lock DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 489 of 548

cIo

CD

m

t

tl

3

Cl

4

Ii

ii

C

l

I

i

I

ll

g

toom

a

ll

CALIFORNIA

ANO

BATTERY

FU

MOOELS

R

G

ff

w

G

M

wr

N

Q

WR

ALTERNATOR

ANO

IC

NON

cALIFOR

IA

VOLTAGE

REGULATOR

ANO

CANAOA

MO

S

I

fh

WR

B

i

W

i

C

@

J

W

l

9

i

j

@

Q

B

LB

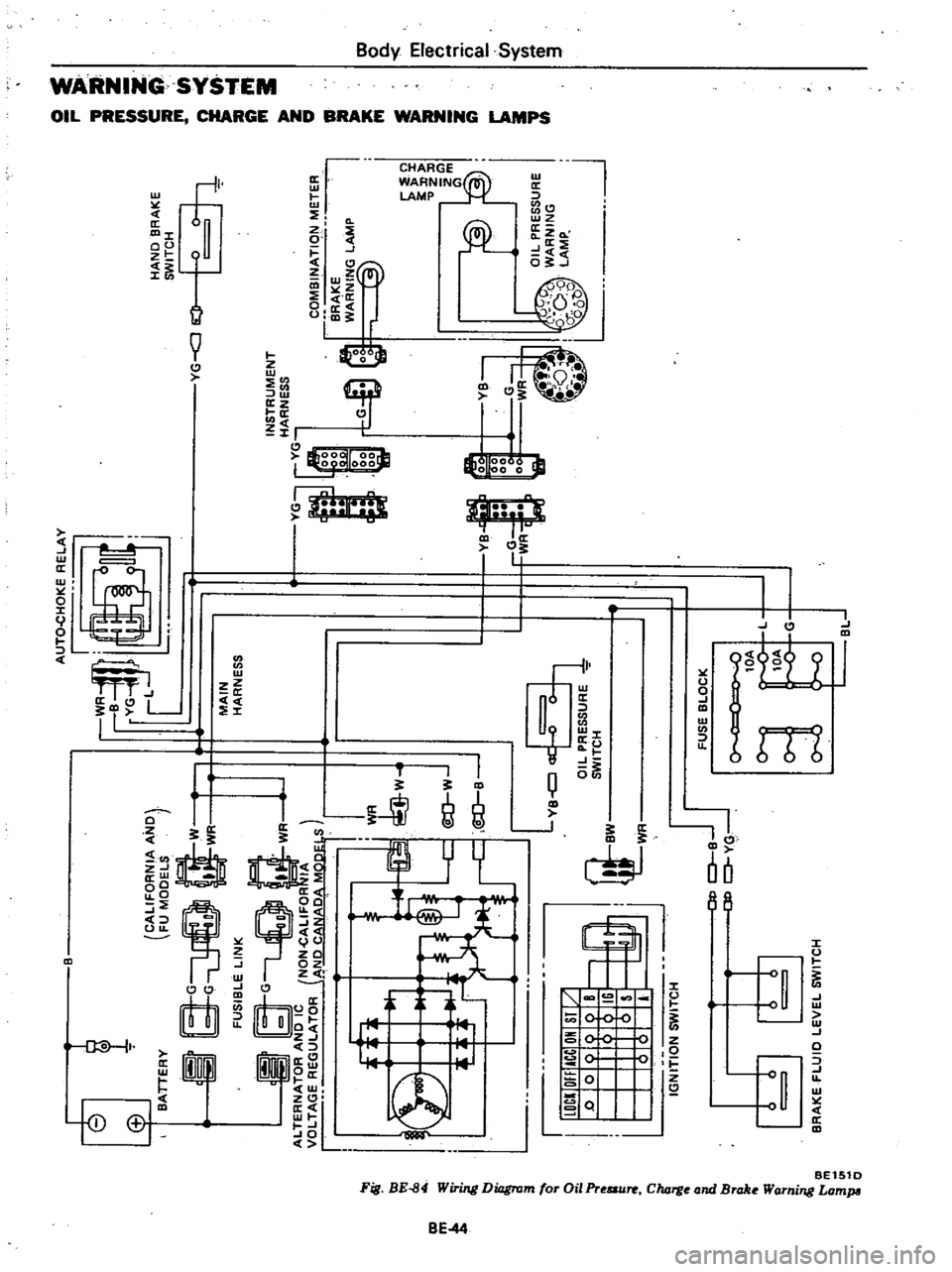

OIL

PRESSURE

SWITCH

0

I

I

l

lOCI

OfflACC

OH

SI

Ys

j

D

01

mQ

IS

i

I

l

I

s

II

10

J

J

SWITCH

IGNITION

iji

BY

wr

1

I

1

IW

BRAKE

FLUIO

LEVEL

SWITCH

Ot

o

BJ

JO

0

Y

l

I

AUTO

cHOKE

RELAY

V

I

r

I

MAIN

HARNESS

FUSE

BLOCK

0

0

lOA

cr

L

lOA

cr

G

1

r

L

BL

HANO

BRAKE

SWITCH

G

J

i

INSTRUMENT

HARN

ESS

fG

YG

10

OMB

N

AT

qN

ETER

o

BRAKE

0

WARNING

LAMP

100

G

O

00

3

YB

f

G

WR

J

I

0

1

Fo

o

e

i

1

z

YB

OIL

PRESSURE

WARNING

LAMP

J

lI

a

Ill

z

11

1

III

Z

G

Ill

11

1

Ut

0

iUt

Ill

alii

11

1

I

a

i

l

i

Ill

Z

i

a

X

OJ

o

Cl

m

CD

o

CIl

l

3

Page 490 of 548

m

l

U1

ii

I

ll

cio

i

t

s

a

Cl

t

m

l

e

BATTERY

8

GtG

ug

ew

FUSIBLE

LINK

BELT

TIMER

I

i

DD

l

J

G

if

I

lOCI

OffIACCI

aNI

Sf

I

0

0

8

i

i

16

I

S

IGNITION

SWITCH

FUSE

BLOCK

B

0

lOA

G

L

BL

ORIVER

S

BELT

SWITCH

tl

WARNING

LAMP

iP

aB

ij

II

VB

L

I

81

WB

I

t

OI

00

00

0

0

B

B

B

B

feB

WARNING

BUZZER

III

e

IIll

a

I

III

Z

i

C

OJ

o

Cl

m

CD

n

o

Q

CIl

en

l

3

