lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 753 of 2643

ENGINE CONTROLS 1F – 507

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0532

A/C PRESSURE SENSOR LOW VOLTAGE

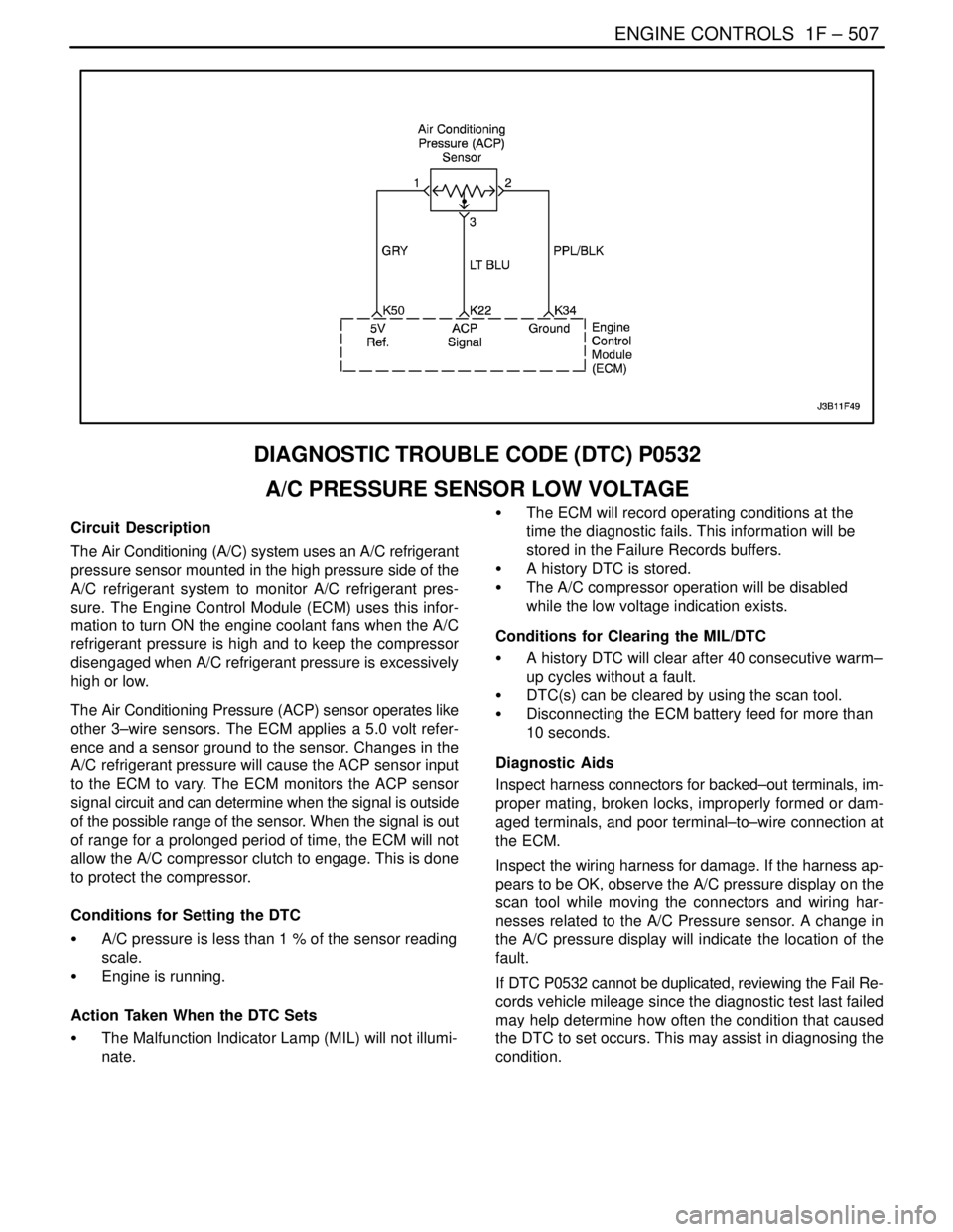

Circuit Description

The Air Conditioning (A/C) system uses an A/C refrigerant

pressure sensor mounted in the high pressure side of the

A/C refrigerant system to monitor A/C refrigerant pres-

sure. The Engine Control Module (ECM) uses this infor-

mation to turn ON the engine coolant fans when the A/C

refrigerant pressure is high and to keep the compressor

disengaged when A/C refrigerant pressure is excessively

high or low.

The Air Conditioning Pressure (ACP) sensor operates like

other 3–wire sensors. The ECM applies a 5.0 volt refer-

ence and a sensor ground to the sensor. Changes in the

A/C refrigerant pressure will cause the ACP sensor input

to the ECM to vary. The ECM monitors the ACP sensor

signal circuit and can determine when the signal is outside

of the possible range of the sensor. When the signal is out

of range for a prolonged period of time, the ECM will not

allow the A/C compressor clutch to engage. This is done

to protect the compressor.

Conditions for Setting the DTC

S A/C pressure is less than 1 % of the sensor reading

scale.

S Engine is running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

S The A/C compressor operation will be disabled

while the low voltage indication exists.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect harness connectors for backed–out terminals, im-

proper mating, broken locks, improperly formed or dam-

aged terminals, and poor terminal–to–wire connection at

the ECM.

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the A/C pressure display on the

scan tool while moving the connectors and wiring har-

nesses related to the A/C Pressure sensor. A change in

the A/C pressure display will indicate the location of the

fault.

If DTC P0532 cannot be duplicated, reviewing the Fail Re-

cords vehicle mileage since the diagnostic test last failed

may help determine how often the condition that caused

the DTC to set occurs. This may assist in diagnosing the

condition.

