tank DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 871 of 2643

ENGINE CONTROLS 1F – 625

DAEWOO V–121 BL4

EVAPORATIVE EMISSION CANISTER

The Evaporative (EVAP) Emission canister is an emission

control device containing activated charcoal granules.

The EVAP emission canister is used to store fuel vapors

from the fuel tank. Once certain conditions are met, the en-

gine control module (ECM) activates the EVAP canister

purge solenoid, allowing the fuel vapors to be drawn into

the engine cylinders and burned.

POSITIVE CRANKCASE

VENTILATION SYSTEM OPERATION

A Positive Crankcase Ventilation (PCV) system is used to

provide complete use of the crankcase vapors. Fresh air

from the air cleaner is supplied to the crankcase. The fresh

air is mixed with blowby gases which are then passed

through a vacuum hose into the intake manifold.

Periodically inspect the hoses and the clamps. Replace

any crankcase ventilation components as required.

A restricted or plugged PCV hose may cause the following

conditions:

S Rough idle

S Stalling or low idle speed

S Oil leaks

S Oil in the air cleaner

S Sludge in the engine

A leaking PCV hose may cause the following conditions:

S Rough idle

S Stalling

S High idle speed

ENGINE COOLANT TEMPERATURE

SENSOR

The Engine Coolant Temperature (ECT) sensor is a

thermistor (a resistor which changes value based on tem-

perature) mounted in the engine coolant stream. Low cool-

ant temperature produces a high resistance (100,000

ohms at –40 °F [–40 °C]) while high temperature causes

low resistance (70 ohms at 266 °F [130 °C]).

The engine control module (ECM) supplies 5 volts to the

ECT sensor through a resistor in the ECM and measures

the change in voltage. The voltage will be high when the

engine is cold, and low when the engine is hot. By measur-

ing the change in voltage, the ECM can determine the

coolant temperature. The engine coolant temperature af-

fects most of the systems that the ECM controls. A failure

in the ECT sensor circuit should set a diagnostic trouble

code P0117 or P0118. Remember, these diagnostic

trouble codes indicate a failure in the ECT sensor circuit,

so proper use of the chart will lead either to repairing a wir-

ing problem or to replacing the sensor to repair a problem

properly.

THROTTLE POSITION SENSOR

The Throttle Position (TP) sensor is a potentiometer con-

nected to the throttle shaft of the throttle body. The TP sen-

sor electrical circuit consists of a 5 volt supply line and a

ground line, both provided by the engine control module

(ECM). The ECM calculates the throttle position by moni-

toring the voltage on this signal line. The TP sensor output

changes as the accelerator pedal is moved, changing the

throttle valve angle. At a closed throttle position, the output

of the TP sensor is low, about 0.5 volt. As the throttle valve

opens, the output increases so that, at Wide Open Throttle

(WOT), the output voltage will be about 5 volts.

The ECM can determine fuel delivery based on throttle

valve angle (driver demand). A broken or loose TP sensor

can cause intermittent bursts of fuel from the injector and

an unstable idle, because the ECM thinks the throttle is

moving. A problem in any of the TP sensor circuits should

set a diagnostic trouble code (DTC) P0121 or P0122.

Once the DTC is set, the ECM will substitute a default val-

ue for the TP sensor and some vehicle performance will

return. A DTC P0121 will cause a high idle speed.

CATALYST MONITOR OXYGEN

SENSORS

Three–way catalytic converters are used to control emis-

sions of hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx). The catalyst within the convert-

ers promotes a chemical reaction. This reaction oxidizes

the HC and CO present in the exhaust gas and converts

them into harmless water vapor and carbon dioxide. The

catalyst also reduces NOx by converting it to nitrogen. The

engine control module (ECM) can monitor this process us-

ing the HO2S1 and HO2S2 sensor. These sensors pro-

duce an output signal which indicates the amount of oxy-

gen present in the exhaust gas entering and leaving the

three–way converter. This indicates the catalyst’s ability to

efficiently convert exhaust gasses. If the catalyst is operat-

ing efficiently, the HO2S1 sensor signals will be more ac-

tive than the signals produced by the HO2S2 sensor. The

catalyst monitor sensors operate the same way as the fuel

control sensors. The sensor’s main function is catalyst

monitoring, but they also have a limited role in fuel control.

If a sensor output indicates a voltage either above or below

the 450 mv bias voltage for an extended period of time, the

ECM will make a slight adjustment to fuel trim to ensure

that fuel delivery is correct for catalyst monitoring.

A problem with the HO2S1 sensor circuit will set DTC

P0131, P0132, P0133 or P0134 depending, on the special

condition. A problem with the HO2S2 sensor signal will set

DTC P0137, P0138, P0140 or P0141, depending on the

special condition.

A fault in the Rear Heated Oxygen Sensor (HO2S2) heat-

er element or its ignition feed or ground will result in lower

oxygen sensor response. This may cause incorrect cata-

lyst monitor diagnostic results.

Page 874 of 2643

1F – 628IENGINE CONTROLS

DAEWOO V–121 BL4

STRATEGY – BASED DIAGNOSTICS

Strategy–Based Diagnostics

The strategy–based diagnostic is a uniform approach to

repair all Electrical/Electronic (E/E) systems. The diag-

nostic flow can always be used to resolve an E/E system

problem and is a starting point when repairs are neces-

sary. The following steps will instruct the technician on

how to proceed with a diagnosis:

S Verify the customer complaint. To verify the cus-

tomer complaint, the technician should know the

normal operation of the system.

