tank DAEWOO LACETTI 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 311 of 2643

ENGINE CONTROLS 1F – 65

DAEWOO V–121 BL4

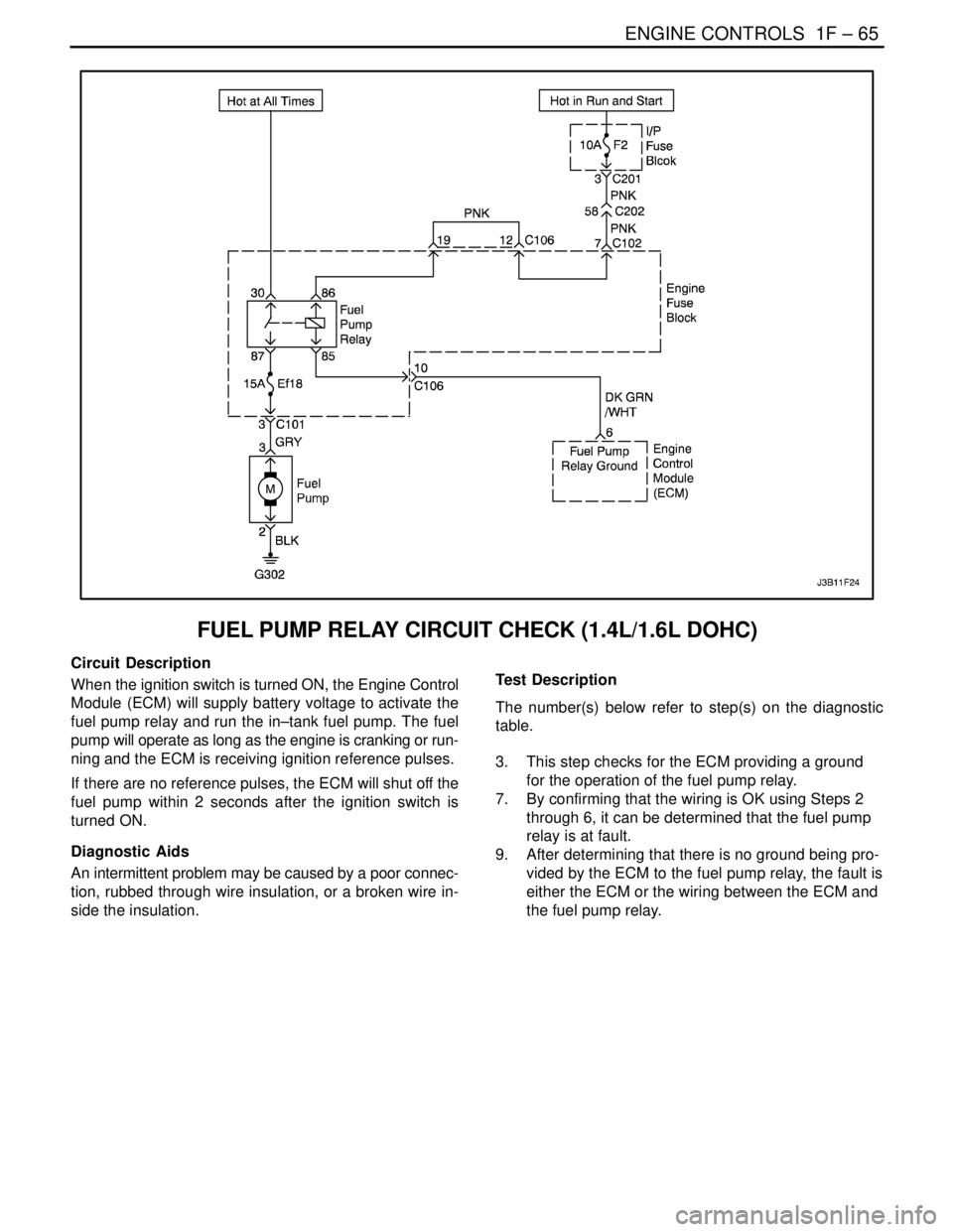

FUEL PUMP RELAY CIRCUIT CHECK (1.4L/1.6L DOHC)

Circuit Description

When the ignition switch is turned ON, the Engine Control

Module (ECM) will supply battery voltage to activate the

fuel pump relay and run the in–tank fuel pump. The fuel

pump will operate as long as the engine is cranking or run-

ning and the ECM is receiving ignition reference pulses.

If there are no reference pulses, the ECM will shut off the

fuel pump within 2 seconds after the ignition switch is

turned ON.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or a broken wire in-

side the insulation.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

3. This step checks for the ECM providing a ground

for the operation of the fuel pump relay.

7. By confirming that the wiring is OK using Steps 2

through 6, it can be determined that the fuel pump

relay is at fault.

9. After determining that there is no ground being pro-

vided by the ECM to the fuel pump relay, the fault is

either the ECM or the wiring between the ECM and

the fuel pump relay.