Page 493 of 548

m

J

Co

5

oil

tl

Cl

s

5

Q

0

0

WAS

ER

MOTOR

t

l

I

o

BATTERY

A

G

ll

J

wr

FUSIB

E

LINK

Off

UN

HI

WASH

11

J

BY

9

n

13

4d

1

o

14

J

I

Q

I

16

m

LW

2

0

u

J

WIPER

ANO

WASHER

SWITCH

I

lGCK

OfF

ACe

OM

Sf

2

0

OnOOB

m

iL

IG

i

I

0

S

00

A

II

WR

LB

IGNITION

SWITCH

Off

ON

WASHV

iW

REAR

WIPER

0

0

11

l

R

SWITCH

I

0

Q

I

2

I

B

HATCHBACK

0

I

I

3

o

II

LR

n

I

I

III

I

I

1

I

1

iI

Y

WIPER

MOTOR

LR

ti

BY

B

R

r

REAR

WASHER

MOTOR

IHATCHBACK

ANO

i

WAGON

Em

I

m

IIIn

zoot

a

11

1

I

a

E

lI

11

1

a

n

Jon

ZII

aen

i

III

a

io

OJ

a

It

8

0

It

m

l

l

In

l

CIl

l

3

HATCHBACK

LR

BOOYHARNESS

z

I

L

I

OO

B

iOl

c

TO

REAR

OEFOGGER

I

LR

rLB

1

I

3

0

i

BW

R

LRh

ftn

WAGON

0

0

r

o

REAR

WIPER

MOTOR

CRWl

T1

c

l

Rlif

1

I

mC

BilW

lJ

I

g

LR

Jj

i

1

FUSE

BLOCK

Page 494 of 548

Body

Electrical

System

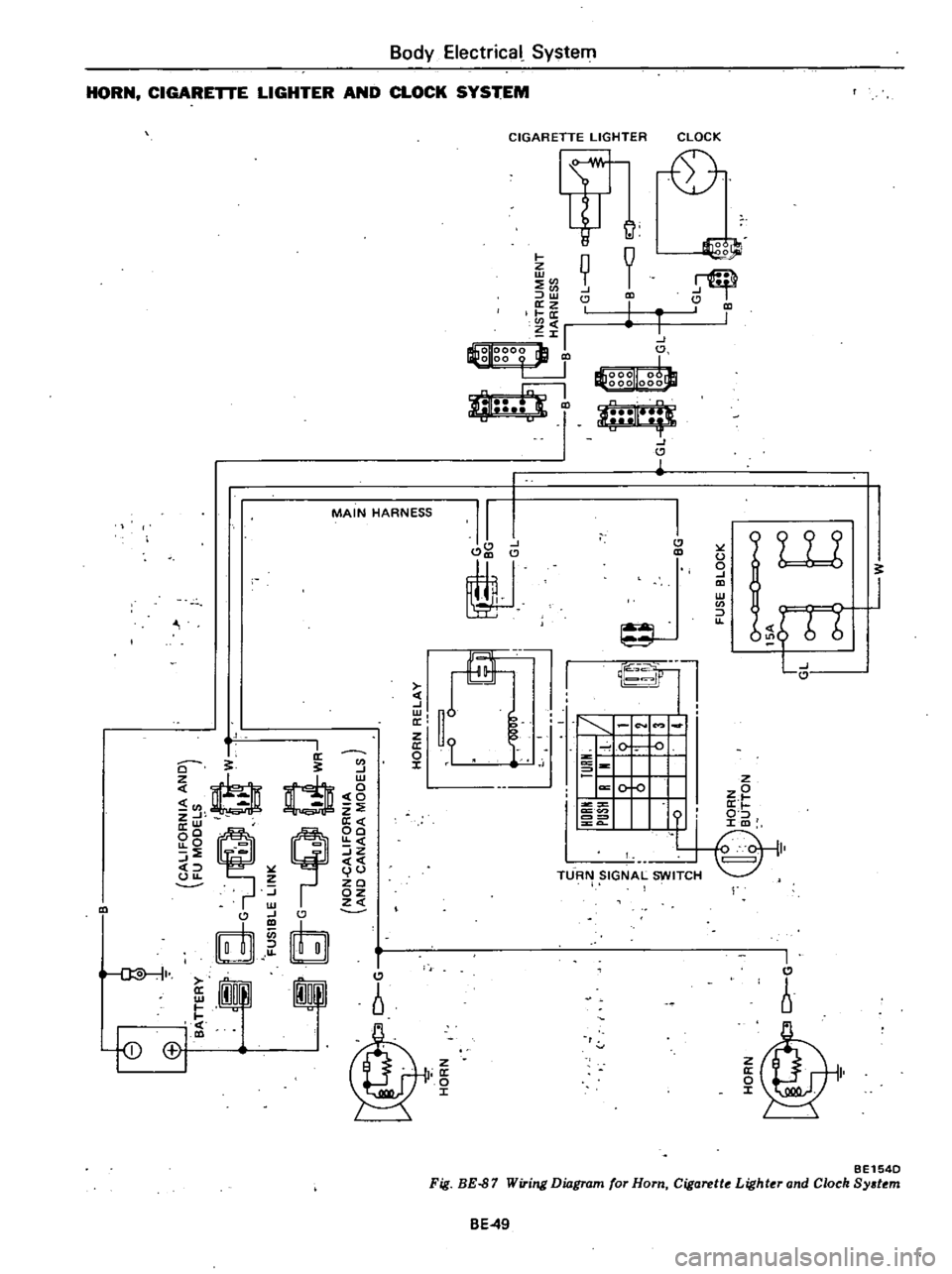

HORN

CIGARETTE

LIGHTER

AND

CLOCK

SYSTEM

I

I

0

W

l

I

fD

CCI

MAIN

HARNESS

I

I

0

en

srb

J

I

U

h

E

0

0

z

t

LL

Z

U

J

w

z

on

QlJ

J

w

0

Y

X

o

I

CIGARETTE

LIGHTER

Itt

9

J

J

I

Z

w

en

l

o

z

1

0

en

Zrl

I

O

tEl

g

r

J

i

I

J

al

I

J

ti

J

ti

1

1

J

J

8ho

f

J1

tf

J

P

II

J

J

1

I

I

e

o

TURN

SIGNAL

SWITCH

CLOCK

01

0

I

J

u

o

J

W

en

u

9W

tutJ

I

j

I

6

I

r

BE154D

Fig

BE

87

Wiring

Diagram

for

Horn

Cigarette

