check engine DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 116 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 73

DAEWOO V–121 BL4

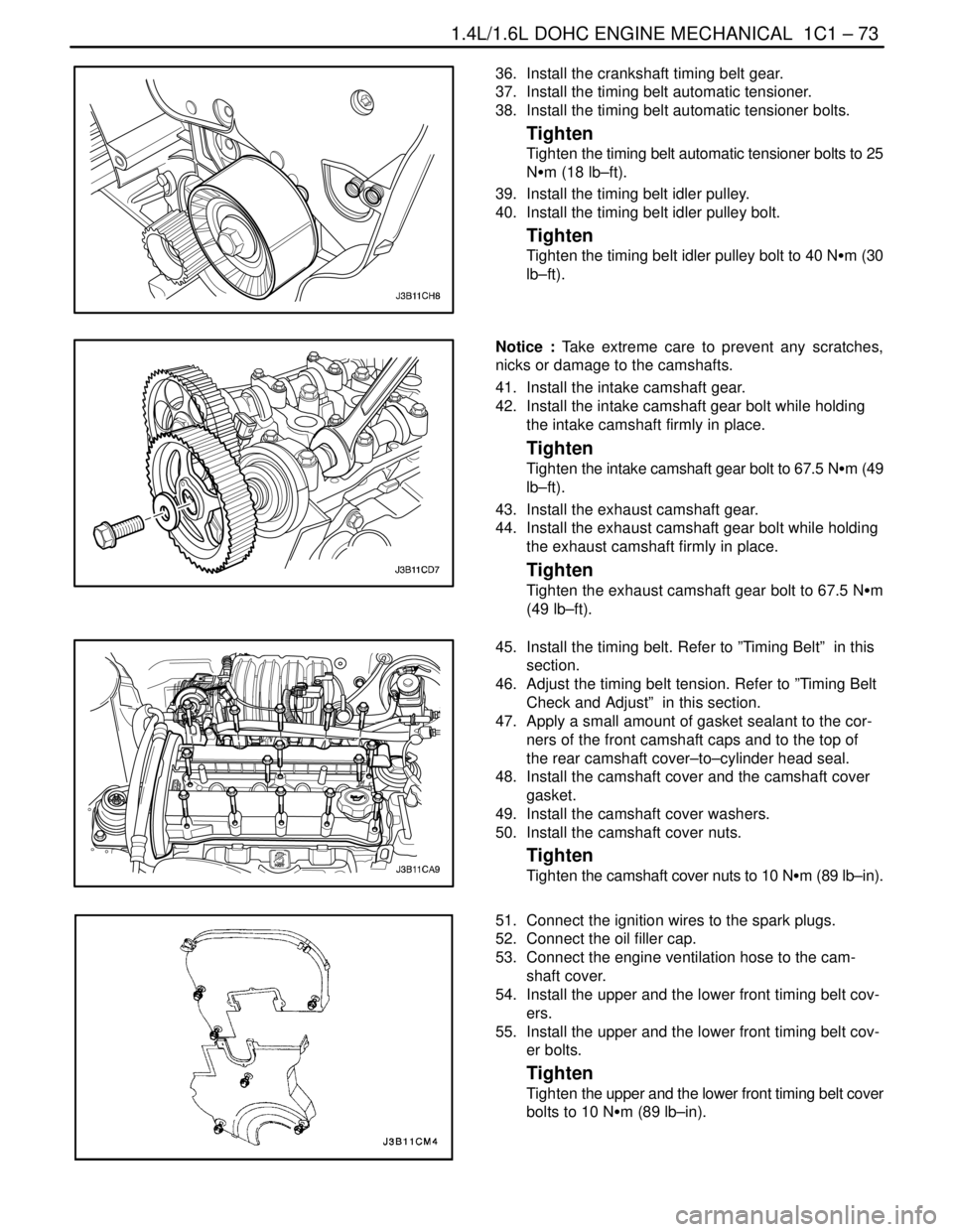

36. Install the crankshaft timing belt gear.

37. Install the timing belt automatic tensioner.

38. Install the timing belt automatic tensioner bolts.

Tighten

Tighten the timing belt automatic tensioner bolts to 25

NSm (18 lb–ft).

39. Install the timing belt idler pulley.

40. Install the timing belt idler pulley bolt.

Tighten

Tighten the timing belt idler pulley bolt to 40 NSm (30

lb–ft).

