Rear switch DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 395 of 2643

ENGINE CONTROLS 1F – 149

DAEWOO V–121 BL4

S Check for an intermittent ground in the wire be-

tween the O2 sensor and the engine control mod-

ule.

S Perform an injector 2alance test to determine if a

restricted fuel injector may be causing the lean con-

dition.S Vacuum of crankcase leaks will cause a lean run-

ning condition.

S An exhaust manifold gasket leak of a cracked ex-

haust manifold may cause outside air to be pulled

into the exhaust and past the sensor.

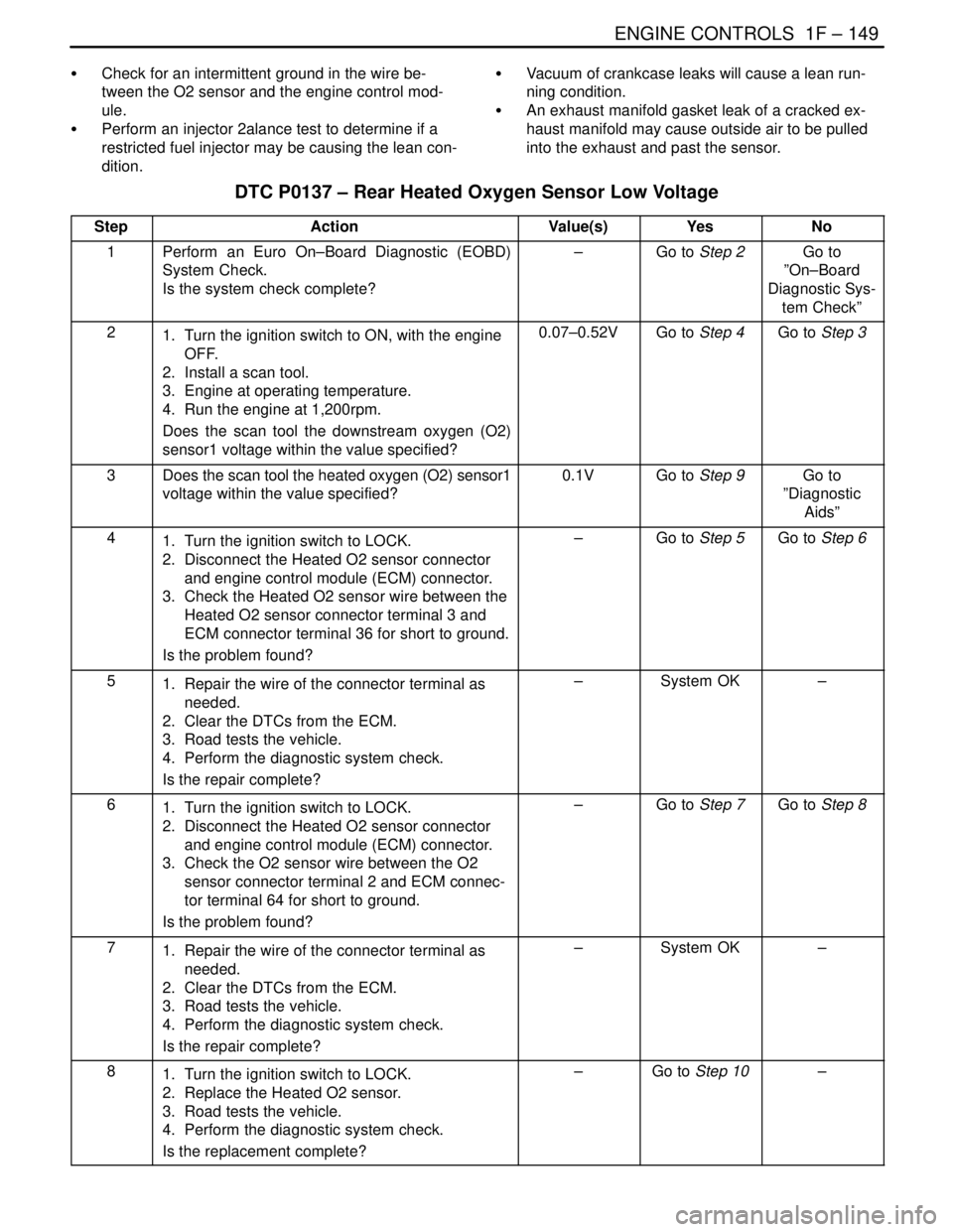

DTC P0137 – Rear Heated Oxygen Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to ON, with the engine

OFF.

2. Install a scan tool.

3. Engine at operating temperature.

4. Run the engine at 1,200rpm.

Does the scan tool the downstream oxygen (O2)

sensor1 voltage within the value specified?0.07–0.52VGo to Step 4Go to Step 3

3Does the scan tool the heated oxygen (O2) sensor1

voltage within the value specified?0.1VGo to Step 9Go to

”Diagnostic

Aids”

41. Turn the ignition switch to LOCK.

2. Disconnect the Heated O2 sensor connector

and engine control module (ECM) connector.

3. Check the Heated O2 sensor wire between the

Heated O2 sensor connector terminal 3 and

ECM connector terminal 36 for short to ground.

Is the problem found?–Go to Step 5Go to Step 6

51. Repair the wire of the connector terminal as

needed.

2. Clear the DTCs from the ECM.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the repair complete?–System OK–

61. Turn the ignition switch to LOCK.

2. Disconnect the Heated O2 sensor connector

and engine control module (ECM) connector.

3. Check the O2 sensor wire between the O2

sensor connector terminal 2 and ECM connec-

tor terminal 64 for short to ground.

Is the problem found?–Go to Step 7Go to Step 8

71. Repair the wire of the connector terminal as

needed.

