air condition DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 517 of 548

I

I

3

Set

temperature

lever

to

max

imum

cold

position

Air

Conditioning

4

Sefblower

to

maximum

speed

S

Check

sight

glass

after

the

lapse

Almost

no

refrigerant

Check

item

Temperature

of

high

prenure

and

low

pressure

lines

Almost

no

difference

between

high

presswc

and

lowpressufC

side

temperature

State

in

sight

gl

ltS3

Bubbles

flow

continu

ously

Bubbles

will

disappear

and

some

thing

like

mist

wiD

flow

when

rerrigel

l

llt

is

nearly

gone

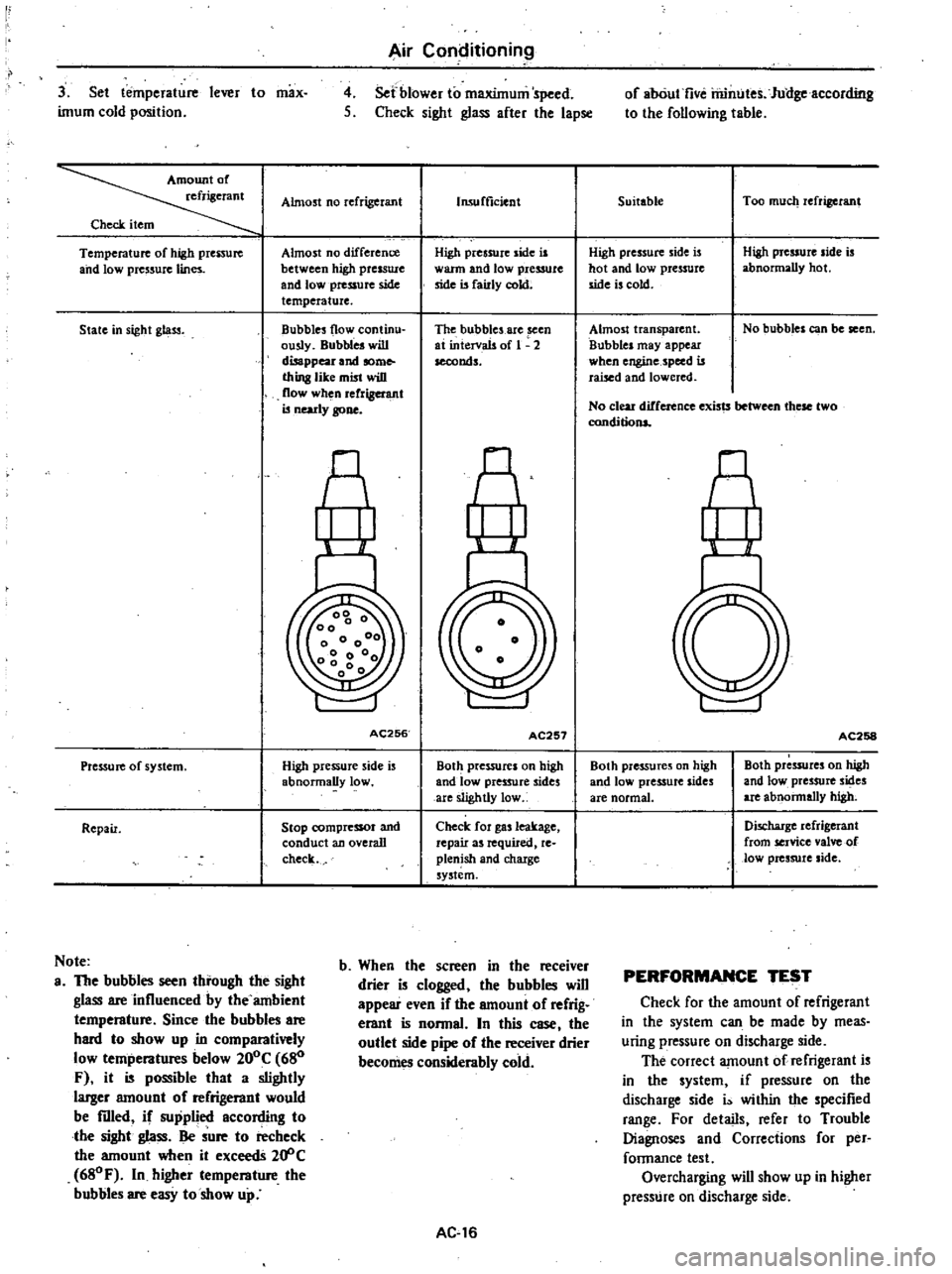

AC256

Pressure

of

system

High

pressure

side

is

abnormally

low

Repair

Stop

compressor

and

conduct

an

overall

check

Note

a

The

bubbles

seen

tbrough

the

sight

glass

are

influenced

by

the

ambient

tempemture

Since

the

bubbles

are

bard

to

show

up

in

comparatively

low

tempemtures

below

200C

680

F

it

is

possible

that

a

slightly

larger

amouot

of

refrigemot

would

be

filled

if

supplied

according

to

tbe

sight

glass

Be

sure

to

recheck

the

amount

when

it

exceedS

20

C

680F

In

higher

tempemture

tbe

bubbles

are

easy

to

show

up

Insufficient

High

pressure

side

is

warm

and

low

pressure

side

is

fairly

cokt

The

bubbles

are

seen

at

intervals

of

1

2

seconds

AC257

Both

pressures

on

high

and

low

pressure

sides

are

slightly

low

Check

for

gas

leakage

repair

as

required

re

plenish

and

chaxge

system

b

Wben

the

screen

in

tbe

receiver

drier

is

clogged

tbe

bubbles

wiD

appear

even

if

the

amount

of

refrig

erant

is

nonnaL

In

this

case

tbe

outlet

side

pipe

of

tbe

receiver

drier

becomes

considembly

cold

AC

16

of

abOut

five

rilintJtes

Jullgeaccording

to

the

following

table

Suitable

Too

much

refrigerant

High

pressure

side

is

hot

and

low

pressure

side

is

cold

High

pressure

side

is

abnormally

hot

Almost

transparent

Bubbles

may

appear

when

engine

speed

is

raised

and

lowered

No

bubbles

can

be

seen

No

clear

difference

exists

these

two

conditions

nl

AC258

Both

pre55ures

on

high

and

low

pressure

sides

are

normal

Both

pressures

on

high

and

low

pressure

sides

are

abnonnally

high

Discharge

refrigerant

from

service

valve

of

low

pressure

side

PERFORMANCE

TEST

Check

for

the

amount

of

refrigerant

in

the

system

can

be

made

by

meas

uring

pressure

on

discharge

side

The

correct

amount

of

refrigerant

is

in

the

system

if

pressure

on

the

discharge

side

i

within

the

specified

range

For

details

refer

to

Trouble

Diagnoses

and

Corrections

for

per

fannance

test

Overcharging

will

show

up

in

higher

presstJre

on

discharge

side

Page 518 of 548

COMPRESSOR

OIL

LEVEL

CHECK

The

oil

used

to

lubricate

compres

sor

circulates

into

system

from

the

oil

sump

while

compressor

is

operating

Therefore

to

correctly

measure

com

pressor

oil

the

amount

of

oil

flowing

to

system

must

be

considered

If

a

considerable

amount

of

leakage

of

refrigerant

gas

happens

the

leakage

of

compressor

oil

is

also

