tank DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 736 of 2643

1F – 490IENGINE CONTROLS

DAEWOO V–121 BL4

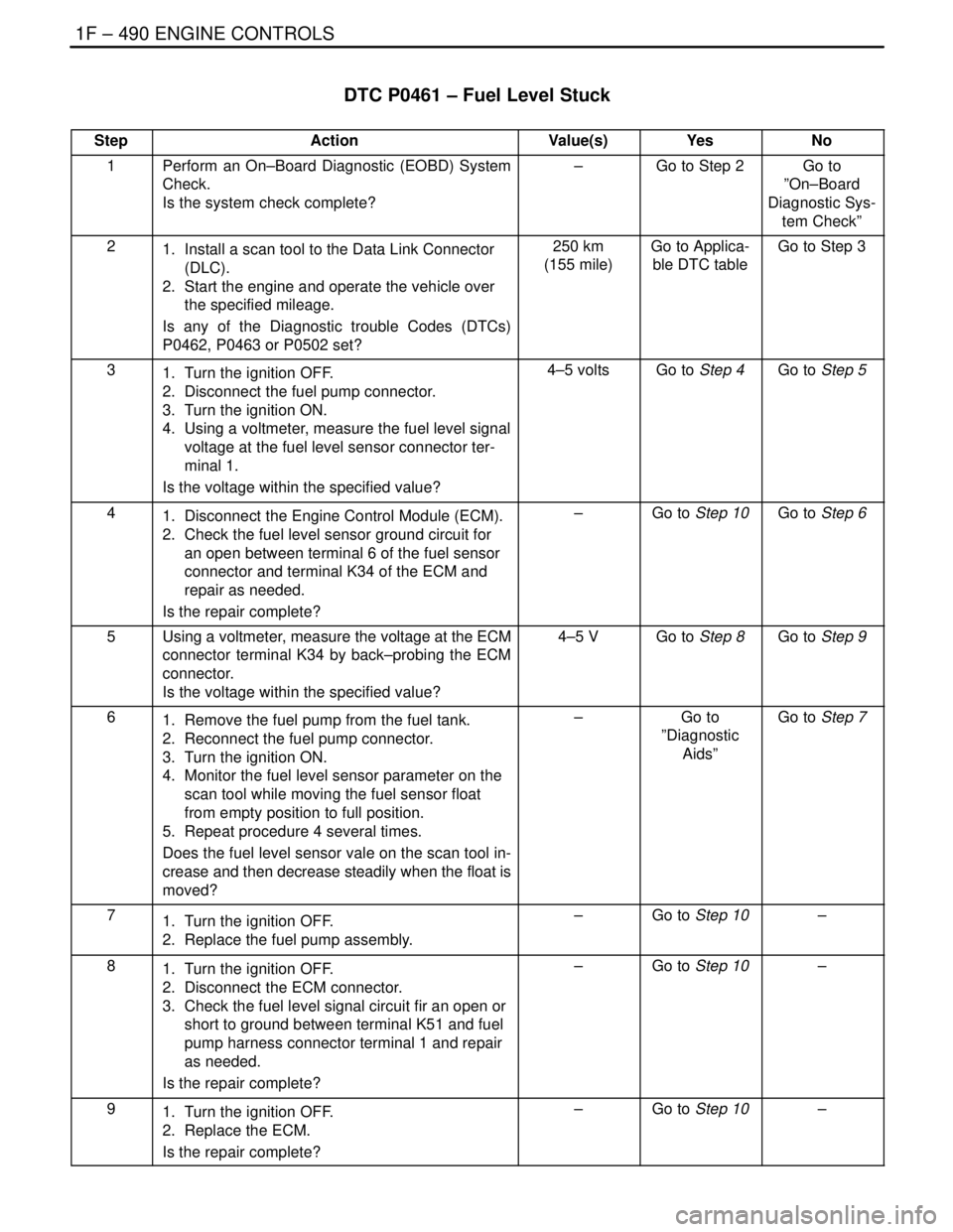

DTC P0461 – Fuel Level Stuck

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and operate the vehicle over

the specified mileage.

Is any of the Diagnostic trouble Codes (DTCs)

P0462, P0463 or P0502 set?250 km

(155 mile)Go to Applica-

ble DTC tableGo to Step 3

31. Turn the ignition OFF.

2. Disconnect the fuel pump connector.

3. Turn the ignition ON.

4. Using a voltmeter, measure the fuel level signal

voltage at the fuel level sensor connector ter-

minal 1.

Is the voltage within the specified value?4–5 voltsGo to Step 4Go to Step 5

41. Disconnect the Engine Control Module (ECM).

2. Check the fuel level sensor ground circuit for

an open between terminal 6 of the fuel sensor

connector and terminal K34 of the ECM and

repair as needed.

Is the repair complete?–Go to Step 10Go to Step 6

5Using a voltmeter, measure the voltage at the ECM

connector terminal K34 by back–probing the ECM

connector.

Is the voltage within the specified value?4–5 VGo to Step 8Go to Step 9

61. Remove the fuel pump from the fuel tank.

2. Reconnect the fuel pump connector.

3. Turn the ignition ON.

4. Monitor the fuel level sensor parameter on the

scan tool while moving the fuel sensor float

from empty position to full position.

5. Repeat procedure 4 several times.

Does the fuel level sensor vale on the scan tool in-

crease and then decrease steadily when the float is

moved?–Go to

”Diagnostic

Aids”Go to Step 7

71. Turn the ignition OFF.

2. Replace the fuel pump assembly.–Go to Step 10–

81. Turn the ignition OFF.

2. Disconnect the ECM connector.

3. Check the fuel level signal circuit fir an open or

short to ground between terminal K51 and fuel

pump harness connector terminal 1 and repair

as needed.

