Vacuum DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 693 of 2643

ENGINE CONTROLS 1F – 447

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0325

KNOCK SENSOR INTERNAL MALFUNCTION

System Description

The Knock Sensor (KS) system is used to detect engine

detonation, allowing the Engine Control Module (ECM) to

retard the ignition control spark timing based on the KS

signal being received. The KS produces an AC signal so

that under a no–knock condition the signal on the KS cir-

cuit measures about 0.007 volts AC. The KS signal’s am-

plitude and frequency depend upon the amount of knock

being experienced. The ECM contains a nonreplaceable

knock filter module called a Digitally Controlled Signal–to–

Noise Enhancement Filter (DSNEF) module. This filter

module in the ECM determines whether or not knock is oc-

curring by comparing the signal level on the KS circuit with

the voltage level on the noise channel. The noise channel

allows the ECM to reject any false knock signal by knowing

the amount of normal engine mechanical noise present.

Normal engine noise varies depending on engine speed

and load. When the ECM determines that an abnormally

low noise channel voltage level is being experienced,

Diagnostic Trouble Code (DTC) P0325 will set.

Conditions for Setting the DTC

S DSNEF A/D reading is less than 1.0% or greater

than 80% any of the 4 cylinders.

S Vacuum is less than the predetermined value (10 to

50 kPa, based on rpm).

S The rpm is greater than 1600.

S DTC(s) P0106, P0107, P0108 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTCS A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check and correct any abnormal engine noise before us-

ing the diagnostic table.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. If the conditions for the test as described above are

met, a DTC P0325 will set and MIL will illuminate.

4. If the engine has an internal knock or audible noise

that causes a knocking type noise on the engine

block, the knock sensor may be responding to the

noise.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0325 – Knock Sensor Internal Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Clear the Diagnostic Trouble Codes (DTCs).

3. Start the engine.

4. Operate the vehicle within the Conditions for

Setting the DTC as noted.