considered

There

will

be

no

compressor

oil

leak

age

from

a

completely

sealed

system

When

system

operates

under

satisfying

condition

the

compressor

oil

level

check

is

unnecessary

When

checking

the

level

of

com

pressor

oil

or

when

replacing

any

component

part

of

the

system

use

the

following

service

procedure

This

facio

litates

to

return

oil

to

compressor

1

Operate

compressor

at

engine

idling

speed

I

OOO

rpm

or

below

with

controls

set

for

maximum

cooling

and

high

blower

speed

for

10

to

15

minutes

in

order

to

return

com

pressor

oil

to

compressor

2

Stop

the

engine

and

discharge

refrigerant

of

system

and

then

remove

compressor

from

the

car

3

Remove

compressor

filler

plug

Drain

compressor

oil

from

compres

sor

oil

sump

and

measure

the

amount

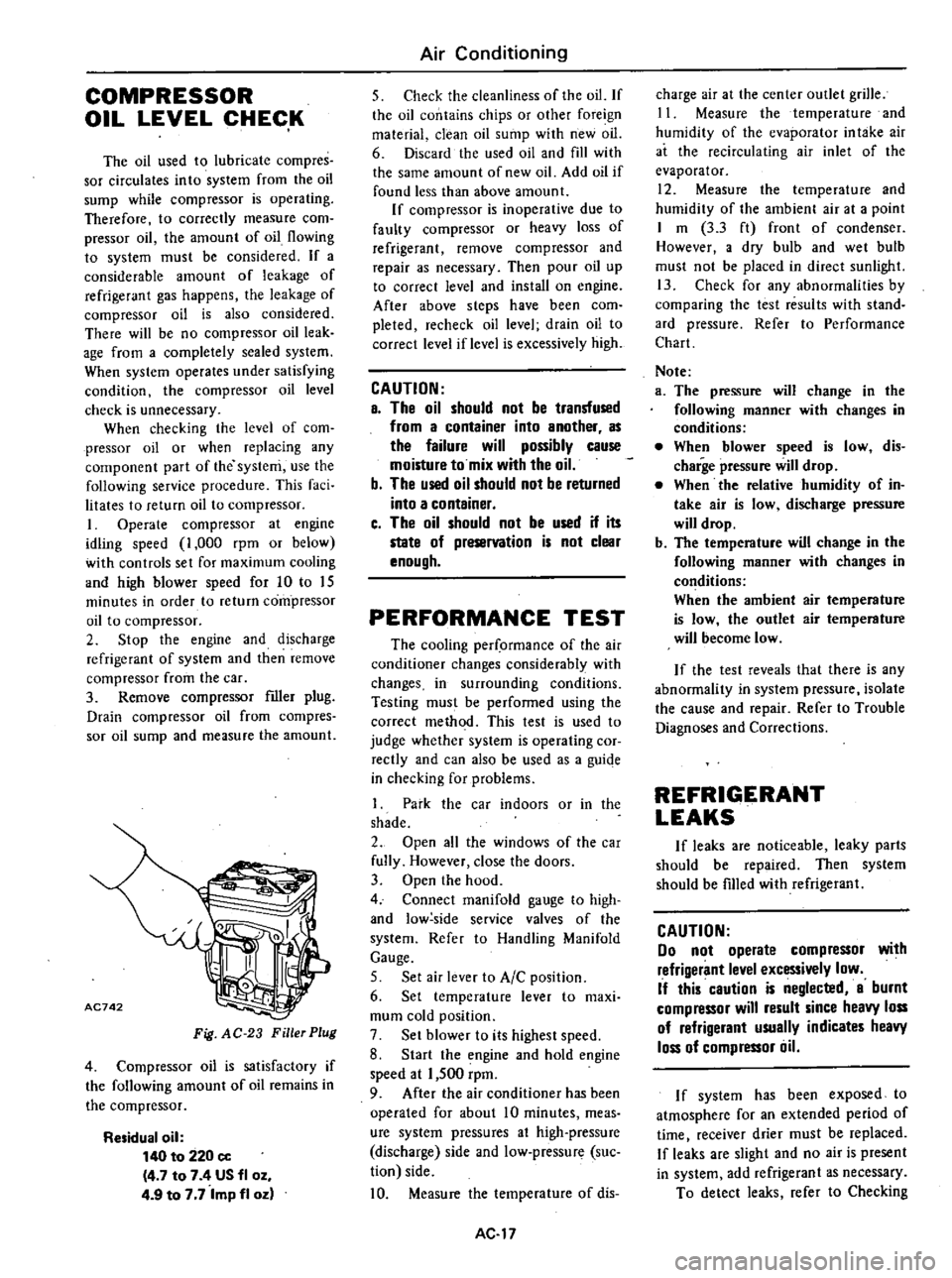

AC742

Fig

AC

23

Filler

Plug

4

Compressor

oil

is

satisfactory

if

the

following

amount

of

oil

remains

in

the

compressor

Residual

oil

140

to

220

cc

4

7

to

7

4

US

fl

oz

4

9

to

7

7

Imp

fl

oz

Air

Conditioning

5

Check

the

cleanliness

of

the

oil

If

the

oil

contains

chips

or

other

foreign

material

clean

oil

sump

with

new

oil

6

Discard

the

used

oil

and

fill

with

the

same

amount

of

new

oil

Add

oil

if

found

less

than

above

amount

If

compressor

is

inoperative

due

to

faulty

compressor

or

heavy

loss

of

refrigerant

remove

compressor

and

repair

as

necessary

Then

pour

oil

up

to

correct

level

and

install

on

engine

After

above

steps

have

been

com

pleted

recheck

oil

level

drain

oil

to

correct

level

if

level

is

excessively

high

CAUTION

a

The

oil

should

not

be

transfused

from

a

container

into

another

as

the

failure

will

possibly

cause

moisture

to

mix

with

the

oil

b

The

used

oil

should

not

be

returned

into

a

container

c

The

oil

should

not

be

used

if

its

state

of

preservation

is

not

clear

enough

PERFORMANCE

TEST

The

cooling

per

ormance

of

the

air

conditioner

changes

considerably

with

changes

in

surrounding

conditions

Testing

must

be

performed

using

the

correct

method

This

test

is

used

to

judge

whether

system

is

operating

cor

rectly

and

can

also

be

used

as

a

guiqe

in

checking

for

problems

1

Park

the

car

indoors

or

in

the

shade

2

Open

all

the

windows

of

the

car

fully

However

close

the

doors

3

Open

the

hood

4

Connect

manifold

gauge

to

high

and

low

side

service

valves

of

the

system

Refer

to

Handling

Manifold

Gauge

5

Set

air

lever

to

AIC

position

6

Set

temperature

lever

to

maxi

mum

cold

position

7

Set

blower

to

its

highest

speed

8

Start

the

engine

and

hold

engine

speed

at

1

500

rpm

9

After

the

air

conditioner

has

been

operated

for

about

10

minutes

meas

ure

system

pressures

at

high

pressure

discharge

side

and

low

pressure

suc

tion

side

10

Measure

the

temperature

of

dis

AC

17

charge

air

at

the

center

outlet

grille

11

Measure

the

temperature

and

humidity

of

the

evaporator

in

take

air

at

