Vacuum DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 625 of 2643

ENGINE CONTROLS 1F – 379

DAEWOO V–121 BL4

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

DTC P0133 or slow response is most likely caused by one

of the following items:

S Fuel pressure – The system will go rich if fuel pres-

sure is too high. The ECM can compensate for

some increase, but if it gets too high, a DTC P0133

may set. Refer to”Fuel System Diagnosis” in this

section.

S Leaking injector – A leaking or malfunctioning injec-

tor can cause the system to go rich.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a higher than

normal manifold pressure (low vacuum) can cause

the system to go rich. Disconnecting the MAP sen-

sor will allow the ECM to set a fixed value for the

MAP sensor. Substitute a different MAP sensor if

the rich condition is gone while the sensor is dis-

connected.S Pressure regulator – Check for a leaking fuel pres-

sure regulator diaphragm by checking for the pres-

ence of liquid fuel in the vacuum line to the pres-

sure regulator.

S Throttle Position (TP) sensor – An intermittent TP

sensor output can cause the system to go rich due

to a false indication of the engine accelerating.

S HO2S1 contamination – Inspect HO2S1 for silicone

contamination from fuel or use of improper room

temperature vulcanizing (RTV) sealant. The sensor

may have a white powdery coating, resulting in a

high but false voltage signal (rich exhaust indica-

tion). The ECM will then reduce the amount of fuel

delivered to the engine causing a severe surge or

driveability problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

14. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

17. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” for additional checks and information.

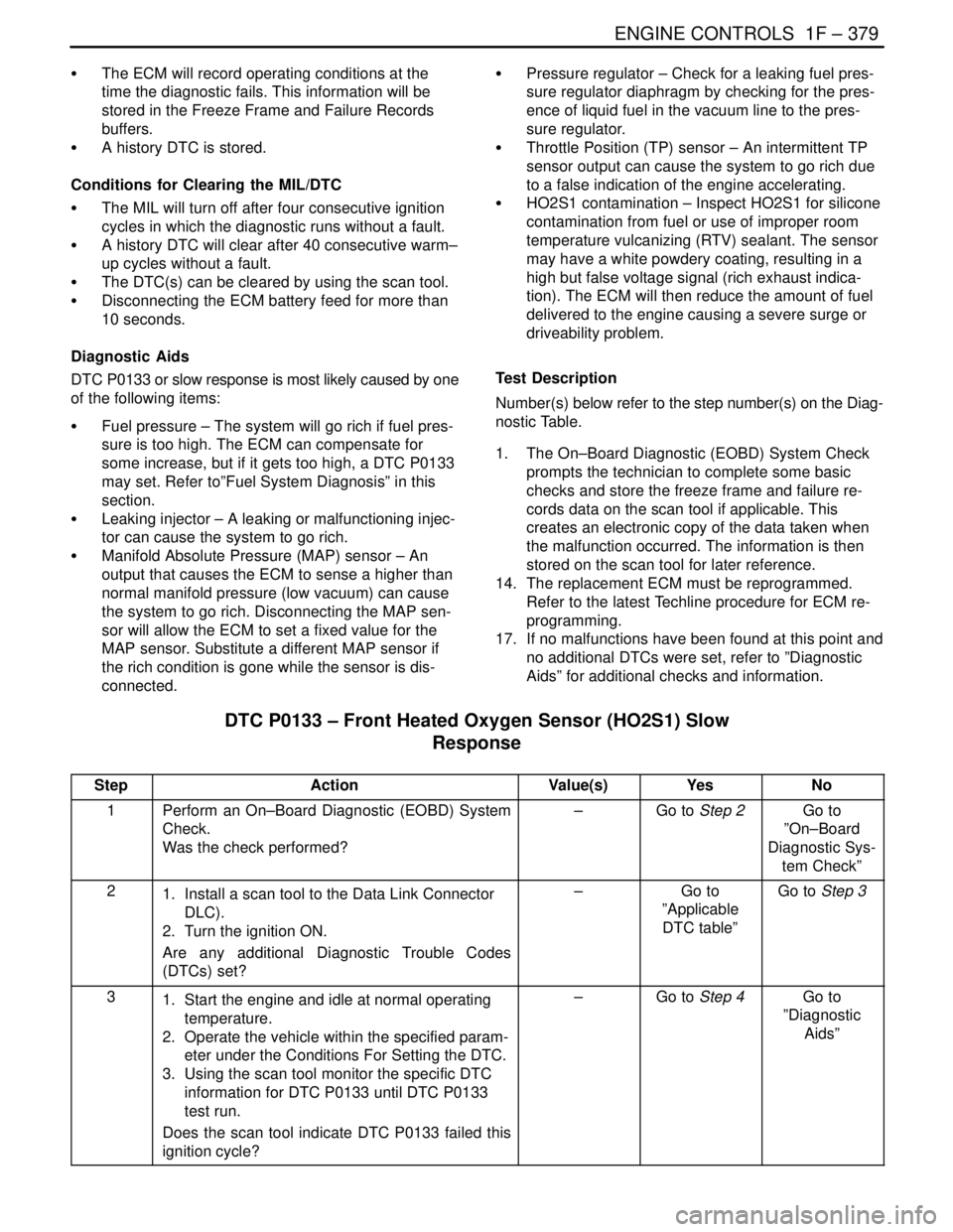

DTC P0133 – Front Heated Oxygen Sensor (HO2S1) Slow

Response

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

DLC).

