Iat DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1532 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 183

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 3–2 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

3rd gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1883 sets, the possible cause of fault

could be TCM.

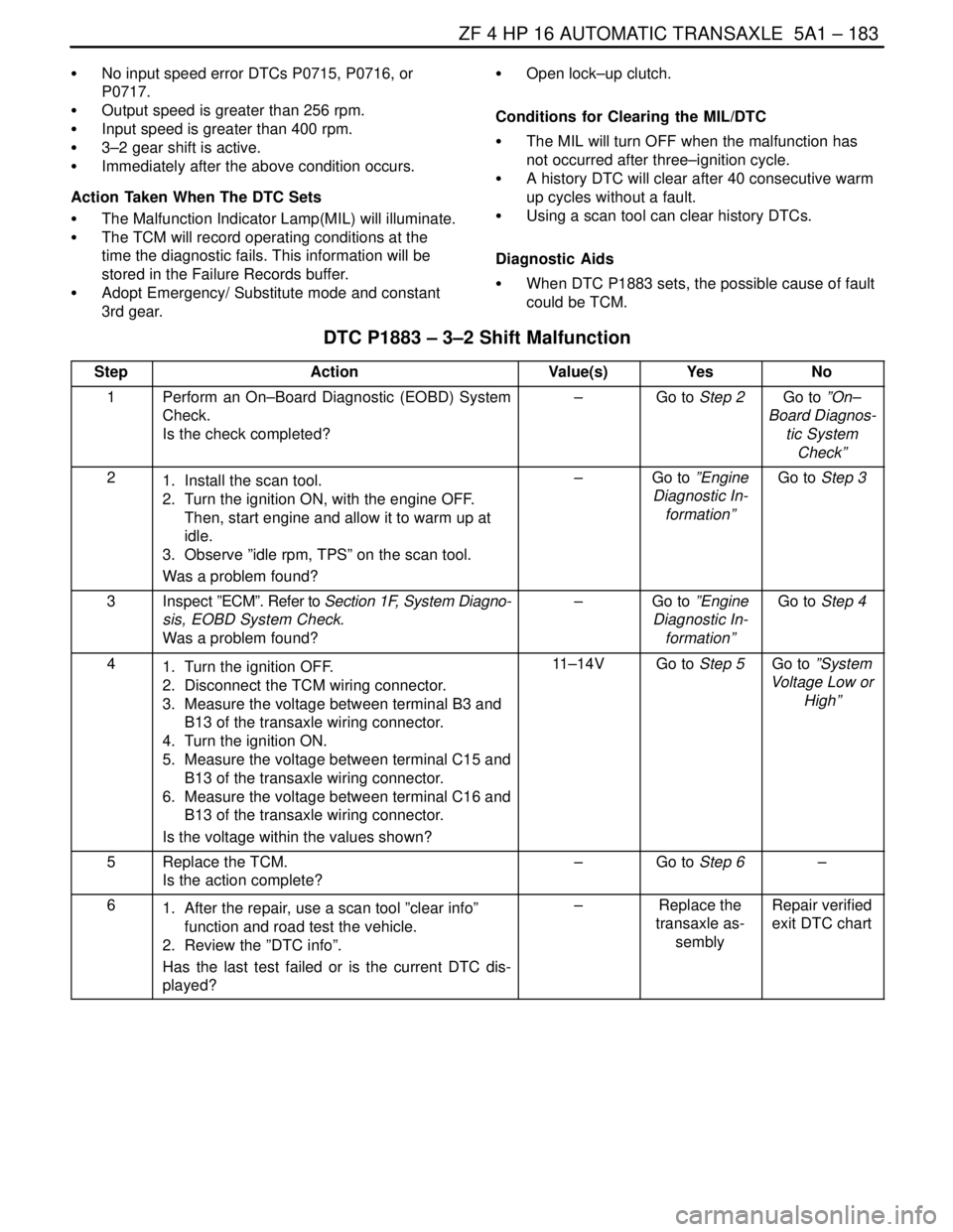

DTC P1883 – 3–2 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1534 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 185

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 4–3 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1884 sets, the possible cause of fault

could be TCM.