the

recirculating

air

inlet

of

the

evaporator

12

Measure

the

temperature

and

humidity

of

the

ambient

air

at

a

point

I

m

3

3

ft

front

of

condenser

However

a

dry

bulb

and

wet

bulb

must

not

be

placed

in

direct

sunlight

13

Check

for

any

abnormalities

by

comparing

the

test

results

with

stand

ard

pressure

Refer

to

Performance

Chart

Note

a

The

pressure

will

change

in

the

following

manner

with

changes

in

conditions

When

blower

speed

is

low

dis

charge

pressure

will

drop

When

the

relative

humidity

of

in

take

air

is

low

discharge

pressure

will

drop

b

The

temperature

will

change

in

the

following

manner

with

changes

in

conditions

When

the

ambient

air

temperature

is

low

the

outlet

air

temperature

will

become

low

If

the

test

reveals

that

there

is

any

abnormality

in

system

pressure

isolate

the

cause

and

repair

Refer

to

Trouble

Diagnoses

and

Corrections

REFRIGERANT

LEAKS

If

leaks

are

noticeable

leaky

parts

should

be

repaired

Then

system

should

be

fIlled

with

refrigerant

CAUTION

00

not

operate

compressor

with

refrigerant

level

excessively

low

If

this

caution

is

neglected

a

burnt

compressor

will

result

since

heavy

loss

of

refrigerant

usually

indicates

heavy

loss

of

compressor

liil

I

f

system

has

been

exposed

to

atmosphere

for

an

extended

period

of

time

I

receiver

drier

must

be

replaced

If

leaks

are

slight

and

no

air

is

present

in

system

add

refrigerant

as

necessary

To

detect

leaks

refer

to

Checking

Page 519 of 548

for

Leaks

Here

is

how

leaks

are

stopped

I

Check

torque

on

the

connection

fitting

and

if

too

loose

tighten

to

the

proper

lorque

Check

for

gas

leakage

with

a

leak

detector

Air

Conditioning

2

If

leakage

continues

ven

after

the

fitting

has

been

retightened

dis

charge

refrigerant

from

system

disc

on

net

the

fittings

and

check

its

seating

face

for

damage

Always

replace

even

if

damage

is

slight

J

Check

compressor

6il

and

add

oil

if

required

4

Charge

refrigerant

and

recheck

for

gas

leaks

If

no

leaks

are

found

evacuate

and

charge

system

SERVICE

PROCEDURES

FAST

IDLE

ACTUATOR

ADJUSTMENT

OF

IDLE

SPEED

Engine

model

Transmission

When

A

C

is

OFF

When

A

C

is

ON

F

LCD

is

actuated

Manual

700

rpm

800

rpm

A14

A15

Automatic

650

rpm

800

rpm

at

D

position

at

N

position

The

fast

idle

control

device

is

used

on

cars

equipped

with

an

air

condi

tioner

to

raise

the

idle

speed

auto

matically

Use

the

following

procedures

when

adjusting

1

Run

engine

until

it

reaches

oper

ating

temperature

2

With

air

conditioner

in

OFF

when

compressor

is

not

operated

make

sure

that

clearance

e

between

levers

A

and

8

is

more

than

J

mm

0

12

in

If

clearance

C

is

less

than

J

mm

0

12

in

loosen

cable

lock

screw

and

push

down

on

lever

A

so

that

clearance

C

is

more

than

J

mm

0

12

in

3

Make

sure

that

engine

is

at

cor

rect

idle

speed

4

With

air

conditioner

in

ON

when

F

LC

D

is

actuated