2. Clear the DTCs from the ECM.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the repair complete?–System OK–

81. Turn the ignition switch to LOCK.

2. Replace the Heated O2 sensor.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the replacement complete?–Go to Step 10–

Page 398 of 2643

1F – 152IENGINE CONTROLS

DAEWOO V–121 BL4

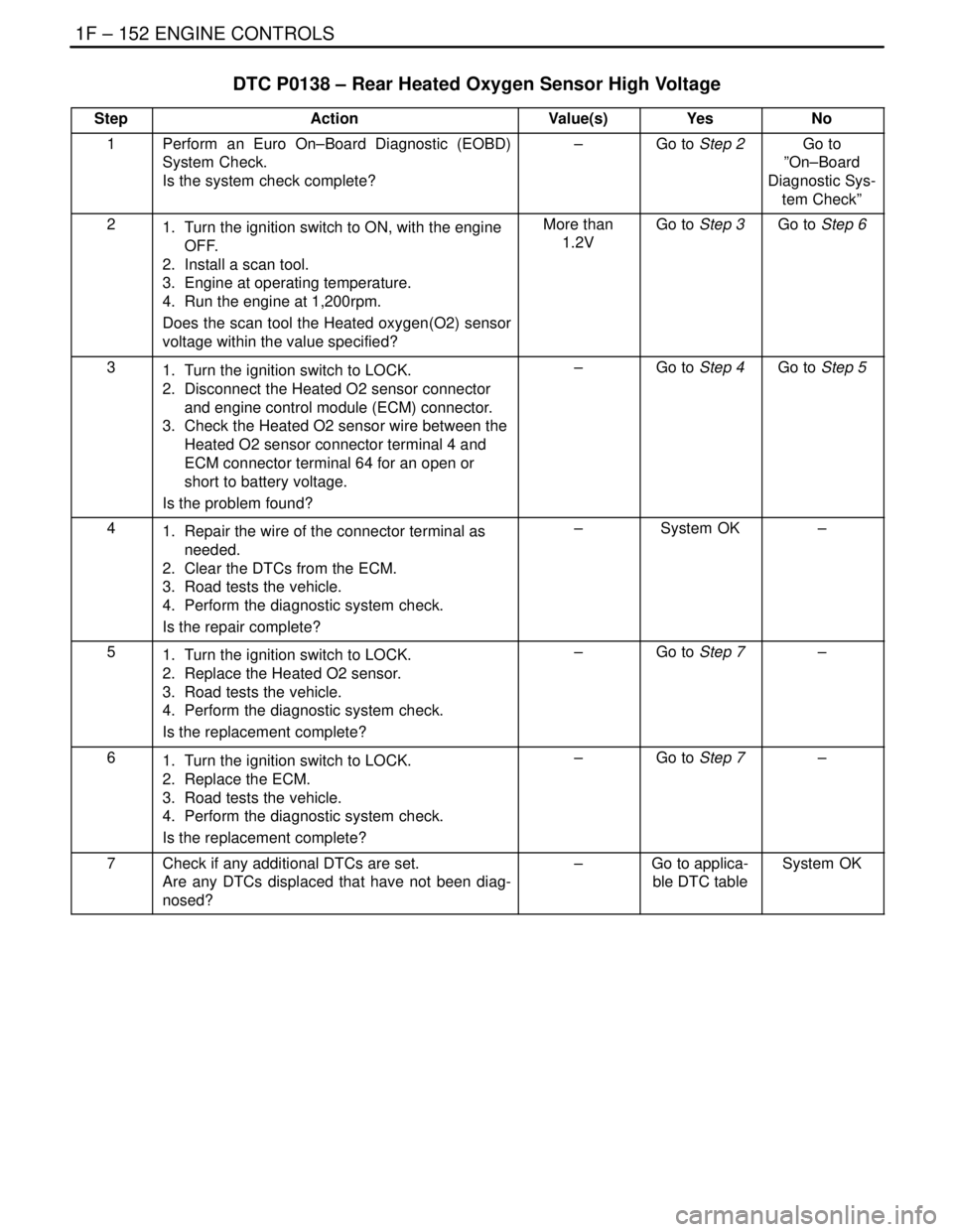

DTC P0138 – Rear Heated Oxygen Sensor High Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to ON, with the engine

OFF.

2. Install a scan tool.

3. Engine at operating temperature.

4. Run the engine at 1,200rpm.

Does the scan tool the Heated oxygen(O2) sensor

voltage within the value specified?More than

1.2VGo to Step 3Go to Step 6

31. Turn the ignition switch to LOCK.

2. Disconnect the Heated O2 sensor connector

and engine control module (ECM) connector.

3. Check the Heated O2 sensor wire between the

Heated O2 sensor connector terminal 4 and

ECM connector terminal 64 for an open or

short to battery voltage.

Is the problem found?–Go to Step 4Go to Step 5

41. Repair the wire of the connector terminal as

needed.

2. Clear the DTCs from the ECM.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the repair complete?–System OK–

51. Turn the ignition switch to LOCK.

2. Replace the Heated O2 sensor.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the replacement complete?–Go to Step 7–

61. Turn the ignition switch to LOCK.

2. Replace the ECM.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the replacement complete?–Go to Step 7–

7Check if any additional DTCs are set.

Are any DTCs displaced that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 400 of 2643

