speed DAEWOO LACETTI 2004 Service Manual Online

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 562 of 2643

1F – 316IENGINE CONTROLS

DAEWOO V–121 BL4

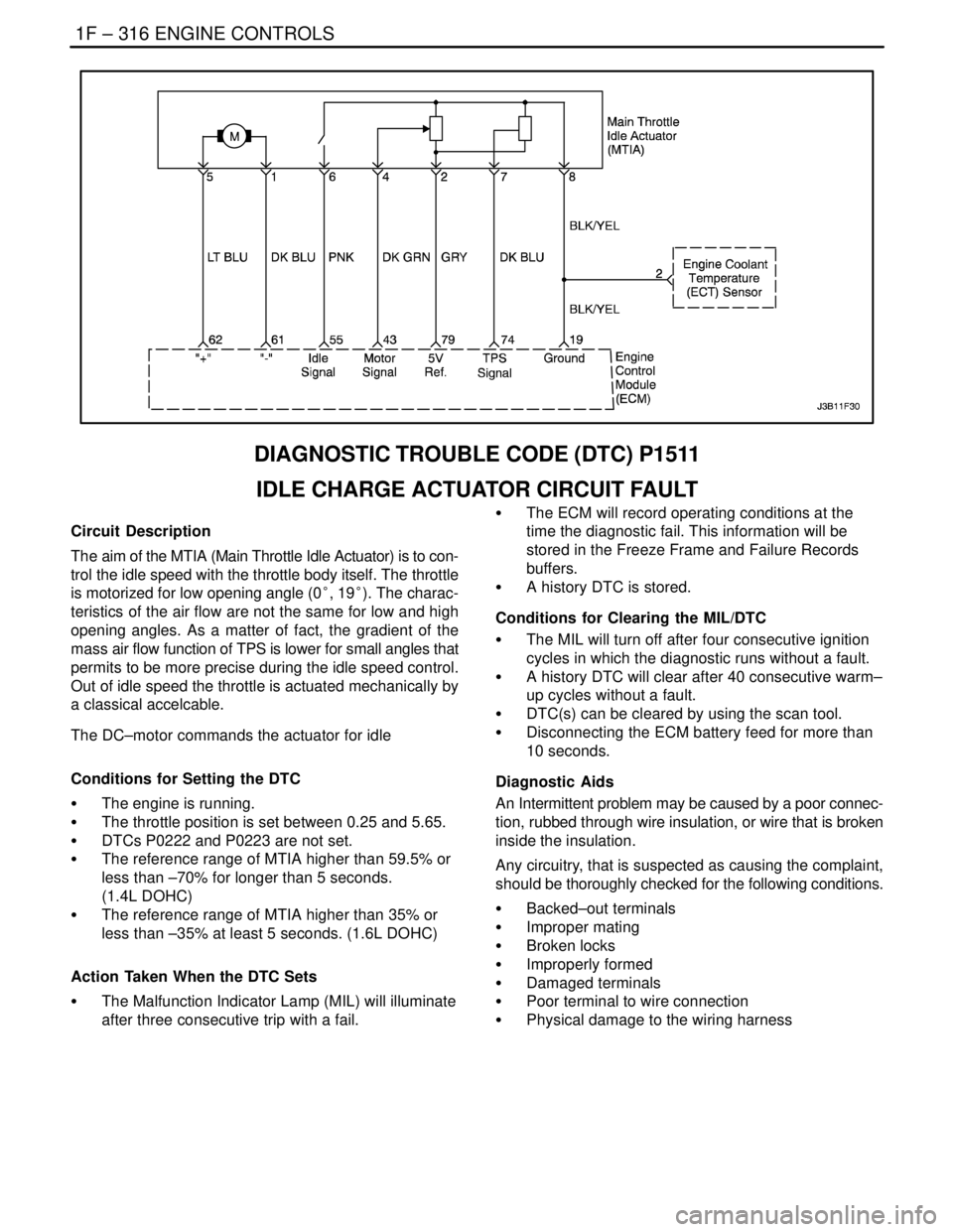

DIAGNOSTIC TROUBLE CODE (DTC) P1511

IDLE CHARGE ACTUATOR CIRCUIT FAULT

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (0°, 19°). The charac-

teristics of the air flow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical accelcable.

The DC–motor commands the actuator for idle

Conditions for Setting the DTC

S The engine is running.

S The throttle position is set between 0.25 and 5.65.

S DTCs P0222 and P0223 are not set.

S The reference range of MTIA higher than 59.5% or

less than –70% for longer than 5 seconds.

(1.4L DOHC)

S The reference range of MTIA higher than 35% or

less than –35% at least 5 seconds. (1.6L DOHC)