set

engine

speed

to

800

rpm

using

following

procedures

as

a

guide

I

Turn

adjusting

screw

until

en

gine

speed

is

800

rpm

On

cars

equipped

with

automatic

transmission

make

this

adjustment

with

shift

control

lever

in

N

posi

tion

2

If

engine

speed

cannot

be

adjust

ed

properly

with

adjusting

screw

check

and

adjust

clearance

e

again

3

Depress

and

release

accelerator

pedal

several

times

and

make

sure

that

engine

speed

reduces

to

800

rpm

as

pedal

is

released

If

correct

adjustment

is

not

made

repeat

steps

I

to

3

above

until

engine

speed

is

800

rpm

at

idling

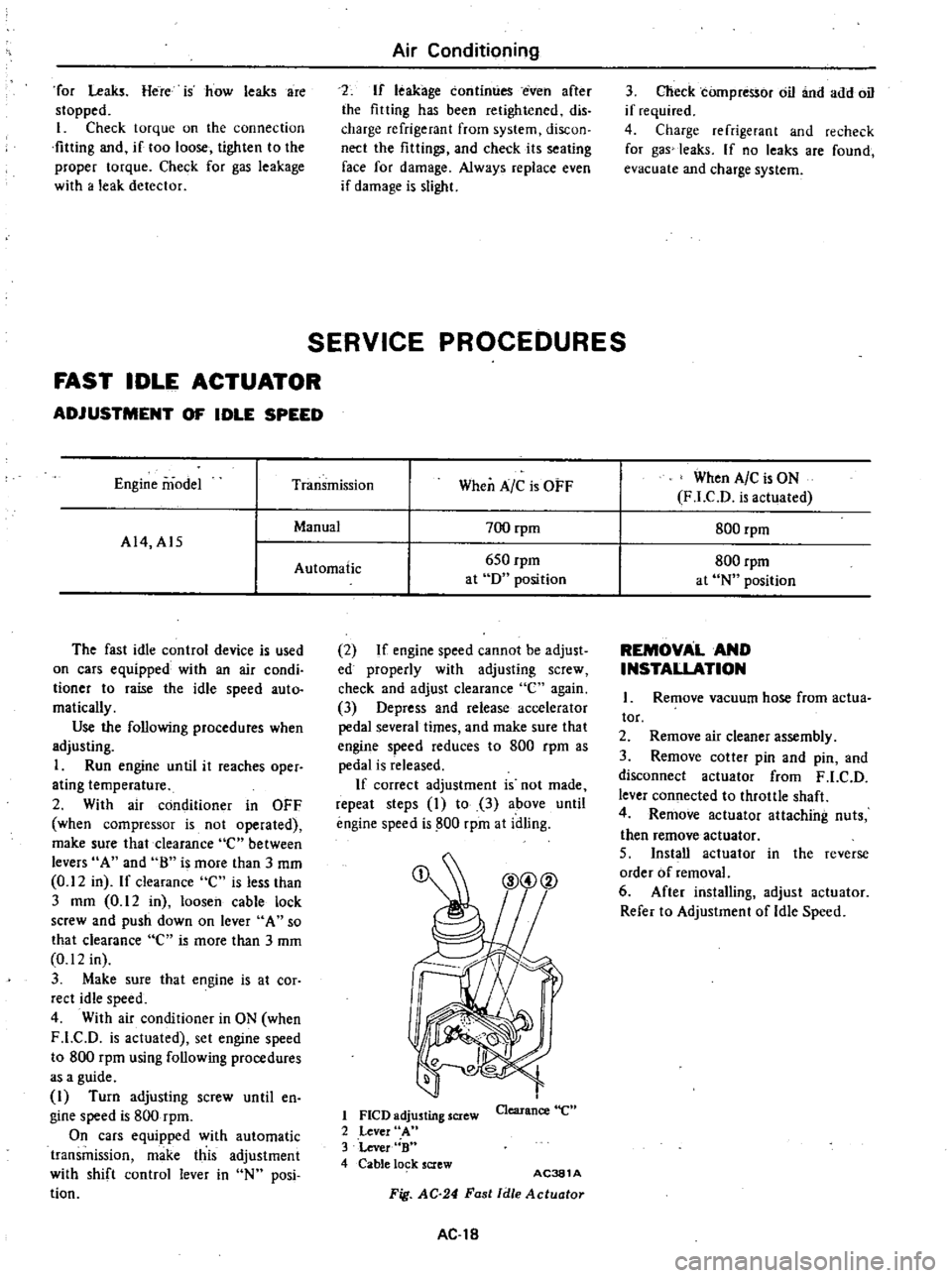

1

FlCD

adjusting

screw

2

Lever

A

3

Lever

B

4

Cable

lo

k

screw

Clearance

e

AC381

A

Fig

AC

24

Fast

Idle

Actuotor

AC

18

REMOVAL

AND

INSTALLATION

Remove

vacuum

hose

from

actua

tor

2

Remove

air

cleaner

assembly

3

Remove

cotter

pin

and

pin

and

disconnect

actuator

from

F

LC

D

lever

connected

to

throttle

shaft

4

Remove

actuator

attaching

nuts

then

remove

actuator

5

Install

actuator

in

the

reverse

order

of

removal

6

After

installing

adjust

actuator

Refer

to

Adjustment

of

Idle

Speed

Page 520 of 548

Air

Conditioning

IDLER

PULLEY

AND

COMPRESSOR

DRIVE

BELT

ADJ

USTMENT

OF

BELT

TENSION

Idler

pulley

Alternator

Crankshaft

pulley

Unit

mm

in

Idler

pulley

Fig

AC

25

Belt

Tension

Specified

compressor

belt

tension

is

8

to

12

mm

0

31

to

0

47

in

when

thumb

pressure

of

10

kg

22

Ib

is

applied

midway

between

idler

pulley

and

compressor

pulley

1

Loosen

idler

pulley

lock

nut

and

then

adjust

pulley

by

turning

adjusting

bolt

2

After

adjustment

tighten

idler

pulley

lock

nut

bolt

3

Remove

idler

pulley

4

Install

pulley

in

the

reverse

order

of

removal

5

Adjust

compressor

belt

tension

REMOVAL

AND

INSTALLATION

1

Jack

up

front

of

car

and

remove

under

cover

2

Remove

idler

pulley

lock

nut

and

loosen

belt

tension

adjusting

Fig

AC26

AC382A

Idler

Pulley

TIghtening

torque

@

3

7

to

5

1

kg

m

27

to

37

ft

lb

AC383A

Fig

AC

27

Compressor

and

Bracket

AC

19

REMOVAL

I

Operate

compressor

if

possible

at

engine

idling

speed

with

air

condi

tioner

controls

set

for

maximum

cool

ing

and

high

blower

speed

for20

to

30

minutes

with

all

windows

open

to

return

oil

into

compressor

2

Disconnect

battery

ground

cables

and

compressor

lead

wire

at

con

nector

3

Discharge

refrigerant

from

cool

ing

system

Refer

to

Discharging

Sys

tem

4

Jack

up

front

of

car

and

remove

under

cover

5

Loosen

idler

pulley

lock

nut

and

loosen

tension

adjusting

bolt

fully

Remove

compressor

drive

belt

See

Fig

AC

26

6

Remove

high

and

low

flexible

hoses

from

compressor

WARNING

Gradually

loosen

discharge

side

hose

fitting

and

remove

it

after

remaining

pressure

has

been

re

leased

CAUTION

Be

sure

to

immediately

put

plug

in

flexible

hose

and

compressor

open

ings

7

Remove

bolts

securing

lower

part

of

compressor

8

Remove

bolts

securing

upper

part

of

