lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2445 of 2643

DOORS 9P – 25

DAEWOO V–121 BL4

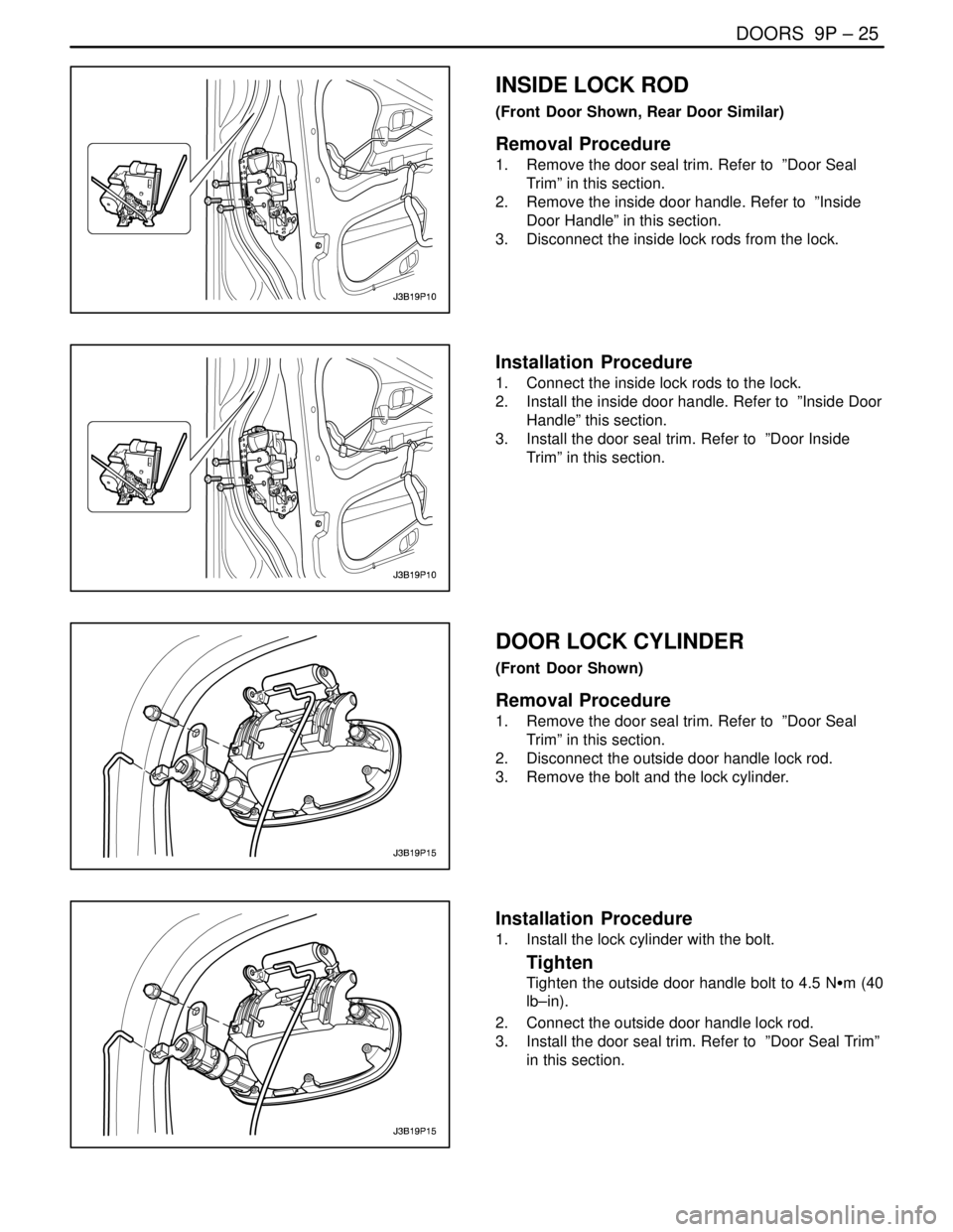

INSIDE LOCK ROD

(Front Door Shown, Rear Door Similar)

Removal Procedure

1. Remove the door seal trim. Refer to ”Door Seal

Trim” in this section.

2. Remove the inside door handle. Refer to ”Inside

Door Handle” in this section.

3. Disconnect the inside lock rods from the lock.

Installation Procedure

1. Connect the inside lock rods to the lock.

2. Install the inside door handle. Refer to ”Inside Door

Handle” this section.

3. Install the door seal trim. Refer to ”Door Inside

Trim” in this section.