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal to wire connection

S Physical damage to the wiring harness

Page 565 of 2643

ENGINE CONTROLS 1F – 319

DAEWOO V–121 BL4

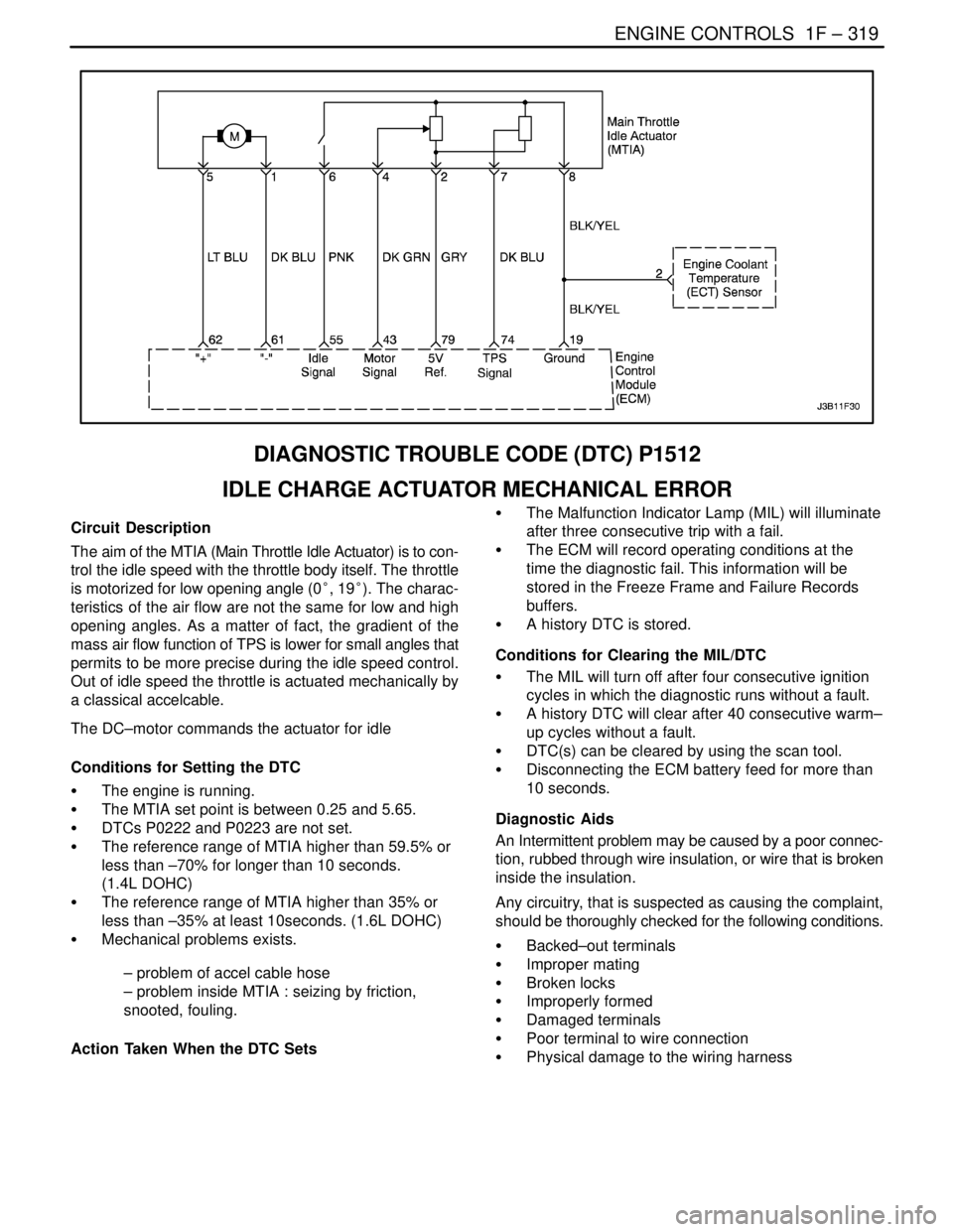

DIAGNOSTIC TROUBLE CODE (DTC) P1512

IDLE CHARGE ACTUATOR MECHANICAL ERROR

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (0°, 19°). The charac-

teristics of the air flow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical accelcable.

The DC–motor commands the actuator for idle

Conditions for Setting the DTC

S The engine is running.

S The MTIA set point is between 0.25 and 5.65.

S DTCs P0222 and P0223 are not set.

S The reference range of MTIA higher than 59.5% or

less than –70% for longer than 10 seconds.

(1.4L DOHC)

S The reference range of MTIA higher than 35% or

less than –35% at least 10seconds. (1.6L DOHC)

S Mechanical problems exists.

– problem of accel cable hose

– problem inside MTIA : seizing by friction,

snooted, fouling.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal to wire connection

S Physical damage to the wiring harness

Page 567 of 2643

ENGINE CONTROLS 1F – 321

DAEWOO V–121 BL4

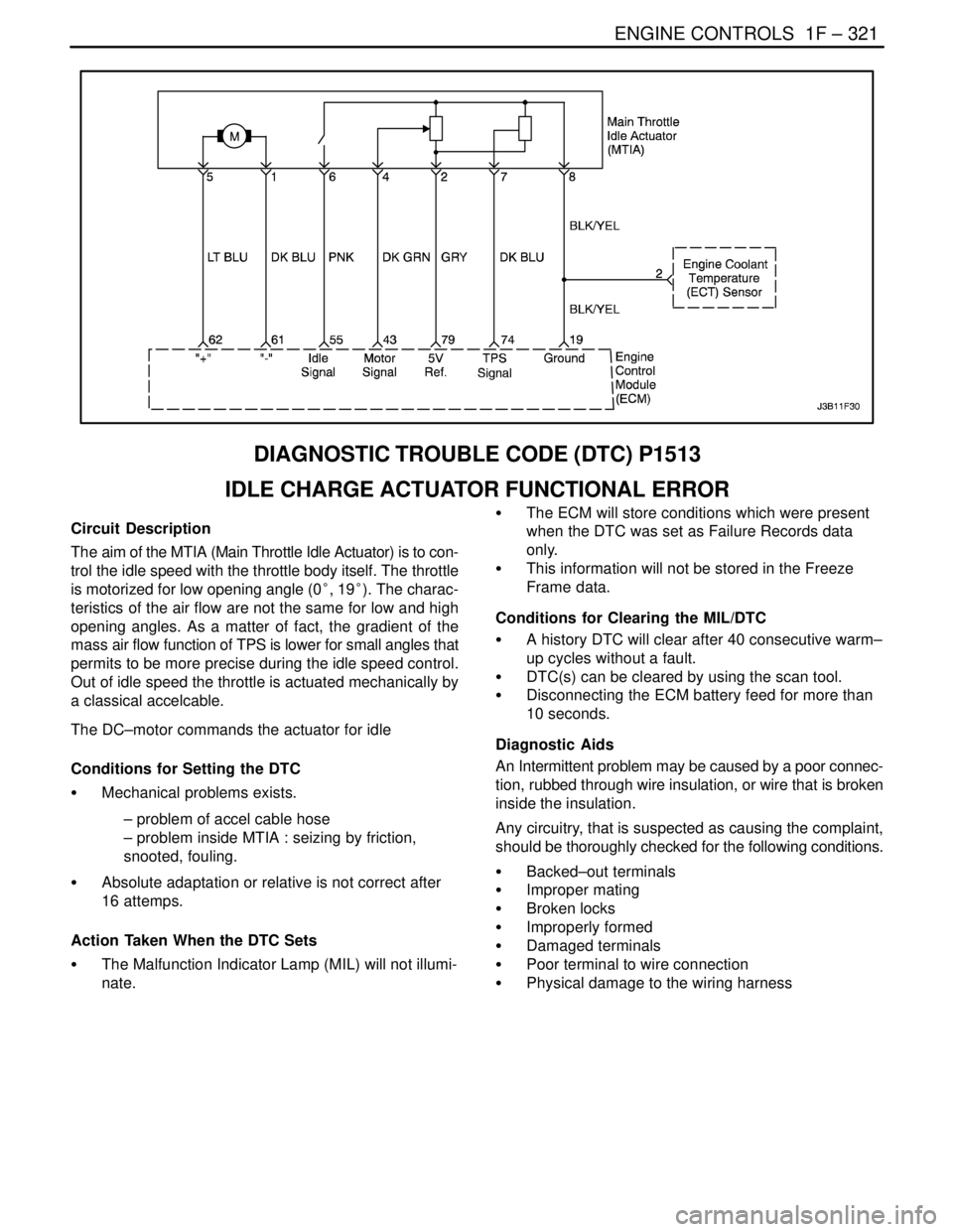

DIAGNOSTIC TROUBLE CODE (DTC) P1513

IDLE CHARGE ACTUATOR FUNCTIONAL ERROR

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (0°, 19°). The charac-

teristics of the air flow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical accelcable.

The DC–motor commands the actuator for idle

Conditions for Setting the DTC

S Mechanical problems exists.

– problem of accel cable hose

– problem inside MTIA : seizing by friction,

snooted, fouling.

