lock DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 440 of 548

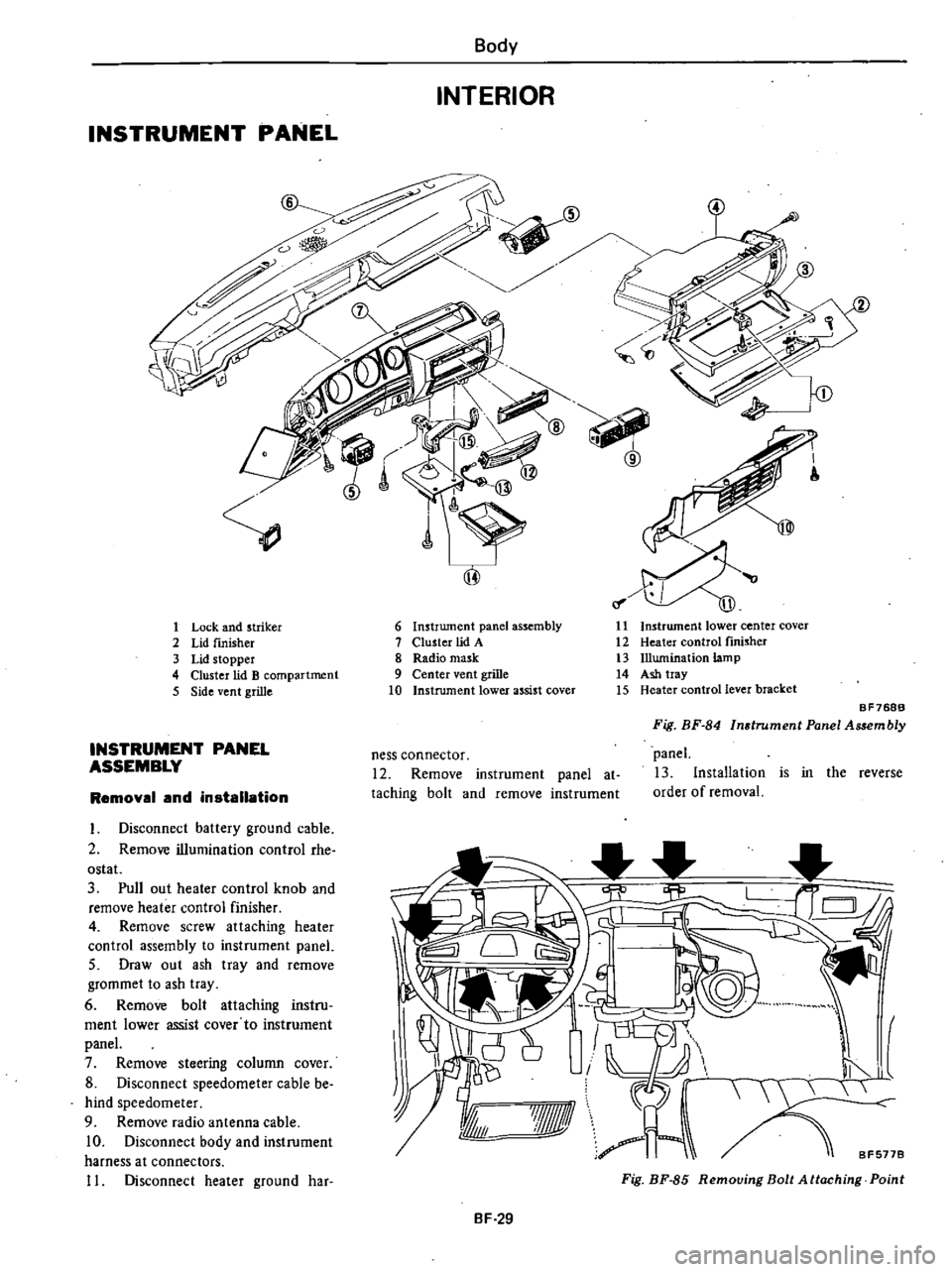

INSTRUMENT

PANEL

Body

INTERIOR

1

Lock

and

striker

2

Lid

fInisher

3

Lid

stopper

4

Cluster

lid

B

compartment

5

Side

vent

grille

INSTRUMENT

PANEL

ASSEMBLY

Removal

and

installation

I

Disconnect

battery

ground

cable

2

Remove

illumination

control

rhe

ostat

3

Pull

out

heater

control

knob

and

remove

heater

control

finisher

4

Remove

screw

attaching

heater

control

assembly

to

instrument

panel

5

Draw

out

ash

tray

and

remove

grommet

to

ash

tray

6

Remove

bolt

attaching

instru

ment

lower

assist

cover

to

instrument

panel

7

Remove

steering

column

cover

8

Disconnect

speedometer

cable

be

hind

speedometer

9

Remove

radio

antenna

cable

10

Disconnect

body

and

instrument

harness

at

connectors

11

Disconnect

heater

ground

har

6

Instrument

panel

assembly

7

Cluster

lid

A

8

Radio

mask

9

Center

vent

grille

10

Instrument

lower

assist

cover

11

Instrument

lower

center

cover

12

Heater

control

fInisher

13

Illumination

lamp

14

Ash

tray

15

Heater

control

lever

bracket

ness

connector

12

Remove

instrument

panel

at

taching

bolt

and

remove

instrument

BF768B

Fig

BF

84

Instrument

Panel

Assembly

panel

13

Installation

is

in

the

reverse

order

of

removal

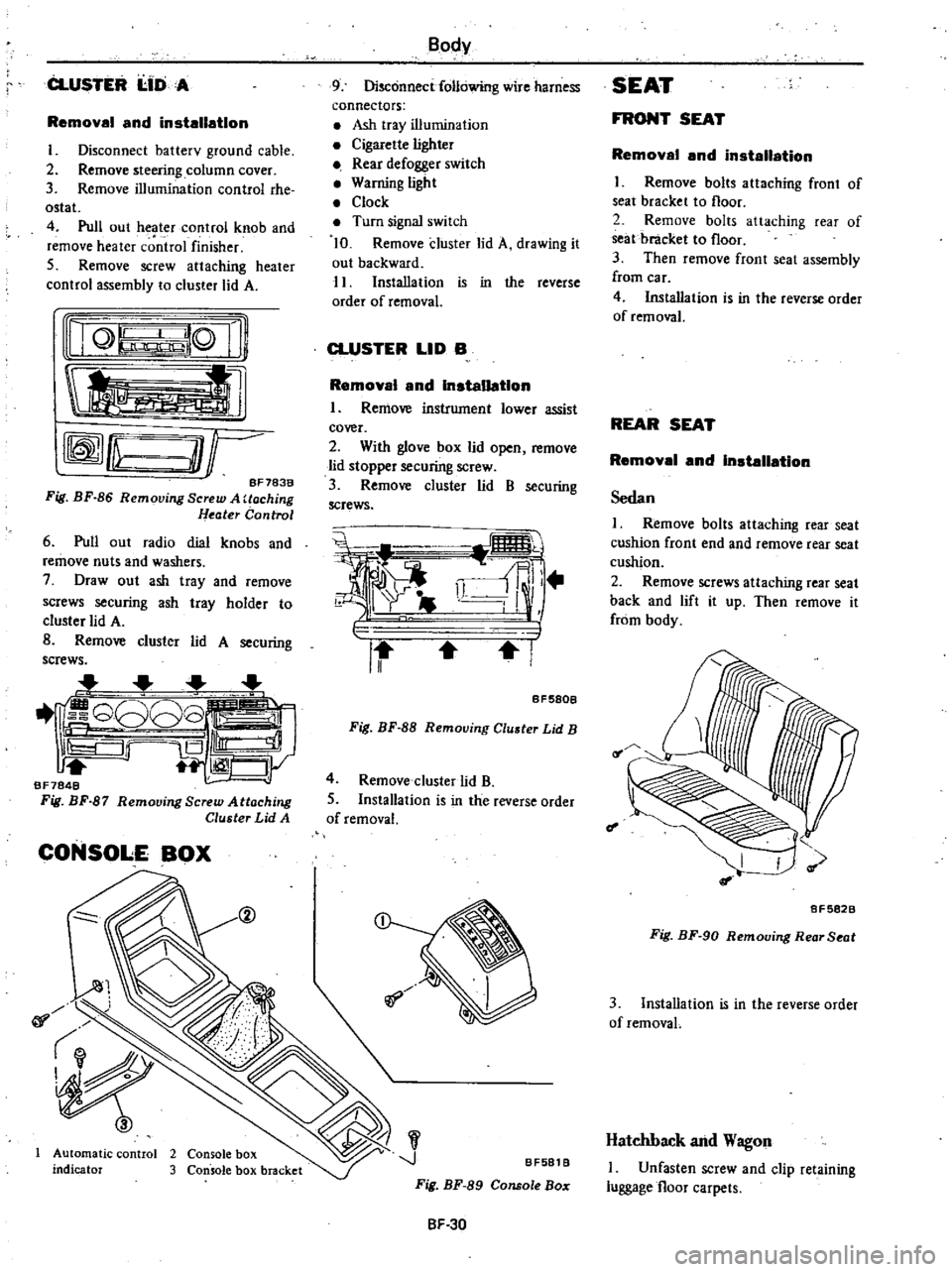

I

I

I

8F5778

7Jf1ll

A

Fig

BF

85

Removing

Bolt

Attaching

Point

BF

29

Page 441 of 548

CLUSTER

I

IDA

Removal

and

installation

I

Disconnect

batterv

ground

cable

2

Remove

steering

column

cover

3

Remove

illumination

control

rhe

ostat

4

Pull

out

heater

control

knob

and

remove

heater

c

ntrol

finisher

5

Remove

screw

attaching

heater

control

assembly

to

cluster

lid

A

nQ

lQ

Ii

tl

rffmfLu

O

r

BF783B

Fig

BF

86

Removing

Screw

A

Uoching

Heater

Control

6

Pull

out

radio

dial

knobs

and

remove

nuts

and

washers

7

Draw

out

ash

tray

and

remove

screws

securing

ash

tray

holder

to

cluster

lid

A

B