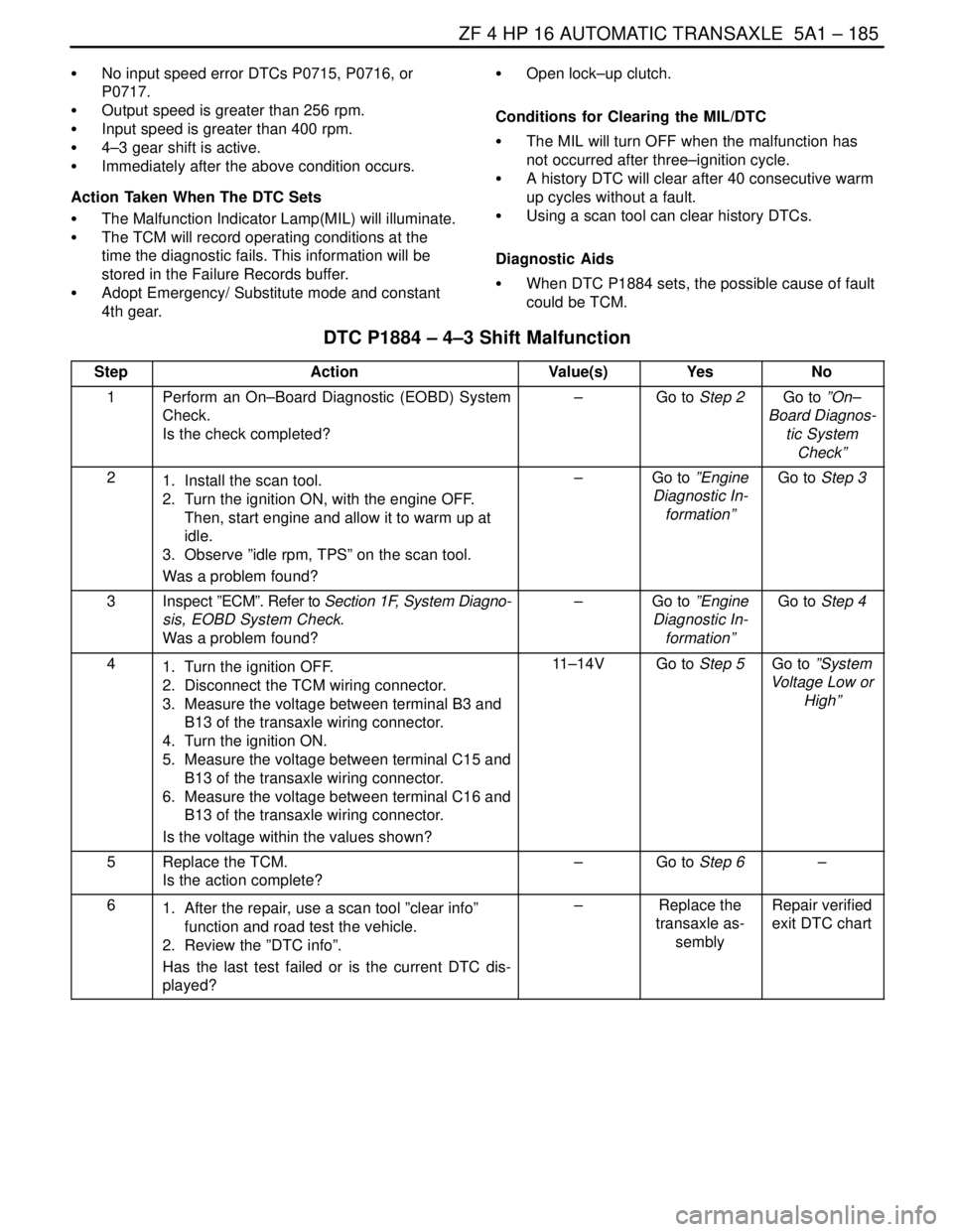

DTC P1884 – 4–3 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1536 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 187

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 3–1 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

3rd gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1885 sets, the possible cause of fault

could be TCM.