Lighter

and

Clock

System

BE49

Page 495 of 548

m

ii

lil

cIo

00

tl

i

3

Cl

0

m

0

g

fB

Jo

0

0

Ef1

CALIFORNIA

ANO

FU

MOOELS

t

f

G

W

g

dG

I

WR

FUSIBLE

LINK

8

G

uQ

t

WR

NON

cALIFORNIA

AND

CANAOA

MOOELS

J

TORQUE

CONVERTER

C

ao

GY

INOICATOR

LAMP

5

l

1

00

GW

I

BATTERY

CCOHST7

i

lOCK

Off

A

B

OO

C

I

ti

II

v

u

1

WITCH

IGNITION

S

2ND

Oil

lS1

B

C

C

AI8

C

I

5

A

8

I

QIQ

Q

Q

J1

0

0

I

0

6

B

6

0

7

Q

QIQIQ

8

0

0

0

9

O

I

LIGHTING

SWITCH

Z

1

D

Z

m

en

WR

LB

1lRG

GW

INSTRUMENT

HARNESS

j

lO

GW

I

oGW

GY

00

GY

LW

LW

I@o

00

og

B

0

u

B

LW

LB

I

I

0

0

J8

RG

w

1

0

r

O

FUSE

BLOCK

LW

ClO

LW

W

t

WB

1

r

GY

GW

RAOIO

ffi

i

n

In

U

L

J

UJ

J

U

WB

O

W

SPEAKER

OJ

o

Cl

m

CD

C

e

CIl

en

3

Page 496 of 548

m

ii

Co

0

i

tl

c

Cl

0

c

o

E

0

Cl

l

l

n

m

iO

t

B

i

BATTERY

A

G

FUSIBLE

LINK

I

I

lOCK

OfF

ACC

ON

S17

o

O

6

16

0

s

l

O

J

IA

IGN

ITION

SWITCH

FUSE

BLOCK

0

3

C

rT

l

WR

Q

BW

WR

I

BL

Z

J

Z

m

en

en

LG

l

LG

BOOY

HARNESS

6

J

1

nUl

I

OEFOGGER

l

C

ISEOAN

M

1R2

106

00

n

03

INSTRUMENT

B

I

II

8

HARNESS

f

i

G

0rF

to

LB

1

2

6

0

3

0

0

0

gg

REAR

WINOOW

OEFOGGER

SWITCH

l

0

II

11

1

Jo

II

E

z

a

11

1

II

o

8

11

1

II

OJ

o

Cl

m

CD

c

Ql

CIl

en

l

3

Page 497 of 548

Body

Electrical

System

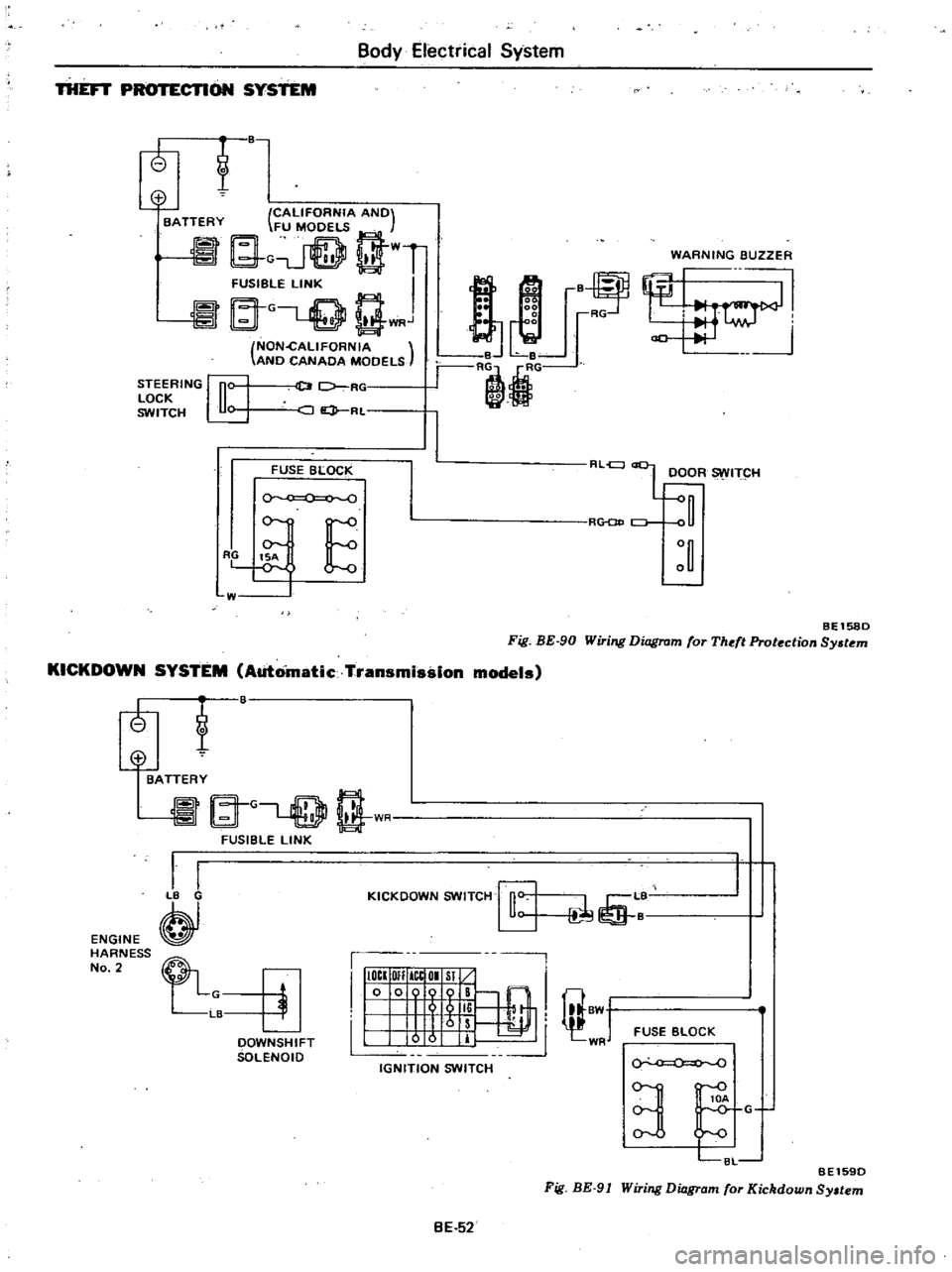

THEFT

CTlON

SYSTEM