Page 756 of 2643

1F – 510IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0533

A/C PRESSURE SENSOR HIGH VOLTAGE

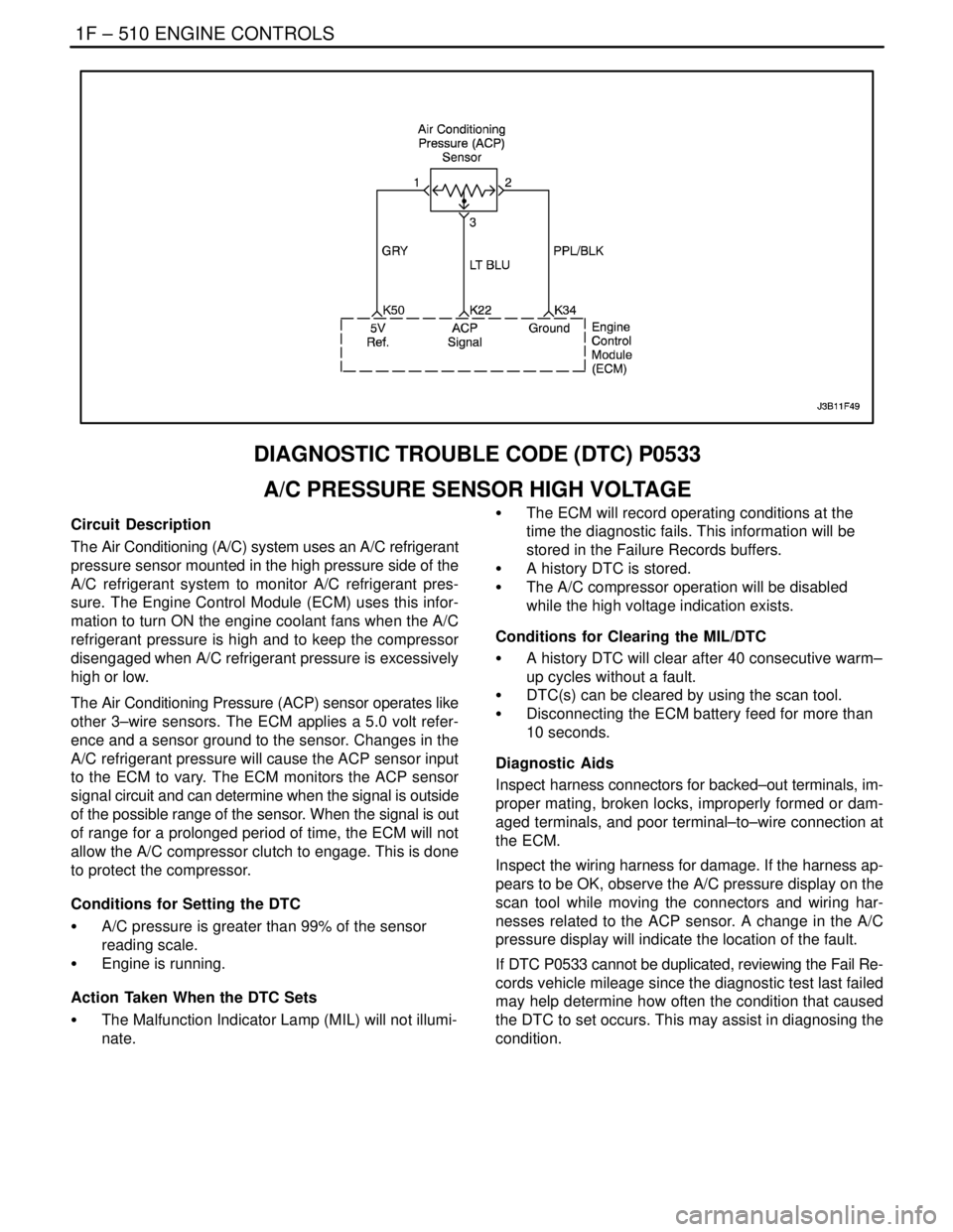

Circuit Description

The Air Conditioning (A/C) system uses an A/C refrigerant

pressure sensor mounted in the high pressure side of the

A/C refrigerant system to monitor A/C refrigerant pres-

sure. The Engine Control Module (ECM) uses this infor-

mation to turn ON the engine coolant fans when the A/C

refrigerant pressure is high and to keep the compressor

disengaged when A/C refrigerant pressure is excessively

high or low.

The Air Conditioning Pressure (ACP) sensor operates like

other 3–wire sensors. The ECM applies a 5.0 volt refer-

ence and a sensor ground to the sensor. Changes in the

A/C refrigerant pressure will cause the ACP sensor input

to the ECM to vary. The ECM monitors the ACP sensor

signal circuit and can determine when the signal is outside

of the possible range of the sensor. When the signal is out

of range for a prolonged period of time, the ECM will not

allow the A/C compressor clutch to engage. This is done

to protect the compressor.

Conditions for Setting the DTC

S A/C pressure is greater than 99% of the sensor

reading scale.

S Engine is running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

S The A/C compressor operation will be disabled

while the high voltage indication exists.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect harness connectors for backed–out terminals, im-

proper mating, broken locks, improperly formed or dam-

aged terminals, and poor terminal–to–wire connection at

the ECM.

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the A/C pressure display on the

scan tool while moving the connectors and wiring har-

nesses related to the ACP sensor. A change in the A/C

pressure display will indicate the location of the fault.

If DTC P0533 cannot be duplicated, reviewing the Fail Re-

cords vehicle mileage since the diagnostic test last failed

may help determine how often the condition that caused

the DTC to set occurs. This may assist in diagnosing the

condition.

