Fork DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 244 of 548

J

xplanation

of

convet

ted

torque

Mainshaft

nut

should

be

tightened

to

10

to

11

kg

m

72

to

80

ft

Ib

torque

with

the

aid

of

Wrench

ST22520000

When

doing

w

the

amount

of

torque

to

be

read

on

wrench

needle

should

be

modified

according

to

the

following

formula

L

C

kg

m

10

x

L

O

I

to

11

L

x

L

O

I

or

C

ft

Ib

n

x

L

O

33

to

L

80

x

L

0

33

Where

C

Value

read

on

the

torque

wrench

kg

m

ft

Ib

L

Effective

length

of

torque

wrench

m

ft

ST22520000

Torque

wrench

r

Lm

ft

0

1

m

0

3

ft

TM587

Fig

MT

124

Setting

Wrench

Example

When

a

0

4

m

Iong

torque

wrench

is

used

the

C

in

Fig

MT

123

will

be

8

0

to

8

8

kg

m

58

to

64

ft

Ib

12

Measure

gear

end

play

Make

sure

that

they

are

held

within

the

specified

values

For

details

refer

to

Page

MT

23

for

Inspection

13

Fit

1

0

IDm

0

039

in

thick

snap

ring

10

the

front

side

of

main

shaft

end

bearing

14

Install

mainshaft

end

bearing

using

Bearing

Drift

ST22350000

Fit

thick

snap

ring

to

the

rear

side

of

bearing

to

eliminate

end

play

Manual

Transmission

Available

Sllap

ring

No

Thickness

IDm

in

1

1

0

0

039

2

1

2

0

047

on

LST22350000

TM250A

Fig

MT

125

In

talling

Main

haft

End

Bearing

Shift

forks

and

fork

rods

1

Insert

1st

reverse

fork

rod

into

its

shift

fork

and

adapter

plate

2

With

1st

reverse

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

3

Insert

2nd

3rd

fork

rod

into

adapter

plate

2nd

3rd

and

4th

5th

shift

forks

4

With

2nd

3rd

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

5

Insert

4th

5th

fork

rod

into

adapter

plate

and

its

s

Uft

fork

6

Secureshift

forks

and

fork

rOd

s

with

new

retaining

pins

Note

a

Be

sure

to

install

interlock

plunger

when

installing

any

adjacent

fork

rods