S Perform preliminary checks as follows:

S Conduct a thorough visual inspection.

S Review the service history.

S Detect unusual sounds or odors.

S Gather Diagnostic Trouble Code (DTC) informa-

tion to achieve an effective repair.

S Check bulletins and other service information. This

includes videos, newsletters, etc.

S Refer to service information (manual) system

check(s).

S Refer to service diagnostics.

No Trouble Found

This condition exists when the vehicle is found to operate

normally. The condition described by the customer may be

normal. Verify the customer complaint against another ve-

hicle that is operating normally. The condition may be in-

termittent. Verify the complaint under the conditions de-

scribed by the customer before releasing the vehicle.

Re–examine the complaint.

When the complaint cannot be successfully found or iso-

lated, a re–evaluation is necessary. The complaint should

be re–verified and could be intermittent as defined in ”In-

termittents,” or could be normal.

After isolating the cause, the repairs should be made. Vali-

date for proper operation and verify that the symptom has

been corrected. This may involve road testing or other

methods to verify that the complaint has been resolved un-

der the following conditions:

S Conditions noted by the customer.

S If a DTC was diagnosed, verify a repair by duplicat-

ing conditions present when the DTC was set as

noted in the Failure Records or Freeze Frame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be more comprehen-

sive for vehicles with On–Board Diagnostic (EOBD) sys-

tem diagnostics. Following a repair, the technician should

perform these steps:

Important : Follow the steps below when you verify re-

pairs on EOBD systems. Failure to follow these steps

could result in unnecessary repairs.S Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Fame data will only be stored

for an A or B type diagnostic and only if the MIL

has been requested).

S Clear the DTC(s).

S Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

S Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

EOBD SERVICEABILITY ISSUES

Based on the knowledge gained from On–Board Diagnos-

tic (EOBD) experience in the 1994 and 1995 model years,

this list of non–vehicle faults that could affect the perfor-

mance of the EOBD system has been compiled. These

non–vehicle faults vary from environmental conditions to

the quality of fuel used. With the introduction of EOBD

diagnostics across the entire passenger car and light–duty

truck market in 1996, illumination of the MIL due to a non–

vehicle fault could lead to misdiagnosis of the vehicle, in-

creased warranty expense and customer dissatisfaction.

The following list of non–vehicle faults does not include ev-

ery possible fault and may not apply equally to all product

lines.

Fuel Quality

Fuel quality is not a new issue for the automotive industry,

but its potential for turning on the Malfunction Indicator

Lamp (MIL) with EOBD systems is new.

Fuel additives such as ”dry gas” and ”octane enhancers”

may affect the performance of the fuel. If this results in an

incomplete combustion or a partial burn, it will set DTC

P0300. The Reed Vapor Pressure of the fuel can also

create problems in the fuel system, especially during the

spring and fall months when severe ambient temperature

swings occur. A high Reed Vapor Pressure could show up

as a Fuel Trim DTC due to excessive canister loading.

High vapor pressures generated in the fuel tank can also

affect the Evaporative Emission diagnostic as well.

Using fuel with the wrong octane rating for your vehicle

may cause driveability problems. Many of the major fuel

companies advertise that using ”premium” gasoline will

improve the performance of your vehicle. Most premium

fuels use alcohol to increase the octane rating of the fuel.

Although alcohol–enhanced fuels may raise the octane

rating, the fuel’s ability to turn into vapor in cold tempera-

tures deteriorates. This may affect the starting ability and

cold driveability of the engine.

Low fuel levels can lead to fuel starvation, lean engine op-

eration, and eventually engine misfire.

Non–OEM Parts

All of the EOBD diagnostics have been calibrated to run

with Original Equipment Manufacturer (OEM) parts.

