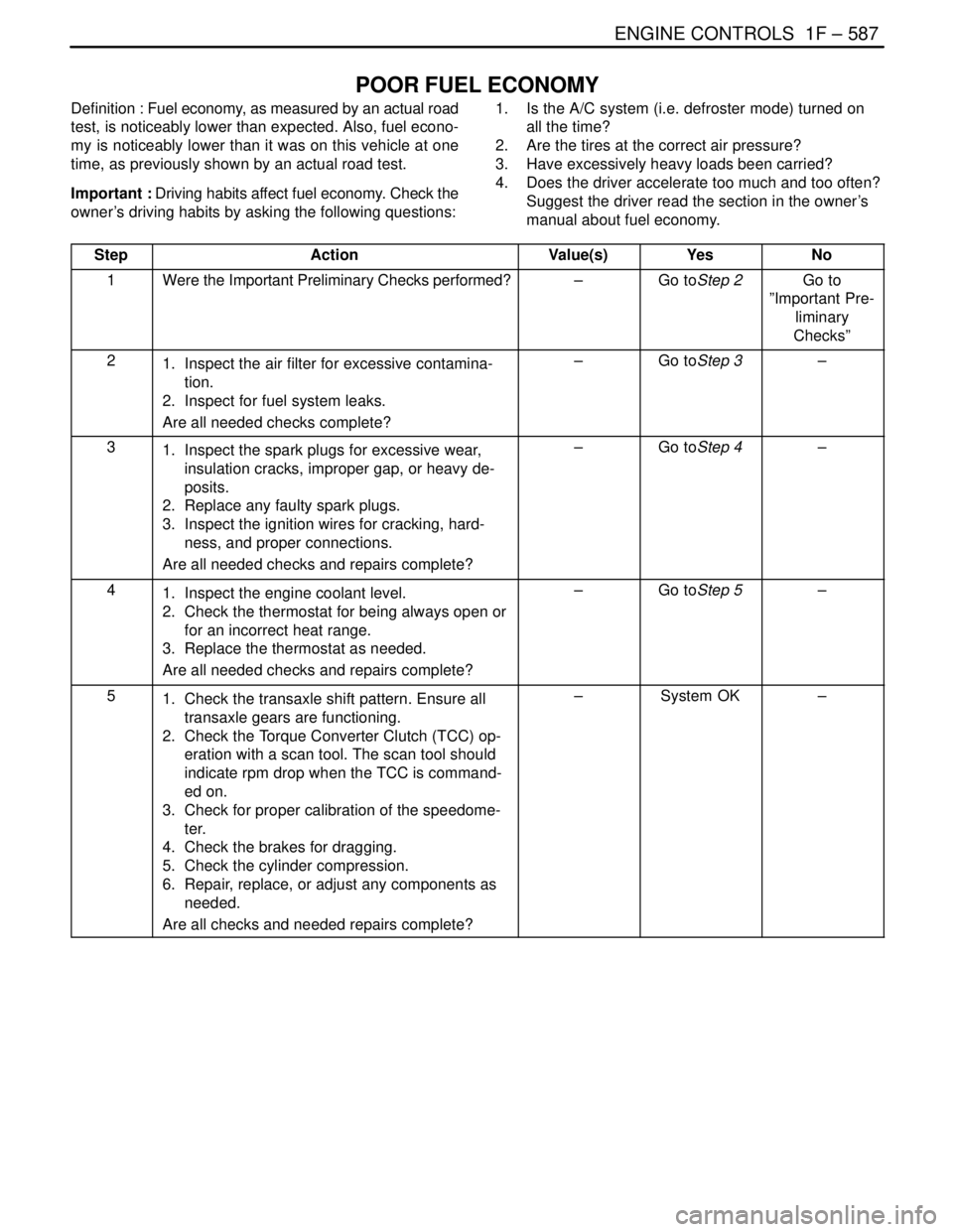

ENGINE CONTROLS 1F – 587

DAEWOO V–121 BL4

POOR FUEL ECONOMY

Definition : Fuel economy, as measured by an actual road

test, is noticeably lower than expected. Also, fuel econo-

my is noticeably lower than it was on this vehicle at one

time, as previously shown by an actual road test.