Page 759 of 2643

ENGINE CONTROLS 1F – 513

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0562

SYSTEM VOLTAGE TOO LOW (ENGINE SIDE)

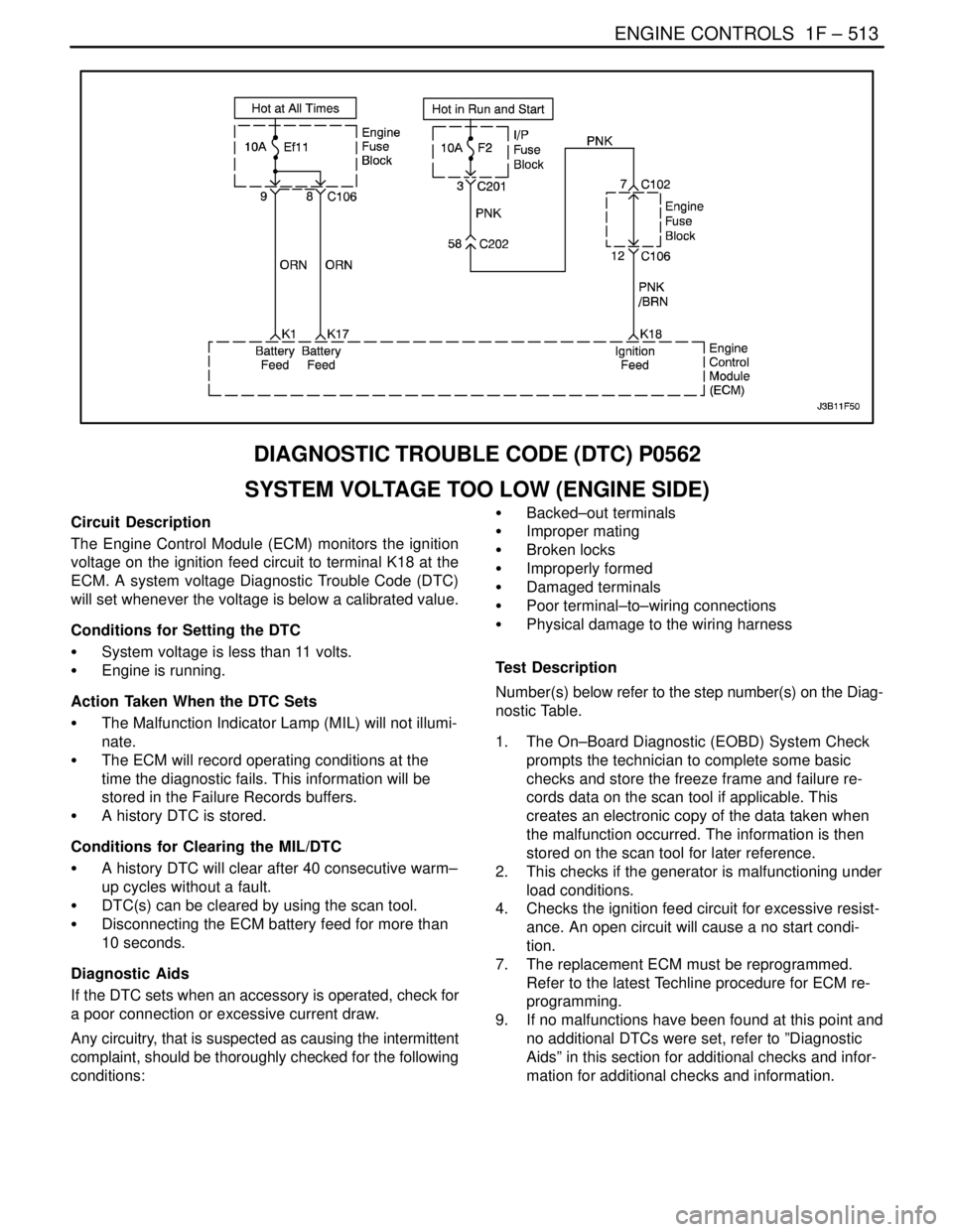

Circuit Description

The Engine Control Module (ECM) monitors the ignition

voltage on the ignition feed circuit to terminal K18 at the

ECM. A system voltage Diagnostic Trouble Code (DTC)

will set whenever the voltage is below a calibrated value.

Conditions for Setting the DTC

S System voltage is less than 11 volts.

S Engine is running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

Any circuitry, that is suspected as causing the intermittent

complaint, should be thoroughly checked for the following

conditions:S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wiring connections

S Physical damage to the wiring harness

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This checks if the generator is malfunctioning under

load conditions.

4. Checks the ignition feed circuit for excessive resist-

ance. An open circuit will cause a no start condi-

tion.

7. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

9. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation for additional checks and information.

Page 761 of 2643

ENGINE CONTROLS 1F – 515

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0563

SYSTEM VOLTAGE TOO HIGH (ENGINE SIDE)