Is the repair complete?–Go to Step 10–

91. Turn the ignition OFF.

2. Replace the ECM.

Is the repair complete?–Go to Step 10–

Page 739 of 2643

ENGINE CONTROLS 1F – 493

DAEWOO V–121 BL4

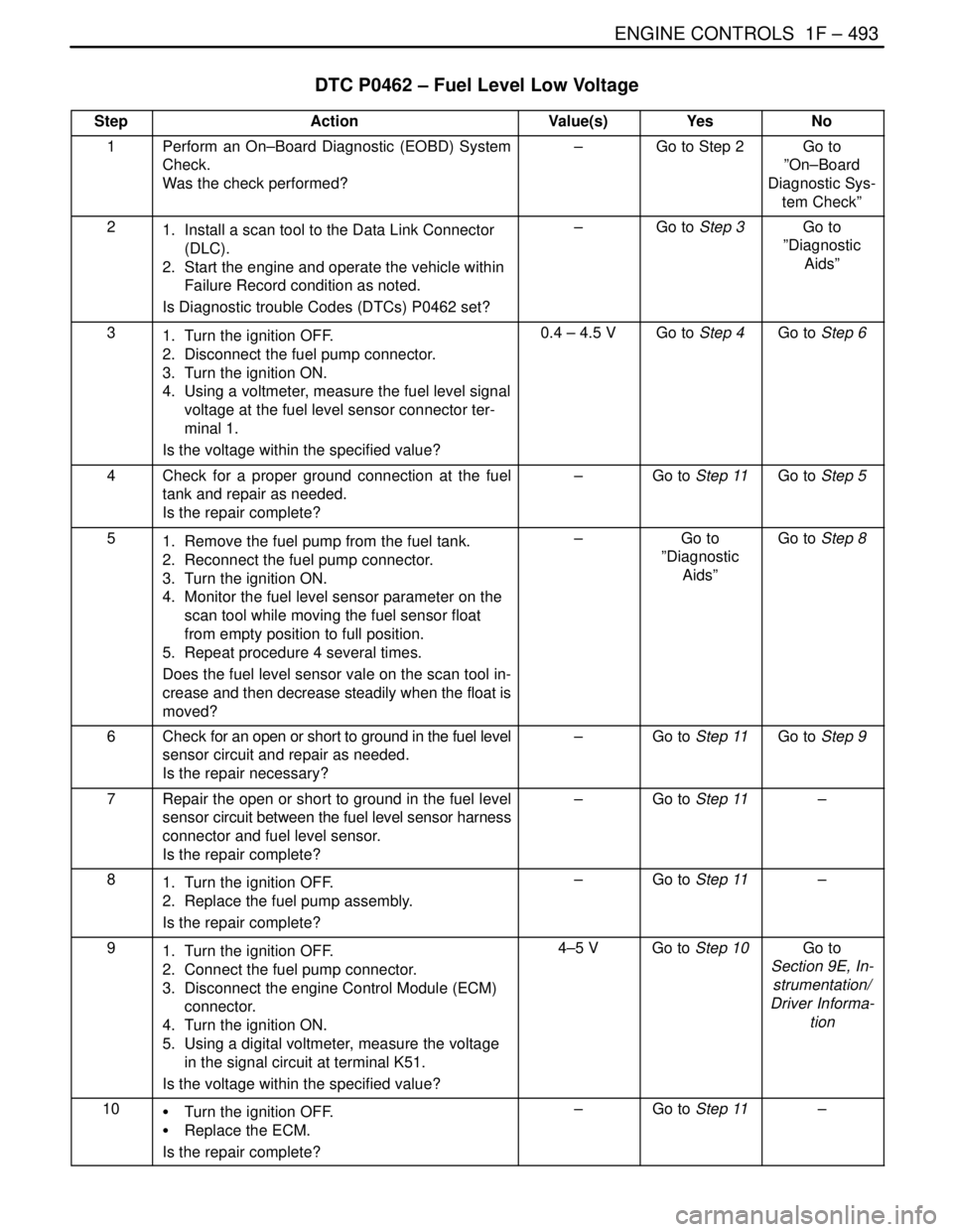

DTC P0462 – Fuel Level Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and operate the vehicle within

Failure Record condition as noted.

Is Diagnostic trouble Codes (DTCs) P0462 set?–Go to Step 3Go to

”Diagnostic

Aids”

31. Turn the ignition OFF.

2. Disconnect the fuel pump connector.

3. Turn the ignition ON.

4. Using a voltmeter, measure the fuel level signal

voltage at the fuel level sensor connector ter-

minal 1.

Is the voltage within the specified value?0.4 – 4.5 VGo to Step 4Go to Step 6

4Check for a proper ground connection at the fuel

tank and repair as needed.

Is the repair complete?–Go to Step 11Go to Step 5

51. Remove the fuel pump from the fuel tank.

2. Reconnect the fuel pump connector.

3. Turn the ignition ON.

4. Monitor the fuel level sensor parameter on the

scan tool while moving the fuel sensor float

from empty position to full position.

5. Repeat procedure 4 several times.

Does the fuel level sensor vale on the scan tool in-

crease and then decrease steadily when the float is

moved?–Go to

”Diagnostic

Aids”Go to Step 8

6Check for an open or short to ground in the fuel level

sensor circuit and repair as needed.

Is the repair necessary?–Go to Step 11Go to Step 9

7Repair the open or short to ground in the fuel level

sensor circuit between the fuel level sensor harness

connector and fuel level sensor.