Important : Driving habits affect fuel economy. Check the

owner’s driving habits by asking the following questions:1. Is the A/C system (i.e. defroster mode) turned on

all the time?

2. Are the tires at the correct air pressure?

3. Have excessively heavy loads been carried?

4. Does the driver accelerate too much and too often?

Suggest the driver read the section in the owner’s

manual about fuel economy.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Inspect the air filter for excessive contamina-

tion.

2. Inspect for fuel system leaks.

Are all needed checks complete?–Go toStep 3–

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Replace any faulty spark plugs.

3. Inspect the ignition wires for cracking, hard-

ness, and proper connections.

Are all needed checks and repairs complete?–Go toStep 4–

41. Inspect the engine coolant level.

2. Check the thermostat for being always open or

for an incorrect heat range.

3. Replace the thermostat as needed.

Are all needed checks and repairs complete?–Go toStep 5–

51. Check the transaxle shift pattern. Ensure all

transaxle gears are functioning.

2. Check the Torque Converter Clutch (TCC) op-

eration with a scan tool. The scan tool should

indicate rpm drop when the TCC is command-

ed on.

3. Check for proper calibration of the speedome-

ter.

4. Check the brakes for dragging.

5. Check the cylinder compression.

6. Repair, replace, or adjust any components as

needed.

