acc DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1830 of 2643

5B – 6IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

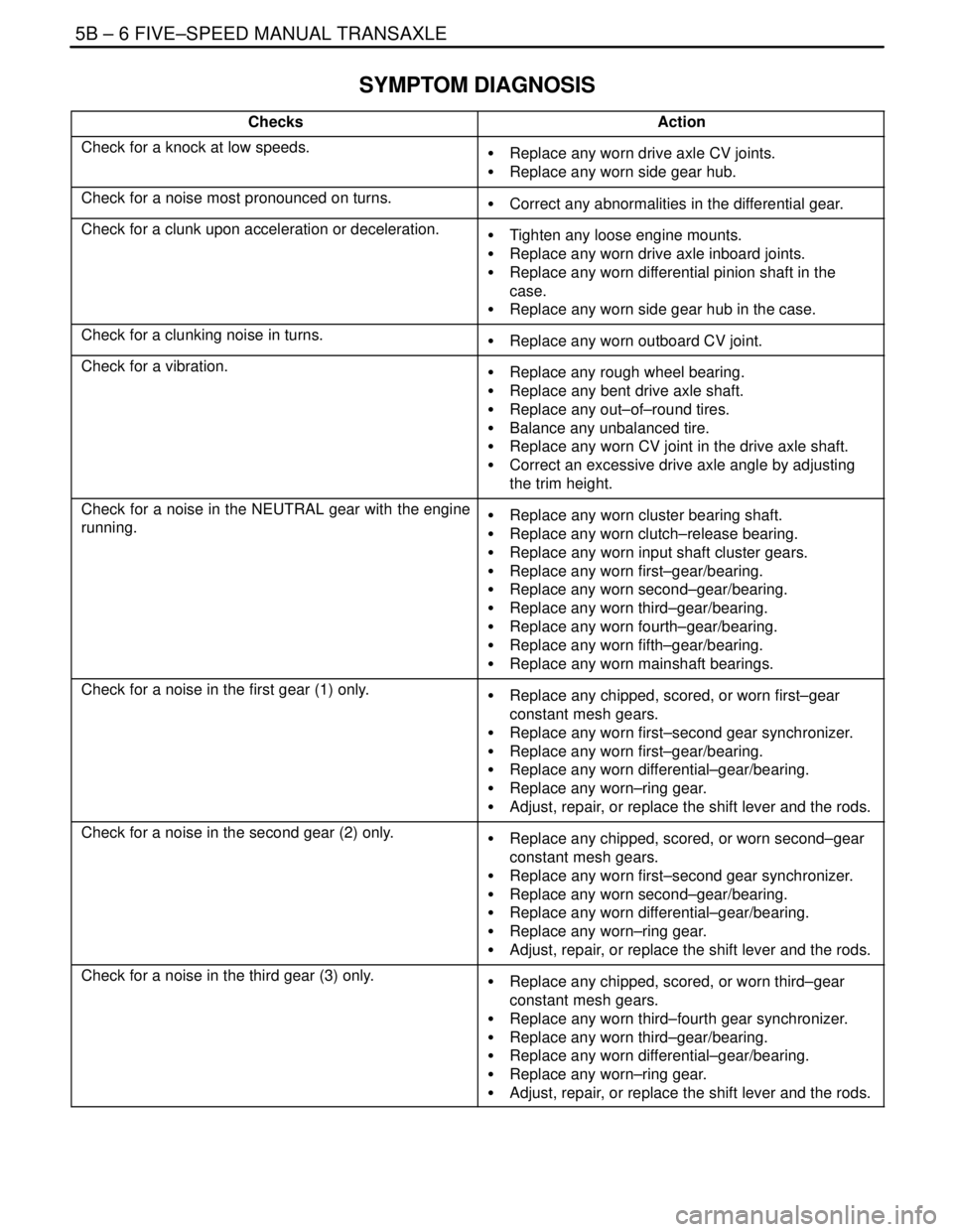

SYMPTOM DIAGNOSIS

ChecksAction

Check for a knock at low speeds.S Replace any worn drive axle CV joints.

S Replace any worn side gear hub.