compressor

Hold

compressor

with

one

hand

when

removing

bolts

and

then

remove

compressor

With

compressor

clutch

up

lift

compressor

out

with

both

hands

CAUTION

00

not

attempt

to

leave

the

com

pressor

on

its

side

or

upside

down

for

more

than

10

minutes

as

the

compressor

oil

will

enter

the

low

pressure

chambers

If

under

that

condition

compressor

should

be

oper

ated

suddenly

internal

damage

would

result

To

expel

oil

from

chambers

hand

crank

compressor

several

times

in

its

installed

condition

Page 522 of 548

REFRIGERANT

LINES

Air

Conditioning

@

I

J

L

S

r

Z

S

t

@

See

Fig

AC

29

When

replacing

flexible

hose

and

tube

observe

the

following

1

Before

starting

work

be

sure

to

discharge

system

2

When

disconnecting

tubes

be

sure

to

use

two

wrenches

on

both

tubes

3

After

discon

ecting

tubes

plug

all

openings

immediately

to

prevent

entrance

of

dirt

and

moisture

4

Compressed

air

must

never

be

used

to

clean

dirty

line

Clean

with

refrigerant

gas

5

In

connecting

tubes

be

sure

to

apply

compressor

oil

to

seating

surface

and

then

tighten

tubes

to

specified

tightening

torque

See

Fig

AC

30

Be

sure

to

use

two

wrenches

when

tightening

a

flare

nut

of

tube

Coat

seat

surfaces

with

com

pressor

oil

and

then

tighten

AC263

Fig

AC

30

Line

Connection

CD

6

Make

sure

refrigerant

line

is

clamped

securely

Start

engine

and

raise

engine

speed

to

inspect

if

there

is

vibration

or

unusual

noise

7

Conduct

leak

t

st

and

make

su

e

that

there

is

no

leak

from

connections

8

Refer

to

General

Service

for

evacuating

and

charging

system

COOLING

UNIT

REMOVAL

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tern

Refer

to

General

Service

3

Loosen

flare

nuts

at

each

con

nection

of

inlet

and

outlet

pipes

of

evaporator

AC

21

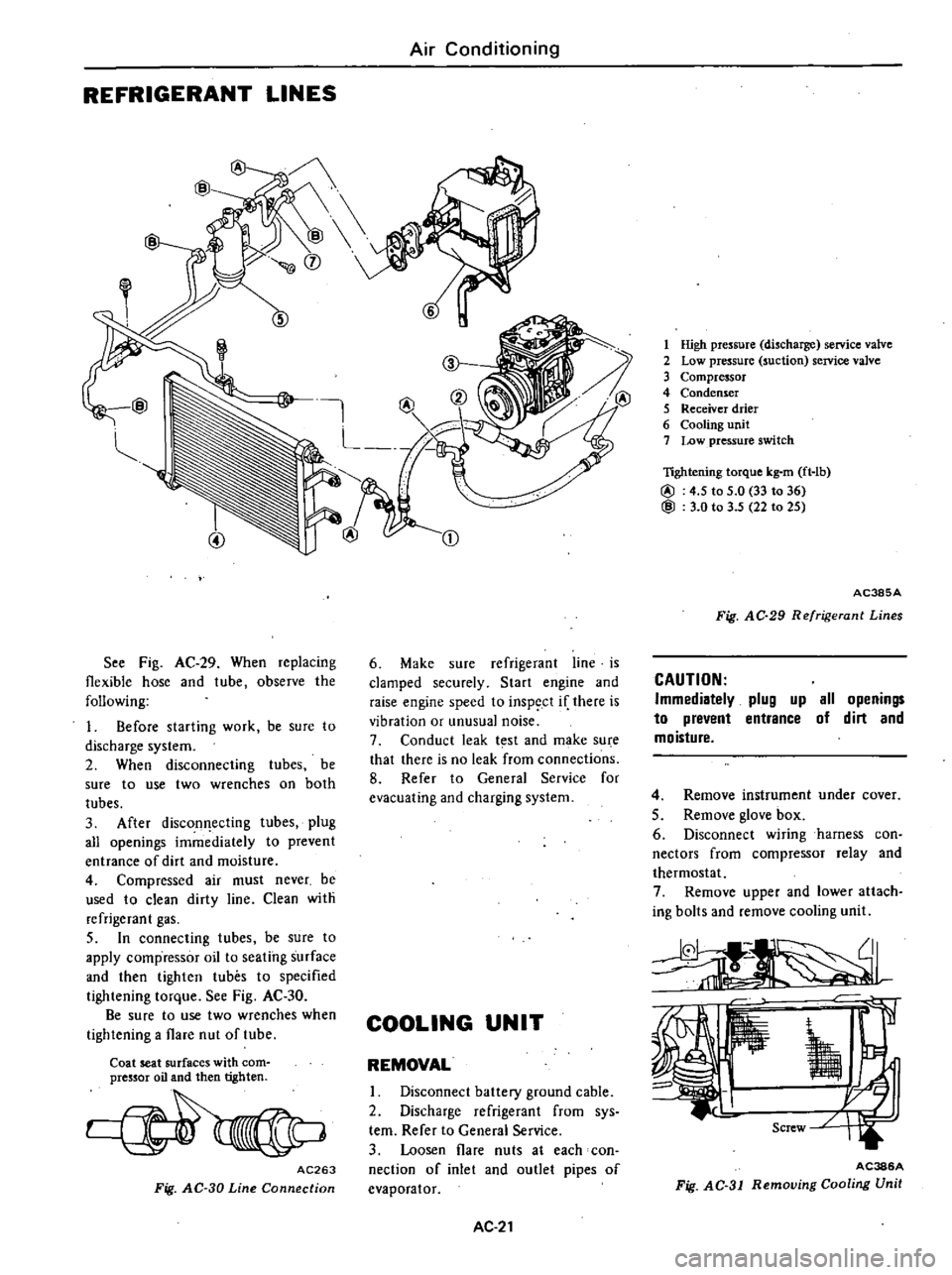

1

High

pressure

discharge

service

valve

2

Low

pressure

suction

service

valve

3

Compressor

4

Condenser

5

Receiver

drier

6

Cooling

unit

7

Low

pressure

switch

lightening

torque

kg

m

ft

lb

@

4

5

to

5

0

33

to

36

@

3

0

to

3

5

22

to

25

AC385A

Fig

AC

29

Refrigerant

Lines

CAUTION

Immediatelv

plug

up

all

openings

to

prevent

entrance

of

dirt

and

moisture

4

Remove

instrument

under

cover

5

Remove

glove

box

6

Disconnect

wiring

harness

con

nectors

from

compressor

relay

and

thermostat

7

Remove

upper

and

lower

attach

ing

bolts

and

remove

cooling

unit

AC386A

Fig

AC

31

Removing

Cooling

Unit

Page 523 of 548

to

DISASSEMBLY

AND

ASSEMBLY

y

1

7

1

r

II

l

1

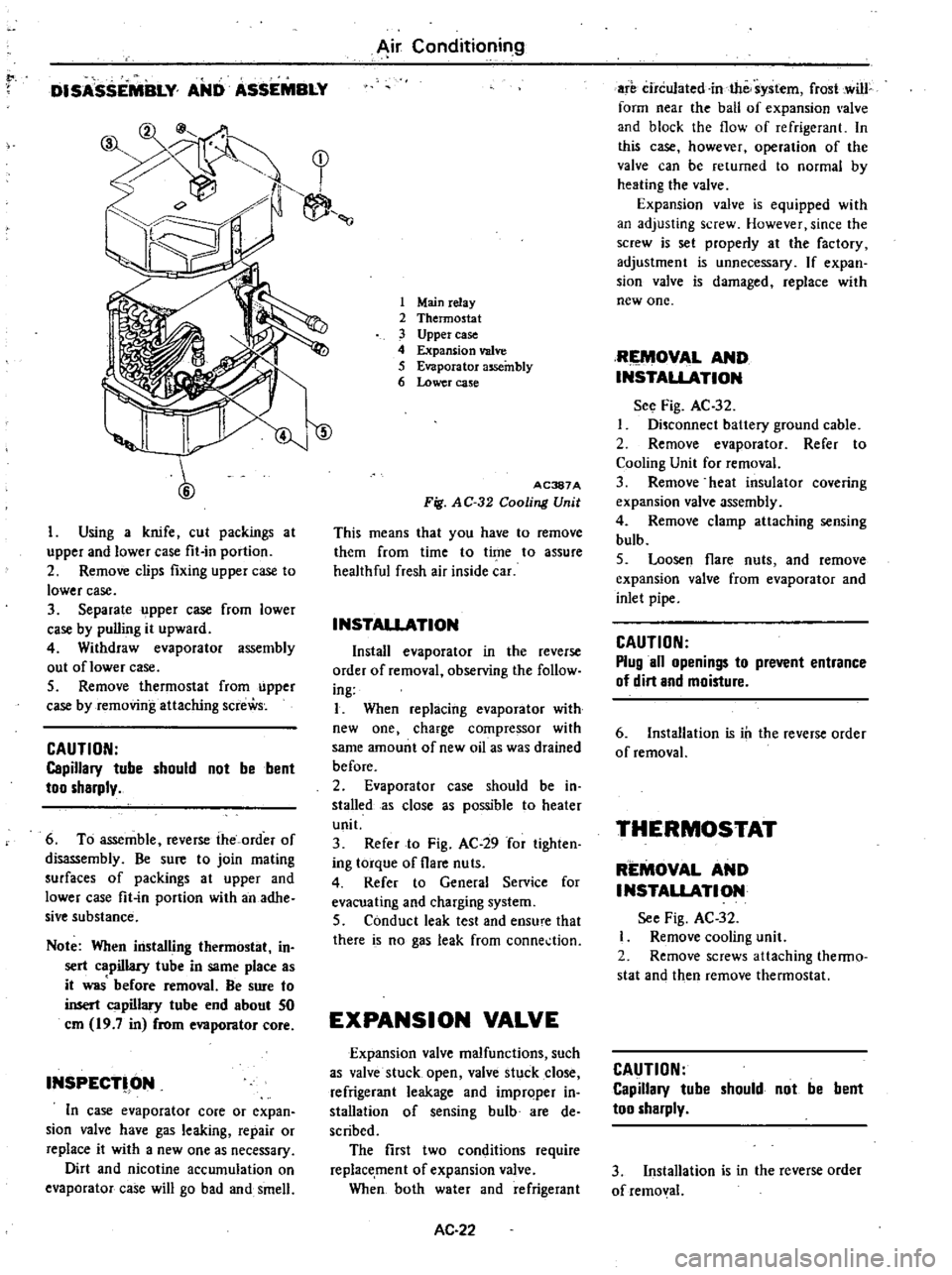

Using

a

knife

cut

packings

at

upper

and

lower

case

fit

in

portion

2

Remove

clips

fixing

upper

case

to

lower

case

3

Separate

upper

case

from

lower

case

by

pulling

it

upward

4

Withdraw

evaporator

assembly

out

oflower

case

5

Remove

thermostat

from

upper

case

by

removing

attaching

screWs

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

6

To

assemble

reverse

the

order

of

disassembly

