belt DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 15 of 548

DATSUN

210

Model

8310

Series

SECTIONET

ET

ENGINE

TUNE

UP

CONTENTS

EMISSION

CONTROL

DEVICES

BASIC

MECHANICAL

SYSTEM

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

CHECKING

AND

ADJUSTING

DRIVE

BELTS

CHANGING

ENGINE

OIL

REPLACING

01

L

FI

L

TER

CHANGING

ENGINE

COOLANT

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

CHECKING

ENGINE

COMPRESSION

IGNITION

AND

FUEL

SYSTEM

CHECKING

BATTERY

CHECKING

AND

ADJUSTING

IGNITION

TIMING

CHECKING

IGNITION

WIRING

CHECKING

AND

REPLACING

SPARK

PLUGS

CHECKING

AND

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

CHECKING

CHOKE

MECHANISM

Choke

plate

and

linkage

CHECKING

FUEL

SHUT

OFF

SYSTEM

FU

models

ET

2

ET

3

ET

3

ET

3

ET

3

ET

3

ET

4

ET

4

ET

4

ET

5

ET

5

ET

5

ET

6

ET

6

ET

7

ET

9

ET

9

REPLACING

FUEL

FILTER

ET

10

CHECKING

FUEL

LINES

Hoses

piping

connections

etc

ET

10

REPLACING

AIR

CLEANER

FILTER

ETlO

CHECKING

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

ET

10

EMISSION

CONTROL

SYSTEM

ET

11

CHECKING

VACUUM

FITTING

HOSES

AND

CONNECTIONS

ET

11

REPLACING

AIR

PUMP

AIR

CLEANER

FILTER

Except

FU

models

and

Canada

models

E

1122i

REPLACING

AIR

INDUCTION

VALVE

FILTER

FU

models

and

Canada

models

E

tlil1r2

C

REPLACING

PCV

VALVE

AND

FILTER

ETf

CHECKING

VENTI

LATION

HOSES

E1P12

CHECKING

VAPOR

LINES

Eli

J2

CHECKING

FUEL

TANK

VACUUM

RELIEF

I

f

III

VALVE

ET

13

REPLACING

CARBON

CANISTER

W

FILTER

ET

d

SERVICE

DATA

AND

SPECIFICATIONS

ET

14

TROUBLE

DIAGNOSES

AND

CORRECTIONS

ET

16

SPECIAL

SERVICE

TOOL

ET

23

Page 17 of 548

Engine

Tune

up

BASIC