S Absolute adaptation or relative is not correct after

16 attemps.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal to wire connection

S Physical damage to the wiring harness

Page 591 of 2643

ENGINE CONTROLS 1F – 345

DAEWOO V–121 BL4

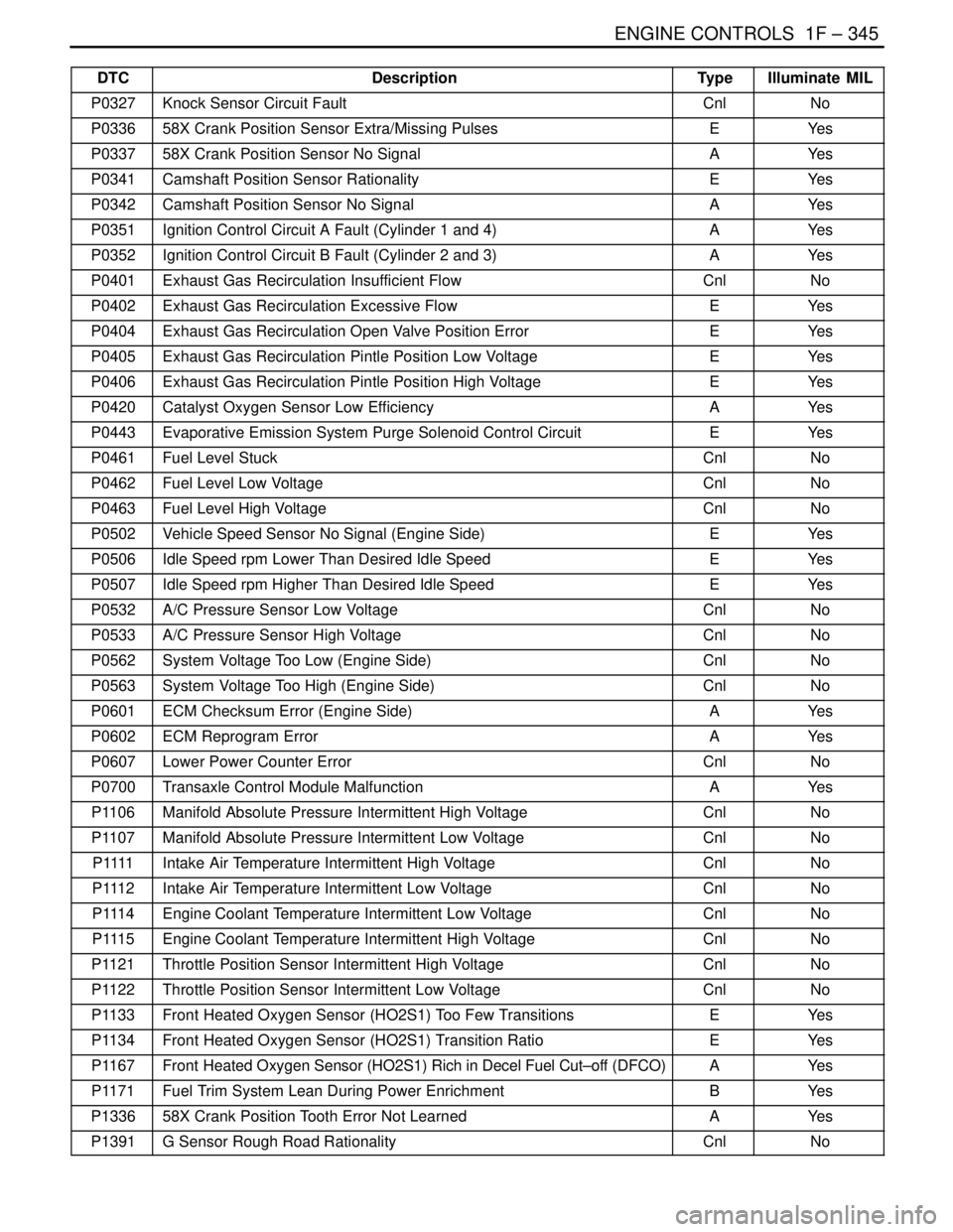

DTCIlluminate MIL Type Description

P0327Knock Sensor Circuit FaultCnlNo

P033658X Crank Position Sensor Extra/Missing PulsesEYe s

P033758X Crank Position Sensor No SignalAYe s

P0341Camshaft Position Sensor RationalityEYe s

P0342Camshaft Position Sensor No SignalAYe s

P0351Ignition Control Circuit A Fault (Cylinder 1 and 4)AYe s

P0352Ignition Control Circuit B Fault (Cylinder 2 and 3)AYe s

P0401Exhaust Gas Recirculation Insufficient FlowCnlNo

P0402Exhaust Gas Recirculation Excessive FlowEYe s

P0404Exhaust Gas Recirculation Open Valve Position ErrorEYe s

P0405Exhaust Gas Recirculation Pintle Position Low VoltageEYe s

P0406Exhaust Gas Recirculation Pintle Position High VoltageEYe s

P0420Catalyst Oxygen Sensor Low EfficiencyAYe s

P0443Evaporative Emission System Purge Solenoid Control CircuitEYe s

P0461Fuel Level StuckCnlNo

P0462Fuel Level Low VoltageCnlNo

P0463Fuel Level High VoltageCnlNo

P0502Vehicle Speed Sensor No Signal (Engine Side)EYe s

P0506Idle Speed rpm Lower Than Desired Idle SpeedEYe s

P0507Idle Speed rpm Higher Than Desired Idle SpeedEYe s

P0532A/C Pressure Sensor Low VoltageCnlNo

P0533A/C Pressure Sensor High VoltageCnlNo

P0562System Voltage Too Low (Engine Side)CnlNo

P0563System Voltage Too High (Engine Side)CnlNo

P0601ECM Checksum Error (Engine Side)AYe s

P0602ECM Reprogram ErrorAYe s

P0607Lower Power Counter ErrorCnlNo

P0700Transaxle Control Module MalfunctionAYe s

P1106Manifold Absolute Pressure Intermittent High VoltageCnlNo

P1107Manifold Absolute Pressure Intermittent Low VoltageCnlNo

P 1111Intake Air Temperature Intermittent High VoltageCnlNo

P1112Intake Air Temperature Intermittent Low VoltageCnlNo

P1114Engine Coolant Temperature Intermittent Low VoltageCnlNo

