acc DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2110 of 2643

8B – 6ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

DIAGNOSIS

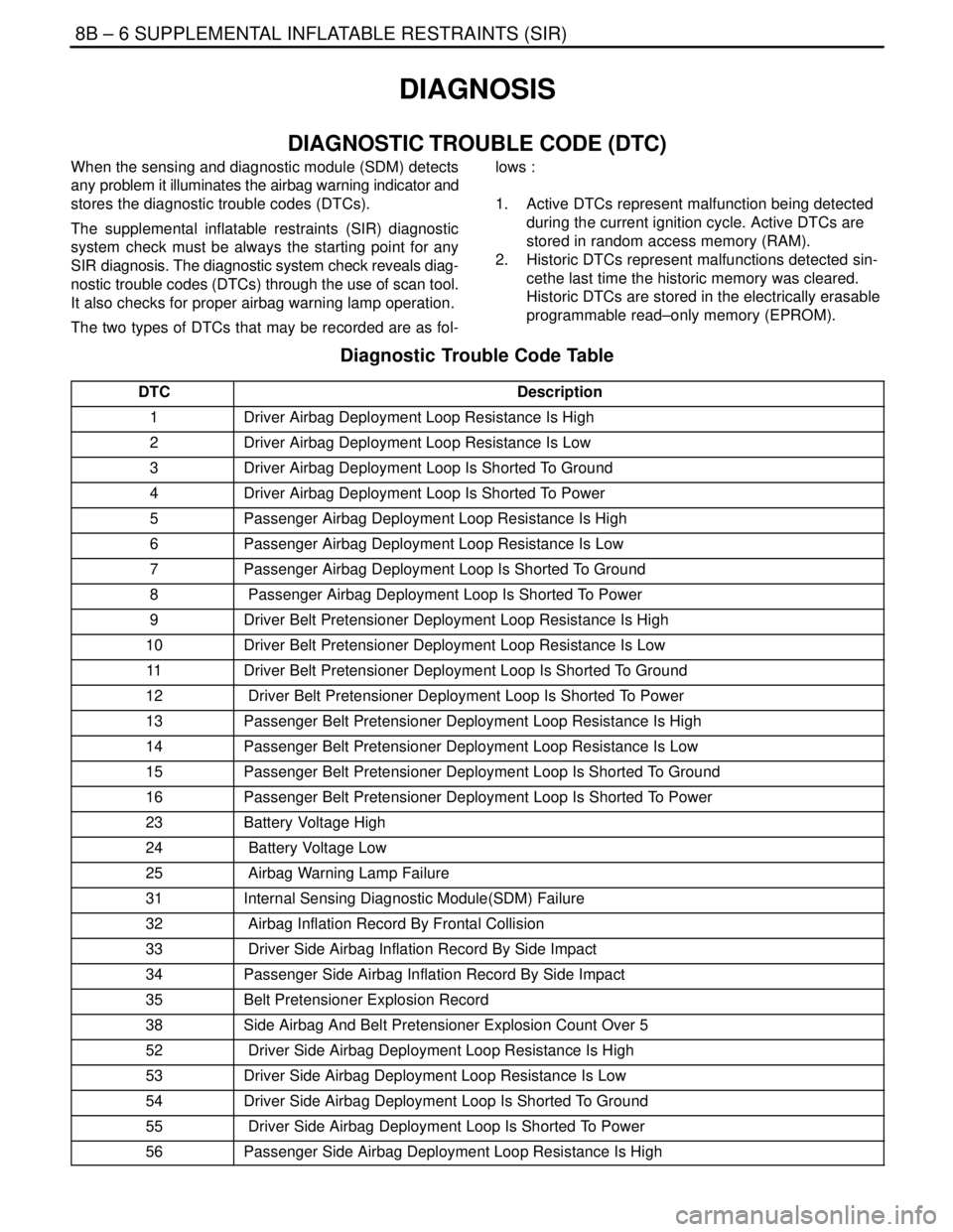

DIAGNOSTIC TROUBLE CODE (DTC)

When the sensing and diagnostic module (SDM) detects

any problem it illuminates the airbag warning indicator and

stores the diagnostic trouble codes (DTCs).

The supplemental inflatable restraints (SIR) diagnostic

system check must be always the starting point for any

SIR diagnosis. The diagnostic system check reveals diag-

nostic trouble codes (DTCs) through the use of scan tool.

It also checks for proper airbag warning lamp operation.

The two types of DTCs that may be recorded are as fol-lows :

1. Active DTCs represent malfunction being detected

during the current ignition cycle. Active DTCs are

stored in random access memory (RAM).

2. Historic DTCs represent malfunctions detected sin-

cethe last time the historic memory was cleared.

Historic DTCs are stored in the electrically erasable

programmable read–only memory (EPROM).