Page 312 of 2643

1F – 66IENGINE CONTROLS

DAEWOO V–121 BL4

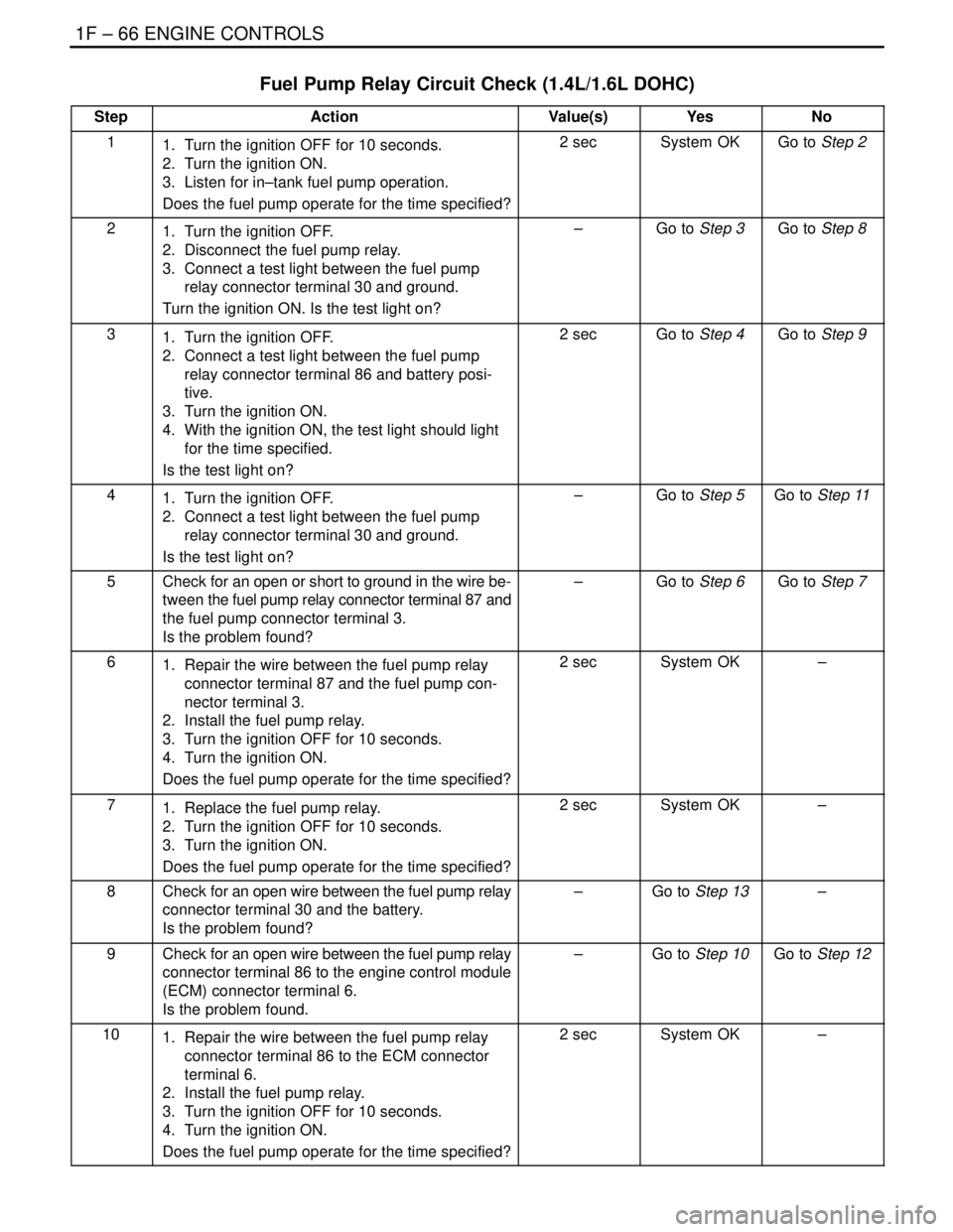

Fuel Pump Relay Circuit Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF for 10 seconds.

2. Turn the ignition ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate for the time specified?2 secSystem OKGo to Step 2

21. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Turn the ignition ON. Is the test light on?–Go to Step 3Go to Step 8

31. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 86 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 5Go to Step 11

5Check for an open or short to ground in the wire be-

tween the fuel pump relay connector terminal 87 and

the fuel pump connector terminal 3.

Is the problem found?–Go to Step 6Go to Step 7

61. Repair the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

71. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

8Check for an open wire between the fuel pump relay

connector terminal 30 and the battery.

Is the problem found?–Go to Step 13–

9Check for an open wire between the fuel pump relay

connector terminal 86 to the engine control module

(ECM) connector terminal 6.