t

o

CALIFORNIA

ANO

BATTERY

FU

MOOELS

G

t

WT

FUSIBGLE

LINK

I

at

L

Q

Q

WRJ

NON

cALlFORNIA

ANO

CANAOA

MOOELS

WARNING

BUZZER

STEERING

n

LOCK

u

SWITCH

U

D

7

RC

JQ

RL

2

2

00

i

r

B

Le

r

RljG

8

RG

FUSE

BLOCK

0

RLel

L

OOOR

ITCH

R

CJ

E

W

BEl580

Fig

BE

90

Wiring

Diagram

for

Theft

Protection

Sy

tem

KICKDOWN

SYSTEM

Automatic

Transmission

models

tf

ENGINE

HARNESS

No

2

@

BATTERY

A

G

rT

l

t

1

I

FUSIBLE

LINK

I

I

B

KICKOOWN

SWITCH

rfi

L

1

I

IIIOCI

OIl

ICtOI

Sl

10

009

B

@

I

I

5

li

I

8W

1

Irs

I

0

0

IT

WR

IGNITION

SWITCH

FUSE

BLOCK

OOWNSHIFT

SOLENOIO

0

0

BE1590

Fig

BE

91

Wiring

Diagram

for

Kickdown

Sy

tem

3

C8L

G

BE

52

Page 500 of 548

m

ii

I

ll

ic

i

tl

Cl

Ul

0

is

B

w

ii

W

oa

LW

L

CALIFORNIA

ANO

I

d

S

R

FUSIBLE

LINK

o

BATTERY

S

JSt

wGLQ

gWR

NON

GALIFORNIA

ANO

CANAOA

MOOELS

LOC

Off

Ace

ON

Sf

o

0

i

IGNITION

SWITCH

L

B

LN

I

15A

0

0

0

0

o

v

E

FUSE

BLOCK

M

F

i

L

11L1

u

R

1

i

ri

1

w

RESISTOR

BW

Il

BLj

L

lljlj

U6

1

BWY

W

B

8

HEAVY

OUTY

TYPE

Standard

for

Canada

and

option

for

U

S

A

LW

HEATER

MOtOR

IOffl

I

2

3

Kro

lli

H

FAN

SWITCH

ST

ANOARO

TYPE

Z

II

II

a

OJ

o

Cl

m

CD

n

n

Ql

CIl

CJ

l

3

Page 507 of 548

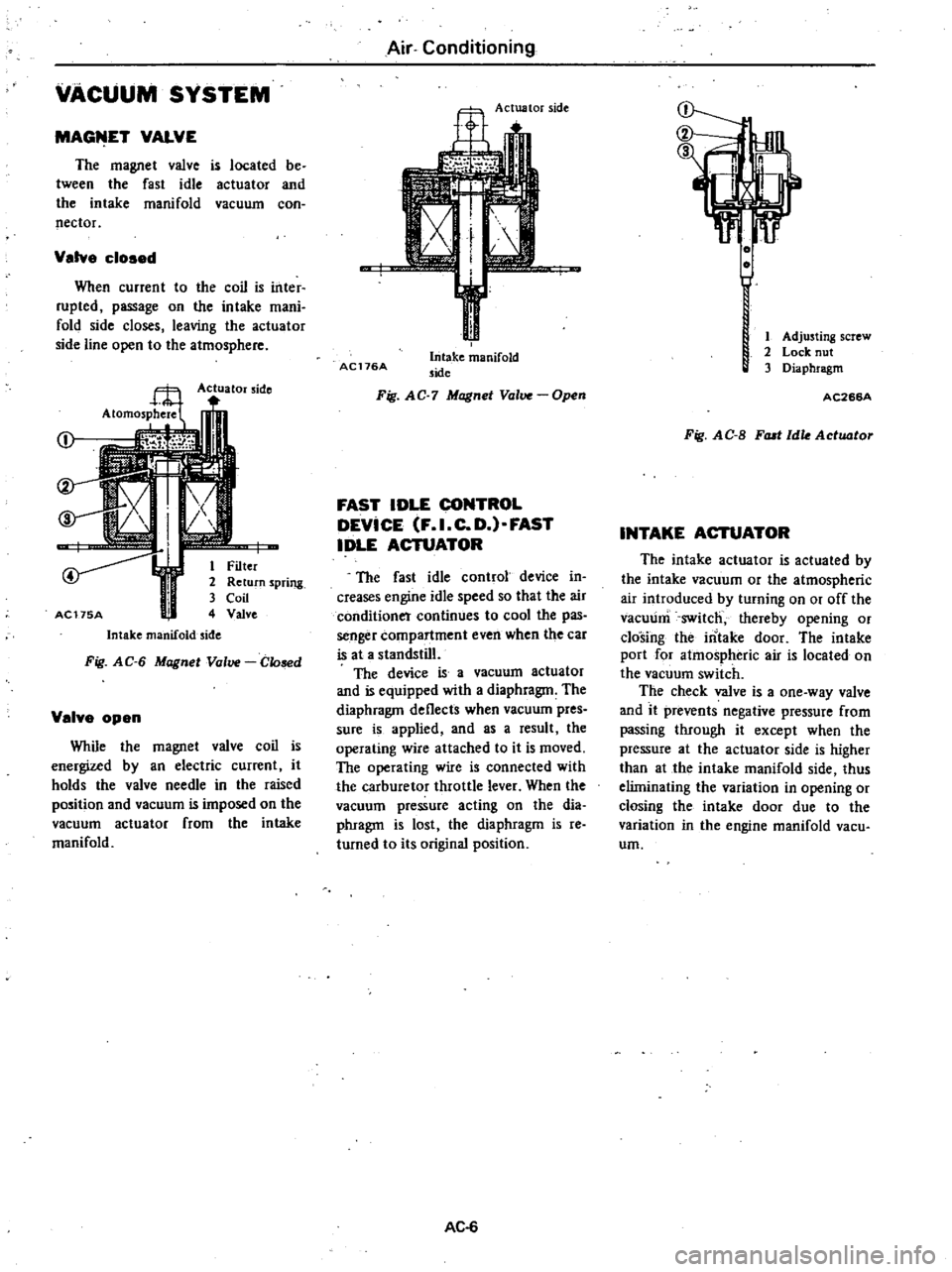

VACUUM

SYSTEM

MAGfilET

VALVE

The

magnet

valve

is

located

be

tween

the

fast

idle

actuator

and

the

intake

manifold