Are all checks and needed repairs complete?–System OK–

Page 834 of 2643

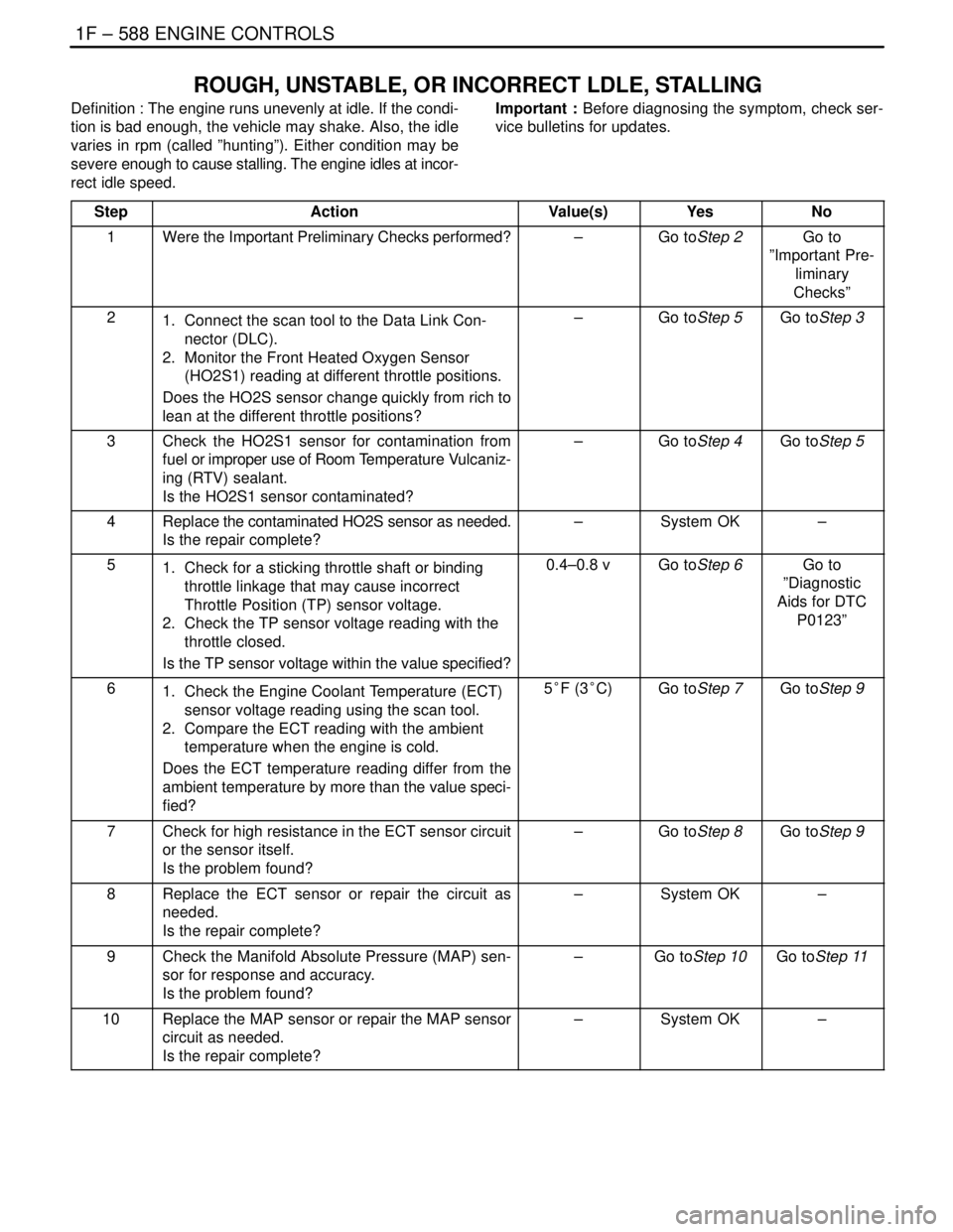

1F – 588IENGINE CONTROLS

DAEWOO V–121 BL4

ROUGH, UNSTABLE, OR INCORRECT LDLE, STALLING

Definition : The engine runs unevenly at idle. If the condi-

tion is bad enough, the vehicle may shake. Also, the idle

varies in rpm (called ”hunting”). Either condition may be

severe enough to cause stalling. The engine idles at incor-

rect idle speed.Important : Before diagnosing the symptom, check ser-

vice bulletins for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Connect the scan tool to the Data Link Con-

nector (DLC).

2. Monitor the Front Heated Oxygen Sensor

(HO2S1) reading at different throttle positions.

Does the HO2S sensor change quickly from rich to

lean at the different throttle positions?–Go toStep 5Go toStep 3

3Check the HO2S1 sensor for contamination from

fuel or improper use of Room Temperature Vulcaniz-

ing (RTV) sealant.

Is the HO2S1 sensor contaminated?–Go toStep 4Go toStep 5

4Replace the contaminated HO2S sensor as needed.

Is the repair complete?–System OK–

51. Check for a sticking throttle shaft or binding

throttle linkage that may cause incorrect

Throttle Position (TP) sensor voltage.

2. Check the TP sensor voltage reading with the

throttle closed.

Is the TP sensor voltage within the value specified?0.4–0.8 vGo toStep 6Go to

”Diagnostic

Aids for DTC

P0123”

61. Check the Engine Coolant Temperature (ECT)

sensor voltage reading using the scan tool.

2. Compare the ECT reading with the ambient

temperature when the engine is cold.

Does the ECT temperature reading differ from the

ambient temperature by more than the value speci-

fied?5°F (3°C)Go toStep 7Go toStep 9

7Check for high resistance in the ECT sensor circuit

or the sensor itself.

Is the problem found?–Go toStep 8Go toStep 9

8Replace the ECT sensor or repair the circuit as

needed.

Is the repair complete?–System OK–

9Check the Manifold Absolute Pressure (MAP) sen-

sor for response and accuracy.

Is the problem found?–Go toStep 10Go toStep 11

10Replace the MAP sensor or repair the MAP sensor

circuit as needed.