Is the problem found.–Go to Step 10Go to Step 12

101. Repair the wire between the fuel pump relay

connector terminal 86 to the ECM connector

terminal 6.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 314 of 2643

1F – 68IENGINE CONTROLS

DAEWOO V–121 BL4

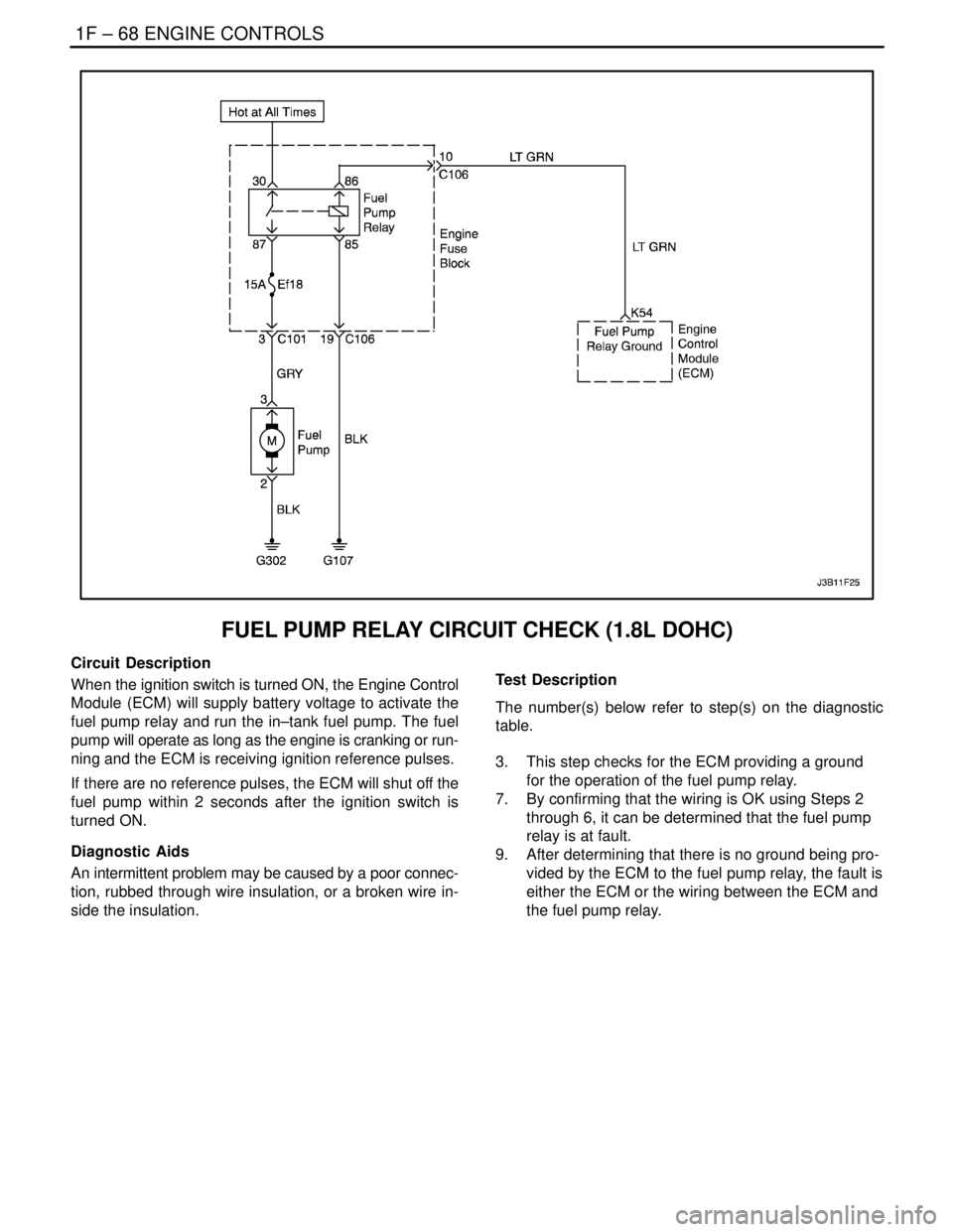

FUEL PUMP RELAY CIRCUIT CHECK (1.8L DOHC)

Circuit Description

When the ignition switch is turned ON, the Engine Control

Module (ECM) will supply battery voltage to activate the

fuel pump relay and run the in–tank fuel pump. The fuel

pump will operate as long as the engine is cranking or run-

ning and the ECM is receiving ignition reference pulses.

If there are no reference pulses, the ECM will shut off the

fuel pump within 2 seconds after the ignition switch is

turned ON.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or a broken wire in-

side the insulation.Test Description

The number(s) below refer to step(s) on the diagnostic

table.

3. This step checks for the ECM providing a ground

for the operation of the fuel pump relay.