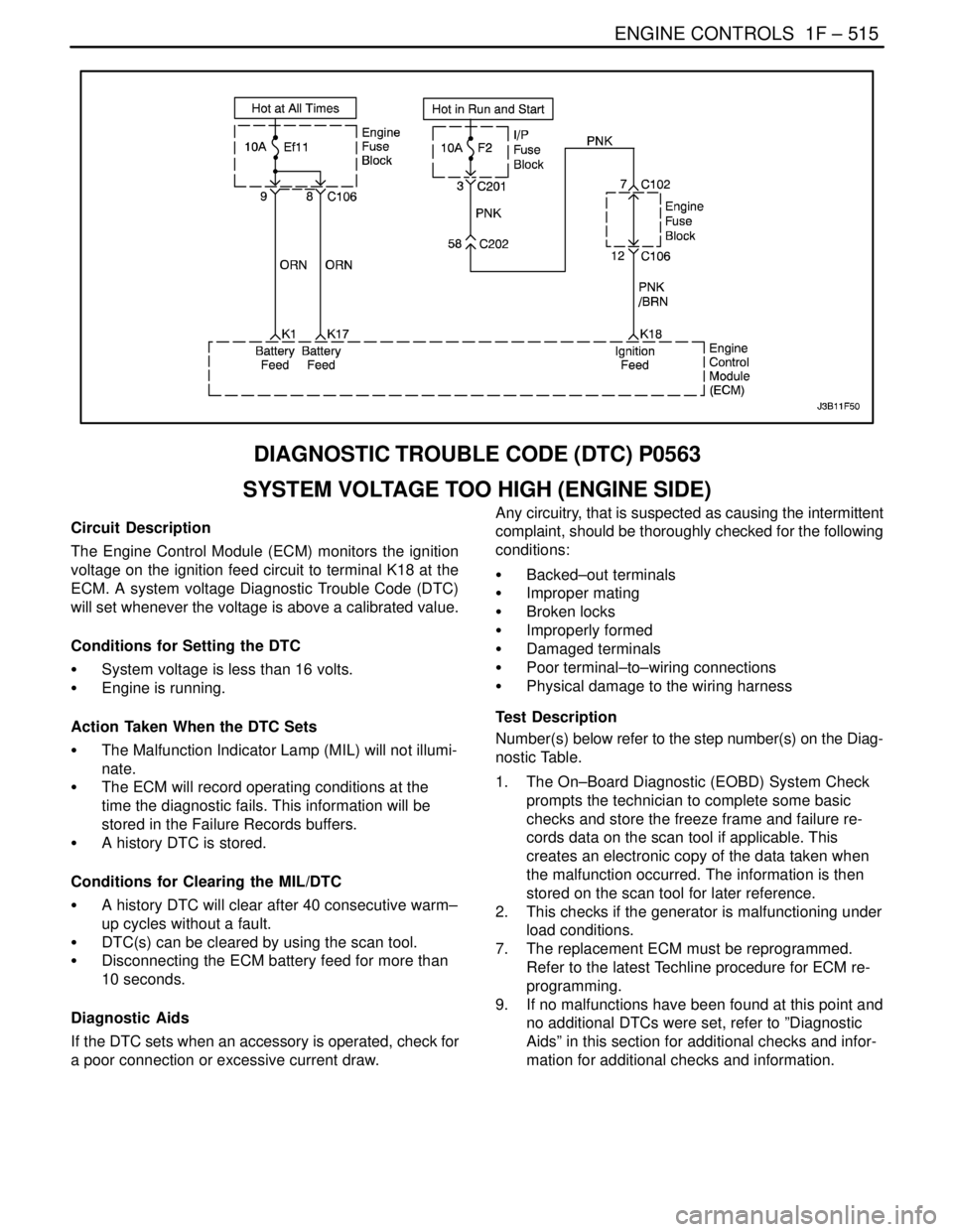

Circuit Description

The Engine Control Module (ECM) monitors the ignition

voltage on the ignition feed circuit to terminal K18 at the

ECM. A system voltage Diagnostic Trouble Code (DTC)

will set whenever the voltage is above a calibrated value.

Conditions for Setting the DTC

S System voltage is less than 16 volts.

S Engine is running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.Any circuitry, that is suspected as causing the intermittent

complaint, should be thoroughly checked for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wiring connections

S Physical damage to the wiring harness

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This checks if the generator is malfunctioning under

load conditions.

7. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

9. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation for additional checks and information.

Page 766 of 2643

1F – 520IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0700

TRANSAXLE CONTROL MODULE MALFUNCTION

Circuit Description

The Transmission Control Module (TCM) and the Engine

Control Module (ECM) are connected through the serial

data link circuit. The TCM sends a Class–II P–code status

message to the ECM every 100 milliseconds to confirm

the transmission is functioning correctly.

If the TCM detects either an A– or B–type malfunction

within the transmission, the TCM will send to the ECM a

P–code status message to turn the Malfunction Indicator

Lamp (MIL) ON and set DTC P0700.

Conditions for Setting the DTC

S Received message from the TCM indicating mal-

function is detected in TCM.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and/or Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation.

Check for a poor connection or damaged ECM/TCM har-

ness. Inspect the serial data link circuit for the following

conditions:

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wiring connections

S Damaged harness

DTC P0700 – Transaxle Control Module Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

3. Select Transmission Control Module (TCM)

Diagnostic Trouble Code (DTC) with scan tool.

Is a transmission DTC displayed?–Go to Step 3Go to Step 4

31. Repair transmission malfunction. Refer to the

applicable DTC table in the transmission repair

section.