P1115Engine Coolant Temperature Intermittent High VoltageCnlNo

P1121Throttle Position Sensor Intermittent High VoltageCnlNo

P1122Throttle Position Sensor Intermittent Low VoltageCnlNo

P1133Front Heated Oxygen Sensor (HO2S1) Too Few TransitionsEYe s

P1134Front Heated Oxygen Sensor (HO2S1) Transition RatioEYe s

P1167Front Heated Oxygen Sensor (HO2S1) Rich in Decel Fuel Cut–off (DFCO)AYe s

P1171Fuel Trim System Lean During Power EnrichmentBYe s

P133658X Crank Position Tooth Error Not LearnedAYe s

P1391G Sensor Rough Road RationalityCnlNo

Page 601 of 2643

ENGINE CONTROLS 1F – 355

DAEWOO V–121 BL4

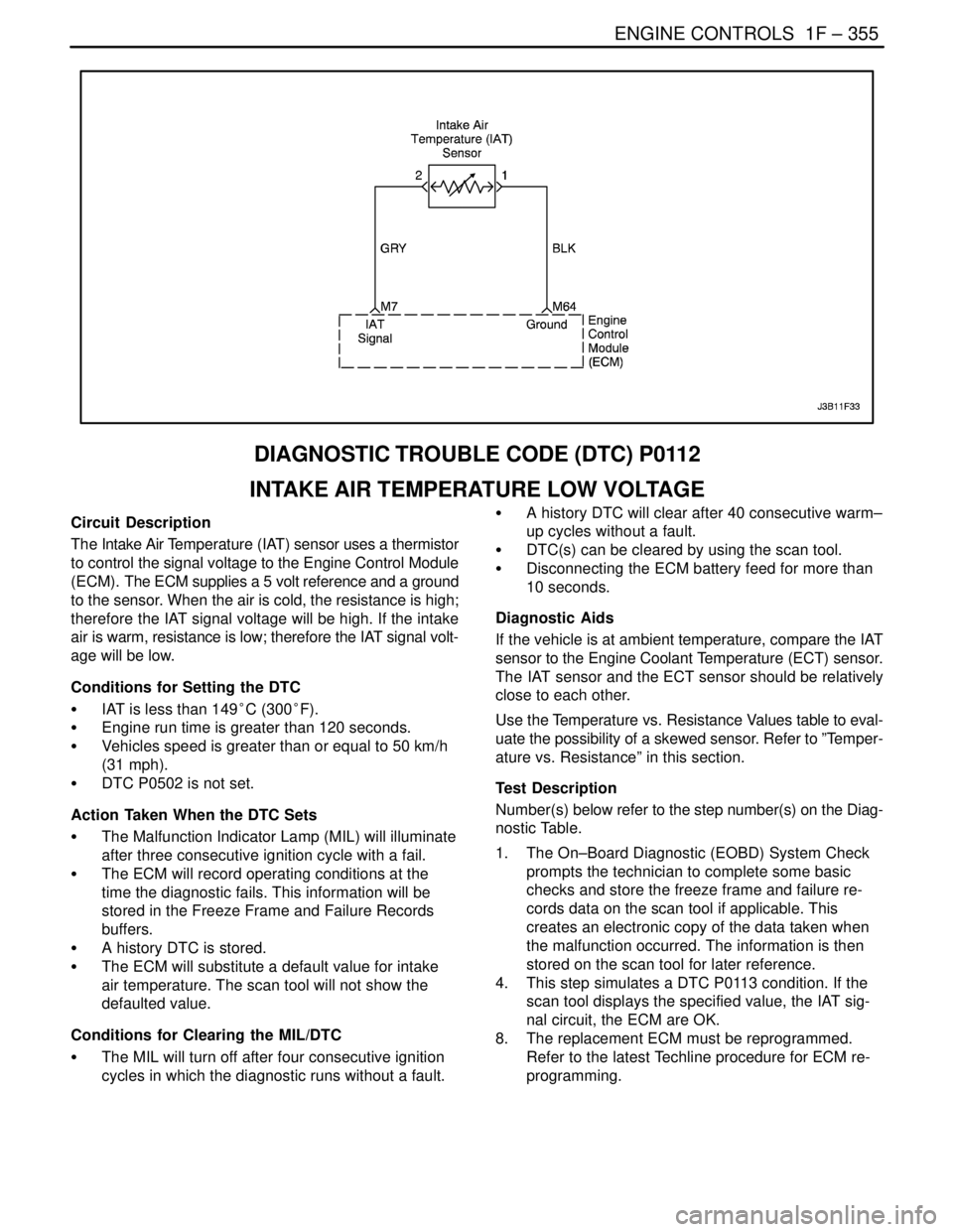

DIAGNOSTIC TROUBLE CODE (DTC) P0112

INTAKE AIR TEMPERATURE LOW VOLTAGE

Circuit Description

The Intake Air Temperature (IAT) sensor uses a thermistor

to control the signal voltage to the Engine Control Module

(ECM). The ECM supplies a 5 volt reference and a ground

to the sensor. When the air is cold, the resistance is high;

therefore the IAT signal voltage will be high. If the intake

air is warm, resistance is low; therefore the IAT signal volt-

age will be low.

Conditions for Setting the DTC

S IAT is less than 149°C (300°F).

S Engine run time is greater than 120 seconds.

S Vehicles speed is greater than or equal to 50 km/h

(31 mph).

S DTC P0502 is not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The ECM will substitute a default value for intake

air temperature. The scan tool will not show the

defaulted value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the vehicle is at ambient temperature, compare the IAT

sensor to the Engine Coolant Temperature (ECT) sensor.

The IAT sensor and the ECT sensor should be relatively

close to each other.

Use the Temperature vs. Resistance Values table to eval-

uate the possibility of a skewed sensor. Refer to ”Temper-

ature vs. Resistance” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

4. This step simulates a DTC P0113 condition. If the

scan tool displays the specified value, the IAT sig-

nal circuit, the ECM are OK.

8. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 604 of 2643

1F – 358IENGINE CONTROLS

DAEWOO V–121 BL4

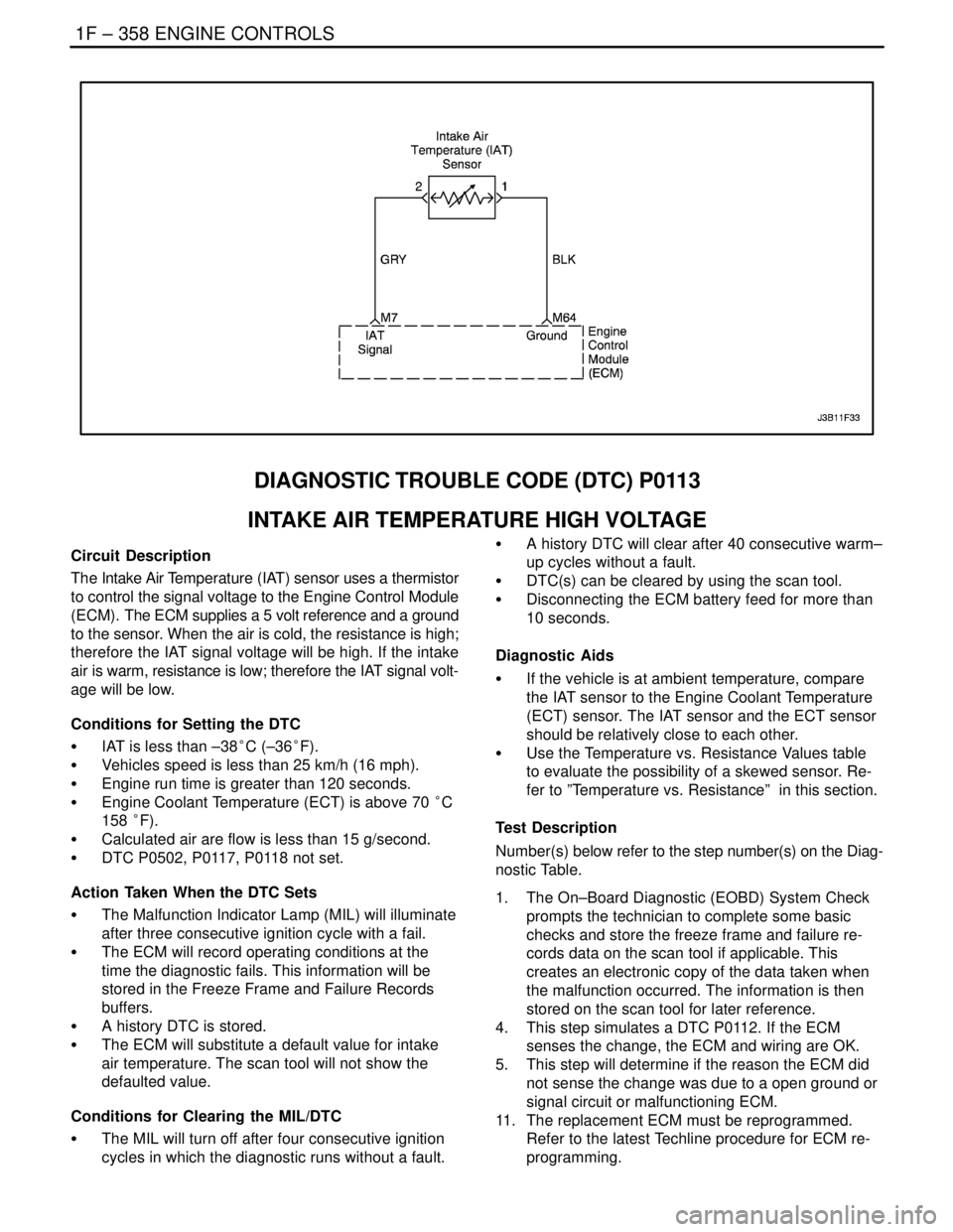

DIAGNOSTIC TROUBLE CODE (DTC) P0113

INTAKE AIR TEMPERATURE HIGH VOLTAGE

Circuit Description

The Intake Air Temperature (IAT) sensor uses a thermistor

to control the signal voltage to the Engine Control Module

(ECM). The ECM supplies a 5 volt reference and a ground

to the sensor. When the air is cold, the resistance is high;

therefore the IAT signal voltage will be high. If the intake

air is warm, resistance is low; therefore the IAT signal volt-

age will be low.

Conditions for Setting the DTC

S IAT is less than –38°C (–36°F).

S Vehicles speed is less than 25 km/h (16 mph).

S Engine run time is greater than 120 seconds.

S Engine Coolant Temperature (ECT) is above 70 °C

158 °F).

S Calculated air are flow is less than 15 g/second.

S DTC P0502, P0117, P0118 not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The ECM will substitute a default value for intake

air temperature. The scan tool will not show the

defaulted value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

S If the vehicle is at ambient temperature, compare

the IAT sensor to the Engine Coolant Temperature

(ECT) sensor. The IAT sensor and the ECT sensor

should be relatively close to each other.

S Use the Temperature vs. Resistance Values table

to evaluate the possibility of a skewed sensor. Re-

fer to ”Temperature vs. Resistance” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

4. This step simulates a DTC P0112. If the ECM

senses the change, the ECM and wiring are OK.

5. This step will determine if the reason the ECM did

not sense the change was due to a open ground or

signal circuit or malfunctioning ECM.

11. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 612 of 2643

1F – 366IENGINE CONTROLS

DAEWOO V–121 BL4

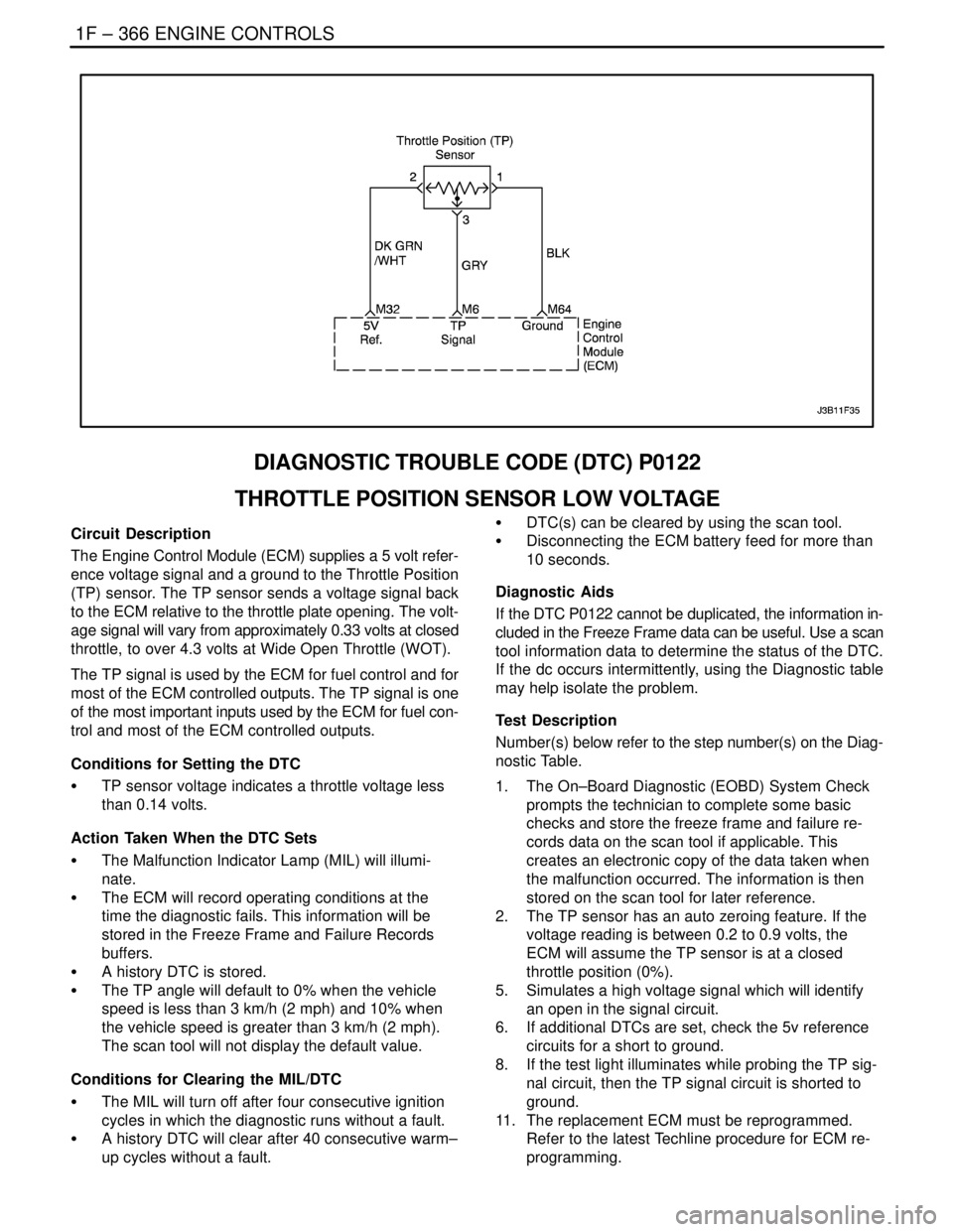

DIAGNOSTIC TROUBLE CODE (DTC) P0122

THROTTLE POSITION SENSOR LOW VOLTAGE

Circuit Description

The Engine Control Module (ECM) supplies a 5 volt refer-

ence voltage signal and a ground to the Throttle Position

(TP) sensor. The TP sensor sends a voltage signal back

to the ECM relative to the throttle plate opening. The volt-

age signal will vary from approximately 0.33 volts at closed

throttle, to over 4.3 volts at Wide Open Throttle (WOT).