7. By confirming that the wiring is OK using Steps 2

through 6, it can be determined that the fuel pump

relay is at fault.

9. After determining that there is no ground being pro-

vided by the ECM to the fuel pump relay, the fault is

either the ECM or the wiring between the ECM and

the fuel pump relay.

Page 315 of 2643

ENGINE CONTROLS 1F – 69

DAEWOO V–121 BL4

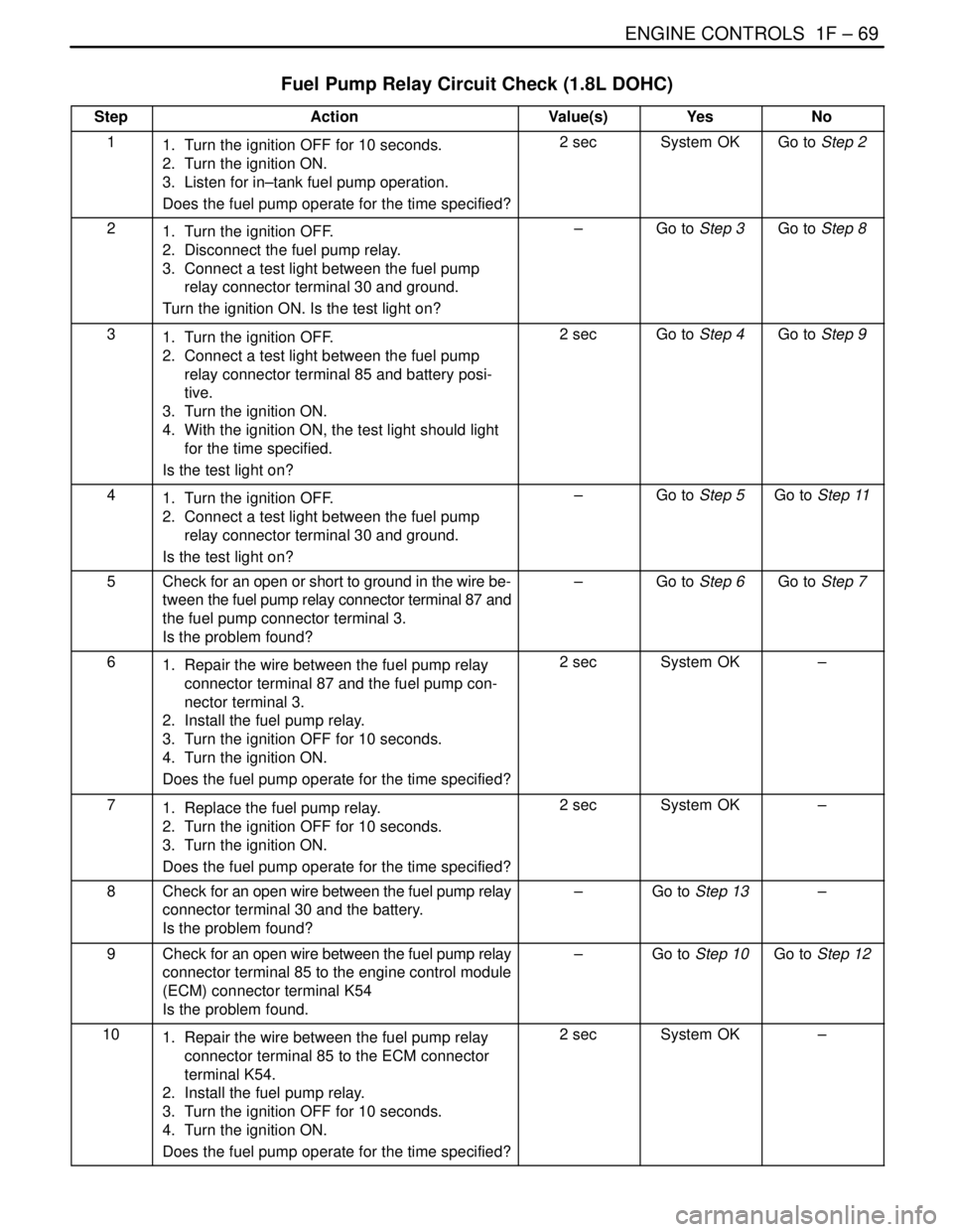

Fuel Pump Relay Circuit Check (1.8L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF for 10 seconds.

2. Turn the ignition ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate for the time specified?2 secSystem OKGo to Step 2

21. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Turn the ignition ON. Is the test light on?–Go to Step 3Go to Step 8

31. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 85 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 5Go to Step 11

5Check for an open or short to ground in the wire be-

tween the fuel pump relay connector terminal 87 and

the fuel pump connector terminal 3.

Is the problem found?–Go to Step 6Go to Step 7

61. Repair the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

71. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

8Check for an open wire between the fuel pump relay

connector terminal 30 and the battery.