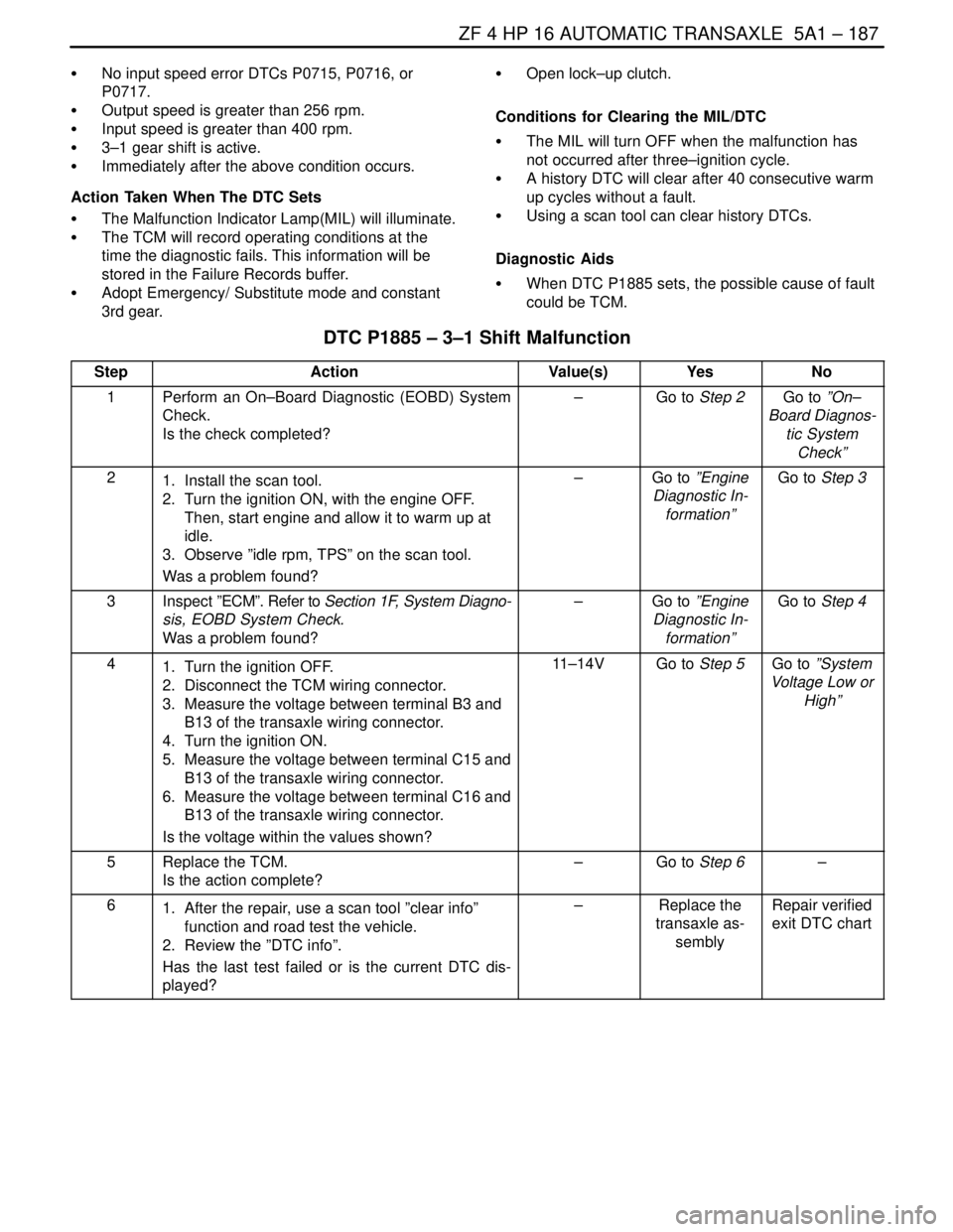

DTC P1885 – 3–1 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1538 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 189

DAEWOO V–121 BL4

S No input speed error DTCs P0715, P0716, or

P0717.

S Output speed is greater than 256 rpm.

S Input speed is greater than 400 rpm.

S 4–2 gear shift is active.

S Immediately after the above condition occurs.

Action Taken When The DTC Sets

S The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.S Open lock–up clutch.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.

Diagnostic Aids

S When DTC P1886 sets, the possible cause of fault

could be TCM.

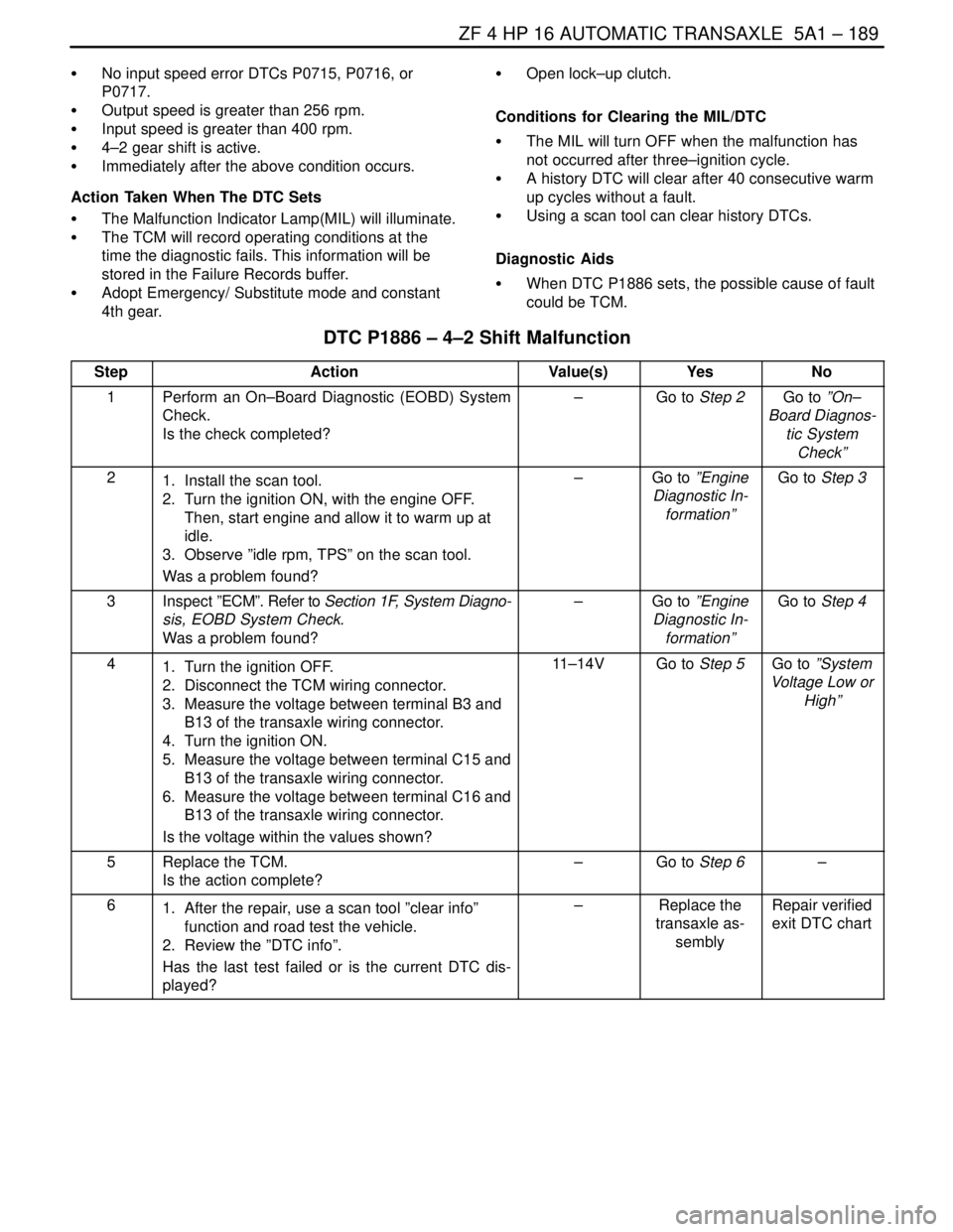

DTC P1886 – 4–2 Shift Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to ”On–

Board Diagnos-

tic System

Check”

21. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

Then, start engine and allow it to warm up at

idle.

3. Observe ”idle rpm, TPS” on the scan tool.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 3

3Inspect ”ECM”. Refer to Section 1F, System Diagno-

sis, EOBD System Check.