Is the repair complete?–Go to Step 11–

81. Turn the ignition OFF.

2. Replace the fuel pump assembly.

Is the repair complete?–Go to Step 11–

91. Turn the ignition OFF.

2. Connect the fuel pump connector.

3. Disconnect the engine Control Module (ECM)

connector.

4. Turn the ignition ON.

5. Using a digital voltmeter, measure the voltage

in the signal circuit at terminal K51.

Is the voltage within the specified value?4–5 VGo to Step 10Go to

Section 9E, In-

strumentation/

Driver Informa-

tion

10S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 11–

Page 742 of 2643

1F – 496IENGINE CONTROLS

DAEWOO V–121 BL4

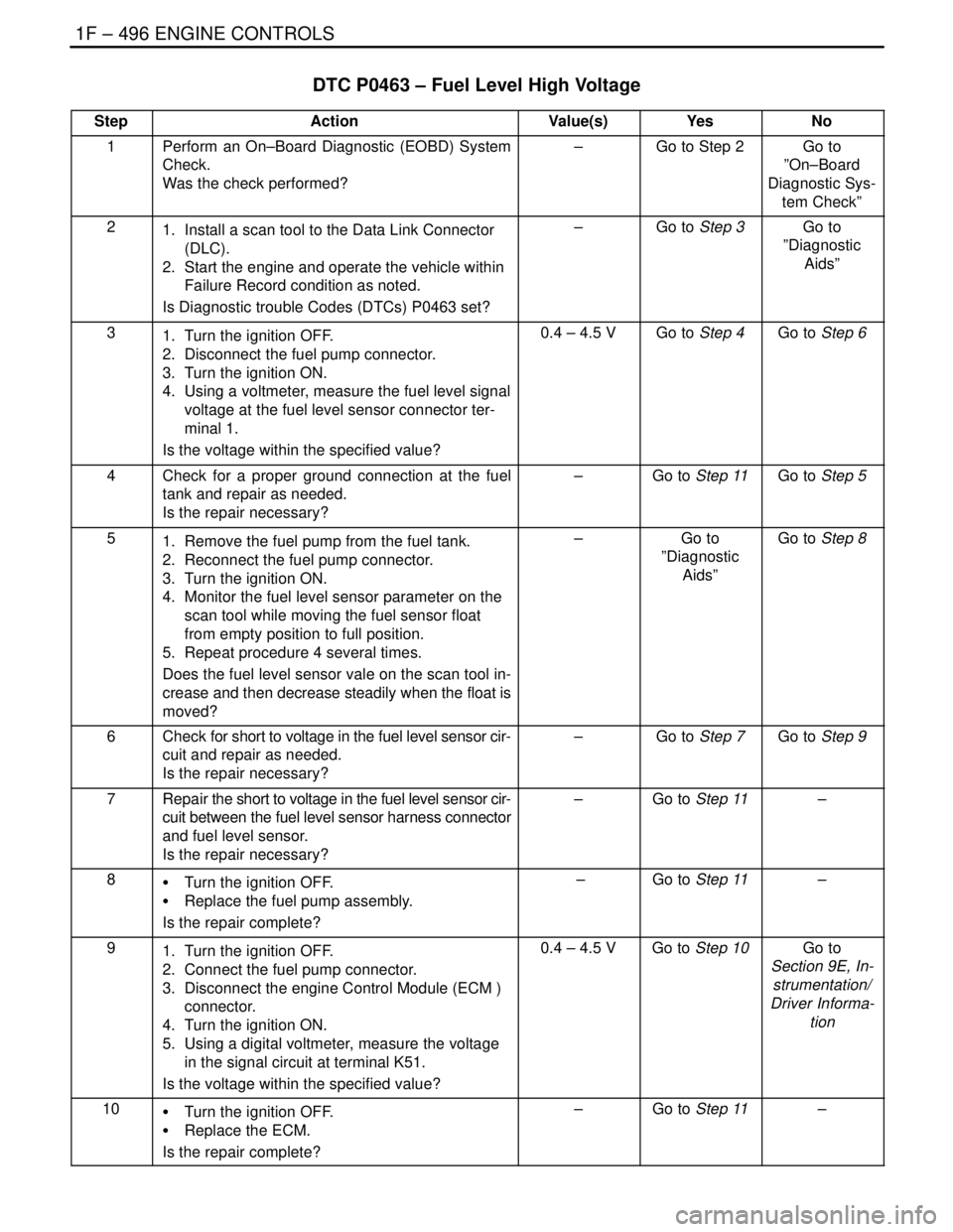

DTC P0463 – Fuel Level High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and operate the vehicle within

Failure Record condition as noted.

Is Diagnostic trouble Codes (DTCs) P0463 set?–Go to Step 3Go to

”Diagnostic

Aids”

31. Turn the ignition OFF.

2. Disconnect the fuel pump connector.

3. Turn the ignition ON.

4. Using a voltmeter, measure the fuel level signal

voltage at the fuel level sensor connector ter-

minal 1.

Is the voltage within the specified value?0.4 – 4.5 VGo to Step 4Go to Step 6

4Check for a proper ground connection at the fuel

tank and repair as needed.

Is the repair necessary?–Go to Step 11Go to Step 5

51. Remove the fuel pump from the fuel tank.

2. Reconnect the fuel pump connector.

3. Turn the ignition ON.

4. Monitor the fuel level sensor parameter on the

scan tool while moving the fuel sensor float

from empty position to full position.

5. Repeat procedure 4 several times.

Does the fuel level sensor vale on the scan tool in-

crease and then decrease steadily when the float is

moved?–Go to

”Diagnostic

Aids”Go to Step 8

6Check for short to voltage in the fuel level sensor cir-

cuit and repair as needed.