MECHANICAL

SYSTEM

ADJUSTING

INTAKE

AND

EXHAUST

VAL

fE

CLEARANCE

Note

After

tightening

cYlinder

head

bolts

adjust

intake

and

exhaust

valve

clearances

Valve

clearance

ai

ljustment

cannot

be

made

while

the

engine

is

in

opera

tion

To

adjust

proceed

as

follows

I

Start

engine

and

warm

it

up

uritil

water

temperature

indicator

points

to

the

middle

of

gauge

Then

stop

engine

2

Rotate

crankshaft

to

bring

No

I

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

Adjust

valve

clearance

at

following

four

points

while

engine

is

still

hot

CD

Exhaust

valve

of

No

I

cylinder

@

Intake

valve

of

No

I

cylinder

@

Intake

valve

of

No

2

cylinder

@

Exhaust

valve

of

No

3

cylinder

Note

Numbers

in

circle

agree

with

those

in

accompanying

sketch

tiri

Fig

ET

1

Adjusting

Value

Clearanu

4

Again

rotate

crankshaft

one

turn

so

that

No

4

piston

is

in

top

dead

center

on

its

ompression

stroke

Ad

just

following

valve

s

CID

Exhaust

valve

of

No

2

cylinder

@

Intake

valve

of

No

3

cylinder

j

Intake

valve

of

No

4

cylinder

@

Exhaust

valve

of

No

4

cylinder

Adjustment

should

be

made

while

engine

is

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

ihe

adjustment

Valve

clearance

Hot

Intake

0

35

mm

0

014

inl

Exhaust

0

35

mm

0

014

in

tJl

Tightening

torque

Valve

rocker

adjusting

nut

1

6

to

2

2

kltm

12

to

16

ft

lb

Alternator

Crankshaft

pulley

Unit

mm

in

Idler

pulley

Fig

ET

2

CHANGING

ENGINE

OIL

1

Check

if

oil

is

diluted

with

water

or

gasoline

Drain

and

refill

oil

if

necessary

Note

a

A

milky

oil

iiulicates

the

presence

of

cooling

water

Isolate

the

cause

and

