acc DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2305 of 2643

9E – 6IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

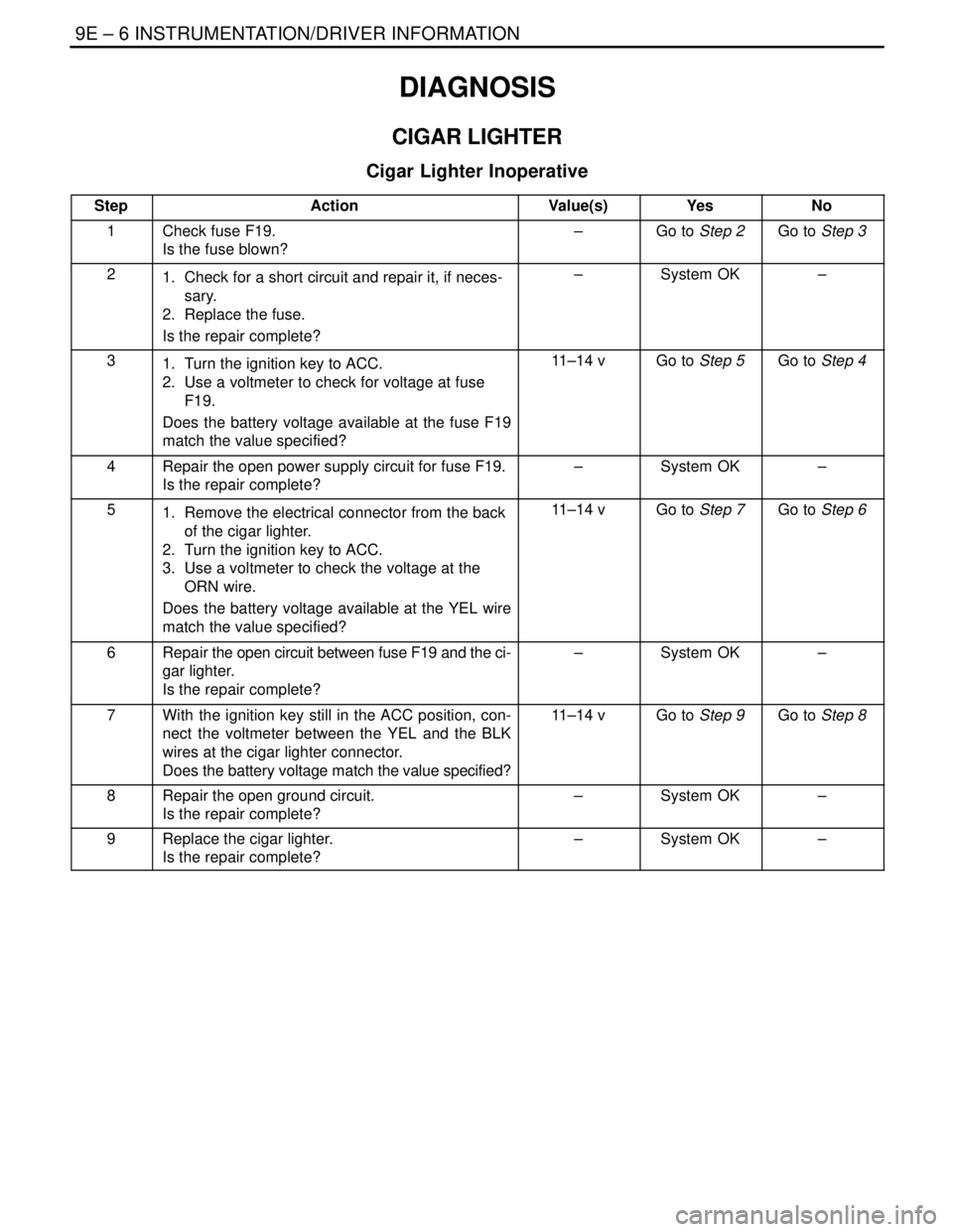

DIAGNOSIS

CIGAR LIGHTER

Cigar Lighter Inoperative

StepActionValue(s)YesNo

1Check fuse F19.

Is the fuse blown?–Go to Step 2Go to Step 3

21. Check for a short circuit and repair it, if neces-

sary.

2. Replace the fuse.

Is the repair complete?–System OK–

31. Turn the ignition key to ACC.

2. Use a voltmeter to check for voltage at fuse

F19.

Does the battery voltage available at the fuse F19

match the value specified?11–14 vGo to Step 5Go to Step 4

4Repair the open power supply circuit for fuse F19.

Is the repair complete?–System OK–

51. Remove the electrical connector from the back

of the cigar lighter.

2. Turn the ignition key to ACC.

3. Use a voltmeter to check the voltage at the

ORN wire.

Does the battery voltage available at the YEL wire

match the value specified?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between fuse F19 and the ci-

gar lighter.

Is the repair complete?–System OK–

7With the ignition key still in the ACC position, con-

nect the voltmeter between the YEL and the BLK

wires at the cigar lighter connector.

Does the battery voltage match the value specified?11–14 vGo to Step 9Go to Step 8

8Repair the open ground circuit.

Is the repair complete?–System OK–

9Replace the cigar lighter.

Is the repair complete?–System OK–

Page 2329 of 2643

9E – 30IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the floor

console. To use the lighter, push it in completely. When the

lighter is hot, it will release itself from contact with the heat-

ing element. The lighter and the heating element can be

damaged if the lighter is not allowed to release itself fully

from the heating element.

ASHTRAY

The ashtray is located below the audio system. To access

the ashtray, pull it out from the center console. The ashtray

lamp will go on when the parking lamps or the headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel can

be adjusted up and down and from side to side. The side

vents can also be aimed toward the side windows in order

to defog them.

GLOVE BOX

The glove box can be opened by pulling up on the latch

handle. The glove box must be removed in order to gain

access to the passenger’s side airbag module.