Diagnostic Trouble Code Table

DTCDescription

1Driver Airbag Deployment Loop Resistance Is High

2Driver Airbag Deployment Loop Resistance Is Low

3Driver Airbag Deployment Loop Is Shorted To Ground

4Driver Airbag Deployment Loop Is Shorted To Power

5Passenger Airbag Deployment Loop Resistance Is High

6Passenger Airbag Deployment Loop Resistance Is Low

7Passenger Airbag Deployment Loop Is Shorted To Ground

8 Passenger Airbag Deployment Loop Is Shorted To Power

9Driver Belt Pretensioner Deployment Loop Resistance Is High

10Driver Belt Pretensioner Deployment Loop Resistance Is Low

11Driver Belt Pretensioner Deployment Loop Is Shorted To Ground

12 Driver Belt Pretensioner Deployment Loop Is Shorted To Power

13Passenger Belt Pretensioner Deployment Loop Resistance Is High

14Passenger Belt Pretensioner Deployment Loop Resistance Is Low

15Passenger Belt Pretensioner Deployment Loop Is Shorted To Ground

16Passenger Belt Pretensioner Deployment Loop Is Shorted To Power

23Battery Voltage High

24 Battery Voltage Low

25 Airbag Warning Lamp Failure

31Internal Sensing Diagnostic Module(SDM) Failure

32 Airbag Inflation Record By Frontal Collision

33 Driver Side Airbag Inflation Record By Side Impact

34Passenger Side Airbag Inflation Record By Side Impact

35Belt Pretensioner Explosion Record

38Side Airbag And Belt Pretensioner Explosion Count Over 5

52 Driver Side Airbag Deployment Loop Resistance Is High

53Driver Side Airbag Deployment Loop Resistance Is Low

54Driver Side Airbag Deployment Loop Is Shorted To Ground

55 Driver Side Airbag Deployment Loop Is Shorted To Power

56Passenger Side Airbag Deployment Loop Resistance Is High

Page 2193 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 89

DAEWOO V–121 BL4

HANDLING, INSTALLATION AND

DIAGNOSIS

S Airbag modules should not be subjected to temper-

ature above 65 degrees Celsius(149 degrees Fahr-

enheit).

S An airbag and SDM should not be used if it has

been dropped from height of 0.9 meters(3 feet) or

greater.

S When an SDM is replaced, it must be oriented with

the arrow on the SDM pointing toward the front of

the vehicle.

S It is very important for the SDM to be installed flat

on the mounting surface, parallel to the vehicle’s

longitudinal axis.

S To avoid setting diagnostic trouble codes(DTCs), do

not apply power to the SIR unless all components

are connected or a diagnostic chart request it.

S The SIR Diagnostic System Check must be the

starting point of any SIR diagnostics. The SIR Diag-

nostic System Check will verify proper airbag indi-

cator operation and will lead you to correct chart to

diagnose any SIR malfunctions. Bypassing these

procedures may result in extended diagnostic time

incorrect parts replacement.

REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT

CAUTION : Any repairs to the vehicle’s structure

must return it to the original production configu-

ration. Deployment requires replacement of

SDM, the inflator modules and a dimensional in-

spection of the steering column.

S If any SIR components are damaged, they must be

replaced. If SIR components mounting points are

damaged, they must be repaired or replaced.

S Never use SIR parts from another vehicle. This

does not include remanufactured parts purchased

from an authorized source.

S Do not attempt to service the SDM, the clock spring

or other airbag modules, these items must be re-

placed if they are defective.

S Verify the part number of replaced airbag modules.

Some inflator modules look identical but contain

different internal components.

Page 2194 of 2643

8B – 90ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

ACCIDENT WITH DEPLOYMENT

COMPONENTS REPLACEMENTS

All SIR components must be replaced after frontal

crash involving airbag deployment. After deployment,

a powdery residue may be on the surface of the air-

bag. The powder consists primarily of corn-

starch(used to lubricate the bag as it inflates) and by–

products of the chemical reaction. The sodium

hydroxide then quickly reacts with atmospheric mois-

ture and is converted to sodium bicarbonate(also

known as baking soda). Therefore, it is unlikely that

sodium hydroxide will be present after deployment.

Replace the following SIR components.

CAUTION : Wear gloves and safely glasses dur-

ing the disposal procedure. Refer to ”Deployed

airbag module disposal procedure” in this sec-

tion.

S The SDM

S Airbag modules and pretensioners

S SIR wiring

S Clock spring

ACCIDENT WITHOUT DEPLOYMENT

COMPONENT INSPECTION

Certain inspection must be performed after any

crash, whether the airbag has deployed or not. :

S The steering column must be dimensionally in-

spected.

S Inspect the knee bolsters and mounting points for

distortion, bending and cracking or other damages.

S Inspect the instrument panel(I/P) and steering col-

umn reinforcement plate for distorsion, bending and

cracking or other damage.

S Inspect the I/P braces for distortion, bending and

cracking or other damage.

S Inspect the seat belt and mounting points. Refer to

Section 8A, Seat Belts.

SENSING AND DIAGNOSTIC

MODULE (SDM)

CAUTION : During service procedure, be very

careful when handling the SDM. Never strike or

jar the SDM. Never power the supplemental inflat-

able restraints(SIR) when the SDM is not rigidly

attached to the vehicle. All SDM mounting bolts

must be carefully tightened , and the arrow on the

SDM must be point toward the front of the vehicle

to ensure proper operation of the SIR. The SDM

could be activated if it is powered when it is not

rigidly attached to the vehicle, resulting in unex-

pected deployment and possible injury.