Be

sure

to

join

mating

surfaces

of

packings

at

upper

and

lower

case

fit

in

portion

with

an

adhe

sive

substance

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

50

em

19

7

in

from

evaporator

core

INSPECT

ON

In

case

evaporator

core

or

expan

sion

valve

have

gas

leaking

repair

or

replace

it

with

a

new

one

as

necessary

Dirt

and

nicotine

accumulation

on

evaporator

case

will

go

b

d

and

smell

Air

Conditioning

1

Mainrelay

2

Thermostat

3

Upper

case

4

Expansion

valve

5

Evaporator

assembly

6

Lower

case

ID

AC387A

Fig

AC

32

Cooling

Unit

This

means

that

you

have

to

remove

them

from

time

to

time

to

assure

healthful

fresh

air

inside

car

INSTAllATION

Install

evaporator

in

the

reverse

order

of

removal

observing

the

follow

ing

I

When

replacing

evaporator

with

new

one

charge

compressor

with

same

amount

of

new

oil

as

was

drained

before

2

Evaporator

case

should

be

in

stalled

as

close

s

possible

to

heater

unit

3

Refer

to

Fig

AC

29

for

tighten

ing

torque

of

flare

nuts

4

Refer

to

General

Service

for

evacuating

and

charging

system

5

Conduct

leak

test

and

ensu

e

that

there

is

no

gas

leak

from

conne

tion

EXPANSION

VALVE

Expansion

valve

malfunctions

such

as

valve

stuck

open

valve

stuck

close

refrigerant

leakage

and

improper

in

stall

tion

of

sensing

bulb

are

de

scribed

The

first

two

conditions

require

replacement

of

expansion

valve

When

both

water

and

refrigerant

AC

22

are

circulated

in

the

system

frost

cwill

form

near

the

ball

of

expansion

alve

and

block

the

flow

of

refrigerant

In

this

case

however

operation

of

the

valve

can

be

returned

to

normal

by

heating

the

valve

Expansion

valve

is

equipped

with

an

adjusting

screw

However

since

the

screw

is

set

properly

at

the

factory

adjustment

is

unnecessary

If

expan

sion

valve

is

damaged

replace

with

new

one

RIEMOV

L

AND

INSTALlATION

See

Fig

AC

32

Disconnect

baltery

ground

cable

2

Remove

ev

porator

Refer

to

Cooling

Unit

for

removal

3

Remove

heat

insulator

covering

expansion

valve

assembly

4

Remove

clamp

attaching

sensing

bulb

5

Loosen

flare

nuts

and

remove

expansion

valve

from

evaporator

and

inlet

pipe

CAUTION

Plug

all

openings

to

prevent

entrance

of

dirt

and

moisture

6

Installation

is

ill

the

reverse

order

of

removal

THERMOSTAT

REMOVAL

AND

INSTALlATION

See

Fig

AC

32

Remove

cooling

unit

2

Remove

screws

attaching

thenno

stat

and

then

remove

thermostat

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

3

Installation

is

in

the

reverse

order

of

removal

Page 524 of 548

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

SO

em

19

7

in

from

evaporator

core

INSPECTION

1

Test

continuity

between

two

switch

terminals

with

test

lamp

or

ohmmerter

Continuity

should

exist

2

With

capillary

tube

end

dipped

into

ice

salt

water

maintained

to

I

oc

300

F

test

continuity

between

two

switch

terminals

Continuity

should

not

exist

3

If

switch

is

found

damaged