Is the DTC set again.–Go to Step 3Go to Step 6

Page 695 of 2643

ENGINE CONTROLS 1F – 449

DAEWOO V–121 BL4

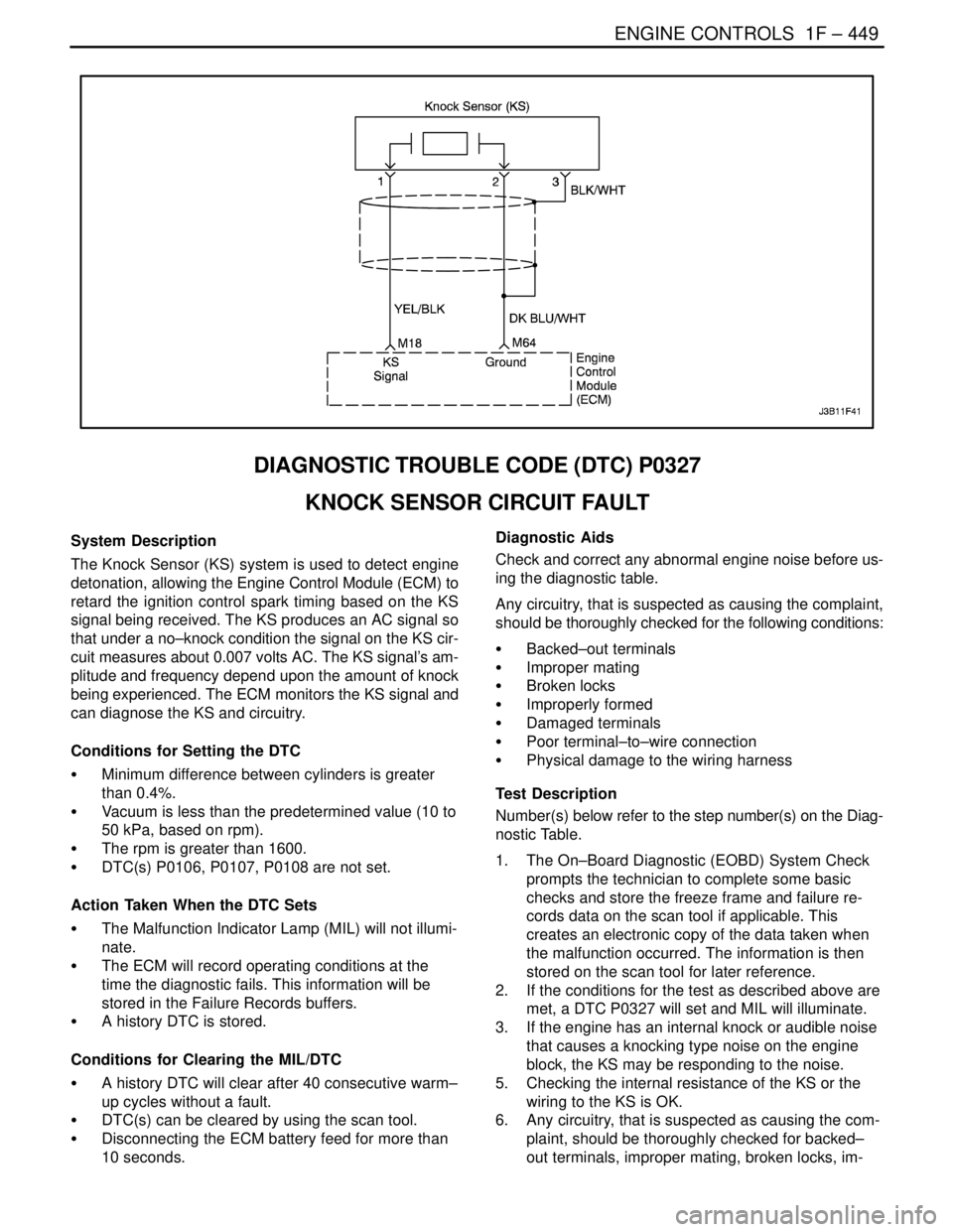

DIAGNOSTIC TROUBLE CODE (DTC) P0327

KNOCK SENSOR CIRCUIT FAULT

System Description

The Knock Sensor (KS) system is used to detect engine

detonation, allowing the Engine Control Module (ECM) to

retard the ignition control spark timing based on the KS

signal being received. The KS produces an AC signal so

that under a no–knock condition the signal on the KS cir-

cuit measures about 0.007 volts AC. The KS signal’s am-

plitude and frequency depend upon the amount of knock

being experienced. The ECM monitors the KS signal and

can diagnose the KS and circuitry.

Conditions for Setting the DTC

S Minimum difference between cylinders is greater

than 0.4%.

S Vacuum is less than the predetermined value (10 to

50 kPa, based on rpm).

S The rpm is greater than 1600.

S DTC(s) P0106, P0107, P0108 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.Diagnostic Aids

Check and correct any abnormal engine noise before us-

ing the diagnostic table.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. If the conditions for the test as described above are

met, a DTC P0327 will set and MIL will illuminate.

3. If the engine has an internal knock or audible noise

that causes a knocking type noise on the engine

block, the KS may be responding to the noise.

5. Checking the internal resistance of the KS or the

wiring to the KS is OK.

6. Any circuitry, that is suspected as causing the com-

plaint, should be thoroughly checked for backed–

out terminals, improper mating, broken locks, im-

Page 714 of 2643

1F – 468IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0401

EXHAUST GAS RECIRCULATION INSUFFICIENT FLOW

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position.

This diagnostic will determine if there is a reduction in EGR

flow.

Conditions for Setting the DTC

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0201, P0202, P0203, P0204,

P0351, P0352, P0402, P0404, P1404, P0405,

P0406 and P0502 are not set.

S Test in Decel Fuel Cutoff (DFCO) mode.

S Barometric Pressure (BARO) is greater than 72

kPa (10.4 psi).

S Vehicle speed is greater than 18 km/h (11.2

mph).

S A/C clutch/transmission clutch are unchanged.

S Rpm is between 1400 and 3000 for manual

transaxle.

S Rpm is between 1300 and 2900 for automatic

transaxle.

S Compensated MAP is with 10.3 to 32 kpa (1.5 to

4.6 psi) range.

S Start test

S Throttle position (TP) sensor is less then 1%.

S EGR is less than 1%.

S Change in MAP is less than 1.0 kpa (0.15 psi)Note : Test will be aborted when:

S Change in vehicle speed is greater than 5km/h (3.1

mph).

S Rpm is increased more than 75.