1F – 154IENGINE CONTROLS

DAEWOO V–121 BL4

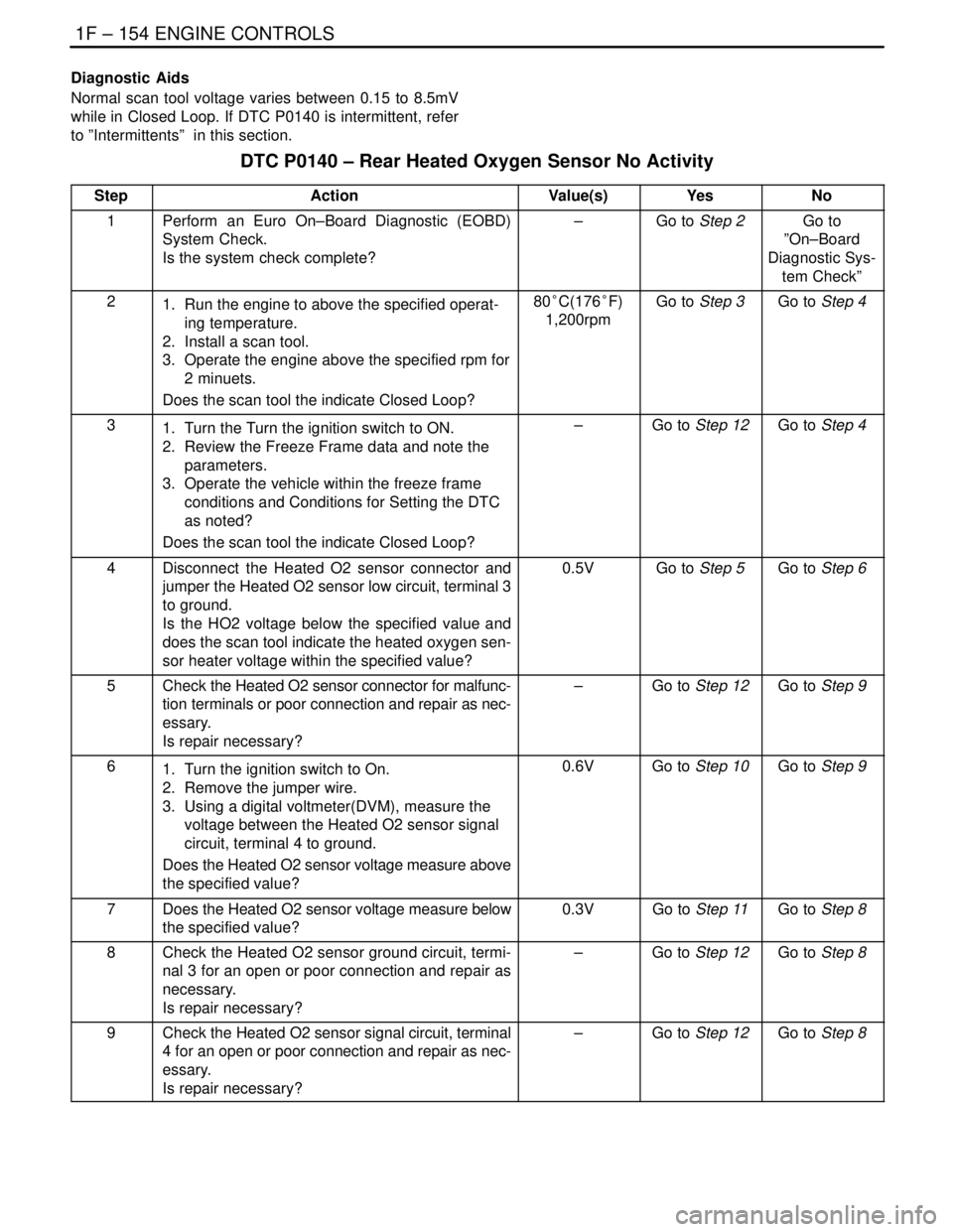

Diagnostic Aids

Normal scan tool voltage varies between 0.15 to 8.5mV

while in Closed Loop. If DTC P0140 is intermittent, refer

to ”Intermittents” in this section.

DTC P0140 – Rear Heated Oxygen Sensor No Activity

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Run the engine to above the specified operat-

ing temperature.

2. Install a scan tool.

3. Operate the engine above the specified rpm for

2 minuets.

Does the scan tool the indicate Closed Loop?80°C(176°F)

1,200rpmGo to Step 3Go to Step 4

31. Turn the Turn the ignition switch to ON.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the freeze frame

conditions and Conditions for Setting the DTC

as noted?

Does the scan tool the indicate Closed Loop?–Go to Step 12Go to Step 4

4Disconnect the Heated O2 sensor connector and

jumper the Heated O2 sensor low circuit, terminal 3

to ground.

Is the HO2 voltage below the specified value and

does the scan tool indicate the heated oxygen sen-

sor heater voltage within the specified value?0.5VGo to Step 5Go to Step 6

5Check the Heated O2 sensor connector for malfunc-

tion terminals or poor connection and repair as nec-

essary.

Is repair necessary?–Go to Step 12Go to Step 9

61. Turn the ignition switch to On.

2. Remove the jumper wire.

3. Using a digital voltmeter(DVM), measure the

voltage between the Heated O2 sensor signal

circuit, terminal 4 to ground.

Does the Heated O2 sensor voltage measure above

the specified value?0.6VGo to Step 10Go to Step 9

7Does the Heated O2 sensor voltage measure below

the specified value?0.3VGo to Step 11Go to Step 8

8Check the Heated O2 sensor ground circuit, termi-

nal 3 for an open or poor connection and repair as

necessary.

Is repair necessary?–Go to Step 12Go to Step 8

9Check the Heated O2 sensor signal circuit, terminal

4 for an open or poor connection and repair as nec-

essary.