Is the repair complete?–System OK–

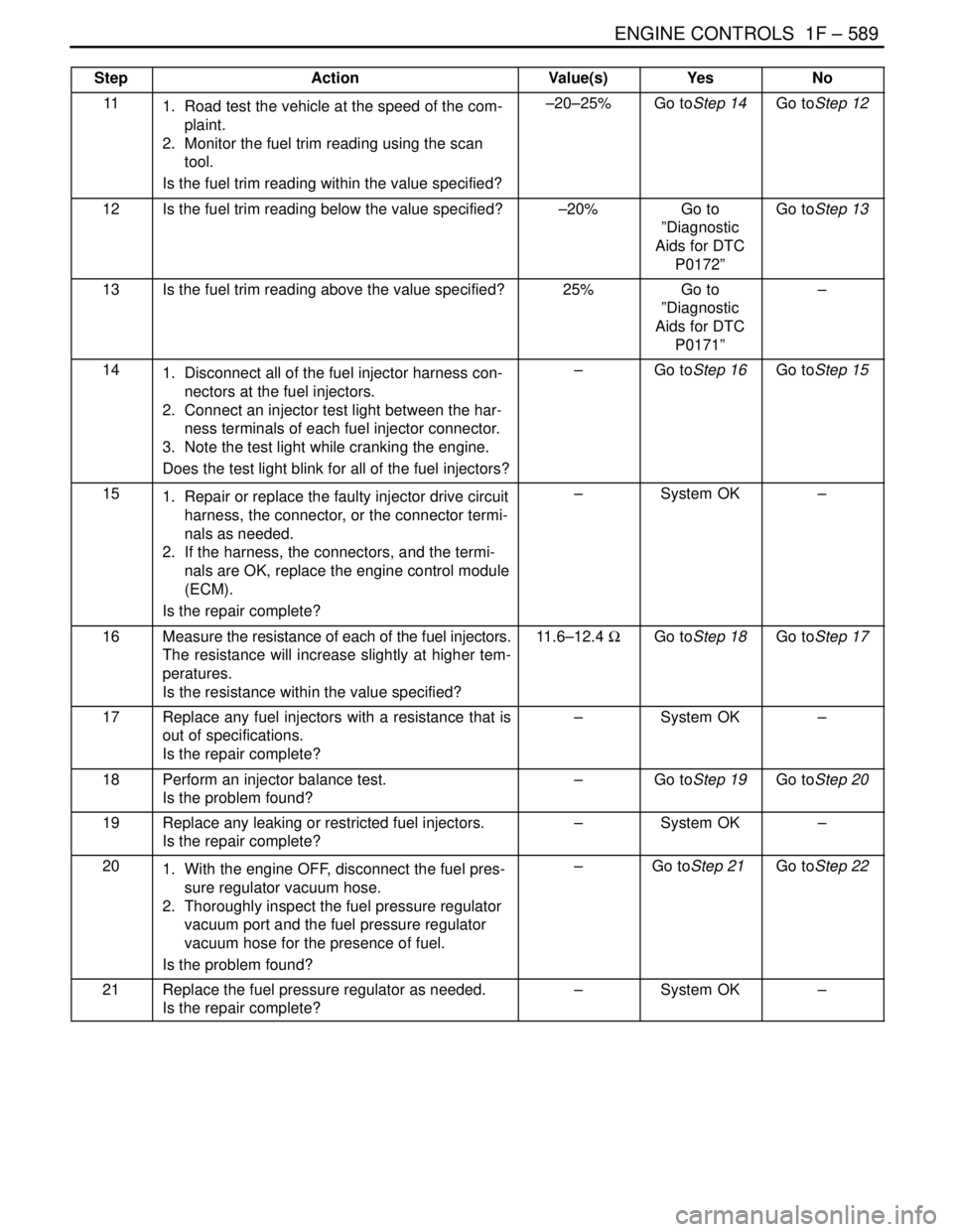

Page 835 of 2643

ENGINE CONTROLS 1F – 589

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

111. Road test the vehicle at the speed of the com-

plaint.