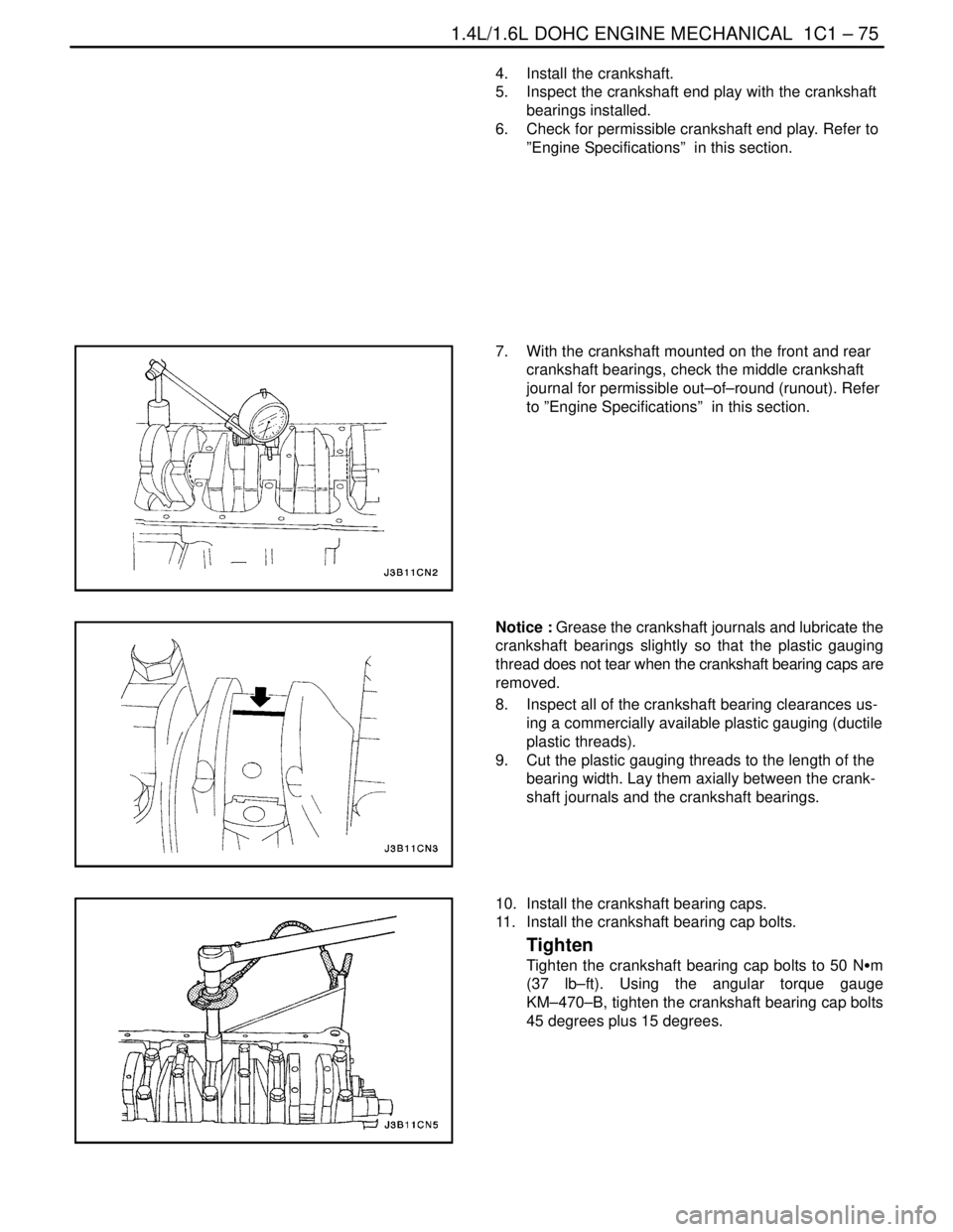

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

41. Install the intake camshaft gear.

42. Install the intake camshaft gear bolt while holding

the intake camshaft firmly in place.

Tighten

Tighten the intake camshaft gear bolt to 67.5 NSm (49

lb–ft).

43. Install the exhaust camshaft gear.

44. Install the exhaust camshaft gear bolt while holding

the exhaust camshaft firmly in place.

Tighten

Tighten the exhaust camshaft gear bolt to 67.5 NSm

(49 lb–ft).

45. Install the timing belt. Refer to ”Timing Belt” in this

section.

46. Adjust the timing belt tension. Refer to ”Timing Belt

Check and Adjust” in this section.

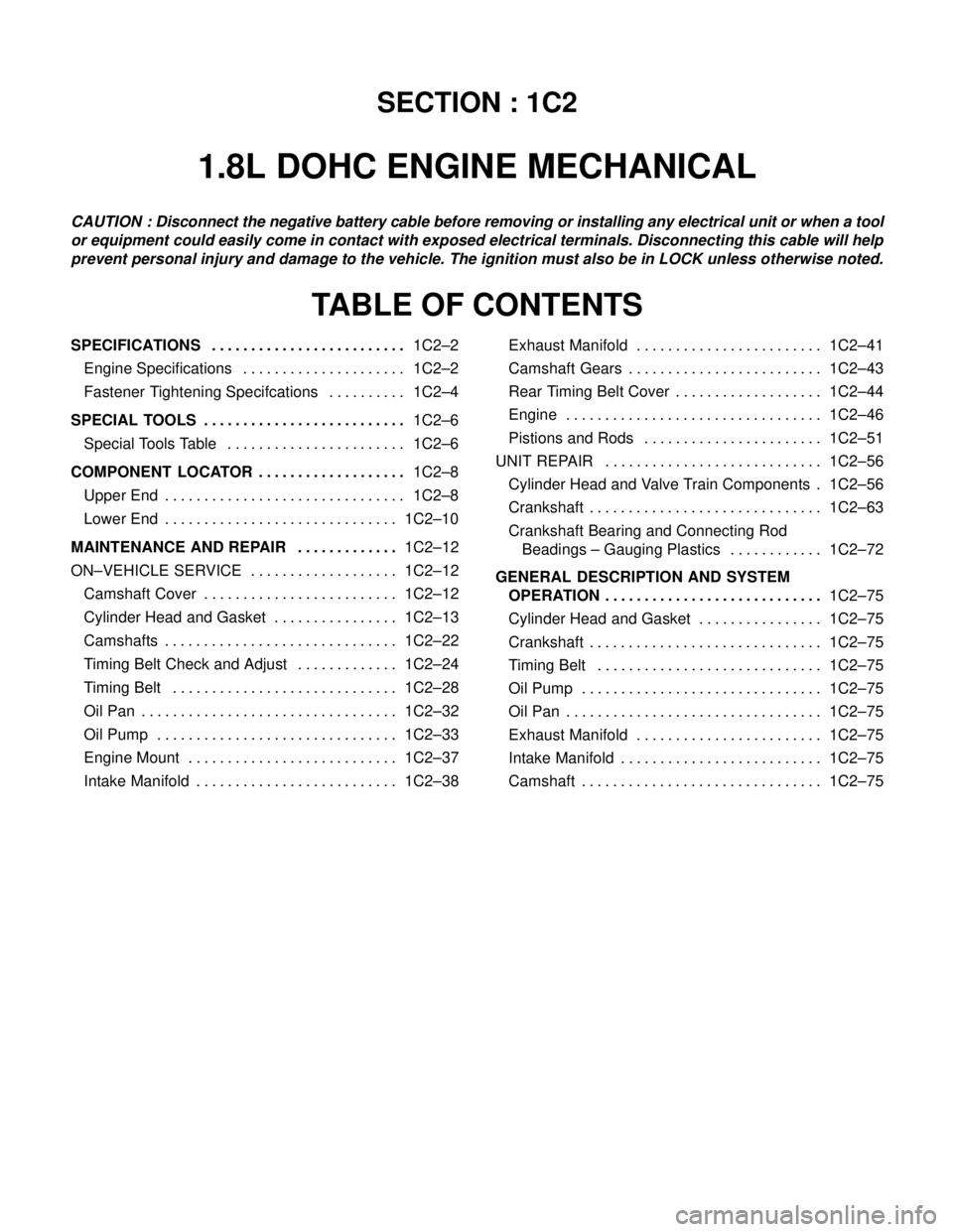

47. Apply a small amount of gasket sealant to the cor-

ners of the front camshaft caps and to the top of

the rear camshaft cover–to–cylinder head seal.