Is repair necessary?–Go to Step 12Go to Step 8

Page 403 of 2643

ENGINE CONTROLS 1F – 157

DAEWOO V–121 BL4

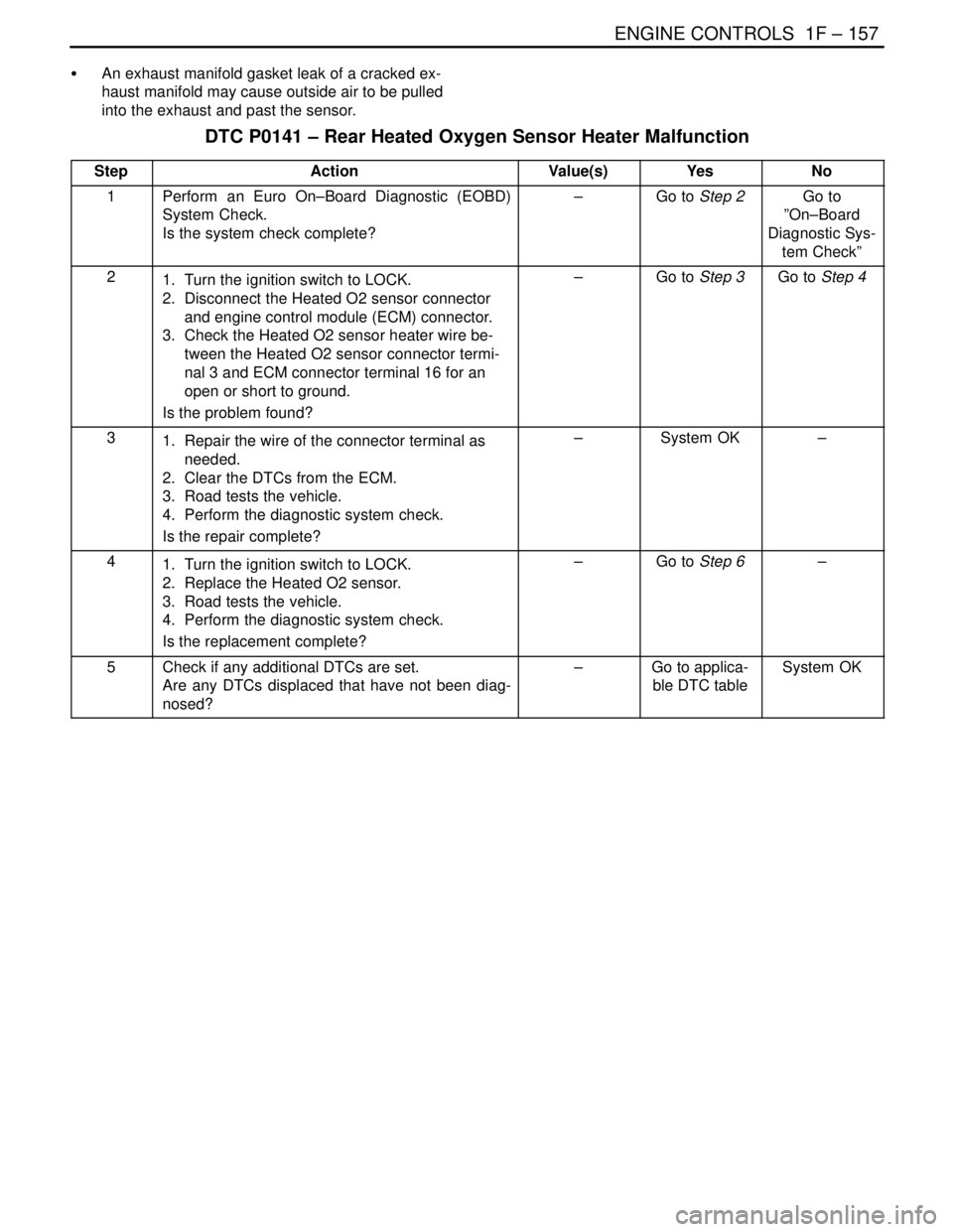

S An exhaust manifold gasket leak of a cracked ex-

haust manifold may cause outside air to be pulled

into the exhaust and past the sensor.

DTC P0141 – Rear Heated Oxygen Sensor Heater Malfunction

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK.

2. Disconnect the Heated O2 sensor connector

and engine control module (ECM) connector.

3. Check the Heated O2 sensor heater wire be-

tween the Heated O2 sensor connector termi-

nal 3 and ECM connector terminal 16 for an

open or short to ground.

Is the problem found?–Go to Step 3Go to Step 4

31. Repair the wire of the connector terminal as

needed.

2. Clear the DTCs from the ECM.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the repair complete?–System OK–

41. Turn the ignition switch to LOCK.

2. Replace the Heated O2 sensor.

3. Road tests the vehicle.

4. Perform the diagnostic system check.

Is the replacement complete?–Go to Step 6–

5Check if any additional DTCs are set.

Are any DTCs displaced that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 879 of 2643

ENGINE CONTROLS 1F – 633

DAEWOO V–121 BL4

Failed This Ig. (Failed This Ignition)

This message display indicates that the diagnostic test

has failed at least once during the current ignition cycle.

This message will clear when DTCs are cleared or the igni-

tion is cycled.

History

This message display indicates that the DTC has been

stored in memory as a valid fault. A DTC displayed as a

History fault may not mean that the fault is no longer pres-

ent. The history description means that all the conditions

necessary for reporting a fault have been met (maybe

even currently), and the information was stored in the con-

trol module memory.

MIL Requested

This message display indicates that the DTC is currently

causing the MIL to be turned ON. Remember that only

type A and type B DTCs can request the MIL. The MIL re-

quest cannot be used to determine if the DTC fault condi-

tions are currently being experienced. This is because the

diagnostic executive will require up to three trips during

which the diagnostic test passes to turn OFF the MIL.

Not Run Since CI (Not Run Since Cleared)

This message display indicates that the selected diagnos-

tic test has not run since the last time DTCs were cleared.

Therefore, the diagnostic test status (passing or failing) is

unknown. After DTCs are cleared, this message will con-

tinue to be displayed until the diagnostic test runs.

Not Run This Ig. (Not Run This Ignition)

This message display indicates that the selected diagnos-

tic test has not run during this ignition cycle.

Test Ran and Passed

This message display indicates that the selected diagnos-

tic test has done the following:

S Passed the last test.

S Run and passed during this ignition cycle.

S Run and passed since DTCs were last cleared.

If the indicated status of the vehicle is ”Test Ran and

Passed” after a repair verification, the vehicle is ready to

be released to the customer.

If the indicated status of the vehicle is ”Failed This Ignition”

after a repair verification, then the repair is incomplete and

further diagnosis is required.

Prior to repairing a vehicle, status information can be used

to evaluate the state of the diagnostic test, and to help

identify an intermittent problem. The technician can con-

clude that although the MIL is illuminated, the fault condi-

tion that caused the code to set is not present. An intermit-

tent condition must be the cause.

PRIMARY SYSTEM – BASED

DIAGNOSTICS

There are primary system–based diagnostics which eval-

uate system operation and its effect on vehicle emissions.

The primary system–based diagnostics are listed below

with a brief description of the diagnostic function:

Oxygen Sensor Diagnosis

The fuel control Front Heated Oxygen Sensor (HO2S1) is

diagnosed for the following conditions:

S Slow response.

S Response time (time to switch R/L or L/R).

S Inactive signal (output steady at bias voltage

approx. 450 mv).

S Signal fixed high.