Was a problem found?–Go to ”Engine

Diagnostic In-

formation”Go to Step 4

41. Turn the ignition OFF.

2. Disconnect the TCM wiring connector.

3. Measure the voltage between terminal B3 and

B13 of the transaxle wiring connector.

4. Turn the ignition ON.

5. Measure the voltage between terminal C15 and

B13 of the transaxle wiring connector.

6. Measure the voltage between terminal C16 and

B13 of the transaxle wiring connector.

Is the voltage within the values shown?11–14VGo to Step 5Go to ”System

Voltage Low or

High”

5Replace the TCM.

Is the action complete?–Go to Step 6–

61. After the repair, use a scan tool ”clear info”

function and road test the vehicle.

2. Review the ”DTC info”.

Has the last test failed or is the current DTC dis-

played?–Replace the

transaxle as-

semblyRepair verified

exit DTC chart

Page 1548 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 199

DAEWOO V–121 BL4

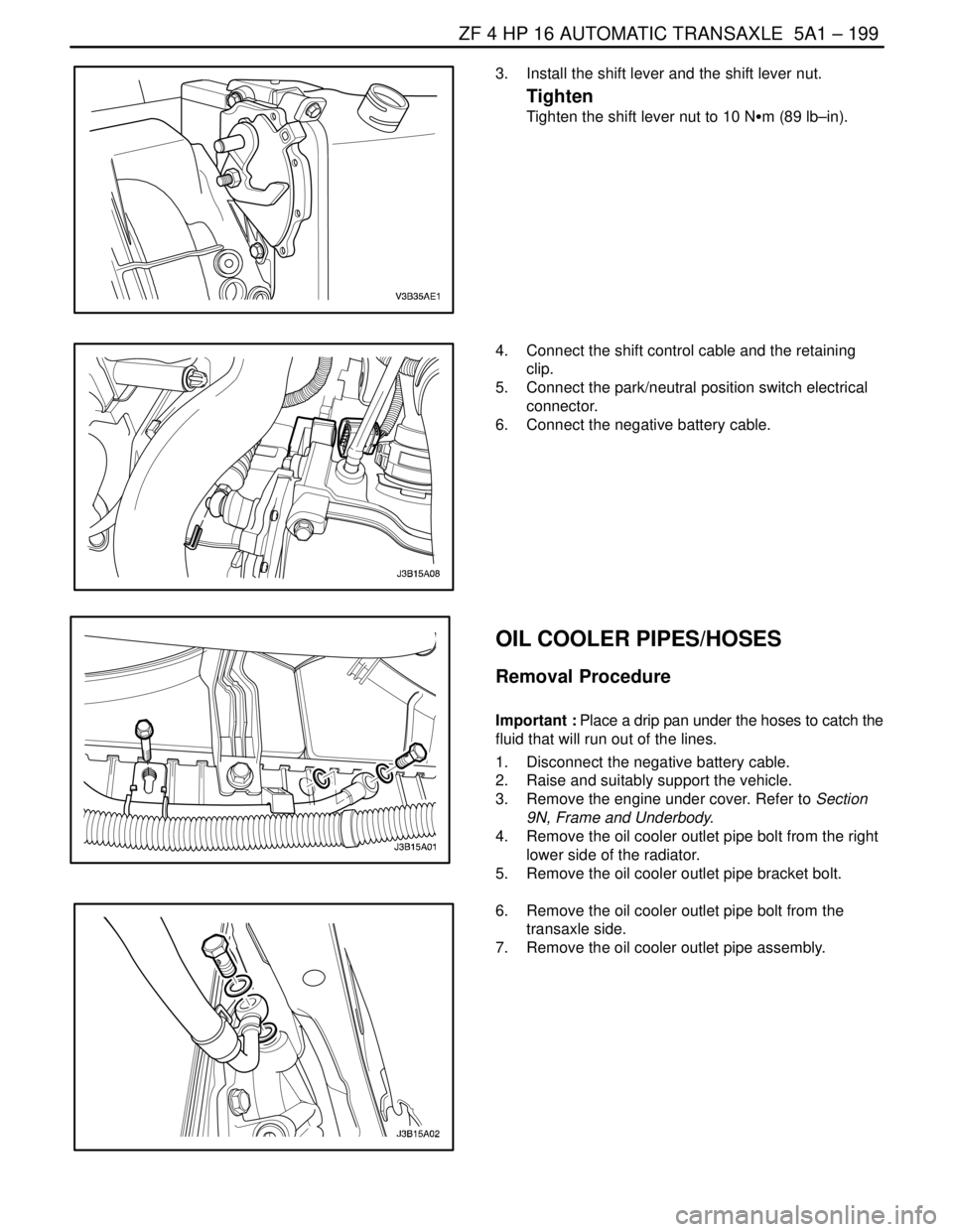

3. Install the shift lever and the shift lever nut.

Tighten

Tighten the shift lever nut to 10 NSm (89 lb–in).

4. Connect the shift control cable and the retaining

clip.

5. Connect the park/neutral position switch electrical

connector.