48. Install the camshaft cover and the camshaft cover

gasket.

49. Install the camshaft cover washers.

50. Install the camshaft cover nuts.

Tighten

Tighten the camshaft cover nuts to 10 NSm (89 lb–in).

51. Connect the ignition wires to the spark plugs.

52. Connect the oil filler cap.

53. Connect the engine ventilation hose to the cam-

shaft cover.

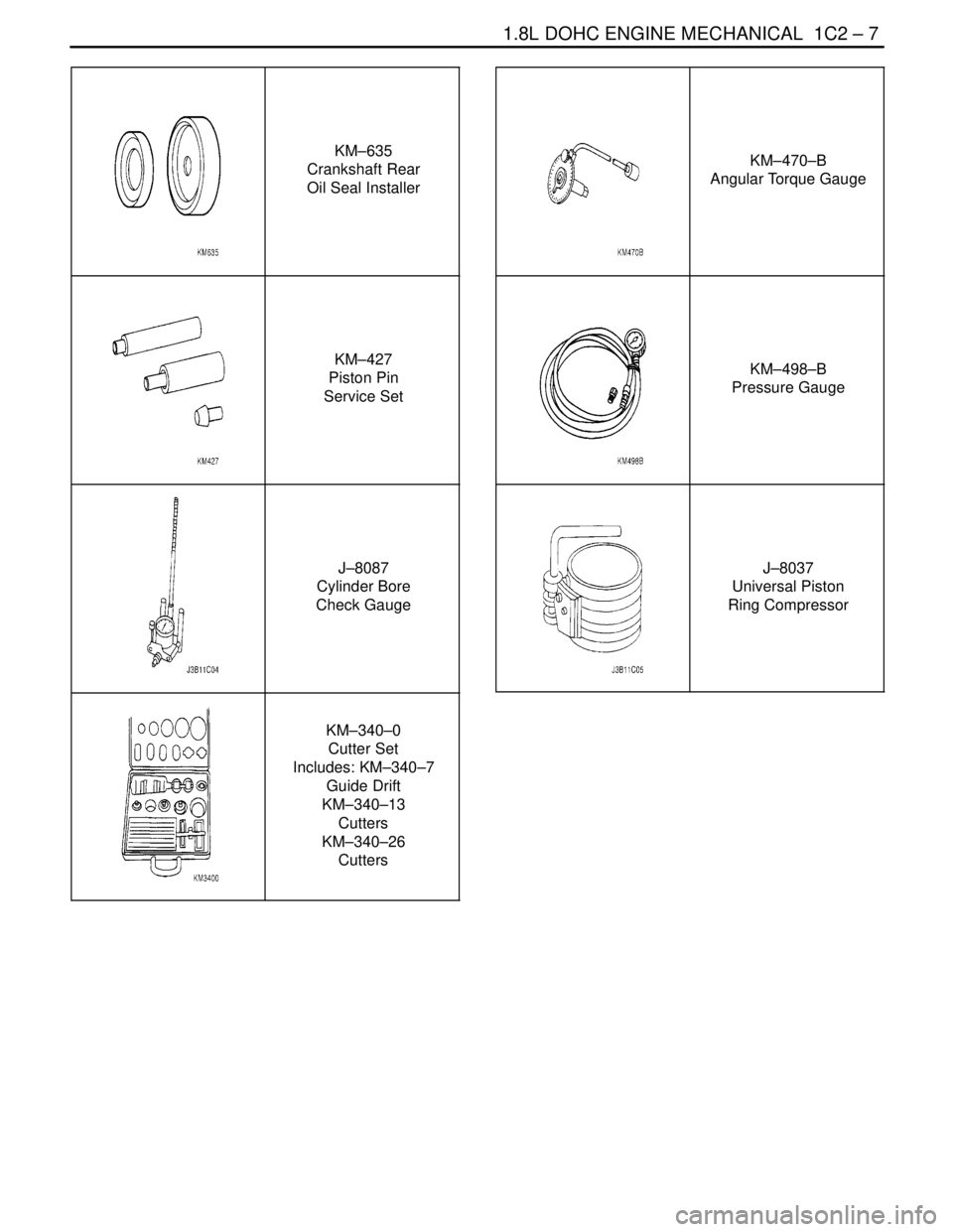

54. Install the upper and the lower front timing belt cov-

ers.

55. Install the upper and the lower front timing belt cov-

er bolts.

Tighten

Tighten the upper and the lower front timing belt cover

bolts to 10 NSm (89 lb–in).

Page 118 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 75

DAEWOO V–121 BL4

4. Install the crankshaft.

5. Inspect the crankshaft end play with the crankshaft

bearings installed.

6. Check for permissible crankshaft end play. Refer to

”Engine Specifications” in this section.

7. With the crankshaft mounted on the front and rear

crankshaft bearings, check the middle crankshaft

journal for permissible out–of–round (runout). Refer

to ”Engine Specifications” in this section.

Notice : Grease the crankshaft journals and lubricate the

crankshaft bearings slightly so that the plastic gauging

thread does not tear when the crankshaft bearing caps are

removed.

8. Inspect all of the crankshaft bearing clearances us-

ing a commercially available plastic gauging (ductile

plastic threads).

9. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the crank-

shaft journals and the crankshaft bearings.

10. Install the crankshaft bearing caps.

11. Install the crankshaft bearing cap bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft). Using the angular torque gauge

KM–470–B, tighten the crankshaft bearing cap bolts

45 degrees plus 15 degrees.

Page 121 of 2643

SECTION : 1C2

1.8L DOHC ENGINE MECHANICAL

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS1C2–2 . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Specifications 1C2–2. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifcations 1C2–4. . . . . . . . . .

SPECIAL TOOLS1C2–6 . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 1C2–6. . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR1C2–8 . . . . . . . . . . . . . . . . . . .

