cooling DAEWOO NUBIRA 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 95 of 2643

1C1 – 52I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Connect the power steering pressure hose.

19. Connect the power steering return hose.

20. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning Systems.

21. Install the generator. Refer to Section 1E, Engine

Electrical.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect all of the necessary vacuum lines, includ-

ing the brake booster vacuum hose.

27. Connect the O2 sensor connector, if equipped.

28. Connect the starter solenoid ”S” terminal wire and

power lead.

29. Connect the generator voltage regulator connector

and power lead.

30. Connect the CTS connector.

31. Connect the MAP, MAT sensor connectors.

32. Connect the TPS connector.

33. Install the electrical wiring harness clamp at the

intake manifold support bracket.

34. Connect the fuel injector harness connectors.

35. Connect the electrical connector at the DIS coil and

the ECM ground terminal at the starter.

36. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

37. Connect the breather tubes to the camshaft cover.

38. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 96 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 53

DAEWOO V–121 BL4

39. Connect the lower radiator hose to the coolant pipe.

40. Connect the upper radiator hose to the thermostat

housing.

41. Connect the surge tank coolant hose to the radia-

tor.

42. Connect the heater inlet hose to the cylinder head.

43. Connect the heater outlet hose to the coolant pipe.

44. Connect the coolant surge tank hose to the coolant

pipe.

45. Connect the surge tank coolant hose to the throttle

body.

46. Connect the throttle cable to the throttle body and

the intake manifold bracket.

47. Install the fuel pump fuse.

48. Connect the negative battery cable.

49. Refill the engine crankcase with engine oil.

50. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

51. Bleed the power steering system. Refer to Section

6A, Power Steering System.

52. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

53. Install the hood. Refer to Section 9R, Body Front

End.

PISTONS AND RODS

Tools Required

KM–427 Piston Pin Service Set

KM 470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts.

4. Remove the oil suction pipe.

5. Move the piston to the bottom of the piston stroke.

6. Mark the connecting rod cap for position.

7. Remove the connecting rod cap bolts.

8. Remove the connecting rod cap and the lower con-

necting rod bearing.

9. Remove the upper piston connecting rod bearing.

10. Ridge ream the cylinder wall.

Page 133 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 13

DAEWOO V–121 BL4

Installation Procedure

1. Apply a small amount of gasket sealant to the cor-

ners of the front camshaft caps and the top of the

rear camshaft cover–to–cylinder head seal.

2. Install the new camshaft cover gasket to the cam-

shaft cover.

3. Install the camshaft cover.

4. Install the camshaft cover bolts.

Tighten

Tighten the camshaft cover bolts to 8 NSm (71 lb–in).

5. Connect the ignition wires to the spark plugs.

6. Install the spark plug cover.

Tighten

Tighten the spark plug cover bolts to 8 NSm (71 lb–in).

7. Install the spark plug cover bolts.

8. Connect the camshaft position sensor connector.

9. Connect all of the necessary vacuum lines.

10. Connect the breather tube to the camshaft cover.

11. Connect the negative battery cable.

CYLINDER HEAD AND GASKET

Tools Required

KM–470–B Angular Torque Gauge

J–28467–B Engine Assembly Support Fixture

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the electronic control mdule (ECM)

ground terminal.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

Page 142 of 2643

1C2 – 22I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

56. Connect the CTS connector.

57. Connect the engine CTS connector.

58. Connect the IAC valve connector.

59. Connect the TPS connector.

60. Install the CCP and the EGR solenoid bracket bolt.

Tighten

Tighten the charcoal canister purge and exhaust gas

recirculation solenoid bracket bolt to 5 NSm (44 lb–in).

61. Connect the DIS coil connector.

62. Connect the O2 sensor connector, if equipped.

63. Connect the ECM ground terminal.

64. Install the fuel pump fuse.

65. Connect the negative battery ground cable.

66. Refill the engine cooling system. Refer to Section

1D, Engine Cooling.

CAMSHAFTS

Removal Procedure

1. Remove the timing belt. Refer to ”Timing Belt” in

this section.

2. Disconnect the breather tube at the camshaft cov-

er.

3. Disconnect the engine ventilation hose at the cam-

shaft cover.

4. Remove the spark plug cover bolts.

5. Remove the spark plug cover.

6. Disconnect the ignition wires from the spark plugs.

7. Remove the camshaft cover bolts.

8. Remove the camshaft cover washers.

9. Remove the camshaft cover and the camshaft cov-

er gasket.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

10. While holding the intake camshaft firmly in place,

remove the intake camshaft gear bolt.

11. Remove the intake camshaft gear.

12. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft gear bolt.