2. Turn the ignition ON.

Are any additional Diagnostic Trouble Codes

(DTCs) set?–Go to

”Applicable

DTC table”Go to Step 3

31. Start the engine and idle at normal operating

temperature.

2. Operate the vehicle within the specified param-

eter under the Conditions For Setting the DTC.

3. Using the scan tool monitor the specific DTC

information for DTC P0133 until DTC P0133

test run.

Does the scan tool indicate DTC P0133 failed this

ignition cycle?–Go to Step 4Go to

”Diagnostic

Aids”

Page 646 of 2643

1F – 400IENGINE CONTROLS

DAEWOO V–121 BL4

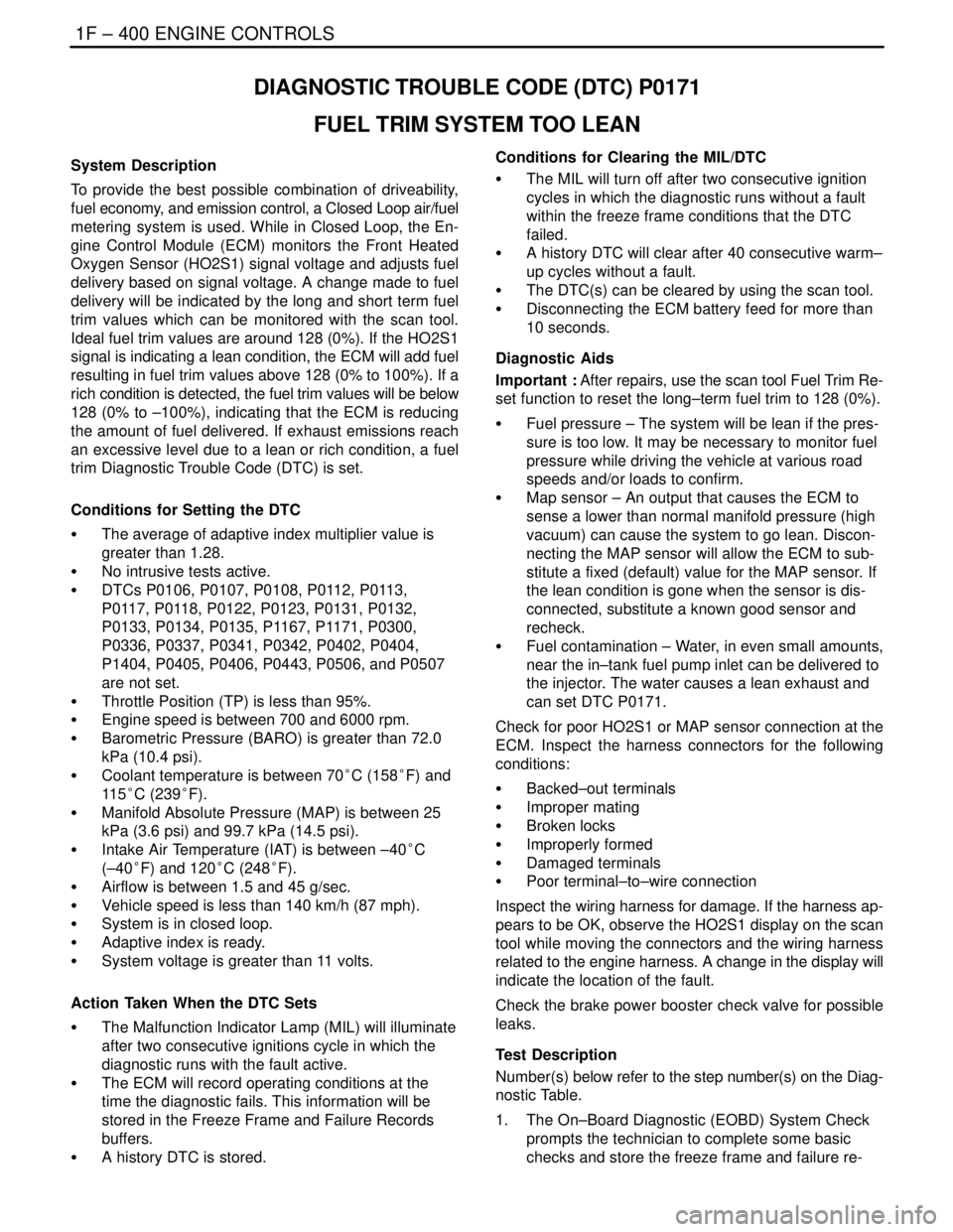

DIAGNOSTIC TROUBLE CODE (DTC) P0171

FUEL TRIM SYSTEM TOO LEAN

System Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a Closed Loop air/fuel

metering system is used. While in Closed Loop, the En-

gine Control Module (ECM) monitors the Front Heated

Oxygen Sensor (HO2S1) signal voltage and adjusts fuel

delivery based on signal voltage. A change made to fuel

delivery will be indicated by the long and short term fuel

trim values which can be monitored with the scan tool.