2. Monitor the fuel trim reading using the scan

tool.

Is the fuel trim reading within the value specified?–20–25%Go toStep 14Go toStep 12

12Is the fuel trim reading below the value specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 13

13Is the fuel trim reading above the value specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

141. Disconnect all of the fuel injector harness con-

nectors at the fuel injectors.

2. Connect an injector test light between the har-

ness terminals of each fuel injector connector.

3. Note the test light while cranking the engine.

Does the test light blink for all of the fuel injectors?–Go toStep 16Go toStep 15

151. Repair or replace the faulty injector drive circuit

harness, the connector, or the connector termi-

nals as needed.

2. If the harness, the connectors, and the termi-

nals are OK, replace the engine control module

(ECM).

Is the repair complete?–System OK–

16Measure the resistance of each of the fuel injectors.

The resistance will increase slightly at higher tem-

peratures.

Is the resistance within the value specified?11.6–12.4 ΩGo toStep 18Go toStep 17

17Replace any fuel injectors with a resistance that is

out of specifications.

Is the repair complete?–System OK–

18Perform an injector balance test.

Is the problem found?–Go toStep 19Go toStep 20

19Replace any leaking or restricted fuel injectors.

Is the repair complete?–System OK–

201. With the engine OFF, disconnect the fuel pres-

sure regulator vacuum hose.

2. Thoroughly inspect the fuel pressure regulator

vacuum port and the fuel pressure regulator

vacuum hose for the presence of fuel.

Is the problem found?–Go toStep 21 Go toStep 22

21Replace the fuel pressure regulator as needed.

Is the repair complete?–System OK–

Page 856 of 2643

1F – 610IENGINE CONTROLS

DAEWOO V–121 BL4

Notice : Do not use methyl ethyl ketone because it can

damage the parts.

6. Clean the IAC valve O–ring seal area, the pintle

valve seat, and the air passage with a suitable fuel

system cleaner.