S Signal fixed low.

The catalyst monitor Rear Heated Oxygen Sensor

(HO2S2) is diagnosed for the following conditions:

S Heater performance (time to activity on cold start).

S Signal fixed low during steady state conditions or

power enrichment (hard acceleration when a rich-

mixture should be indicated).

S Signal fixed high during steady state conditions or

deceleration mode (deceleration when a lean mix-

ture should be indicated).

S Inactive sensor (output steady at approximately 438

mv).

If the oxygen sensor pigtail wiring, connector or terminal

are damaged, the entire oxygen sensor assembly must be

replaced. Do not attempt to repair the wiring, connector or

terminals. In order for the sensor to function properly, it

must have clean reference air provided to it. This clean air

reference is obtained by way of the oxygen sensor wire(s).

Any attempt to repair the wires, connector or terminals

could result in the obstruction of the reference air and de-

grade oxygen sensor performance.

Misfire Monitor Diagnostic Operation

The misfire monitor diagnostic is based on crankshaft

rotational velocity (reference period) variations. The en-

gine control module (ECM) determines crankshaft rota-

tional velocity using the Crankshaft Position (CKP) sensor

and the Camshaft Position (CMP) sensor. When a cylinder

misfires, the crankshaft slows down momentarily. By mon-

itoring the CKP and CMP sensor signals, the ECM can cal-

culate when a misfire occurs.

For a non–catalyst damaging misfire, the diagnostic will be

required to monitor a misfire present for between

1000–3200 engine revolutions.

For catalyst–damaging misfire, the diagnostic will respond

to misfire within 200 engine revolutions.

Rough roads may cause false misfire detection. A rough

road will cause torque to be applied to the drive wheels and

drive train. This torque can intermittently decrease the

crankshaft rotational velocity. This may be falsely de-

tected as a misfire.

Page 902 of 2643

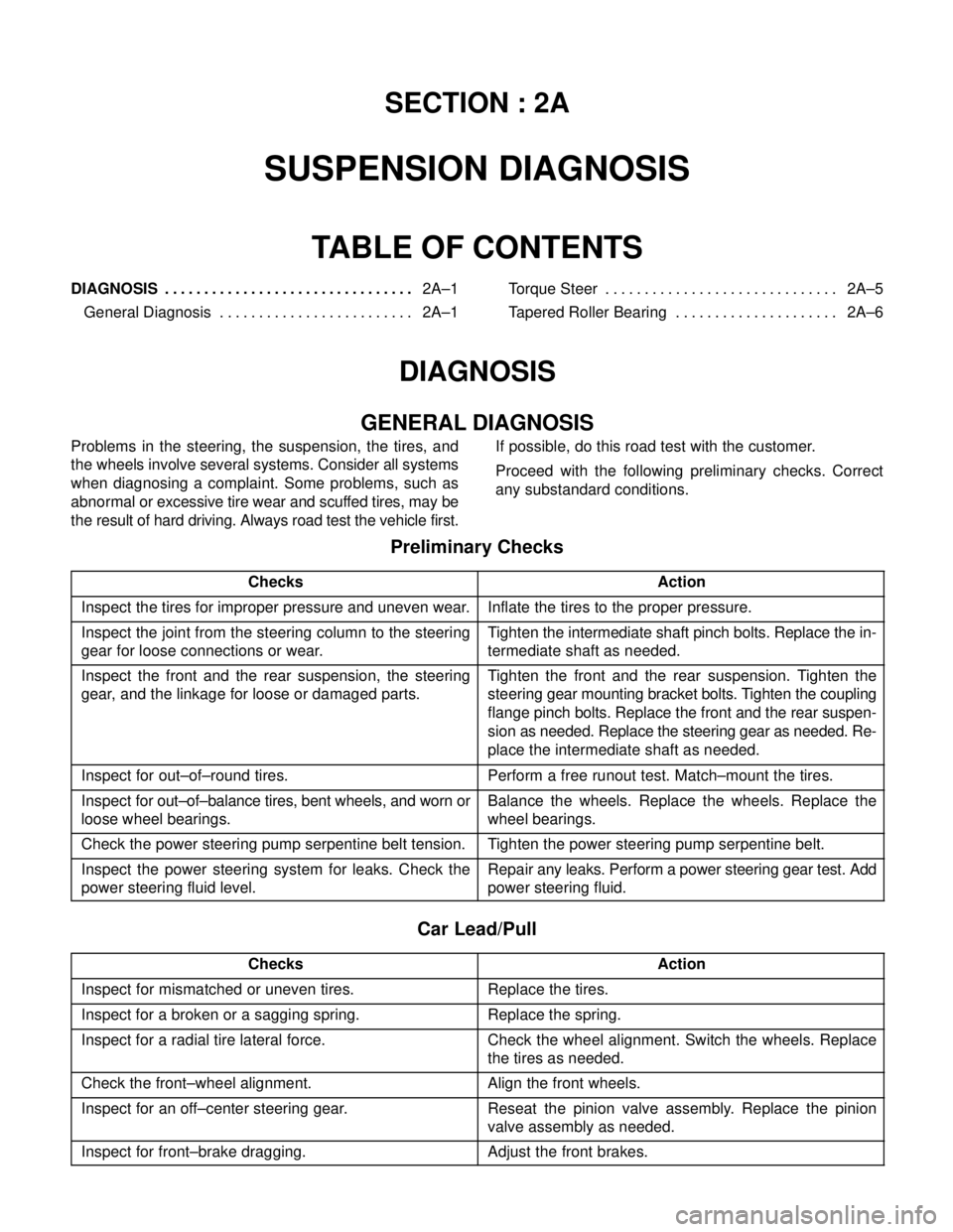

SECTION : 2A

SUSPENSION DIAGNOSIS

TABLE OF CONTENTS

DIAGNOSIS2A–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis 2A–1. . . . . . . . . . . . . . . . . . . . . . . . . Torque Steer 2A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tapered Roller Bearing 2A–6. . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

GENERAL DIAGNOSIS

Problems in the steering, the suspension, the tires, and

the wheels involve several systems. Consider all systems

when diagnosing a complaint. Some problems, such as

abnormal or excessive tire wear and scuffed tires, may be

the result of hard driving. Always road test the vehicle first.If possible, do this road test with the customer.