take

corrective

measure

b

An

oil

with

extremely

low

viscosity

indicates

dilution

with

gasoline

2

Check

oil

level

If

below

the

specified

level

raise

it

up

to

the

H

level

3

Change

engine

oil

in

accordance

with

the

maintenance

schedule

Engine

oil

capacity

A14

With

oil

filter

3

7

liters

3

U

US

qt

3

Yo

Imp

qtl

ET3

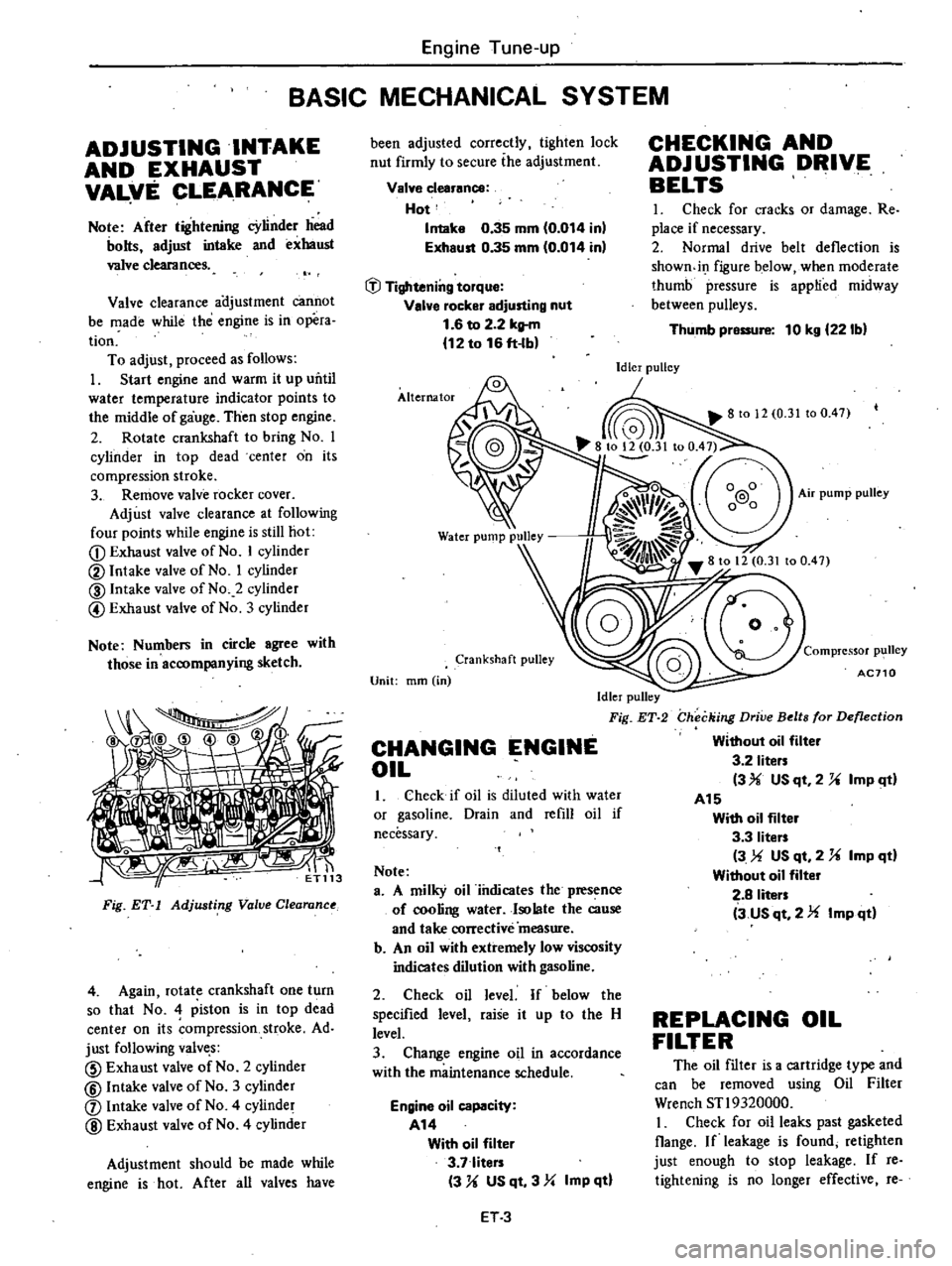

CHECKING

AND

ADJUSTING

DRIVE

BELTS

I

Check

for

cracks

or

damage

Re

place

if

necessary

2

Normal

drive

belt

deflection

is

showndI

figure

below

when

moderate

thumb

pressure

is

applied

midway

between

pulleys

Thumb

pressure

10

kg

221bl

Idler

pulley

Compressor

p1

111ey

AC710

Checking

Drive

Belts

for

Deflection

Without

oil

filter

3

2

liters

3

USqt

2

U

ImP

ltl

A15

With

oil

filter

3

3

liters

3

US

qt

2

U

Imp

qd

Without

oil

filter

2

8

liters

3

us

qt

2

Imp

qd

REPLACING

OIL

FILTER

The

oil

filter

is

a

cartridge

type

and

can

be

removed

using

Oil

Filter

Wrench

STl9320000

I

Check

for

oil

leaks

past

gasketed

Oange

If

leakage

is

found

retighten

just

enough

to

stop

leakage

If

reo

tightening

is

no

longer

effective

re

Page 28 of 548

Engine

T

une

up

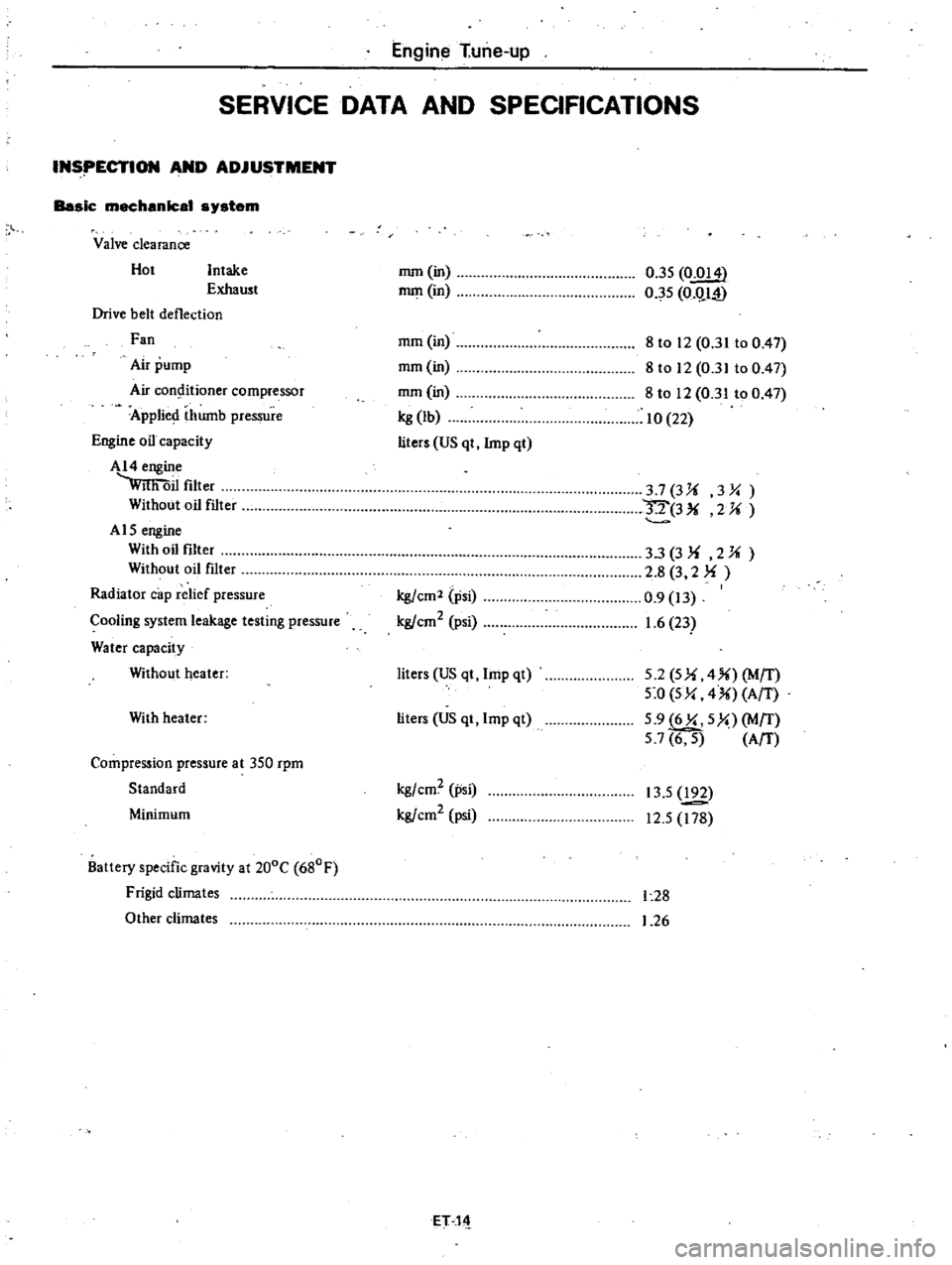

SERVICE

DATA

AND

SPECIFICATIONS

INSpECTION

AND

ADJUSTMENT

Basic

mechanical

s

stem

Valve

clearance

Hot

Intake

Exhaust

Drive

belt

deflection

Fan

Air

pump

Air

COo9itioner

compressor

Applied

thumb

pressure

Engine

oil

capacity

AI4

engine

wmi

oil

filter

Without

oil

filter

A

15

engine

With

oil

fIlter

Without

oil

filter

Radiator

cap

relief

pressure

Cooling

system

leakage

testing

pressure

Water

capacity

Without