13. Remove the exhaust camshaft gear.

Page 158 of 2643

1C2 – 38I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

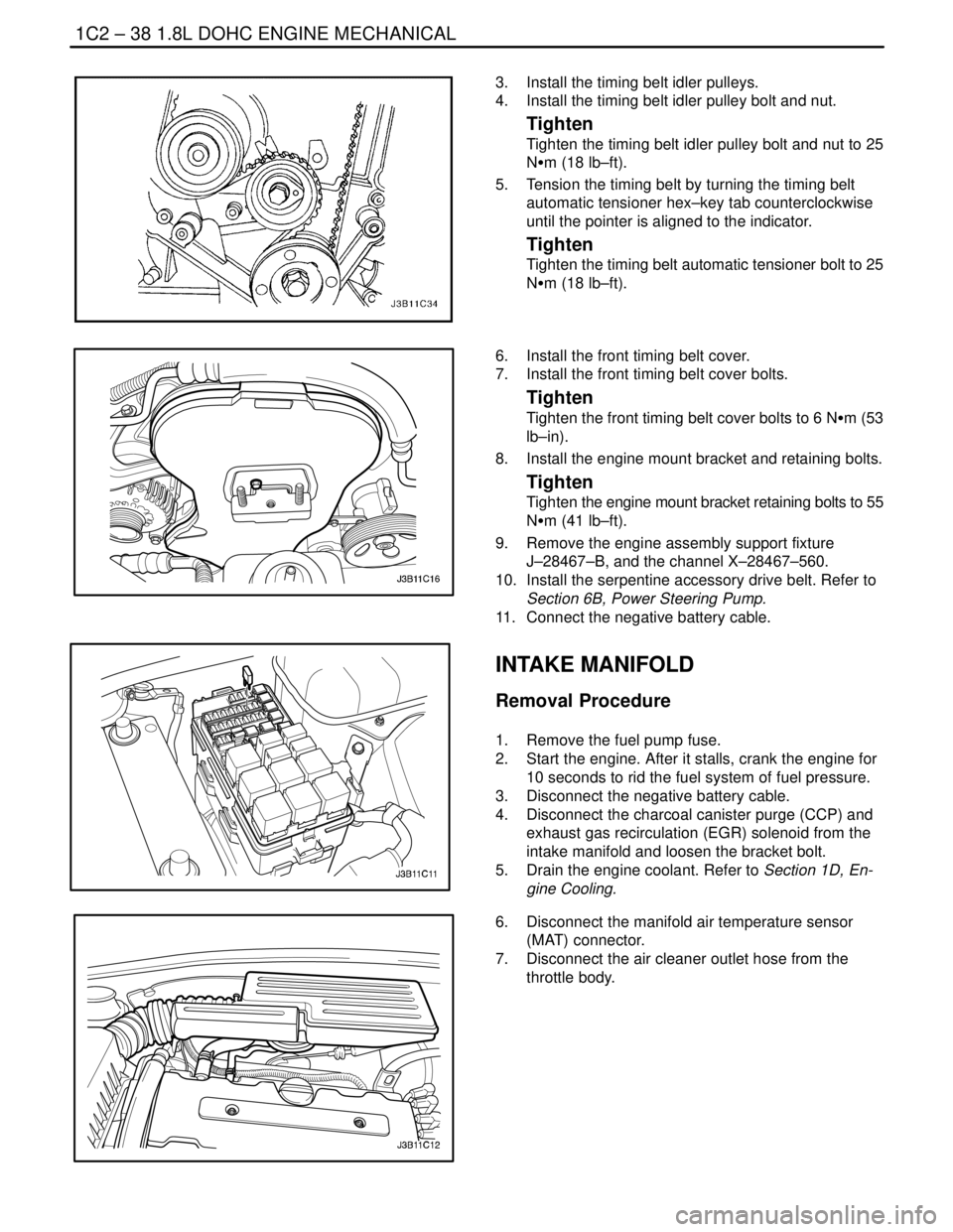

3. Install the timing belt idler pulleys.

4. Install the timing belt idler pulley bolt and nut.

Tighten

Tighten the timing belt idler pulley bolt and nut to 25

NSm (18 lb–ft).

5. Tension the timing belt by turning the timing belt

automatic tensioner hex–key tab counterclockwise

until the pointer is aligned to the indicator.

Tighten

Tighten the timing belt automatic tensioner bolt to 25

NSm (18 lb–ft).

6. Install the front timing belt cover.

7. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

8. Install the engine mount bracket and retaining bolts.

Tighten

Tighten the engine mount bracket retaining bolts to 55

NSm (41 lb–ft).

9. Remove the engine assembly support fixture

J–28467–B, and the channel X–28467–560.

10. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

11. Connect the negative battery cable.

INTAKE MANIFOLD

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the charcoal canister purge (CCP) and

exhaust gas recirculation (EGR) solenoid from the

intake manifold and loosen the bracket bolt.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

6. Disconnect the manifold air temperature sensor

(MAT) connector.