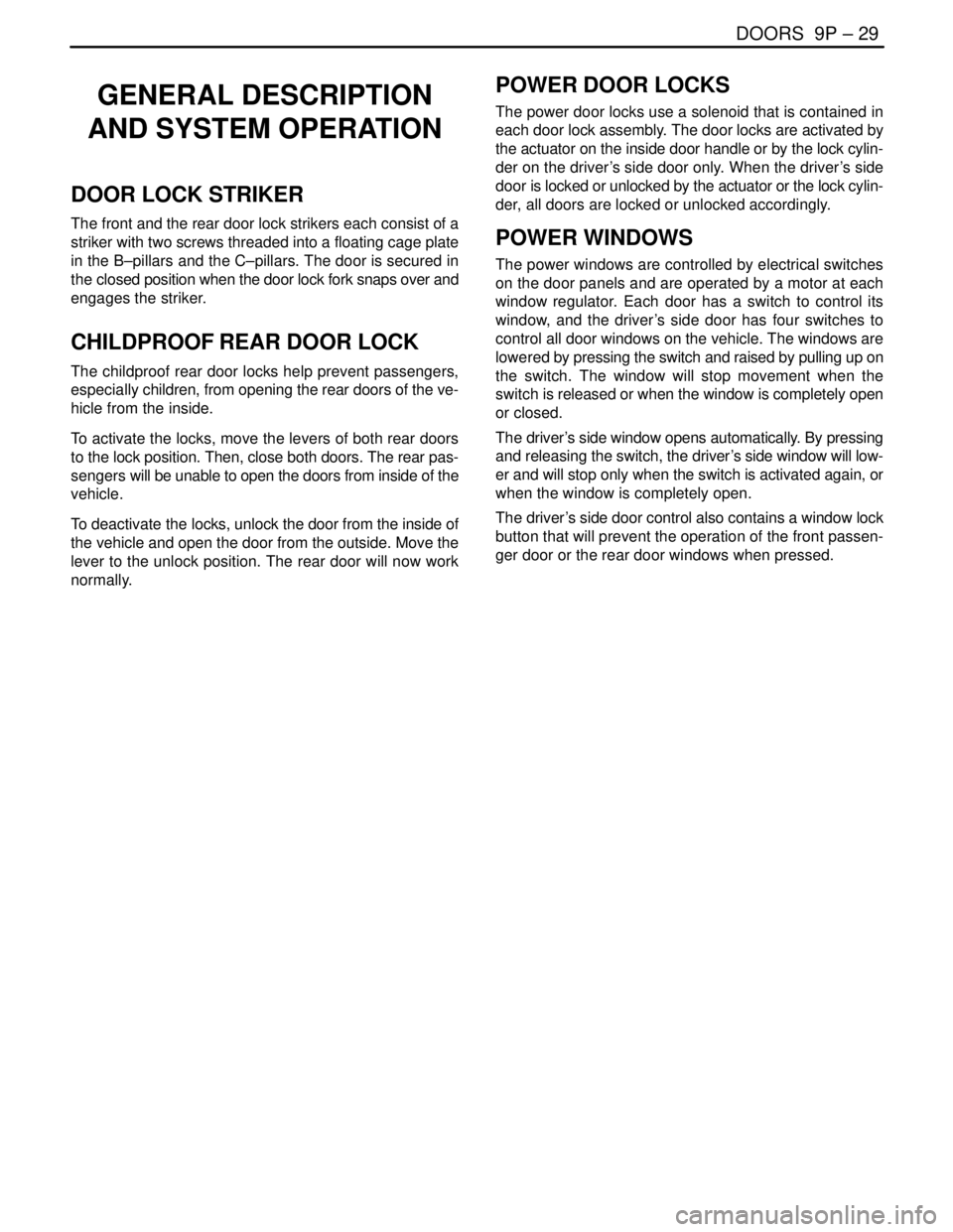

DOOR LOCK CYLINDER

(Front Door Shown)

Removal Procedure

1. Remove the door seal trim. Refer to ”Door Seal

Trim” in this section.

2. Disconnect the outside door handle lock rod.

3. Remove the bolt and the lock cylinder.

Installation Procedure

1. Install the lock cylinder with the bolt.

Tighten

Tighten the outside door handle bolt to 4.5 NSm (40

lb–in).

2. Connect the outside door handle lock rod.

3. Install the door seal trim. Refer to ”Door Seal Trim”

in this section.

Page 2449 of 2643

DOORS 9P – 29

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DOOR LOCK STRIKER

The front and the rear door lock strikers each consist of a

striker with two screws threaded into a floating cage plate

in the B–pillars and the C–pillars. The door is secured in

the closed position when the door lock fork snaps over and

engages the striker.