Check for a noise most pronounced on turns.S Correct any abnormalities in the differential gear.

Check for a clunk upon acceleration or deceleration.S Tighten any loose engine mounts.

S Replace any worn drive axle inboard joints.

S Replace any worn differential pinion shaft in the

case.

S Replace any worn side gear hub in the case.

Check for a clunking noise in turns.S Replace any worn outboard CV joint.

Check for a vibration.S Replace any rough wheel bearing.

S Replace any bent drive axle shaft.

S Replace any out–of–round tires.

S Balance any unbalanced tire.

S Replace any worn CV joint in the drive axle shaft.

S Correct an excessive drive axle angle by adjusting

the trim height.

Check for a noise in the NEUTRAL gear with the engine

running.S Replace any worn cluster bearing shaft.

S Replace any worn clutch–release bearing.

S Replace any worn input shaft cluster gears.

S Replace any worn first–gear/bearing.

S Replace any worn second–gear/bearing.

S Replace any worn third–gear/bearing.

S Replace any worn fourth–gear/bearing.

S Replace any worn fifth–gear/bearing.

S Replace any worn mainshaft bearings.

Check for a noise in the first gear (1) only.S Replace any chipped, scored, or worn first–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn first–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the second gear (2) only.S Replace any chipped, scored, or worn second–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn second–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the third gear (3) only.S Replace any chipped, scored, or worn third–gear

constant mesh gears.

S Replace any worn third–fourth gear synchronizer.

S Replace any worn third–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Page 1887 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 63

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FIVE–SPEED MANUAL TRANSAXLE

This five–speed transaxle assembly is a transmission of

constant–mesh design.

Combined in the assembly are:

S All forward gears.

S The reverse gear.

S The differential output.

The basic components of the five–speed transaxle as-

sembly units are the:

S Transaxle case.

S Input shaft.

S Input shaft gears.S Output shaft.

S Output shaft gears.

S Ring gear and differential assembly.

Forward Gear

Shifting to a forward gear is accomplished through a com-

bination of synchronizers with blocker rings controlled by

sliding shift forks.

Reverse Gear

Reverse gear is not synchronized and uses a sliding idler

gear arrangement.

Differential Assembly

The differential is a conventional arrangement of gears

that is supported by tapered roller bearings. The final out-

put gear turns the ring gear and differential assembly

which turns the drive axle shafts.

Page 1904 of 2643

POWER STEERING SYSTEM 6A – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

BLEEDING THE POWER STEERING

SYSTEM

If the power steering hydraulic system has been serviced,

an accurate fluid level reading cannot be obtained until the

air is bled from the system. Follow these steps to bleed the

air from the system.

1. Turn the wheels all the way to the left and add the

power steering fluid to the MIN mark on the fluid

level indicator.

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

2. Start the engine. With the engine running at fast

idle, recheck the fluid level. If necessary, add fluid

to bring the level up to the MIN mark.

3. Bleed the system by turning the wheels from side to

side without reaching the stop at either end. Keep

the fluid level at the MIN mark. The air must be

eliminated from the fluid before normal steering ac-

tion can be obtained.

4. Return the wheels to the center position. Continue

running the engine for 2 to 3 minutes.

5. Road test the car to be sure the steering functions

normally and is free from noise.

6. Recheck the fluid level as described in steps 1 and

2. Make sure the fluid level is at the MAX mark af-

ter the system has stabilized at its normal operating

temperature. Add fluid as needed.

CHECKING AND ADDING FLUID

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

1. The power steering fluid level is indicated either by

marks on a see–through fluid reservoir or by marks

on a fluid level indicator on the fluid reservoir cap.

2. If the fluid is warmed up to 66°C (150°F), the fluid

level should be between the MAX and MIN marks.

Add fluid as needed.

3. If the fluid is cool, 21°C (70°F), the fluid level

should be at the MIN mark. Add fluid as needed.