re

place

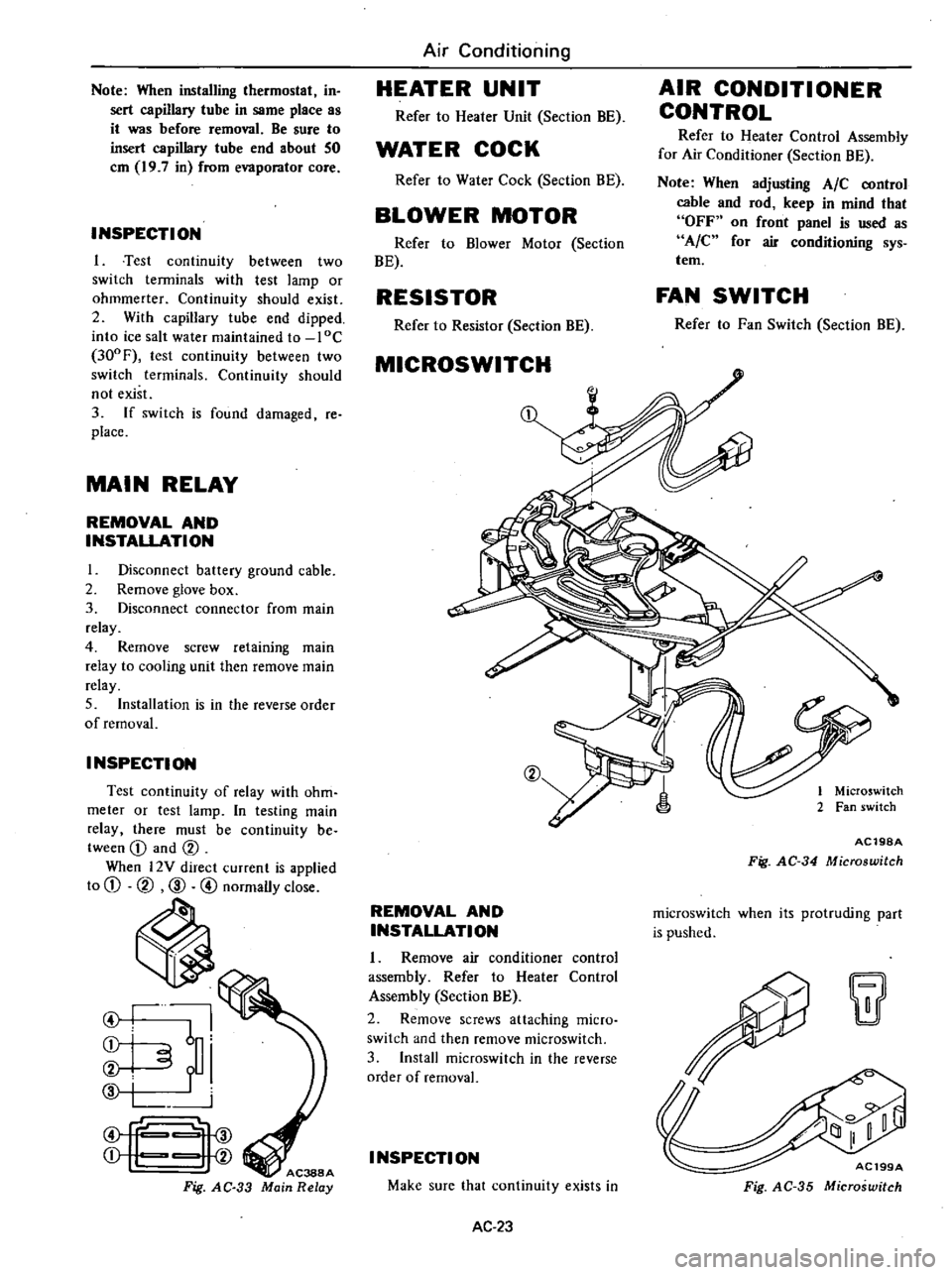

MAIN

RELAY

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

connector

from

main

relay

4

Remove

screw

retaining

main

relay

to

cooling

unit

then

remove

main

relay

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Test

continuity

of

relay

with

ohm

meter

or

test

lamp

In

testing

main

relay

there

must

be

continuity

be

tween

CD

and

CV

When

l2Y

direct

current

is

applied

to

CD

CV

CID

@

normally

close

ti

I

I

6

i

i

f

i

f

Fig

AC

33

Air

Conditioning

HEATER

UNIT

Refer

to

Heater

Unit

Section

BE

WATER

COCK

Refer

to

Water

Cock

Section

BE

BLOWER

MOTOR

Refer

to

Blower

Motor

Section

BE

RESISTOR

Refer

to

Resistor

Section

BE

MICROSWITCH

CV

REMOVAL

AND

INSTALLATION

1

Remove

air

conditioner

control

assembly

Refer

to

Heater

Control

Assembly

Section

BE

2

Remove

screws

attaching

micro

switch

and

then

remove

rnicroswitch

3

Install

rnicroswitch

in

the

reverse

order

of

removal

I

NSPECTI

ON

Make

sure

that

continuity

exists

in

AC

23

AIR

CONDITIONER

CONTROL

Refer

to

Heater

Control

Assembly

for

Air

Conditioner

Section

BE

Note

When

adjusting

AIC

control

cable

and

rod

keep

in

mind

that

OFF

on

front

panel

is

used

as

A

C

for

air

conditioning

sys

tem

FAN

SWITCH

Refer

to

Fan

Switch

Section

BE

1

Microswitch

2

Fan

switch

AC19SA

Fig

AC

34

Microswitch

rnicroswitch

when

its

protruding

part

is

pushed

w

AC199A

Fig

AC

35

Microswitch

Page 525 of 548

LOW

PRESSURE

SWITCH

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tem

Refer

to

General

Service

3

Disconnect

connector

to

low

pressure

switch

4

Remove

low

pressure

switch

by

turning

the

switch

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Using

a

circuit

tester

make

sure

that

low

pressure

switch

exhibits

con

tinuity

when

gas

pressure

of

refriger

ant

in

system

is

normal

and

that

low

pressure

switch

does

not

exhibit

con

tinuity

when

gas

pressure

drops

below

2

2

kg

cm2

31

p

i

MAGNET

VALVE

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Disconnect

magnet

valve

lead

wires

and

vacuum

hoses

3

Remove

magnet

valve

securing

screws

and

then

remove

magnet

valve

i

i

WrE

AC389A

Fig

AC

36

Removjng

Magnet

Valve

4

Installation

is

in

the

reverse

order

of

removal

INSPECTION

I

rest

continuity

with

ohmmeter

2

Apply

D

C

12

volts

across

termi

Air

Conditioning

031

under

this

state

orally

blow

through

one

vacuum

port

to

ensure

that

there

is

air

flow

at

the

other

FUSE

REPLACEMENT

REPLACEMENT

A

20

ampere

in

line

fuse

is

part

of

air

conditioner

harness

located

behind

glove

box

J

Disconnect

batiery

ground

cable

2

Remove

instrument

under

cover

3

Remove

glove

box

4

Take

out

fuse

holder

from

air

conditioner

harness

and

replace

fuse

with

a

new

one

CAUTION

If

fuse

is

blown

be

sure

to

climi

nate

the

cause

befure

installing

new

fuse

in

position

r

AC276A

Fig

AC

37

Fu

e

Replacement

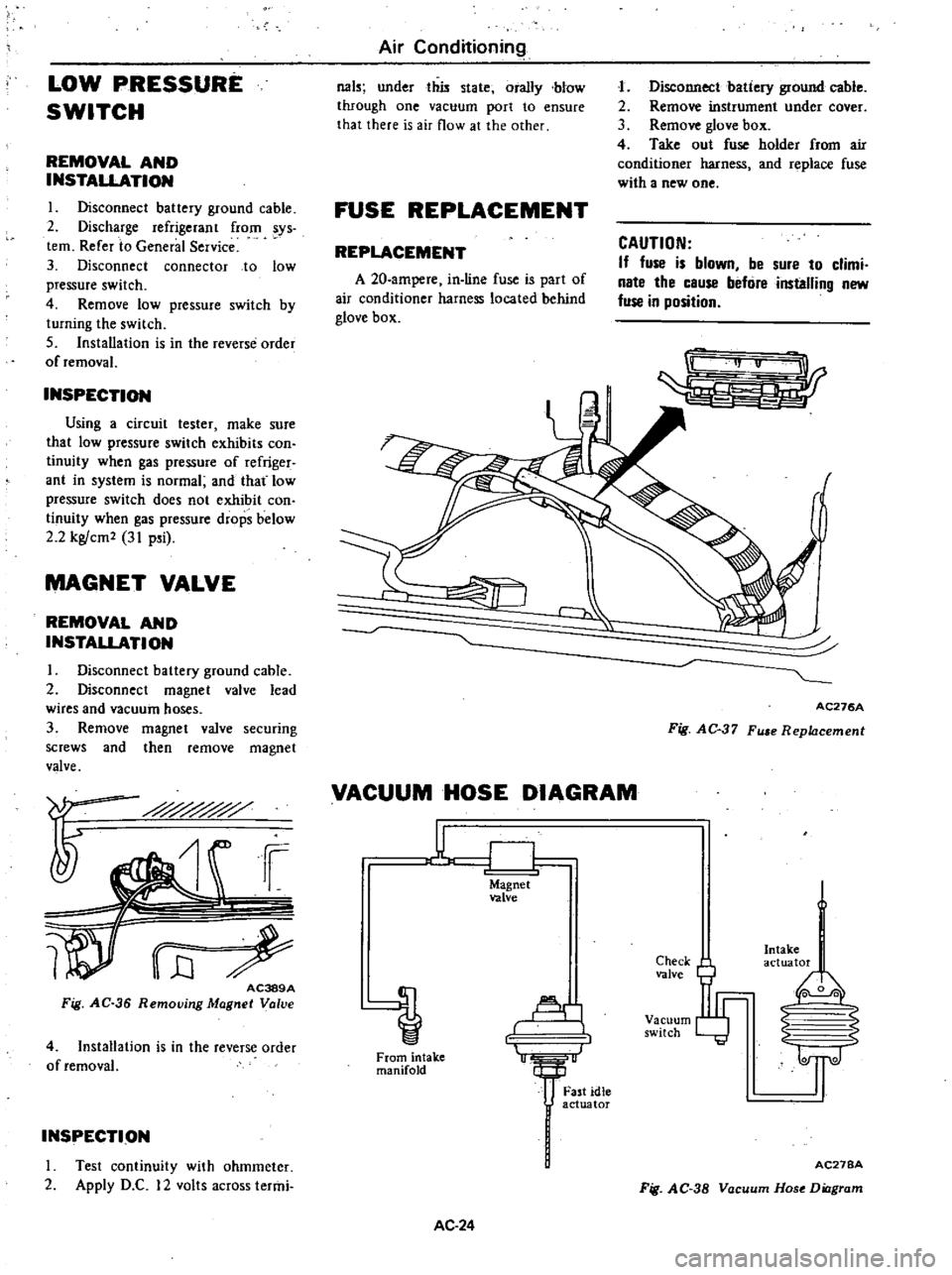

VACUUM

HOSE