2. Using a scan tool, clear the TCM DTC.

Is the repair complete?–Go to Step 4–

Page 768 of 2643

1F – 522IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1106

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT HIGH

VOLTAGE

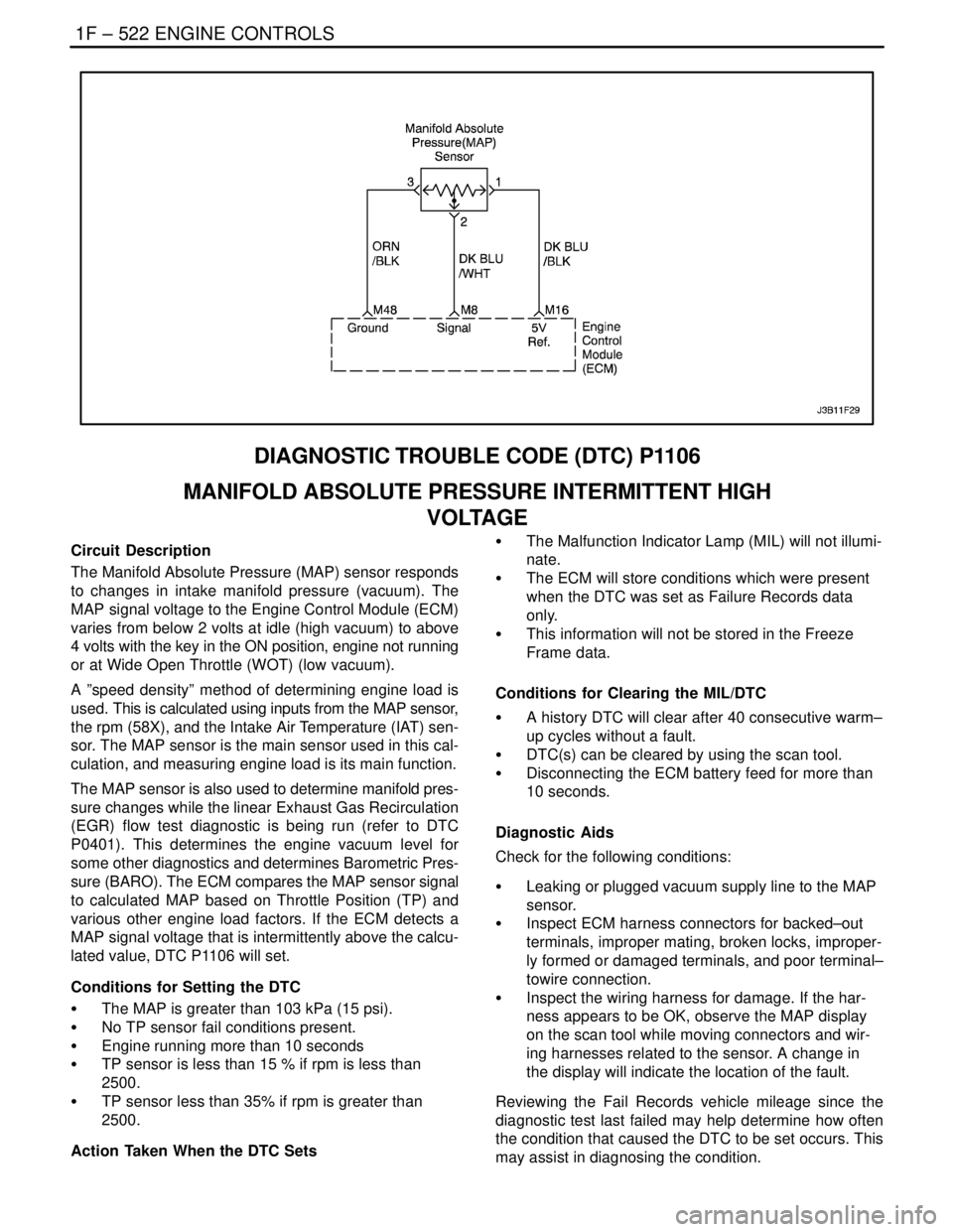

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently above the calcu-

lated value, DTC P1106 will set.

Conditions for Setting the DTC

S The MAP is greater than 103 kPa (15 psi).

S No TP sensor fail conditions present.

S Engine running more than 10 seconds

S TP sensor is less than 15 % if rpm is less than

2500.

S TP sensor less than 35% if rpm is greater than

2500.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

towire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 770 of 2643

1F – 524IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1107

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT LOW

VOLTAGE

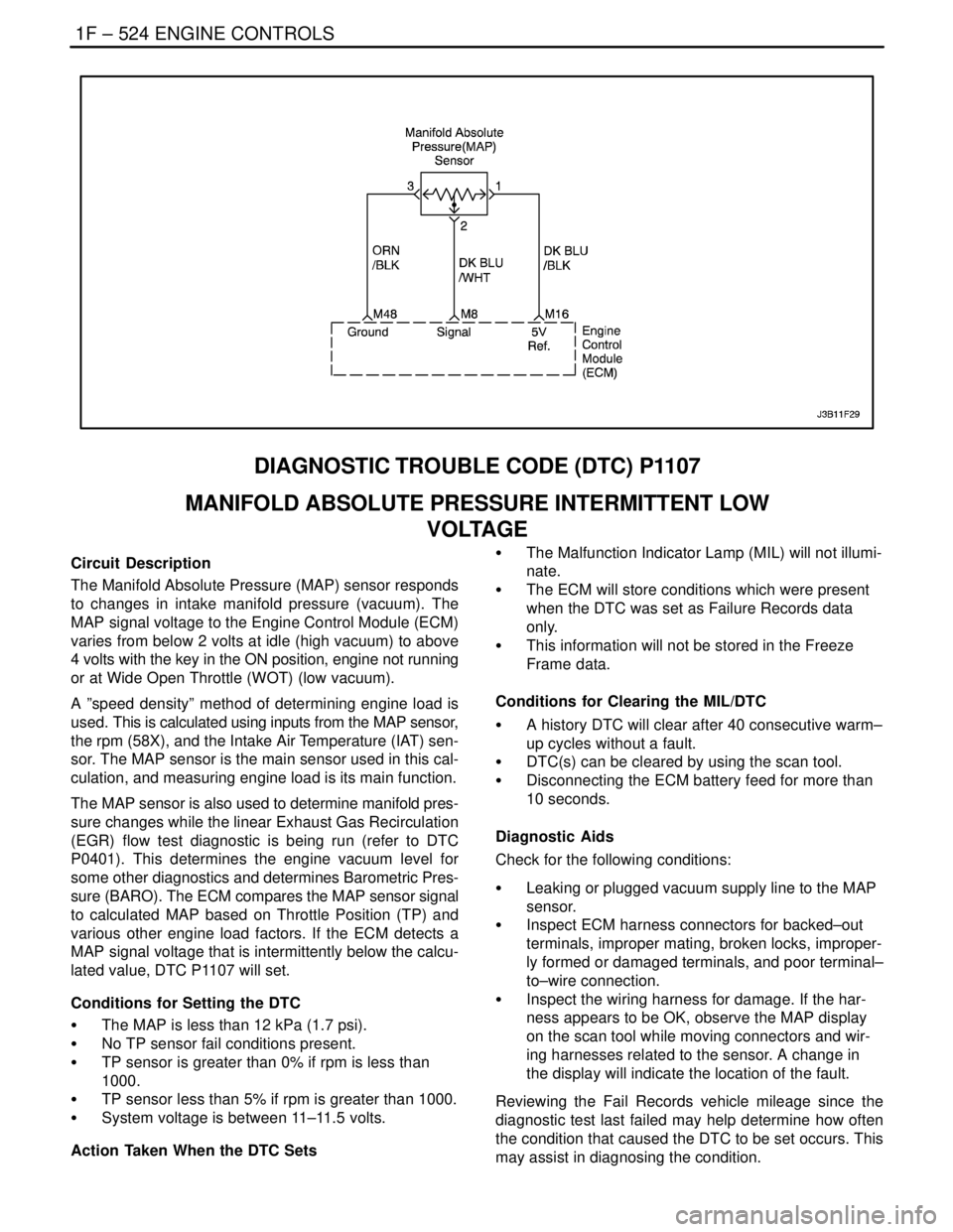

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently below the calcu-

lated value, DTC P1107 will set.