S EGR opened less than 90% commanded position.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored in the Freeze

Frame data.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

The EGR Decel Filter value can be a great aid in determin-

ing if a problem exists and to verify repairs. The EGR De-

cel Filter is an average of the difference in the expected

MAP change and the actual MAP change caused by open-

ing the EGR valve during a deceleration, and is used to de-

termine when the MIL is illuminated. By driving the vehicle

up to approximately 97 km/h (60 mph) and decelerating to

32 km/h (20 mph), it can be determined if the EGR system

is OK, partially restricted, or fully restricted.

A more negative number (less than –3) indicates that the

system is working normally, whereas a positive number in-

dicates that the system is being restricted and that the ex-

pected amount of EGR flow is was not seen. A number

that falls between negative 3 and positive 2 indicates that

the system is partially restricted but not restricted enough

to cause an emissions impact.

The EGR Decel Filter value should always be at –3 or low-

er. If the EGR Decel Filter number becomes more positive

(towards 0 or more), then the EGR system is becoming re-

stricted. Look for possible damage to the EGR pipe or for

a restriction caused by carbon deposits in the EGR pas-

sages or on the EGR valve.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

Page 716 of 2643

1F – 470IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0402

EXHAUST GAS RECIRCULATION EXCESSIVE FLOW

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position.

This Diagnostic Trouble Code (DTC) will detect an EGR

open to a large valve during crank. Crank time may be ex-

cessive with an open EGR valve.Conditions for Setting the DTC

S EGR position is greater than 70% for more than 3

seconds during cranking.

S Engine cranking (not running).

S Ignition voltage is between 10 and 16 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S The MIL will turns off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watching

the Actual EGR and Desired EGR Positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the freeze frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

Page 720 of 2643

1F – 474IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0404

EXHAUST GAS RECIRCULATION OPEN VALVE POSITION

ERROR

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position.

This Diagnostic Trouble Code (DTC) will detect an open

valve position.

Conditions for Setting the DTCS Difference between current and commended posi-

tion is greater than 15%.

S Desired EGR position is greater than 0.

S Change in Desired EGR is less than 3%.

S Engine is running.

S Ignition voltage is between 11.7 and 16 volts.

S Air temperature is greater than 3°C.

S DTCs P0112, P0113 P0405, P0406, and P0502 are

not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate, after three concecutive ignition cycle with a

fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S The MIL will turns off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watching