Page 2205 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 101

DAEWOO V–121 BL4

FRONT SEAT BELT

PRETENSIONERS

CAUTION : Tempering with seat belt pretensioner

creates the risk of an injury from unexpected deploy-

ment. Therefore, the driver airbag module should

never be disassembled.

The seat belt pretensioners(with load limiter for some ve-

hicles) are assembled with each front seat belt retractors

to retract the seat belt webbing when accounted frontal

collision. The seat belt pretensioners are controlled by

sensing and diagnostic module(SDM). The seat belt pre-

tensioner contains an igniter charge and a gas generator

to pull the seat belt webbing. The seat belt pretensioner

must be replaced after an accident that causes its activa-

tion.

The seat belt pretensioner also contains a shorting bar to

prevent current from travelling through the seat belt pre-

tensioner during servicing. The shorting bar is disengaged

when the connector is connected.

SENSING AND DIAGNOSTIC

MODULE (SDM)

CAUTION : During the service procedures, be careful

when handling the SDM. Never shake or jar the SDM.

Never apply power to SIR when the SDM is not rigidly

attached to the vehicle. All SDM mounting bolts and

grounding nuts must be fully tightened. Failure to fol-

low these precautions could cause deployment and

result in personal injury.

The SDM is located on the floor beneath the floor console

assembly. The SDM performs the following functions :

S Monitors the supplemental inflatable restraints(SIR)

electrical components and sets a diagnostic trouble

code(DTC) when malfunction is detected.

S Records any faults that are discovered.

S Displays SIR diagnostic trouble codes and system

status information when connected to a scan tool.

S Illuminates the airbag indicator to alert the driver to

any fault.S Provides a reserve power source to deploy the air-

bags and pretensioners if an accident has disabled

the normal power source.

S Monitors vehicle velocity changes to detect frontal

impacts, which are severe enough to warrant de-

ployment.

S Causes current to flow through the airbag modules

and pretensioner to cause deployment if a frontal

impact of sufficient force is detected.

The SDM contains no user–serviceable parts.

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indica-

tor and sensing and diagnostic module(SDM). The SDM

performs a turn–on test when the ignition is turned ON.

The SDM flashes the airbag indicator seven times by sup-

plying an intermittent ground to the indicator lamp circuit.

After flashing seven times, the airbag indicator will turn off

if no more malfunctions have been detected.

If the SDM has detected malfunctions in the internal and

external circuits, which could potentially affect the opera-

tion of the supplemental inflatable restraints(SIR), the air-

bag indicator stays on. Some malfunctions could result in

non–deployment when necessary or deployment under

conditions which would not normally result in deployment.

When the SDM is not properly attached to its connector,

the airbag circuit is shorted to ground because there is a

shorting bar in the SDM electrical connector. The shorting

bar is disengaged when proper connection is made, but if

a poor connection exists the SDM connector supplied a

ground to the airbag indicator independently of the SDM,

and the airbag indicator turns on.

CLOCK SPRING

CAUTION : Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

CAUTION : Over–rotating the clock spring (over 3 and

one quarter turns to one direction) without the steer-

ing wheel in position could damage the clock spring

and result in an inoperative driver airbag.