Conditions for Setting the DTC

S The MAP is less than 12 kPa (1.7 psi).

S No TP sensor fail conditions present.

S TP sensor is greater than 0% if rpm is less than

1000.

S TP sensor less than 5% if rpm is greater than 1000.

S System voltage is between 11–11.5 volts.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

to–wire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 772 of 2643

1F – 526IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1111

INTAKE AIR TEMPERATURE INTERMITTENT HIGH

VOLTAGE

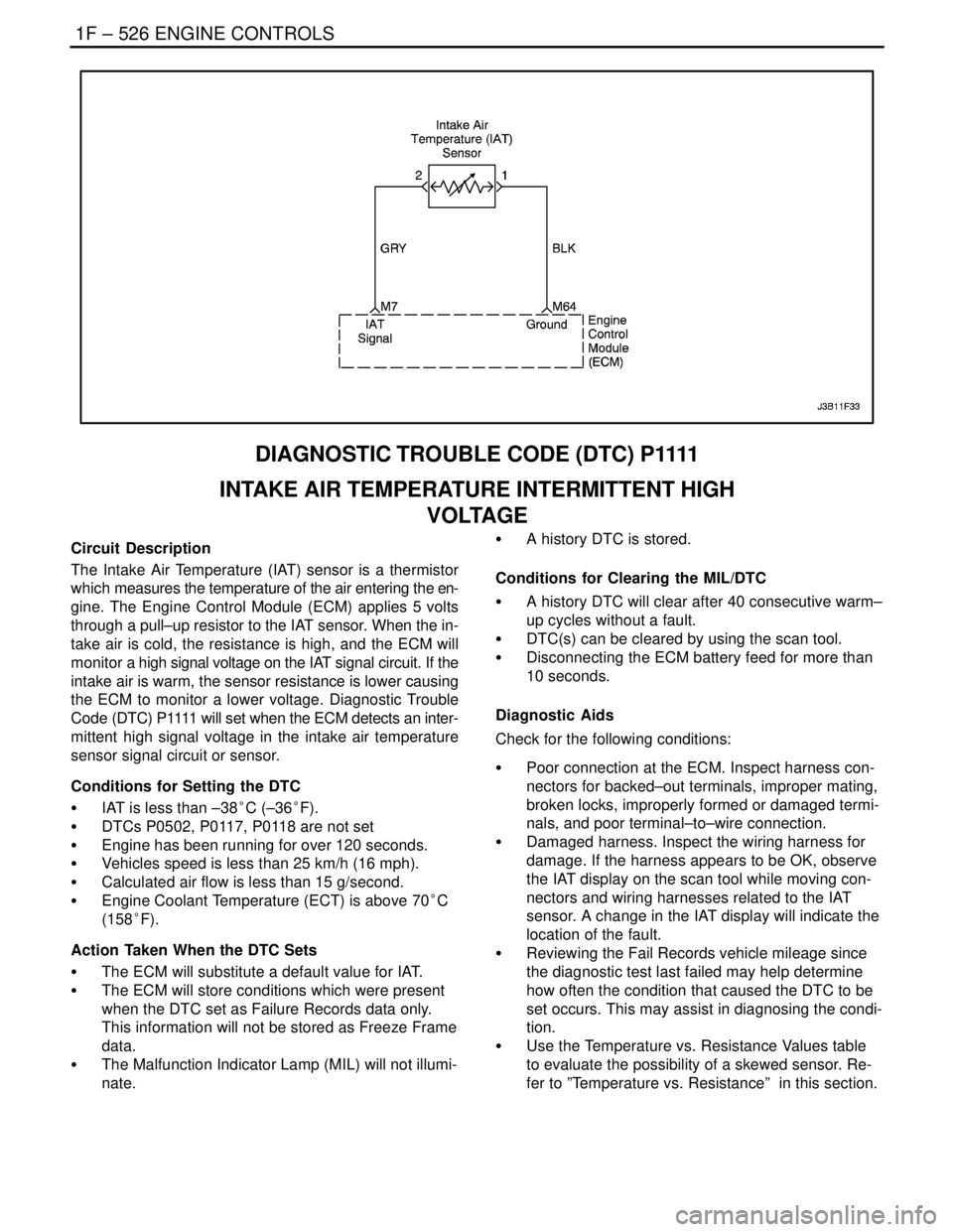

Circuit Description

The Intake Air Temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the en-

gine. The Engine Control Module (ECM) applies 5 volts

through a pull–up resistor to the IAT sensor. When the in-

take air is cold, the resistance is high, and the ECM will

monitor a high signal voltage on the IAT signal circuit. If the

intake air is warm, the sensor resistance is lower causing

the ECM to monitor a lower voltage. Diagnostic Trouble

Code (DTC) P1111 will set when the ECM detects an inter-

mittent high signal voltage in the intake air temperature

sensor signal circuit or sensor.

Conditions for Setting the DTC

S IAT is less than –38°C (–36°F).

S DTCs P0502, P0117, P0118 are not set

S Engine has been running for over 120 seconds.

S Vehicles speed is less than 25 km/h (16 mph).

S Calculated air flow is less than 15 g/second.

S Engine Coolant Temperature (ECT) is above 70°C

(158°F).

Action Taken When the DTC Sets

S The ECM will substitute a default value for IAT.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored as Freeze Frame

data.