Proceed with the following preliminary checks. Correct

any substandard conditions.

Preliminary Checks

ChecksAction

Inspect the tires for improper pressure and uneven wear.Inflate the tires to the proper pressure.

Inspect the joint from the steering column to the steering

gear for loose connections or wear.Tighten the intermediate shaft pinch bolts. Replace the in-

termediate shaft as needed.

Inspect the front and the rear suspension, the steering

gear, and the linkage for loose or damaged parts.Tighten the front and the rear suspension. Tighten the

steering gear mounting bracket bolts. Tighten the coupling

flange pinch bolts. Replace the front and the rear suspen-

sion as needed. Replace the steering gear as needed. Re-

place the intermediate shaft as needed.

Inspect for out–of–round tires.Perform a free runout test. Match–mount the tires.

Inspect for out–of–balance tires, bent wheels, and worn or

loose wheel bearings.Balance the wheels. Replace the wheels. Replace the

wheel bearings.

Check the power steering pump serpentine belt tension.Tighten the power steering pump serpentine belt.

Inspect the power steering system for leaks. Check the

power steering fluid level.Repair any leaks. Perform a power steering gear test. Add

power steering fluid.

Car Lead/Pull

ChecksAction

Inspect for mismatched or uneven tires.Replace the tires.

Inspect for a broken or a sagging spring.Replace the spring.

Inspect for a radial tire lateral force.Check the wheel alignment. Switch the wheels. Replace

the tires as needed.

Check the front–wheel alignment.Align the front wheels.

Inspect for an off–center steering gear.Reseat the pinion valve assembly. Replace the pinion

valve assembly as needed.

Inspect for front–brake dragging.Adjust the front brakes.

Page 911 of 2643

2B – 4IWHEEL ALIGNMENT

DAEWOO V–121 BL4

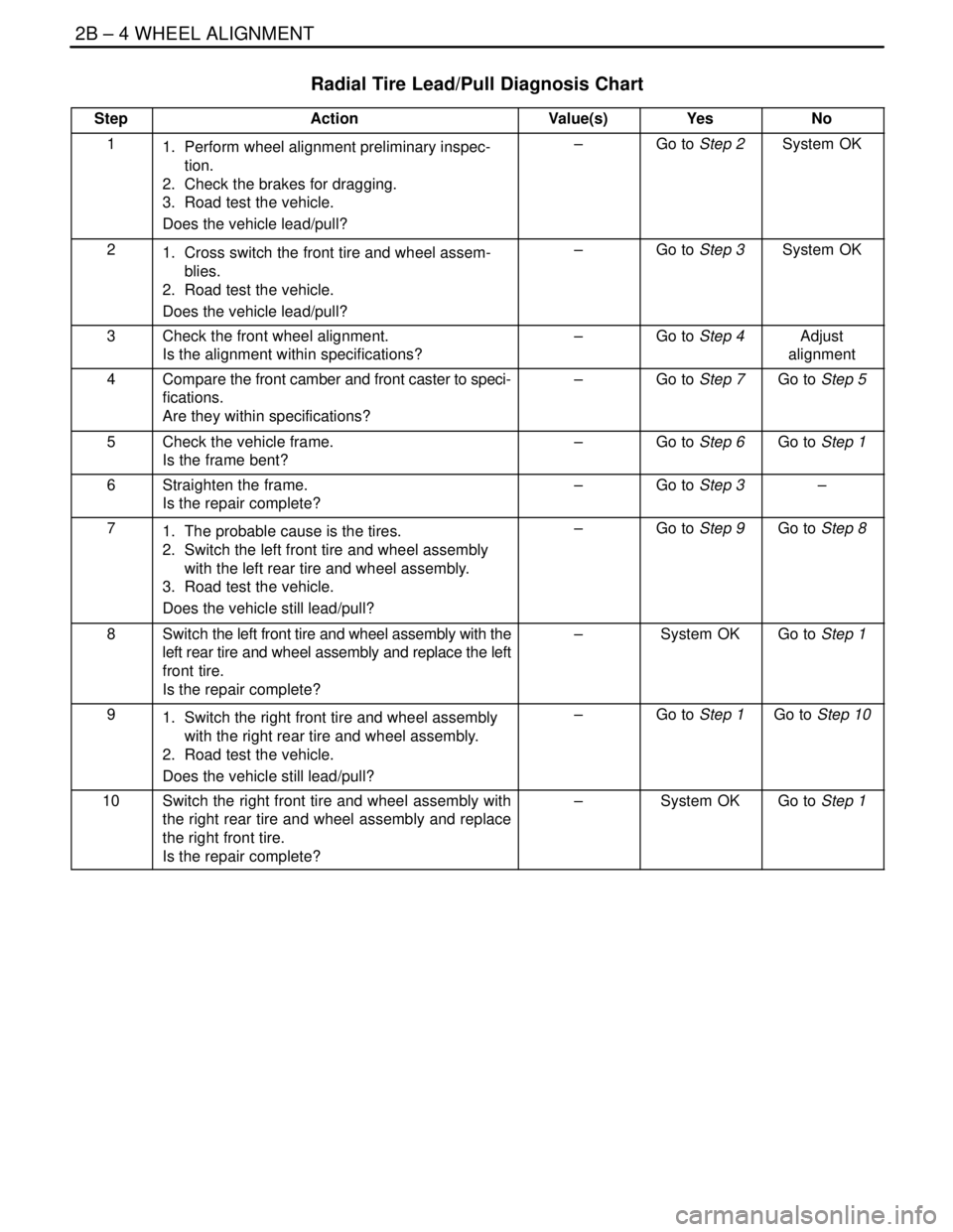

Radial Tire Lead/Pull Diagnosis Chart

StepActionValue(s)YesNo

11. Perform wheel alignment preliminary inspec-

tion.

2. Check the brakes for dragging.

3. Road test the vehicle.

Does the vehicle lead/pull?–Go to Step 2System OK

21. Cross switch the front tire and wheel assem-

blies.