Page 724 of 2643

1F – 478IENGINE CONTROLS

DAEWOO V–121 BL4

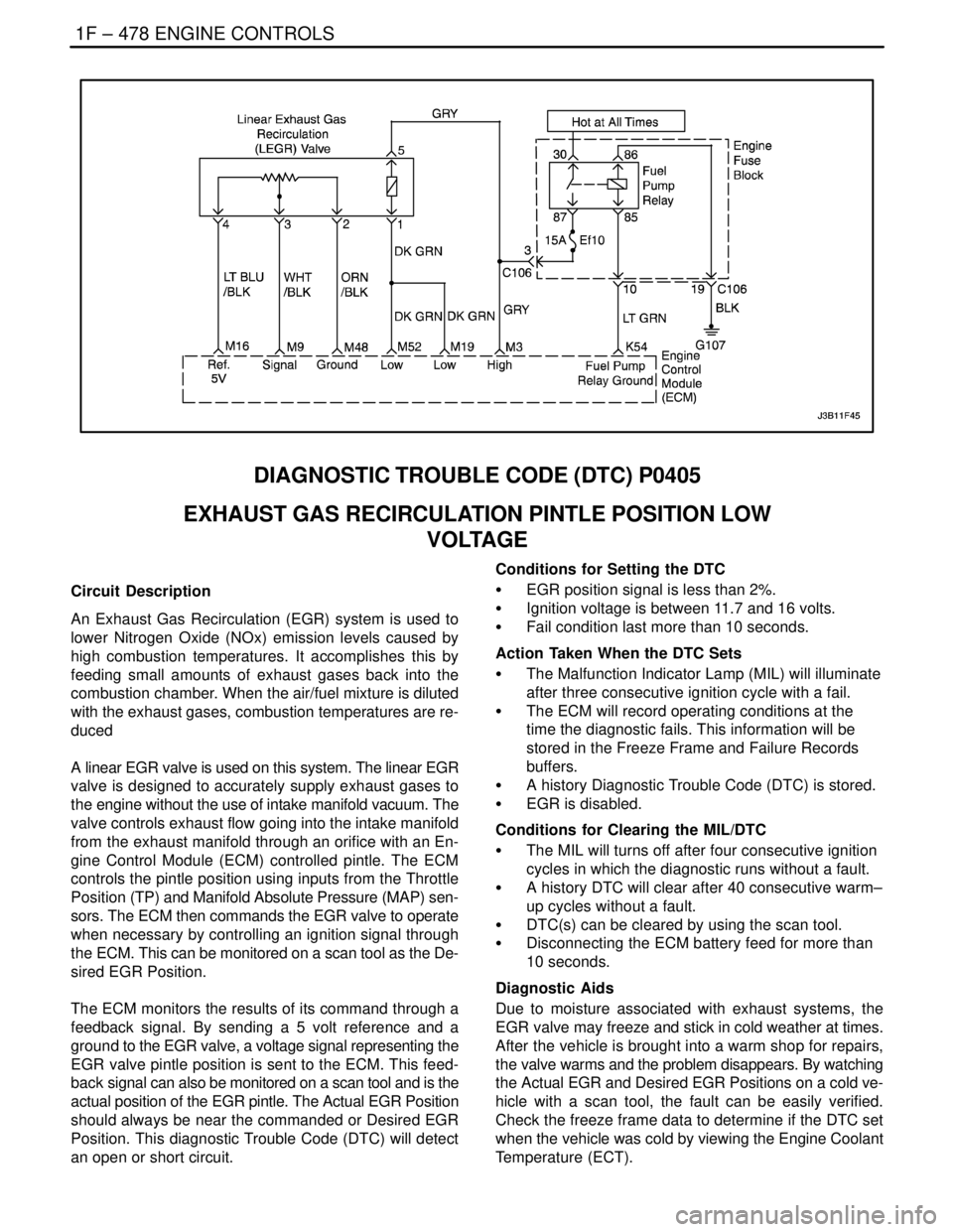

DIAGNOSTIC TROUBLE CODE (DTC) P0405

EXHAUST GAS RECIRCULATION PINTLE POSITION LOW

VOLTAGE

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position. This diagnostic Trouble Code (DTC) will detect

an open or short circuit.Conditions for Setting the DTC

S EGR position signal is less than 2%.

S Ignition voltage is between 11.7 and 16 volts.

S Fail condition last more than 10 seconds.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S The MIL will turns off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watching

the Actual EGR and Desired EGR Positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the freeze frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