to

adapter

plate

Properly

align

the

groove

in

assem

bleMork

rod

with

inle

rlQck

plung

er

See

Fig

MT

SO

b

Be

su

to

align

4th

5th

shift

fork

with

the

groove

in

their

coupling

sleeve

befo

instalting

c

Also

align

2nd

3rd

shift

fork

with

their

coupling

sleeve

properly

be

fore

instalting

7

Install

check

balls

and

check

ball

springs

Applying

locking

sealer

to

check

ball

plug

and

install

in

place

Align

center

notch

in

each

fork

rod

with

check

ball

Note

a

Check

ball

plug

for

1st

reverse

fork

rod

is

longer

than

those

for

2nd

3rd

fork

rod

and

4th

5th

fork

rod

b

To

insure

that

interlock

plunger

i

installed

properly

slide

2nd

3rd

fork

rnd

andoperate

the

other

fork

rod

Make

sure

thaI

gear

except

20d

or

3rd

gear

doe

not

mesh

8

Apply

gear

oil

to

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

engage

smoothly

L

1

u

Revene

TM251A

Fig

MT

126

In

talling

Shift

Forks

and

Fork

Roth

MT

28

Page 245 of 548

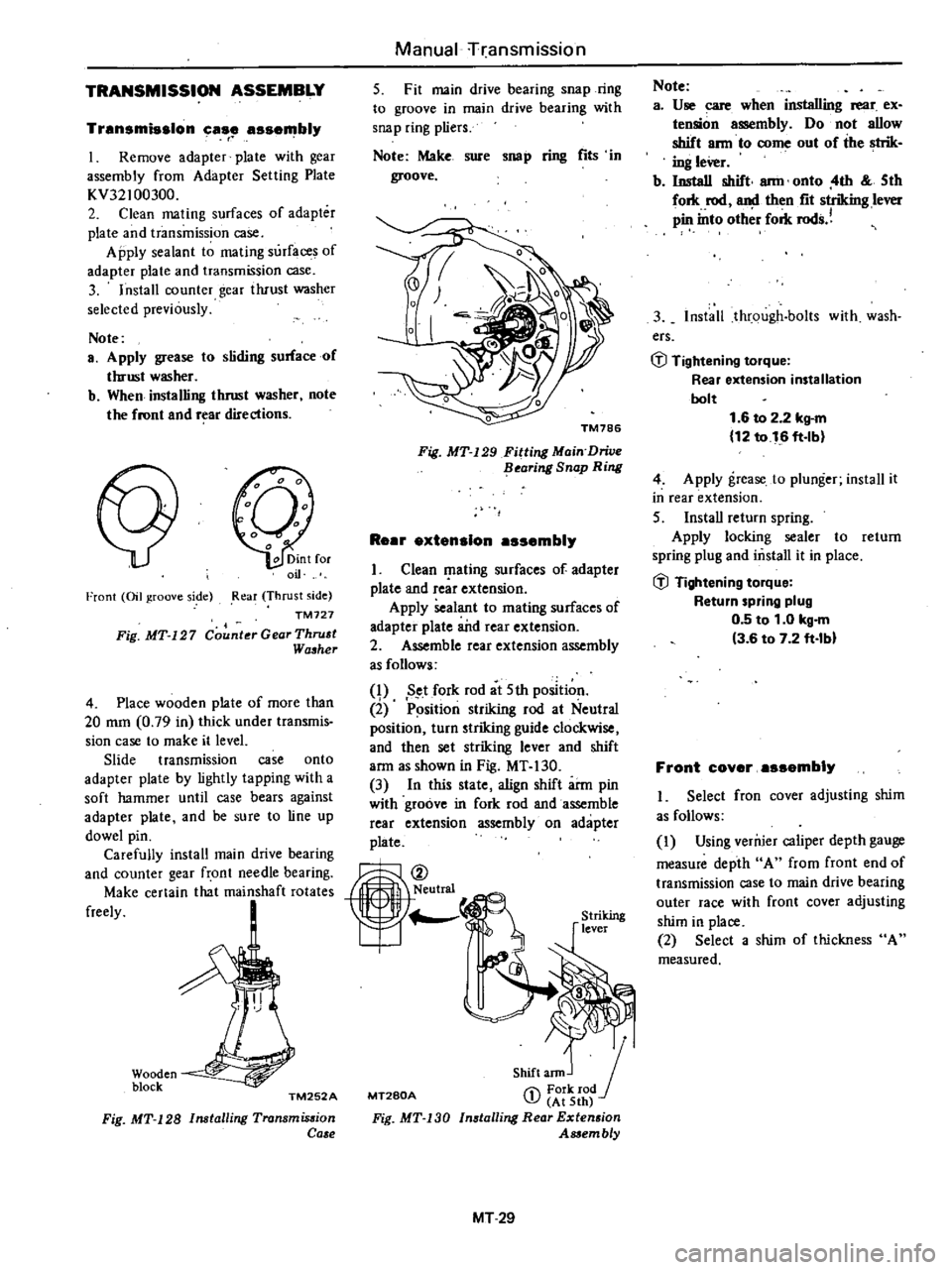

TRANSMISSION

ASSEMBLY

Transmission

case

assembly

r

I

Remove

adapter

plate

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

transmission

case

3

Install

counter

gear

tluust

washer

selected

previously

Note

a

Apply

grease

to

sliding

surface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

r

ar

directions

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

127

Counter

Gear

Thru

t

Wa

her

4

Place

wooden

plate

of

more

than

20

mm

0

79

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

mainshaft

rotates

freely

Wooden

block

TM252A

Fig

MT

128

Installing

Transmis

ion

Ca

e

Manual

rransmission

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

sno

p

ring

fits

in

groove

Fig

MT

129

Fitting

Main

Drive

flearing

Snap

Ring

ReBr

extension

assembly

I

Clean

I

lating

surfaces

of

adapter

plate

and

rcar

extension

Apply

sealant