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Poor connection at the ECM. Inspect harness con-

nectors for backed–out terminals, improper mating,

broken locks, improperly formed or damaged termi-

nals, and poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the IAT display on the scan tool while moving con-

nectors and wiring harnesses related to the IAT

sensor. A change in the IAT display will indicate the

location of the fault.

S Reviewing the Fail Records vehicle mileage since

the diagnostic test last failed may help determine

how often the condition that caused the DTC to be

set occurs. This may assist in diagnosing the condi-

tion.

S Use the Temperature vs. Resistance Values table

to evaluate the possibility of a skewed sensor. Re-

fer to ”Temperature vs. Resistance” in this section.

Page 775 of 2643

ENGINE CONTROLS 1F – 529

DAEWOO V–121 BL4

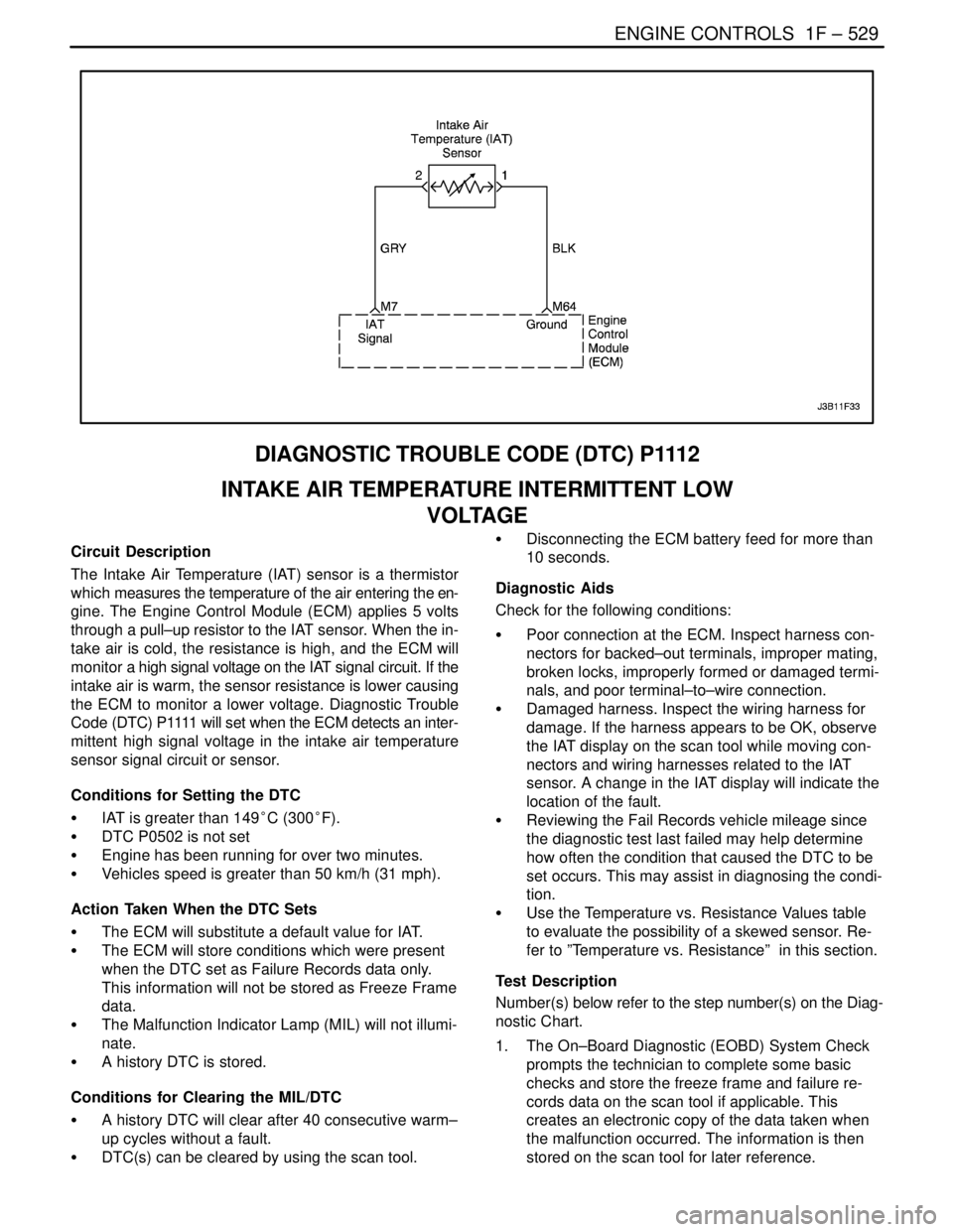

DIAGNOSTIC TROUBLE CODE (DTC) P1112

INTAKE AIR TEMPERATURE INTERMITTENT LOW

VOLTAGE

Circuit Description

The Intake Air Temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the en-

gine. The Engine Control Module (ECM) applies 5 volts

through a pull–up resistor to the IAT sensor. When the in-

take air is cold, the resistance is high, and the ECM will

monitor a high signal voltage on the IAT signal circuit. If the

intake air is warm, the sensor resistance is lower causing

the ECM to monitor a lower voltage. Diagnostic Trouble

Code (DTC) P1111 will set when the ECM detects an inter-

mittent high signal voltage in the intake air temperature

sensor signal circuit or sensor.

Conditions for Setting the DTC

S IAT is greater than 149°C (300°F).

S DTC P0502 is not set

S Engine has been running for over two minutes.

S Vehicles speed is greater than 50 km/h (31 mph).

Action Taken When the DTC Sets

S The ECM will substitute a default value for IAT.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored as Freeze Frame

data.

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Poor connection at the ECM. Inspect harness con-

nectors for backed–out terminals, improper mating,

broken locks, improperly formed or damaged termi-

nals, and poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the IAT display on the scan tool while moving con-

nectors and wiring harnesses related to the IAT

sensor. A change in the IAT display will indicate the

location of the fault.