vacuum

con

nector

Valve

cloaed

When

current

to

the

coil

is

inter

rupted

passage

on

the

intake

mani

fold

side

closes

leaving

the

actuator

side

line

open

to

the

atmosphere

Actuator

side

j

I

i

r

1

Filter

2

Return

spring

3

Coil

AC175A

4

Valve

Intake

manifold

side

Fig

AG

6

Magnet

Valve

Glosed

Velve

open

While

the

magnet

valve

coil

is

energized

by

an

electric

current

it

holds

the

valve

needle

in

the

raised

position

and

vacuum

is

imposed

on

the

vacuum

actuator

from

the

intake

manifold

Air

Conditioning

Actuator

side

AC176A

Intake

manifold

side

Fig

AG

7

Magnet

Valve

Open

FAST

IDLE

CONTROL

DEVICE

F

I

C

D

FAST

IDLE

ACTUATOR

The

fast

idle

control

device

in

creases

engine

idle

speed

so

that

the

air

conditioner

continues

to

cool

the

pas

senger

compartment

even

when

the

car

is

at

a

standstill

The

device

is

a

vacuum

actuator

and

is

equipped

with

a

diaphragm

The

diaphragm

deflects

when

vacuum

pres

sure

is

applied

and

as

a

result

the

operating

wire

attached

to

it

is

moved

The

operating

wire

is

connected

with

the

carburetor

throttle

lever

When

the

vacuum

pressure

acting

on

the

dia

phragm

is

lost

the

diaphragm

is

reo

turned

to

its

original

position

AC

6

1

Adjusting

screw

2

Lock

nut

3

Diaphragm

AC266A

Fig

AG

B

FlUI

Idle

Actuator

INTAKE

ACTUATOR

The

intake

actuator

is

actuated

by

the

intake

vacuum