6. Connect the negative battery cable.

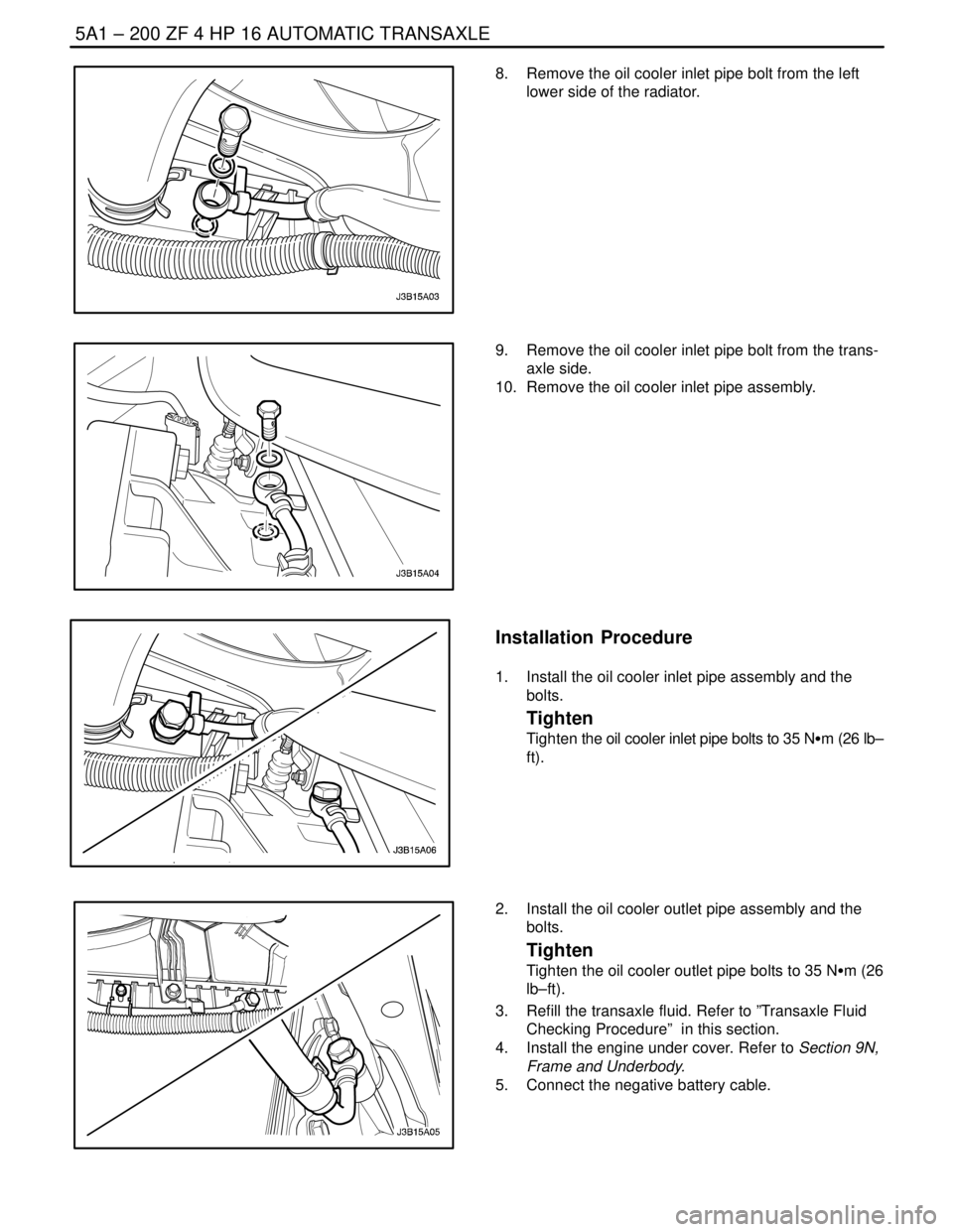

OIL COOLER PIPES/HOSES

Removal Procedure

Important : Place a drip pan under the hoses to catch the

fluid that will run out of the lines.

1. Disconnect the negative battery cable.

2. Raise and suitably support the vehicle.

3. Remove the engine under cover. Refer to Section

9N, Frame and Underbody.

4. Remove the oil cooler outlet pipe bolt from the right

lower side of the radiator.

5. Remove the oil cooler outlet pipe bracket bolt.

6. Remove the oil cooler outlet pipe bolt from the

transaxle side.

7. Remove the oil cooler outlet pipe assembly.

Page 1549 of 2643

5A1 – 200IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

8. Remove the oil cooler inlet pipe bolt from the left

lower side of the radiator.

9. Remove the oil cooler inlet pipe bolt from the trans-

axle side.

10. Remove the oil cooler inlet pipe assembly.

Installation Procedure

1. Install the oil cooler inlet pipe assembly and the

bolts.

Tighten

Tighten the oil cooler inlet pipe bolts to 35 NSm (26 lb–

ft).

2. Install the oil cooler outlet pipe assembly and the

bolts.

Tighten

Tighten the oil cooler outlet pipe bolts to 35 NSm (26

lb–ft).

3. Refill the transaxle fluid. Refer to ”Transaxle Fluid

Checking Procedure” in this section.

4. Install the engine under cover. Refer to Section 9N,

Frame and Underbody.