Ideal fuel trim values are around 128 (0%). If the HO2S1

signal is indicating a lean condition, the ECM will add fuel

resulting in fuel trim values above 128 (0% to 100%). If a

rich condition is detected, the fuel trim values will be below

128 (0% to –100%), indicating that the ECM is reducing

the amount of fuel delivered. If exhaust emissions reach

an excessive level due to a lean or rich condition, a fuel

trim Diagnostic Trouble Code (DTC) is set.

Conditions for Setting the DTC

S The average of adaptive index multiplier value is

greater than 1.28.

S No intrusive tests active.

S DTCs P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0134, P0135, P1167, P1171, P0300,

P0336, P0337, P0341, P0342, P0402, P0404,

P1404, P0405, P0406, P0443, P0506, and P0507

are not set.

S Throttle Position (TP) is less than 95%.

S Engine speed is between 700 and 6000 rpm.

S Barometric Pressure (BARO) is greater than 72.0

kPa (10.4 psi).

S Coolant temperature is between 70°C (158°F) and

11 5°C (239°F).

S Manifold Absolute Pressure (MAP) is between 25

kPa (3.6 psi) and 99.7 kPa (14.5 psi).

S Intake Air Temperature (IAT) is between –40°C

(–40°F) and 120°C (248°F).

S Airflow is between 1.5 and 45 g/sec.

S Vehicle speed is less than 140 km/h (87 mph).

S System is in closed loop.

S Adaptive index is ready.

S System voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignitions cycle in which the

diagnostic runs with the fault active.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.Conditions for Clearing the MIL/DTC

S The MIL will turn off after two consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

S Fuel pressure – The system will be lean if the pres-

sure is too low. It may be necessary to monitor fuel

pressure while driving the vehicle at various road

speeds and/or loads to confirm.

S Map sensor – An output that causes the ECM to

sense a lower than normal manifold pressure (high

vacuum) can cause the system to go lean. Discon-

necting the MAP sensor will allow the ECM to sub-

stitute a fixed (default) value for the MAP sensor. If

the lean condition is gone when the sensor is dis-

connected, substitute a known good sensor and

recheck.

S Fuel contamination – Water, in even small amounts,

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0171.

Check for poor HO2S1 or MAP sensor connection at the

ECM. Inspect the harness connectors for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the HO2S1 display on the scan

tool while moving the connectors and the wiring harness

related to the engine harness. A change in the display will

indicate the location of the fault.

Check the brake power booster check valve for possible

leaks.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

Page 647 of 2643

ENGINE CONTROLS 1F – 401

DAEWOO V–121 BL4

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

5. Visually/physically checking items which may cause

a lean condition may determine the cause of the

DTC being set and save diagnosis time.

9. A vacuum leak can change the Fuel Trim Index and

set DTC P0171. This step checks the intake man-ifold for vacuum leaks.

11. Contaminants in fuel, such as alcohol or water, can

create a lean condition setting DTC P0171. Check-

ing for these contaminants could identify the mal-

function.

17. If no faults have been found at this point and no

additional DTCs were set, refer to ”Diagnostic Aids”

for additional checks and information.

DTC P0171 – Fuel Trim System Too Lean

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install the scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any component related Diagnostic Trouble

Codes (DTCs) set?–Go to applica-

ble DTC tableGo to Step 3

3With the engine running, operate the vehicle until the

LOOP STATUS indicates closed.

Is the Long Term Fuel Trim value below the specified

value?25%Go to Step 4Go to Step 5

41. Turn the ignition switch ON, with the engine

OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Does the Long Term Fuel Trim value go below the

specified value while operating under the specified

conditions?25%Go to Step 16Go to Step 5

5Visually/physically check the following items:

S Vacuum hoses for splits, kinks and improper

connections.

S Crankcase ventilation oil/air separator for prop-

er installation.

S Exhaust system for corrosion, leaks, loose or

missing hardware.

S Front Heated Oxygen Sensor (HO2S1) is

installed securely and the pigtail harness is not

contacting exhaust manifold or engine.

S Fuel for excessive water, alcohol, or other con-

taminants.

S Engine Control Module (ECM) and sensor

grounds are clean, tight, and in their proper

locations.