Page 727 of 2643

ENGINE CONTROLS 1F – 481

DAEWOO V–121 BL4

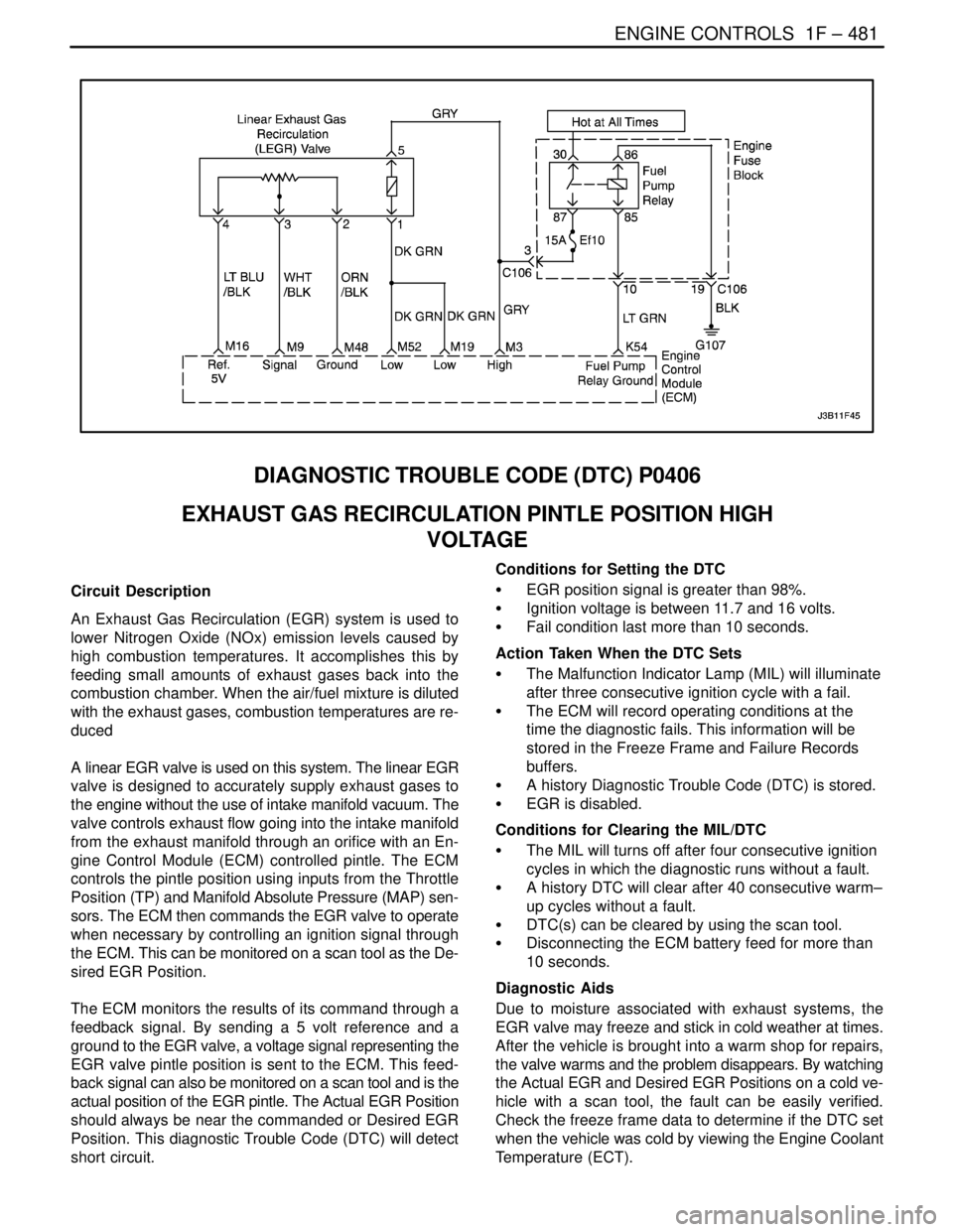

DIAGNOSTIC TROUBLE CODE (DTC) P0406

EXHAUST GAS RECIRCULATION PINTLE POSITION HIGH

VOLTAGE

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position. This diagnostic Trouble Code (DTC) will detect

short circuit.Conditions for Setting the DTC

S EGR position signal is greater than 98%.

S Ignition voltage is between 11.7 and 16 volts.

S Fail condition last more than 10 seconds.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S The MIL will turns off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watching

the Actual EGR and Desired EGR Positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the freeze frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