Upper End 1C2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower End 1C2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR1C2–12 . . . . . . . . . . . . .

ON–VEHICLE SERVICE 1C2–12. . . . . . . . . . . . . . . . . . .

Camshaft Cover 1C2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1C2–13. . . . . . . . . . . . . . . .

Camshafts 1C2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt Check and Adjust 1C2–24. . . . . . . . . . . . .

Timing Belt 1C2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1C2–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1C2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Mount 1C2–37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1C2–38. . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust Manifold 1C2–41. . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Gears 1C2–43. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Timing Belt Cover 1C2–44. . . . . . . . . . . . . . . . . . .

Engine 1C2–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistions and Rods 1C2–51. . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 1C2–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Valve Train Components 1C2–56.

Crankshaft 1C2–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Bearing and Connecting Rod

Beadings – Gauging Plastics 1C2–72. . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION1C2–75 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1C2–75. . . . . . . . . . . . . . . .

Crankshaft 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold 1C2–75. . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 127 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 7

DAEWOO V–121 BL4

KM–635

Crankshaft Rear

Oil Seal Installer

KM–427

Piston Pin

Service Set

J–8087

Cylinder Bore

Check Gauge

KM–340–0

Cutter Set

Includes: KM–340–7

Guide Drift

KM–340–13

Cutters

KM–340–26

Cutters

KM–470–B

Angular Torque Gauge

KM–498–B

Pressure Gauge

J–8037

Universal Piston

Ring Compressor

Page 141 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 21

DAEWOO V–121 BL4

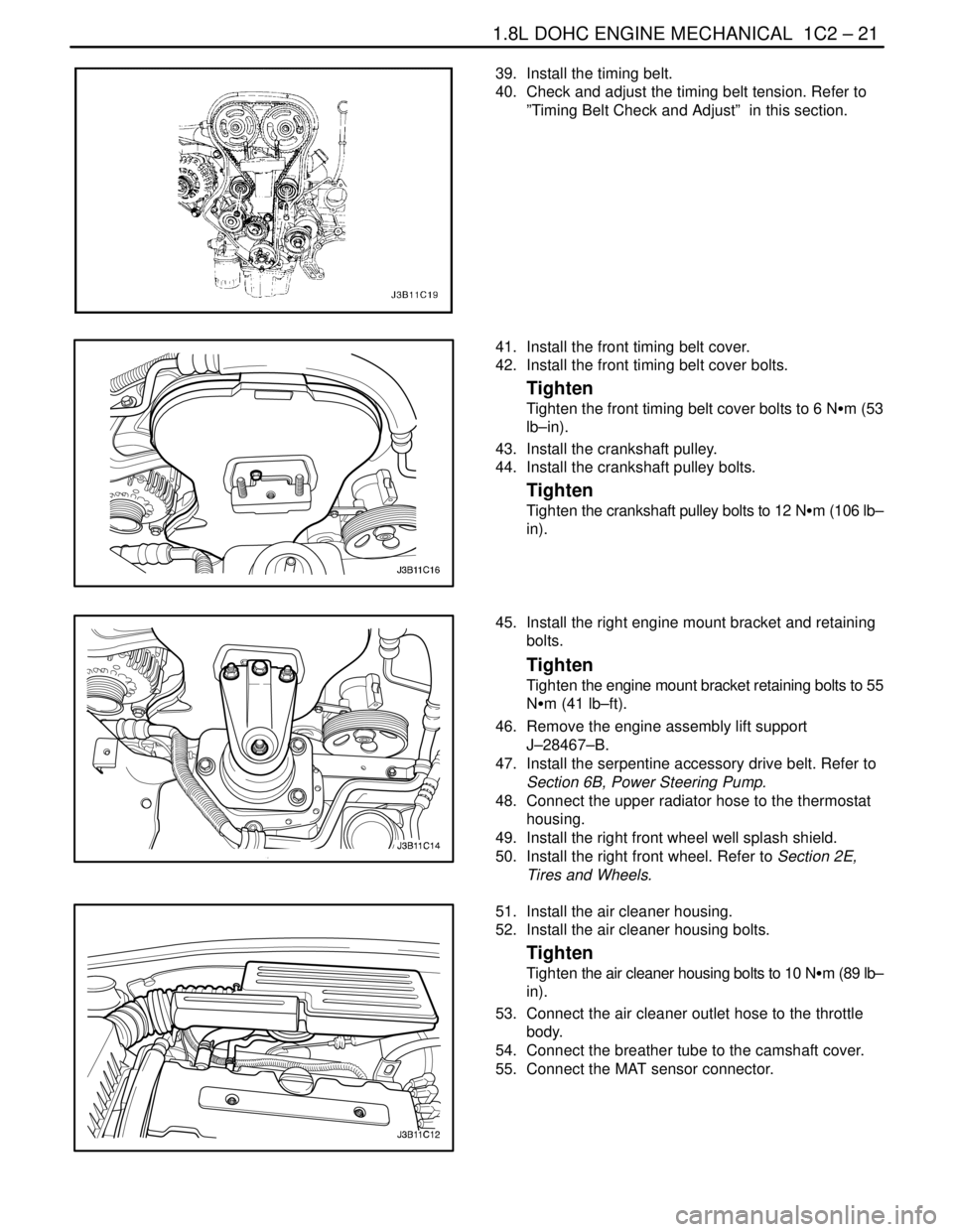

39. Install the timing belt.

40. Check and adjust the timing belt tension. Refer to

”Timing Belt Check and Adjust” in this section.

41. Install the front timing belt cover.

42. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

43. Install the crankshaft pulley.

44. Install the crankshaft pulley bolts.

Tighten

Tighten the crankshaft pulley bolts to 12 NSm (106 lb–

in).

45. Install the right engine mount bracket and retaining

bolts.

Tighten

Tighten the engine mount bracket retaining bolts to 55

NSm (41 lb–ft).

46. Remove the engine assembly lift support

J–28467–B.

47. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

48. Connect the upper radiator hose to the thermostat

housing.

49. Install the right front wheel well splash shield.

50. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

51. Install the air cleaner housing.

52. Install the air cleaner housing bolts.

Tighten

Tighten the air cleaner housing bolts to 10 NSm (89 lb–

in).