CHILDPROOF REAR DOOR LOCK

The childproof rear door locks help prevent passengers,

especially children, from opening the rear doors of the ve-

hicle from the inside.

To activate the locks, move the levers of both rear doors

to the lock position. Then, close both doors. The rear pas-

sengers will be unable to open the doors from inside of the

vehicle.

To deactivate the locks, unlock the door from the inside of

the vehicle and open the door from the outside. Move the

lever to the unlock position. The rear door will now work

normally.

POWER DOOR LOCKS

The power door locks use a solenoid that is contained in

each door lock assembly. The door locks are activated by

the actuator on the inside door handle or by the lock cylin-

der on the driver’s side door only. When the driver’s side

door is locked or unlocked by the actuator or the lock cylin-

der, all doors are locked or unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical switches

on the door panels and are operated by a motor at each

window regulator. Each door has a switch to control its

window, and the driver’s side door has four switches to

control all door windows on the vehicle. The windows are

lowered by pressing the switch and raised by pulling up on

the switch. The window will stop movement when the

switch is released or when the window is completely open

or closed.

The driver’s side window opens automatically. By pressing

and releasing the switch, the driver ’s side window will low-

er and will stop only when the switch is activated again, or

when the window is completely open.

The driver’s side door control also contains a window lock

button that will prevent the operation of the front passen-

ger door or the rear door windows when pressed.

Page 2450 of 2643

SECTION : 9Q

ROOF

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9Q–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9Q–2. . . . . . . . . . .

SPECIAL TOOLS9Q–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 9Q–2. . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9Q–3 . . . . .

Power Sunroof System 9Q–3. . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS9Q–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Sunroof 9Q–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9Q–6 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9Q–6. . . . . . . . . . . . . . . . . . . . .

Power Sunroof 9Q–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sun Shade 9Q–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sunroof Glass 9Q–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formed Headliner 9Q–8. . . . . . . . . . . . . . . . . . . . . . . . .

Sun Visors with Vanity Mirror 9Q–10. . . . . . . . . . . . . . .

Passenger Assist Handles 9Q–10. . . . . . . . . . . . . . . . .

Power Sunroof Control Switch 9Q–11. . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9Q–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roof 9Q–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Sunroof/Sunroof Control Switch 9Q–12. . . . . .

Sun Visors with Vanity Mirror 9Q–12. . . . . . . . . . . . . . .

Passenger Assist Handles 9Q–12. . . . . . . . . . . . . . . . .

Coat Hooks 9Q–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2461 of 2643

9Q – 12IROOF

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

ROOF

The roof is a one–piece painted metal unit which incorpo-

rates a single solid headliner. There are two moldings, one

per side on the vehicle’s roof, which enclose and hide the

roof rail seams. The roof moldings are serviceable as indi-

vidual units.

The one–piece formed headliner consists of a molded

substrate covered with a foam–backed cloth facing. The

one–piece construction requires that the headliner be ser-

viced as a complete assembly.

POWER SUNROOF/SUNROOF

CONTROL SWITCH

The sunroof has the following characteristics:

S Intended to provide light and air through the roof

the vehicle.

S Built into the roof.

S Made of glass.

S Equipped with a sunshade that opens and closes

manually.

S Powered by an electric motor.

S Controlled by a toggle switch built into the interior

courtesy lamp assembly.

The sunroof control switch is a toggle button located on the

right side of the interior courtesy lamp assembly.

To operate the sunroof, the ignition must be ON.Tilting the Sunroof, Open and Closed

To tilt open the rear end of the sunroof, press and hold the

forward portion of the toggle button until the sunroof tilts

open.

To close the sunroof from a tilted–open position, press and

hold the rear portion of the toggle button until the sunroof

tilts closed.

Sliding the Sunroof, Open and Closed

To slide open the sunroof, press the rear portion of the

toggle button until the sunroof slides. If the sun shade is

closed, the sunroof will pull the sunshade open when the

sunroof slides open.

To close the sunroof from a slid–open position, press the

forward portion of the toggle button until the sunroof slides

closed.

SUN VISORS WITH VANITY MIRROR

The sun visors swing down in order to block out glare.

They also swing to the side when they are released from

the support. To replace the vanity mirror lamp, refer to

Section 9B, Lighting Systems.

PASSENGER ASSIST HANDLES

There is a passenger assist handle for each rear outboard

seat and for the front passenger seat. Passengers can use

these handles to assist in keeping their balance over rough

roads or during sharp turns.