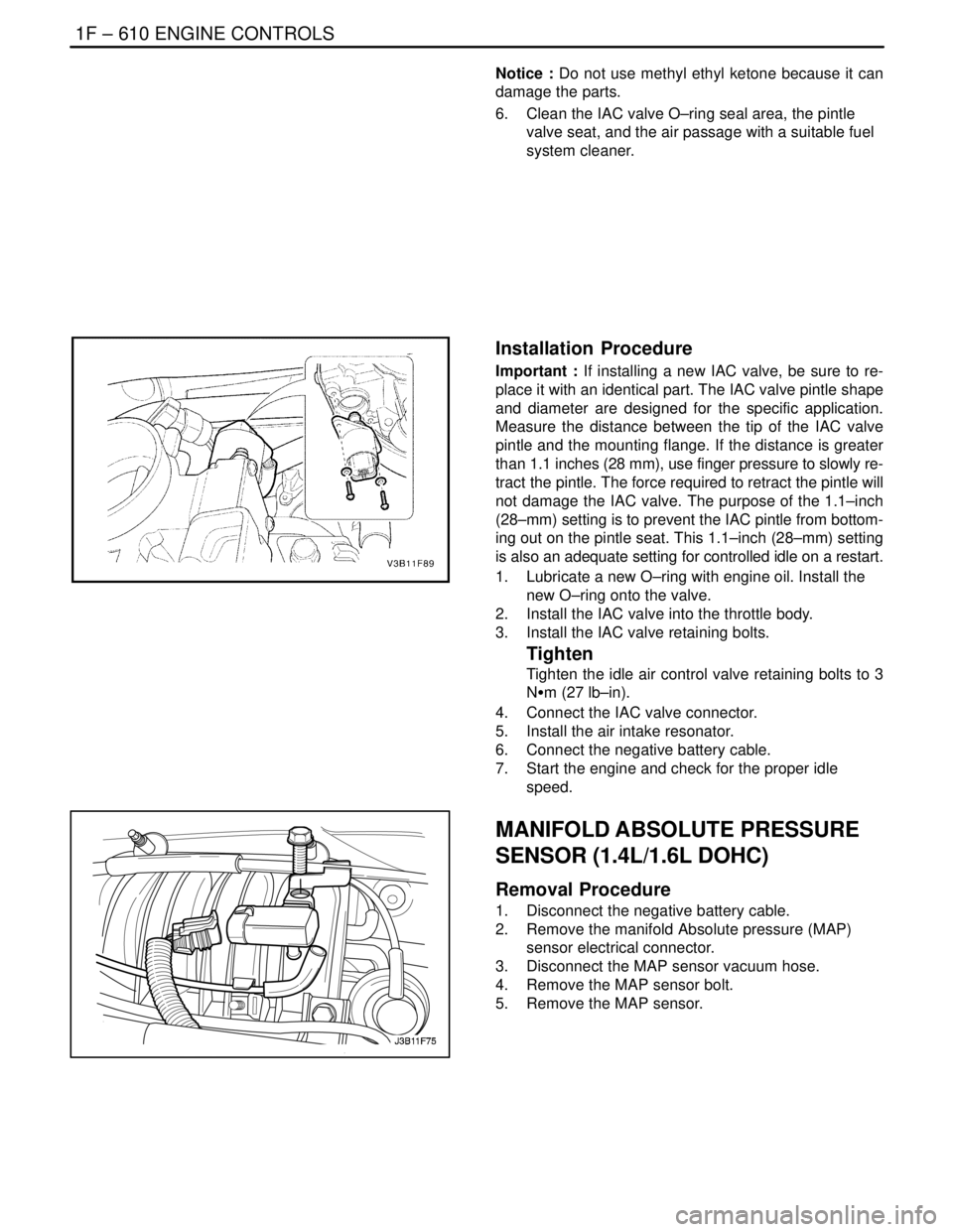

Installation Procedure

Important : If installing a new IAC valve, be sure to re-

place it with an identical part. The IAC valve pintle shape

and diameter are designed for the specific application.

Measure the distance between the tip of the IAC valve

pintle and the mounting flange. If the distance is greater

than 1.1 inches (28 mm), use finger pressure to slowly re-

tract the pintle. The force required to retract the pintle will

not damage the IAC valve. The purpose of the 1.1–inch

(28–mm) setting is to prevent the IAC pintle from bottom-

ing out on the pintle seat. This 1.1–inch (28–mm) setting

is also an adequate setting for controlled idle on a restart.

1. Lubricate a new O–ring with engine oil. Install the

new O–ring onto the valve.

2. Install the IAC valve into the throttle body.

3. Install the IAC valve retaining bolts.

Tighten

Tighten the idle air control valve retaining bolts to 3

NSm (27 lb–in).

4. Connect the IAC valve connector.

5. Install the air intake resonator.

6. Connect the negative battery cable.

7. Start the engine and check for the proper idle

speed.

MANIFOLD ABSOLUTE PRESSURE

SENSOR (1.4L/1.6L DOHC)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the manifold Absolute pressure (MAP)

sensor electrical connector.

3. Disconnect the MAP sensor vacuum hose.

4. Remove the MAP sensor bolt.

5. Remove the MAP sensor.

Page 869 of 2643

ENGINE CONTROLS 1F – 623

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distribu-

tor and coil. It uses a crankshaft position sensor input to

the engine control module (ECM). The ECM then deter-

mines Electronic Spark Timing (EST) and triggers the di-

rect ignition system ignition coil.

This type of distributorless ignition system uses a ”waste

spark” method of spark distribution. Each cylinder is

paired with the cylinder that is opposite it (1–4 or 2–3). The

spark occurs simultaneously in the cylinder coming up on

the compression stroke and in the cylinder coming up on

the exhaust stroke. The cylinder on the exhaust stroke re-

quires very little of the available energy to fire the spark

plug. The remaining energy is available to the spark plug

in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to con-

trol the electronic spark timing. The ECM uses the follow-

ing information:

S Engine load (manifold pressure or vacuum).