Page 768 of 2643

1F – 522IENGINE CONTROLS

DAEWOO V–121 BL4

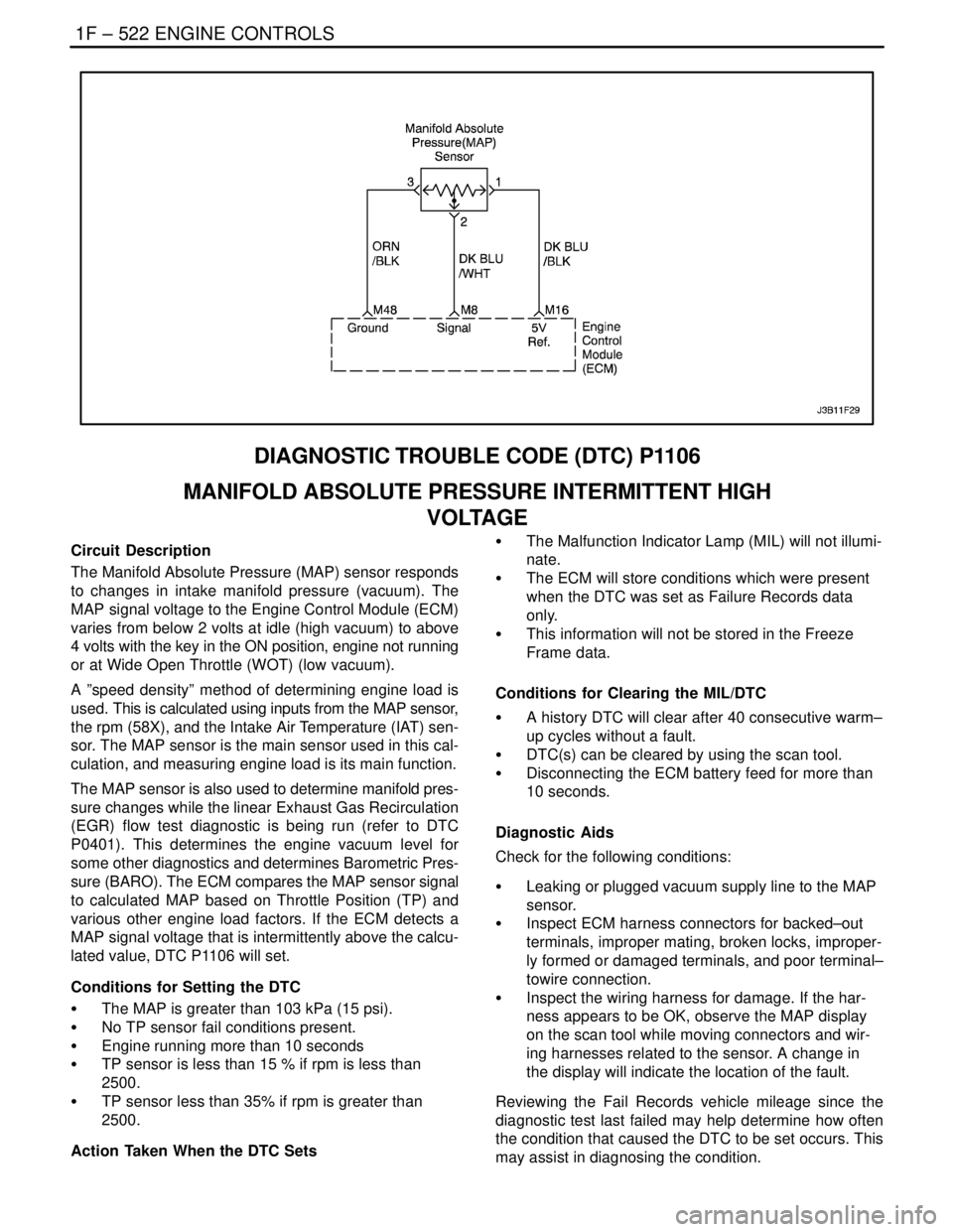

DIAGNOSTIC TROUBLE CODE (DTC) P1106

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT HIGH

VOLTAGE

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently above the calcu-

lated value, DTC P1106 will set.

Conditions for Setting the DTC

S The MAP is greater than 103 kPa (15 psi).

S No TP sensor fail conditions present.

S Engine running more than 10 seconds

S TP sensor is less than 15 % if rpm is less than

2500.