Something as simple as a high–performance exhaust sys-

tem that affects exhaust system back pressure could po-

Page 908 of 2643

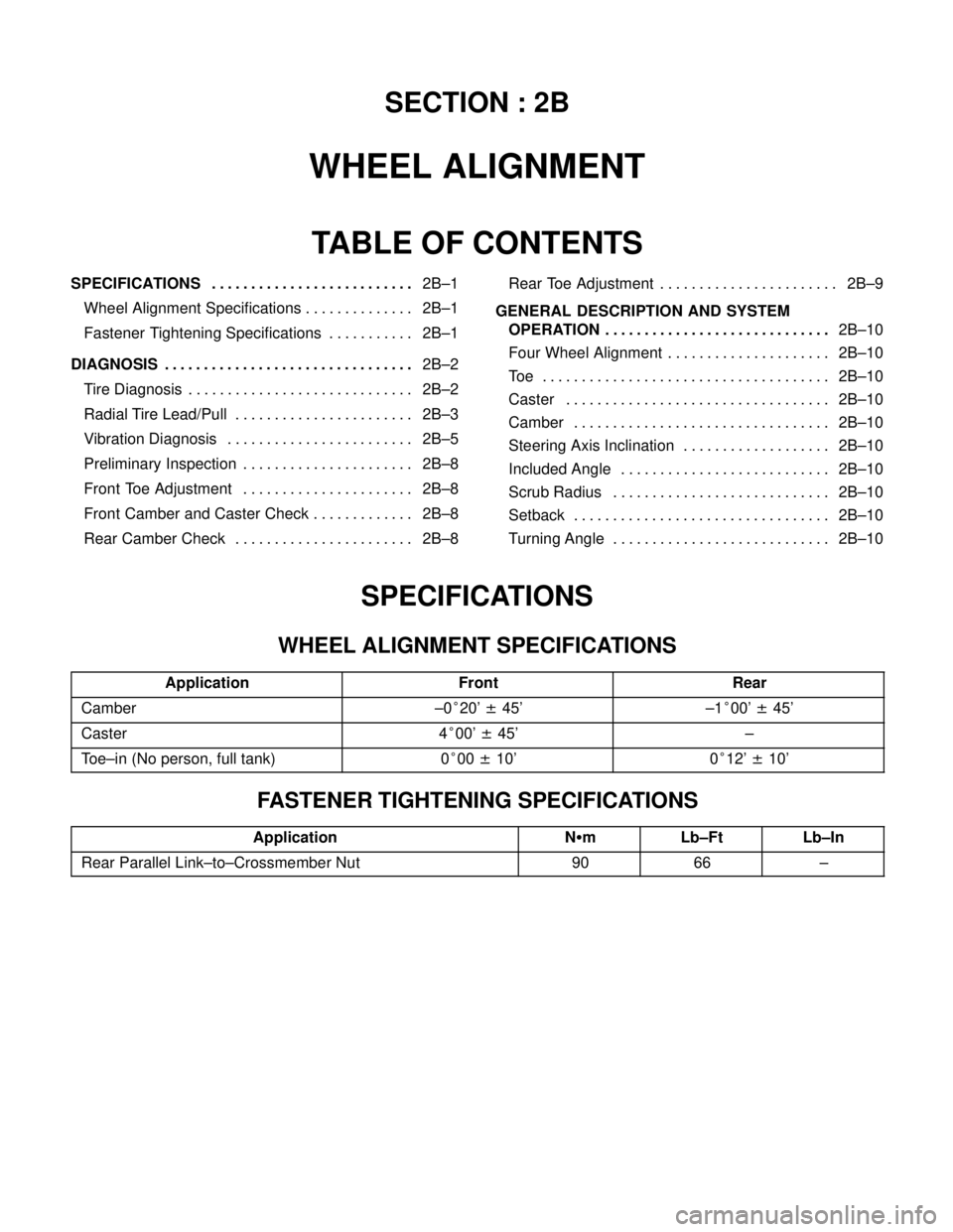

SECTION : 2B

WHEEL ALIGNMENT

TABLE OF CONTENTS

SPECIFICATIONS2B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Alignment Specifications 2B–1. . . . . . . . . . . . . .

Fastener Tightening Specifications 2B–1. . . . . . . . . . .

DIAGNOSIS2B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tire Diagnosis 2B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radial Tire Lead/Pull 2B–3. . . . . . . . . . . . . . . . . . . . . . .

Vibration Diagnosis 2B–5. . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Inspection 2B–8. . . . . . . . . . . . . . . . . . . . . .

Front Toe Adjustment 2B–8. . . . . . . . . . . . . . . . . . . . . .

Front Camber and Caster Check 2B–8. . . . . . . . . . . . .

Rear Camber Check 2B–8. . . . . . . . . . . . . . . . . . . . . . . Rear Toe Adjustment 2B–9. . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION2B–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Four Wheel Alignment 2B–10. . . . . . . . . . . . . . . . . . . . .

Toe 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camber 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Axis Inclination 2B–10. . . . . . . . . . . . . . . . . . .

Included Angle 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Scrub Radius 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setback 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning Angle 2B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS

ApplicationFrontRear

Camber–0°20’ ± 45’–1°00’ ± 45’

Caster4°00’ ± 45’–

Toe–in (No person, full tank)0°00 ± 10’0°12’ ± 10’

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Rear Parallel Link–to–Crossmember Nut9066–