heater

With

heater

Compression

pressure

at

350

rpm

Standard

Minimum

Battery

specific

gravity

at

200C

680F

Frigid

climates

Other

climates

mm

in

mm

in

0

35

0

014

0

5

O

QI

i

mm

in

mm

in

mm

in

kg

lb

liters

US

qt

lmp

qt

8

to

12

0

31

to

0

47

8

to

12

0

31

to

0

47

8

to

12

0

31

to

0

47

10

22

37

3Ji

3

Y

IT

3

2Ji

kgfcm2

psi

kg

cm2

psi

33

3

Ji

2

Ji

2

8

3

2

f

0

9

13

1

6

23

liters

US

qt

lmp

qt

5

2

5

f

4

MfT

5

0

5Y

4

AfT

5

9

6Y

5

MfT

57

6

5

AfT

liters

US

qt

lmp

qt

kgfcm2

psi

kgfcm2

psi

13

5

192

12

5

178

1

28

1

26

ET11

Page 30 of 548

Engine

Tune

up

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

CANNOT

CRANK

ENGINE

OR

SLOW

CRANKING

Improper

grade

oil

Discharged

battery

Faulty

battery

Loose

fan

belt

Malfunction

in

charge

system

Wiring

connection

loose

in

starting

circuit

F

ul1Y

ignition

switch

Faulty

starter

motor

Trouble

shooting

procedure

on

starting

circuit

Switch

on

the

starting

motor

with

light

ON

WheJlIJght

gOO

off

or

Ii

J1S

considerably

a

Check

battery

b

Check

connection

and

cable

c

Check

starter

motor

When

light

stays

bright

Corrective

action

Replace

with

proper

grade

oil

Charge

battery

Replace

Adjust

Inspect

Correct

Repair

or

replace

Repair

or

replace

a

Check

wlflng

connection

between

battery

and

starter

motor

b

Check

ignition

switch

c

Check

starter

motor

ENGINE

WILL

CRANK

NOR

LLY

BUT

WILL

NOT

START

In

this

case

the

following

trouble

causes

may

exist

but

in

many

cases

ignition

system

or

fuel

system

is

in

trouble

19

ition

syst

m

in

trouble

FII

1

system

in

trowb

Val

mechanism

do

not

work

properly

Low

compression

Trouble

shooting

procedure

Check

spark

plug

firstly

by

following

procedure

Disconnect

high

tension

cable

from

one

spark

plug

and

hold

it

about

10

mm

0

39

in

from

the

engine

metal

part

and

crank

the

engine

Good

spark

occurs

a

Check

spark

plug

b

Checkignition

timing

c

Check

fuel

system

d

Check

cylinder

compression

Check

the

current

now

in

primary

circuit

Very

high

current

Inspect

primary

circuit

for

short

Check

breaker

point

operation

except

tran

sistor

ignition

system

No

spark

occurs

ET

l

6

Page 33 of 548

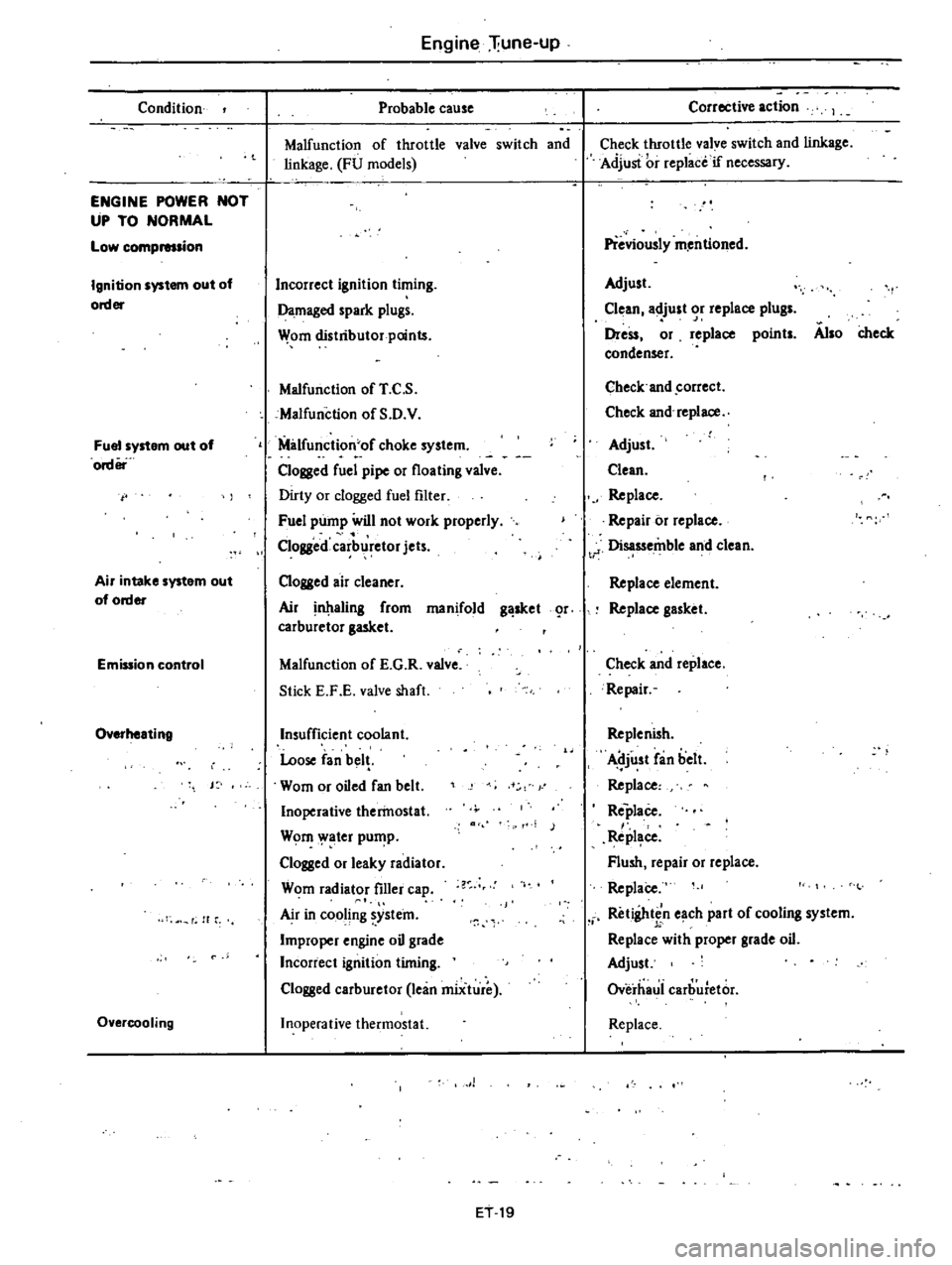

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compmsion

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

J

f

H

r

Overcooling

Engine

liune

up

Probable

cause

Malfunction

of

throttle

valve

switch

and

linkage

FU

models

Incorrect

ignition

timing

Damaged

spark

plugs

Wom

distributor

points

Malfunction

of

T

C

S

cMalfunction

of

S

D

V

Milfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

filter

Fuel

pump

will

not

work

properly

Clogged

carb

retor

jets

Clogged

air

cleaner

Air

aling

from

manifold

g

sket

r

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

bel

Wom

or

oiled

fan

belt

Inoperative

therinostat

Wom

ater

pu

p

Clogged

or

leaky

radiator

Wom

radiator

filler

ca

Air

in

cooling

ystein

Improper

engine

oil

grade

Incorrect

ignition

timing

Clogged

carburetor

lean

miiture

Inoperative

thermostat

1

ET

19

Corrective

action

Check

throttle

valve

switch

and

linkage

Adjusi

i

r

replace

if

necessary

Previously

m

entioned

Adjust

Clean

adjust

or

replace

plugs

Dress

or

replace

points

Also

check

condenser

Check

and

correct

Check

and

replace

Adjust

Clean

Replace

Repair

or

replace

t

J

Disassemble

and

clean

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Repl

ce

Flush

repair

or

replace

ReplaCe

Retightin

e

ch

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaui

carburetor

Replace

Page 40 of 548

PRELIMINARY

CLEANING

AND

INSPECTION

Before

disassembling

engine

ob

serve

the

following

items

I

Prior

to

disassembling

check

outer

parts

for

sign

of

leak

past

their

gasketed

surfaces

2

Check

carburetor

and

fuel

pump

for

condition

fuel

hoses

for

deteriora

t

ion

cracks

or

otherwise

leakage

of

fuel

past

their

jointed

or

connected

surfaces

3

Wipe

dust

and

mud

off

engine

4

Inspect

outer

parts

for

visual

faults

and

broken

or

missing

parts

such

as

bolts

and

nuts

5

Check

piping

and

electrical

cir

cuits

for

deterioration

breakage

fittings

discontinuity

or

insulation

DISASSEMBLY

To

remove

engine

from

car

refer

to

Section

ER

for

Removal

1

Remove

starting

motor

then

re

move

transmission

from

engine

2

Remove

clutch

assembly

3

Remove

alternator

fan

belt

alter

nator

bracket

and

alternator

adjusting

bar

4

Remove

idler

pulley

air

pump

belt

and

idier

pulley

bracket

If

so

equipped

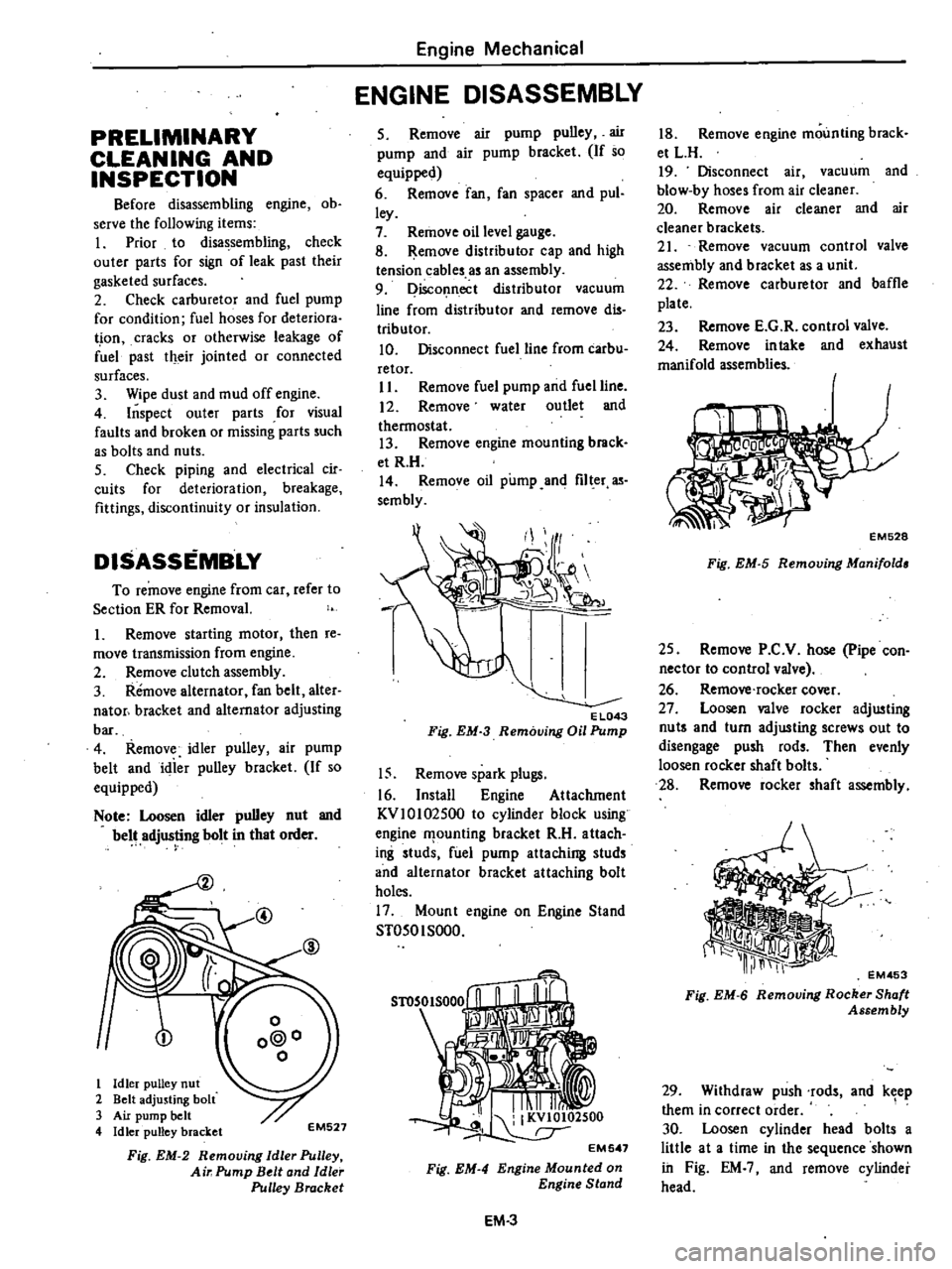

Note

Loosen

idler

pulley

nut

and

belt

adjusting

bolt

in

that

order

@

1

Idler

pulley

nut

2

Belt

adjusting

bolt

3

Air

pump

belt

4

Idler

pulley

bracket

EM527

Fig

EM

2

Removing

Idle

Pulley

Air

Pump

Belt

and

Idle

Pulley

Bracket

Engine

Mechanical

ENGINE

DISASSEMBLY

5

Remove

air

pump

pulley

air

pump

and

air

pump

bracket