to

mating

surfaces

of

adapter

plate

a

itd

rear

extension

2

Assemble

rear

extension

assembly

as

follows

q

Set

fork

rod

at

5th

position

2

P

sition

striking

rod

at

Neutral

position

turn

striking

guide

clockwise

and

then

set

striking

lever

and

shift

arm

as

shown

in

Fig

MT

130

3

In

this

state

align

shift

arm

pin

with

groove

in

fork

rod

and

assemble

rear

extension

assembly

on

adapter

plate

MT280A

Shift

ann

J

1

Fork

rod

J

At

5th

Installing

Rear

Extension

Assembly

Fig

MT

130

MT29

Note

a

Use

care

when

installing

rear

ex

tension

assembly

Do

not

allow

shift

ann

to

come

out

of

the

strik

ing

leVer

b

Install

shift

ann

onto

4th

5th

fork

rod

and

then

fit

striking

lever

pin

into

oth

r

fork

rods

3

Install

through

bolts

with

wash

ers

GJ

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb

4

Apply

grease

to

plunger

install

it

in

rear

extension

5

InstaU

return

spring

Apply

locking

sealer

to

return

spring

plug

and

mstall

it

in

place

GJ

Tightening

torque

Return

spring

plug

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lbl

Front

coyer

assembly

I

Select

fron

cover

adjusting

shim

as

follows

I

Using

verruer

caliper

depth

gauge

measure

depth

A

from

front

end

of

transmission

case

to

main

drive

bearing

outer

race

with

front

cover

adjusting

shim

in

place

2

Select

a

shim

of

thickness

A

measured

Page 250 of 548

Manual

Transmission

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classi

fie

t

o

ro

lb

c

QncerlJing

coJltr

1

syste

and

transmission

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmjssion

Gear

slips

out

of

mesh

In

most

cases

this

troubk

occurs

when

check

baD

and

or

spring

is

waIn

or

weaken

ed

or

when

control

system

is

faulty

In

this

case

the

troubk

cannot

be

correct

by

replacing

gears

and

therefore

trouble

shoot

ing

must

be