Is the repair necessary?–Go to Step 7Go to Step 9

7Repair the short to voltage in the fuel level sensor cir-

cuit between the fuel level sensor harness connector

and fuel level sensor.

Is the repair necessary?–Go to Step 11–

8S Turn the ignition OFF.

S Replace the fuel pump assembly.

Is the repair complete? –Go to Step 11–

91. Turn the ignition OFF.

2. Connect the fuel pump connector.

3. Disconnect the engine Control Module (ECM )

connector.

4. Turn the ignition ON.

5. Using a digital voltmeter, measure the voltage

in the signal circuit at terminal K51.

Is the voltage within the specified value?0.4 – 4.5 VGo to Step 10Go to

Section 9E, In-

strumentation/

Driver Informa-

tion

10S Turn the ignition OFF.

S Replace the ECM.

Is the repair complete?–Go to Step 11–

Page 794 of 2643

1F – 548IENGINE CONTROLS

DAEWOO V–121 BL4

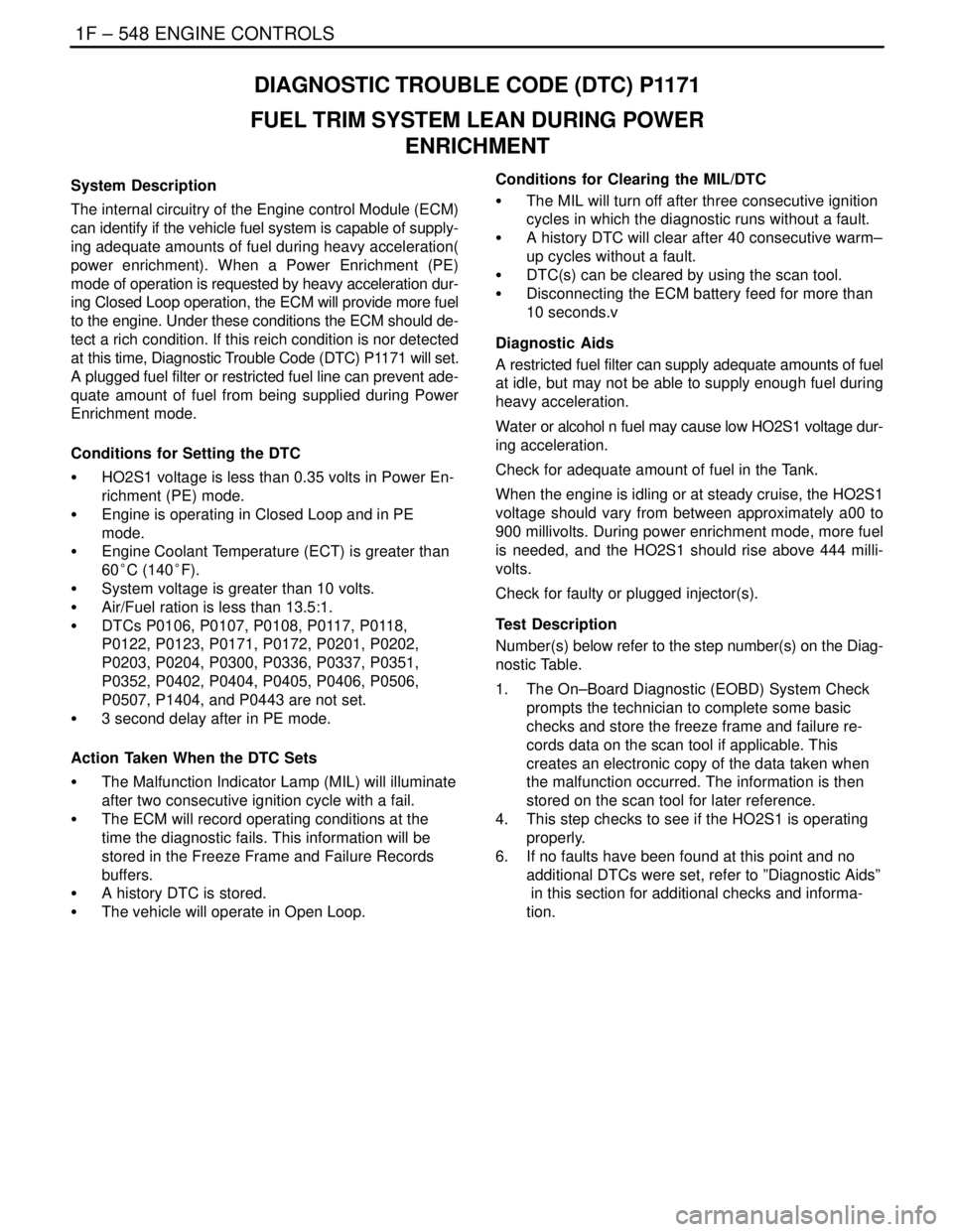

DIAGNOSTIC TROUBLE CODE (DTC) P1171

FUEL TRIM SYSTEM LEAN DURING POWER

ENRICHMENT

System Description

The internal circuitry of the Engine control Module (ECM)

can identify if the vehicle fuel system is capable of supply-

ing adequate amounts of fuel during heavy acceleration(

power enrichment). When a Power Enrichment (PE)

mode of operation is requested by heavy acceleration dur-

ing Closed Loop operation, the ECM will provide more fuel

to the engine. Under these conditions the ECM should de-

tect a rich condition. If this reich condition is nor detected

at this time, Diagnostic Trouble Code (DTC) P1171 will set.