Page 919 of 2643

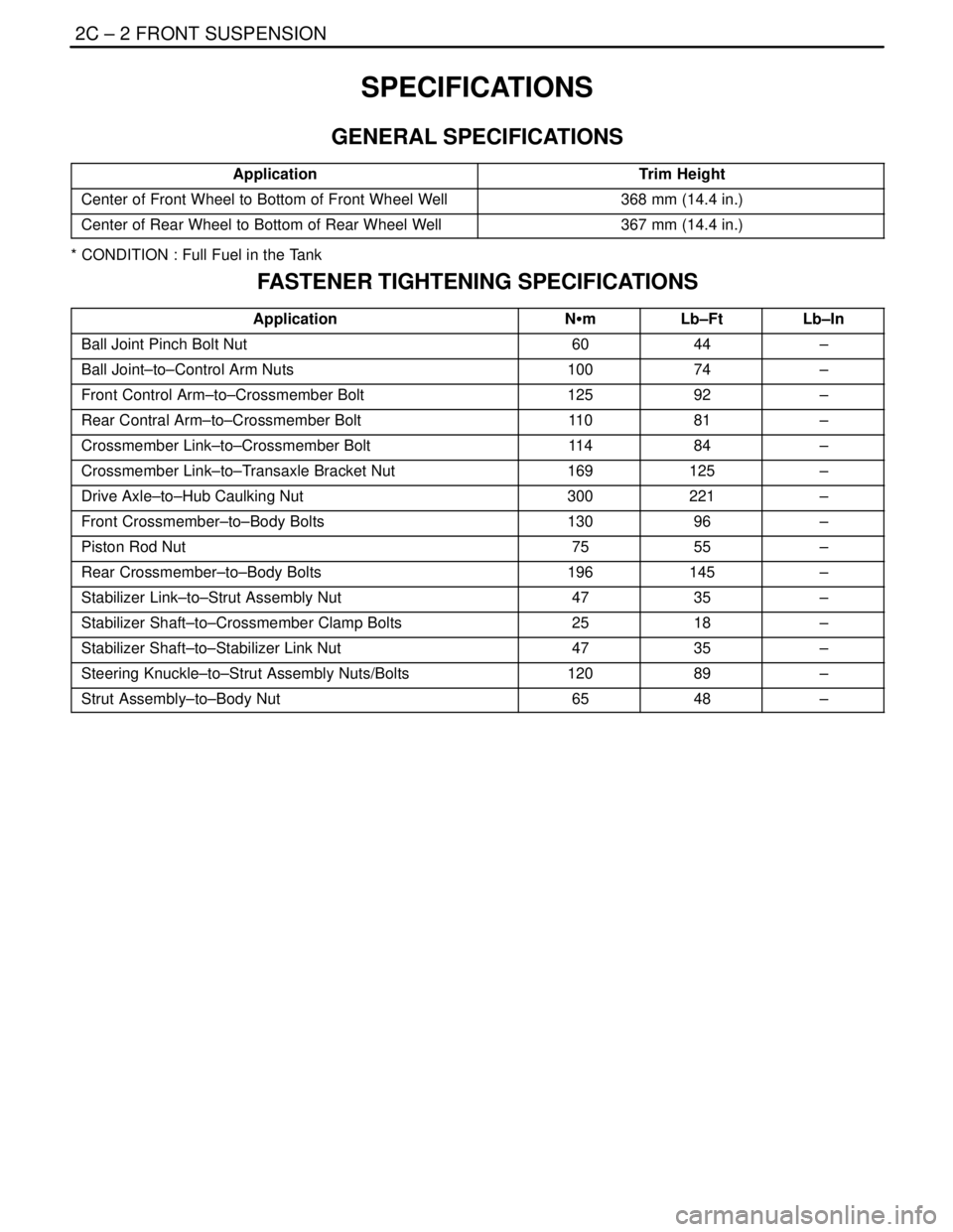

2C – 2IFRONT SUSPENSION

DAEWOO V–121 BL4

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationTrim Height

Center of Front Wheel to Bottom of Front Wheel Well368 mm (14.4 in.)

Center of Rear Wheel to Bottom of Rear Wheel Well367 mm (14.4 in.)

* CONDITION : Full Fuel in the Tank

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ball Joint Pinch Bolt Nut6044–

Ball Joint–to–Control Arm Nuts10074–

Front Control Arm–to–Crossmember Bolt12592–

Rear Contral Arm–to–Crossmember Bolt11 081–

Crossmember Link–to–Crossmember Bolt11 484–

Crossmember Link–to–Transaxle Bracket Nut169125–

Drive Axle–to–Hub Caulking Nut300221–

Front Crossmember–to–Body Bolts13096–

Piston Rod Nut7555–

Rear Crossmember–to–Body Bolts196145–

Stabilizer Link–to–Strut Assembly Nut4735–

Stabilizer Shaft–to–Crossmember Clamp Bolts2518–

Stabilizer Shaft–to–Stabilizer Link Nut4735–

Steering Knuckle–to–Strut Assembly Nuts/Bolts12089–

Strut Assembly–to–Body Nut6548–

Page 1146 of 2643

ANTILOCK BRAKE SYSTEM 4F – 65

DAEWOO V–121 BL4

GENERAL DESCRIPTION AND SYSTEM

OPERATION

BASIC KNOWLEDGE REQUIRED

Before using this section, it is important that you have a ba-

sic knowledge of the following items. Without this knowl-

edge, it will be difficult to use the diagnostic procedures

contained in this section.

S Basic Electrical Circuits : You should understand

the basic theory of electricity and know the mean-

ing of voltage, current (amps), and resistance

(ohms). You should understand what happens in a

circuit with an open or shorted wire. You should be

able to read and understand a wiring diagram.

S Use of Circuit Testing Tools : You should know how

to use a test light and how to bypass components

to test circuits using fused jumper wires. You should

be familiar with a digital multimeter. You should be

able to measure voltage, resistance, and current,

and be familiar with the controls and how to use

them correctly.

ABS SYSTEM COMPONENTS

The ABS 5.3 Antilock Braking System (ABS) consists of

a conventional hydraulic brake system plus antilock com-

ponents. The conventional brake system includes a vacu-

um booster, master cylinder, front disc brakes, rear lead-

ing/trailing drum brakes, interconnecting hydraulic brake

pipes and hoses, brake fluid level sensor and the BRAKE

indicator.

The ABS components include a hydraulic unit, an elec-

tronic brake control module (EBCM), two system fuses,

four wheel speed sensors (one at each wheel), intercon-

necting wiring, the ABS indicator, the EBD indicator (which

is connected to the parking lamp) and the rear disk brakes.

See “ABS Component Locator” in this section for the gen-

eral layout of this system.

The hydraulic unit with the attached EBCM is located be-

tween the surge tank and the fire wall on the left side of the

vehicle.

The basic hydraulic unit configuration consists of hydraulic

check valves, two solenoid valves for each wheel, a hy-

draulic pump, two accumulators, and two damper. The hy-

draulic unit controls hydraulic pressure to the front calipers

and rear wheel cylinders by modulating hydraulic pressure

to prevent wheel lockup.

Nothing in the hydraulic unit or the EBCM is serviceable.

In the event of any failure, the entire ABS unit with at-

tached EBCM must be replaced. For more information, re-

fer to ”Base Braking Mode” and ”Antilock Braking Mode”

in this section.