or

the

atmospheric

air

introduced

by

turning

on

or

off

the

vacuum

switch

thereby

opening

or

closing

the

intake

door

The

intake

port

for

atmospheric

air

is

located

on

the

vacuum

switch

The

check

valve

is

a

one

way

valve

and

it

prevents

negative

pressure

from

passing

through

it

except

when

the

pressure

at

the

actuator

side

is

higher

than

at

the

intake

manifold

side

thus

eliminating

the

variation

in

opening

or

closing

the

intake

door

due

to

the

variation

in

the

engine

manifold

vacu

urn

Page 511 of 548

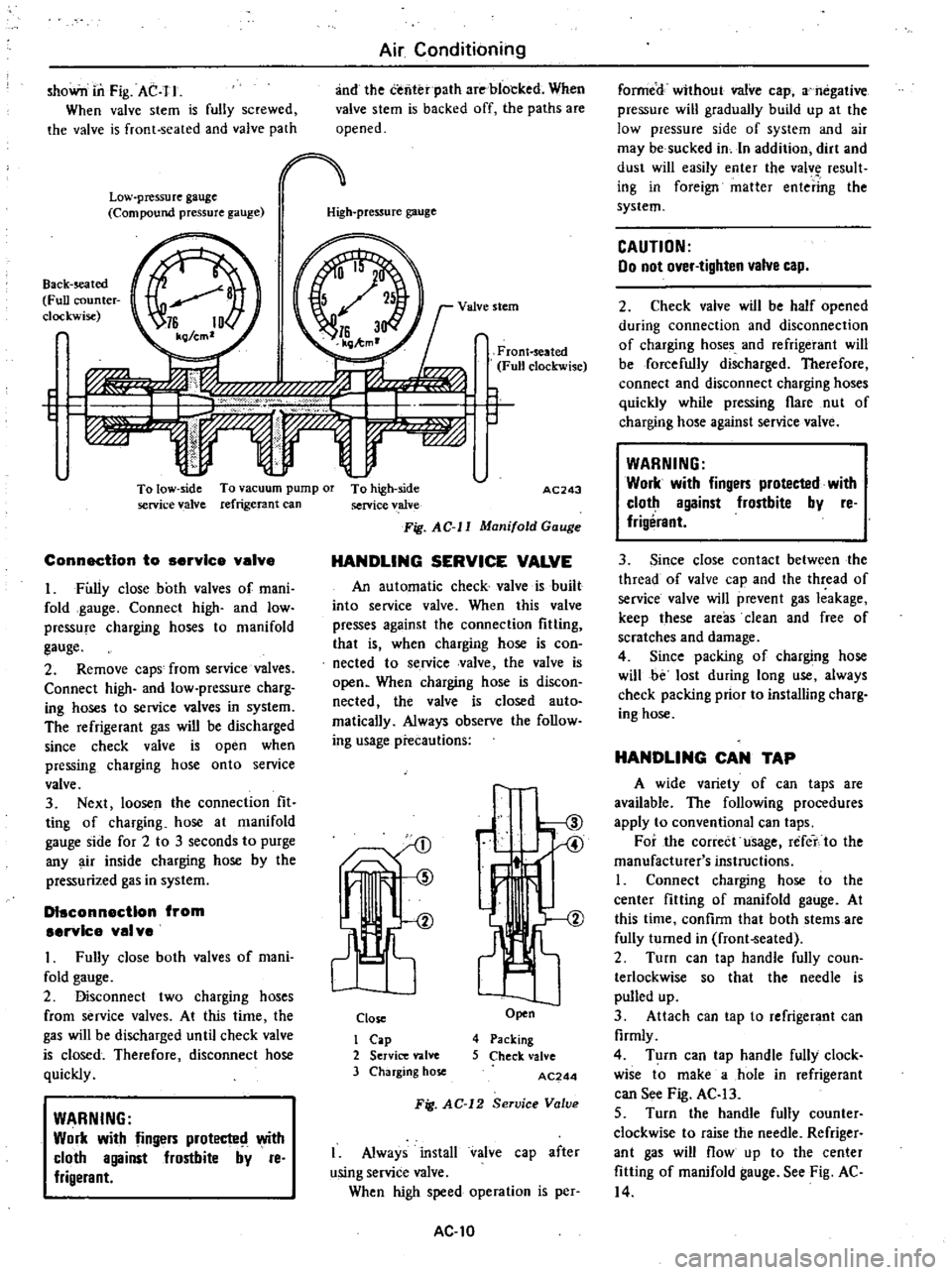

shoWn

in

Fig

AC

I

I

When

valve

stem

is

fully

screwed

the

valve

is

front

seated

and

valve

path

Low

pressure

gauge

Compound

pressure

gauge

Air

Conditioning

and

the

tenter

path

are

blocked

When

valve

stem

is

backed

off

the

paths

are

opened

High

pressure

gauge

Back

seated

Full

counter

clockwise

I

VA

l

C

f

f

f

J

l

r

To

low

side

To

vacuum

pump

01

To

high

side

service

valve

refrigerant

can

service

valve

Fig

AC

II

Manifold

Gauge

ConnectIon

to

service

valve

I

Fully

close

both

valves

of

mani

fold

gauge

Connect

high

and

low

pressure

charging

hoses

to

manifold

gauge

2

Remove

caps

from

service

valves

Connect

high

and

low

pressure

charg

ing

hoses

to

service

valves

in

system

The

refrigerant

gas

will

be

discharged

since

check

valve

is

open

when

pressing

charging

hose