53. Connect the air cleaner outlet hose to the throttle

body.

54. Connect the breather tube to the camshaft cover.

55. Connect the MAT sensor connector.

Page 143 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 23

DAEWOO V–121 BL4

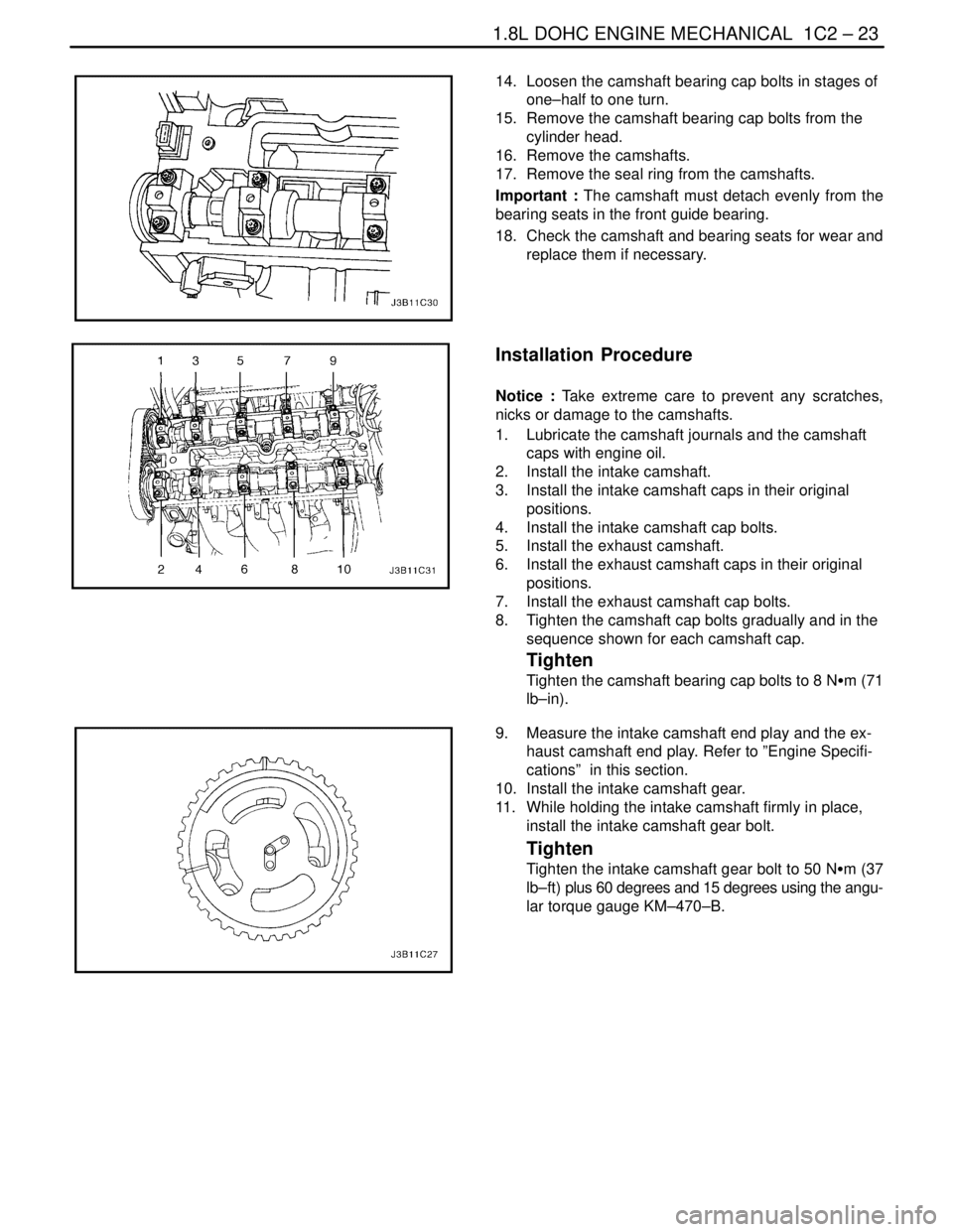

14. Loosen the camshaft bearing cap bolts in stages of

one–half to one turn.

15. Remove the camshaft bearing cap bolts from the

cylinder head.

16. Remove the camshafts.

17. Remove the seal ring from the camshafts.

Important : The camshaft must detach evenly from the

bearing seats in the front guide bearing.

18. Check the camshaft and bearing seats for wear and

replace them if necessary.

Installation Procedure

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

1. Lubricate the camshaft journals and the camshaft

caps with engine oil.

2. Install the intake camshaft.

3. Install the intake camshaft caps in their original

positions.

4. Install the intake camshaft cap bolts.

5. Install the exhaust camshaft.

6. Install the exhaust camshaft caps in their original

positions.

7. Install the exhaust camshaft cap bolts.

8. Tighten the camshaft cap bolts gradually and in the

sequence shown for each camshaft cap.

Tighten

Tighten the camshaft bearing cap bolts to 8 NSm (71

lb–in).

9. Measure the intake camshaft end play and the ex-

haust camshaft end play. Refer to ”Engine Specifi-

cations” in this section.

10. Install the intake camshaft gear.

11. While holding the intake camshaft firmly in place,

install the intake camshaft gear bolt.

Tighten

Tighten the intake camshaft gear bolt to 50 NSm (37

lb–ft) plus 60 degrees and 15 degrees using the angu-

lar torque gauge KM–470–B.