S Atmospheric (barometric) pressure.

S Engine temperature.

S Intake air temperature.

S Crankshaft position.

S Engine speed (rpm).

ELECTRONIC IGNITION SYSTEM

IGNITION COIL

The Electronic Ignition (EI) system ignition coil provides

the spark for two spark plugs simultaneously. The EI sys-

tem ignition coil is not serviceable and must be replaced

as an assembly.

CRANKSHAFT POSITION SENSOR

This direct ignition system uses a magnetic crankshaft

position sensor. This sensor protrudes through its mount

to within approximately 0.05 inch (1.3 mm) of the crank-

shaft reluctor. The reluctor is a special wheel attached to

the crankshaft or crankshaft pulley with 58 slots machined

into it, 57 of which are equally spaced in 6 degree intervals.

The last slot is wider and serves to generate a ”sync

pulse.” As the crankshaft rotates, the slots in the reluctor

change the magnetic field of the sensor, creating an in-

duced voltage pulse. The longer pulse of the 58th slot

identifies a specific orientation of the crankshaft and al-

lows the engine control module (ECM) to determine the

crankshaft orientation at all times. The ECM uses this in-

formation to generate timed ignition and injection pulses

that it sends to the ignition coils and to the fuel injectors.

CAMAHAFT POSITION SENSOR

The Camshaft Position (CMP) sensor sends a CMP sen-

sor signal to the engine control module (ECM). The ECM

uses this signal as a ”sync pulse” to trigger the injectors in

the proper sequence. The ECM uses the CMP sensor sig-

nal to indicate the position of the #1 piston during its power

stroke. This allows the ECM to calculate true sequential

fuel injection mode of operation. If the ECM detects an in-

correct CMP sensor signal while the engine is running,

DTC P0341 will set. If the CMP sensor signal is lost while

the engine is running, the fuel injection system will shift to

a calculated sequential fuel injection mode based on the

last fuel injection pulse, and the engine will continue to run.

As long as the fault is present, the engine can be restarted.

It will run in the calculated sequential mode with a 1–in–6

chance of the injector sequence being correct.

IDLE AIR SYSTEM OPERATION

The idle air system operation is controlled by the base idle

setting of the throttle body and the Idle Air Control (IAC)

valve.

The engine control module (ECM) uses the IAC valve to

set the idle speed dependent on conditions. The ECM

uses information from various inputs, such as coolant tem-

perature, manifold vacuum, etc., for the effective control

of the idle speed.

FUEL CONTROL SYSTEM

OPERATION

The function of the fuel metering system is to deliver the

correct amount of fuel to the engine under all operating

conditions. The fuel is delivered to the engine by the indi-

vidual fuel injectors mounted into the intake manifold near

each cylinder.

The two main fuel control sensors are the Manifold Abso-

lute Pressure (MAP) sensor, the Front Heated Oxygen

Sensor (HO2S1) and the Rear Heated Oxygen Sensor

(HO2S2).

The MAP sensor measures or senses the intake manifold

vacuum. Under high fuel demands the MAP sensor reads

a low vacuum condition, such as wide open throttle. The

engine control module (ECM) uses this information to ri-

chen the mixture, thus increasing the fuel injector on–time,

to provide the correct amount of fuel. When decelerating,

the vacuum increases. This vacuum change is sensed by

the MAP sensor and read by the ECM, which then de-

creases the fuel injector on–time due to the low fuel de-

mand conditions.

HO2S Sensors

The HO2S sensor is located in the exhaust manifold. The

HO2S sensor indicates to the ECM the amount of oxygen

in the exhaust gas and the ECM changes the air/fuel ratio

to the engine by controlling the fuel injectors. The best air/

fuel ratio to minimize exhaust emissions is 14.7 to 1, which

allows the catalytic converter to operate most efficiently.