Remove

cluster

lid

A

securing

screws

1

G808

iS

Ill

1

CJy

BF7848

Fig

BF

87

Remooing

Screw

Attaching

Cluster

Lid

A

CONSOLE

BOX

@

01

Automatic

control

2

Console

box

indicator

3

Console

box

bracket

Body

9

Disconnect

following

wire

harness

connectors

Ash

tray

illumination

Cigarette

lighter

Rear

defogger

switch

Warning

light

Clock

Turn

signal

switch

10

Remove

cluster

lid

A

drawing

it

out

backward

11

Installation

is

in

the

reverse

order

of

removal

CLUSTER

LID

B

Removal

and

Installation

I

Remove

instrument

lower

assist

cover

2

With

glove

box

lid

open

remove

lid

stopper

securing

screw

3

Remove

cluster

lid

B

securing

screws

i

i

ll

r

II

I

BF580B

Fig

BF

88

Removing

Cluster

Lid

B

4

Remove

cluster

lid

B

5

Installation

is

in

the

reverse

order

of

removal

J

BF581

B

Fig

BF

89

Console

Bo

SF

30

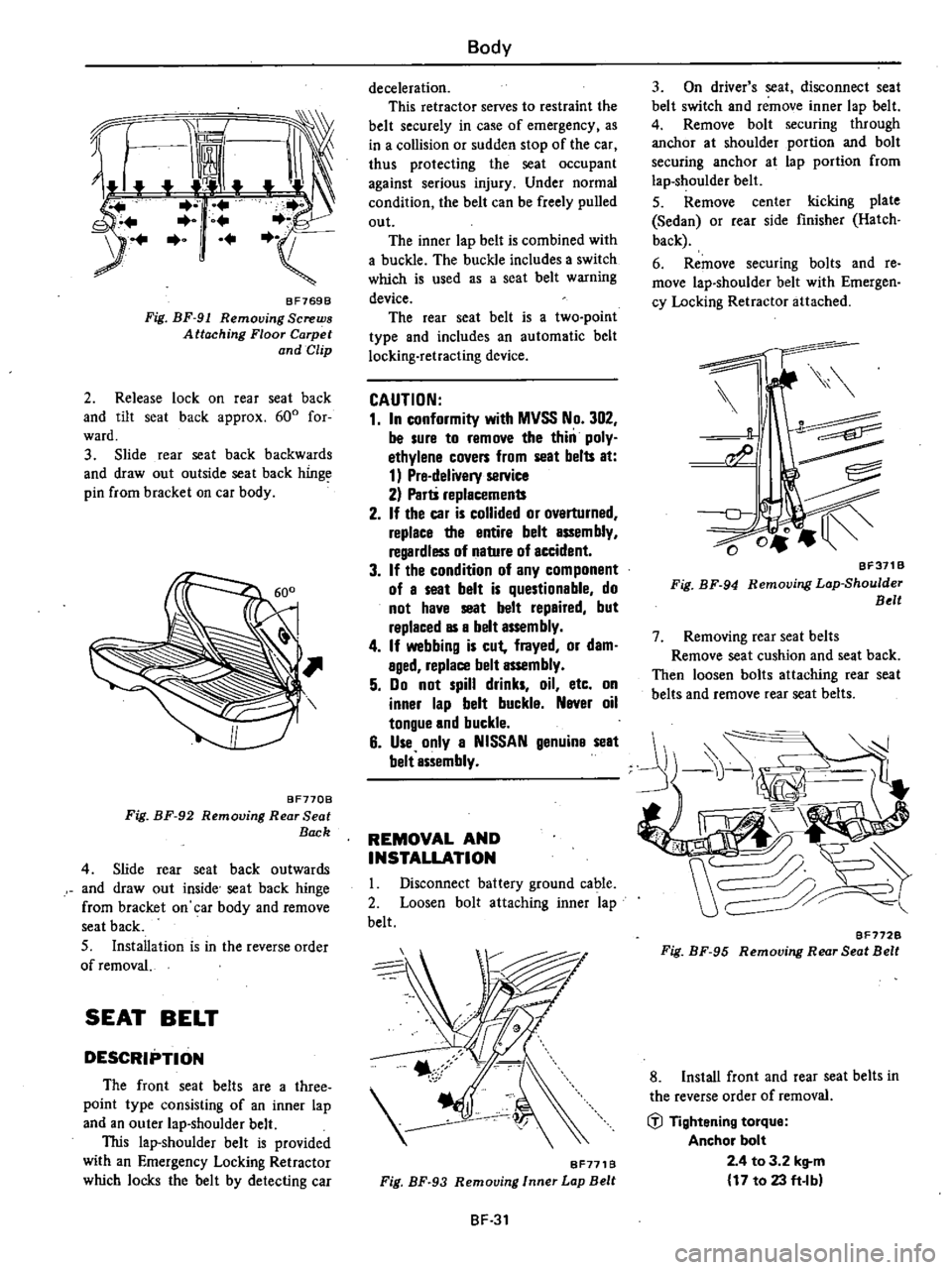

SEAT

FRONT

SEAT

Removal

and

installation

I

Remove

bolts

attaching

front

of

seat

bracket

to

floor

2

Remove

bolts

attaching

rear

of

seat

bracket

to

floor

3

Then

remove

front

seat

assembly

from

car

4

Installation

is

in

the

reverse

order

of

removal

REAR

SEAT

Removal

and

Installation

Sedan

I

Remove

bolts

attaching

rear

seat

cushion

front

end

and

remove

rear

seat

cushion

2

Remove

screws

attaching

rear

seat

back

and

lift

it

up

Then

remove

it

from

body

f

I

8F5828

Fig

BF

90

Removing

Rear

Seat

3

Installation

is

in

the

reverse

order

of

removaL

Hatchback

and

Wagon

I

Unfasten

screw

and

clip

retaining

luggage

floor

carpets

Page 442 of 548

Z

jJ

BF769B

Fig

BF

91

Removing

Screws

Attaching

Floor

Carpet

and

Clip

2

Release

lock

on

rear

seat

back

and

tilt

seat

back

approx

600

for

ward

3

Slide

rear

seat

back

backwards

and

draw

out

outside

seat

back

hinge

pin

from

bracket

on

car

body

BF770B

Fig

BF

92

Removing

Rear

Seat

Back

4

Slide

rear

seat

back

outwards

and

draw

out

inside

seat

back

hinge

from

bracket

on

car

body

and

remove

seat

back

S

Installation

is

in

the

reverse

order

of

removal

SEAT

BELT

DESCRIPTION

The

front

seat

belts

are

a

three

point

type

consisting

of

an

inner

lap

and

an

outer

lap

shoulder

belt

This

lap

shoulder

belt

is

provided

with

an

Emergency

Locking

Retractor

which

locks

the

belt

by

detecting

car

Body

deceleration

This

retractor

serves

to

restraint

the

belt

securely

in

case

of

emergency

as

in

a

collision

or

sudden

stop

of

the

car

thus

protecting

the

seat

occupant

against

serious

injury

Under

normal

condition

the

belt

can

be

freely

pulled

out

The

inner

lap

belt

is

combined

with

a

buckle

The

buckle

includes

a

switch

which

is

used

as

a

seat

belt

warning

device

The

rear

seat

belt

is

a

two

point

type

and

includes

an

automatic

belt

locking

retracting

device

CAUTION

1

In

conformity

with

MVSS

No

302

be

sure

to

remove

the

thin

poly

ethylene

covers

from

seat

belts

at

1

Pre

delivery

service

2

Parti

replacements

2

If

the

car

is

collided

or

ovarturned

replace

the

entire

belt

assembly

regardless

of

nature

of

accident

3

If

the

condition

of

any

component

of

a

seat

belt

is

questionable

do

not

have

seat

belt

repaired

but

raplaced

as

a

belt

assembly

4

If

webbing

is

cut

frayed

or

dam

aged

replace

belt

assembly

5

Do

not

spill

drinks

oil

etc

on

inner

lap

belt

buckla

Naver

oil

tongue

and

buckle

6

Use

only

a

NISSAN

genuina

seat

belt

assembly

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Loosen

bolt

attaching

inner

lap

belt

BF771B

Fig

BF

93

Removing

Inner

Lap

Belt

BF

31

3

On

driver

s

seat

disconnect

seat

belt

switch

and

remove

inner

lap

belt

4

Remove

bolt

securing

through

anchor

at

shoulder

portion

and

bolt

securing

anchor

at

lap

portion

from

lap

shoulder

belt

5

Remove

center

kicking

plate

Sedan

or

rear

side

finisher

Hatch

back

6

Remove

securing

bolts

and

re

move

lap

shoulder

belt

with

Emergen

cy

Locking

Retractor

attached

BF311B

Fig

BF

94

Removing

Lop

Shoulder

Belt

7

Removing

rear

seat

belts

Remove

seat

cushion

and

seat

back

Then

loosen

bolts

attaching

rear

seat

belts

and

remove

rear

seat

belts

BF772B

Fig

BF

95

Removing

Rear

Seat

Belt

8

Install

front

and

rear

seat

belts

in

the

reverse

order

of

removal

iil

Tightening

torque

Anchor

bolt

2

4

to

3

2

kg

m

17

to

23

ft

Ibl

Page 446 of 548

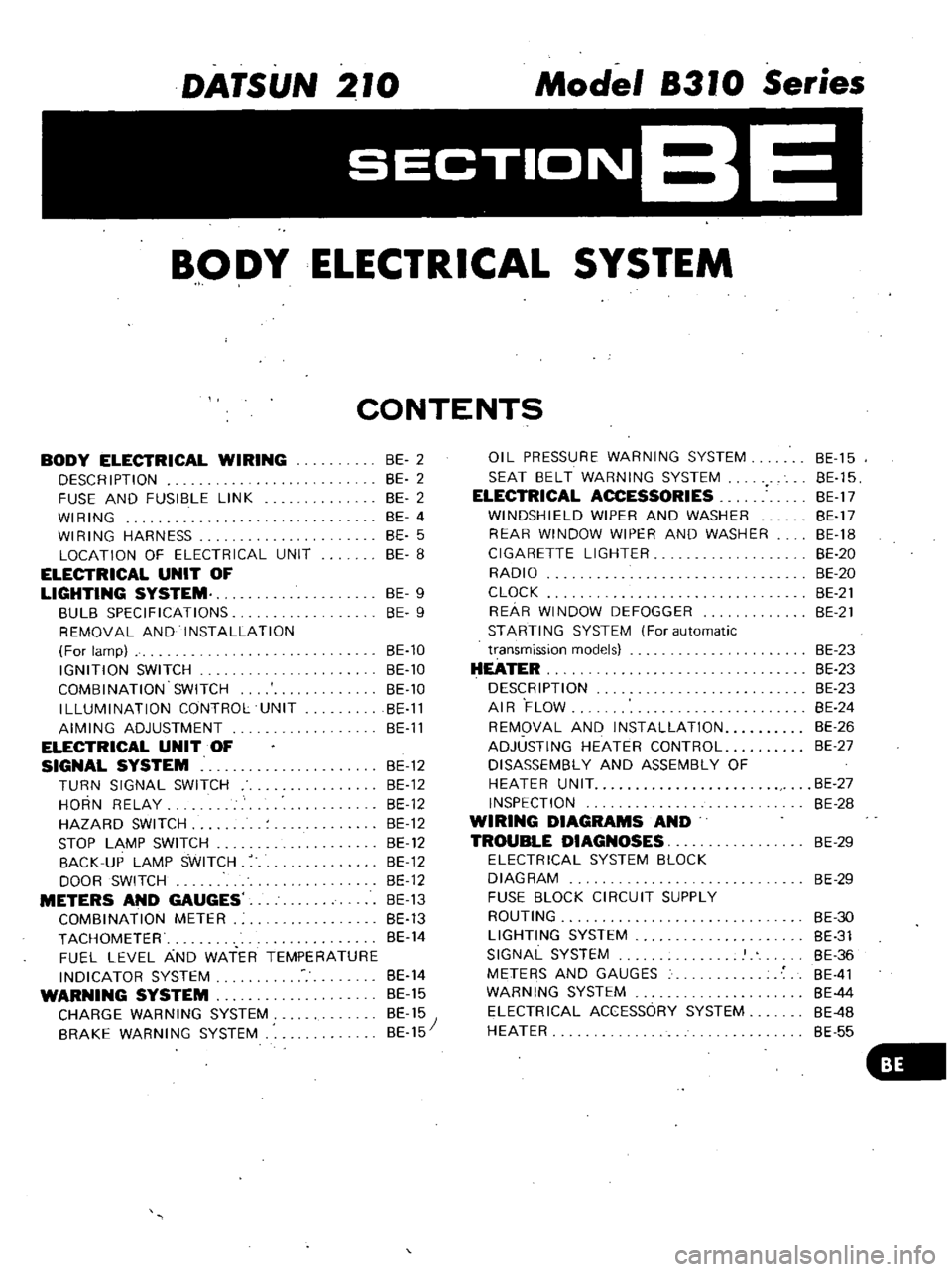

DATSUN

210

Model

8310

Series

SECTIONBE

BODY

ELECTRICAL

SYSTEM

CONTENTS

BODY

ELECTRICAL

WIRING

DESCRIPTION

FUSE

AND

FUSIBLE

LINK

WIRING

WIRING

HARNESS

LOCATION

OF

ELECTRICAL

UNIT

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

BULB

SPECIFICATIONS

REMOVAL

AND

INSTALLATION

For

lamp

IGNITION

SWITCH

COMBINATION

SWITCH

ILLUMINATION

CONTROL

UNIT

AIMING

ADJUSTMENT

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

BE

12

TURN

SIGNAL

SWITCH

BE

12

HORN

RELAY

BE

12

HAZARD

SWITCH

BE

12

STOP

LAMP

SWITCH

BE

12

BACK

UP

LAMP

SWITCH

BE

12

DOOR

SWITCH

BE

12

METERS

AND

GAUGES

BE

13

COMBINATION

METER

BE

13

TACHOMETER

BE

14

FUEL

LEVEL

AND

WATER

TEMPERATURE

INDICATOR

SYSTEM

BE

14

WARNING

SYSTEM

BE

15

CHARGE

WARNING

SYSTEM

BE

15

BRAKE

WARNING

SYSTEM

BE

15

BE

2

BE

2

BE

2

BE

4

BE

5

BE

8

BE

9

BE

9

BE

10

BE

10

BE

10

BE

11

BE

11

OIL

PRESSURE

WARNING

SYSTEM

SEAT

BELT

WARNING

SYSTEM

ELECTRICAL

ACCESSORIES

WINDSHIELD

WIPER

AND

WASHER

REAR

WINDOW

WIPER

AND

WASHER

CIGARETTE

LIGHTER

RADIO

CLOCK

REAR

WINDOW

DEFOGGER

STARTING

SYSTEM

For

automatic

transmission

models

HEATER

DESCRIPTION

AIR

FLOW

REMOVAL

AND

INSTALLATION

ADJUSTING

HEATER

CONTROL

DISASSEMBLY

AND

ASSEMBLY

OF

HEATER

UNIT

INSPECTION

WIRING

DIAGRAMS

AND

TROUBLE

DIAGNOSES

ELECTRICAL

SYSTEM

BLOCK

DIAGRAM

FUSE

BLOCK

CIRCUIT

SUPPLY

ROUTING

LIGHTING

SYSTEM

SIGNAL

SYSTEM

METERS

AND

GAUGES

WARNING

SYSTEM

ELECTRICAL

ACCESSORY

SYSTEM

HEATER

BE

15

BE

15

BE

17

BE

17

BE

18

BE

20

BE