There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance to

the type of spring used in a mechanical clock. The coil

Page 2220 of 2643

9A – 14IBODY WIRING SYSTEM

DAEWOO V–121 BL4

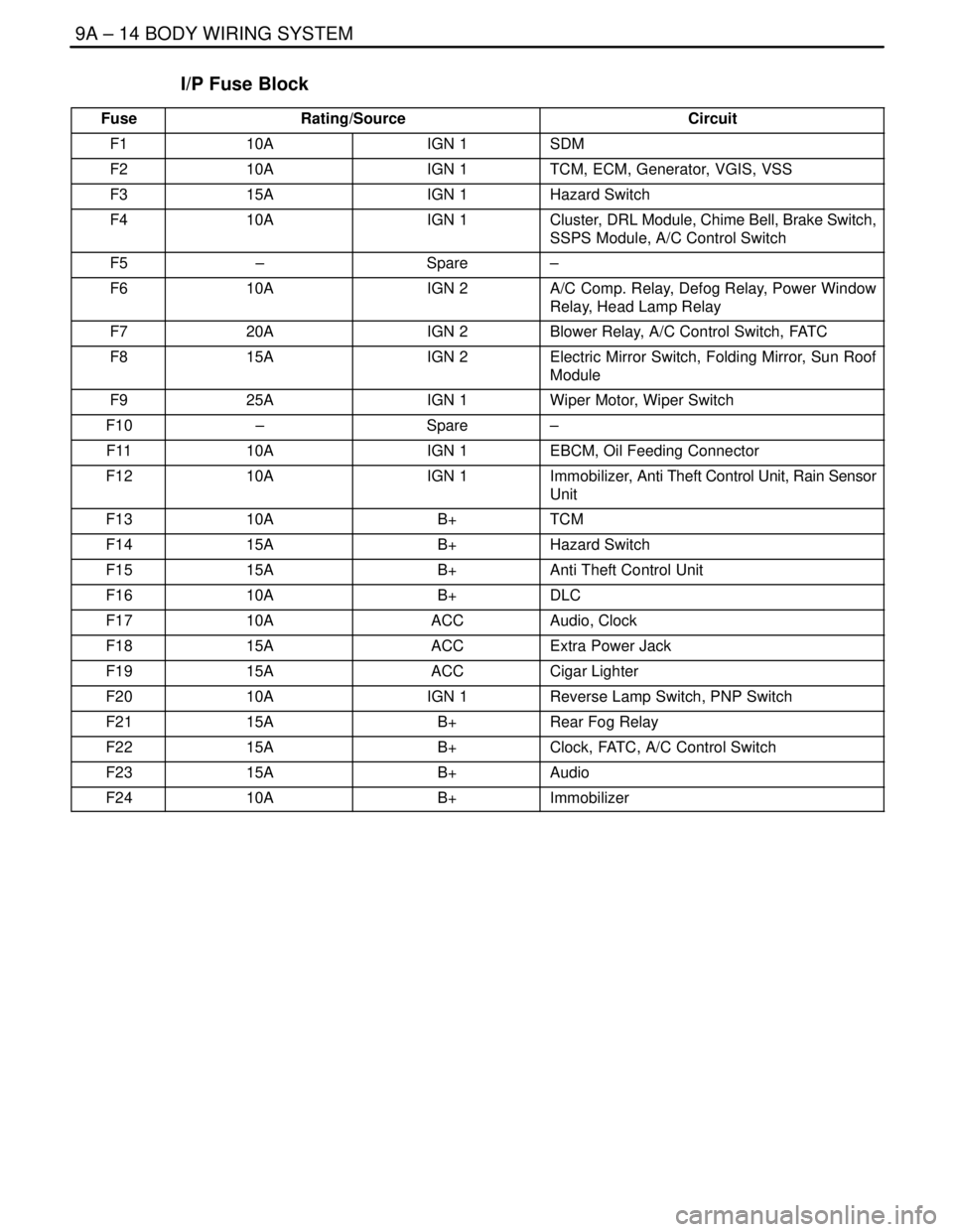

I/P Fuse Block

FuseRating/SourceCircuit

F110AIGN 1SDM

F210AIGN 1TCM, ECM, Generator, VGIS, VSS

F315AIGN 1Hazard Switch

F410AIGN 1Cluster, DRL Module, Chime Bell, Brake Switch,

SSPS Module, A/C Control Switch

F5–Spare–

F610AIGN 2A/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720AIGN 2Blower Relay, A/C Control Switch, FATC