Is the problem found?–Go to Step 13–

9Check for an open wire between the fuel pump relay

connector terminal 85 to the engine control module

(ECM) connector terminal K54

Is the problem found.–Go to Step 10Go to Step 12

101. Repair the wire between the fuel pump relay

connector terminal 85 to the ECM connector

terminal K54.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 404 of 2643

1F – 158IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0171

FUEL TRIM SYSTEM TOO LEAN

System Description

If the adaptation value threshold is permanently exceed-

ed, the deviation of the adaptive terms enables to detect

a slow default coming out. Two time counters (one for the

rich side and another one for the lean side) are increased

while the lambda controller exceeds the adaptation

thresholds. As soon as one of the time counters reaches

its maximum value, the error is detected.

The aim of this test is to simulate a failure that would result

in exceeding the adaptive terms. Two kinds of failure must

be created.

S A lean side deviation: P0171

S A rich side deviation : P0172

It is thus necessary to determine, for each kind of failure,

the limit good and the limit bad. For a given failure, mea-

sure the emission threshold until the legal emission

thresholds are exceeded.

Note that the problem is due to the emission thresholds re-

quired, it is not simple to disturb the system so that the

emission thresholds will be exceeded. The tuning has

been made thanks to a dedicated calibration but, as such

a procedure is not permitted by the regulation, it is neces-

sary to create some material malfunction (fuel pressure

regulator, fuel injector, air leakage...).

Conditions for Setting the DTC

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0132, P0337,

P0338, P0341, P0342, P0400, P1319, P1402,

P1404, P1405, P1671 and P1672 are not set.

S Coolant temperature is greater than 20°C (68°F).

(1.4L DOHC)

S Coolant temperature is greater than 80°C (176°F).

(1.6L DOHC)

S Manifold Absolute Pressure (MAP) is greater than

70 kPa (10.2 psi).

S System is in closed loop.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

S Fuel pressure – The system will be lean if the pres-

sure is too low. It may be necessary to monitor fuel

pressure while driving the vehicle at various road

speeds and/or loads to confirm.

S Map sensor – An output that causes the ECM to

sense a lower than normal manifold pressure (high

vacuum) can cause the system to go lean. Discon-

necting the MAP sensor will allow the ECM to sub-

stitute a fixed (default) value for the MAP sensor. If

the lean condition is gone when the sensor is dis-

connected, substitute a known good sensor and

recheck.

S Fuel contamination – Water, in even small amounts,

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0171.

Check for poor O2S or MAP sensor connection at the

ECM. Inspect the harness connectors for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the O2S display on the scan tool

while moving the connectors and the wiring harness re-

lated to the engine harness. A change in the display will

indicate the location of the fault.

Check the brake power booster check valve for possible

leaks.

Page 434 of 2643

1F – 188IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0300

MULTIPLE CYLINDER MISFIRE (CATALYST DAMAGE)

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 200 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC), the Malfunction Indicator

Lamp (MIL). Severe misfire will flash the MIL, indicating

that catalyst damage is possible.

Conditions for Setting the DTC

S The engine speed is less than 4,500 rpm.

S The fuel tank level is greater than 20%.

S No anti–jerk correction.

S No rough road detection.

S No crankshaft oscillation detection.

S DTCs P0107, P0108, P0122, P0123, P0341,

P0342, P0336 and P0337 are not set.

Action Taken When the DTC SetsS The malfunction Indicator Lamp (MIL) will blinking.

S The ECM will record operating conditions at the

time the diagnostic fails. The information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

DTC P0300 – Multiple Cylinder Misfire(Catalyst Damage)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON, with the engine OFF.

3. Request Diagnostic Trouble Codes (DTCs).

Are DTCs P0261, P0262, P0264, P0265, P0267,

P0268, P0270, P0271 set?–Go to

Applicable DTC

tableGo to Step 3

3Perform a visual/physical inspection.

Make any repairs that are necessary.

Is the repair complete?–Go to Step 27Go to Step 4

4Start the engine and allow it to idle.

Are any Misfire Current counters incrementing?–Go to Step 5Go to Step 6

5Are all counters equal (within a percentage of each

other)?–Go to Step 7Go to Step 11

61. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data, and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and conditions for setting this DTC

as noted.

Are any Misfire Current counters incrementing?–Go to Step 5Go to

”Diagnostic

Aids”

Page 438 of 2643

1F – 192IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0300

MULTIPLE CYLINDER MISFIRE (INCREASE EMISSION)

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 1,000 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL).

Conditions for Setting the DTC

S The engine speed is less than 4,500 rpm.

S The fuel tank level is greater than 20%.

S No anti–jerk correction.

S No rough road detection.

S No crankshaft oscillation detection.

S DTCs P0107, P0108, P0122, P0123, P0341,

P0342, P0336 and P0337 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.S The ECM will record operating conditions at the

time the diagnostic fails. The information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

DTC P0300 – Multiple Cylinder Misfire(Increase Emission)

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON, with the engine OFF.