DIAGRAM

u

CJ

Magnet

valve

Al

1

From

intake

manifold

AC

24

Fast

idle

actuator

Check

valve

Vacuum

switch

Intake

actuator

I

0

0

2

S

1l

AC27BA

Fig

AC

38

Vacuum

Hose

Diagram

Page 526 of 548

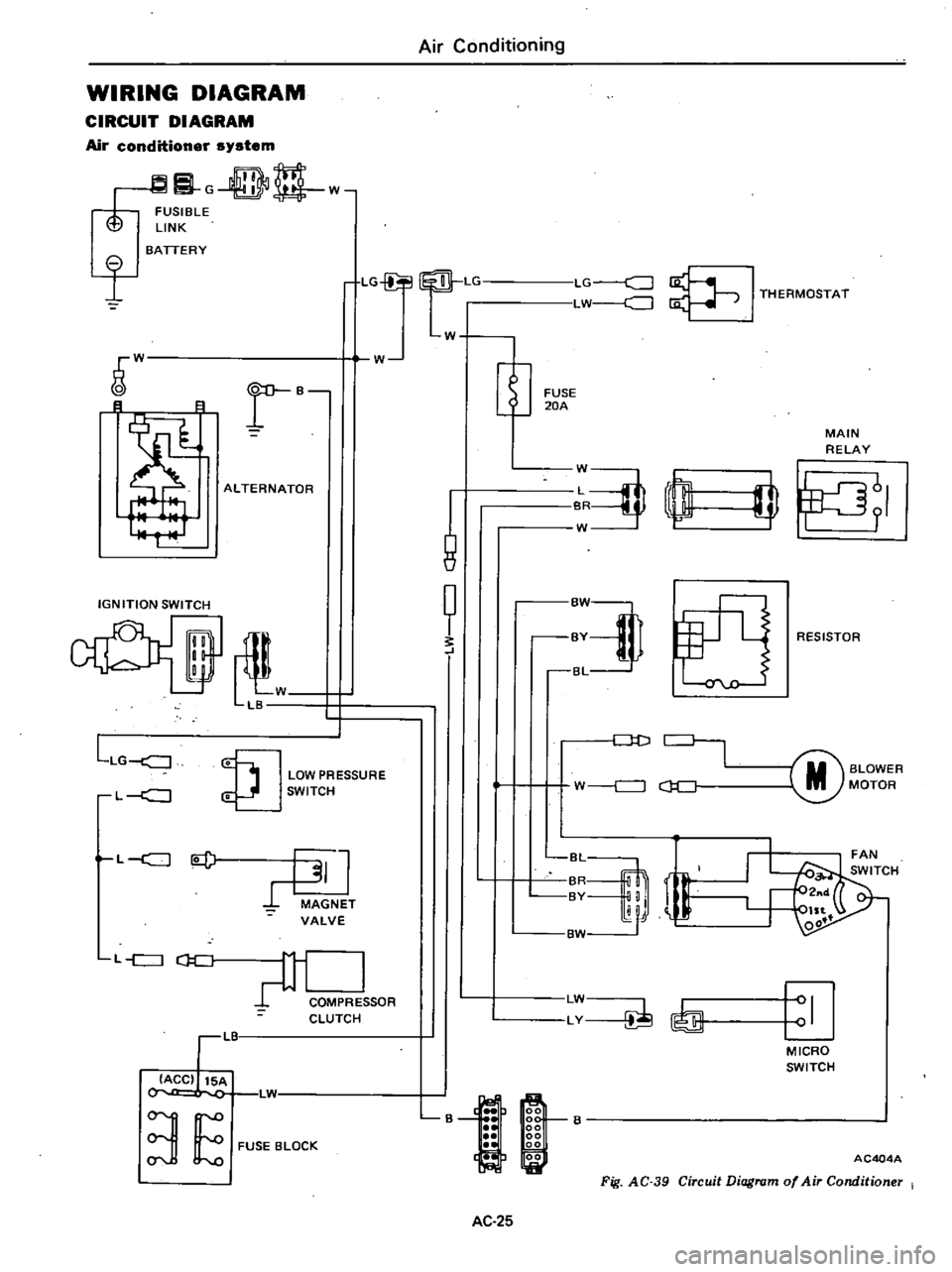

WIRING

DIAGRAM

CIRCUIT

DIAGRAM

Air

conditioner

system

G

DD

w

FUSIBLE

LINK

I

BATTERY

LG

Lr

LG

c

J

LW

J

I

THERMOSTAT

W

W

r

B

B

8

ALTERNATOR

IGNITION

SWITCH

il

W

LB

LLG

J

LOW

PRESSURE

SWITCH

L

c

J

L

c

J

l

J

MAGNET

VALVE

L

c

J

CJ

C

COMPRE

SOR

CLUTCH

LIT

IACC

15A

L1

3

E

FUSE

BLOCK

Air

Conditioning

W

1

8

t

FUSE

20A

MAIN

RELAY

J

rn

W

I

fJ

RESISTOR

Dt

J

M

BLOWER

MOTOR

W

c

J

c

J

C

r

BvM

LW

LY

I

MICRO

SWITCH

B

AC404A

Fig

AC

39

Circuit

Diagram

of

Air

Conditioner

I

AC

25

Page 528 of 548

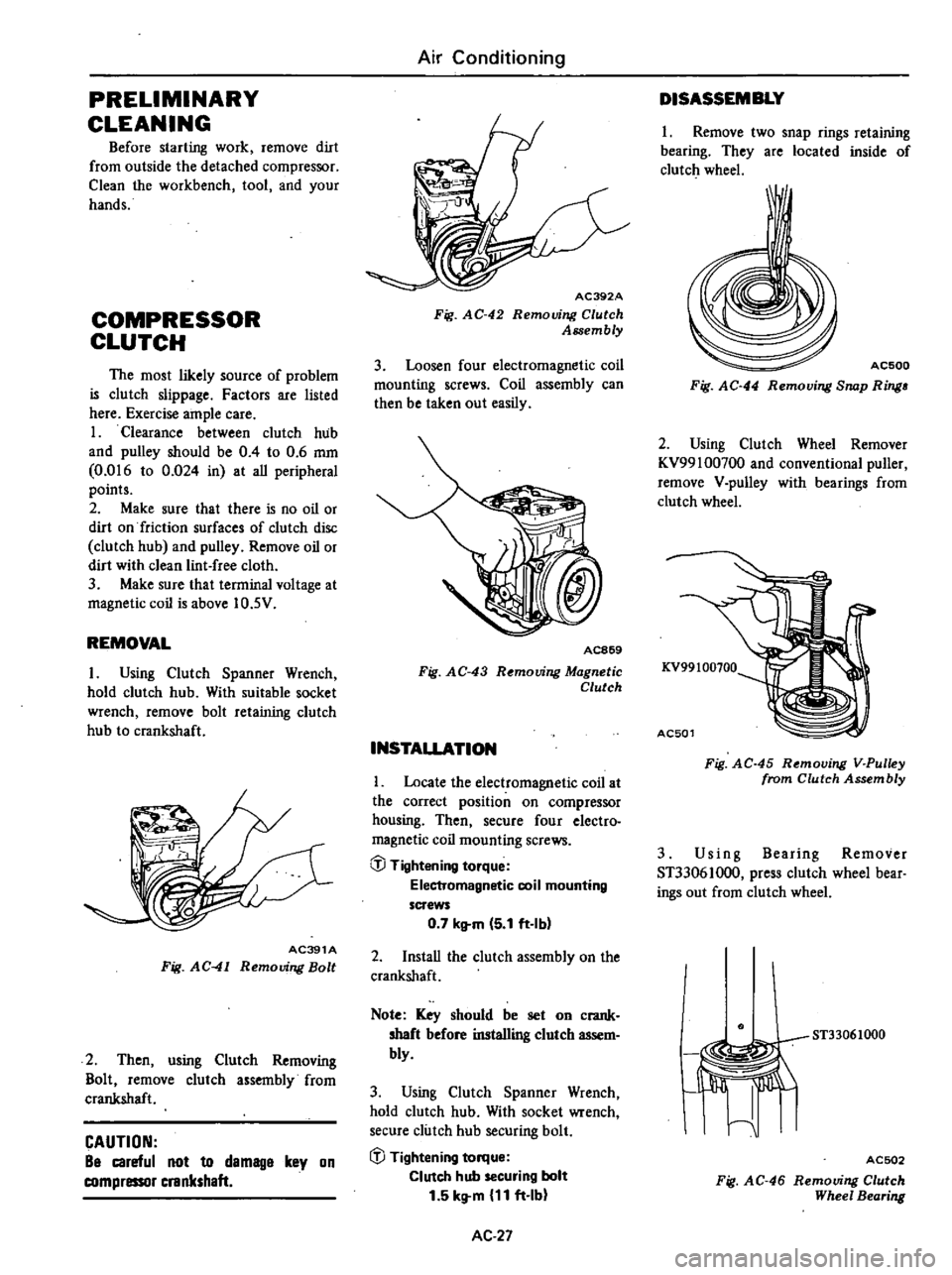

PRELIMINARY

CLEANING

Before

starting

work

remove

dirt

from

outside

the

detached

compressor

Clean

the

workbench

tool

and

your

hands

COMPRESSOR

CLUTCH

The

most

likely

source

of

problem

is

clutch

slippage

Factors

are

listed

here

Exercise

ample

care

1

Clearance

between

clutch

hub

and

pulley

should

be

0

4

to

0

6

mm

0

016

to

0

024

in

at

aU

peripheral

points

2

Make

sure

that

there

is

no

oil

or

dirt

on

friction

surfaces

of

clutch

disc

clutch

hub

and

pulley

Remove

oil

or

dirt

with

clean

lint

free

cloth

3

Make

sure

that

terminal

voltage

at

magnetic

coil

is

above

10

5V

REMOVAL

I

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

suitable

socket

wrench

remove

bolt

retaining

clutch

hub

to

crankshaft

AC391A

Fig

AC

41

Removing

Bolt

2

Then

using

Clutch

Removing

Bolt

remove

clutch

assembly

from

crankshaft

CAUTION

Be

careful

not

to

demage

key

on

compressor

crankshaft

Air

Conditioning

AC392A

Fig

AC

42

Removing

Clutch

Assembly

3

Loosen

four

electromagnetic

coil

mounting

screws

Coil

assembly

can

then

be

taken

out

easily

AC869

Fig

AC

43

R

mouing

Magnetic

Clutch

INSTALLATION

Locate

the

electromagnetic

coil

at

the

correct

position

on

compressor

housing

Then

secure

four

electro

magnetic

coil

mounting

screws

@

Tightening

torque

Electromagnetic

coil

mounting

screws

0

7

kltm

5

1

ft

Ibl

2

InstaU

the

clutch

assembly

on

the

crankshaft

Note

Key

should

be

set

on

crank

shaft

before

installing

clutch

assem

bly

3

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

socket

wrench

secure

clutch

hub

securing

bolt

iJJ

Tightening

torque

Clutch

hub

securing

bolt

1

5

kg

m

11

ft

Ib

AC

27

DISASSEMBLY

1

Remove

two

snap

rings

retaining

bearing

They

are

located

inside

of

clutch

wheel

I

AC500

Fig

AC

44

Removing

Snap

Ring

2

Using

Clutch

Wheel

Remover

KV99100700

and

conventional

puller

remove

V

pulley

with

bearings

from

clutch

wheel

KV99100100

AC501

Fig

AC

45

Removing

V

Pulley

from

Clutch

Assembly

3

Us

i

n

g

Bearing

Remover

ST33061000

press

clutch

wheel

bear

ings

out

from

clutch

wheel

ST33061000

I

Jiffi

I

ACSD2

Fig

AC

46

Removing

Clutch

Wheel

Bearing