F815AIGN 2Electric Mirror Switch, Folding Mirror, Sun Roof

Module

F925AIGN 1Wiper Motor, Wiper Switch

F10–Spare–

F1110AIGN 1EBCM, Oil Feeding Connector

F1210AIGN 1Immobilizer, Anti Theft Control Unit, Rain Sensor

Unit

F1310AB+TCM

F1415AB+Hazard Switch

F1515AB+Anti Theft Control Unit

F1610AB+DLC

F1710AACCAudio, Clock

F1815AACCExtra Power Jack

F1915AACCCigar Lighter

F2010AIGN 1Reverse Lamp Switch, PNP Switch

F2115AB+Rear Fog Relay

F2215AB+Clock, FATC, A/C Control Switch

F2315AB+Audio

F2410AB+Immobilizer

Page 2265 of 2643

LITHING SYSTEMS 9B – 39

DAEWOO V–121 BL4

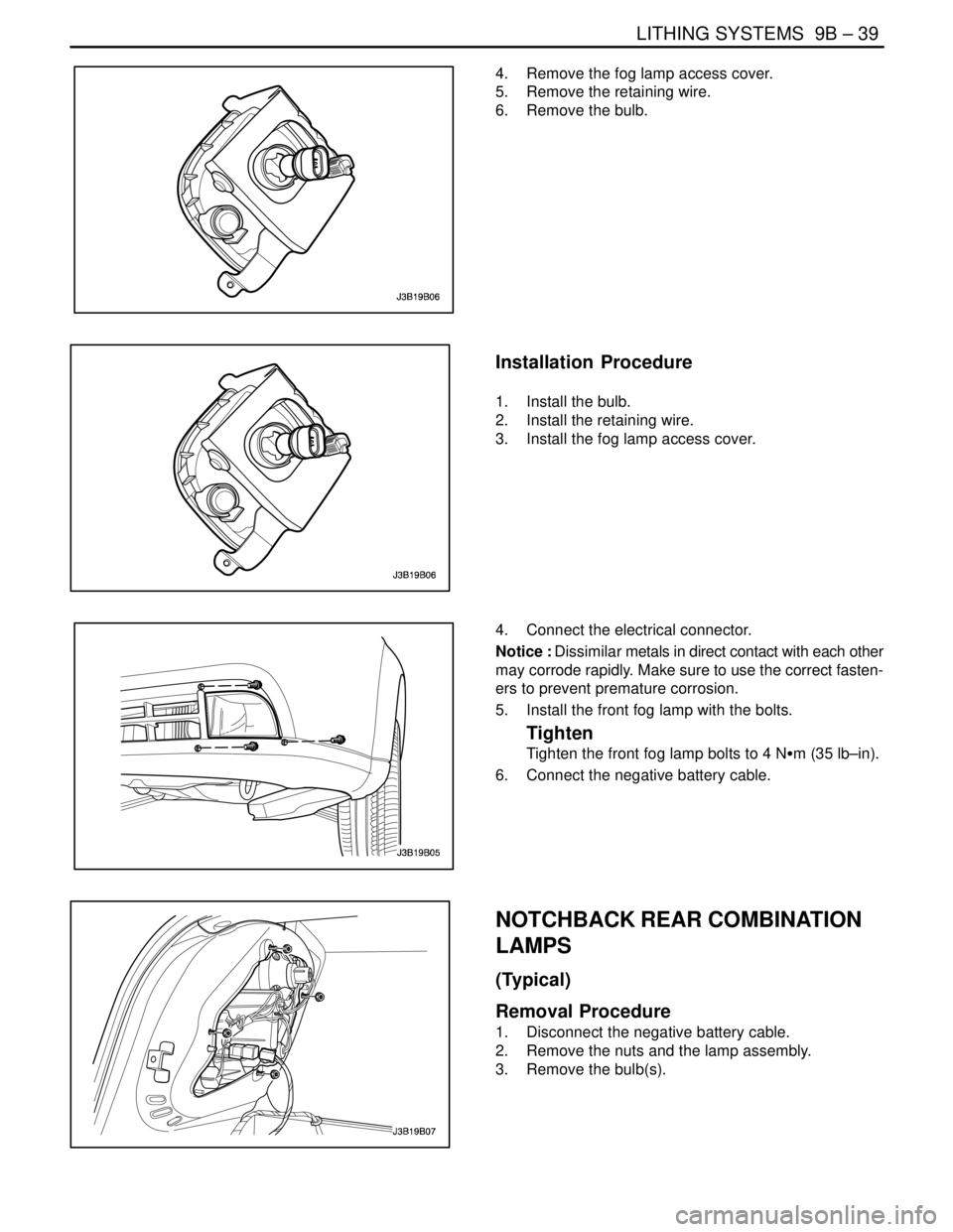

4. Remove the fog lamp access cover.

5. Remove the retaining wire.

6. Remove the bulb.

Installation Procedure

1. Install the bulb.

2. Install the retaining wire.

3. Install the fog lamp access cover.

4. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

5. Install the front fog lamp with the bolts.

Tighten

Tighten the front fog lamp bolts to 4 NSm (35 lb–in).

6. Connect the negative battery cable.

NOTCHBACK REAR COMBINATION

LAMPS

(Typical)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the nuts and the lamp assembly.