A plugged fuel filter or restricted fuel line can prevent ade-

quate amount of fuel from being supplied during Power

Enrichment mode.

Conditions for Setting the DTC

S HO2S1 voltage is less than 0.35 volts in Power En-

richment (PE) mode.

S Engine is operating in Closed Loop and in PE

mode.

S Engine Coolant Temperature (ECT) is greater than

60°C (140°F).

S System voltage is greater than 10 volts.

S Air/Fuel ration is less than 13.5:1.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0171, P0172, P0201, P0202,

P0203, P0204, P0300, P0336, P0337, P0351,

P0352, P0402, P0404, P0405, P0406, P0506,

P0507, P1404, and P0443 are not set.

S 3 second delay after in PE mode.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The vehicle will operate in Open Loop.Conditions for Clearing the MIL/DTC

S The MIL will turn off after three consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.v

Diagnostic Aids

A restricted fuel filter can supply adequate amounts of fuel

at idle, but may not be able to supply enough fuel during

heavy acceleration.

Water or alcohol n fuel may cause low HO2S1 voltage dur-

ing acceleration.

Check for adequate amount of fuel in the Tank.

When the engine is idling or at steady cruise, the HO2S1

voltage should vary from between approximately a00 to

900 millivolts. During power enrichment mode, more fuel

is needed, and the HO2S1 should rise above 444 milli-

volts.

Check for faulty or plugged injector(s).

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

4. This step checks to see if the HO2S1 is operating

properly.

6. If no faults have been found at this point and no

additional DTCs were set, refer to ”Diagnostic Aids”

in this section for additional checks and informa-

tion.

Page 795 of 2643

ENGINE CONTROLS 1F – 549

DAEWOO V–121 BL4

DTC P1171 – Fuel Trim Supply System Lean During Power

Enrichment

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any component related Diagnostic Trouble

Codes (DTCs) set?–Go to

applicable DTC

tableGo to Step 3

31. Check the vehicle for an adequate amount of

fuel.

2. Add fuel to the vehicles fuel tank if the tank is

almost empty.

Did the fuel tank require fuel?–Go to Step 5Go to Step 4

41. Using a scan tool, observe the Front Heated

Oxygen Sensor (HO2S1) voltage while acceler-

ating the engine over 1200 rpm.

2. The HO2S1 voltage should vary from specified

voltage (100––900 mV) and occasionally toggle

above the specified voltage while accelerating.

Is the HO2S1 voltage toggle?3507 mVGo to

”Fuel System

Diagnosis”Go to

”DTC P0134

Oxygen Sensor

No Activity”

51. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 6Go to Step 2

6Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 840 of 2643

1F – 594IENGINE CONTROLS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

FUEL SYSTEM PRESSURE RELIEF

Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Remove the fuel cap.

2. Remove the fuel pump fuse Ef18 from the engine

fuse block.

3. Start the engine and allow the engine to stall.

4. Crank the engine for an additional 10 seconds.

FUEL TANK

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel pressure. Refer to ” Fuel System

Pressure Relief ” in this section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank.

4. Remove the front muffler. Refer to Section 1G, Ex-

haust System

5. Remove the fuel tank filler tube clamp at the fuel

tank.

6. Disconnect the fuel tank filler tube.

7. Disconnect the fuel vapor line near the fuel tank

filler tube.

8. Disconnect the fuel pump harness connector.

Page 841 of 2643

ENGINE CONTROLS 1F – 595

DAEWOO V–121 BL4

9. Disconnect the fuel inlet line and the fuel return line

near the right front of the fuel tank.

10. Remove the Fuel pump. Refer to ”Fuel Pump” in

this section.

11. Remove the parking brake cables support brackets.

12. Support the fuel tank.

13. Remove the fuel tank strap retaining nuts.

14. Remove the fuel tank strap.

15. Carefully lower the fuel tank.

16. Remove the fuel tank.

17. Transfer any parts as needed.

Installation Procedure

1. Raise the fuel tank into position.

2. Install the fuel tank straps.

3. Install the fuel tank strap retaining nuts.

Tighten

Tighten the fuel tank strap retaining nuts to 20 NSm

(15 lb–ft).

4. Install the parking brake cables support bracket.

5. Install the fuel pump. Refer to ”Fuel Pump” in this

section.

6. Connect the fuel outlet line and the fuel return line.

Page 842 of 2643

1F – 596IENGINE CONTROLS

DAEWOO V–121 BL4

7. Connect the fuel pump harness connector.

8. Connect the fuel vapor line.

9. Connect the fuel tank filler tube.

10. Connect the fuel tank vent tube.

11. Install the fuel tank filler tube clamp at the fuel tank.

12. Install the front muffler. Refer to Section 1G, Ex-

haust System

13. Connect the negative battery cable.

14. Fill the fuel tank.

15. Perform a leak check of the fuel tank and the fuel

line connections.

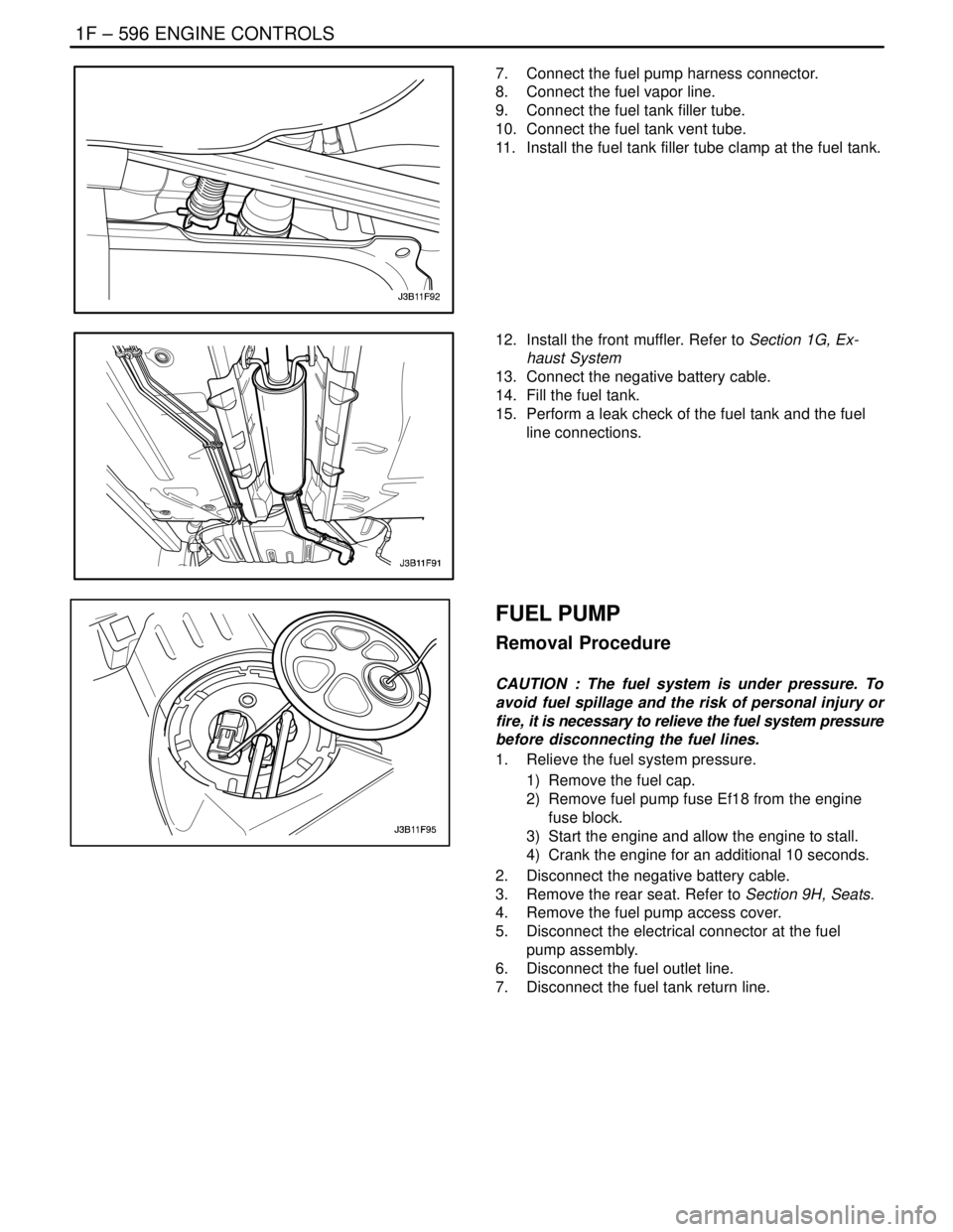

FUEL PUMP

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel system pressure.

1) Remove the fuel cap.

2) Remove fuel pump fuse Ef18 from the engine

fuse block.

3) Start the engine and allow the engine to stall.

4) Crank the engine for an additional 10 seconds.

2. Disconnect the negative battery cable.

3. Remove the rear seat. Refer to Section 9H, Seats.

4. Remove the fuel pump access cover.

5. Disconnect the electrical connector at the fuel

pump assembly.