20

BE

21

BE

21

BE

23

BE

23

BE

23

BE

24

BE

26

BE

27

BE

27

BE

28

BE

29

BE

29

BE

30

BE

31

BE

36

BE

41

BE

44

BE

4B

BE

55

Page 447 of 548

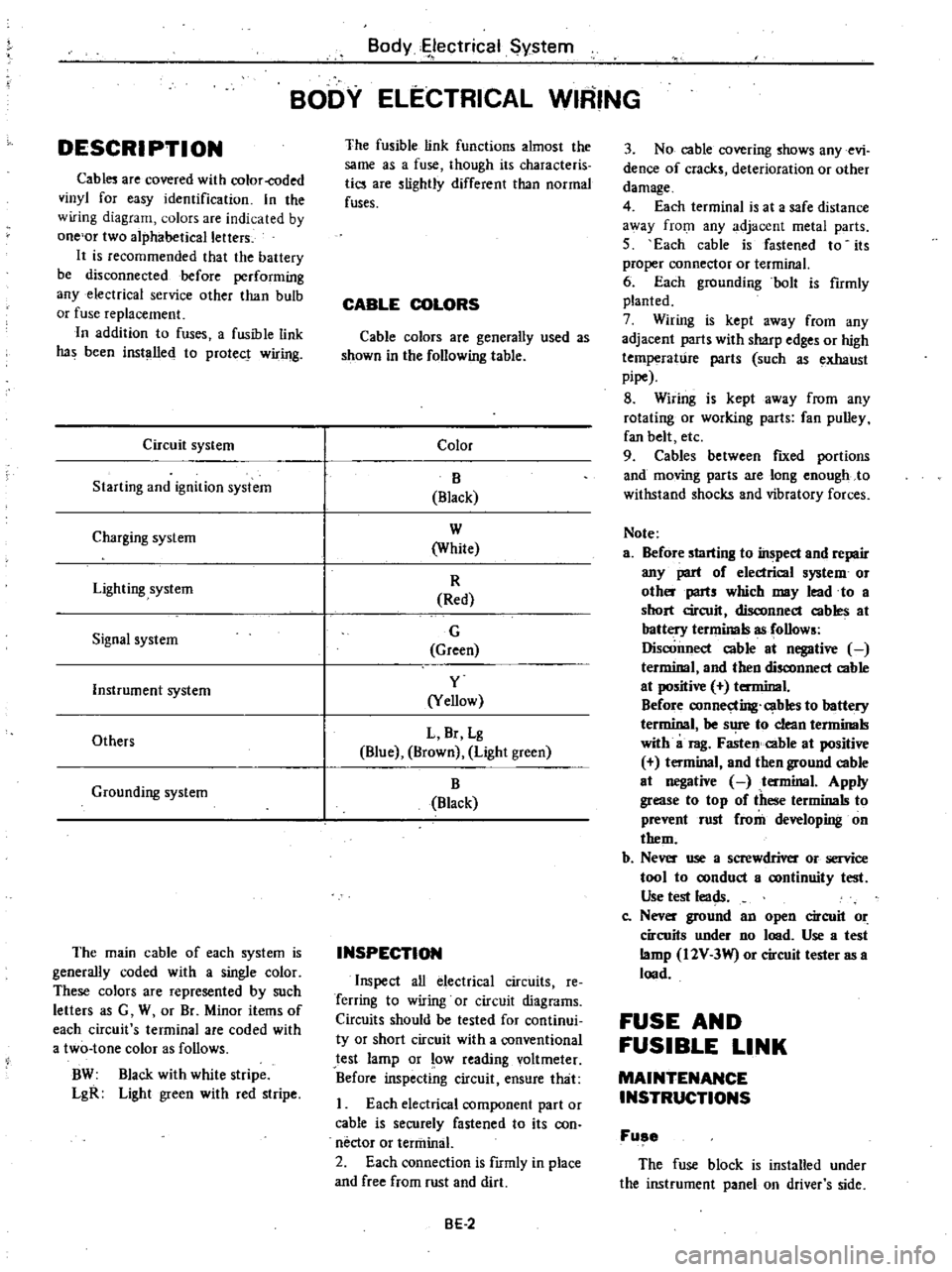

DESCRI

PTI

ON

Cabl

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

olors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

Circuit

system

Starting

and

ignition

system

Charging

system

Lighting

system

Signal

system

Instrument

system

Others

Grounding

system

The

main

cable

of

each

system

is

generally

coded

with

a

single

color

These

colors

are

represented

by

such

letters

as

G

W

or

Br

Minor

items

of

each

circuit

s

terminal

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

Body

ectrical

System

BODY

ELECTRICAL

WIRING

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

characteris

tics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

generally

used

as

shown

in

the

following

table

Color

B

Black

W

White

R

Red

G

Green

y

Yellow

L

Br

Lg

Blue

Brown

Light

green

B

Black

INSPECTION

Inspect

all

electrical

circuits

Ie

Terring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

continui

ty

or

short

circuit

with

a

conventional

test

lamp

or

low

reading

voltmeter

Before

inspecting

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

tenninal

2

Each

connection

is

fIrmly

in

place

and

free

from

rust

and

dirt

BE

2

3

No

cable

covering

shows

any

evi

dence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

3

Vay

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

6

Each

grounding

bolt

is

fumly

planted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

fIXed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Note

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

oth

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

s

1

to

clean

tenninals

with

a

rag

Fasten

cable

at

positive

t

minal

and

then

ground

cable

at

negative

tenninal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Ne

use

a

screwdriver

or

service

tool

to

oonduct

a

oontinuity

test

Use

test

leads

Co

Nev

ground

an

open

circuit

or

circuits

under

no

lood

Use

a

test

lamp

I2V

3W

or

circuit

tester

as

a

lood

FUSE

AND

FUSIBLE

LINK

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

driver

s

side

Page 448 of 548

When

for

one

reason

or

another

fuse

has

melted

use

systematic

proce

dure

to

check

and

eliminate

cause

of

problem

before

installing

new

fuse

Note

a

If

fuse

is

blown

be

sure

to

elimi

nate

cause

of

problem

before

in

stalling

new

fuse

b

Use

fuse

of

specified

rating

Never

use

fuse

of

more

than

specified

rating

c

Check

condition

of

fuse

holders

If

much

rust

or

dirt

is

found

thereon

clean

metal

parts

with

fine

grained

sandpaper

until

proper

metal

to

metal

contact

is

made

Poor

contact

in

any

fuse

holder

will

often

lead

to

voltage

drop

or

heat

ing

in

the

circuit

and

could

result

in

improper

circuit

operation

Body

Electrical

System

W

BE1100

Fig

BE

l

FU

e

Block

Fusible

link

Fusible

link

protects

starting

he

d

lamp

ignition

and

charge

circuits

and

wiring

between

fuse

and

fusible

link

BE1110

Fig

BE

2

Fusible

Link

BE

3

CAUTION

a

If

fusible

link

should

melt

it

is

possible

that

critical

circuit

power

supply

or

large

current

carrying

circuit

is

shorted

In

such

a

case

carefully

check

and

eliminate

cause

of

problem

b

Never

wrap

periphery

of

fusible

link

with

vinyl

tape

Extreme

care

should

be

taken

with

this

link

to

ensure

that

it

does

not

come

into

contact

with

any

other

wiring

har

ness

or

vinyl

or

rubber

parts

A

melted

fusible

link

can

be

detect

ed

either

by

visual

inspection

or

by

feeling

with

finger

tip

If

its

condition

is

questionable

use

circuit

tester

or

test

lamp

as

required

to

conduct

continuity

test

This

continuity

test

can

be

performed

in

the

same

manner

as

for

any

conventional

fuse

Page 450 of 548

m

c

n

to

l

l

I

g

iF

0

1

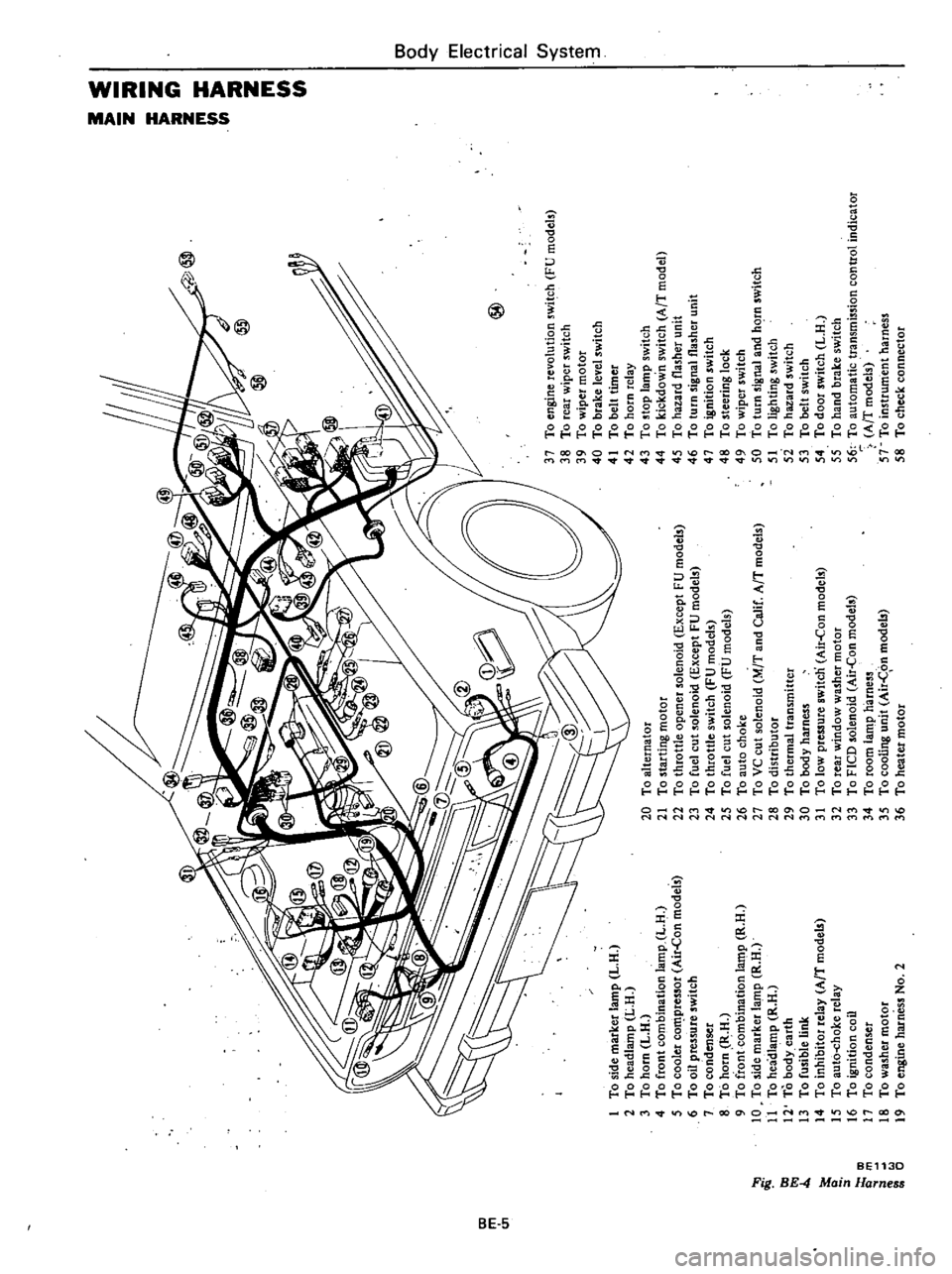