7. Disconnect the air cleaner outlet hose from the

throttle body.

Page 161 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 41

DAEWOO V–121 BL4

14. Connect the MAP sensor connector.

15. Connect the coolant hoses to the throttle body.

16. Connect the IAC valve connector.

17. Connect the TPS connector.

18. Connect the air cleaner outlet hose to the throttle

body.

19. Connect the MAT sensor connector.

20. Connect the CCP and EGR solenoid at the intake

manifold and tighten the bracket bolt.

Tighten

Tighten the charcoal canister purge and exhaust gas

recirculation solenoid bracket bolt to 5 NSm (44 lb–in).

21. Install the fuel pump fuse.

22. Connect the negative battery cable.

23. Refill the engine cooling system. Refer to Section

1D, Engine Cooling.

EXHAUST MANIFOLD

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the oxygen (O2) sensor connector, if

equipped.

3. Remove the exhaust manifold heat shield bolts.

4. Remove the exhaust manifold heat shield.

5. Remove the exhaust flex pipe retaining nuts from

the exhaust manifold studs.

Page 166 of 2643

1C2 – 46I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

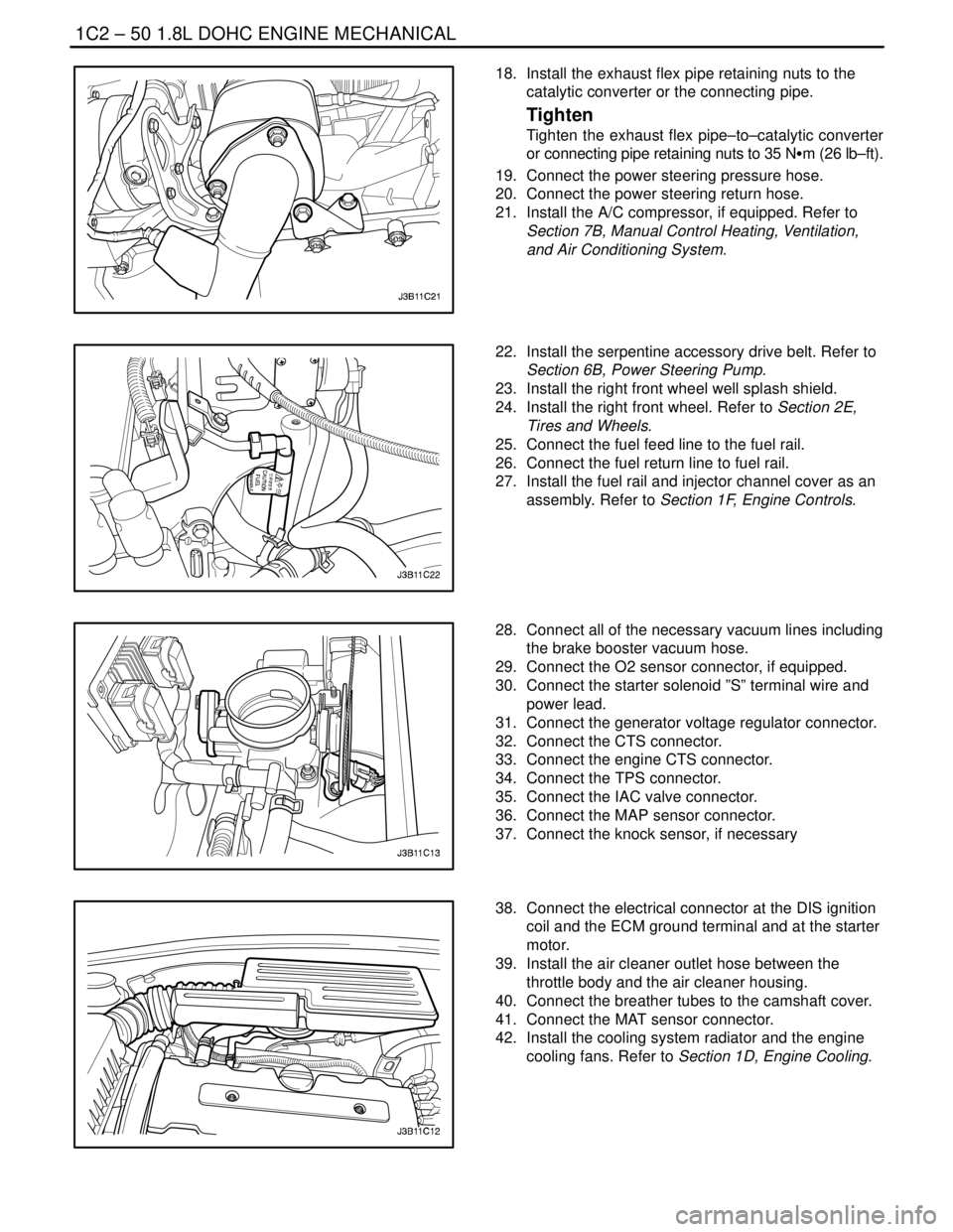

7. Install the timing belt automatic tensioner and bolt.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

10. Connect the negative battery cable.

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Discharge the air conditioning (A/C) system, if

equipped. Refer to Section 7B, Manual Control

Heating, Ventilation, and Air Conditioning Systems.