The TP signal is used by the ECM for fuel control and for

most of the ECM controlled outputs. The TP signal is one

of the most important inputs used by the ECM for fuel con-

trol and most of the ECM controlled outputs.

Conditions for Setting the DTC

S TP sensor voltage indicates a throttle voltage less

than 0.14 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The TP angle will default to 0% when the vehicle

speed is less than 3 km/h (2 mph) and 10% when

the vehicle speed is greater than 3 km/h (2 mph).

The scan tool will not display the default value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC P0122 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful. Use a scan

tool information data to determine the status of the DTC.

If the dc occurs intermittently, using the Diagnostic table

may help isolate the problem.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. The TP sensor has an auto zeroing feature. If the

voltage reading is between 0.2 to 0.9 volts, the

ECM will assume the TP sensor is at a closed

throttle position (0%).

5. Simulates a high voltage signal which will identify

an open in the signal circuit.

6. If additional DTCs are set, check the 5v reference

circuits for a short to ground.

8. If the test light illuminates while probing the TP sig-

nal circuit, then the TP signal circuit is shorted to

ground.

11. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 615 of 2643

ENGINE CONTROLS 1F – 369

DAEWOO V–121 BL4

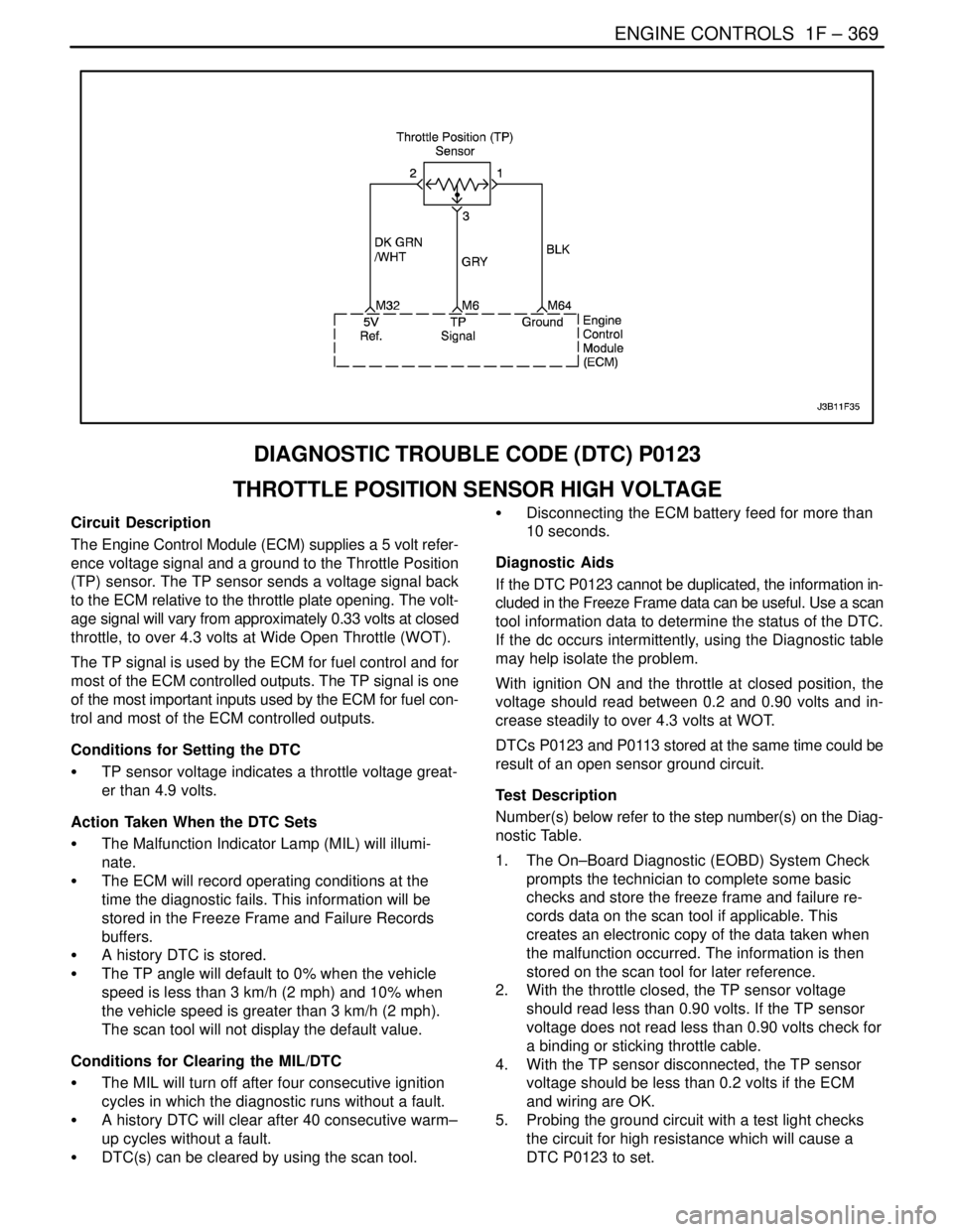

DIAGNOSTIC TROUBLE CODE (DTC) P0123

THROTTLE POSITION SENSOR HIGH VOLTAGE

Circuit Description

The Engine Control Module (ECM) supplies a 5 volt refer-

ence voltage signal and a ground to the Throttle Position

(TP) sensor. The TP sensor sends a voltage signal back

to the ECM relative to the throttle plate opening. The volt-

age signal will vary from approximately 0.33 volts at closed

throttle, to over 4.3 volts at Wide Open Throttle (WOT).

The TP signal is used by the ECM for fuel control and for

most of the ECM controlled outputs. The TP signal is one

of the most important inputs used by the ECM for fuel con-

trol and most of the ECM controlled outputs.

Conditions for Setting the DTC

S TP sensor voltage indicates a throttle voltage great-

er than 4.9 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The TP angle will default to 0% when the vehicle

speed is less than 3 km/h (2 mph) and 10% when

the vehicle speed is greater than 3 km/h (2 mph).

The scan tool will not display the default value.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

If the DTC P0123 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful. Use a scan

tool information data to determine the status of the DTC.

If the dc occurs intermittently, using the Diagnostic table

may help isolate the problem.