S TP sensor less than 35% if rpm is greater than

2500.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

towire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 770 of 2643

1F – 524IENGINE CONTROLS

DAEWOO V–121 BL4

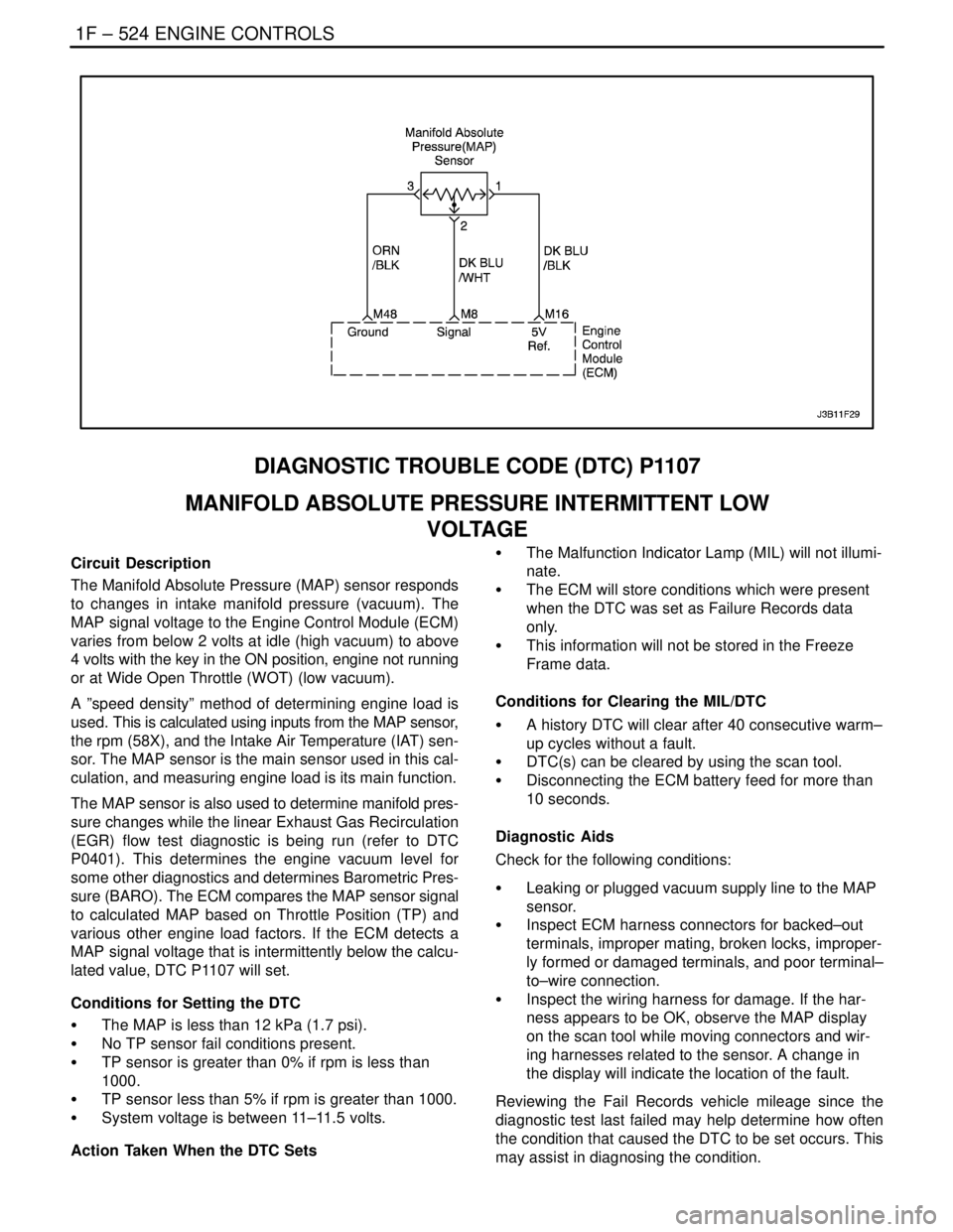

DIAGNOSTIC TROUBLE CODE (DTC) P1107

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT LOW

VOLTAGE

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently below the calcu-

lated value, DTC P1107 will set.

Conditions for Setting the DTC

S The MAP is less than 12 kPa (1.7 psi).

S No TP sensor fail conditions present.

S TP sensor is greater than 0% if rpm is less than

1000.

S TP sensor less than 5% if rpm is greater than 1000.

S System voltage is between 11–11.5 volts.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