6. Disconnect the fuel outlet line.

7. Disconnect the fuel tank return line.

Page 843 of 2643

ENGINE CONTROLS 1F – 597

DAEWOO V–121 BL4

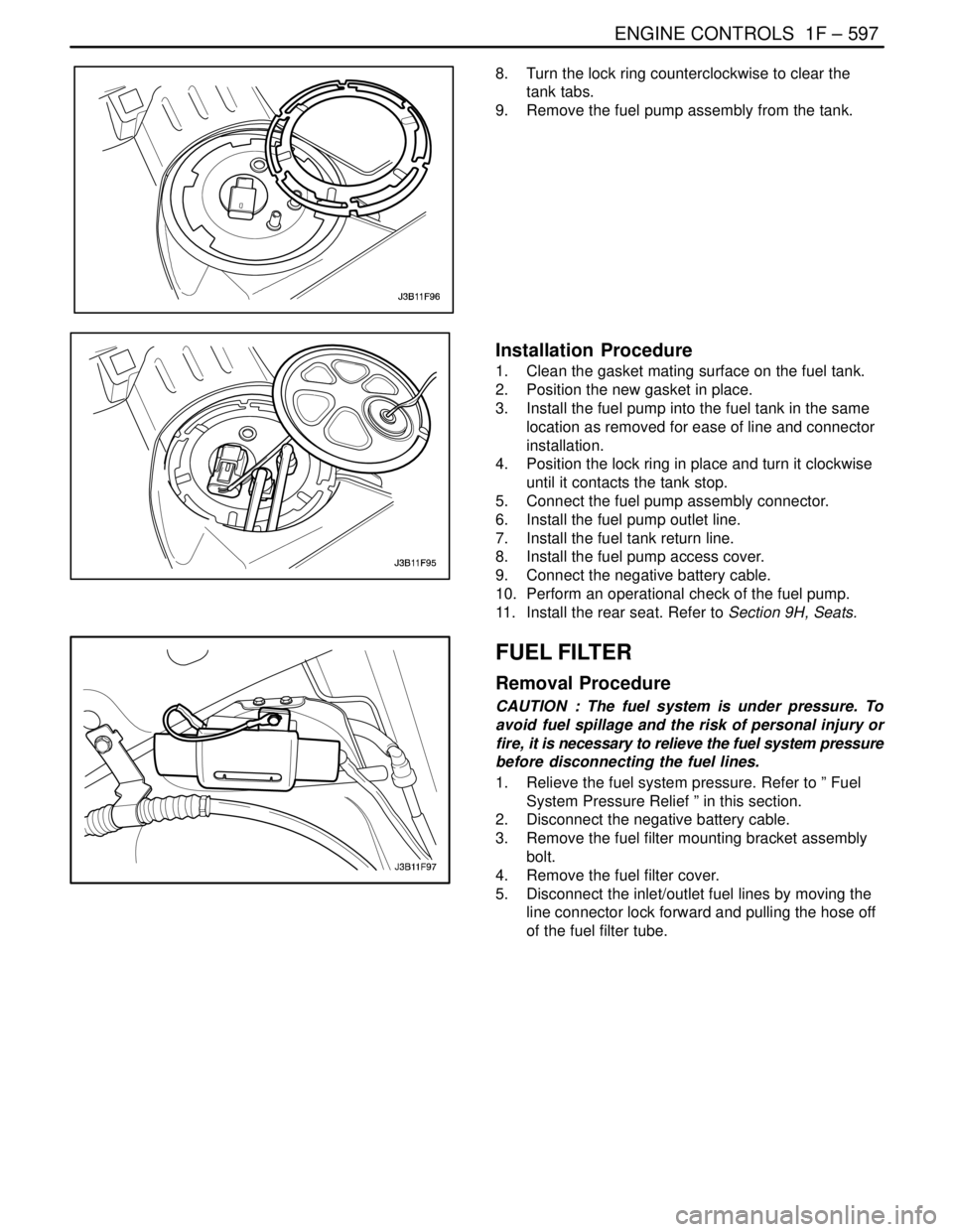

8. Turn the lock ring counterclockwise to clear the

tank tabs.

9. Remove the fuel pump assembly from the tank.

Installation Procedure

1. Clean the gasket mating surface on the fuel tank.

2. Position the new gasket in place.

3. Install the fuel pump into the fuel tank in the same

location as removed for ease of line and connector

installation.

4. Position the lock ring in place and turn it clockwise

until it contacts the tank stop.