onto

service

valve

3

Next

loosen

the

connection

fit

ting

of

charging

hose

at

manifold

gauge

side

for

2

to

3

seconds

to

purge

any

air

inside

charging

hose

by

the

pressurized

gas

in

system

DIsconnection

from

servIce

val

ve

I

Fully

close

both

valves

of

mani

fold

gauge

2

Disconnect

two

charging

hoses

from

service

valves

At

this

time

the

gas

will

be

discharged

until

check

valve

is

closed

Therefore

disconnect

hose

quickly

WARNING

Work

with

fingers

protecte

with

cloth

against

frostbite

by

reo

frigerant

FronHeated

Fun

clockwise

r

AC243

HANDLING

SERVICE

VALVE

An

automatic

check

valve

is

built

into

service

valve

When

this

valve

presses

against

the

connection

fiUing

that

is

when

charging

hose

is

con

nected

to

service

valve

the

valve

is

open

When

charging

hose

is

discon

nected

the

valve

is

closed

auto

matically

Always

observe

the

follow

ing

usage

precautions

1ts

Close

I

Cap

2

Service

valve

3

Charging

hose

ir

Open

4

Packing

5

Check

valve

AC244

Fig

AC

12

Service

Valve

I

Always

install

valve

cap

after

using

service

valve

When

high

speed

operation

is

per

AC

I0

formed

without

valve

cap

a

negative

pressure

will

gradually

build

up

at

the

low

pressure

side

of

system

and

air

may

be

sucked

in

In

addition

dirt

and

dust

will

easily

enter

the

valv

result

ing

in

foreign

matter

entering

the

system

CAUTION

00