Do any of the above checks isolate a condition re-

quiring repair?–Go to Step 7Go to Step 6

Page 648 of 2643

1F – 402IENGINE CONTROLS

DAEWOO V–121 BL4

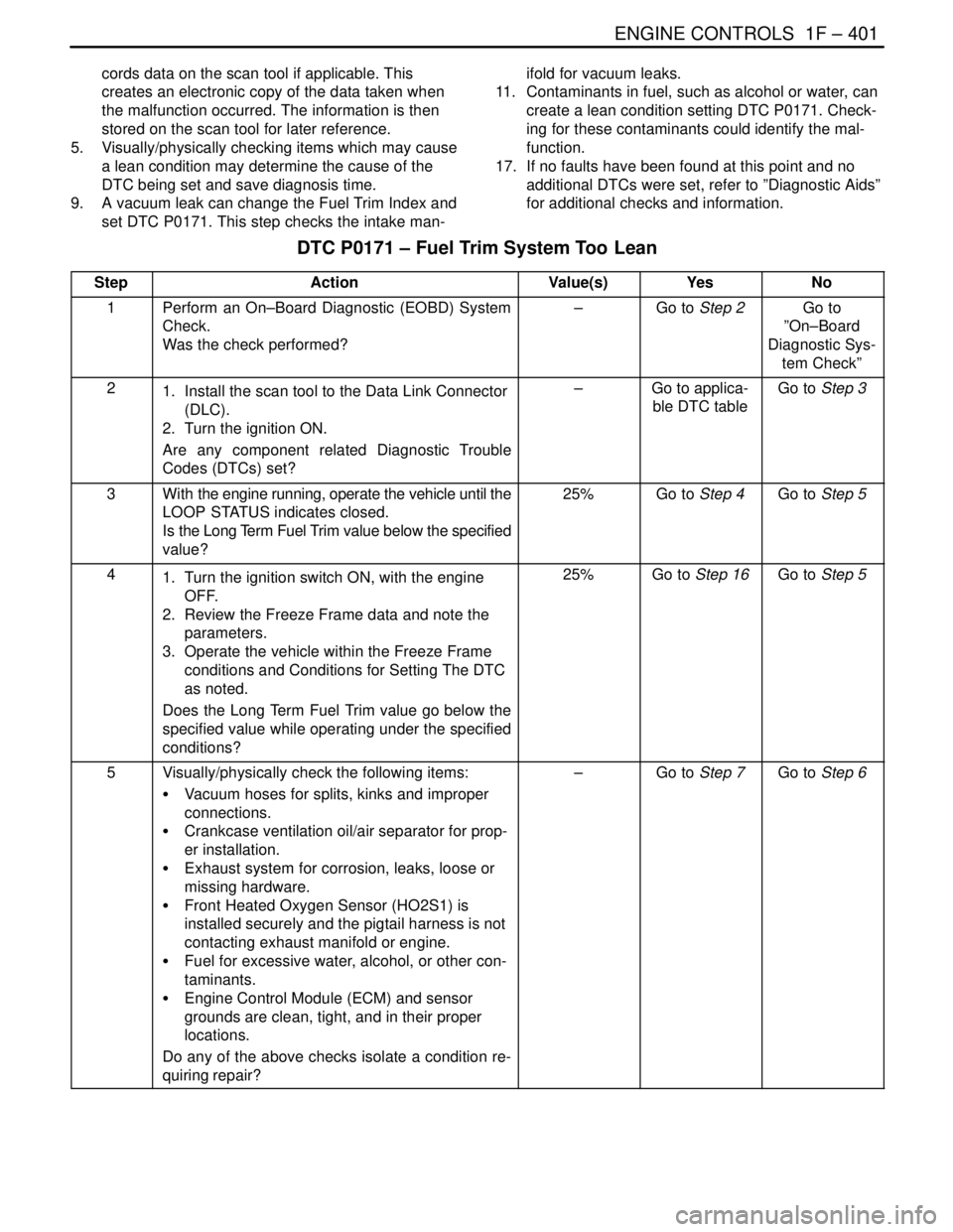

StepNo Yes Value(s) Action

61. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

2. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Is the Long Term Fuel Trim value below the specified

value?25%Go to Step 15Go to Step 9

71. Repair the malfunction found in Step 5.

2. Recheck the Long Term Fuel Trim value while

operating the engine.

Is the Long Term Fuel Trim value below the specified

value?25%Go to Step 8Go to Step 9

8Lean condition is not present.

Does a driveability problem exist?–Go to

”Symptom

Diagnosis”Go to Step 16

91. Visually/physically inspect the following items

for vacuum leaks:

S Intake manifold.

S Throttle body.

S Injector O–rings.

2. Repair any leaks found as necessary.

Is the repair complete?–Go to Step 16Go to Step 10

10Allow the engine to idle.

Are the Idle Air Control (IAC) counts above the spe-

cified value?5Go to Step 11Go to Step 12

11Check the fuel for excessive water, alcohol, or other

contaminants and correct the contaminated fuel

condition if present.

Is the repair complete?–Go to Step 16Go to Step 13

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed” in this section and repair

as necessary.

Is the repair complete?–Go to Step 16Go to Step 13

131. Connect a fuel pressure gauge to the fuel sys-

tem.

2. Turn the ignition OFF for at least 10 seconds.

3. Turn the ignition ON, with the engine OFF. The

fuel pump will run for approximately 2–3 sec-

onds. It may be necessary to cycle the ignition

switch ON more than once to obtain maximum

fuel pressure.

4. Note the fuel pressure with the fuel pump run-

ning. The pressure should be within the speci-

fied value. When the fuel pump stops, the pres-

sure may vary slightly then hold steady.

Is the fuel pressure steady and does the fuel pres-

sure hold?241–276 kPa

(35–40 psi)Go to Step 14Go to

”Fuel System

Diagnosis”