5. Connect the fuel pump assembly connector.

6. Install the fuel pump outlet line.

7. Install the fuel tank return line.

8. Install the fuel pump access cover.

9. Connect the negative battery cable.

10. Perform an operational check of the fuel pump.

11. Install the rear seat. Refer to Section 9H, Seats.

FUEL FILTER

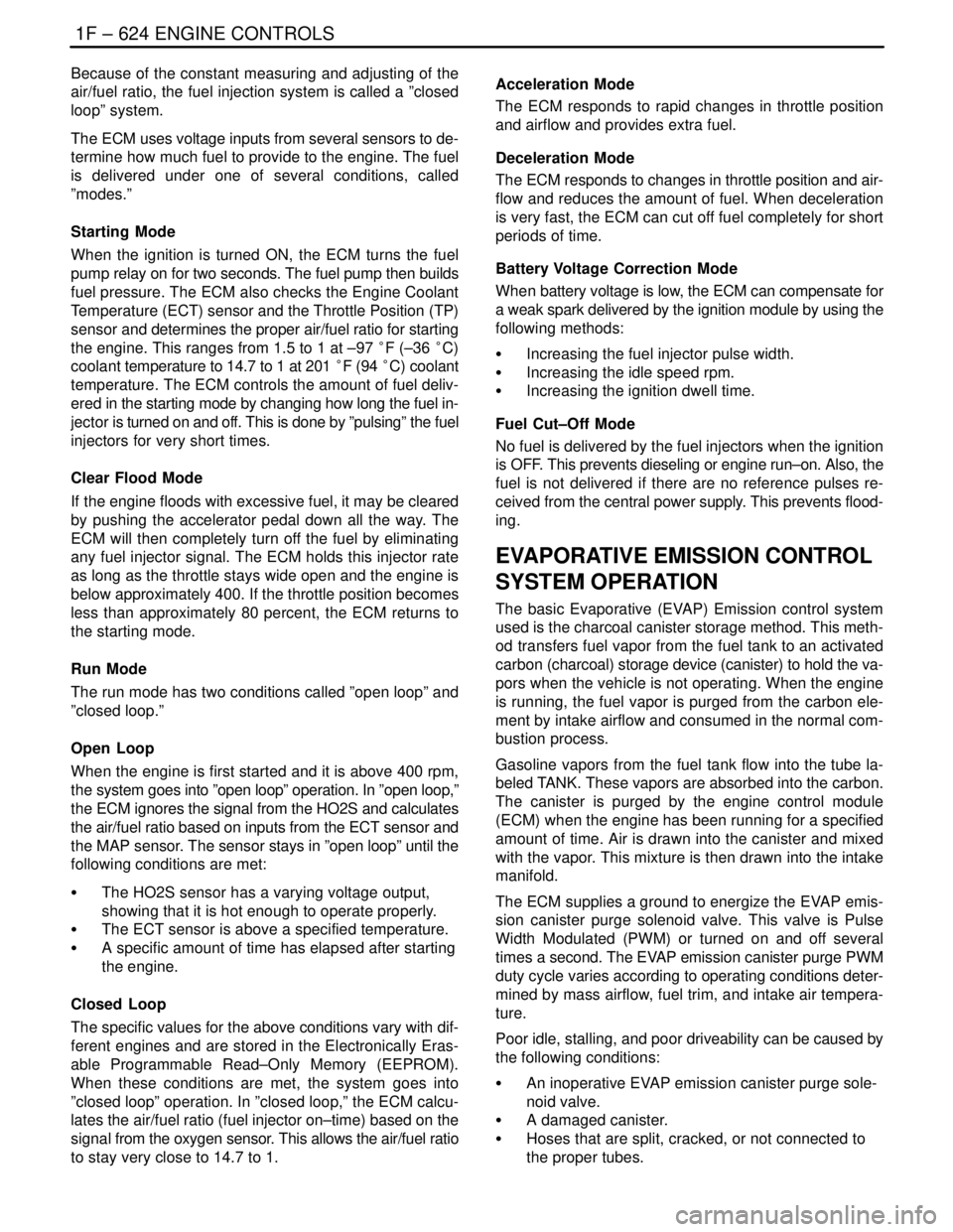

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel system pressure. Refer to ” Fuel

System Pressure Relief ” in this section.

2. Disconnect the negative battery cable.

3. Remove the fuel filter mounting bracket assembly

bolt.

4. Remove the fuel filter cover.

5. Disconnect the inlet/outlet fuel lines by moving the

line connector lock forward and pulling the hose off

of the fuel filter tube.

Page 870 of 2643

1F – 624IENGINE CONTROLS

DAEWOO V–121 BL4

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a ”closed

loop” system.

The ECM uses voltage inputs from several sensors to de-

termine how much fuel to provide to the engine. The fuel

is delivered under one of several conditions, called

”modes.”

Starting Mode

When the ignition is turned ON, the ECM turns the fuel

pump relay on for two seconds. The fuel pump then builds

fuel pressure. The ECM also checks the Engine Coolant

Temperature (ECT) sensor and the Throttle Position (TP)

sensor and determines the proper air/fuel ratio for starting

the engine. This ranges from 1.5 to 1 at –97 °F (–36 °C)

coolant temperature to 14.7 to 1 at 201 °F (94 °C) coolant

temperature. The ECM controls the amount of fuel deliv-

ered in the starting mode by changing how long the fuel in-

jector is turned on and off. This is done by ”pulsing” the fuel

injectors for very short times.

Clear Flood Mode

If the engine floods with excessive fuel, it may be cleared

by pushing the accelerator pedal down all the way. The

ECM will then completely turn off the fuel by eliminating

any fuel injector signal. The ECM holds this injector rate

as long as the throttle stays wide open and the engine is

below approximately 400. If the throttle position becomes

less than approximately 80 percent, the ECM returns to

the starting mode.

Run Mode

The run mode has two conditions called ”open loop” and

”closed loop.”

Open Loop

When the engine is first started and it is above 400 rpm,

the system goes into ”open loop” operation. In ”open loop,”

the ECM ignores the signal from the HO2S and calculates

the air/fuel ratio based on inputs from the ECT sensor and

the MAP sensor. The sensor stays in ”open loop” until the

following conditions are met:

S The HO2S sensor has a varying voltage output,

showing that it is hot enough to operate properly.

S The ECT sensor is above a specified temperature.

S A specific amount of time has elapsed after starting

the engine.

Closed Loop

The specific values for the above conditions vary with dif-

ferent engines and are stored in the Electronically Eras-

able Programmable Read–Only Memory (EEPROM).

When these conditions are met, the system goes into

”closed loop” operation. In ”closed loop,” the ECM calcu-

lates the air/fuel ratio (fuel injector on–time) based on the

signal from the oxygen sensor. This allows the air/fuel ratio

to stay very close to 14.7 to 1.Acceleration Mode

The ECM responds to rapid changes in throttle position

and airflow and provides extra fuel.

Deceleration Mode

The ECM responds to changes in throttle position and air-

flow and reduces the amount of fuel. When deceleration

is very fast, the ECM can cut off fuel completely for short

periods of time.

Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for

a weak spark delivered by the ignition module by using the

following methods:

S Increasing the fuel injector pulse width.

S Increasing the idle speed rpm.

S Increasing the ignition dwell time.

Fuel Cut–Off Mode

No fuel is delivered by the fuel injectors when the ignition

is OFF. This prevents dieseling or engine run–on. Also, the

fuel is not delivered if there are no reference pulses re-

ceived from the central power supply. This prevents flood-

ing.

EVAPORATIVE EMISSION CONTROL

SYSTEM OPERATION

The basic Evaporative (EVAP) Emission control system

used is the charcoal canister storage method. This meth-

od transfers fuel vapor from the fuel tank to an activated

carbon (charcoal) storage device (canister) to hold the va-

pors when the vehicle is not operating. When the engine

is running, the fuel vapor is purged from the carbon ele-

ment by intake airflow and consumed in the normal com-

bustion process.

Gasoline vapors from the fuel tank flow into the tube la-

beled TANK. These vapors are absorbed into the carbon.

The canister is purged by the engine control module

(ECM) when the engine has been running for a specified

amount of time. Air is drawn into the canister and mixed

with the vapor. This mixture is then drawn into the intake

manifold.

The ECM supplies a ground to energize the EVAP emis-

sion canister purge solenoid valve. This valve is Pulse

Width Modulated (PWM) or turned on and off several

times a second. The EVAP emission canister purge PWM

duty cycle varies according to operating conditions deter-

mined by mass airflow, fuel trim, and intake air tempera-

ture.

Poor idle, stalling, and poor driveability can be caused by

the following conditions:

S An inoperative EVAP emission canister purge sole-

noid valve.

S A damaged canister.

S Hoses that are split, cracked, or not connected to

the proper tubes.