5. Connect the negative battery cable.

Page 1572 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 223

DAEWOO V–121 BL4

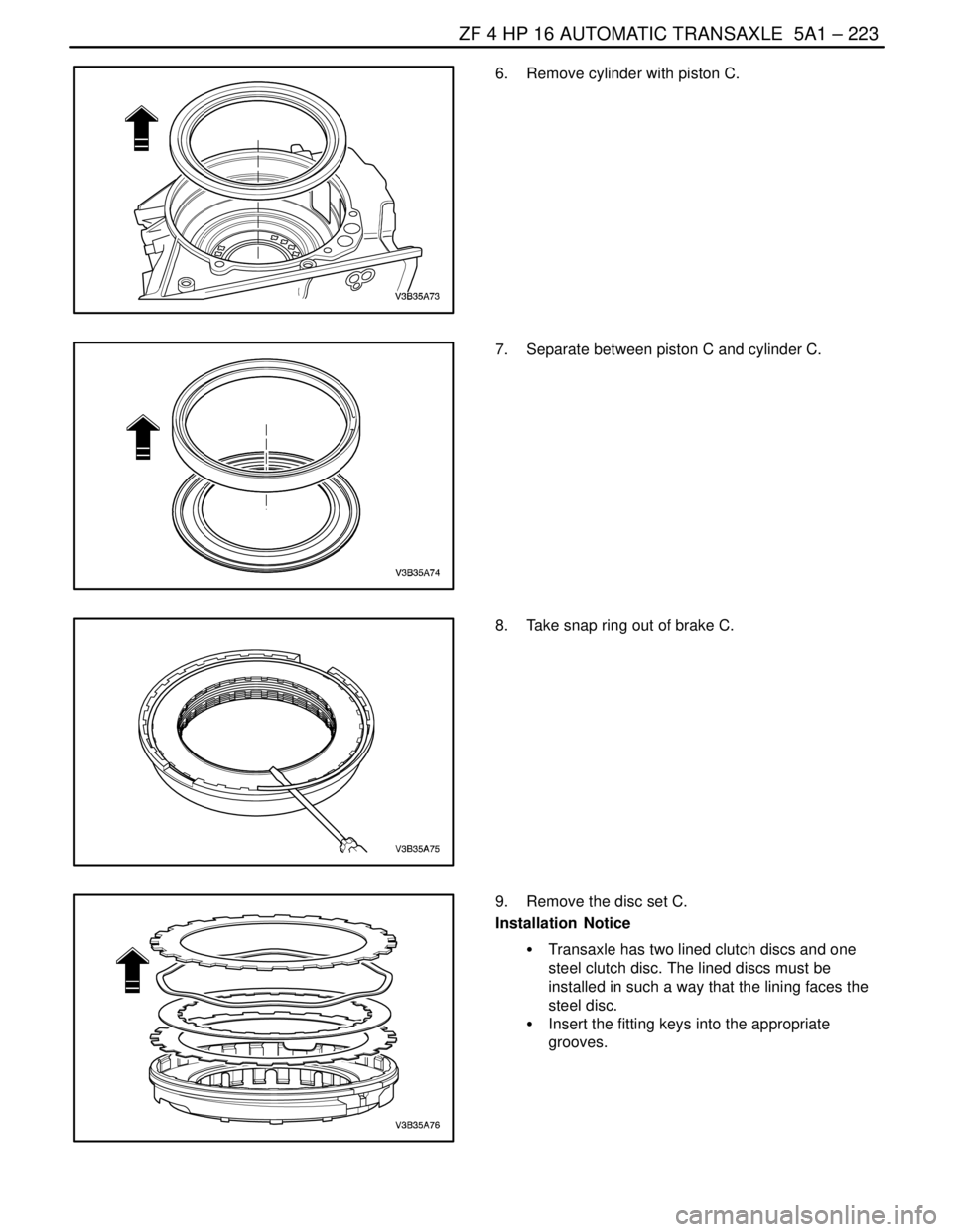

6. Remove cylinder with piston C.

7. Separate between piston C and cylinder C.

8. Take snap ring out of brake C.

9. Remove the disc set C.

Installation Notice

S Transaxle has two lined clutch discs and one

steel clutch disc. The lined discs must be

installed in such a way that the lining faces the

steel disc.

S Insert the fitting keys into the appropriate

grooves.

Page 1585 of 2643

5A1 – 236IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

ELECTRONICAL COMPONENTS

Selector Lever/Program Switch

The driver engages the travel position via the selector le-

ver:

P : Park Position

R : Reverse

N : Neutral

D : Forward Speeds

Park/Neutral Position Switch

The Park/Neutral Position Switch is located on the selec-

tor shaft and informs the TCM of the current selector lever

position P–R–N–D–3–2–1.

The selector lever position is transmitted to the TCM in en-

coded form along 4 lines. The encoding is such that mal-

functions in the connecting lead are identified.

The Park/Neutral Position Switch is located on the selec-

tor shaft, which is connected to the selector lever via a pull

cable. In addition, the Park/Neutral Position Switch con-

trols the starter interlock, the reversing light and the selec-

tor lever position indicator on the instrument panel.