3. Request Diagnostic Trouble Codes (DTCs).

Are DTCs P0261, P0262, P0264, P0265, P0267,

P0268, P0270, P0271 set?–Go to

Applicable DTC

tableGo to Step 3

3Perform a visual/physical inspection.

Make any repairs that are necessary.

Is the repair complete?–Go to Step 27Go to Step 4

4Start the engine and allow it to idle.

Are any Misfire Current counters incrementing?–Go to Step 5Go to Step 6

5Are all counters equal (within a percentage of each

other)?–Go to Step 7Go to Step 11

61. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data, and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and conditions for setting this DTC

as noted.

Are any Misfire Current counters incrementing?–Go to Step 5Go to

”Diagnostic

Aids”

Page 478 of 2643

1F – 232IENGINE CONTROLS

DAEWOO V–121 BL4

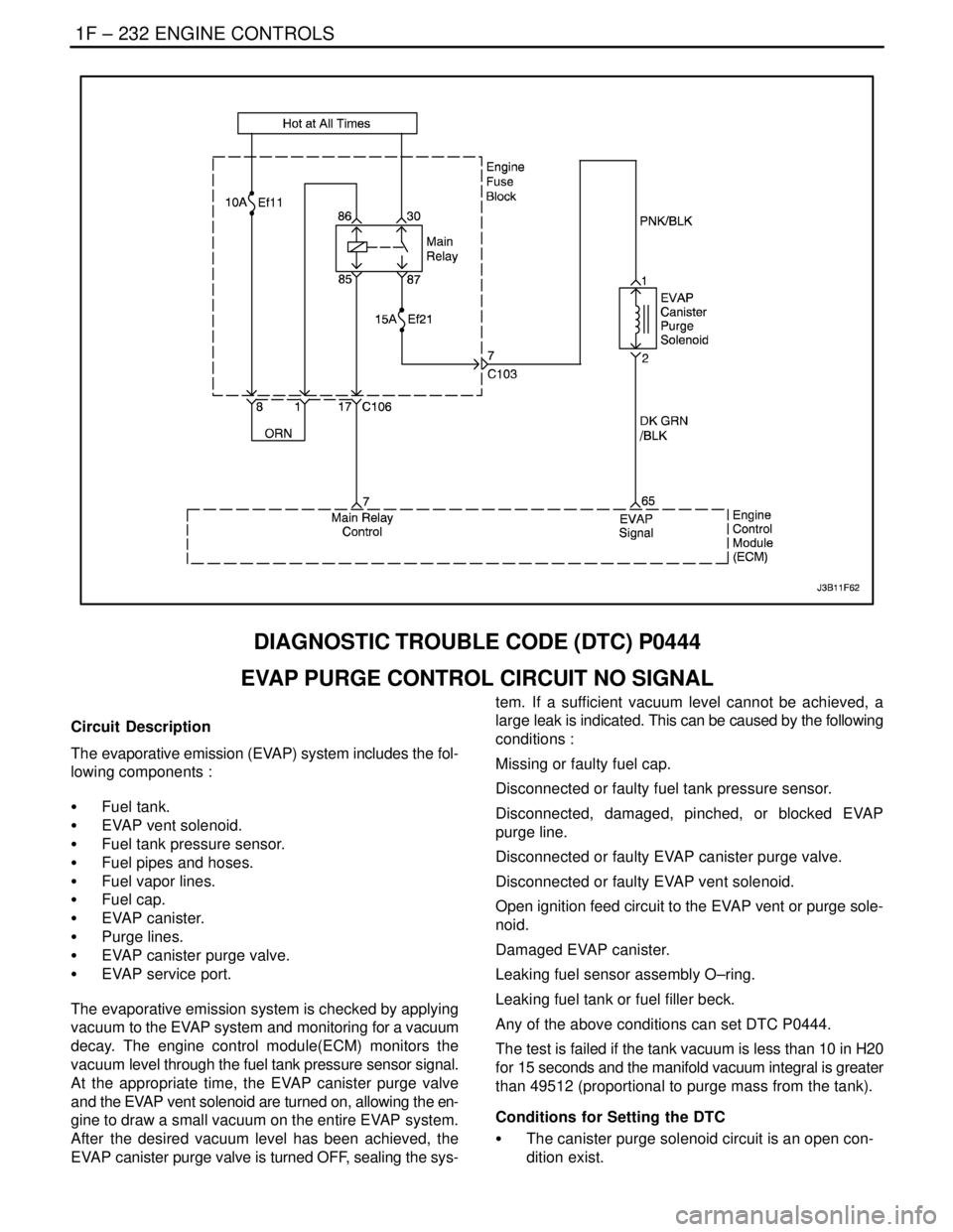

DIAGNOSTIC TROUBLE CODE (DTC) P0444

EVAP PURGE CONTROL CIRCUIT NO SIGNAL

Circuit Description

The evaporative emission (EVAP) system includes the fol-

lowing components :

S Fuel tank.