BASE BRAKING MODE

The baseline braking mode of the ABS 5.3 system used

in this vehicle is a diagonal split system. In this system,

one master cylinder circuit supplies pressure to the right

front and the left rear brakes; the other circuit supplies

pressure to the left front and the right rear brakes. All

valves in the hydraulic modulator are in their normal, non–

energized positions as shown in the drawings found in

”ABS System Components” in this section.

Page 1158 of 2643

4G – 6IPARKING BRAKE

DAEWOO V–121 BL4

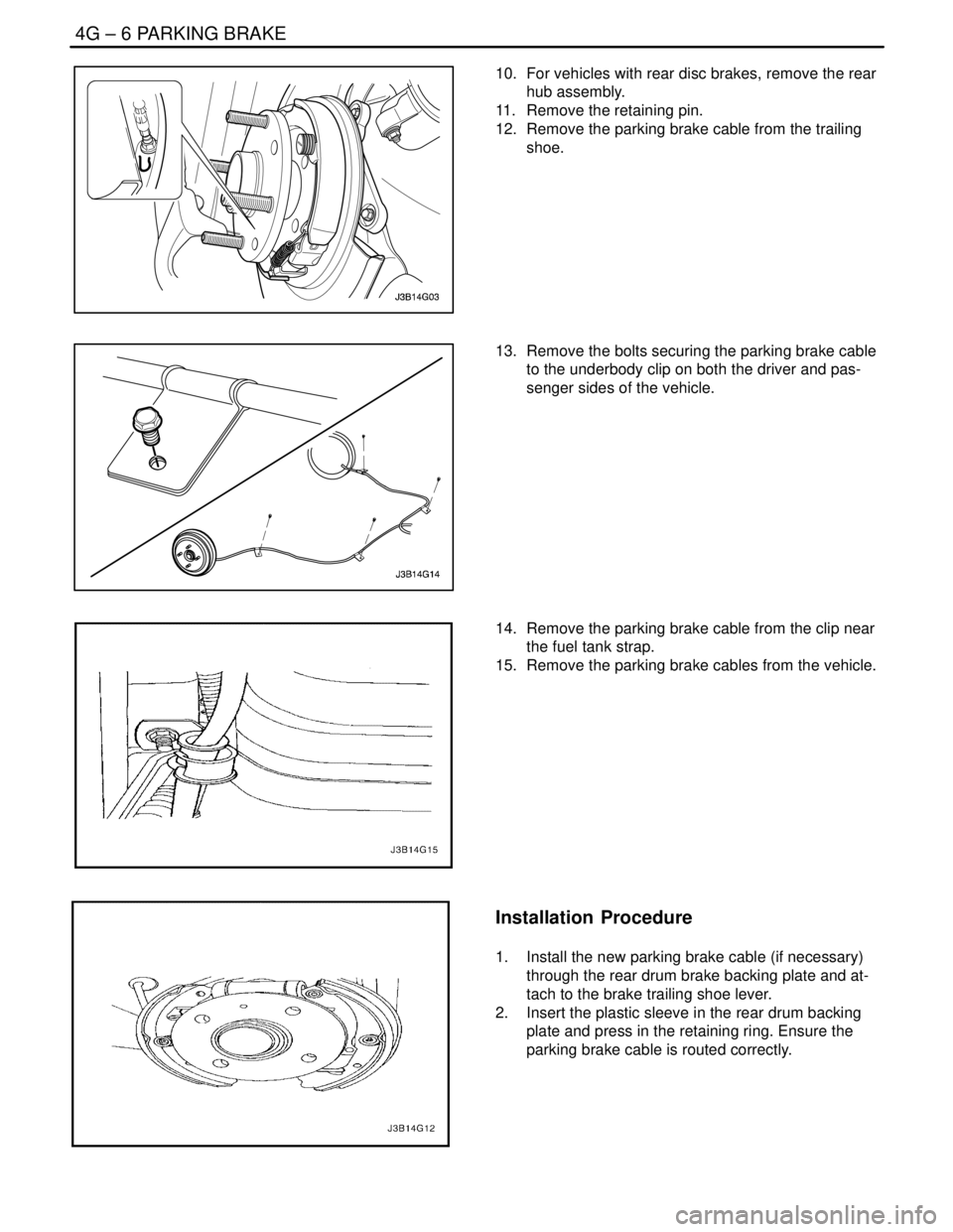

10. For vehicles with rear disc brakes, remove the rear

hub assembly.

11. Remove the retaining pin.

12. Remove the parking brake cable from the trailing

shoe.

13. Remove the bolts securing the parking brake cable

to the underbody clip on both the driver and pas-

senger sides of the vehicle.

14. Remove the parking brake cable from the clip near

the fuel tank strap.

15. Remove the parking brake cables from the vehicle.

Installation Procedure

1. Install the new parking brake cable (if necessary)

through the rear drum brake backing plate and at-

tach to the brake trailing shoe lever.

2. Insert the plastic sleeve in the rear drum backing

plate and press in the retaining ring. Ensure the

parking brake cable is routed correctly.