3. Remove the bulb(s).

Page 2267 of 2643

LITHING SYSTEMS 9B – 41

DAEWOO V–121 BL4

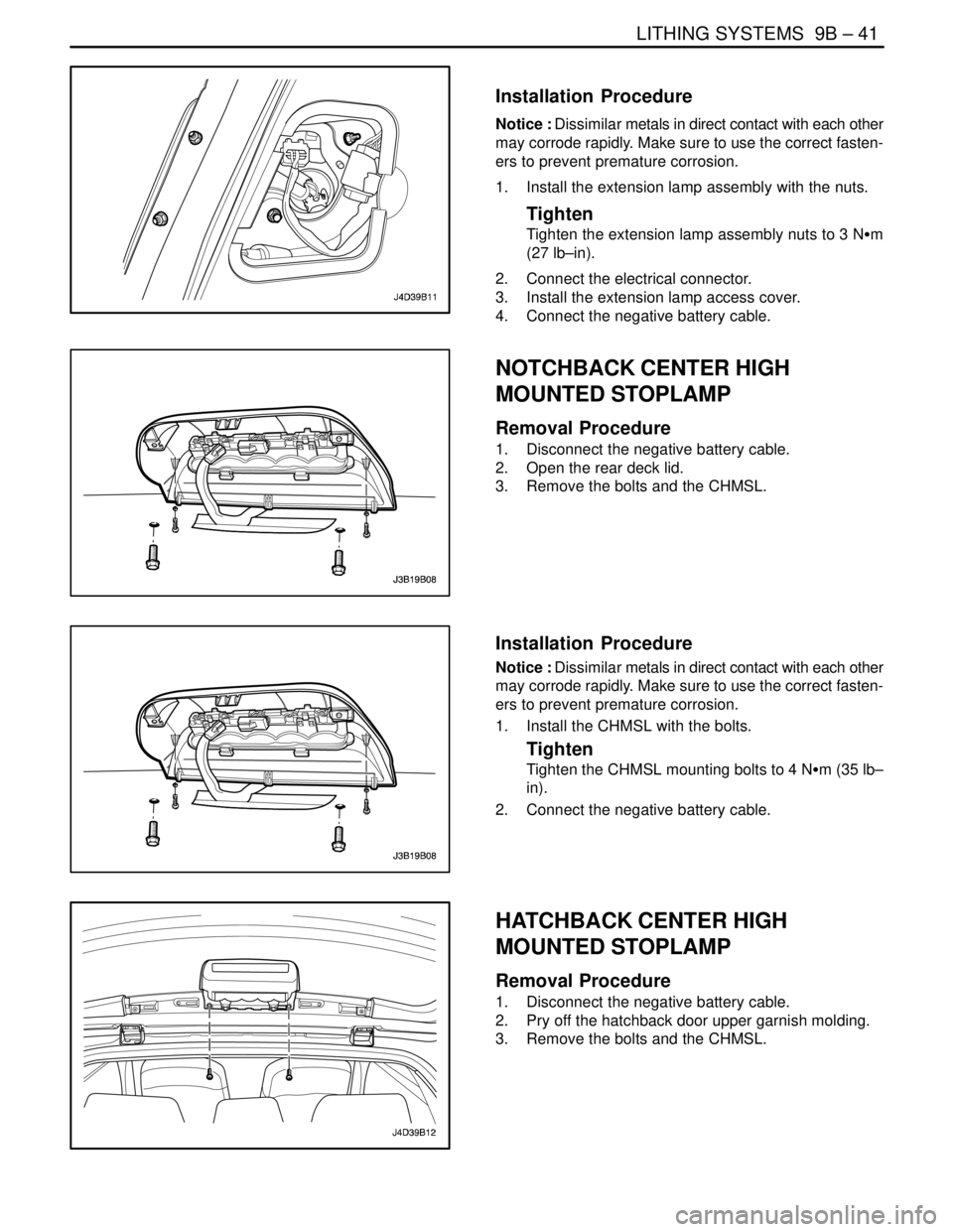

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the extension lamp assembly with the nuts.

Tighten

Tighten the extension lamp assembly nuts to 3 NSm

(27 lb–in).

2. Connect the electrical connector.

3. Install the extension lamp access cover.

4. Connect the negative battery cable.

NOTCHBACK CENTER HIGH

MOUNTED STOPLAMP

Removal Procedure

1. Disconnect the negative battery cable.

2. Open the rear deck lid.

3. Remove the bolts and the CHMSL.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the CHMSL with the bolts.

Tighten

Tighten the CHMSL mounting bolts to 4 NSm (35 lb–

in).

2. Connect the negative battery cable.

HATCHBACK CENTER HIGH

MOUNTED STOPLAMP

Removal Procedure

1. Disconnect the negative battery cable.

2. Pry off the hatchback door upper garnish molding.

3. Remove the bolts and the CHMSL.

Page 2272 of 2643

9B – 46ILITHING SYSTEMS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

HEADLAMPS–ON REMINDER CHIME

When the headlamp switch is in the headlamps–on or

parking lamps–on position, voltage is applied to the chime

module. When the ignition is in ON, ACC or START, volt-

age is applied through the fuse block to the module. These

two voltages are sensed, and the chime module is not

sounded.

When the ignition is not in ON, ACC or START, the module

loses voltage. The chime module senses change. If the

voltage is still available, it is applied to sound the chime.

The chime can be turned off by turning the headlamp

switch off. The module no longer senses voltage from the

headlamp switch, so the chime module does not sound.

HEADLAMPS

The headlamps are controlled by the multifunction lever

located on the left side of the steering column. They will

come on with the ignition switch in any position. Turning

the headlamp switch to the first position turns on the park-

ing lamps, the license plate lamps and the instrument pan-

el illumination. Turning the switch to the second position

turns on all of the previous lamps and the headlamps.

Turning the switch to the OFF position turns off all the

lamps.

Headlamp high beams and low beams are also controlled

by this lever. When the headlamps are on, pushing the le-

ver away from the driver until the switch clicks changes the

lamp from low beam to high beam. An indicator lamp on

the instrument cluster assembly will come on when the

high beam headlamps are on. To return the headlamps to

low beam, pull the lever toward the driver.

The headlamps must be aimed for proper illumination of

the road. Headlamp aim should be checked whenever a

new headlamp assembly is installed, or whenever service

repairs to the front end area may have disturbed the head-

lamp assembly or its mountings.

DAYTIME RUNNING LAMPS

The Daytime Running Lamps (DRL) will come on when:

S The ignition is ON.

S The light is OFF.

S The parking brake is released.

When the exterior lights are on, the DRL will turn off. To

turn the DRL off when idling, apply the parking brake.

PARKING AND TURN SIGNAL LAMPS

The parking lamps can be turned on by turning the lighting

switch to the first position. The parking lamps can be

turned off by turning the switch to the OFF position.When the turn signals are activated, the front and rear turn

signal lamps flash to signal a turn. The turn signals work

only when the ignition is ON.

The turn signals are controlled by the light switch on the

left side of the steering column. Moving the lever all the

way up or down (past the detent) will turn on the front and

rear turn signals. When the turn is completed, the lever will

return to horizontal and the turn signals will stop flashing.

For changing lanes, or for shallow turns in which the steer-

ing wheel does not turn far enough to cancel the signal,

move the signal lever only to the first detent and hold it

there. When the lever is released, it will return to horizontal

and the turn signals will cancel.

FOG LAMPS

The fog lamp switch is on the instrument panel to the right

of the steering column. To use the fog lamps, first turn on

the headlamps or the parking lamps. Then push the fog

lamp switch. The indicator light in the switch will illuminate

to indicate that the fog lamps are on. Push the switch again

to turn off the fog lamps. The indicator light will then go off.

The fog lamps should not be used as a substitute for the

headlamps.

The fog lamps must be aimed for proper illumination of the

road. Fog lamp aim should be checked when a new bulb

is installed or if service or repairs in the front end area may

have disturbed the fog lamp mountings.