S EVAP vent solenoid.

S Fuel tank pressure sensor.

S Fuel pipes and hoses.

S Fuel vapor lines.

S Fuel cap.

S EVAP canister.

S Purge lines.

S EVAP canister purge valve.

S EVAP service port.

The evaporative emission system is checked by applying

vacuum to the EVAP system and monitoring for a vacuum

decay. The engine control module(ECM) monitors the

vacuum level through the fuel tank pressure sensor signal.

At the appropriate time, the EVAP canister purge valve

and the EVAP vent solenoid are turned on, allowing the en-

gine to draw a small vacuum on the entire EVAP system.

After the desired vacuum level has been achieved, the

EVAP canister purge valve is turned OFF, sealing the sys-tem. If a sufficient vacuum level cannot be achieved, a

large leak is indicated. This can be caused by the following

conditions :

Missing or faulty fuel cap.

Disconnected or faulty fuel tank pressure sensor.

Disconnected, damaged, pinched, or blocked EVAP

purge line.

Disconnected or faulty EVAP canister purge valve.

Disconnected or faulty EVAP vent solenoid.

Open ignition feed circuit to the EVAP vent or purge sole-

noid.

Damaged EVAP canister.

Leaking fuel sensor assembly O–ring.

Leaking fuel tank or fuel filler beck.

Any of the above conditions can set DTC P0444.

The test is failed if the tank vacuum is less than 10 in H20

for 15 seconds and the manifold vacuum integral is greater

than 49512 (proportional to purge mass from the tank).

Conditions for Setting the DTC

S The canister purge solenoid circuit is an open con-

dition exist.

Page 479 of 2643

ENGINE CONTROLS 1F – 233

DAEWOO V–121 BL4

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Although this DTC is considered a type. A diagnostic, it

acts like a type B diagnostic under certain conditions.

Whenever this diagnostic reports the system has passed,

or if the battery is disconnected, the diagnostic must fail

twice before setting a DTC. The initial failure is not re-ported to the diagnostic executive or displayed on a scan

tool. A passing system always reports to the diagnostic

executive immediately.

Check for the following conditions :

S Missing or damaged fuel cap.

S Missing or damaged O–rings at fuel vapor and

EVAP purge line canister fittings.

S Cracked or punctured EVAP canister.

S Damaged source vacuum line, EVAP purge line,

EVAP vent hose or fuel tank vapor line.

S Poor connection at the ECM. Inspect the harness

connectors for the following conditions.

S Backed–out terminals.

S Improper mating.

S Broken locks.

S Improperly formed.

S Damaged terminals.

S Poor terminal–to–wire connection.

S Damaged harness. Inspect the wiring harness to

the EVAP vent solenoid, EVAP canister purge

valve, and the fuel tank pressure sensor for an in-

termittent open or short circuit.

S Kinked, pinched or plugged vacuum source, EVAP

purge, or fuel tank vapor line. Verify that the lines

are not restricted.

DTC P0444 – EVAP Purge Control Circuit No Signal

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Disconnect the evaporative emission (EVAP)

canister purge valve connector.

2. Connect a test light between the EVAP canister

purge valve connector terminal 1 and battery

positive.

Is the test light ON?–Go to Step 3Go to Step 5

31. Disconnect the ECM connector.

2. Connect a test light between the ECM connec-

tor terminal 65 and ground.

Is the test light ON?–Go to Step 4Go to Step 6

41. Repair the line break in the wire between the

EVAP canister purge valve connector 2 and the

ECM connector terminal 65.