Signal Combination

L1L2L3L4

P00120

R00012

N01200

D1212120

31212012

21201212

10121212

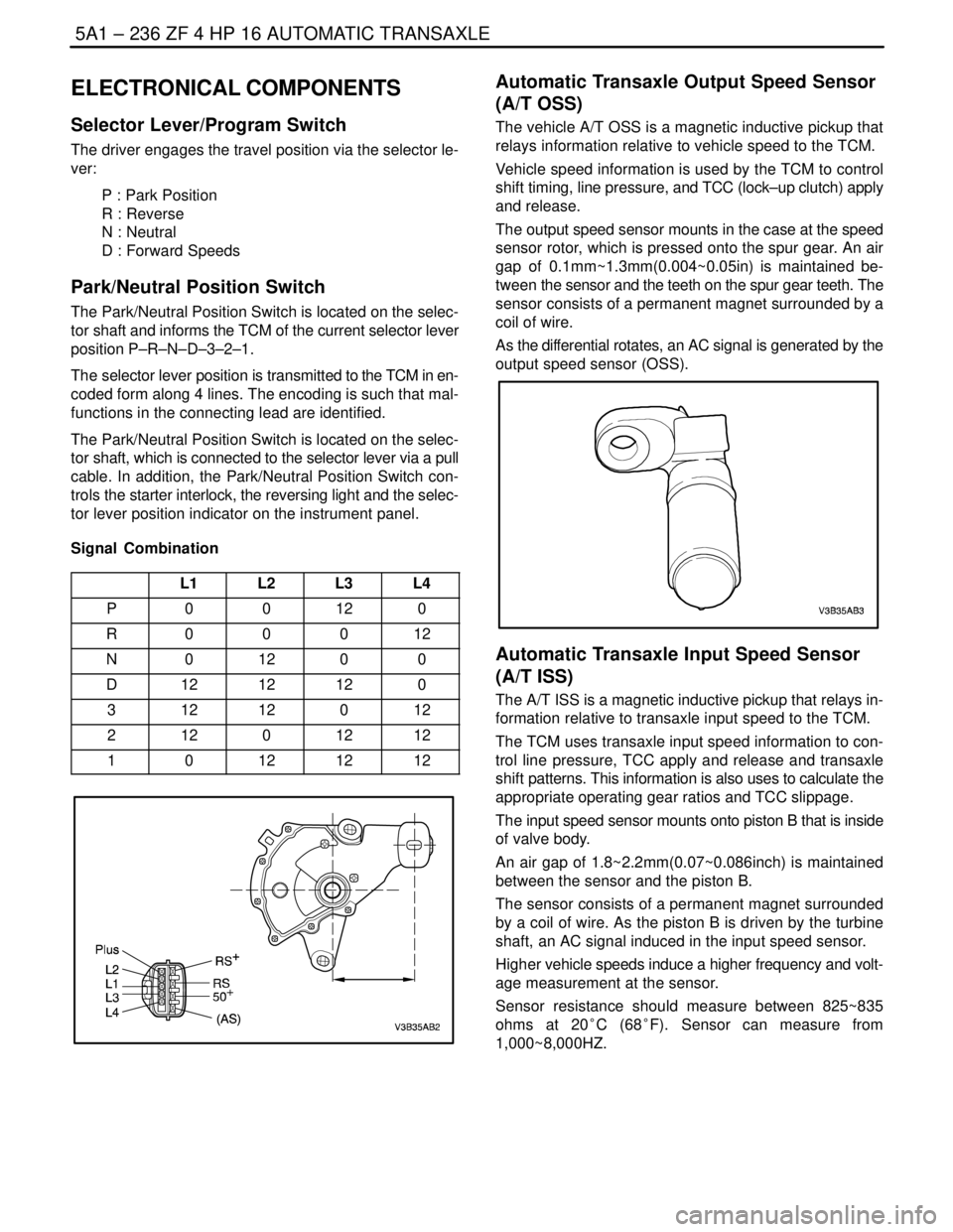

Automatic Transaxle Output Speed Sensor

(A/T OSS)

The vehicle A/T OSS is a magnetic inductive pickup that

relays information relative to vehicle speed to the TCM.

Vehicle speed information is used by the TCM to control

shift timing, line pressure, and TCC (lock–up clutch) apply

and release.

The output speed sensor mounts in the case at the speed

sensor rotor, which is pressed onto the spur gear. An air

gap of 0.1mm~1.3mm(0.004~0.05in) is maintained be-

tween the sensor and the teeth on the spur gear teeth. The

sensor consists of a permanent magnet surrounded by a

coil of wire.

As the differential rotates, an AC signal is generated by the

output speed sensor (OSS).

Automatic Transaxle Input Speed Sensor

(A/T ISS)

The A/T ISS is a magnetic inductive pickup that relays in-

formation relative to transaxle input speed to the TCM.

The TCM uses transaxle input speed information to con-

trol line pressure, TCC apply and release and transaxle

shift patterns. This information is also uses to calculate the

appropriate operating gear ratios and TCC slippage.

The input speed sensor mounts onto piston B that is inside

of valve body.

An air gap of 1.8~2.2mm(0.07~0.086inch) is maintained

between the sensor and the piston B.

The sensor consists of a permanent magnet surrounded

by a coil of wire. As the piston B is driven by the turbine

shaft, an AC signal induced in the input speed sensor.

Higher vehicle speeds induce a higher frequency and volt-

age measurement at the sensor.

Sensor resistance should measure between 825~835

ohms at 20°C (68°F). Sensor can measure from

1,000~8,000HZ.