Page 144 of 2643

1C2 – 24I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

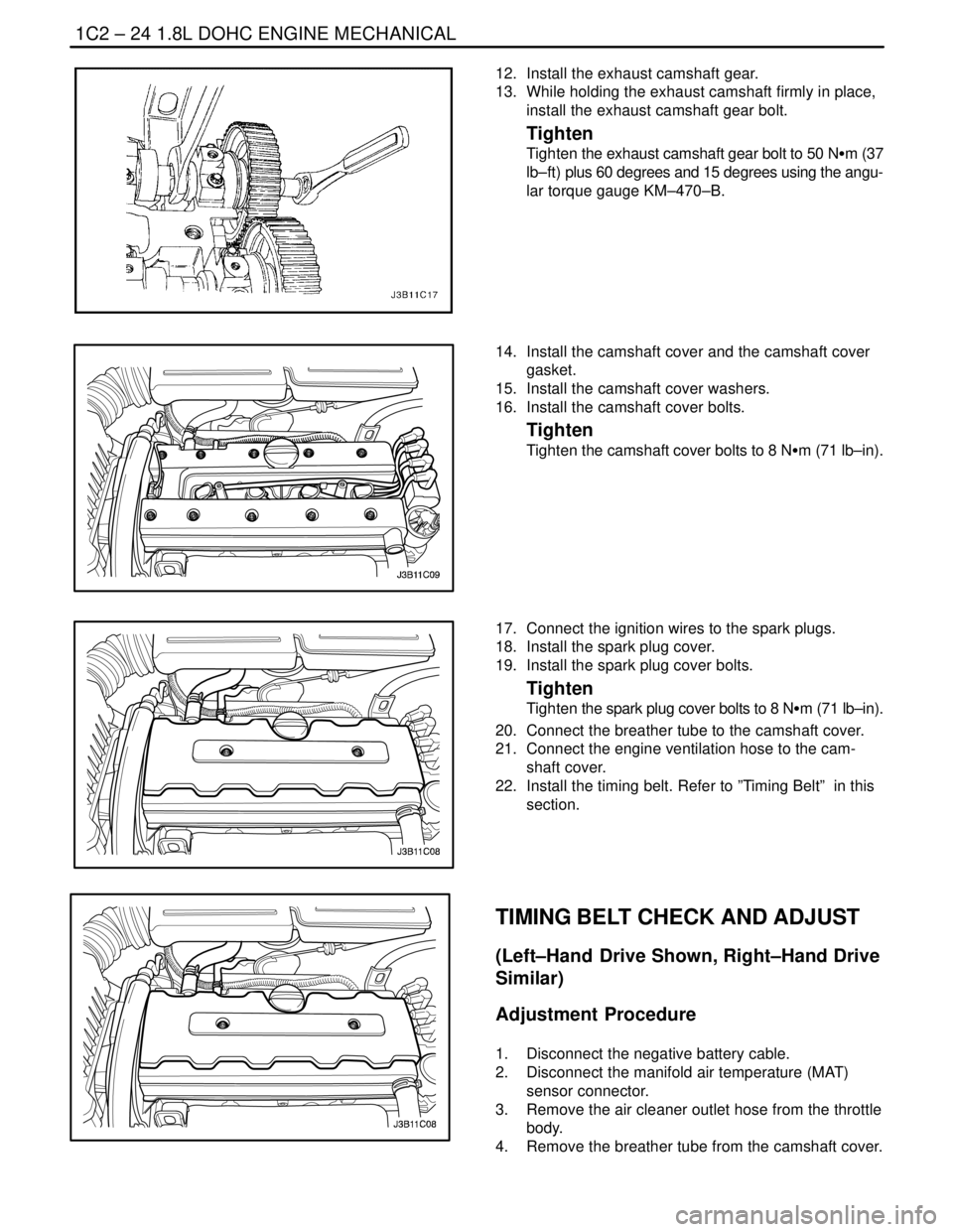

12. Install the exhaust camshaft gear.

13. While holding the exhaust camshaft firmly in place,

install the exhaust camshaft gear bolt.

Tighten

Tighten the exhaust camshaft gear bolt to 50 NSm (37

lb–ft) plus 60 degrees and 15 degrees using the angu-

lar torque gauge KM–470–B.

14. Install the camshaft cover and the camshaft cover

gasket.

15. Install the camshaft cover washers.

16. Install the camshaft cover bolts.

Tighten

Tighten the camshaft cover bolts to 8 NSm (71 lb–in).

17. Connect the ignition wires to the spark plugs.

18. Install the spark plug cover.

19. Install the spark plug cover bolts.

Tighten

Tighten the spark plug cover bolts to 8 NSm (71 lb–in).

20. Connect the breather tube to the camshaft cover.

21. Connect the engine ventilation hose to the cam-

shaft cover.

22. Install the timing belt. Refer to ”Timing Belt” in this

section.

TIMING BELT CHECK AND ADJUST

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Adjustment Procedure

1. Disconnect the negative battery cable.

2. Disconnect the manifold air temperature (MAT)

sensor connector.

3. Remove the air cleaner outlet hose from the throttle

body.