DIGTAL CLOCK

The digital clock is located in the instrument panel, above

the audio system. The clock is capable of a 12–hour or a

24–hour display.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering col-

umn and in the instrument cluster trim panel. The instru-

ment cluster contains the instruments that provide the

driver with vehicle performance information. The instru-

ment cluster contains a speedometer, an odometer, a trip

odometer, a temperature gauge, a fuel gauge, and several

indicator lamps. For replacement of the indicator lamp

bulbs contained in the instrument cluster, refer to ”Instru-

ment Cluster Indicator Lamps Specifications” and”Instru-

ment Cluster Indicator Lamps” in this section.

SPEEDOMETER/ODOMETER/TRIP

ODOMETER

The speedometer measures the speed of the vehicle in

km/h (mph in some countries). It consists of an instrument

cluster gauge connected to the vehicle speed sensor

(VSS) on the transaxle output shaft.The odometer measures in kilometers (miles in some

countries) the total distance the vehicle has traveled since

it was manufactured. It consists of an instrument cluster

gauge connected to the VSS on the transaxle output shaft.

The trip odometer measures the distance the vehicle has

traveled since the odometer was last reset. It consists of

an instrument cluster gauge connected to the VSS on the

transaxle output shaft. The trip odometer can be reset to

zero at any time so that the driver can record the distance

traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank.

The fuel gauge indicates the quantity of fuel in the tank

only when the ignition switch is turned to ON or ACC.

When the ignition is turned to LOCK or START, the pointer

may come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument cluster

gauge connected to a temperature sensor that is in con-

tact with the circulating engine coolant.

The temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of the

gauge. The engine is overheating if the pointer moves into

the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER INDICATOR

LAMPS

The instrument cluster contains indicator lamps that indi-

cate the functioning of certain systems or the existence of

potential problems with the operation of the vehicle. The

indicator lamps are replaceable. For replacement of the in-

dicator lamps contained in the instrument cluster, refer to

”Instrument Cluster Indicator Lamps Specifications”

and”Instrument Cluster Indicator Lamps” in this section.

CHIME MODULE

The chime module is located above the instrument panel

fuse block and will sound in order to bring attention to one

or more of the following conditions:

S The lamps are on, the door is ajar, and the ignition

switch is not in ACC, ON, or START.

S The seat belt is unbuckled when the ignition switch

is in ON or START.

S The door is open when the ignition switch is in ON

or START.

S The key is left in the ignition switch when the igni-

tion is in LOCK and the door is open.

Page 2375 of 2643

SECTION : 9J

WINDNOISE

TABLE OF CONTENTS

DIAGNOSIS9J–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windnoise Diagnosis 9J–1. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9J–2 . . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9J–2. . . . . . . . . . . . . . . . . . . . . .

Windnoise Repair 9J–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

WINDNOISE DIAGNOSIS

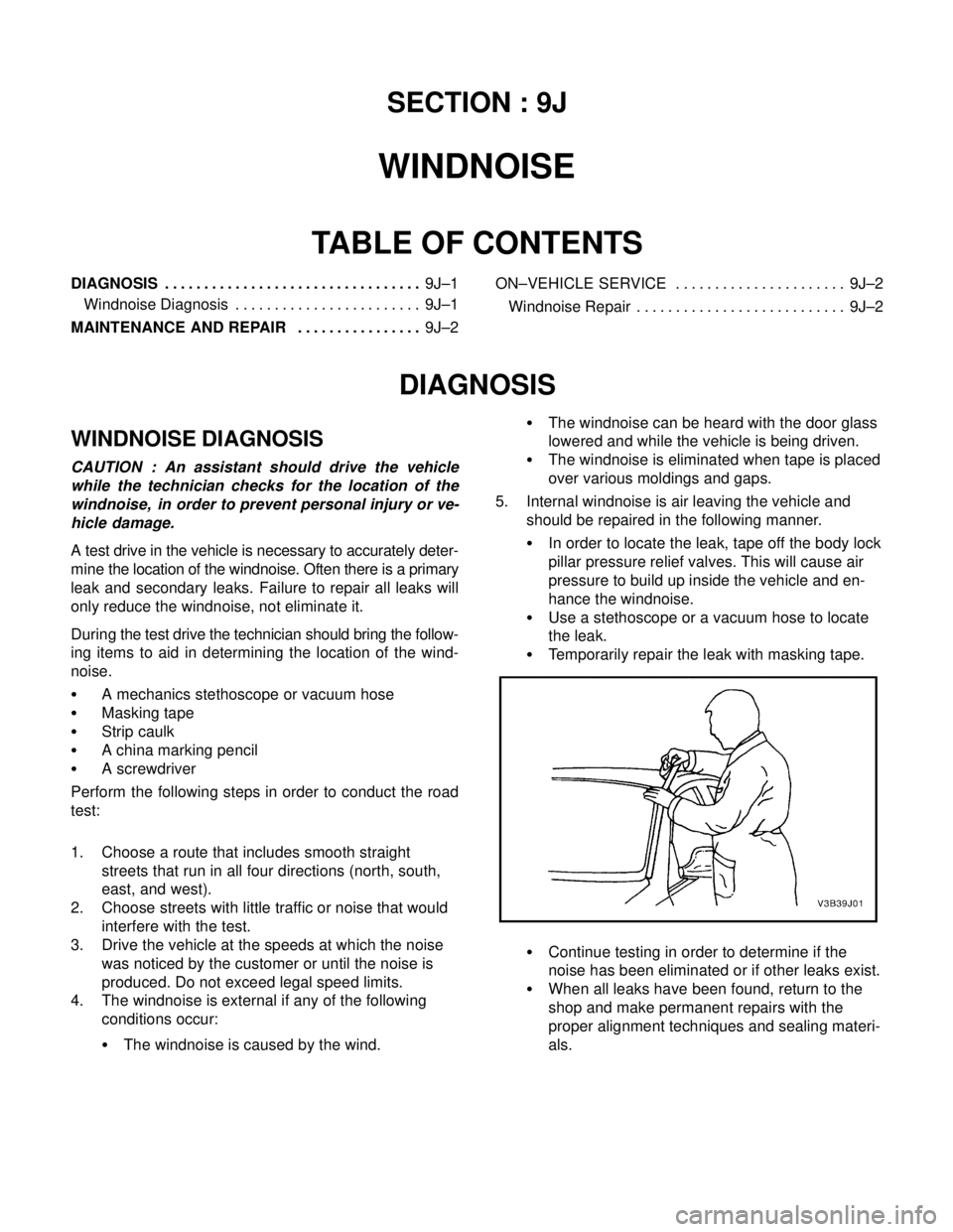

CAUTION : An assistant should drive the vehicle

while the technician checks for the location of the

windnoise, in order to prevent personal injury or ve-

hicle damage.