2. Road test the vehicle.

Does the vehicle lead/pull?–Go to Step 3System OK

3Check the front wheel alignment.

Is the alignment within specifications?–Go to Step 4Adjust

alignment

4Compare the front camber and front caster to speci-

fications.

Are they within specifications?–Go to Step 7Go to Step 5

5Check the vehicle frame.

Is the frame bent?–Go to Step 6Go to Step 1

6Straighten the frame.

Is the repair complete?–Go to Step 3–

71. The probable cause is the tires.

2. Switch the left front tire and wheel assembly

with the left rear tire and wheel assembly.

3. Road test the vehicle.

Does the vehicle still lead/pull?–Go to Step 9Go to Step 8

8Switch the left front tire and wheel assembly with the

left rear tire and wheel assembly and replace the left

front tire.

Is the repair complete?–System OKGo to Step 1

91. Switch the right front tire and wheel assembly

with the right rear tire and wheel assembly.

2. Road test the vehicle.

Does the vehicle still lead/pull?–Go to Step 1Go to Step 10

10Switch the right front tire and wheel assembly with

the right rear tire and wheel assembly and replace

the right front tire.

Is the repair complete?–System OKGo to Step 1

Page 1015 of 2643

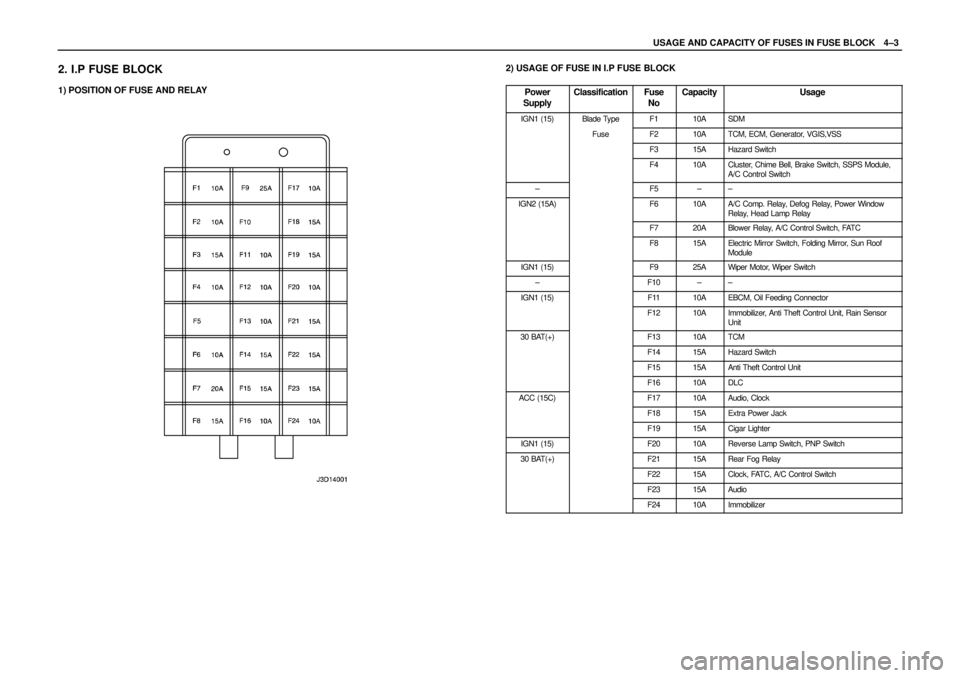

USAGE AND CAPACITY OF FUSES IN FUSE BLOCKW4–3

2. I.P FUSE BLOCK

1) POSITION OF FUSE AND RELAY

2) USAGE OF FUSE IN I.P FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

IGN1 (15)Blade TypeF110ASDM

FuseF210ATCM, ECM, Generator, VGIS,VSS

F315AHazard Switch

F410ACluster, Chime Bell, Brake Switch, SSPS Module,

A/C Control Switch

–F5––

IGN2 (15A)F610AA/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720ABlower Relay, A/C Control Switch, FATC

F815AElectric Mirror Switch, Folding Mirror, Sun Roof

Module

IGN1 (15)F925AWiper Motor, Wiper Switch

–F10––

IGN1 (15)F1110AEBCM, Oil Feeding Connector

F1210AImmobilizer, Anti Theft Control Unit, Rain Sensor

Unit

30 BAT(+)F1310ATCM

F1415AHazard Switch

F1515AAnti Theft Control Unit

F1610ADLC

ACC (15C)F1710AAudio, Clock

F1815AExtra Power Jack

F1915ACigar Lighter

IGN1 (15)F2010AReverse Lamp Switch, PNP Switch

30 BAT(+)F2115ARear Fog Relay

F2215AClock, FATC, A/C Control Switch

F2315AAudio

F2410AImmobilizer

Page 1017 of 2643

SECTION : 4A

HYDRAULIC BRAKES

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS4A–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifcations 4A–2. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4A–2. . . . . . . . . .

COMPONENT LOCATOR4A–3 . . . . . . . . . . . . . . . . . . . .

Brake System (ABS) 4A–3. . . . . . . . . . . . . . . . . . . . . . .

Brake System (NON–ABS) 4A–4. . . . . . . . . . . . . . . . .

DIAGNOSIS4A–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake System Testing 4A–5. . . . . . . . . . . . . . . . . . . . .

Brake Hose Inspection 4A–5. . . . . . . . . . . . . . . . . . . . .

Warning Lamp Operation 4A–5. . . . . . . . . . . . . . . . . . .

Stop Lamp Warning Circuit Diagnosis 4A–6. . . . . . . . MAINTENANCE AND REPAIR4A–10 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4A–10. . . . . . . . . . . . . . . . . . . .

Manual Bleeding the Brakes 4A–10. . . . . . . . . . . . . . .

Pressure Bleeding the Brakes 4A–12. . . . . . . . . . . . . .

Brake Hose Rear 4A–13. . . . . . . . . . . . . . . . . . . . . . . . .

Brake Hose Front 4A–14. . . . . . . . . . . . . . . . . . . . . . . . .