S Reviewing the Fail Records vehicle mileage since

the diagnostic test last failed may help determine

how often the condition that caused the DTC to be

set occurs. This may assist in diagnosing the condi-

tion.

S Use the Temperature vs. Resistance Values table

to evaluate the possibility of a skewed sensor. Re-

fer to ”Temperature vs. Resistance” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Chart.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

Page 777 of 2643

ENGINE CONTROLS 1F – 531

DAEWOO V–121 BL4

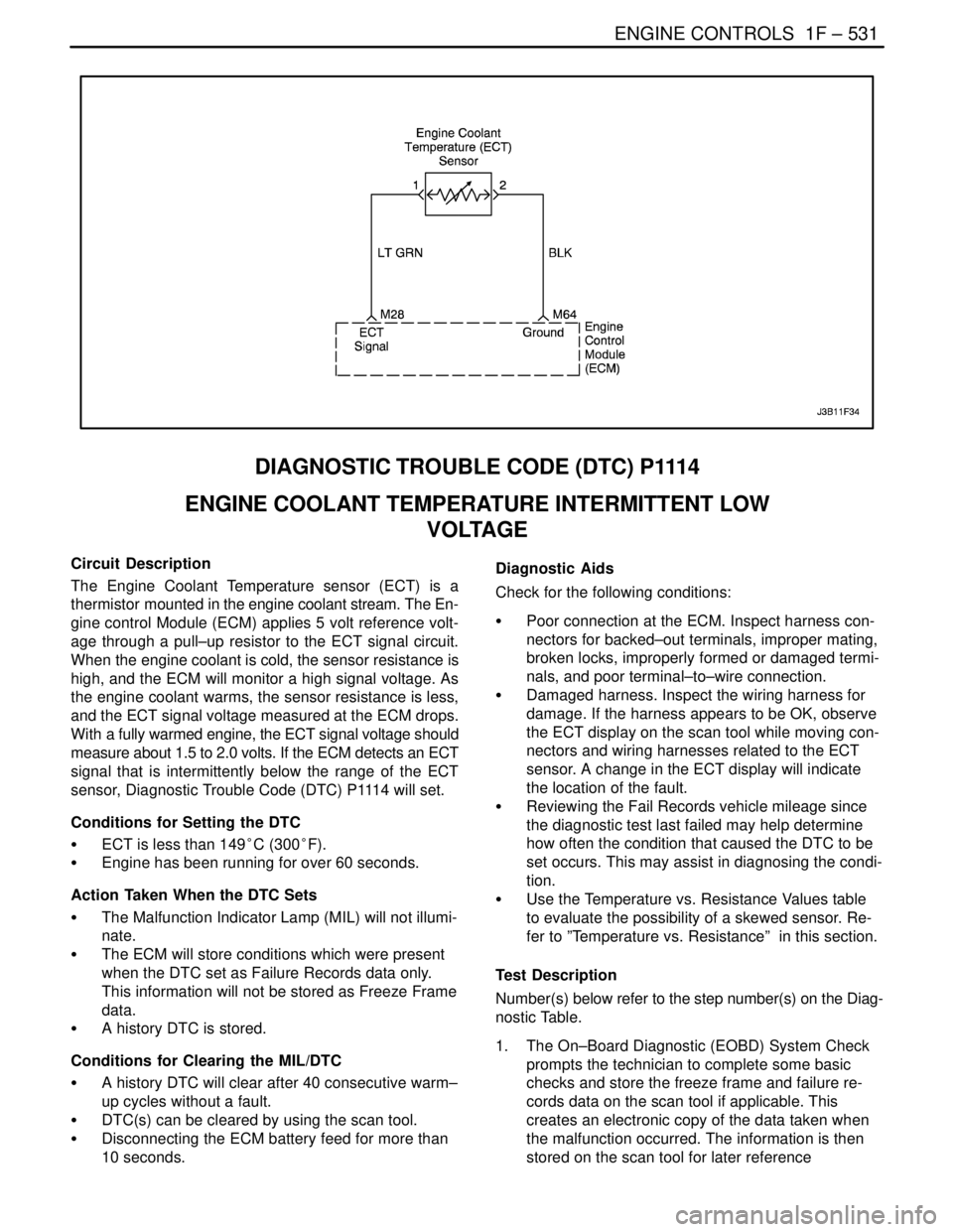

DIAGNOSTIC TROUBLE CODE (DTC) P1114

ENGINE COOLANT TEMPERATURE INTERMITTENT LOW

VOLTAGE

Circuit Description

The Engine Coolant Temperature sensor (ECT) is a

thermistor mounted in the engine coolant stream. The En-

gine control Module (ECM) applies 5 volt reference volt-

age through a pull–up resistor to the ECT signal circuit.

When the engine coolant is cold, the sensor resistance is

high, and the ECM will monitor a high signal voltage. As

the engine coolant warms, the sensor resistance is less,

and the ECT signal voltage measured at the ECM drops.

With a fully warmed engine, the ECT signal voltage should

measure about 1.5 to 2.0 volts. If the ECM detects an ECT

signal that is intermittently below the range of the ECT

sensor, Diagnostic Trouble Code (DTC) P1114 will set.

Conditions for Setting the DTC

S ECT is less than 149°C (300°F).

S Engine has been running for over 60 seconds.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored as Freeze Frame

data.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.Diagnostic Aids

Check for the following conditions:

S Poor connection at the ECM. Inspect harness con-

nectors for backed–out terminals, improper mating,

broken locks, improperly formed or damaged termi-

nals, and poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the ECT display on the scan tool while moving con-

nectors and wiring harnesses related to the ECT

sensor. A change in the ECT display will indicate

the location of the fault.

S Reviewing the Fail Records vehicle mileage since

the diagnostic test last failed may help determine

how often the condition that caused the DTC to be

set occurs. This may assist in diagnosing the condi-

tion.

S Use the Temperature vs. Resistance Values table

to evaluate the possibility of a skewed sensor. Re-

fer to ”Temperature vs. Resistance” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference