lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2252 of 2643

9B – 26ILIGHTING SYSTEMS

DAEWOO V–121 BL4

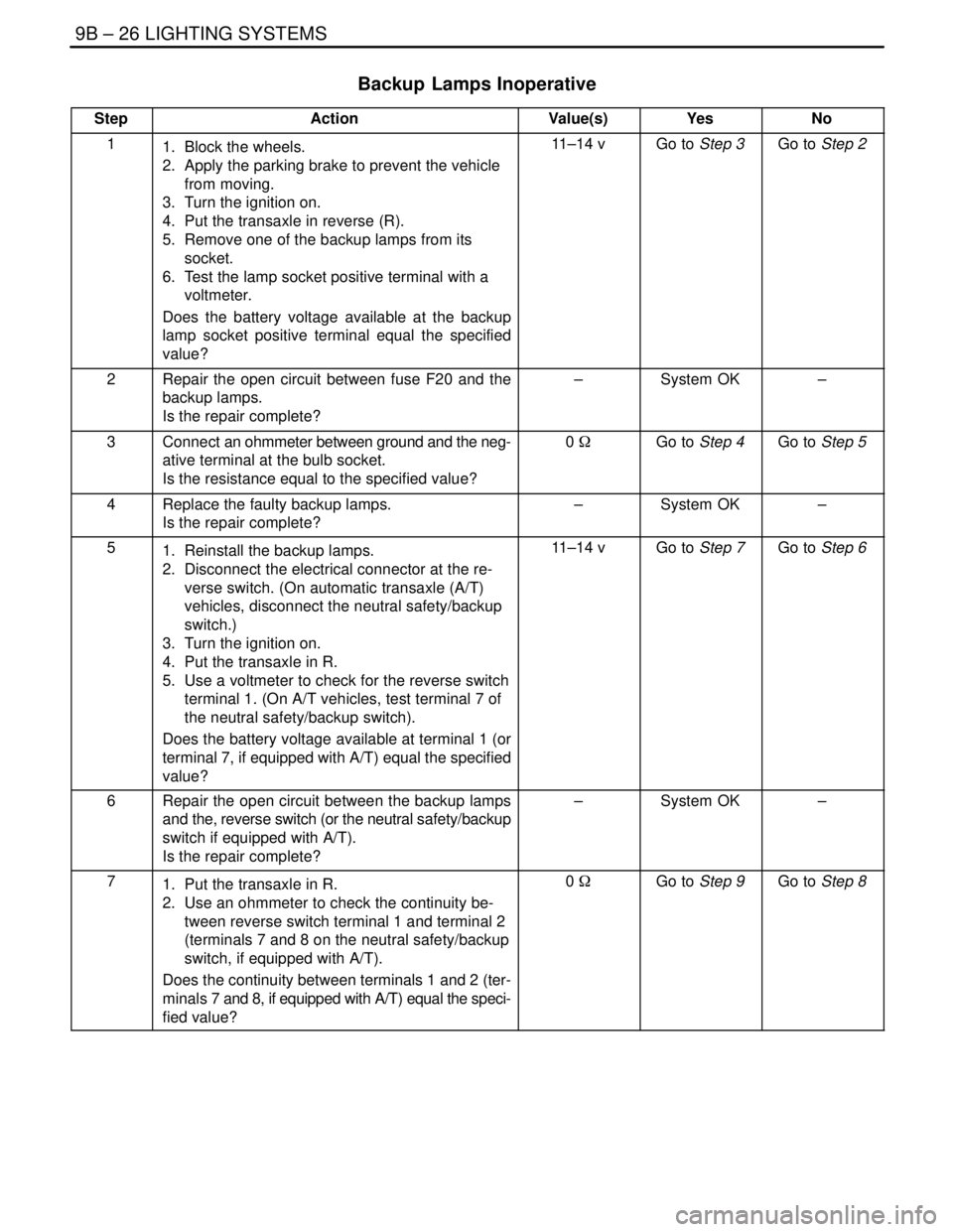

Backup Lamps Inoperative

StepActionValue(s)YesNo

11. Block the wheels.

2. Apply the parking brake to prevent the vehicle

from moving.

3. Turn the ignition on.

4. Put the transaxle in reverse (R).

5. Remove one of the backup lamps from its

socket.

6. Test the lamp socket positive terminal with a

voltmeter.

Does the battery voltage available at the backup

lamp socket positive terminal equal the specified

value?11–14 vGo to Step 3Go to Step 2

2Repair the open circuit between fuse F20 and the

backup lamps.

Is the repair complete?–System OK–

3Connect an ohmmeter between ground and the neg-

ative terminal at the bulb socket.

Is the resistance equal to the specified value?0 WGo to Step 4Go to Step 5

4Replace the faulty backup lamps.

Is the repair complete?–System OK–

51. Reinstall the backup lamps.

2. Disconnect the electrical connector at the re-

verse switch. (On automatic transaxle (A/T)

vehicles, disconnect the neutral safety/backup

switch.)

3. Turn the ignition on.

4. Put the transaxle in R.

5. Use a voltmeter to check for the reverse switch

terminal 1. (On A/T vehicles, test terminal 7 of

the neutral safety/backup switch).

Does the battery voltage available at terminal 1 (or

terminal 7, if equipped with A/T) equal the specified

value?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between the backup lamps

and the, reverse switch (or the neutral safety/backup

switch if equipped with A/T).

Is the repair complete?–System OK–

71. Put the transaxle in R.

2. Use an ohmmeter to check the continuity be-

tween reverse switch terminal 1 and terminal 2

(terminals 7 and 8 on the neutral safety/backup

switch, if equipped with A/T).

Does the continuity between terminals 1 and 2 (ter-

minals 7 and 8, if equipped with A/T) equal the speci-

fied value?0 WGo to Step 9Go to Step 8

Page 2272 of 2643

9B – 46ILITHING SYSTEMS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

HEADLAMPS–ON REMINDER CHIME

When the headlamp switch is in the headlamps–on or

parking lamps–on position, voltage is applied to the chime

module. When the ignition is in ON, ACC or START, volt-

age is applied through the fuse block to the module. These

two voltages are sensed, and the chime module is not

sounded.

When the ignition is not in ON, ACC or START, the module

loses voltage. The chime module senses change. If the

voltage is still available, it is applied to sound the chime.

The chime can be turned off by turning the headlamp

switch off. The module no longer senses voltage from the

headlamp switch, so the chime module does not sound.

HEADLAMPS

The headlamps are controlled by the multifunction lever

located on the left side of the steering column. They will

come on with the ignition switch in any position. Turning

the headlamp switch to the first position turns on the park-

ing lamps, the license plate lamps and the instrument pan-

el illumination. Turning the switch to the second position

turns on all of the previous lamps and the headlamps.

Turning the switch to the OFF position turns off all the

lamps.

Headlamp high beams and low beams are also controlled

by this lever. When the headlamps are on, pushing the le-

ver away from the driver until the switch clicks changes the

lamp from low beam to high beam. An indicator lamp on

the instrument cluster assembly will come on when the

high beam headlamps are on. To return the headlamps to

low beam, pull the lever toward the driver.

The headlamps must be aimed for proper illumination of

the road. Headlamp aim should be checked whenever a

new headlamp assembly is installed, or whenever service

repairs to the front end area may have disturbed the head-

lamp assembly or its mountings.

DAYTIME RUNNING LAMPS

The Daytime Running Lamps (DRL) will come on when:

S The ignition is ON.

S The light is OFF.

S The parking brake is released.

When the exterior lights are on, the DRL will turn off. To

turn the DRL off when idling, apply the parking brake.

PARKING AND TURN SIGNAL LAMPS

The parking lamps can be turned on by turning the lighting

switch to the first position. The parking lamps can be

turned off by turning the switch to the OFF position.When the turn signals are activated, the front and rear turn

signal lamps flash to signal a turn. The turn signals work

only when the ignition is ON.

The turn signals are controlled by the light switch on the

left side of the steering column. Moving the lever all the

way up or down (past the detent) will turn on the front and

rear turn signals. When the turn is completed, the lever will

return to horizontal and the turn signals will stop flashing.

For changing lanes, or for shallow turns in which the steer-

ing wheel does not turn far enough to cancel the signal,

move the signal lever only to the first detent and hold it

there. When the lever is released, it will return to horizontal

and the turn signals will cancel.

FOG LAMPS

The fog lamp switch is on the instrument panel to the right

of the steering column. To use the fog lamps, first turn on

the headlamps or the parking lamps. Then push the fog

lamp switch. The indicator light in the switch will illuminate

to indicate that the fog lamps are on. Push the switch again

to turn off the fog lamps. The indicator light will then go off.

The fog lamps should not be used as a substitute for the

headlamps.

The fog lamps must be aimed for proper illumination of the

road. Fog lamp aim should be checked when a new bulb

is installed or if service or repairs in the front end area may

have disturbed the fog lamp mountings.

REAR COMBINATION LAMPS

The taillamps, stoplamps, turn signal lamps and backup

lamp are one assembly.

Turning on either the headlamps or the parking lamps will

also turn on the taillamps. When the brake pedal is

pushed, the taillamps will glow brighter to serve as sto-

plamps.

The center high–mounted stoplamp is located in the rear

window and will come on when the brake pedal is pressed.

LICENSE PLATE LAMP

The license plate lamps will come on when the headlamps

or the parking lamps are on. The license plate lamps are

mounted above the license plate.

INTERIOR COURTESY LAMP

The courtesy lamp is located on the headliner just behind

the front seats. The lamp switch has three positions. If the

switch is left in the center position, the lamp will go on

whenever a door is opened and go off when it is closed.

In the ON position, the lamp will stay on until it is turned off.

In the OFF position, the lamp will not come on, even when

a door is opened.

LUGGAGE COMPARTMENT LAMP

The luggage compartment lamp is located under the deck

lid sill plate on the notchback. The lamp is located on the

left–side wheelhouse trim panel on the hatchback. It will

come on whenever the luggage compartment is opened.

Page 2274 of 2643

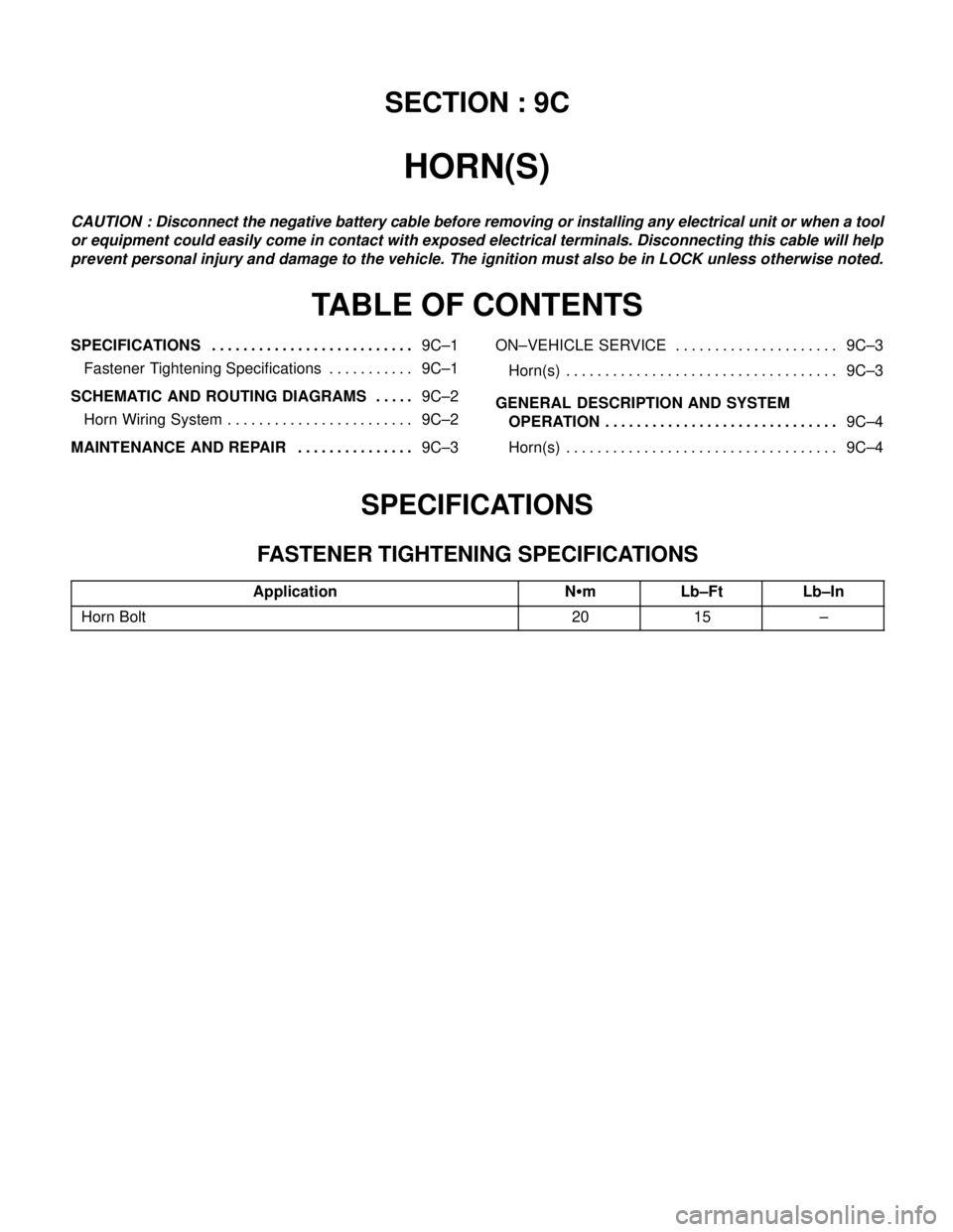

SECTION : 9C

HORN(S)

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9C–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9C–2 . . . . .

Horn Wiring System 9C–2. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9C–3 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9C–3. . . . . . . . . . . . . . . . . . . . .

Horn(s) 9C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9C–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn(s) 9C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Horn Bolt2015–

Page 2278 of 2643

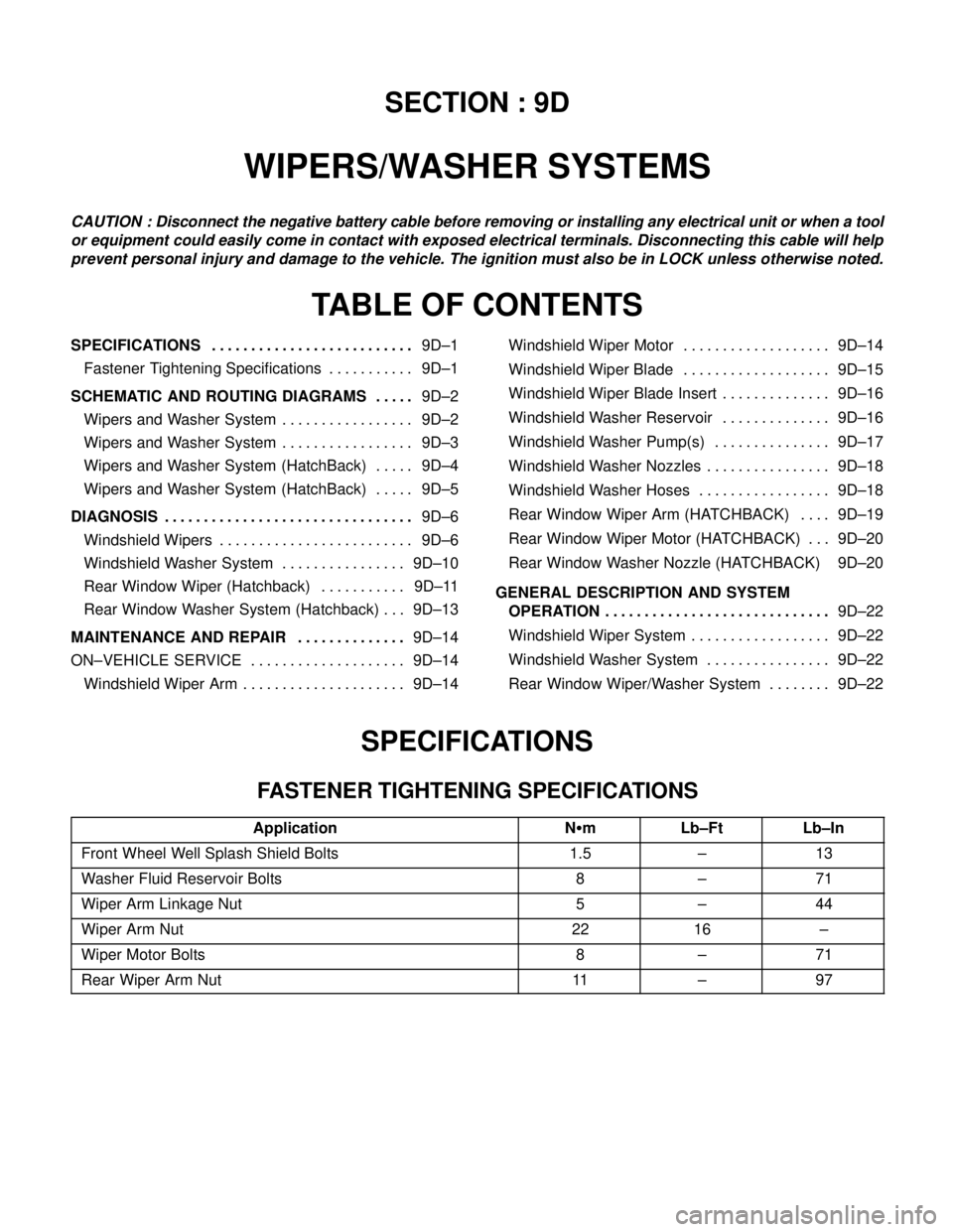

SECTION : 9D

WIPERS/WASHER SYSTEMS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9D–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9D–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9D–2 . . . . .

Wipers and Washer System 9D–2. . . . . . . . . . . . . . . . .

Wipers and Washer System 9D–3. . . . . . . . . . . . . . . . .

Wipers and Washer System (HatchBack) 9D–4. . . . .

Wipers and Washer System (HatchBack) 9D–5. . . . .

DIAGNOSIS9D–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wipers 9D–6. . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–10. . . . . . . . . . . . . . . .

Rear Window Wiper (Hatchback) 9D–11. . . . . . . . . . .

Rear Window Washer System (Hatchback) 9D–13. . .

MAINTENANCE AND REPAIR9D–14 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9D–14. . . . . . . . . . . . . . . . . . . .

Windshield Wiper Arm 9D–14. . . . . . . . . . . . . . . . . . . . . Windshield Wiper Motor 9D–14. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade 9D–15. . . . . . . . . . . . . . . . . . .

Windshield Wiper Blade Insert 9D–16. . . . . . . . . . . . . .

Windshield Washer Reservoir 9D–16. . . . . . . . . . . . . .

Windshield Washer Pump(s) 9D–17. . . . . . . . . . . . . . .

Windshield Washer Nozzles 9D–18. . . . . . . . . . . . . . . .

Windshield Washer Hoses 9D–18. . . . . . . . . . . . . . . . .

Rear Window Wiper Arm (HATCHBACK) 9D–19. . . .

Rear Window Wiper Motor (HATCHBACK) 9D–20. . .

Rear Window Washer Nozzle (HATCHBACK) 9D–20

GENERAL DESCRIPTION AND SYSTEM

OPERATION9D–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windshield Wiper System 9D–22. . . . . . . . . . . . . . . . . .

Windshield Washer System 9D–22. . . . . . . . . . . . . . . .

Rear Window Wiper/Washer System 9D–22. . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Front Wheel Well Splash Shield Bolts1.5–13

Washer Fluid Reservoir Bolts8–71

Wiper Arm Linkage Nut5–44

Wiper Arm Nut2216–

Wiper Motor Bolts8–71

Rear Wiper Arm Nut11–97

Page 2300 of 2643

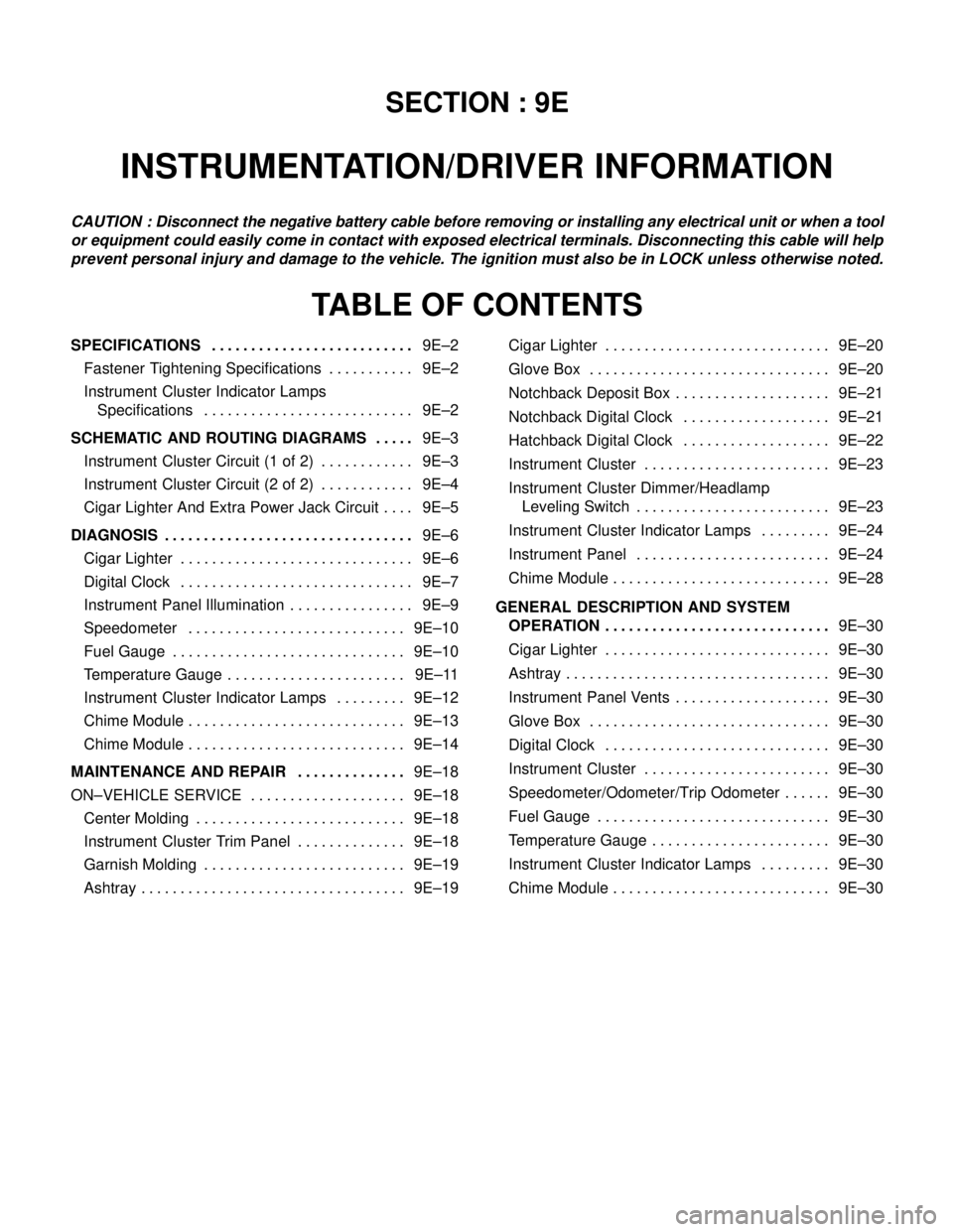

SECTION : 9E

INSTRUMENTATION/DRIVER INFORMATION

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9E–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9E–2. . . . . . . . . . .

Instrument Cluster Indicator Lamps

Specifications 9E–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9E–3 . . . . .

Instrument Cluster Circuit (1 of 2) 9E–3. . . . . . . . . . . .

Instrument Cluster Circuit (2 of 2) 9E–4. . . . . . . . . . . .

Cigar Lighter And Extra Power Jack Circuit 9E–5. . . .

DIAGNOSIS9E–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Illumination 9E–9. . . . . . . . . . . . . . . .

Speedometer 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge 9E–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–11. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–12. . . . . . . . .

Chime Module 9E–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9E–18 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9E–18. . . . . . . . . . . . . . . . . . . .

Center Molding 9E–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Trim Panel 9E–18. . . . . . . . . . . . . .

Garnish Molding 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cigar Lighter 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glove Box 9E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notchback Deposit Box 9E–21. . . . . . . . . . . . . . . . . . . .

Notchback Digital Clock 9E–21. . . . . . . . . . . . . . . . . . .

Hatchback Digital Clock 9E–22. . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–23. . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Dimmer/Headlamp

Leveling Switch 9E–23. . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–24. . . . . . . . .

Instrument Panel 9E–24. . . . . . . . . . . . . . . . . . . . . . . . .

Chime Module 9E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9E–30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cigar Lighter 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ashtray 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Vents 9E–30. . . . . . . . . . . . . . . . . . . .

Glove Box 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Clock 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster 9E–30. . . . . . . . . . . . . . . . . . . . . . . .

Speedometer/Odometer/Trip Odometer 9E–30. . . . . .

Fuel Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Gauge 9E–30. . . . . . . . . . . . . . . . . . . . . . .

Instrument Cluster Indicator Lamps 9E–30. . . . . . . . .

Chime Module 9E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2301 of 2643

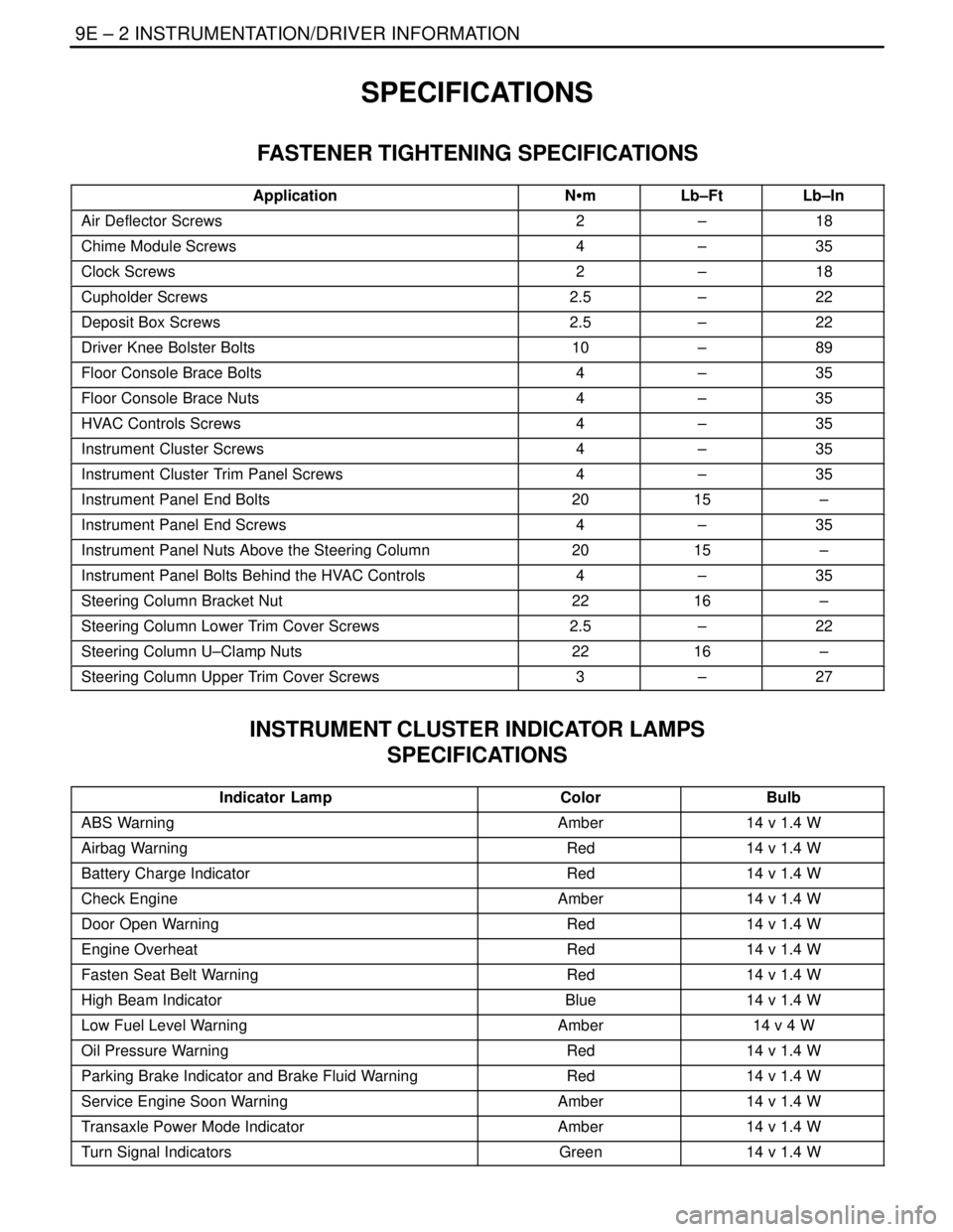

9E – 2IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Air Deflector Screws2–18

Chime Module Screws4–35

Clock Screws2–18

Cupholder Screws2.5–22

Deposit Box Screws2.5–22

Driver Knee Bolster Bolts10–89

Floor Console Brace Bolts4–35

Floor Console Brace Nuts4–35

HVAC Controls Screws4–35

Instrument Cluster Screws4–35

Instrument Cluster Trim Panel Screws4–35

Instrument Panel End Bolts2015–

Instrument Panel End Screws4–35

Instrument Panel Nuts Above the Steering Column2015–

Instrument Panel Bolts Behind the HVAC Controls4–35

Steering Column Bracket Nut2216–

Steering Column Lower Trim Cover Screws2.5–22

Steering Column U–Clamp Nuts2216–

Steering Column Upper Trim Cover Screws3–27

INSTRUMENT CLUSTER INDICATOR LAMPS

SPECIFICATIONS

Indicator LampColorBulb

ABS WarningAmber14 v 1.4 W

Airbag WarningRed14 v 1.4 W

Battery Charge IndicatorRed14 v 1.4 W

Check EngineAmber14 v 1.4 W

Door Open WarningRed14 v 1.4 W

Engine OverheatRed14 v 1.4 W

Fasten Seat Belt WarningRed14 v 1.4 W

High Beam IndicatorBlue14 v 1.4 W

Low Fuel Level WarningAmber14 v 4 W

Oil Pressure WarningRed14 v 1.4 W

Parking Brake Indicator and Brake Fluid WarningRed14 v 1.4 W

Service Engine Soon WarningAmber14 v 1.4 W

Transaxle Power Mode IndicatorAmber14 v 1.4 W

Turn Signal IndicatorsGreen14 v 1.4 W

Page 2306 of 2643

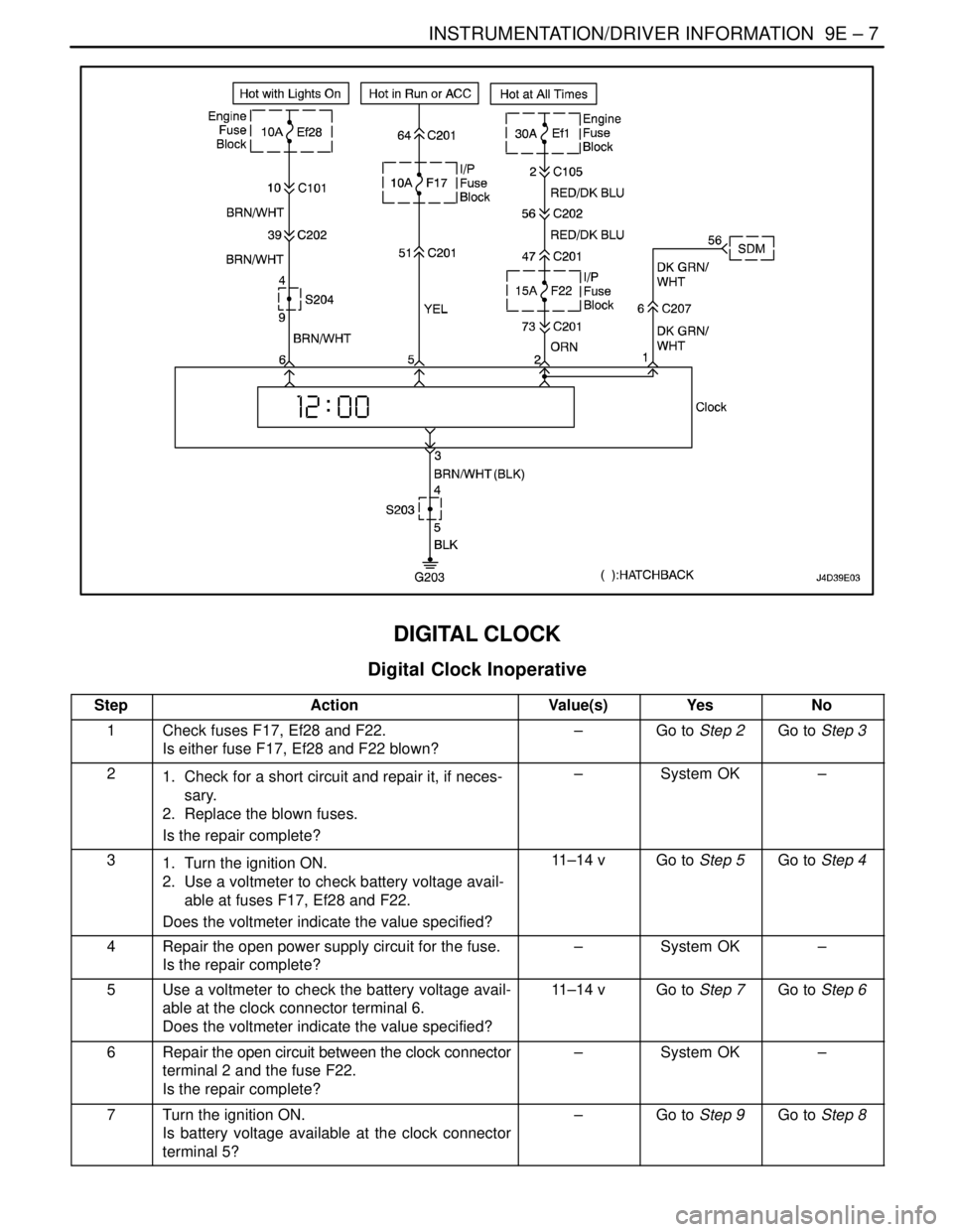

INSTRUMENTATION/DRIVER INFORMATION 9E – 7

DAEWOO V–121 BL4

DIGITAL CLOCK

Digital Clock Inoperative

StepActionValue(s)YesNo

1Check fuses F17, Ef28 and F22.

Is either fuse F17, Ef28 and F22 blown?–Go to Step 2Go to Step 3

21. Check for a short circuit and repair it, if neces-

sary.

2. Replace the blown fuses.

Is the repair complete?–System OK–

31. Turn the ignition ON.

2. Use a voltmeter to check battery voltage avail-

able at fuses F17, Ef28 and F22.

Does the voltmeter indicate the value specified?11–14 vGo to Step 5Go to Step 4

4Repair the open power supply circuit for the fuse.

Is the repair complete?–System OK–

5Use a voltmeter to check the battery voltage avail-

able at the clock connector terminal 6.

Does the voltmeter indicate the value specified?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between the clock connector

terminal 2 and the fuse F22.

Is the repair complete?–System OK–

7Turn the ignition ON.

Is battery voltage available at the clock connector

terminal 5?–Go to Step 9Go to Step 8

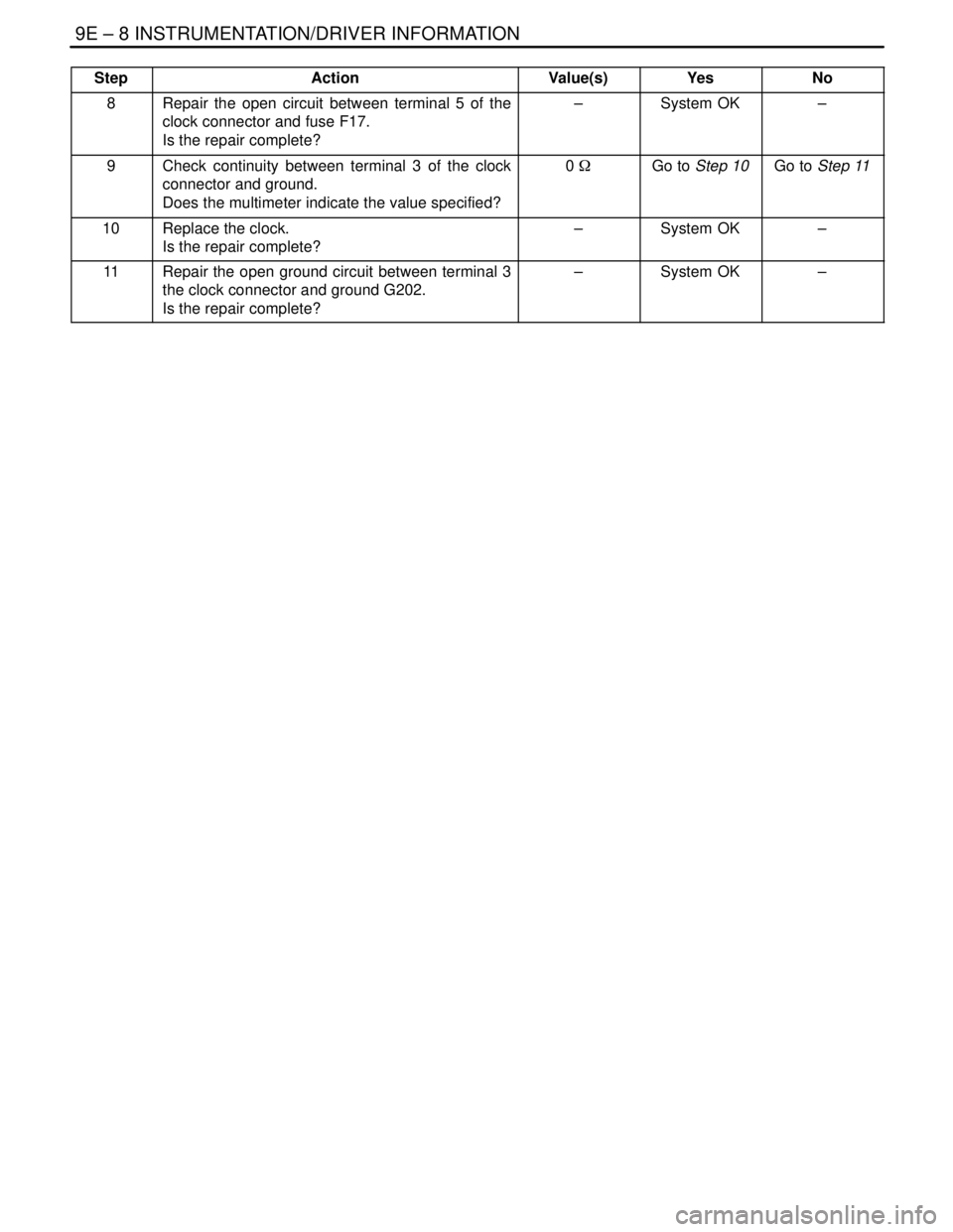

Page 2307 of 2643

9E – 8IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

8Repair the open circuit between terminal 5 of the

clock connector and fuse F17.

Is the repair complete?–System OK–

9Check continuity between terminal 3 of the clock

connector and ground.

Does the multimeter indicate the value specified?0 WGo to Step 10Go to Step 11

10Replace the clock.

Is the repair complete?–System OK–

11Repair the open ground circuit between terminal 3

the clock connector and ground G202.