Page 1159 of 2643

PARKING BRAKE 4G – 7

DAEWOO V–121 BL4

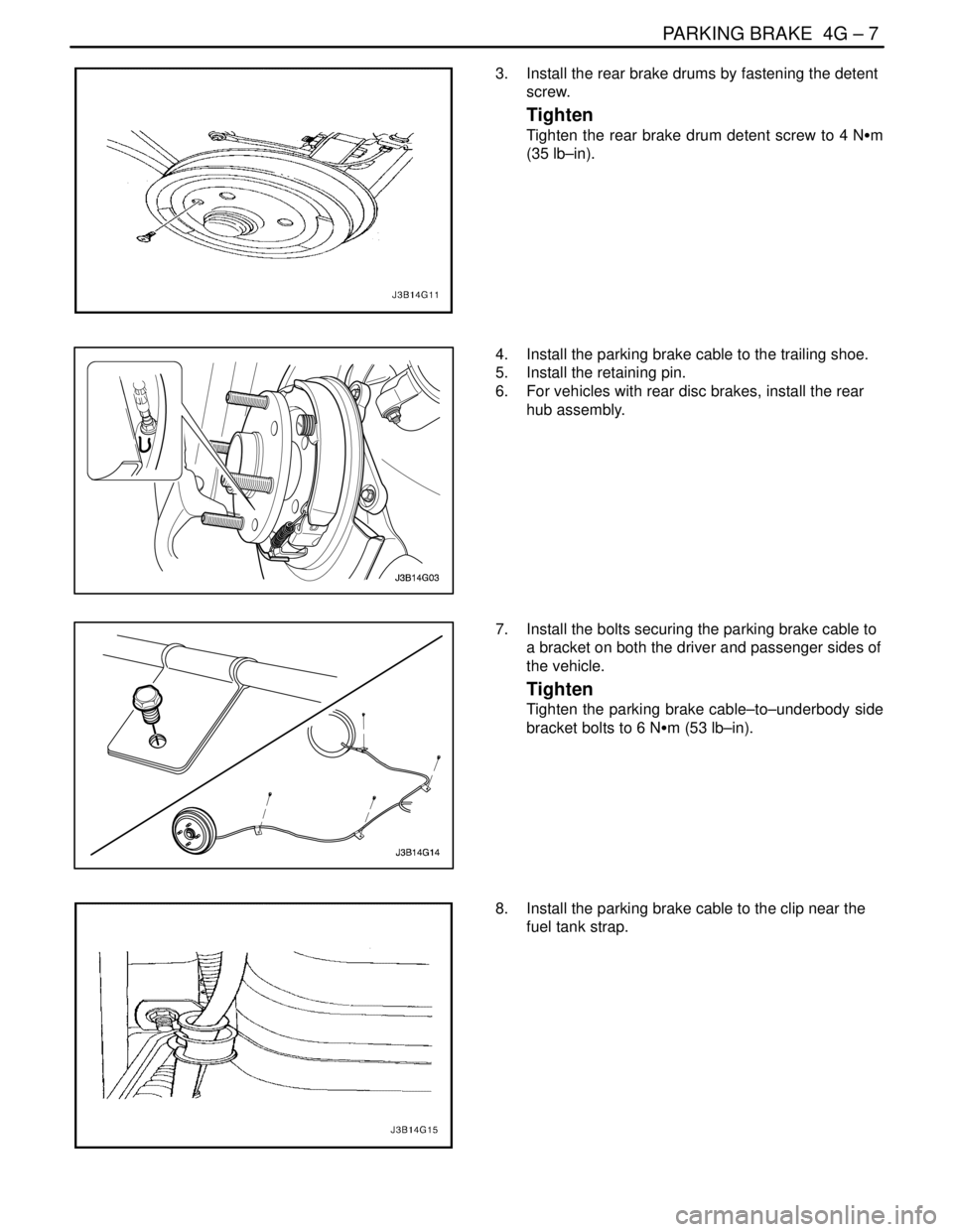

3. Install the rear brake drums by fastening the detent

screw.

Tighten

Tighten the rear brake drum detent screw to 4 NSm

(35 lb–in).

4. Install the parking brake cable to the trailing shoe.

5. Install the retaining pin.

6. For vehicles with rear disc brakes, install the rear

hub assembly.

7. Install the bolts securing the parking brake cable to

a bracket on both the driver and passenger sides of

the vehicle.

Tighten

Tighten the parking brake cable–to–underbody side

bracket bolts to 6 NSm (53 lb–in).

8. Install the parking brake cable to the clip near the

fuel tank strap.

Page 1897 of 2643

5C – 10ICLUTCH

DAEWOO V–121 BL4

Installation Procedure

1. Coat the spline on the clutch disc with multi–pur-

pose grease.

2. Align the pressure plate and the clutch disc onto

the flywheel using the clutch arbor J–42474.

3. Install the pressure plate bolts.

Tighten

Tighten the bolts to 15 NSm (11 lb–ft).

4. Remove the clutch arbor J–42474.

5. Install the transaxle into the vehicle. Refer to Sec-

tion 5B, Five–Speed Manual Transaxle.

6. Connect the negative battery cable.

CLUTCH MASTER CYLINDER

ASSEMBLY

Removal Procedure

Before disconnecting the reservoir tank hose, remove the

clutch/brake fluid from the reservoir tank.

1. Remove the locking clip.

2. Remove the push rod fixing pin and push rod.

3. Disconnect the hose clamp on the master cylinder.

4. Disconnect the master cylinder hose.

5. Remove the master cylinder pipe.

Page 1980 of 2643

7A – 6IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

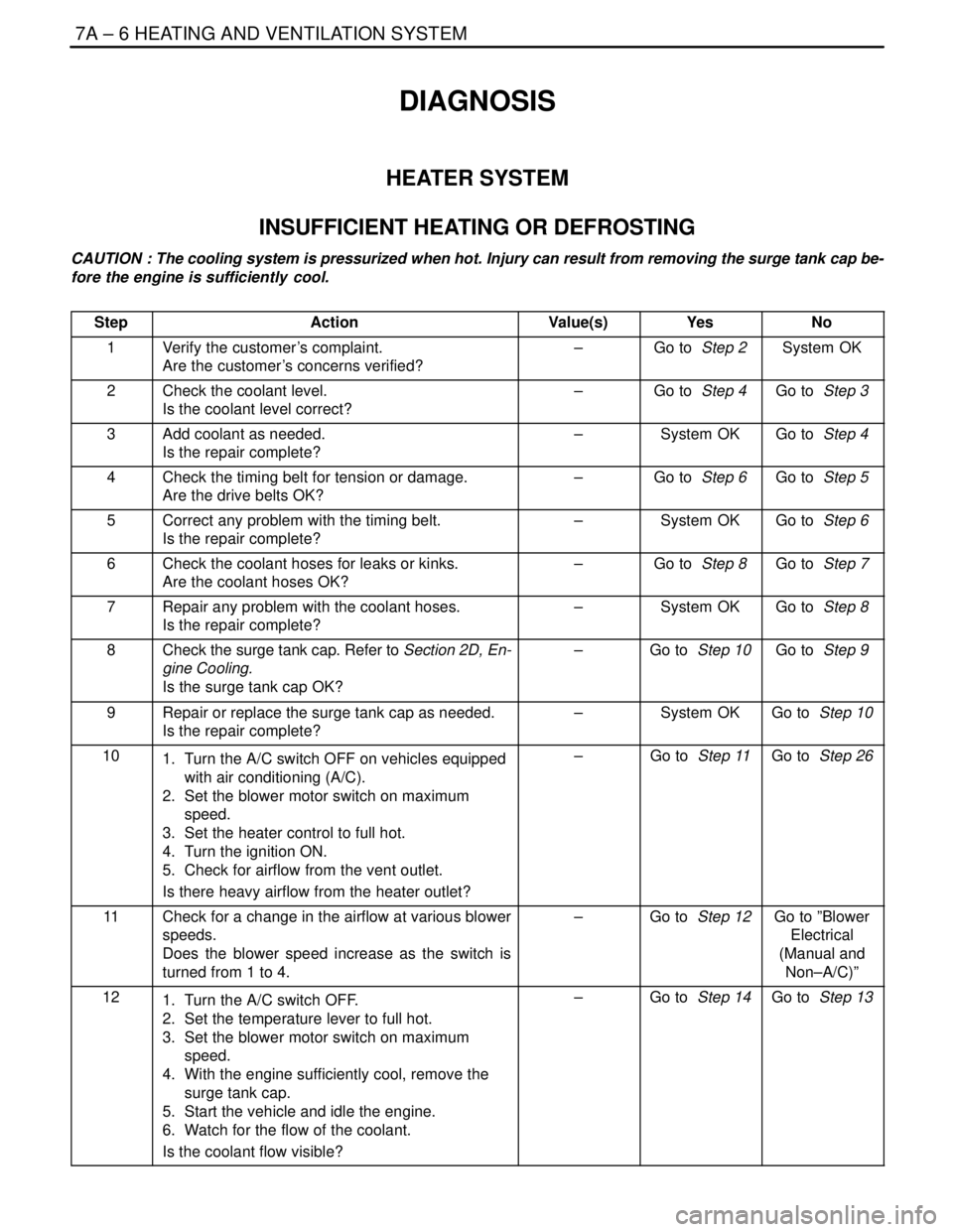

DIAGNOSIS

HEATER SYSTEM

INSUFFICIENT HEATING OR DEFROSTING

CAUTION : The cooling system is pressurized when hot. Injury can result from removing the surge tank cap be-

fore the engine is sufficiently cool.

Step

ActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

2Check the coolant level.

Is the coolant level correct?–Go to Step 4Go to Step 3

3Add coolant as needed.

Is the repair complete?–System OKGo to Step 4

4Check the timing belt for tension or damage.

Are the drive belts OK?–Go to Step 6Go to Step 5

5Correct any problem with the timing belt.

Is the repair complete?–System OKGo to Step 6

6Check the coolant hoses for leaks or kinks.

Are the coolant hoses OK?–Go to Step 8Go to Step 7

7Repair any problem with the coolant hoses.

Is the repair complete?–System OKGo to Step 8

8Check the surge tank cap. Refer to Section 2D, En-

gine Cooling.

Is the surge tank cap OK?–Go to Step 10Go to Step 9

9Repair or replace the surge tank cap as needed.

Is the repair complete?–System OKGo to Step 10

101. Turn the A/C switch OFF on vehicles equipped

with air conditioning (A/C).

2. Set the blower motor switch on maximum

speed.

3. Set the heater control to full hot.

4. Turn the ignition ON.

5. Check for airflow from the vent outlet.

Is there heavy airflow from the heater outlet?–Go to Step 11Go to Step 26

11Check for a change in the airflow at various blower

speeds.

Does the blower speed increase as the switch is

turned from 1 to 4.–Go to Step 12Go to ”Blower

Electrical

(Manual and

Non–A/C)”

121. Turn the A/C switch OFF.

2. Set the temperature lever to full hot.

3. Set the blower motor switch on maximum

speed.

4. With the engine sufficiently cool, remove the

surge tank cap.