COAT HOOKS

The coat hooks are located on the left and the right rear

passenger assist handles.

Page 2463 of 2643

9R – 2IBODY FRONT END

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

LUBRICATION

The hood hinges and the locking mechanisms require pe-

riodic lubrication for proper operation. Refer to Section 0B,

General Information for the specific types and intervals of

lubrication.

FASTENERS

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

Many aluminum components are used on current models.

Aluminum in contact with steel may corrode rapidly if it is

not protected by special finishes or isolators.

The fasteners used have a special finish which provides

adequate protection from corrosion. These special fasten-

ers differ in color in order to easily identify them from the

standard metric fasteners, which are medium blue.

When replacing fasteners, avoid substituting otherwise

similar fasteners in the same location.

ANTICORROSION MATERIALS

In order to provide rust resistance, anticorrosion materials

have been applied to the interior surfaces of most of the

metal panels. When you service these panels, properly re-

coat them with a service–type anticorrosion material if any

of the original material has been disturbed.

FRONT END SEALING

All locations where waterleaks may occur are sealed dur-

ing production with high quality, durable sealers. If it be-

comes necessary to reseal specific areas, use a high–

quality sealer of medium–bodied consistency which will

retain its flexible characteristics after curing and can be

painted, if necessary.

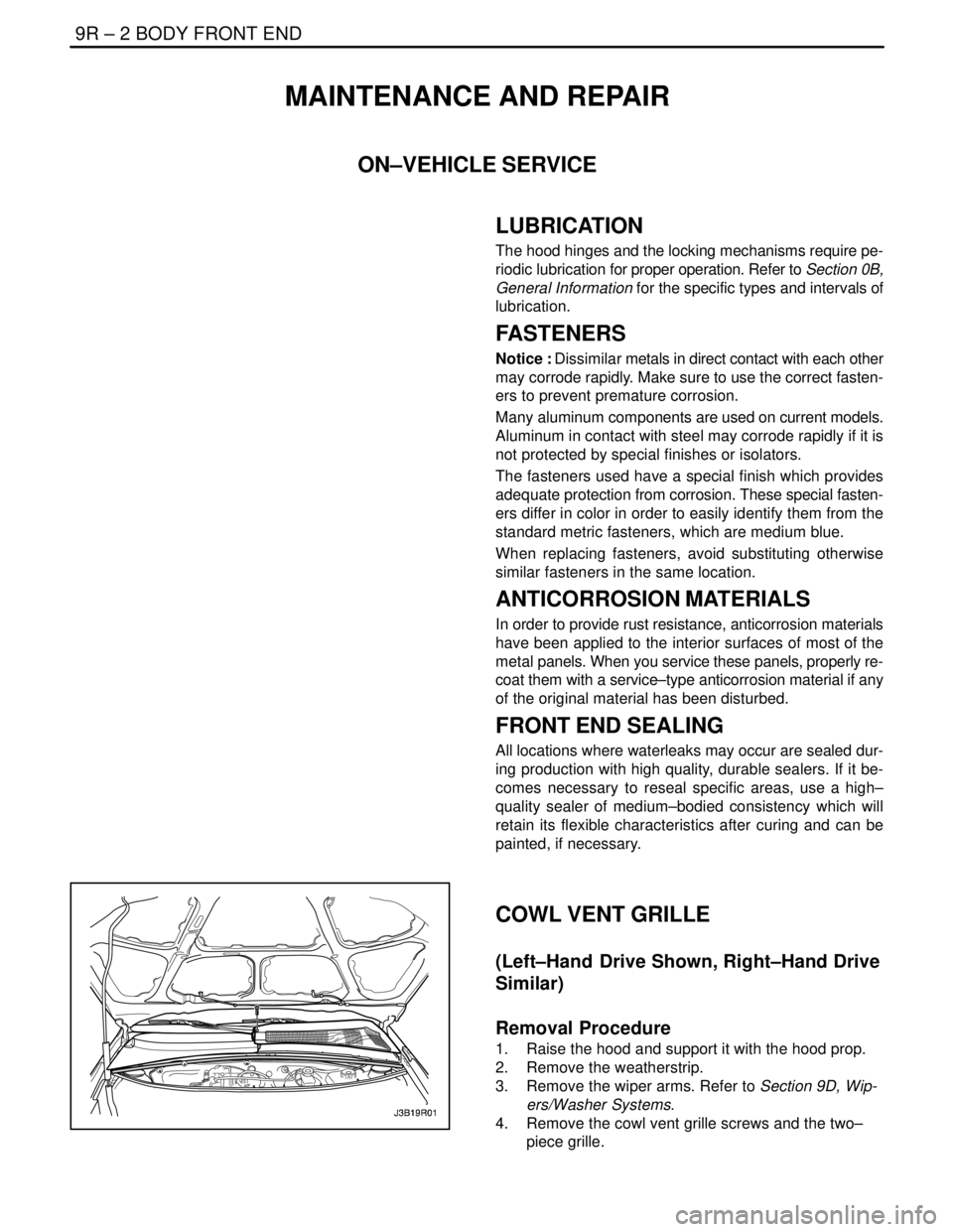

COWL VENT GRILLE

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Raise the hood and support it with the hood prop.

2. Remove the weatherstrip.

3. Remove the wiper arms. Refer to Section 9D, Wip-

ers/Washer Systems.

4. Remove the cowl vent grille screws and the two–

piece grille.

Page 2472 of 2643

SECTION : 9S

BODY REAR END

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9S–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9S–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9S–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9S–2. . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door Remote Handle and Cable 9S–2. . . .

Rear Deck Lid 9S–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid Torque Rods 9S–5. . . . . . . . . . . . . . . . .

Luggage Compartment Lock Cylinder 9S–5. . . . . . . .

Luggage Compartment Lock Striker 9S–6. . . . . . . . . .

Luggage Compartment Lock 9S–6. . . . . . . . . . . . . . . . Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . .

Hatchback Door 9S–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Support Assemblies 9S–8. . . . . . . . . . . . . . . . . . .

Hatchback Door Lock Striker 9S–9. . . . . . . . . . . . . . . .

Hatchback Door Lock 9S–9. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9S–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid (Notchback) 9S–10. . . . . . . . . . . . . . . .

Hatchback Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Fuel Filler Door Screws4–35