to–wire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 786 of 2643

1F – 540IENGINE CONTROLS

DAEWOO V–121 BL4

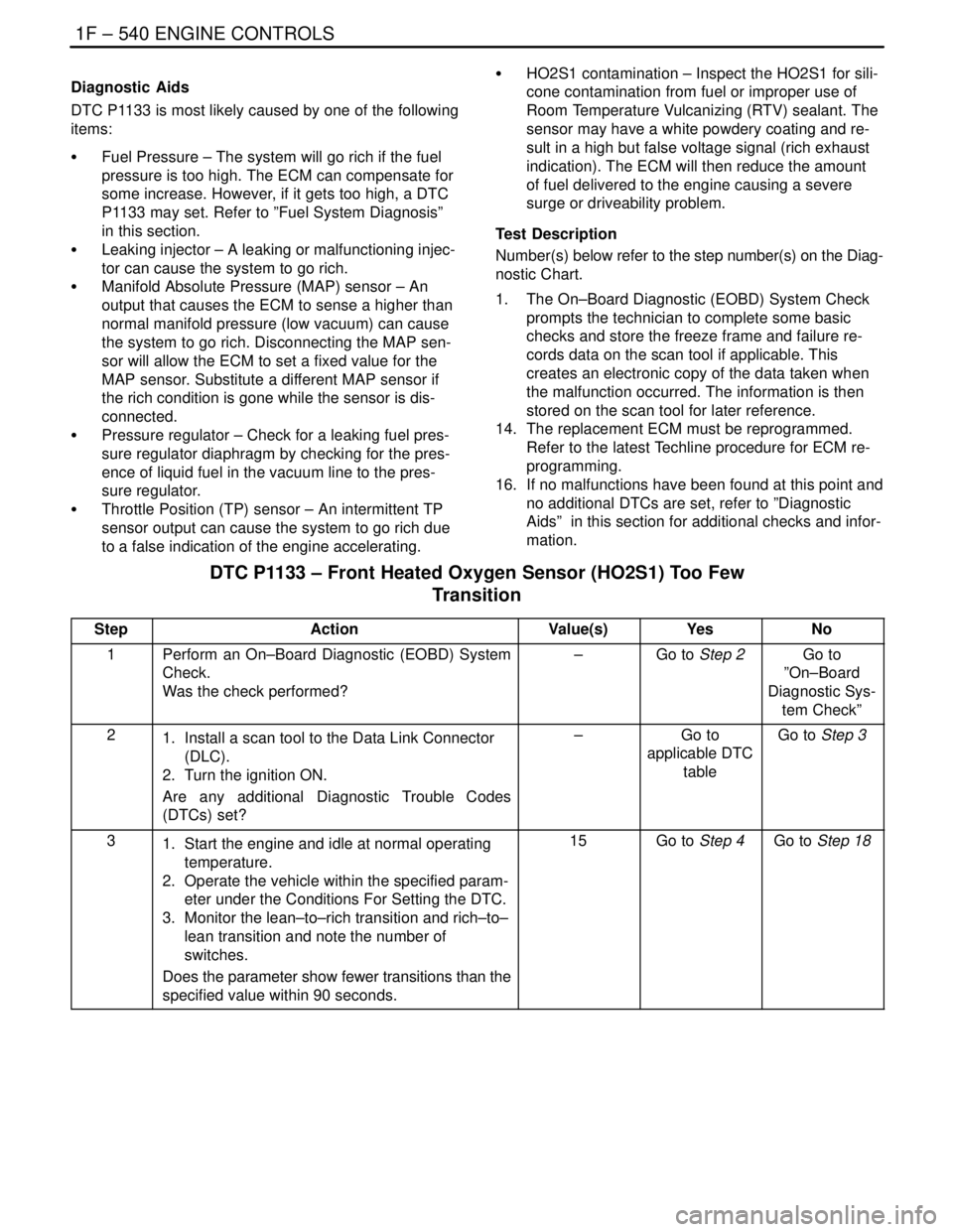

Diagnostic Aids

DTC P1133 is most likely caused by one of the following

items:

S Fuel Pressure – The system will go rich if the fuel

pressure is too high. The ECM can compensate for

some increase. However, if it gets too high, a DTC

P1133 may set. Refer to ”Fuel System Diagnosis”

in this section.

S Leaking injector – A leaking or malfunctioning injec-

tor can cause the system to go rich.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a higher than

normal manifold pressure (low vacuum) can cause

the system to go rich. Disconnecting the MAP sen-

sor will allow the ECM to set a fixed value for the

MAP sensor. Substitute a different MAP sensor if

the rich condition is gone while the sensor is dis-

connected.

S Pressure regulator – Check for a leaking fuel pres-

sure regulator diaphragm by checking for the pres-

ence of liquid fuel in the vacuum line to the pres-

sure regulator.

S Throttle Position (TP) sensor – An intermittent TP

sensor output can cause the system to go rich due

to a false indication of the engine accelerating.S HO2S1 contamination – Inspect the HO2S1 for sili-

cone contamination from fuel or improper use of

Room Temperature Vulcanizing (RTV) sealant. The

sensor may have a white powdery coating and re-

sult in a high but false voltage signal (rich exhaust

indication). The ECM will then reduce the amount

of fuel delivered to the engine causing a severe

surge or driveability problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Chart.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

14. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

16. If no malfunctions have been found at this point and

no additional DTCs are set, refer to ”Diagnostic

Aids” in this section for additional checks and infor-

mation.

DTC P1133 – Front Heated Oxygen Sensor (HO2S1) Too Few

Transition

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any additional Diagnostic Trouble Codes

(DTCs) set?–Go to

applicable DTC

tableGo to Step 3

31. Start the engine and idle at normal operating

temperature.

2. Operate the vehicle within the specified param-

eter under the Conditions For Setting the DTC.

3. Monitor the lean–to–rich transition and rich–to–

lean transition and note the number of

switches.

Does the parameter show fewer transitions than the

specified value within 90 seconds.15Go to Step 4Go to Step 18