carried

out

carefuDy

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

enigne

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indication

that

the

noise

is

from

trans

mission

Transmission

may

rallk

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gears

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Worn

or

damaged

syncluonizer

Worn

check

baD

and

or

weakened

or

broken

spring

Worn

fork

rod

baU

groove

Worn

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

damaged

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

low

speed

Worn

spline

Worn

bushing

MT34

Corrective

action

Replace

Repair

ClI

replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

or

replace

Replace

Replace

Replace

Replace

as

a

rear

ex

tension

assembly

Page 251 of 548

Manual

Transmission

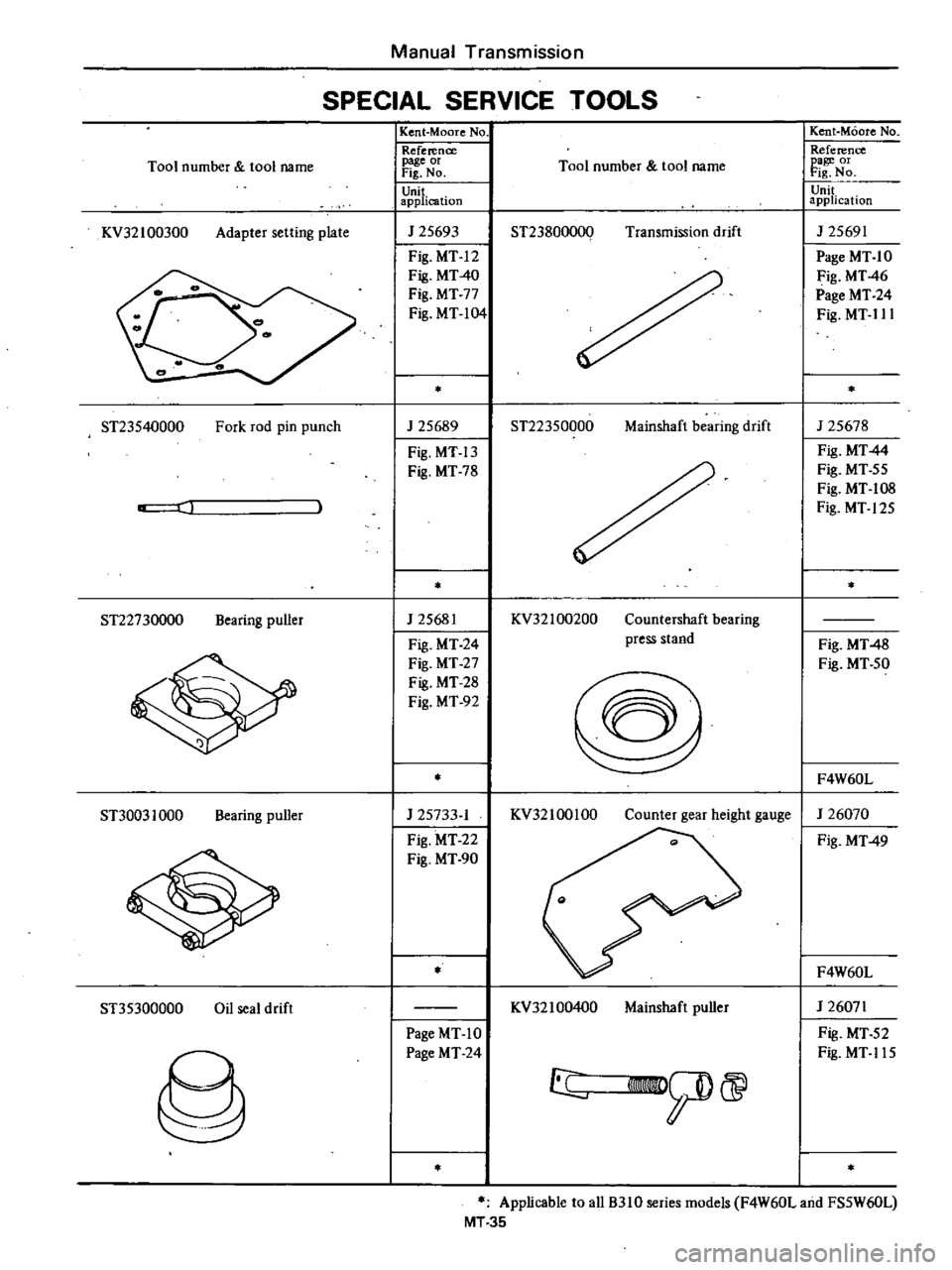

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

KV32

I

00300

Adapter

setting

plate

ST23540000

Fork

rod

pin

punch

ST22730000

Bearing

puller

STJ0031000

Bearing

puller

STJ5300000

Oil

seal

drift

I

Kent

Moore

No

Reference

page

or

Fig

No

Unit

application

Tool

number

tool

name

J

25693

ST23800000

Fig

MT

12

Fig

MT

40

Fig

MT

77

Fig

MT

104

J

25689

Fig

MT

13

Fig

MT

78

J

2568

1

Fig

MT

24

Fig

MT

27

Fig

MT

28

Fig

MT

92

J

25733

1

Fig

MT

22

Fig

MT

90

Page

MT

IO

Page

MT

24

Transmission

drift

ST22350000

Mainshaft

bearing

drift

I

Kent

Moore

No

I

Reference

page

or

Fig

No

Unit

application

J

25691

Page

MT

IO

Fig

MT

46

Page

MT

24

Fig

MT

I

II

J

25678

Fig

MT

44

Fig

MT

55

Fig

MT

I08

Fig

MT

I

25

Fig

MT

48

Fig

MT

50

F4W60L

KV32

100100

Counter

gear

height

gauge

J

26070

Fig

MT

49

F4W60L

J

26071

Fig

MT

52

Fig

MT

115

Applicable

to

all

B310

series

models

F4W60L

and

FS5W60L

MT35

KV32

100200

Countershaft

bearing

press

stand

KV32

100400

Mainshaft

puller

Fe

rnuffiUQ

cP