With ignition ON and the throttle at closed position, the

voltage should read between 0.2 and 0.90 volts and in-

crease steadily to over 4.3 volts at WOT.

DTCs P0123 and P0113 stored at the same time could be

result of an open sensor ground circuit.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. With the throttle closed, the TP sensor voltage

should read less than 0.90 volts. If the TP sensor

voltage does not read less than 0.90 volts check for

a binding or sticking throttle cable.

4. With the TP sensor disconnected, the TP sensor

voltage should be less than 0.2 volts if the ECM

and wiring are OK.

5. Probing the ground circuit with a test light checks

the circuit for high resistance which will cause a

DTC P0123 to set.

Page 619 of 2643

ENGINE CONTROLS 1F – 373

DAEWOO V–121 BL4

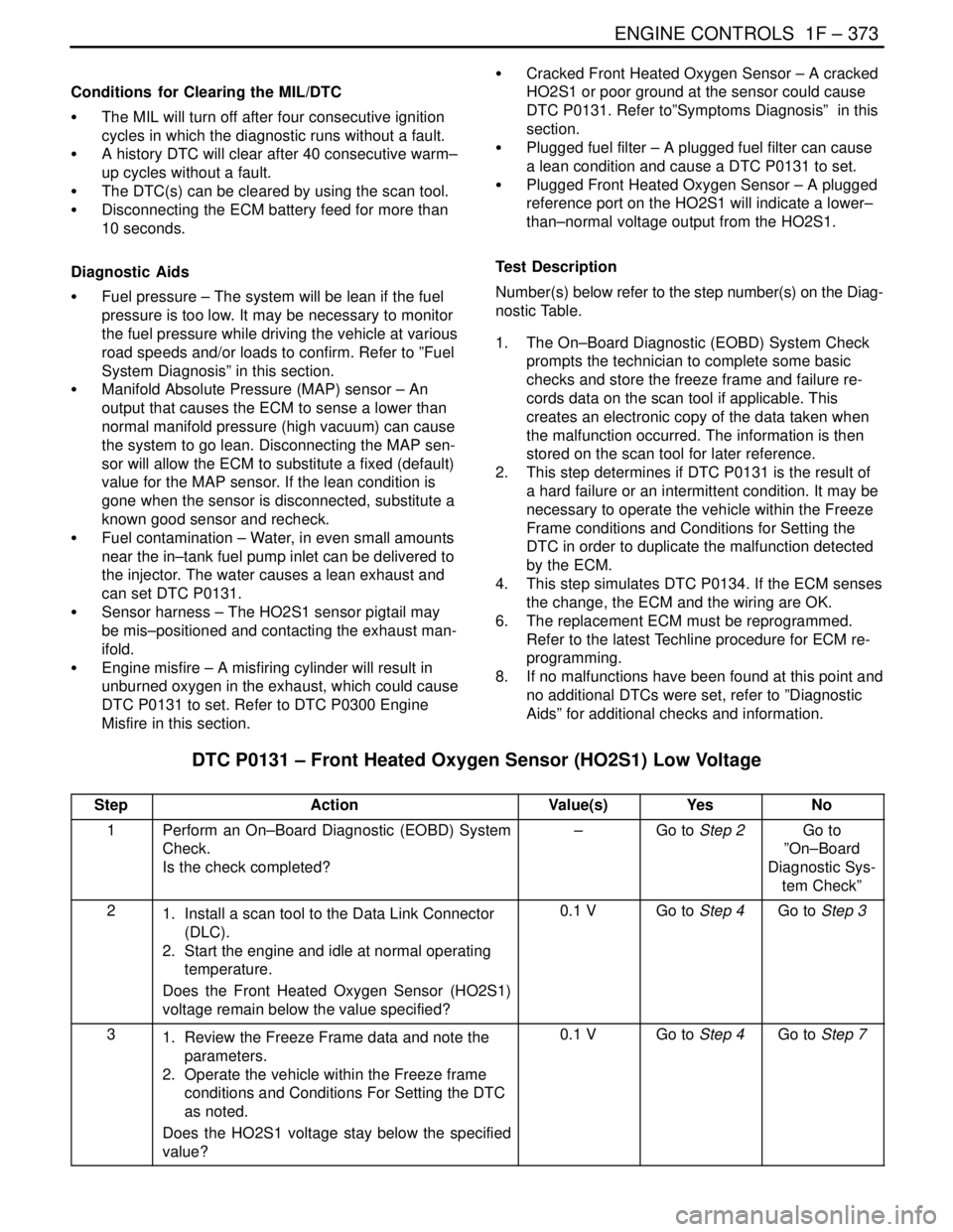

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

S Fuel pressure – The system will be lean if the fuel

pressure is too low. It may be necessary to monitor

the fuel pressure while driving the vehicle at various

road speeds and/or loads to confirm. Refer to ”Fuel

System Diagnosis” in this section.

S Manifold Absolute Pressure (MAP) sensor – An

output that causes the ECM to sense a lower than

normal manifold pressure (high vacuum) can cause

the system to go lean. Disconnecting the MAP sen-

sor will allow the ECM to substitute a fixed (default)

value for the MAP sensor. If the lean condition is

gone when the sensor is disconnected, substitute a

known good sensor and recheck.

S Fuel contamination – Water, in even small amounts

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0131.

S Sensor harness – The HO2S1 sensor pigtail may

be mis–positioned and contacting the exhaust man-

ifold.

S Engine misfire – A misfiring cylinder will result in

unburned oxygen in the exhaust, which could cause

DTC P0131 to set. Refer to DTC P0300 Engine

Misfire in this section.S Cracked Front Heated Oxygen Sensor – A cracked

HO2S1 or poor ground at the sensor could cause

DTC P0131. Refer to”Symptoms Diagnosis” in this

section.

S Plugged fuel filter – A plugged fuel filter can cause

a lean condition and cause a DTC P0131 to set.

S Plugged Front Heated Oxygen Sensor – A plugged

reference port on the HO2S1 will indicate a lower–

than–normal voltage output from the HO2S1.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0131 is the result of

a hard failure or an intermittent condition. It may be

necessary to operate the vehicle within the Freeze

Frame conditions and Conditions for Setting the

DTC in order to duplicate the malfunction detected

by the ECM.

4. This step simulates DTC P0134. If the ECM senses

the change, the ECM and the wiring are OK.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

8. If no malfunctions have been found at this point and

no additional DTCs were set, refer to ”Diagnostic

Aids” for additional checks and information.