4. Remove the breather tube from the camshaft cover.

Page 146 of 2643

1C2 – 26I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

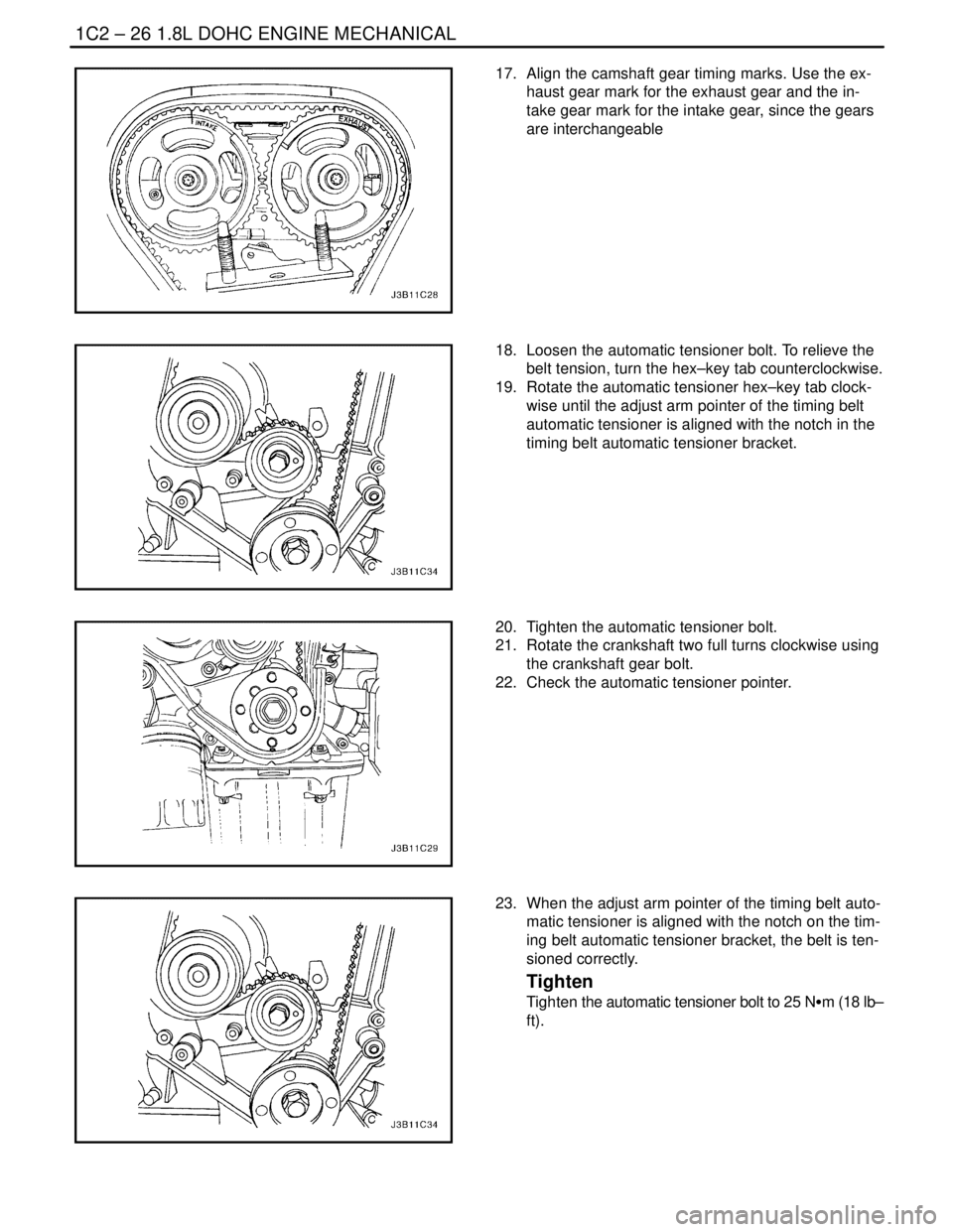

17. Align the camshaft gear timing marks. Use the ex-

haust gear mark for the exhaust gear and the in-

take gear mark for the intake gear, since the gears

are interchangeable

18. Loosen the automatic tensioner bolt. To relieve the

belt tension, turn the hex–key tab counterclockwise.

19. Rotate the automatic tensioner hex–key tab clock-

wise until the adjust arm pointer of the timing belt

automatic tensioner is aligned with the notch in the

timing belt automatic tensioner bracket.

20. Tighten the automatic tensioner bolt.

21. Rotate the crankshaft two full turns clockwise using

the crankshaft gear bolt.

22. Check the automatic tensioner pointer.

23. When the adjust arm pointer of the timing belt auto-

matic tensioner is aligned with the notch on the tim-

ing belt automatic tensioner bracket, the belt is ten-

sioned correctly.

Tighten

Tighten the automatic tensioner bolt to 25 NSm (18 lb–

ft).

Page 150 of 2643

1C2 – 30I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

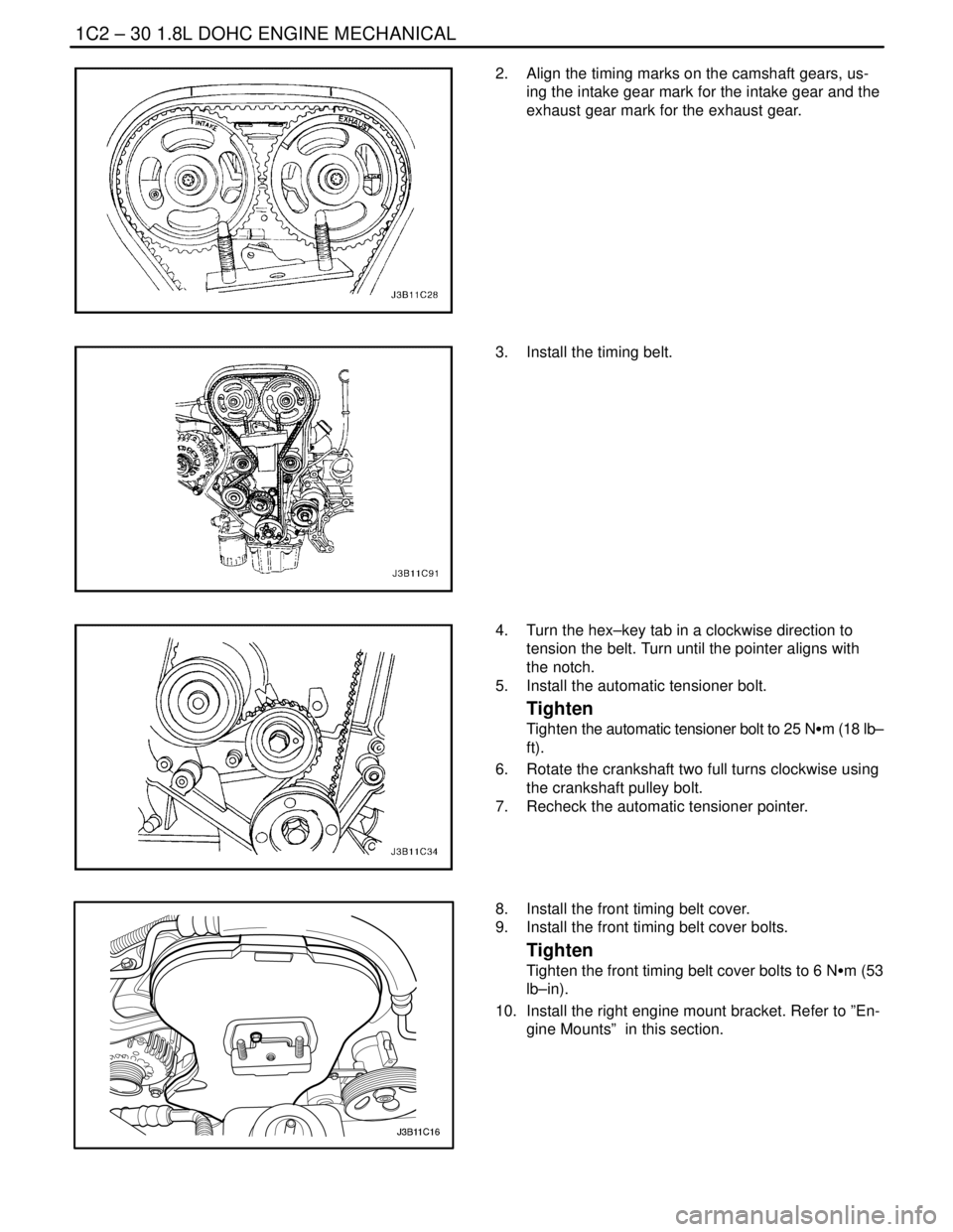

2. Align the timing marks on the camshaft gears, us-

ing the intake gear mark for the intake gear and the

exhaust gear mark for the exhaust gear.