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 451 of 548

BodyElectrital

System

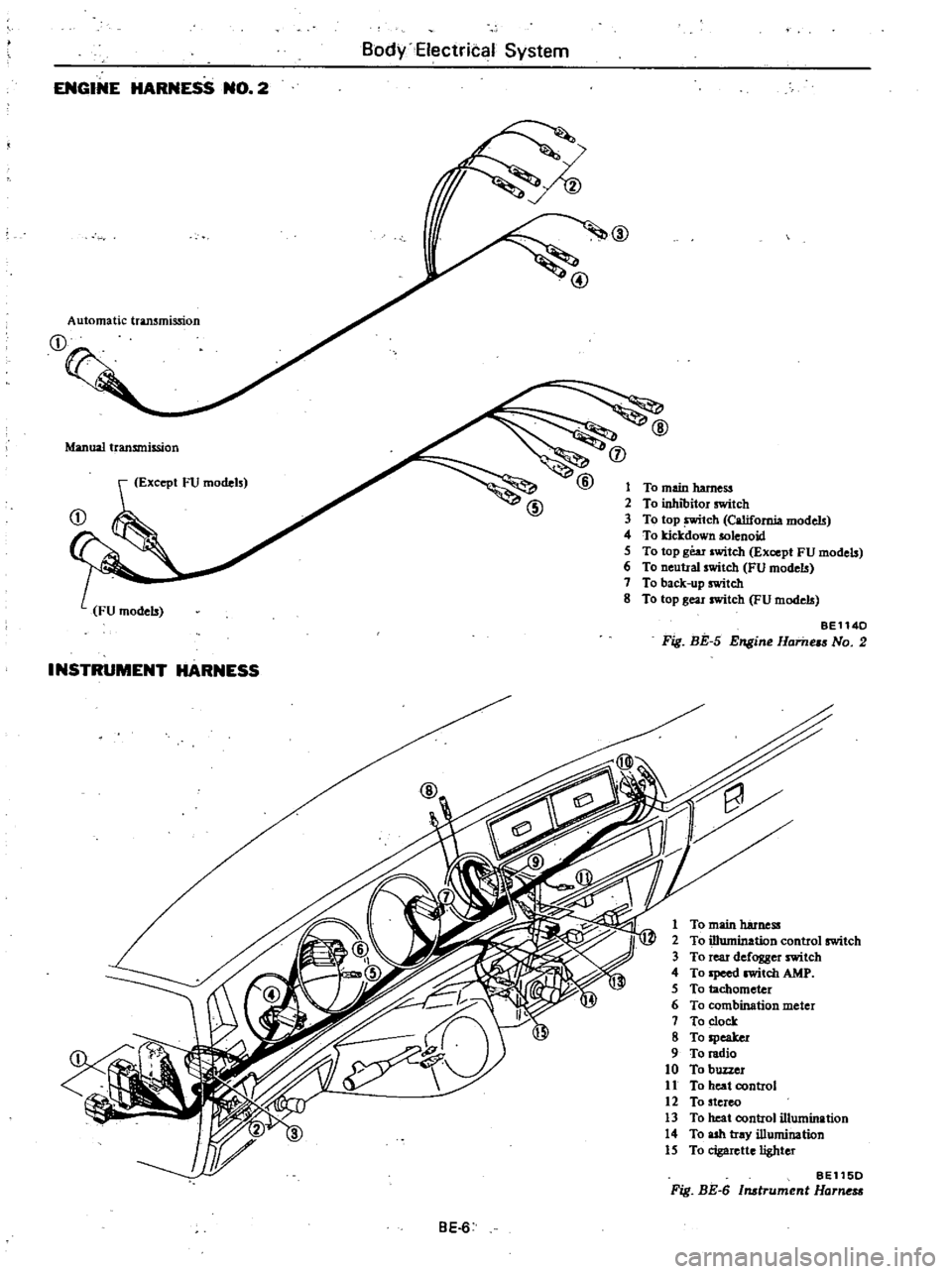

ENGINE

HARNESS

NO

2

@

Automatic

transmission

Manual

transmission

j

Except

FU

models

1

To

main

harness

2

To

inhibitor

switch

3

To

top

tch

California

models

4

To

kicJcdown

solenoid

5

To

top

gear

switch

Except

FU

models

6

To

neutral

switch

FU

models

7

To

back

up

switch

8

To

top

gear

switch

FU

models

BE1140

Fig

BE

5

Engine

Hame

No

2

INSTRUMENT

HARNESS

1

To

main

harness

2

To

illumination

control

switch

3

To

rear

defogger

switch

4

To

Ipeed

witch

AMP

5

To

tachometer

6

To

combination

meter

7

To

clock

8

To

speaker

9

To

radio

10

To

buzzer

11

To

heat

control

12

To

stereo

13

To

heat

control

illumination

14

To

ash

tray

illumination

15

To

cigarette

lighter

BE115D

Fig

BE

6

Instrument

Harne

BE

6

Page 455 of 548

REMOVAL

AND

INSTALLATION

For

lamp

Note

a

Disconnect

battery

ground

cable

before

starting

to

work

b

To

repJaoe

bull

push

ill

n

bulb

turn

it

counterclockwise

and

re

move

it

from

socket

Install

new

bulb

in

tbe

reverse

order

of

re

moval

9

Removing

bulb

Installing

bulb

BE259C

Fig

BE

9

Replacing

Bulb

c

To

repbce

wedge

base

type

bulb

puD

out

bulb

from

socket

To

inslaD

new

bulb

pusb

bulb

into

socket

Removing

bulb

Installing

bulb

Fig

BE

10

BE260C

R

eplac

ing

Wedge

BlUe

Type

Bulb

Body

Electrical

System

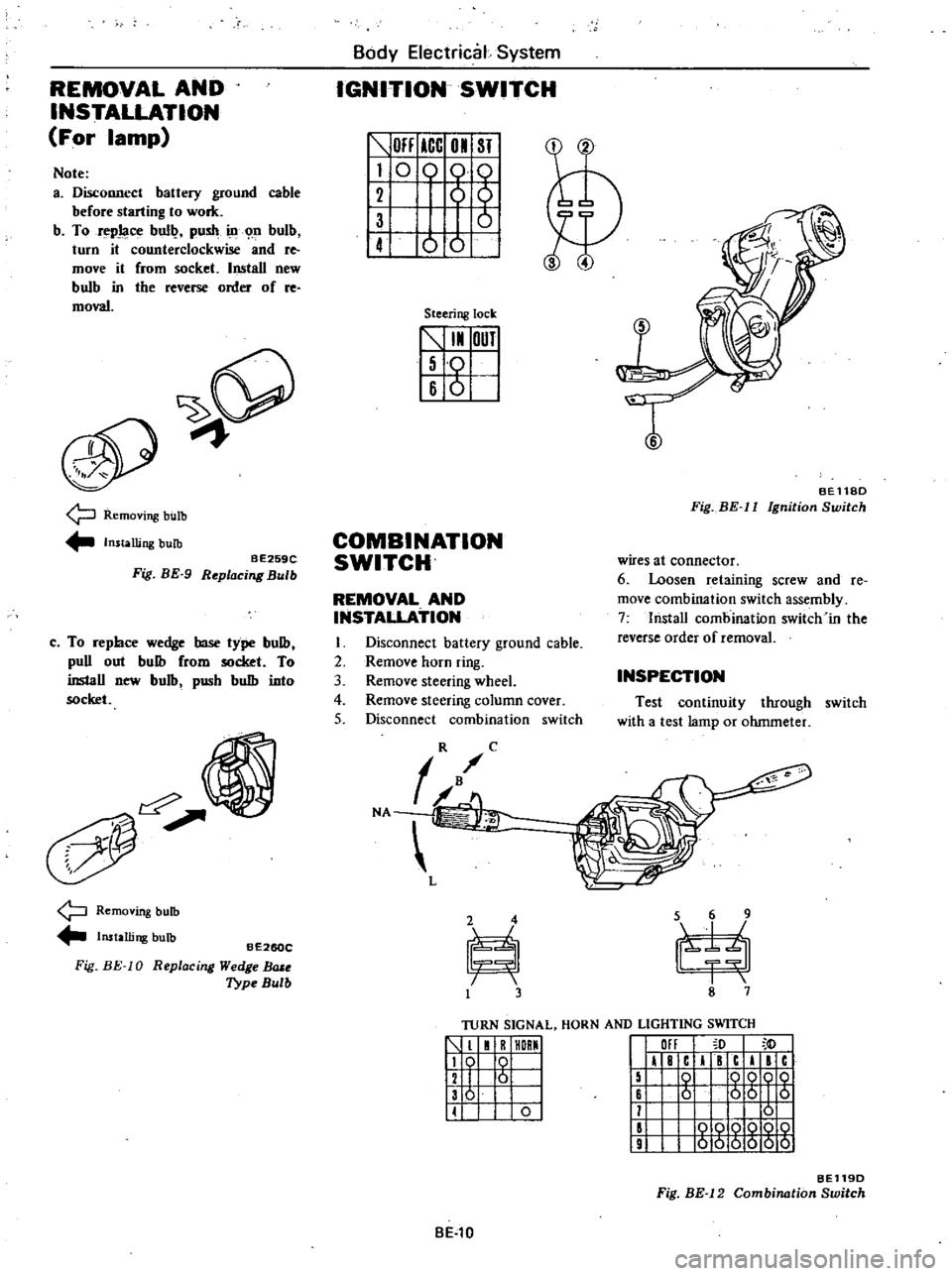

IGNITION

SWITCH

OFF

ICC

01

ST

I

0

0

61

1

ot

Steering

lock

5

I

OUT

I

Iso

16

6

I

T

BEll8D

Fig

BE

II

Ignition

Switch

COMBINATION

SWITCH

wires

at

connector

6

Loosen

retaining

screw

and

Ie

move

combination

switch

assembly

7

lnstaD

combination

switch

in

the

reverse

order

of

removal

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

horn

ring

3

Remove

steering

wheel

4

Remove

steering

column

cover

5

Disconnect

combination

switch

INSPECTION

Test

continuity

through

switch

with