REAR COMBINATION LAMPS

The taillamps, stoplamps, turn signal lamps and backup

lamp are one assembly.

Turning on either the headlamps or the parking lamps will

also turn on the taillamps. When the brake pedal is

pushed, the taillamps will glow brighter to serve as sto-

plamps.

The center high–mounted stoplamp is located in the rear

window and will come on when the brake pedal is pressed.

LICENSE PLATE LAMP

The license plate lamps will come on when the headlamps

or the parking lamps are on. The license plate lamps are

mounted above the license plate.

INTERIOR COURTESY LAMP

The courtesy lamp is located on the headliner just behind

the front seats. The lamp switch has three positions. If the

switch is left in the center position, the lamp will go on

whenever a door is opened and go off when it is closed.

In the ON position, the lamp will stay on until it is turned off.

In the OFF position, the lamp will not come on, even when

a door is opened.

LUGGAGE COMPARTMENT LAMP

The luggage compartment lamp is located under the deck

lid sill plate on the notchback. The lamp is located on the

left–side wheelhouse trim panel on the hatchback. It will

come on whenever the luggage compartment is opened.

Page 2296 of 2643

WIPERS/WASHER SYSTEMS 9D – 19

DAEWOO V–121 BL4

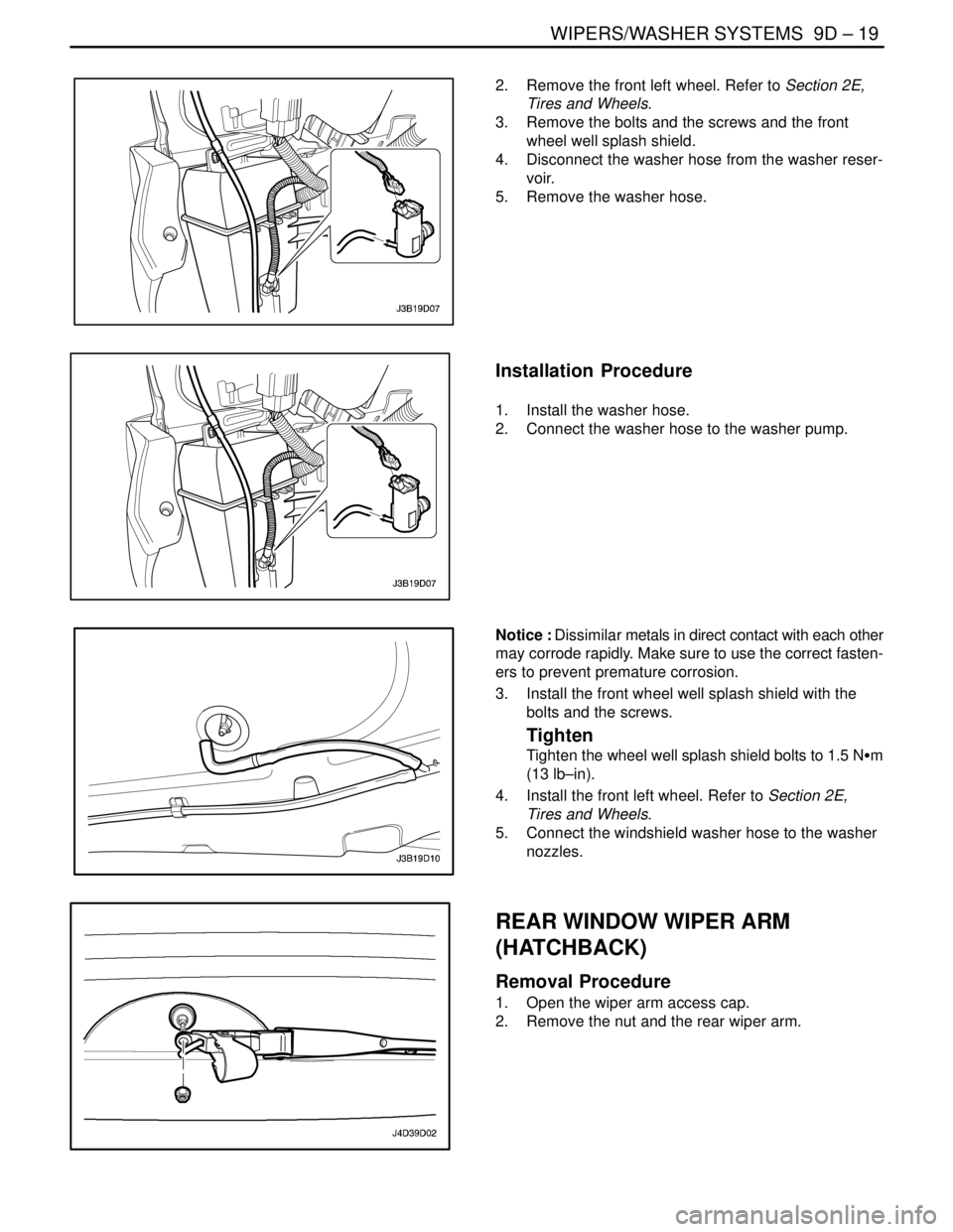

2. Remove the front left wheel. Refer to Section 2E,

Tires and Wheels.

3. Remove the bolts and the screws and the front

wheel well splash shield.