Fuel Filler Door Remote Cable Handle Cover Screw3–27

Fuel Filler Door Remote Cable Handle Screws10–89

Lower B–Pillar Seat Belt Anchor Bolt3828–

Luggage Compartment Lock Cylinder Nuts8–71

Luggage Compartment Lock Screws6–53

Luggage Compartment Lock Striker Bolts8–71

Rear Deck Lid Bolts10–89

Page 2476 of 2643

BODY REAR END 9S – 5

DAEWOO V–121 BL4

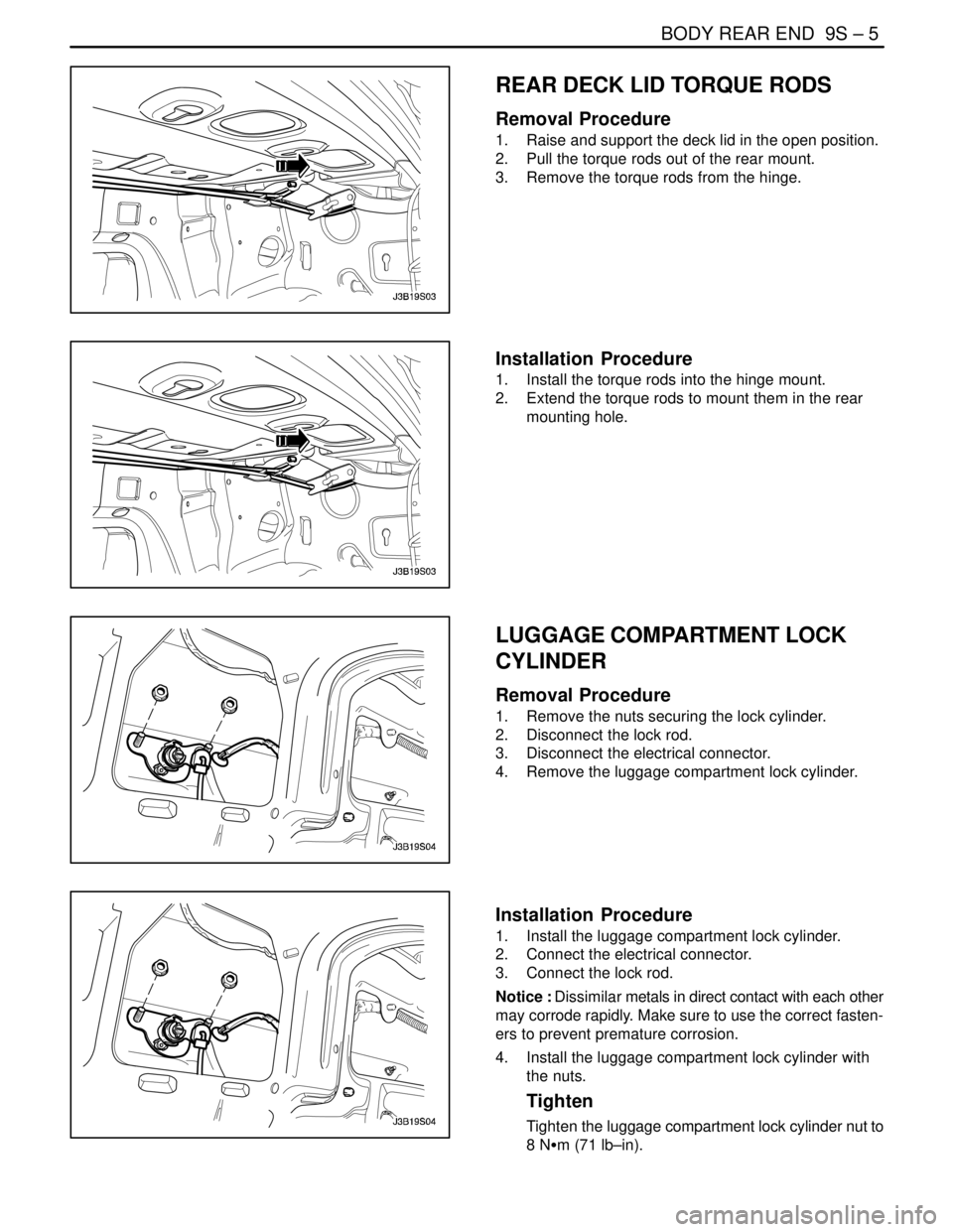

REAR DECK LID TORQUE RODS

Removal Procedure

1. Raise and support the deck lid in the open position.

2. Pull the torque rods out of the rear mount.

3. Remove the torque rods from the hinge.

Installation Procedure

1. Install the torque rods into the hinge mount.

2. Extend the torque rods to mount them in the rear

mounting hole.

LUGGAGE COMPARTMENT LOCK

CYLINDER

Removal Procedure

1. Remove the nuts securing the lock cylinder.

2. Disconnect the lock rod.

3. Disconnect the electrical connector.

4. Remove the luggage compartment lock cylinder.

Installation Procedure

1. Install the luggage compartment lock cylinder.

2. Connect the electrical connector.

3. Connect the lock rod.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

4. Install the luggage compartment lock cylinder with

the nuts.

Tighten

Tighten the luggage compartment lock cylinder nut to

8 NSm (71 lb–in).

Page 2477 of 2643

9S – 6IBODY REAR END

DAEWOO V–121 BL4

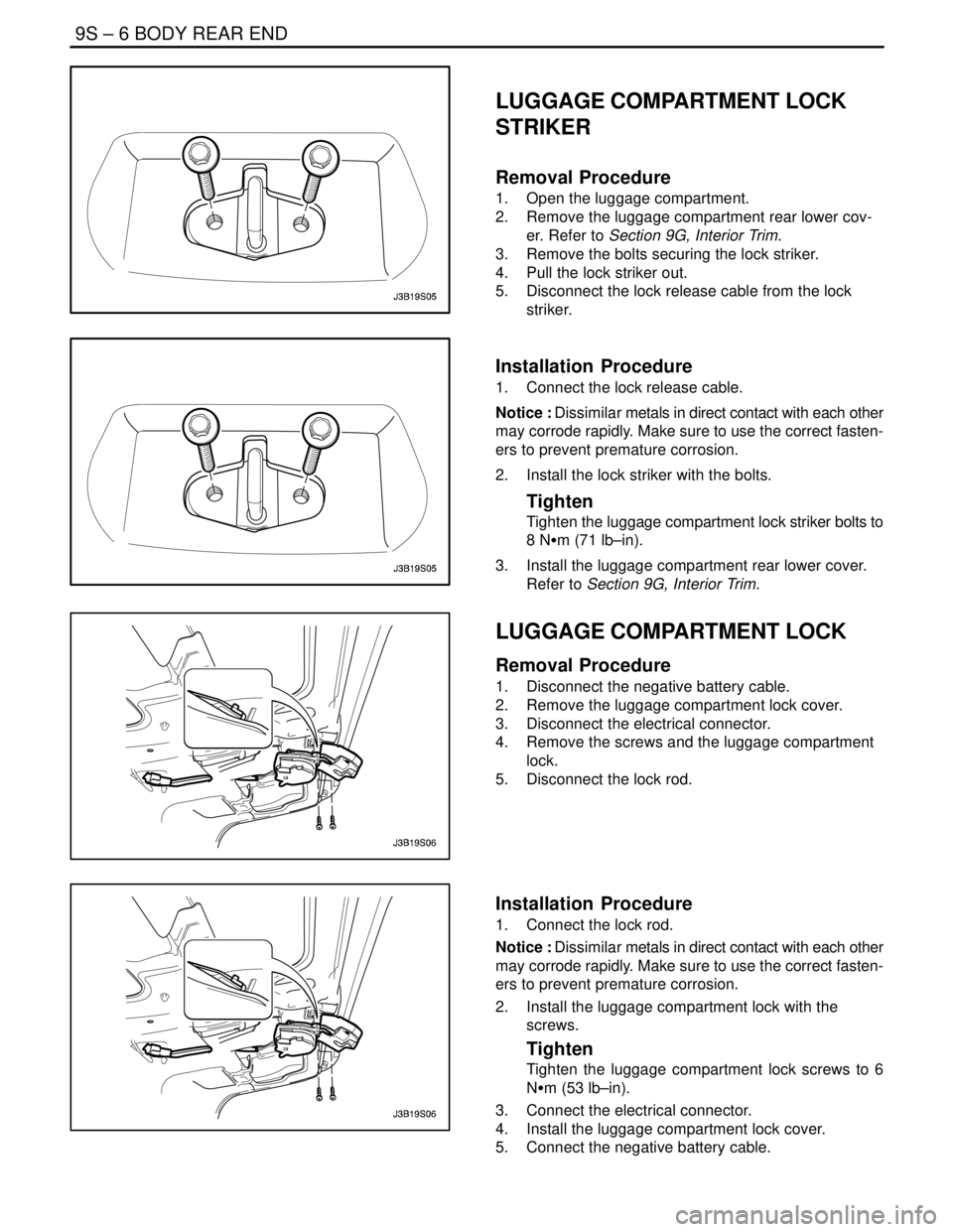

LUGGAGE COMPARTMENT LOCK

STRIKER

Removal Procedure

1. Open the luggage compartment.

2. Remove the luggage compartment rear lower cov-

er. Refer to Section 9G, Interior Trim.

3. Remove the bolts securing the lock striker.

4. Pull the lock striker out.

5. Disconnect the lock release cable from the lock

striker.

Installation Procedure

1. Connect the lock release cable.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the lock striker with the bolts.

Tighten

Tighten the luggage compartment lock striker bolts to

8 NSm (71 lb–in).

3. Install the luggage compartment rear lower cover.

Refer to Section 9G, Interior Trim.

LUGGAGE COMPARTMENT LOCK

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the luggage compartment lock cover.

3. Disconnect the electrical connector.

4. Remove the screws and the luggage compartment

lock.

5. Disconnect the lock rod.

Installation Procedure

1. Connect the lock rod.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the luggage compartment lock with the

screws.

Tighten

Tighten the luggage compartment lock screws to 6

NSm (53 lb–in).

3. Connect the electrical connector.

4. Install the luggage compartment lock cover.

5. Connect the negative battery cable.

Page 2480 of 2643

BODY REAR END 9S – 9

DAEWOO V–121 BL4

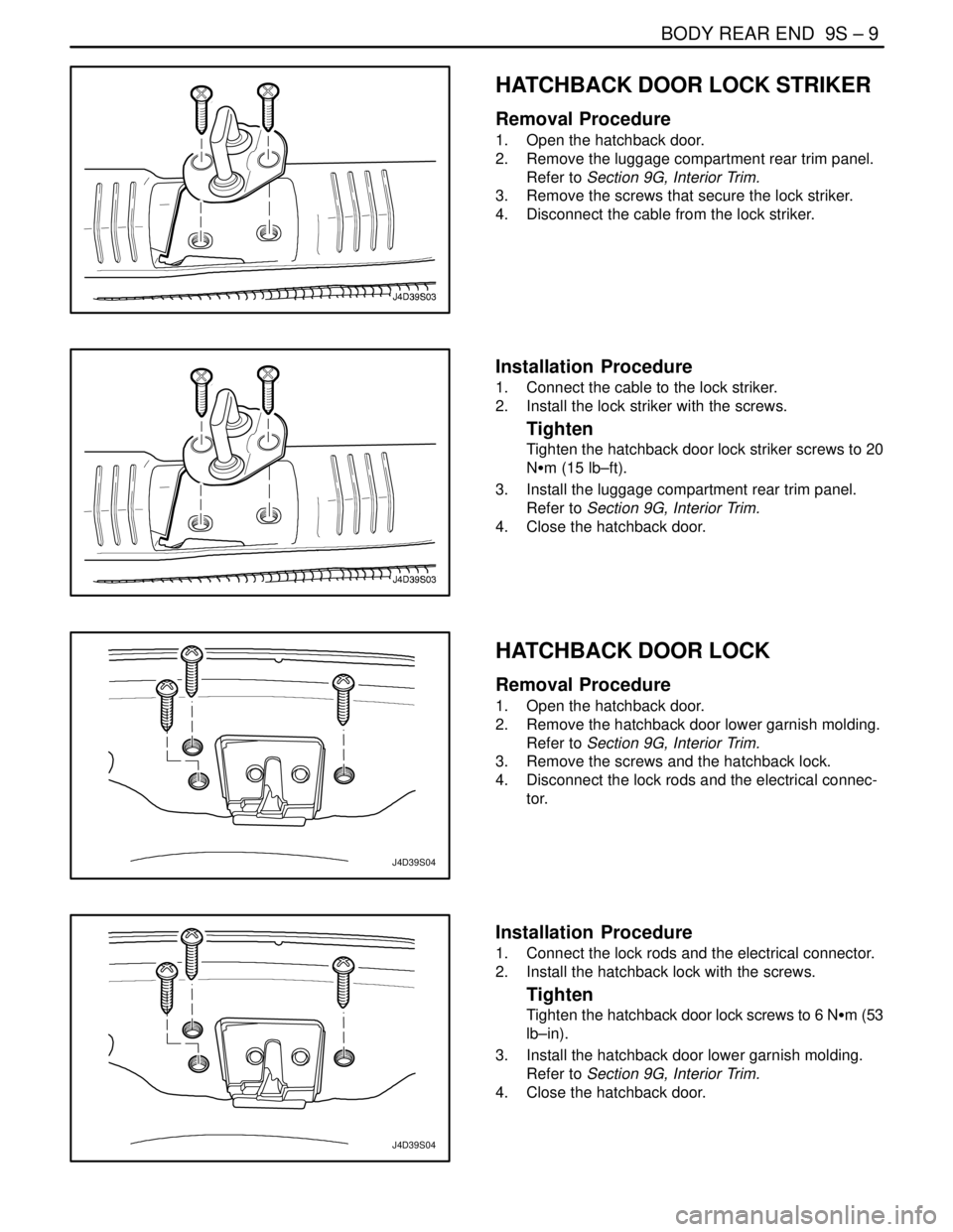

HATCHBACK DOOR LOCK STRIKER

Removal Procedure

1. Open the hatchback door.

2. Remove the luggage compartment rear trim panel.

Refer to Section 9G, Interior Trim.

3. Remove the screws that secure the lock striker.

4. Disconnect the cable from the lock striker.

Installation Procedure

1. Connect the cable to the lock striker.

2. Install the lock striker with the screws.

Tighten

Tighten the hatchback door lock striker screws to 20

NSm (15 lb–ft).

3. Install the luggage compartment rear trim panel.

Refer to Section 9G, Interior Trim.

4. Close the hatchback door.

J4D39S04

HATCHBACK DOOR LOCK

Removal Procedure

1. Open the hatchback door.

2. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

3. Remove the screws and the hatchback lock.

4. Disconnect the lock rods and the electrical connec-

tor.

J4D39S04

Installation Procedure

1. Connect the lock rods and the electrical connector.

2. Install the hatchback lock with the screws.

Tighten

Tighten the hatchback door lock screws to 6 NSm (53

lb–in).

3. Install the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Close the hatchback door.

Page 2482 of 2643

SECTION : 9T1

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9T1–1. . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9T1–2 . . . .

Notchback Remote Keyless Entry and Anti–Theft

System 9T1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Remote Keyless Entry and Anti–Theft

System 9T1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Module/Receiver Connector 9T1–4. . . . . . . . .

MAINTENANCE AND REPAIR9T1–5 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T1–5. . . . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–5. . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–5. . . . . . . . . . . . . . . . . . . . . . Remote Keyless Entry Transmitter

Programming 9T1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T1–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keyless Entry and Anti–Theft System 9T1–8

Remote Locking and Unlocking 9T1–8. . . . . . . . . . . . .

Security Indicator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Intrusion Sensing 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–8. . . . . . . . . . . . . . . . . . . . . .

Vehicle Locator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Autolocking (Safety Lock) 9T1–9. . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–9. . . . . . . . . . . . . . . . . . .

Fault or Alarm Indication 9T1–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Siren Braket Mounting Bolts.8–71