Page 652 of 2643

1F – 406IENGINE CONTROLS

DAEWOO V–121 BL4

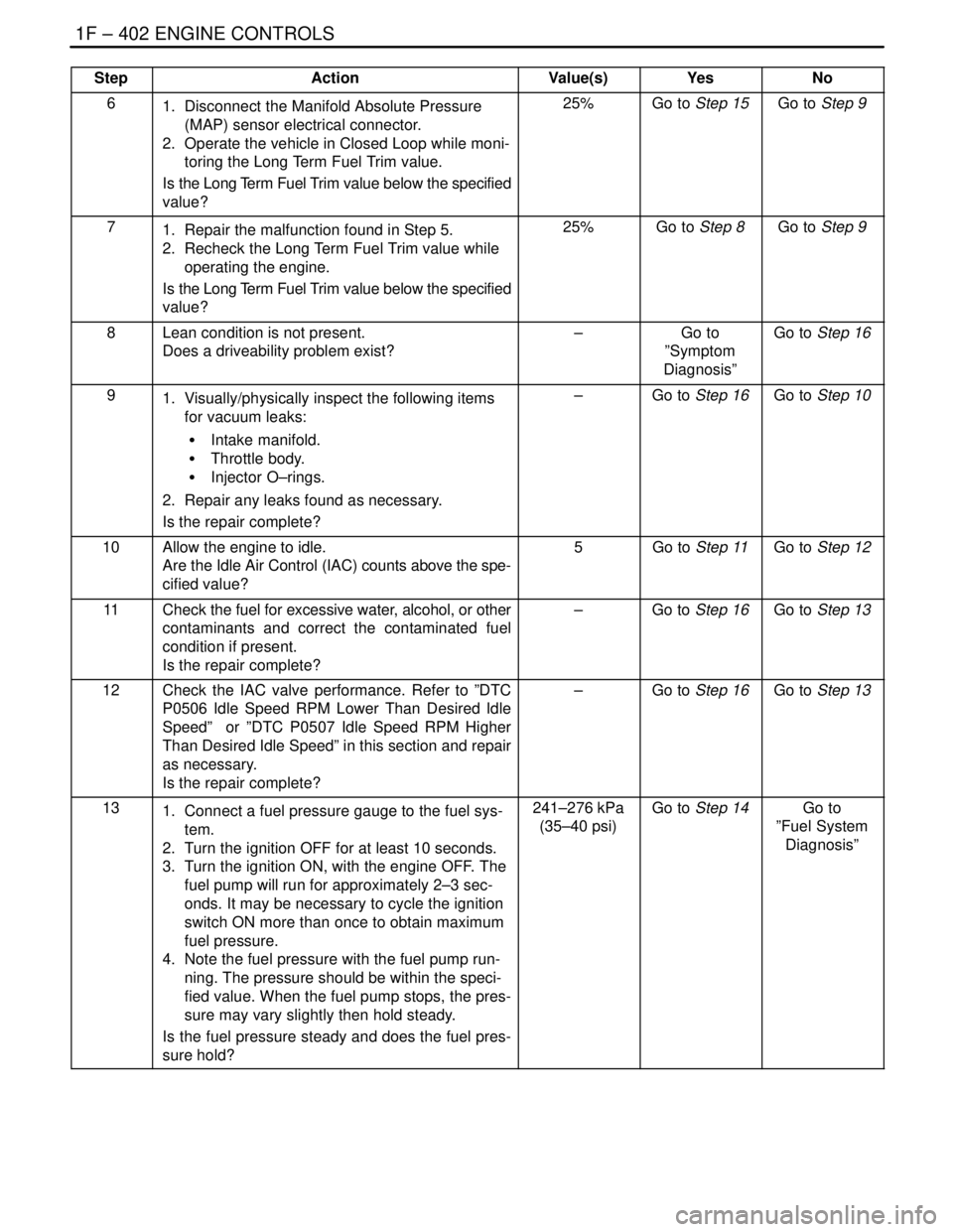

StepNo Yes Value(s) Action

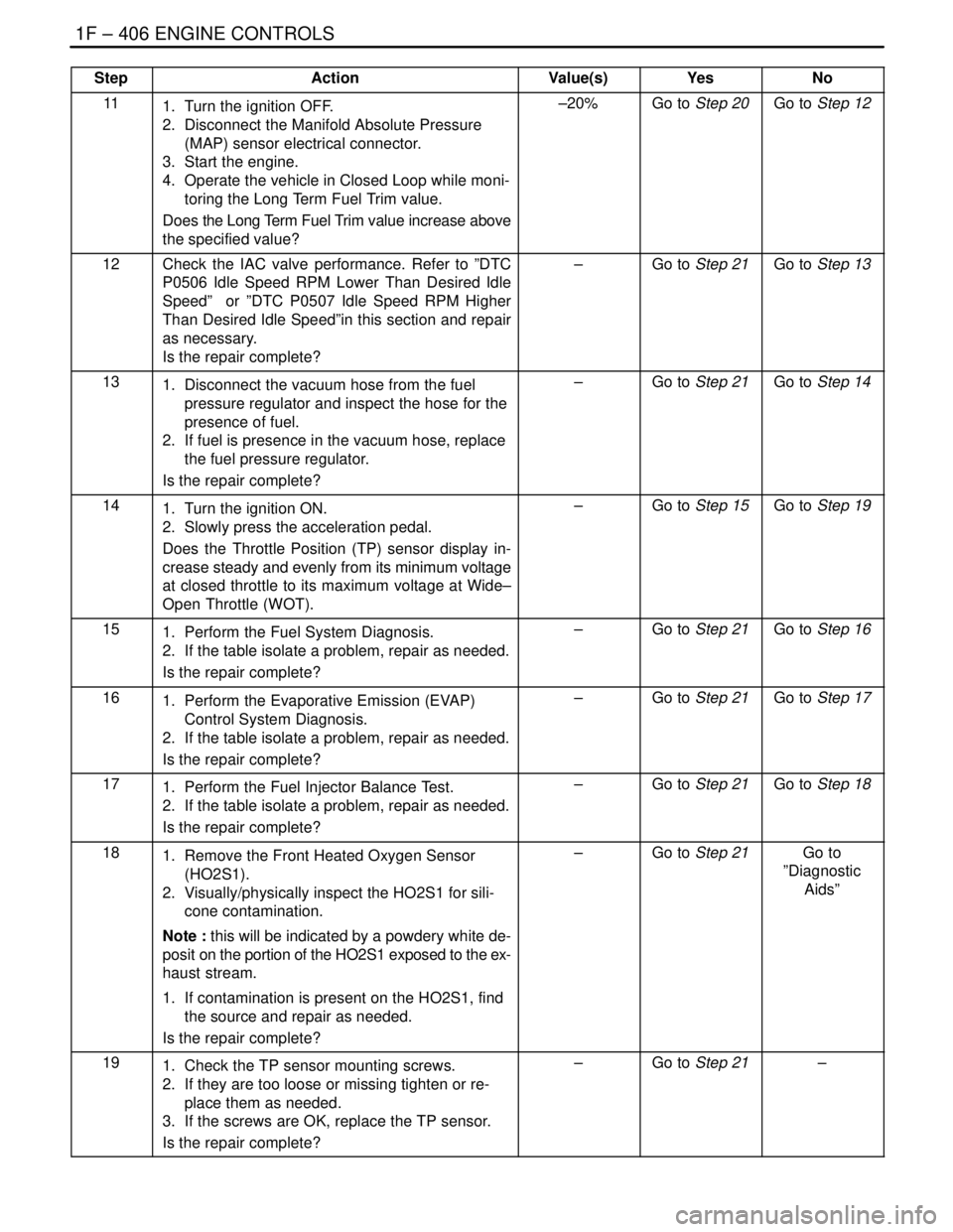

111. Turn the ignition OFF.

2. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

3. Start the engine.

4. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Does the Long Term Fuel Trim value increase above

the specified value?–20%Go to Step 20Go to Step 12

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed”in this section and repair

as necessary.

Is the repair complete?–Go to Step 21Go to Step 13

131. Disconnect the vacuum hose from the fuel

pressure regulator and inspect the hose for the

presence of fuel.

2. If fuel is presence in the vacuum hose, replace

the fuel pressure regulator.

Is the repair complete?–Go to Step 21Go to Step 14

141. Turn the ignition ON.

2. Slowly press the acceleration pedal.

Does the Throttle Position (TP) sensor display in-

crease steady and evenly from its minimum voltage

at closed throttle to its maximum voltage at Wide–

Open Throttle (WOT).–Go to Step 15Go to Step 19

151. Perform the Fuel System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 16

161. Perform the Evaporative Emission (EVAP)

Control System Diagnosis.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 17

171. Perform the Fuel Injector Balance Test.

2. If the table isolate a problem, repair as needed.

Is the repair complete?–Go to Step 21Go to Step 18

181. Remove the Front Heated Oxygen Sensor

(HO2S1).

2. Visually/physically inspect the HO2S1 for sili-

cone contamination.

Note : this will be indicated by a powdery white de-

posit on the portion of the HO2S1 exposed to the ex-

haust stream.

1. If contamination is present on the HO2S1, find

the source and repair as needed.

Is the repair complete?–Go to Step 21Go to

”Diagnostic

Aids”

191. Check the TP sensor mounting screws.

2. If they are too loose or missing tighten or re-

place them as needed.