a

test

lamp

or

ohmmeter

TURN

SIGNAL

HORN

AND

LIGHTING

SWITCH

1

1

R

HORMI

119

0

I

12

I

6

I

136

I

II

0

I

III

I

F

c

I

c

I

c

15

0

QQOQ

16

6

56

I

5

11

0

II

000Q

10

9

000000

BE119D

Fig

BE

12

Combination

Switch

BE

l0

Page 457 of 548

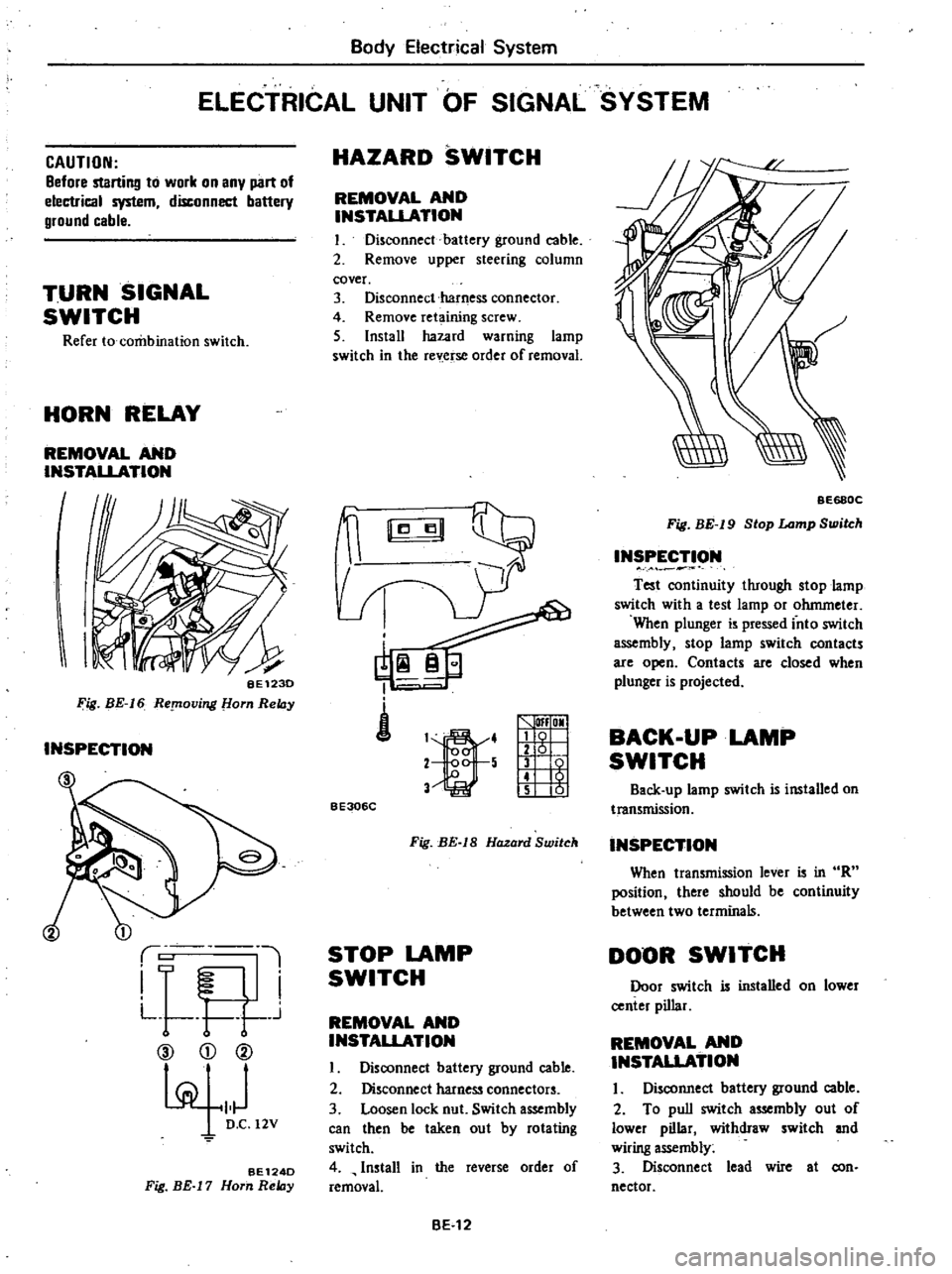

Body

Electrical

System

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

CAUTION

Before

startill1l

to

work

on

any

part

of

electrical

system

disconnect

battery

ground

cable

TURN

SIGNAL

SWITCH

Refer

to

combination

switch

HORN

RELAY

REMOVAL

AND

INSTALLATION

I

I

BE123D

Fig

BE

16

ReplOving

om

ReIDy

INSPECTION

1

i

L

l

I

F

I

L

t

r

j

CV

CD

@

pi

101

D

C

12V

BE124D

Fig

BE

17

Horn

ReIDy

HAZARD

SWITCH

REMOVAL

AND

INSTAUATION

I

Disconnect

battery

ground

cable

2

Remove

upper

steering

column

cover

3

Disconnect

harness

connector

4

Remove

ret

ining

screw

5

Install

hazard

warning

lamp

switch

in

the

rev

erse

order

of

removal

i

1

4

2

5

V

lfI

OMI

g

1

t

5

01

BE306C

Fig

BE

IS

Hazard

Switch

STOP

LAMP

SWITCH

REMOVAL

AND

INSTALLATION

I

Disoonnect

battery

ground

cable

2

Disconnect

harness

connectors

3

Loosen

lock

nut

Switch

assembly

can

then

be

taken

out

by

rotating

switch

4

Install

in

the

reverse

order

of

removal

BE

12

BE68QC

Fig

BE

19

Stop

Lamp

Switch

INSPECTION

Test

oontinuity

through

stop

lamp

switch

with

a

test

lamp

or

ohmmeter

When

plunger

is

pressed

into

switch

assembly

stop

lamp

switch

contacts

are

open

Contacts

are

closed

when

plunger

is

projected

BACK

UP

LAMP

SWITCH

Back

up

lamp

switch

is

installed

on

transmission

INSPECTION

When

transmission

lever

is

in

R

position

there

should

be

continuity

between

two

terminals

DOOR

SWITCH

Door

switch

is

installed

on

lower

center

pillar

REMOVAL

AND

INSTAUATION

I

Disconnect

battery

ground

cable

2

To

pull

switch

assembly

out

of

lower

pillar

withdraw

switch

and

wiring

assembly

3

Disconnect

lead

wire

at

con

nector