not

over

tighten

valve

cap

2

Check

valve

wiJI

be

half

opened

during

connection

and

disconnection

of

charging

hoses

and

refrigerant

will

be

forcefully

discharged

Therefore

connect

and

disconnect

charging

hoses

quickly

while

pressing

flare

nut

of

charging

hose

against

service

valve

WARNING

Work

with

fingers

protected

with

cloth

against

frostbite

by

reo

frigerant

3

Since

close

contact

between

the

thread

of

valve

cap

and

the

thread

of

service

valve

will

prevent

gas

leakage

keep

these

areas

clean

and

free

of

scratches

and

damage

4

Since

packing

of

charging

hose

will

be

lost

during

long

use

always

check

packing

prior

to

installing

charg

ing

hose

HANDLING

CAN

TAP

A

wide

variety

of

can

taps

are

available

The

following

procedures

apply

to

conventional

can

taps

For

the

correct

usage

refet

to

the

manufacturer

s

instructions

I

Connect

charging

hose

to

the

center

fitting

of

manifold

gauge

At

this

time

confirm

that

both

stems

are

fully

turned

in

frontoSeated

2

Turn

can

tap

handle

fully

coun

terlockwise

so

that

the

needle

is

pulled

up

3

Attach

can

tap

to

refrigerant

can

firmly

4

Turn

can

tap

handle

fully

clock

wise

to

make

a

hole

in

refrigerant

can

See

Fig

AC

13

5

Turn

the

handle

fully

counter

clockwise

to

raise

the

needle

Refriger

ant

gas

will

flow

up

to

the

center

fitting

of

manifold

gauge

See

Fig

AC

14