A test drive in the vehicle is necessary to accurately deter-

mine the location of the windnoise. Often there is a primary

leak and secondary leaks. Failure to repair all leaks will

only reduce the windnoise, not eliminate it.

During the test drive the technician should bring the follow-

ing items to aid in determining the location of the wind-

noise.

S A mechanics stethoscope or vacuum hose

S Masking tape

S Strip caulk

S A china marking pencil

S A screwdriver

Perform the following steps in order to conduct the road

test:

1. Choose a route that includes smooth straight

streets that run in all four directions (north, south,

east, and west).

2. Choose streets with little traffic or noise that would

interfere with the test.

3. Drive the vehicle at the speeds at which the noise

was noticed by the customer or until the noise is

produced. Do not exceed legal speed limits.

4. The windnoise is external if any of the following

conditions occur:

S The windnoise is caused by the wind.S The windnoise can be heard with the door glass

lowered and while the vehicle is being driven.

S The windnoise is eliminated when tape is placed

over various moldings and gaps.

5. Internal windnoise is air leaving the vehicle and

should be repaired in the following manner.

S In order to locate the leak, tape off the body lock

pillar pressure relief valves. This will cause air

pressure to build up inside the vehicle and en-

hance the windnoise.

S Use a stethoscope or a vacuum hose to locate

the leak.

S Temporarily repair the leak with masking tape.

S Continue testing in order to determine if the

noise has been eliminated or if other leaks exist.

S When all leaks have been found, return to the

shop and make permanent repairs with the

proper alignment techniques and sealing materi-

als.

Page 2400 of 2643

9M – 2IEXTERIOR TRIM

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

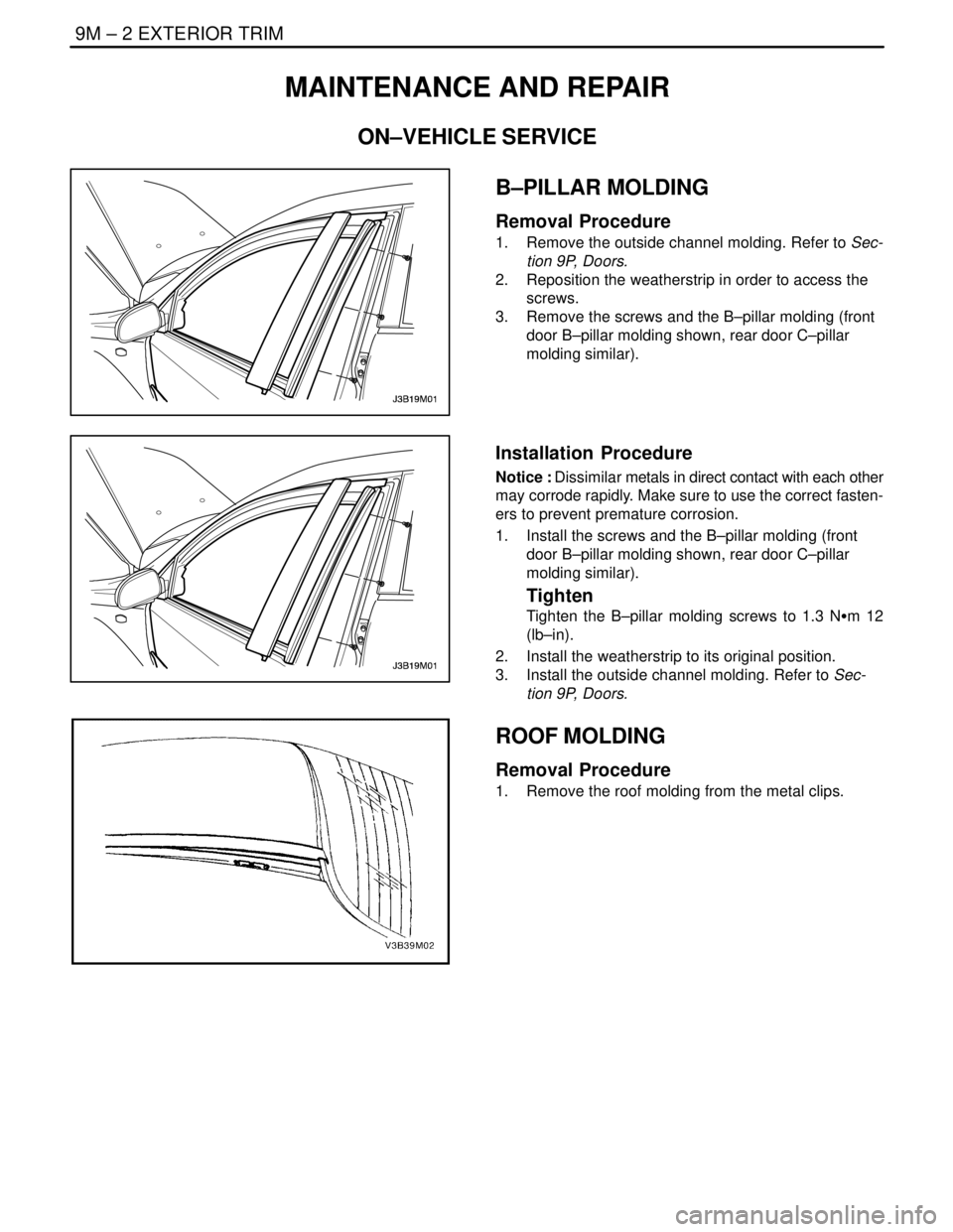

B–PILLAR MOLDING

Removal Procedure

1. Remove the outside channel molding. Refer to Sec-

tion 9P, Doors.