Page 1910 of 2643

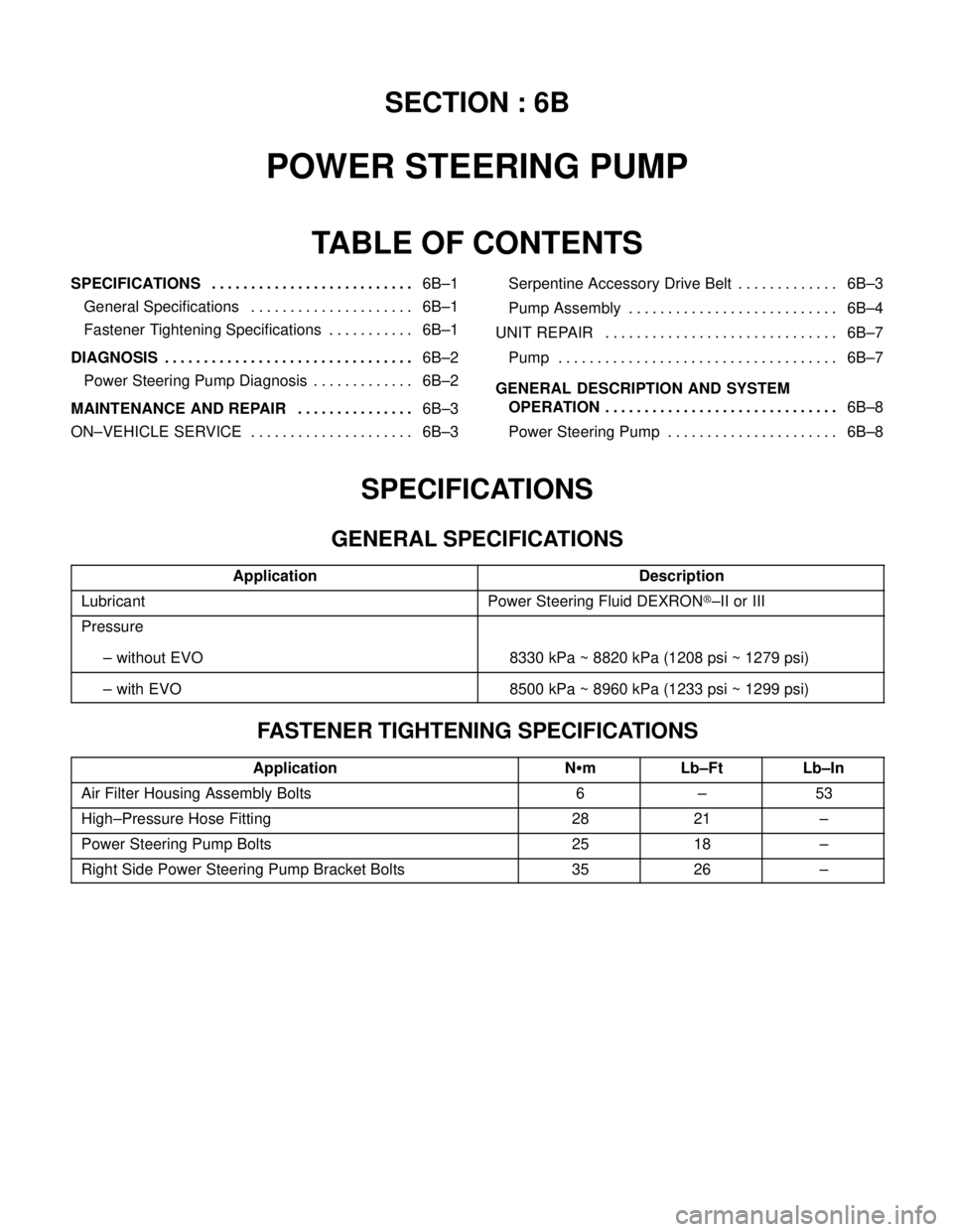

SECTION : 6B

POWER STEERING PUMP

TABLE OF CONTENTS

SPECIFICATIONS6B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6B–1. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6B–1. . . . . . . . . . .

DIAGNOSIS6B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pump Diagnosis 6B–2. . . . . . . . . . . . .

MAINTENANCE AND REPAIR6B–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6B–3. . . . . . . . . . . . . . . . . . . . . Serpentine Accessory Drive Belt 6B–3. . . . . . . . . . . . .