5. Start the vehicle and idle the engine.

6. Watch for the flow of the coolant.

Is the coolant flow visible?–Go to Step 14Go to Step 13

Page 1981 of 2643

HEATING AND VENTILATION SYSTEM 7A – 7

DAEWOO V–121 BL4

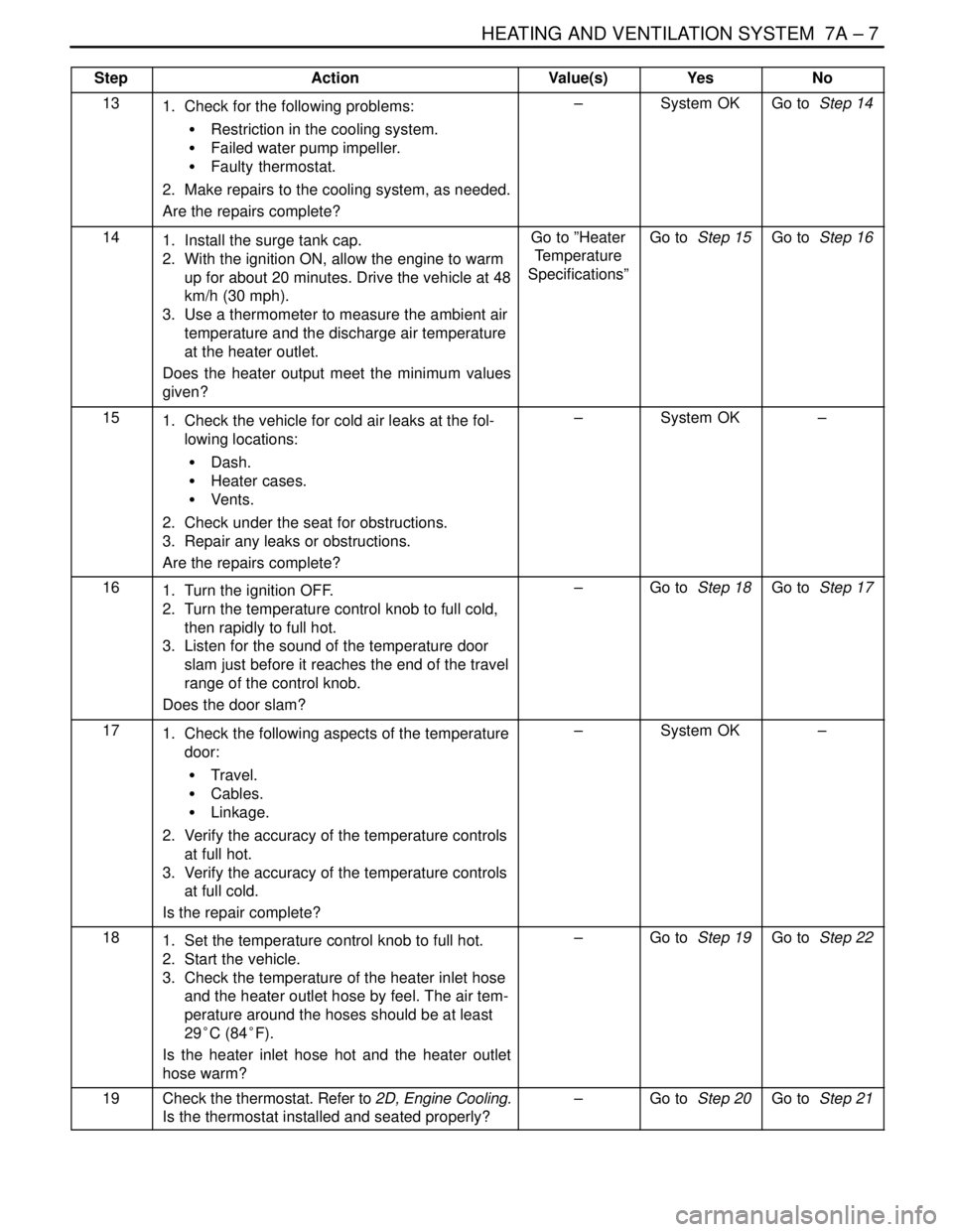

StepNo Yes Value(s) Action

131. Check for the following problems:

S Restriction in the cooling system.

S Failed water pump impeller.

S Faulty thermostat.

2. Make repairs to the cooling system, as needed.

Are the repairs complete?–System OKGo to Step 14

141. Install the surge tank cap.

2. With the ignition ON, allow the engine to warm

up for about 20 minutes. Drive the vehicle at 48

km/h (30 mph).

3. Use a thermometer to measure the ambient air

temperature and the discharge air temperature

at the heater outlet.

Does the heater output meet the minimum values

given?Go to ”Heater

Temperature

Specifications”Go to Step 15Go to Step 16

151. Check the vehicle for cold air leaks at the fol-

lowing locations:

S Dash.

S Heater cases.

S Vents.

2. Check under the seat for obstructions.

3. Repair any leaks or obstructions.

Are the repairs complete?–System OK–

161. Turn the ignition OFF.

2. Turn the temperature control knob to full cold,

then rapidly to full hot.

3. Listen for the sound of the temperature door

slam just before it reaches the end of the travel

range of the control knob.

Does the door slam?–Go to Step 18Go to Step 17

171. Check the following aspects of the temperature

door:

S Travel.

S Cables.

S Linkage.

2. Verify the accuracy of the temperature controls

at full hot.

3. Verify the accuracy of the temperature controls

at full cold.

Is the repair complete?–System OK–

181. Set the temperature control knob to full hot.

2. Start the vehicle.

3. Check the temperature of the heater inlet hose

and the heater outlet hose by feel. The air tem-

perature around the hoses should be at least

29°C (84°F).

Is the heater inlet hose hot and the heater outlet

hose warm?–Go to Step 19Go to Step 22

19Check the thermostat. Refer to 2D, Engine Cooling.

Is the thermostat installed and seated properly?–Go to Step 20Go to Step 21