Page 1586 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 237

DAEWOO V–121 BL4

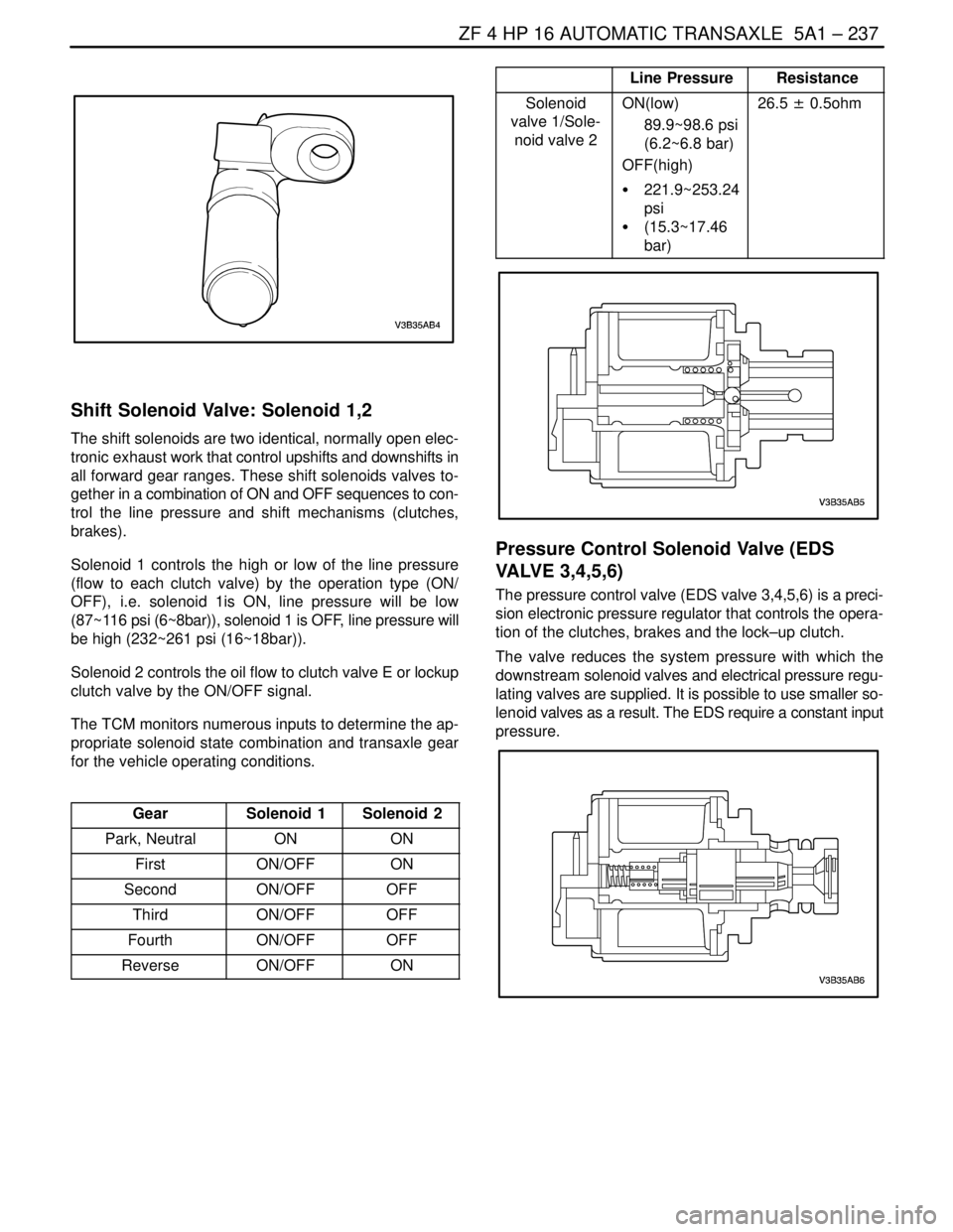

Shift Solenoid Valve: Solenoid 1,2

The shift solenoids are two identical, normally open elec-

tronic exhaust work that control upshifts and downshifts in

all forward gear ranges. These shift solenoids valves to-

gether in a combination of ON and OFF sequences to con-

trol the line pressure and shift mechanisms (clutches,

brakes).

Solenoid 1 controls the high or low of the line pressure

(flow to each clutch valve) by the operation type (ON/

OFF), i.e. solenoid 1is ON, line pressure will be low

(87~116 psi (6~8bar)), solenoid 1 is OFF, line pressure will

be high (232~261 psi (16~18bar)).

Solenoid 2 controls the oil flow to clutch valve E or lockup

clutch valve by the ON/OFF signal.

The TCM monitors numerous inputs to determine the ap-

propriate solenoid state combination and transaxle gear

for the vehicle operating conditions.

Gear

Solenoid 1Solenoid 2

Park, NeutralONON

FirstON/OFFON

SecondON/OFFOFF

ThirdON/OFFOFF

FourthON/OFFOFF

ReverseON/OFFON

Line PressureResistance

Solenoid

valve 1/Sole-

noid valve 2ON(low)

89.9~98.6 psi

(6.2~6.8 bar)

OFF(high)

S 221.9~253.24

psi

S (15.3~17.46

bar)26.5 ± 0.5ohm

Pressure Control Solenoid Valve (EDS

VALVE 3,4,5,6)

The pressure control valve (EDS valve 3,4,5,6) is a preci-

sion electronic pressure regulator that controls the opera-

tion of the clutches, brakes and the lock–up clutch.

The valve reduces the system pressure with which the

downstream solenoid valves and electrical pressure regu-

lating valves are supplied. It is possible to use smaller so-

lenoid valves as a result. The EDS require a constant input

pressure.

Page 1699 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 109

DAEWOO V–121 BL4

Installation Procedure

1. Connect the negative battery cable.

2. Install the TCM and retaining bolts.

Tighten

Tighten the TCM retaining bolts to 5 NSm (44 Ib–in).

3. Connect the TCM electrical connector.

4. Connect the negative battery cable.

FLUID COOLER INLET PIPES AND

HOSES

Removal Procedure

1. Raise and support the vehicle.

2. Drain the transaxle fluid.

3. Remove the clip from the hose, then disconnect the

hose from the fluid cooler inlet pipe.

4. Remove the inlet pipe union bolt from the radiator.

5. Remove the fluid cooler inlet pipe bolt from the

transaxle.

6. Remove the inlet pipe fitting nut from the transaxle.

7. Remove the fluid cooler inlet pipe and hoses.