Pump Assembly 6B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6B–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pump 6B–8. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

LubricantPower Steering Fluid DEXRON®–II or III

Pressure

– without EVO8330 kPa ~ 8820 kPa (1208 psi ~ 1279 psi)

– with EVO8500 kPa ~ 8960 kPa (1233 psi ~ 1299 psi)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Air Filter Housing Assembly Bolts6–53

High–Pressure Hose Fitting2821–

Power Steering Pump Bolts2518–

Right Side Power Steering Pump Bracket Bolts3526–

Page 1911 of 2643

6B – 2IPOWER STEERING PUMP

DAEWOO V–121 BL4

DIAGNOSIS

POWER STEERING PUMP DIAGNOSIS

Foaming or Milky Power Steering Fluid (Air in Fluid)

ChecksAction

Check for internal leakage in the power steering pump,

causing an overflow.Repair the internal pump leakage.

Bleed the system.

Check for a low fluid level.Repair the internal pump leakage.

Bleed the system.

Cold temperatures will cause the air bubbles in the system

if the fluid level is low.

Low Pressure Due to Power Steering Pump

ChecksAction

Check for an external leakage of the power steering pump

at the seals.Replace the seals.

Repair the leak.

Bleed the system.

Check for a worn serpentine accessory drive belt.Replace the serpentine accessory drive belt.

Low Pressure Due to Power Steering Gear

ChecksAction

Check for a scored housing bore.Replace the housing bore.

Check for leakage at the valve rings or the seals.Repair the leak.

Bleed the system.

Groaning Noise in the Power Steering Pump

ChecksAction

Check for air in the power steering fluid.Perform the checks listed in ”Foaming or Milky Power

Steering Fluid (Air in Fluid)” above.

Check for a low level of power steering fluid.Repair any internal or external leaks.

Bleed the system.

Check for a loose mounting of the power steering pump.Tighten the pump mounting to specifications.

Page 1912 of 2643

POWER STEERING PUMP 6B – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

SERPENTINE ACCESSORY DRIVE

BELT

Removal Procedure

1. Remove the air filter housing assembly bolts and

the air intake tube.

2. Remove the air filter housing assembly from the

vehicle.

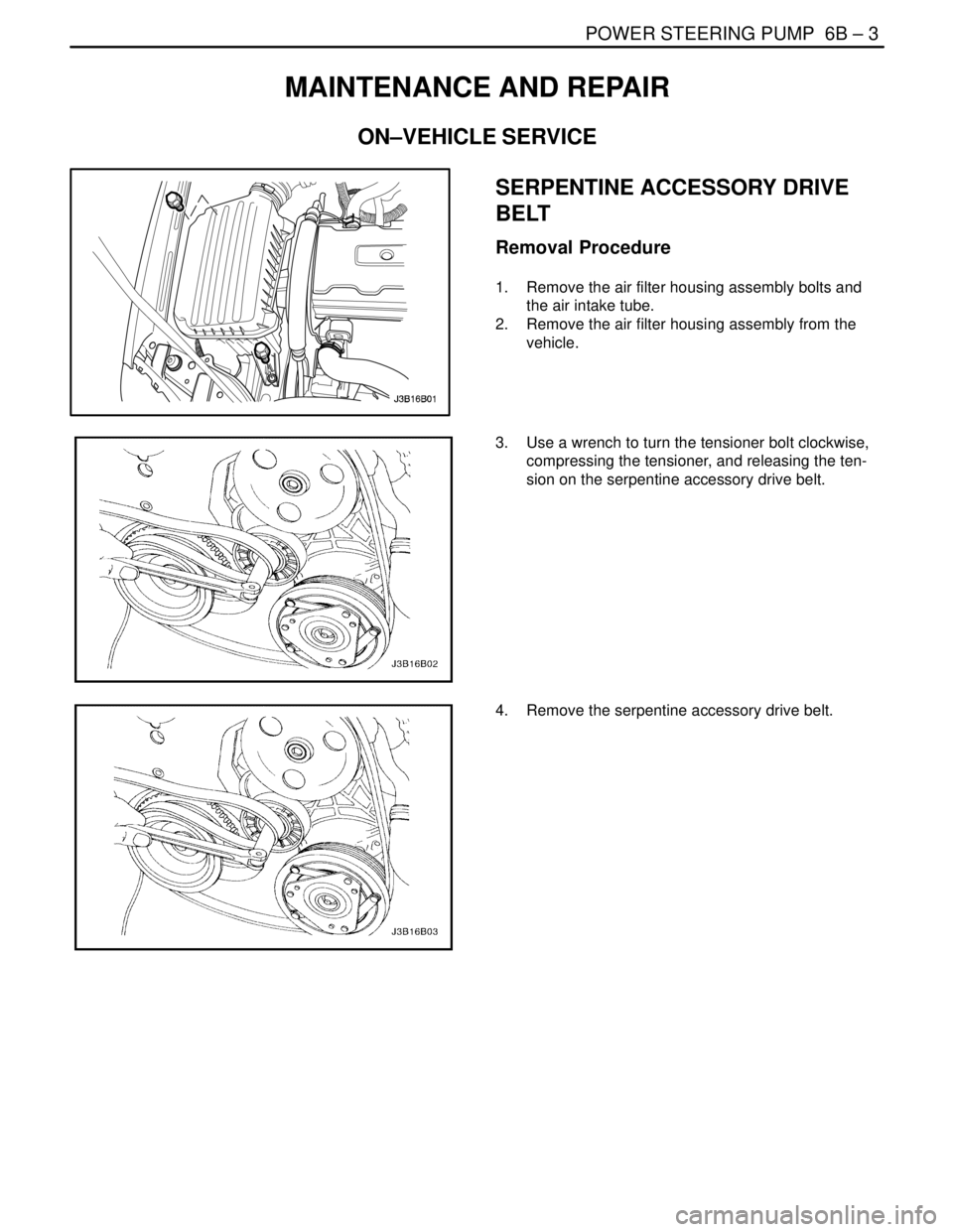

3. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the ten-

sion on the serpentine accessory drive belt.

4. Remove the serpentine accessory drive belt.

Page 1913 of 2643

6B – 4IPOWER STEERING PUMP

DAEWOO V–121 BL4

Installation Procedure

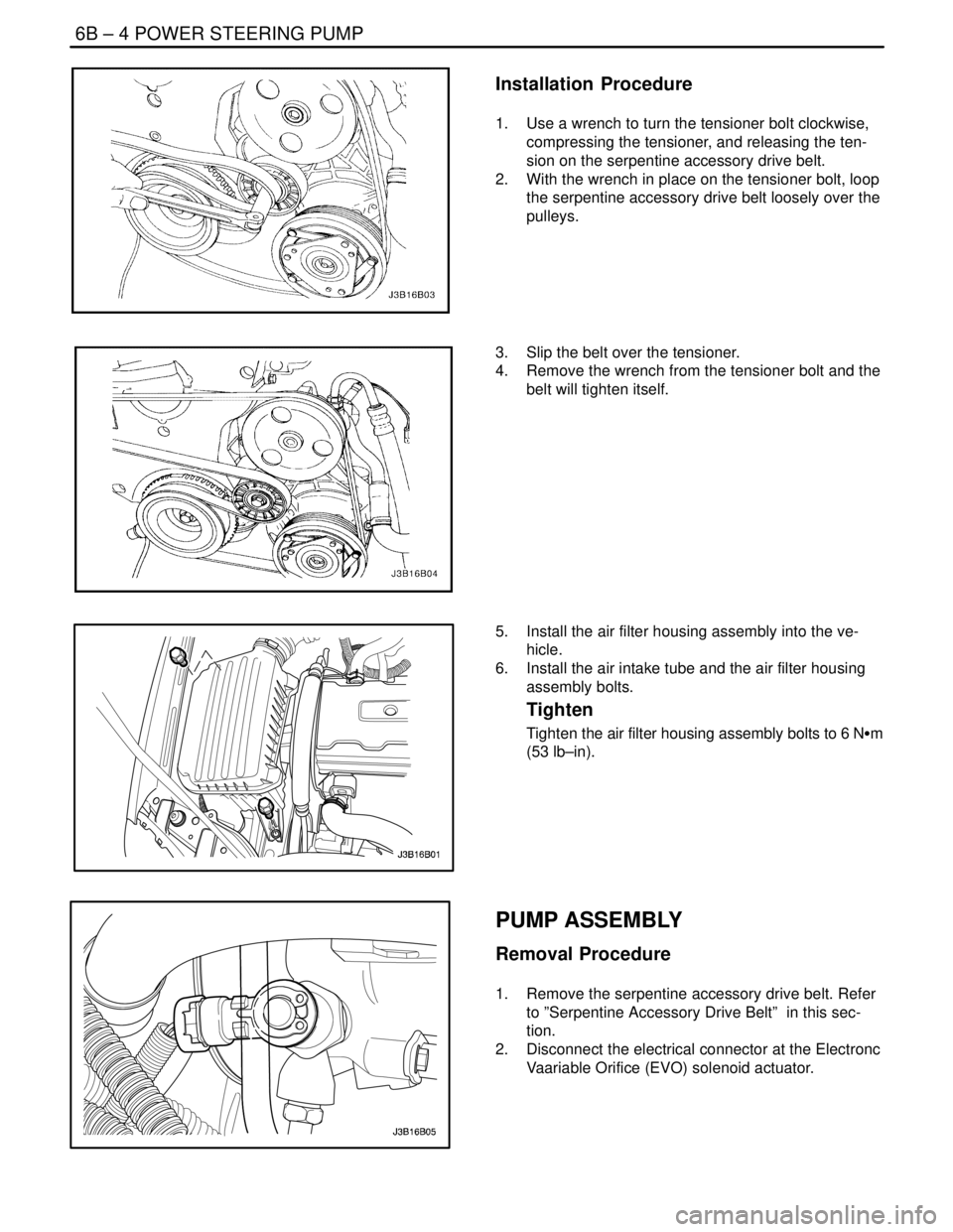

1. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the ten-

sion on the serpentine accessory drive belt.

2. With the wrench in place on the tensioner bolt, loop

the serpentine accessory drive belt loosely over the

pulleys.

3. Slip the belt over the tensioner.

4. Remove the wrench from the tensioner bolt and the

belt will tighten itself.

5. Install the air filter housing assembly into the ve-

hicle.

6. Install the air intake tube and the air filter housing

assembly bolts.

Tighten

Tighten the air filter housing assembly bolts to 6 NSm

(53 lb–in).

PUMP ASSEMBLY

Removal Procedure

1. Remove the serpentine accessory drive belt. Refer

to ”Serpentine Accessory Drive Belt” in this sec-

tion.

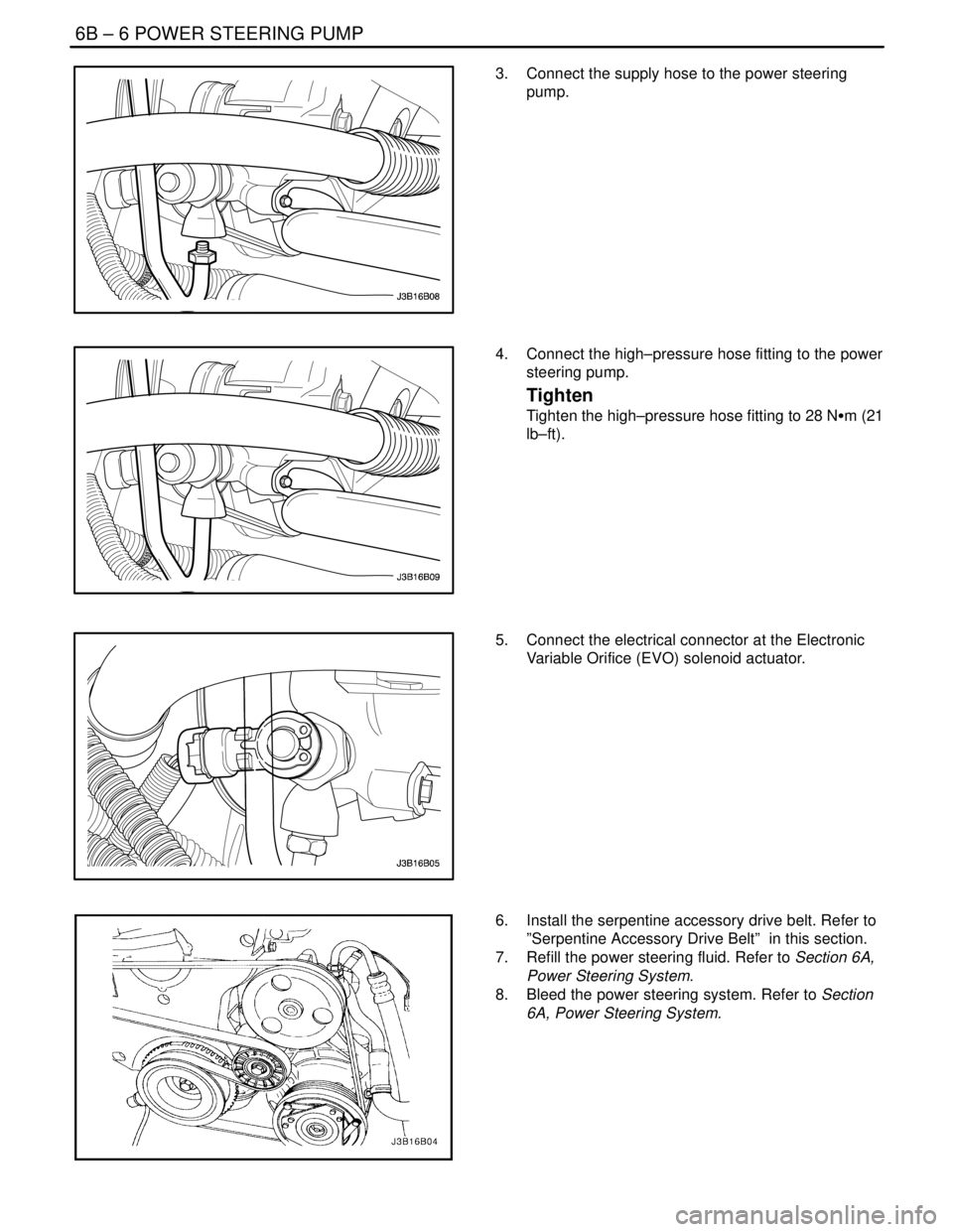

2. Disconnect the electrical connector at the Electronc

Vaariable Orifice (EVO) solenoid actuator.

Page 1915 of 2643

6B – 6IPOWER STEERING PUMP

DAEWOO V–121 BL4

3. Connect the supply hose to the power steering

pump.

4. Connect the high–pressure hose fitting to the power

steering pump.

Tighten

Tighten the high–pressure hose fitting to 28 NSm (21

lb–ft).

5. Connect the electrical connector at the Electronic

Variable Orifice (EVO) solenoid actuator.

6. Install the serpentine accessory drive belt. Refer to

”Serpentine Accessory Drive Belt” in this section.

7. Refill the power steering fluid. Refer to Section 6A,

Power Steering System.

8. Bleed the power steering system. Refer to Section

6A, Power Steering System.

Page 1917 of 2643

6B – 8IPOWER STEERING PUMP

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

POWER STEERING PUMP

The power steering pump is a multivaned hydraulic pump.

The serpentine accessory drive belt on the engine drives

the power steering pump.The power steering pump provides the hydraulic pressure

to the power steering gear.

The power steering gear uses the hydraulic pressure to

assist in steering the vehicle.

The power steering system uses a remote reservoir in or-

der to make available more space in the engine compart-

ment.

Page 1935 of 2643

6C – 18IPOWER STEERING GEAR

DAEWOO V–121 BL4

3. Turn the steering wheel so that the upper pinch bolt

is accessible. Remove the upper pinch bolt from

the universal joint on the intermediate shaft.

4. Remove the nuts from the dash seal retaining ring

and remove the dash seal retaining ring.

5. Remove the coupling from the power steering gear

and pull the intermediate shaft out of the engine

compartment.

Installation Procedure

1. Install the intermediate shaft into the vehicle.