7. Disconnect the manifold air temperature (MAT)

sensor connector.

8. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

9. Disconnect the breather tubes from the camshaft

cover.

10. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

11. Remove the right front wheel well splash shield.

Refer to Section 9R, Body Font End.

12. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

13. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

14. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

15. Disconnect the upper radiator hose from the ther-

mostat housing.

16. Disconnect the power steering return hose from the

power steering pump.

17. Disconnect the power steering pressure hose from

the power steering pump.

18. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal and at the starter

motor.

Page 170 of 2643

1C2 – 50I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

19. Connect the power steering pressure hose.

20. Connect the power steering return hose.

21. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect the fuel return line to fuel rail.

27. Install the fuel rail and injector channel cover as an

assembly. Refer to Section 1F, Engine Controls.

28. Connect all of the necessary vacuum lines including

the brake booster vacuum hose.

29. Connect the O2 sensor connector, if equipped.

30. Connect the starter solenoid ”S” terminal wire and

power lead.

31. Connect the generator voltage regulator connector.

32. Connect the CTS connector.

33. Connect the engine CTS connector.

34. Connect the TPS connector.

35. Connect the IAC valve connector.

36. Connect the MAP sensor connector.

37. Connect the knock sensor, if necessary

38. Connect the electrical connector at the DIS ignition

coil and the ECM ground terminal and at the starter

motor.

39. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

40. Connect the breather tubes to the camshaft cover.

41. Connect the MAT sensor connector.

42. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 171 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 51

DAEWOO V–121 BL4

43. Connect the lower radiator hose to the coolant pipe.

44. Connect the upper radiator hose to the thermostat

housing.

45. Connect the heater inlet hose to the cylinder head.

46. Connect the heater outlet hose to the coolant pipe.

47. Connect the coolant surge tank hose to the coolant

pipe.

48. Connect the coolant hose to the throttle body.

49. Connect the throttle cable to the throttle body and

the intake manifold bracket.

50. Install the fuel pump fuse.

51. Connect the negative battery cable.

52. Refill the engine crankcase with engine oil.

53. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

54. Bleed the power steering system. Refer to Section

6A, Power Steering.

55. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

56. Install the hood. Refer to Section 9R, Body Front

End.

PISTONS AND RODS

Tools Required

J–8037 Universal Piston Ring Compressor

J–8087 Cylinder Bore Check Gauge

KM–427 Piston Pin Service Set

KM–470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and exhaust manifold attached. Refer to ”Cylinder

Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts and support

bracket bolts.

4. Remove the oil suction pipe.

5. Remove the crankshaft bearing bridge and the oil

pan scraper bolts.

6. Remove the crankshaft bearing bridge and the oil

pan scraper.

Page 196 of 2643

SECTION : 1D

ENGINE COOLING

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS1D–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacity 1D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 1D–2. . . . . . . . . . .

SPECIAL TOOLS1D–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 1D–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS1D–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat Test 1D–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Surge Tank Cap Test 1D–3. . . . . . . . . . . . . . . . . . . . . . .

Cooling System Diagnosis 1D–4. . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR1D–5 . . . . . . . . . . . . . . . . . . . .

Radiator/Fan 1D–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Pump/Thermostat (1.4L/1.6L DOHC) 1D–6. . .

Water Pump/Thermostat (1.8L DOHC) 1D–7. . . . . . .

MAINTENANCE AND REPAIR1D–8 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 1D–8. . . . . . . . . . . . . . . . . . . . . Draining and Refilling the Cooling System 1D–8. . . . .

Thermostat (1.4L/1.6L DOHC) 1D–9. . . . . . . . . . . . . . .

Thermostat (1.8L DOHC) 1D–10. . . . . . . . . . . . . . . . . .

Water Pump 1D–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Cooling Fan – Main or Auxiliary 1D–13. . . . . .

Surge Tank 1D–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator 1D–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION1D–18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 1D–18. . . . . . . . . . . . . . . . . . . . . . .

Radiator 1D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Surge Tank 1D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Pump 1D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat 1D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Cooling Fan 1D–19. . . . . . . . . . . . . . . . . . . . . . .

Engine Block Heater 1D–19. . . . . . . . . . . . . . . . . . . . . .