3. Install the timing belt.

4. Turn the hex–key tab in a clockwise direction to

tension the belt. Turn until the pointer aligns with

the notch.

5. Install the automatic tensioner bolt.

Tighten

Tighten the automatic tensioner bolt to 25 NSm (18 lb–

ft).

6. Rotate the crankshaft two full turns clockwise using

the crankshaft pulley bolt.

7. Recheck the automatic tensioner pointer.

8. Install the front timing belt cover.

9. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

10. Install the right engine mount bracket. Refer to ”En-

gine Mounts” in this section.

Page 154 of 2643

1C2 – 34I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

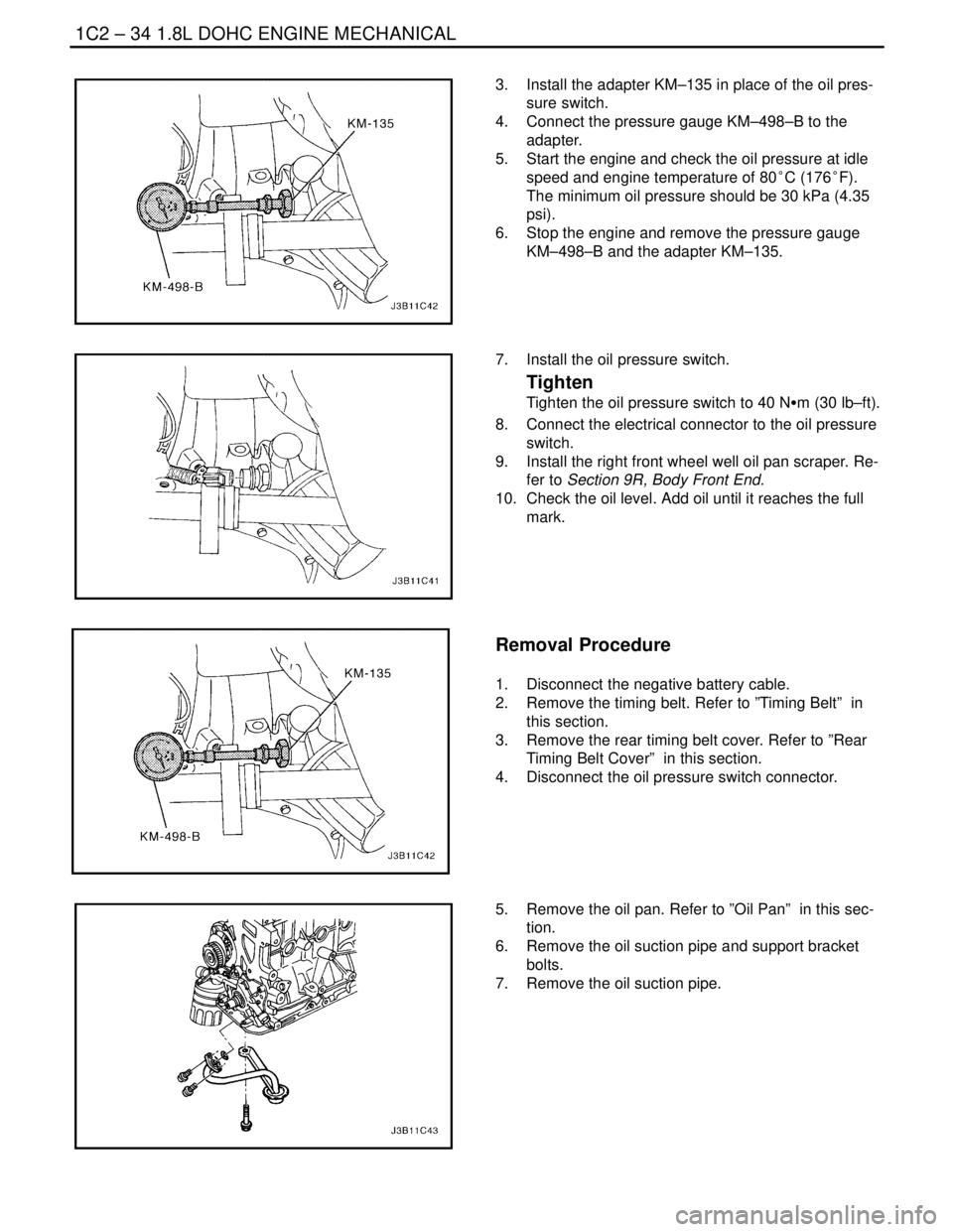

3. Install the adapter KM–135 in place of the oil pres-

sure switch.

4. Connect the pressure gauge KM–498–B to the

adapter.

5. Start the engine and check the oil pressure at idle

speed and engine temperature of 80°C (176°F).

The minimum oil pressure should be 30 kPa (4.35

psi).

6. Stop the engine and remove the pressure gauge

KM–498–B and the adapter KM–135.

7. Install the oil pressure switch.

Tighten

Tighten the oil pressure switch to 40 NSm (30 lb–ft).

8. Connect the electrical connector to the oil pressure

switch.

9. Install the right front wheel well oil pan scraper. Re-

fer to Section 9R, Body Front End.

10. Check the oil level. Add oil until it reaches the full

mark.

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to ”Timing Belt” in

this section.

3. Remove the rear timing belt cover. Refer to ”Rear

Timing Belt Cover” in this section.

4. Disconnect the oil pressure switch connector.

5. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

6. Remove the oil suction pipe and support bracket

bolts.

7. Remove the oil suction pipe.