3. If the screws are OK, replace the TP sensor.

Is the repair complete?–Go to Step 21–

Page 667 of 2643

ENGINE CONTROLS 1F – 421

DAEWOO V–121 BL4

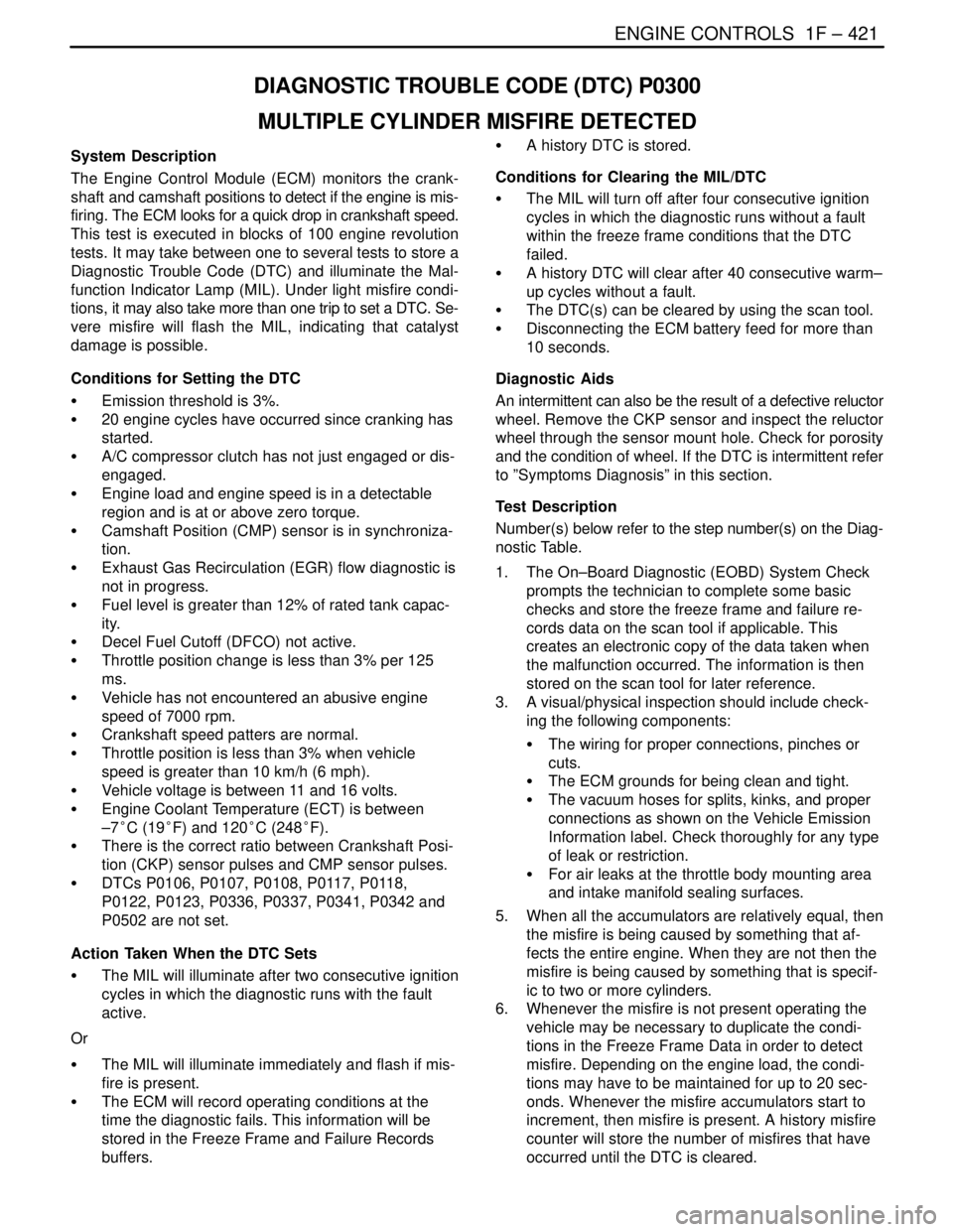

DIAGNOSTIC TROUBLE CODE (DTC) P0300

MULTIPLE CYLINDER MISFIRE DETECTED

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 672 of 2643

1F – 426IENGINE CONTROLS

DAEWOO V–121 BL4

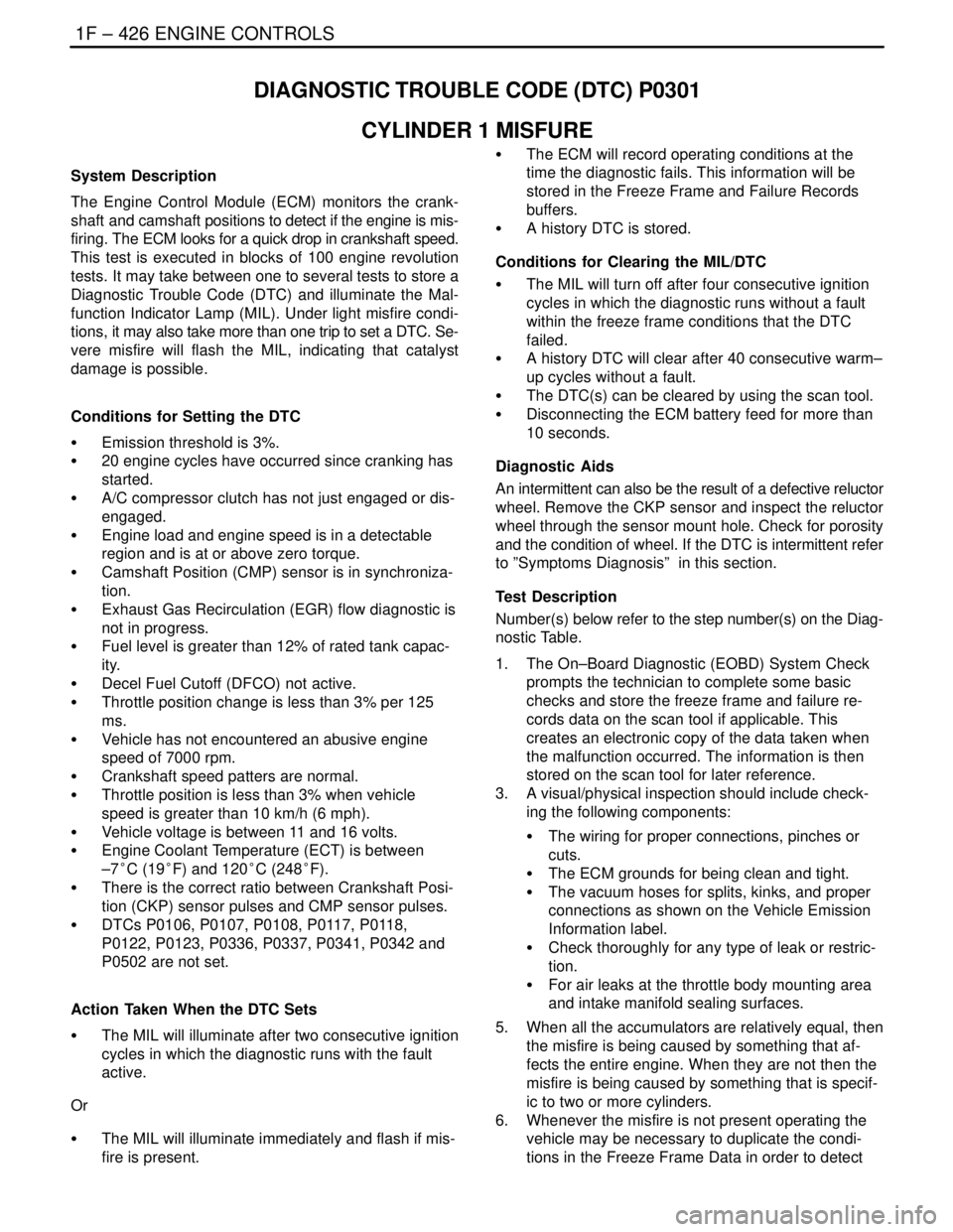

DIAGNOSTIC TROUBLE CODE (DTC) P0301

CYLINDER 1 MISFURE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label.

S Check thoroughly for any type of leak or restric-