Stoplamp Switch 4A–15. . . . . . . . . . . . . . . . . . . . . . . . .

Brake Pedal 4A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4A–17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Lamp Operation 4A–17. . . . . . . . . . . . . . . . . .

Page 1035 of 2643

4B – 2IMASTER CYLINDER

DAEWOO V–121 BL4

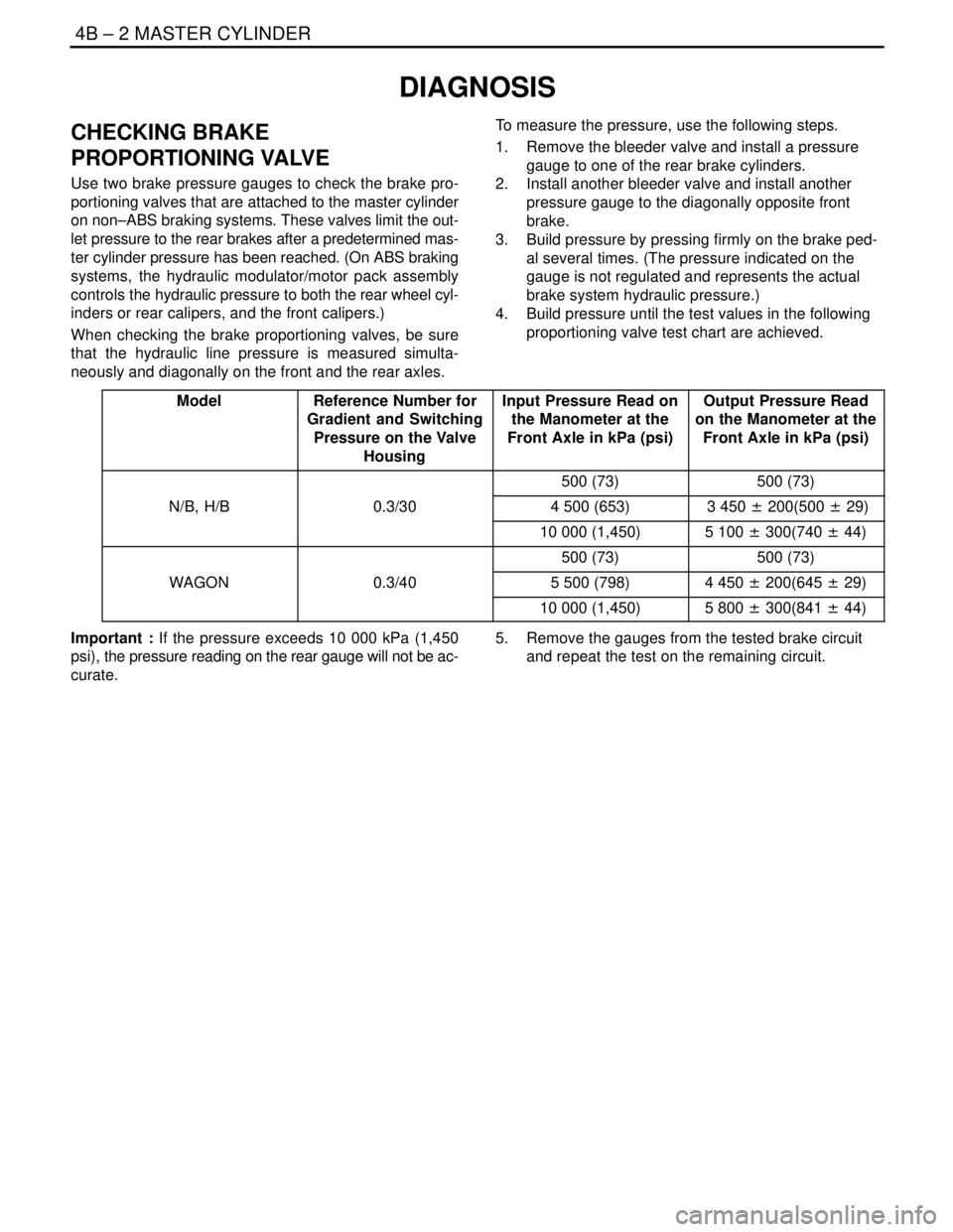

DIAGNOSIS

CHECKING BRAKE

PROPORTIONING VALVE

Use two brake pressure gauges to check the brake pro-

portioning valves that are attached to the master cylinder

on non–ABS braking systems. These valves limit the out-

let pressure to the rear brakes after a predetermined mas-

ter cylinder pressure has been reached. (On ABS braking

systems, the hydraulic modulator/motor pack assembly

controls the hydraulic pressure to both the rear wheel cyl-

inders or rear calipers, and the front calipers.)

When checking the brake proportioning valves, be sure

that the hydraulic line pressure is measured simulta-

neously and diagonally on the front and the rear axles.To measure the pressure, use the following steps.

1. Remove the bleeder valve and install a pressure

gauge to one of the rear brake cylinders.

2. Install another bleeder valve and install another

pressure gauge to the diagonally opposite front

brake.

3. Build pressure by pressing firmly on the brake ped-

al several times. (The pressure indicated on the

gauge is not regulated and represents the actual

brake system hydraulic pressure.)

4. Build pressure until the test values in the following

proportioning valve test chart are achieved.

Model

Reference Number for

Gradient and Switching

Pressure on the Valve

HousingInput Pressure Read on

the Manometer at the

Front Axle in kPa (psi)Output Pressure Read

on the Manometer at the

Front Axle in kPa (psi)

500 (73)500 (73)

N/B, H/B0.3/304 500 (653) 3 450 ± 200(500 ± 29)

10 000 (1,450)5 100 ± 300(740 ± 44)

500 (73)500 (73)

WAGON0.3/405 500 (798)4 450 ± 200(645 ± 29)

10 000 (1,450)5 800 ± 300(841 ± 44)

Important : If the pressure exceeds 10 000 kPa (1,450

psi), the pressure reading on the rear gauge will not be ac-

curate.5. Remove the gauges from the tested brake circuit

and repeat the test on the remaining circuit.