4. Disconnect the washer hose from the washer reser-

voir.

5. Remove the washer hose.

Installation Procedure

1. Install the washer hose.

2. Connect the washer hose to the washer pump.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

3. Install the front wheel well splash shield with the

bolts and the screws.

Tighten

Tighten the wheel well splash shield bolts to 1.5 NSm

(13 lb–in).

4. Install the front left wheel. Refer to Section 2E,

Tires and Wheels.

5. Connect the windshield washer hose to the washer

nozzles.

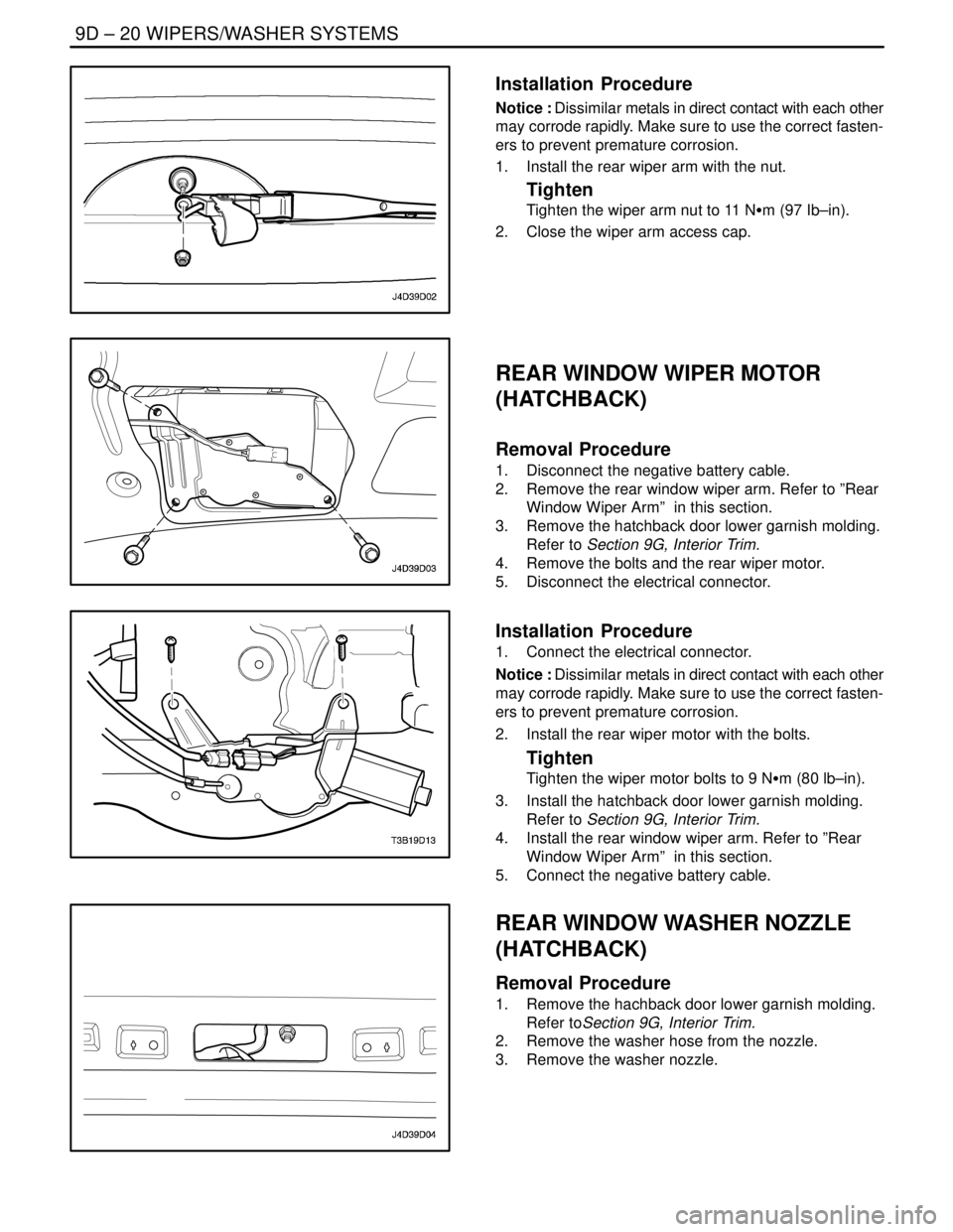

REAR WINDOW WIPER ARM

(HATCHBACK)

Removal Procedure

1. Open the wiper arm access cap.

2. Remove the nut and the rear wiper arm.

Page 2297 of 2643

9D – 20IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the rear wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 11 NSm (97 Ib–in).

2. Close the wiper arm access cap.

REAR WINDOW WIPER MOTOR

(HATCHBACK)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

3. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Remove the bolts and the rear wiper motor.

5. Disconnect the electrical connector.

Installation Procedure

1. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the rear wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 9 NSm (80 lb–in).

3. Install the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Install the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

5. Connect the negative battery cable.

REAR WINDOW WASHER NOZZLE

(HATCHBACK)

Removal Procedure

1. Remove the hachback door lower garnish molding.

Refer toSection 9G, Interior Trim.

2. Remove the washer hose from the nozzle.

3. Remove the washer nozzle.