Is the repair complete?–System OK–

Page 2320 of 2643

INSTRUMENTATION/DRIVER INFORMATION 9E – 21

DAEWOO V–121 BL4

Installation Procedure

1. Install the glove box with the screws.

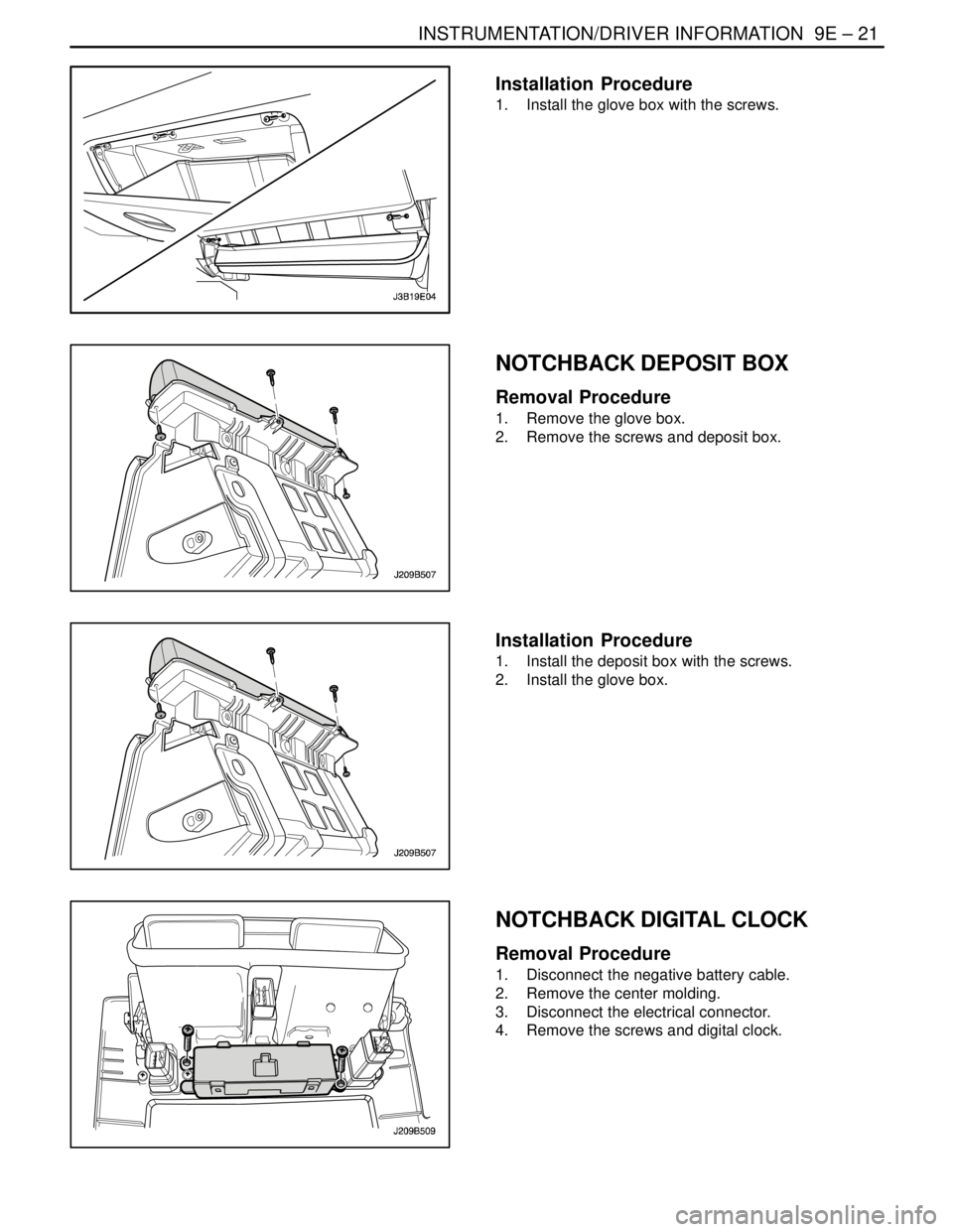

NOTCHBACK DEPOSIT BOX

Removal Procedure

1. Remove the glove box.

2. Remove the screws and deposit box.

Installation Procedure

1. Install the deposit box with the screws.

2. Install the glove box.

NOTCHBACK DIGITAL CLOCK

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the center molding.

3. Disconnect the electrical connector.

4. Remove the screws and digital clock.

Page 2321 of 2643

9E – 22IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

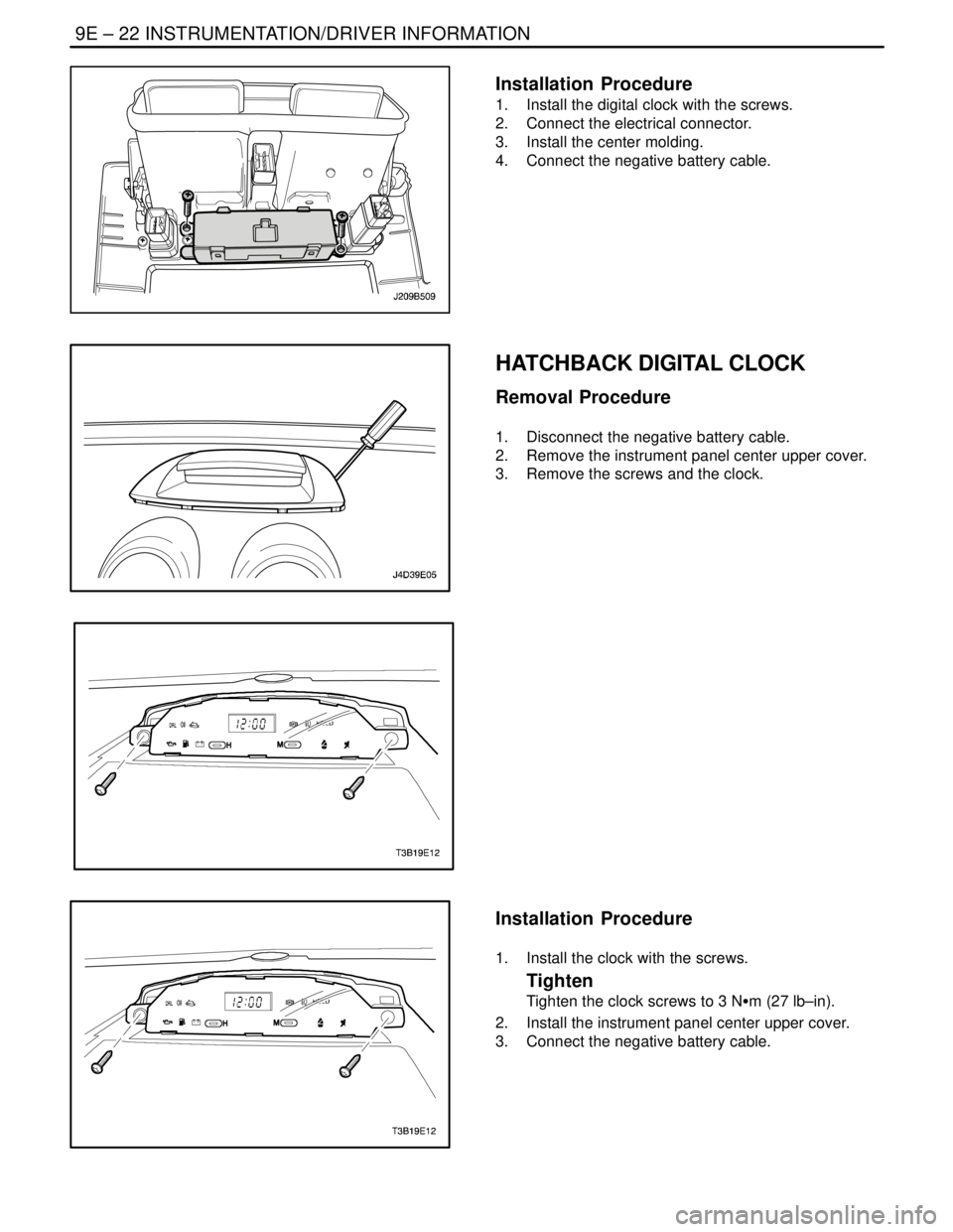

Installation Procedure

1. Install the digital clock with the screws.

2. Connect the electrical connector.

3. Install the center molding.

4. Connect the negative battery cable.

HATCHBACK DIGITAL CLOCK

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel center upper cover.

3. Remove the screws and the clock.

Installation Procedure

1. Install the clock with the screws.

Tighten

Tighten the clock screws to 3 NSm (27 lb–in).

2. Install the instrument panel center upper cover.

3. Connect the negative battery cable.