2. Clear any Diagnostic Trouble Codes (DTCs)

from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

Page 481 of 2643

ENGINE CONTROLS 1F – 235

DAEWOO V–121 BL4

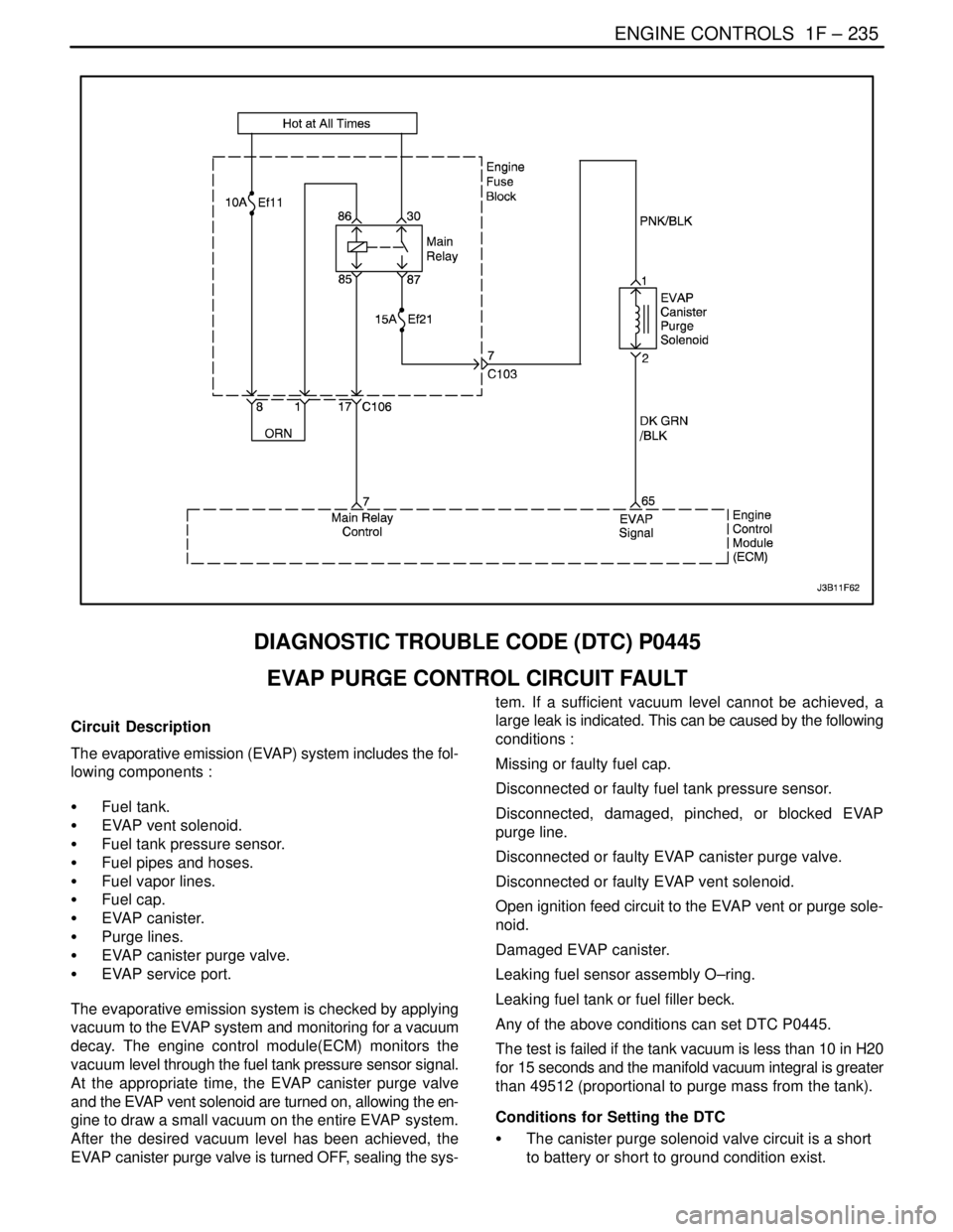

DIAGNOSTIC TROUBLE CODE (DTC) P0445

EVAP PURGE CONTROL CIRCUIT FAULT

Circuit Description

The evaporative emission (EVAP) system includes the fol-

lowing components :

S Fuel tank.

S EVAP vent solenoid.

S Fuel tank pressure sensor.

S Fuel pipes and hoses.

S Fuel vapor lines.

S Fuel cap.

S EVAP canister.

S Purge lines.

S EVAP canister purge valve.

S EVAP service port.

The evaporative emission system is checked by applying

vacuum to the EVAP system and monitoring for a vacuum

decay. The engine control module(ECM) monitors the

vacuum level through the fuel tank pressure sensor signal.

At the appropriate time, the EVAP canister purge valve

and the EVAP vent solenoid are turned on, allowing the en-

gine to draw a small vacuum on the entire EVAP system.

After the desired vacuum level has been achieved, the

EVAP canister purge valve is turned OFF, sealing the sys-tem. If a sufficient vacuum level cannot be achieved, a

large leak is indicated. This can be caused by the following

conditions :

Missing or faulty fuel cap.

Disconnected or faulty fuel tank pressure sensor.

Disconnected, damaged, pinched, or blocked EVAP

purge line.

Disconnected or faulty EVAP canister purge valve.

Disconnected or faulty EVAP vent solenoid.

Open ignition feed circuit to the EVAP vent or purge sole-

noid.

Damaged EVAP canister.

Leaking fuel sensor assembly O–ring.

Leaking fuel tank or fuel filler beck.

Any of the above conditions can set DTC P0445.

The test is failed if the tank vacuum is less than 10 in H20

for 15 seconds and the manifold vacuum integral is greater

than 49512 (proportional to purge mass from the tank).

Conditions for Setting the DTC

S The canister purge solenoid valve circuit is a short

to battery or short to ground condition exist.