2. Reposition the weatherstrip in order to access the

screws.

3. Remove the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Tighten

Tighten the B–pillar molding screws to 1.3 NSm 12

(lb–in).

2. Install the weatherstrip to its original position.

3. Install the outside channel molding. Refer to Sec-

tion 9P, Doors.

ROOF MOLDING

Removal Procedure

1. Remove the roof molding from the metal clips.

Page 2409 of 2643

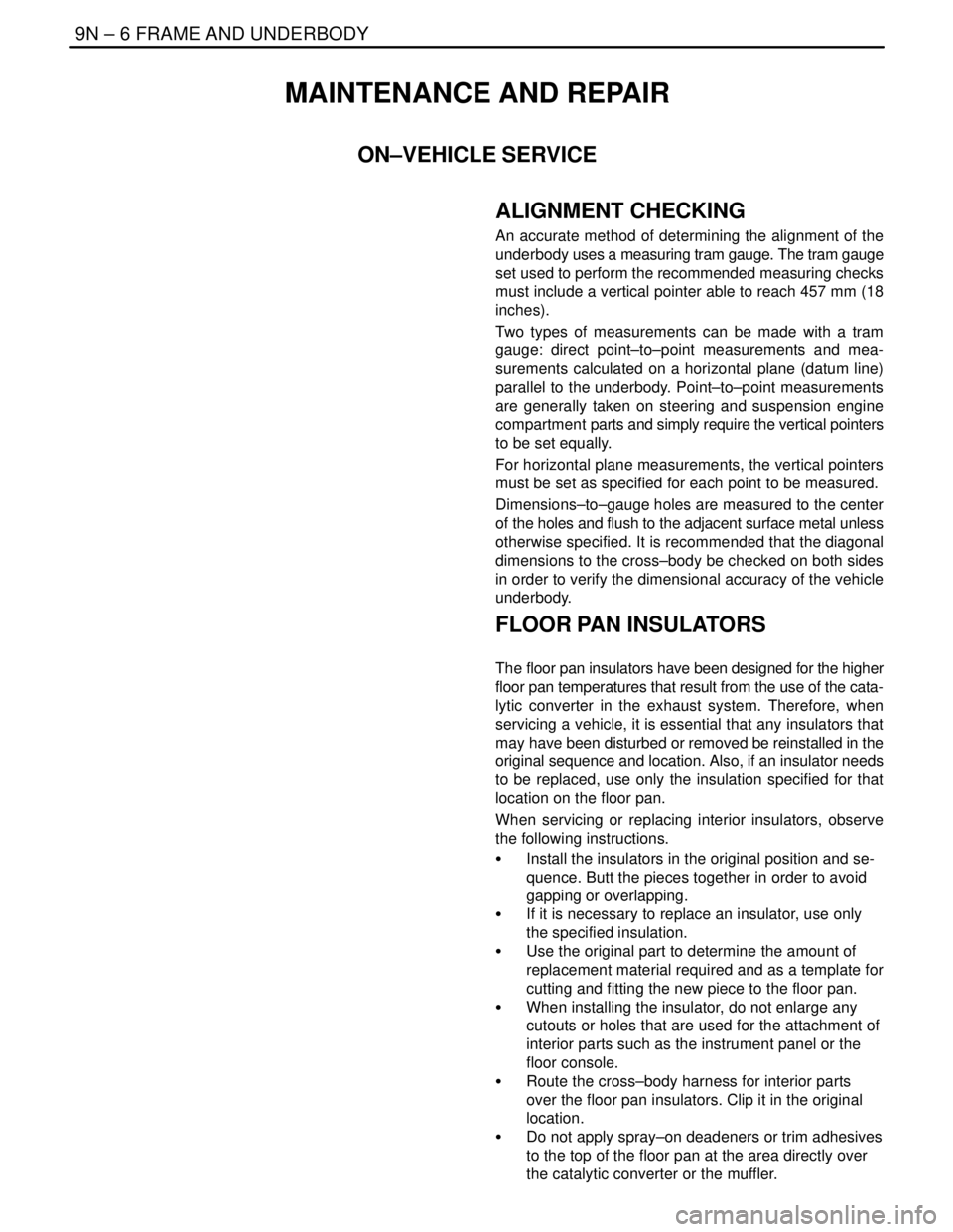

9N – 6IFRAME AND UNDERBODY

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

ALIGNMENT CHECKING

An accurate method of determining the alignment of the

underbody uses a measuring tram gauge. The tram gauge

set used to perform the recommended measuring checks

must include a vertical pointer able to reach 457 mm (18

inches).

Two types of measurements can be made with a tram

gauge: direct point–to–point measurements and mea-

surements calculated on a horizontal plane (datum line)

parallel to the underbody. Point–to–point measurements

are generally taken on steering and suspension engine

compartment parts and simply require the vertical pointers

to be set equally.

For horizontal plane measurements, the vertical pointers

must be set as specified for each point to be measured.

Dimensions–to–gauge holes are measured to the center

of the holes and flush to the adjacent surface metal unless

otherwise specified. It is recommended that the diagonal

dimensions to the cross–body be checked on both sides

in order to verify the dimensional accuracy of the vehicle

underbody.

FLOOR PAN INSULATORS

The floor pan insulators have been designed for the higher

floor pan temperatures that result from the use of the cata-

lytic converter in the exhaust system. Therefore, when

servicing a vehicle, it is essential that any insulators that

may have been disturbed or removed be reinstalled in the

original sequence and location. Also, if an insulator needs

to be replaced, use only the insulation specified for that

location on the floor pan.

When servicing or replacing interior insulators, observe

the following instructions.

S Install the insulators in the original position and se-

quence. Butt the pieces together in order to avoid

gapping or overlapping.

S If it is necessary to replace an insulator, use only

the specified insulation.

S Use the original part to determine the amount of

replacement material required and as a template for

cutting and fitting the new piece to the floor pan.

S When installing the insulator, do not enlarge any

cutouts or holes that are used for the attachment of

interior parts such as the instrument panel or the

floor console.

S Route the cross–body harness for interior parts

over the floor pan insulators. Clip it in the original

location.

S Do not apply spray–on deadeners or trim adhesives

to the top of the floor pan at the area directly over

the catalytic converter or the muffler.

Page 2426 of 2643

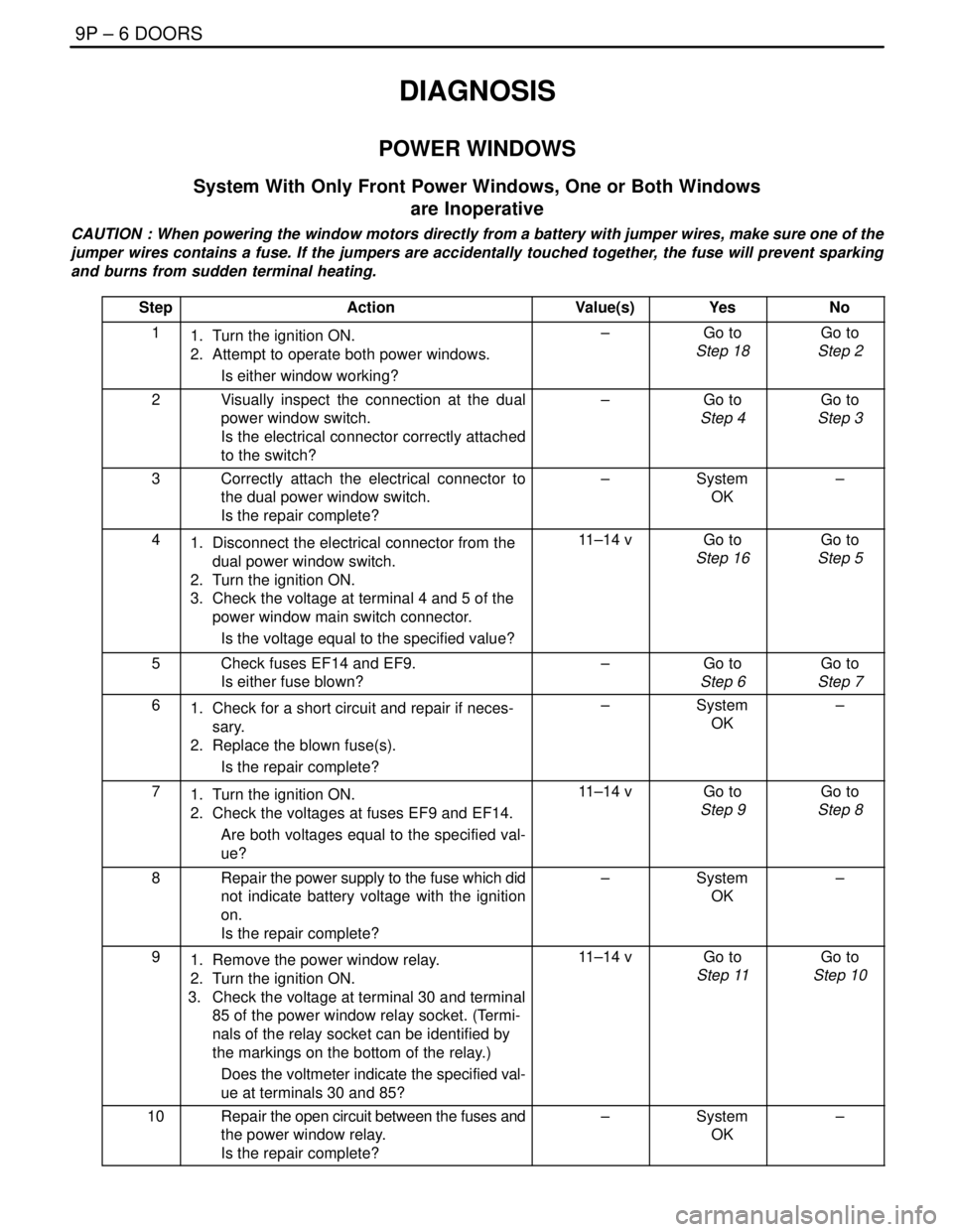

9P – 6IDOORS

DAEWOO V–121 BL4

DIAGNOSIS

POWER WINDOWS

System With Only Front Power Windows, One or Both Windows

are Inoperative

CAUTION : When powering the window motors directly from a battery with jumper wires, make sure one of the

jumper wires contains a fuse. If the jumpers are accidentally touched together, the fuse will prevent sparking

and burns from sudden terminal heating.

Step

ActionValue(s)YesNo

11. Turn the ignition ON.

2. Attempt to operate both power windows.

Is either window working?–Go to

Step 18Go to

Step 2

2Visually inspect the connection at the dual

power window switch.

Is the electrical connector correctly attached

to the switch?–Go to

Step 4Go to

Step 3

3Correctly attach the electrical connector to

the dual power window switch.

Is the repair complete?–System

OK–

41. Disconnect the electrical connector from the

dual power window switch.

2. Turn the ignition ON.

3. Check the voltage at terminal 4 and 5 of the

power window main switch connector.

Is the voltage equal to the specified value?11–14 vGo to

Step 16Go to

Step 5

5Check fuses EF14 and EF9.

Is either fuse blown?–Go to

Step 6Go to

Step 7

61. Check for a short circuit and repair if neces-

sary.

2. Replace the blown fuse(s).

Is the repair complete?–System

OK–

71. Turn the ignition ON.

2. Check the voltages at fuses EF9 and EF14.

Are both voltages equal to the specified val-

ue?11–14 vGo to

Step 9Go to

Step 8

8Repair the power supply to the fuse which did

not indicate battery voltage with the ignition

on.

Is the repair complete?–System

OK–

91. Remove the power window relay.

2. Turn the ignition ON.

3. Check the voltage at terminal 30 and terminal

85 of the power window relay socket. (Termi-

nals of the relay socket can be identified by

the markings on the bottom of the relay.)

Does the voltmeter indicate the specified val-

ue at terminals 30 and 85?11–14 vGo to

Step 11Go to

Step 10

10Repair the open circuit between the fuses and

the power window relay.

Is the repair complete?–System

OK–

Page 2429 of 2643

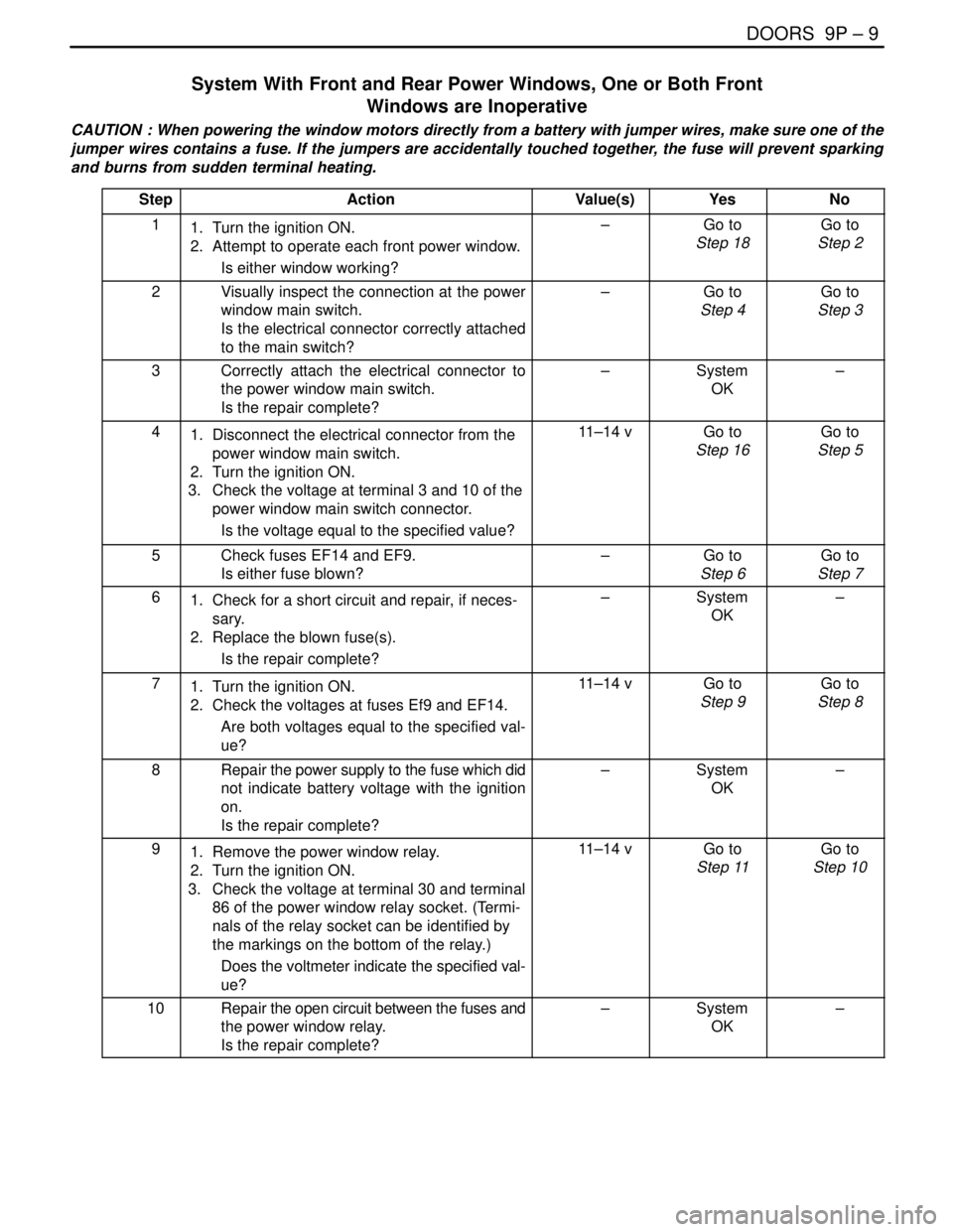

DOORS 9P – 9

DAEWOO V–121 BL4

System With Front and Rear Power Windows, One or Both Front

Windows are Inoperative

CAUTION : When powering the window motors directly from a battery with jumper wires, make sure one of the

jumper wires contains a fuse. If the jumpers are accidentally touched together, the fuse will prevent sparking

and burns from sudden terminal heating.

Step

ActionValue(s)YesNo

11. Turn the ignition ON.

2. Attempt to operate each front power window.

Is either window working?–Go to

Step 18Go to

Step 2

2Visually inspect the connection at the power

window main switch.

Is the electrical connector correctly attached

to the main switch?–Go to

Step 4Go to

Step 3

3Correctly attach the electrical connector to

the power window main switch.

Is the repair complete?–System

OK–

41. Disconnect the electrical connector from the

power window main switch.

2. Turn the ignition ON.

3. Check the voltage at terminal 3 and 10 of the

power window main switch connector.

Is the voltage equal to the specified value?11–14 vGo to

Step 16Go to

Step 5

5Check fuses EF14 and EF9.

Is either fuse blown?–Go to

Step 6Go to

Step 7

61. Check for a short circuit and repair, if neces-

sary.

2. Replace the blown fuse(s).

Is the repair complete?–System

OK–

71. Turn the ignition ON.

2. Check the voltages at fuses Ef9 and EF14.

Are both voltages equal to the specified val-

ue?11–14 vGo to

Step 9Go to

Step 8

8Repair the power supply to the fuse which did

not indicate battery voltage with the ignition

on.

Is the repair complete?–System

OK–

91. Remove the power window relay.

2. Turn the ignition ON.

3. Check the voltage at terminal 30 and terminal

86 of the power window relay socket. (Termi-

nals of the relay socket can be identified by

the markings on the bottom of the relay.)

Does the voltmeter indicate the specified val-

ue?11–14 vGo to

Step 11Go to

Step 10

10Repair the open circuit between the fuses and

the power window relay.

Is the repair complete?–System

OK–

Page 2432 of 2643

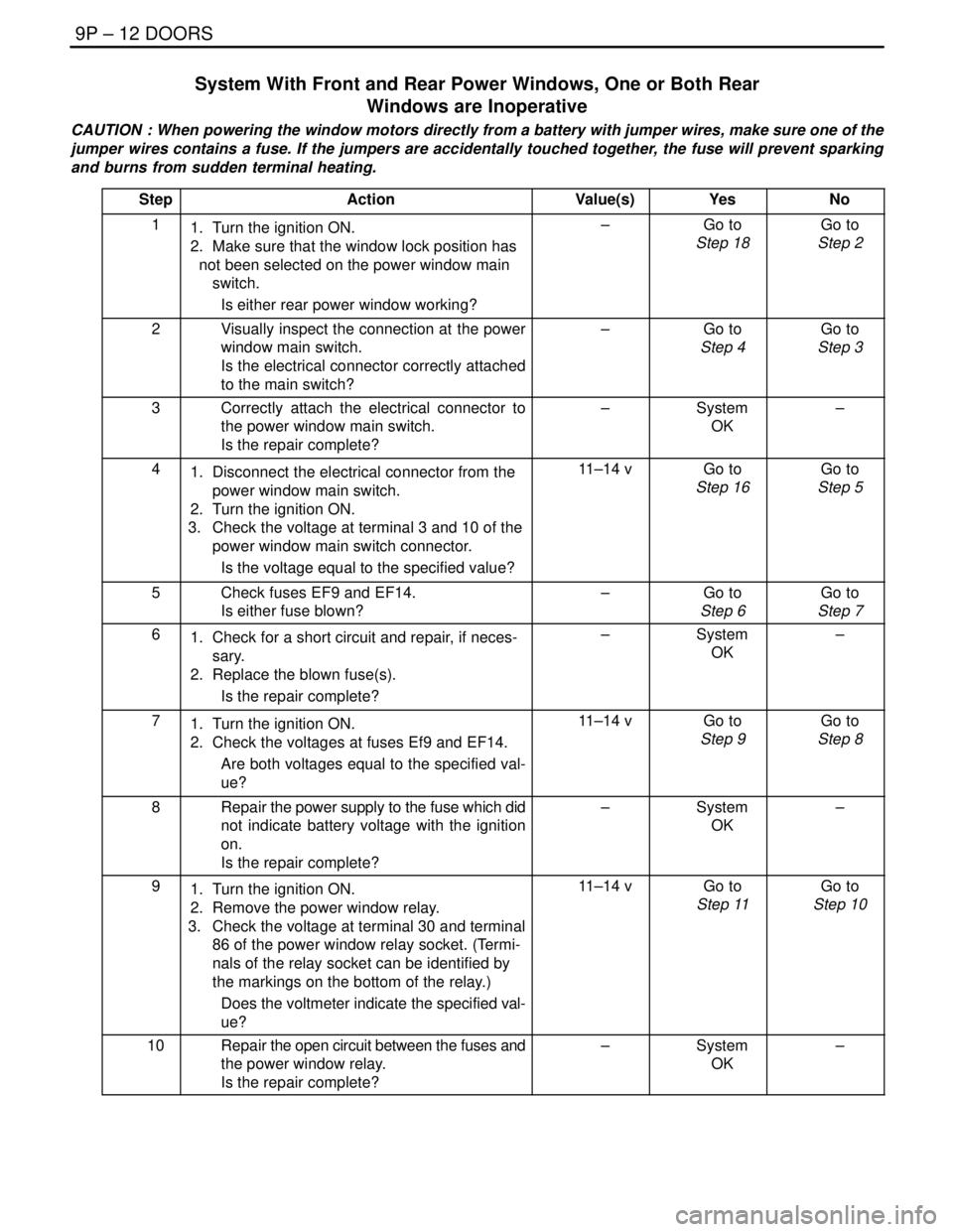

9P – 12IDOORS

DAEWOO V–121 BL4

System With Front and Rear Power Windows, One or Both Rear

Windows are Inoperative

CAUTION : When powering the window motors directly from a battery with jumper wires, make sure one of the

jumper wires contains a fuse. If the jumpers are accidentally touched together, the fuse will prevent sparking

and burns from sudden terminal heating.

Step

ActionValue(s)YesNo

11. Turn the ignition ON.

2. Make sure that the window lock position has

not been selected on the power window main

switch.

Is either rear power window working?–Go to

Step 18Go to

Step 2

2Visually inspect the connection at the power

window main switch.

Is the electrical connector correctly attached

to the main switch?–Go to

Step 4Go to

Step 3

3Correctly attach the electrical connector to

the power window main switch.

Is the repair complete?–System

OK–

41. Disconnect the electrical connector from the

power window main switch.

2. Turn the ignition ON.

3. Check the voltage at terminal 3 and 10 of the

power window main switch connector.

Is the voltage equal to the specified value?11–14 vGo to

Step 16Go to

Step 5

5Check fuses EF9 and EF14.

Is either fuse blown?–Go to

Step 6Go to

Step 7

61. Check for a short circuit and repair, if neces-

sary.

2. Replace the blown fuse(s).

Is the repair complete?–System

OK–

71. Turn the ignition ON.

2. Check the voltages at fuses Ef9 and EF14.

Are both voltages equal to the specified val-

ue?11–14 vGo to

Step 9Go to

Step 8

8Repair the power supply to the fuse which did

not indicate battery voltage with the ignition

on.

Is the repair complete?–System

OK–

91. Turn the ignition ON.

2. Remove the power window relay.

3. Check the voltage at terminal 30 and terminal

86 of the power window relay socket. (Termi-

nals of the relay socket can be identified by

the markings on the bottom of the relay.)

Does the voltmeter indicate the specified val-

ue?11–14 vGo to

Step 11Go to

Step 10

10Repair the open circuit between the fuses and

the power window relay.

Is the repair complete?–System

OK–

Page 2449 of 2643

DOORS 9P – 29

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DOOR LOCK STRIKER

The front and the rear door lock strikers each consist of a

striker with two screws threaded into a floating cage plate

in the B–pillars and the C–pillars. The door is secured in

the closed position when the door lock fork snaps over and

engages the striker.

CHILDPROOF REAR DOOR LOCK

The childproof rear door locks help prevent passengers,

especially children, from opening the rear doors of the ve-

hicle from the inside.

To activate the locks, move the levers of both rear doors

to the lock position. Then, close both doors. The rear pas-

sengers will be unable to open the doors from inside of the

vehicle.

To deactivate the locks, unlock the door from the inside of

the vehicle and open the door from the outside. Move the

lever to the unlock position. The rear door will now work

normally.

POWER DOOR LOCKS

The power door locks use a solenoid that is contained in

each door lock assembly. The door locks are activated by

the actuator on the inside door handle or by the lock cylin-

der on the driver’s side door only. When the driver’s side

door is locked or unlocked by the actuator or the lock cylin-

der, all doors are locked or unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical switches

on the door panels and are operated by a motor at each

window regulator. Each door has a switch to control its

window, and the driver’s side door has four switches to

control all door windows on the vehicle. The windows are

lowered by pressing the switch and raised by pulling up on

the switch. The window will stop movement when the

switch is released or when the window is completely open

or closed.

The driver’s side window opens automatically. By pressing

and releasing the switch, the driver ’s side window will low-

er and will stop only when the switch is activated again, or

when the window is completely open.

The driver’s side door control also contains a window lock

button that will prevent the operation of the front passen-

ger door or the rear door windows when pressed.

Page 2501 of 2643

IMMOBILIZER ANTI–THEFT SYSTEM 9T2 – 11

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IMMOBILIZER SYSTEM

The purpose of the Immobilizer system is to provide addi-

tional theft deterrence to the vehicle in which it is installed

and to prevent it from being stolen or driven by unautho-

rized users.

The verification of the user authorization is done by an igni-

tion key with integrated transponder.

The external LED displays the Immobilizer status and has

an additional theft deterrence function.

To secure the communication, the status is exchanged be-

tween the Immobilizer and the ECM in a 5 byte of encoded

data.

These 5 bytes are composed by a mixture of random data

and two types of fixed code

S a vehicle model identification number : MIN

S a vehicle specific identification : VIN

The MIN is known from the first supply of the system.

The VIN is realized by ICU on the special order from the

key coding (reading of transponder code and storing it as

valid key code in Immobilizer EEPROM).

A different random data is computed at each key transi-

tion.

All the immobilization communication between the ECM

and ICU is made on K–line (K line : Serial data line ’7’).

Due to the learning of the Vehicle specific identification

Number, both ICU and ECM can stay in 3 stable modes

S Virgin mode (VIN not learnt)

S Learnt mode (VIN learnt)

S Neutral mode (for a new VIN learning)

In case of using valid key, the release message commu-

nication with the ECM take place and the LED displays the

Immobilizer status valid key In case of using invalid key,

the ECM disables the fuel injector circuit with coded inter-

vention and sets DTC(Diagnostic Trouble Code)

The above conditions are maintained until the ignition is

switched off.

An ECM without an immobilizer control unit cannot be in-

terchanged for an ECM that is used with an immobilizer

control unit system. The Immobilizer control unit and ECM

must have a matching ID code. ID coding and key coding

are accomplished by using Scanner–100

The Immobilizer system consists of

S a maximum or 5 ignition keys with integrated trans-

ponder

S the toroidal coil (Detection coil) for energizing and

reading the transponder mounted at the ignition

lock.S the Immobilizer control unit(ICU) with :

– power supply

– ignition input circuit

– transponder modulation and demodulation unit

– EEPROM

– driver electronic for the external status LED

– serial data link hardware

S the external status LED for displaying the Immobi-

lizer status

S the serial data link between Immobilizer and ECM

ELECTRONICALLY CODED KEYS

Each valid ignition key has an internal transponder which

is a read /write transponder.

The transponder contains an implementation of a crypto–

algorithm with 96 bits of user configurable s cret–key con-

tained in EEPROM and transmits data to the ICU by mod-

ulating the amplitude of the ele tromagnetic field, and

receives data and commands in a similar way.

DETECTION COIL

The toroidal coil is mounted at the ignition lock in front of

the key barrel.

It is connected to the ICU with a four terminal connector

fixed at the body of the coil.

The length of the connection between coil and Immobilizer

is restricted to 50cm. The correct placement on the ignition

lock and the exact electrical data is very important for the

reading distance of transponder.

he toroidal coil and receiving coil inside the transponder

built a transformer. During the readingprocess the coil in-

duces energy into the transponder. The transponder

charges the field and generates an amplitude modulated

signal with the manchester coded data. This charge of the

field is demodulated inside the Immobilizer.

The Immobilizer contains the coil driver hardware for di-

rect connection of the toroidal coil.

IMMOBILIZER CONTROL UNIT

The function of the Immobilizer System is shared between

the ICU and the ECM.

The task of the Immobilizer Electronic Control unit (ICU)

are:

S Reading of the input information ”ignition ON/OFF”

S Controlling the states LED

S Controlling the transponder read/write process

(modulation, demodulation, decoding, comparison

of the read code with the code of the valid keys).

S Communication with the ECM after ignition ON (re-

ceiving of the ECM–request and transmission of

release message).

S Special functions for calculation and handling of the

VIN–code.

The VIN code is calculated by the Immobilizer using a ran-

dom generator.