DTC P0131 – Front Heated Oxygen Sensor (HO2S1) Low Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check completed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and idle at normal operating

temperature.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage remain below the value specified?0.1 VGo to Step 4Go to Step 3

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Does the HO2S1 voltage stay below the specified

value?0.1 VGo to Step 4Go to Step 7

Page 646 of 2643

1F – 400IENGINE CONTROLS

DAEWOO V–121 BL4

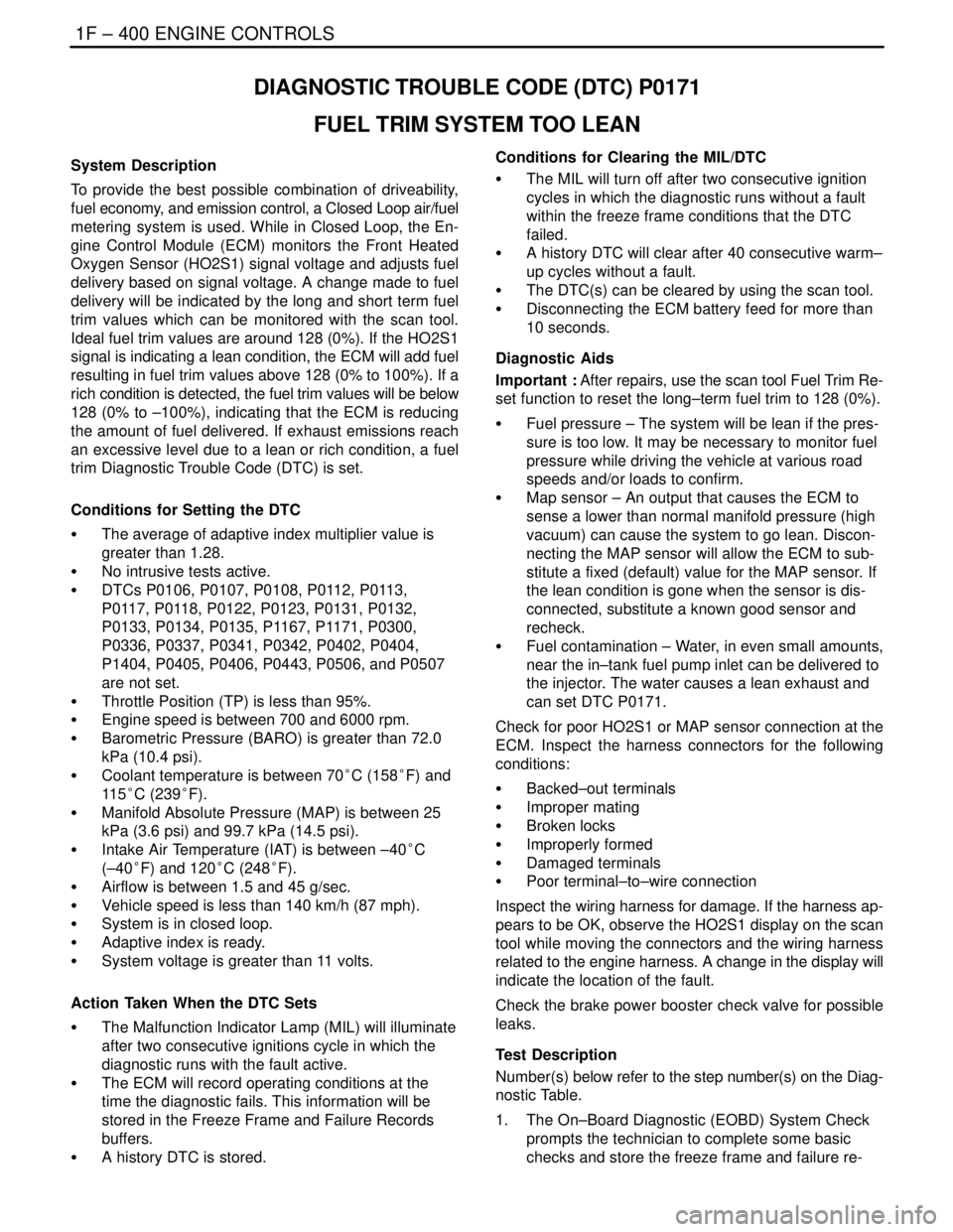

DIAGNOSTIC TROUBLE CODE (DTC) P0171

FUEL TRIM SYSTEM TOO LEAN

System Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a Closed Loop air/fuel

metering system is used. While in Closed Loop, the En-

gine Control Module (ECM) monitors the Front Heated

Oxygen Sensor (HO2S1) signal voltage and adjusts fuel

delivery based on signal voltage. A change made to fuel

delivery will be indicated by the long and short term fuel

trim values which can be monitored with the scan tool.

Ideal fuel trim values are around 128 (0%). If the HO2S1

signal is indicating a lean condition, the ECM will add fuel

resulting in fuel trim values above 128 (0% to 100%). If a

rich condition is detected, the fuel trim values will be below

128 (0% to –100%), indicating that the ECM is reducing

the amount of fuel delivered. If exhaust emissions reach

an excessive level due to a lean or rich condition, a fuel

trim Diagnostic Trouble Code (DTC) is set.

Conditions for Setting the DTC

S The average of adaptive index multiplier value is

greater than 1.28.

S No intrusive tests active.

S DTCs P0106, P0107, P0108, P0112, P0113,

P0117, P0118, P0122, P0123, P0131, P0132,

P0133, P0134, P0135, P1167, P1171, P0300,

P0336, P0337, P0341, P0342, P0402, P0404,

P1404, P0405, P0406, P0443, P0506, and P0507

are not set.

S Throttle Position (TP) is less than 95%.

S Engine speed is between 700 and 6000 rpm.

S Barometric Pressure (BARO) is greater than 72.0

kPa (10.4 psi).

S Coolant temperature is between 70°C (158°F) and

11 5°C (239°F).

S Manifold Absolute Pressure (MAP) is between 25

kPa (3.6 psi) and 99.7 kPa (14.5 psi).

S Intake Air Temperature (IAT) is between –40°C

(–40°F) and 120°C (248°F).

S Airflow is between 1.5 and 45 g/sec.

S Vehicle speed is less than 140 km/h (87 mph).

S System is in closed loop.

S Adaptive index is ready.

S System voltage is greater than 11 volts.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignitions cycle in which the

diagnostic runs with the fault active.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.Conditions for Clearing the MIL/DTC

S The MIL will turn off after two consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Important : After repairs, use the scan tool Fuel Trim Re-

set function to reset the long–term fuel trim to 128 (0%).

S Fuel pressure – The system will be lean if the pres-

sure is too low. It may be necessary to monitor fuel

pressure while driving the vehicle at various road

speeds and/or loads to confirm.

S Map sensor – An output that causes the ECM to

sense a lower than normal manifold pressure (high

vacuum) can cause the system to go lean. Discon-

necting the MAP sensor will allow the ECM to sub-

stitute a fixed (default) value for the MAP sensor. If

the lean condition is gone when the sensor is dis-

connected, substitute a known good sensor and

recheck.

S Fuel contamination – Water, in even small amounts,

near the in–tank fuel pump inlet can be delivered to

the injector. The water causes a lean exhaust and

can set DTC P0171.

Check for poor HO2S1 or MAP sensor connection at the

ECM. Inspect the harness connectors for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Inspect the wiring harness for damage. If the harness ap-

pears to be OK, observe the HO2S1 display on the scan

tool while moving the connectors and the wiring harness

related to the engine harness. A change in the display will

indicate the location of the fault.

Check the brake power booster check valve for possible

leaks.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-