tion.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

Page 677 of 2643

ENGINE CONTROLS 1F – 431

DAEWOO V–121 BL4

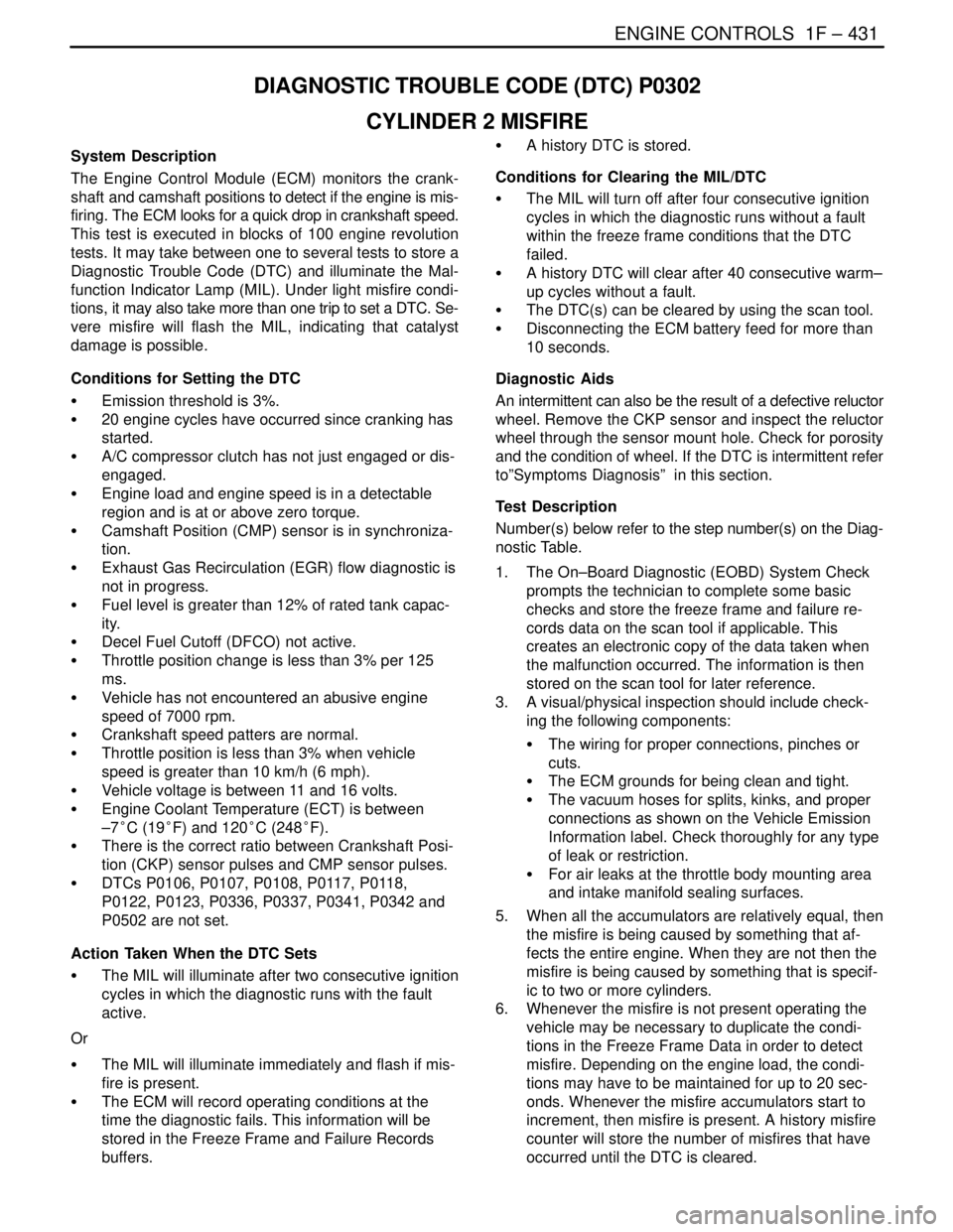

DIAGNOSTIC TROUBLE CODE (DTC) P0302

CYLINDER 2 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 682 of 2643

1F – 436IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0303

CYLINDER 3 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 687 of 2643

ENGINE CONTROLS 1F – 441

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0304

CYLINDER 4 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.