If

so

equipped

6

Remove

fan

fan

spacer

and

pul

ley

7

Remove

oil

level

gauge

8

Remove

distributor

cap

and

high

tension

cables

as

an

assembly

9

Disconnect

distributor

vacuum

line

from

distributor

and

remove

dis

tributor

10

Disconnect

fuel

line

from

carbu

retor

II

Remove

fuel

pump

and

fuel

line

12

Remove

water

outlet

and

thermostat

13

Remove

engine

mounting

brack

et

R

H

14

Remove

oil

pump

and

filter

as

sembly

EL043

Fig

EM

3

Removing

Oil

Pump

15

Remove

spark

plugs

16

Install

Engine

Attachment

KVlOI02500

to

cylinder

block

using

engine

f1

ounling

bracket

R

H

attach

ing

studs

fuel

pump

attaching

studs

and

alternator

bracket

attaching

bolt

holes

17

Mount

engine

on

Engine

Stand

ST050I

SOOO

Fig

EM

4

EM

3

18

Remove

engine

mounting

brack

et

L

H

19

Disconnect

air

vacuum

and

blow

by

hoses

from

air

cleaner

20

Remove

air

cleaner

and

air

cleaner

brackets

21

Remove

vacuum

control

valve

assembly

and

bracket

as

a

unit

22

Remove

carburetor

and

baffle

plate

23

Remove

E

G

R

control

valve

24

Remove

intake

and

exhaust

manifold

assemblies

EM528

Fig

EM

5

Removing

Manifold

25

Remove

P

C

V

hose

pipe

con

nector

to

control

valve

26

Remove

rocker

cover

27

Loosen

valve

rocker

adjusting

nut

and

turn

adjusting

screws

out

to

disengage

push

rods

Then

evenly

loosen

rocker

shaft

bolts

28

Remove

rocker

shaft

assembly

EM453

Fig

EM

6

Removing

Rocker

Shaft

Assembly

29

Withdraw

push

rods

and

keep

them

in

correct

order

1

30

Loosen

cylinder

head

bolts

a

little

at

a

time

in

the

sequence

shown

in

Fig

EM

and

remove

cylinder

head

Page 54 of 548

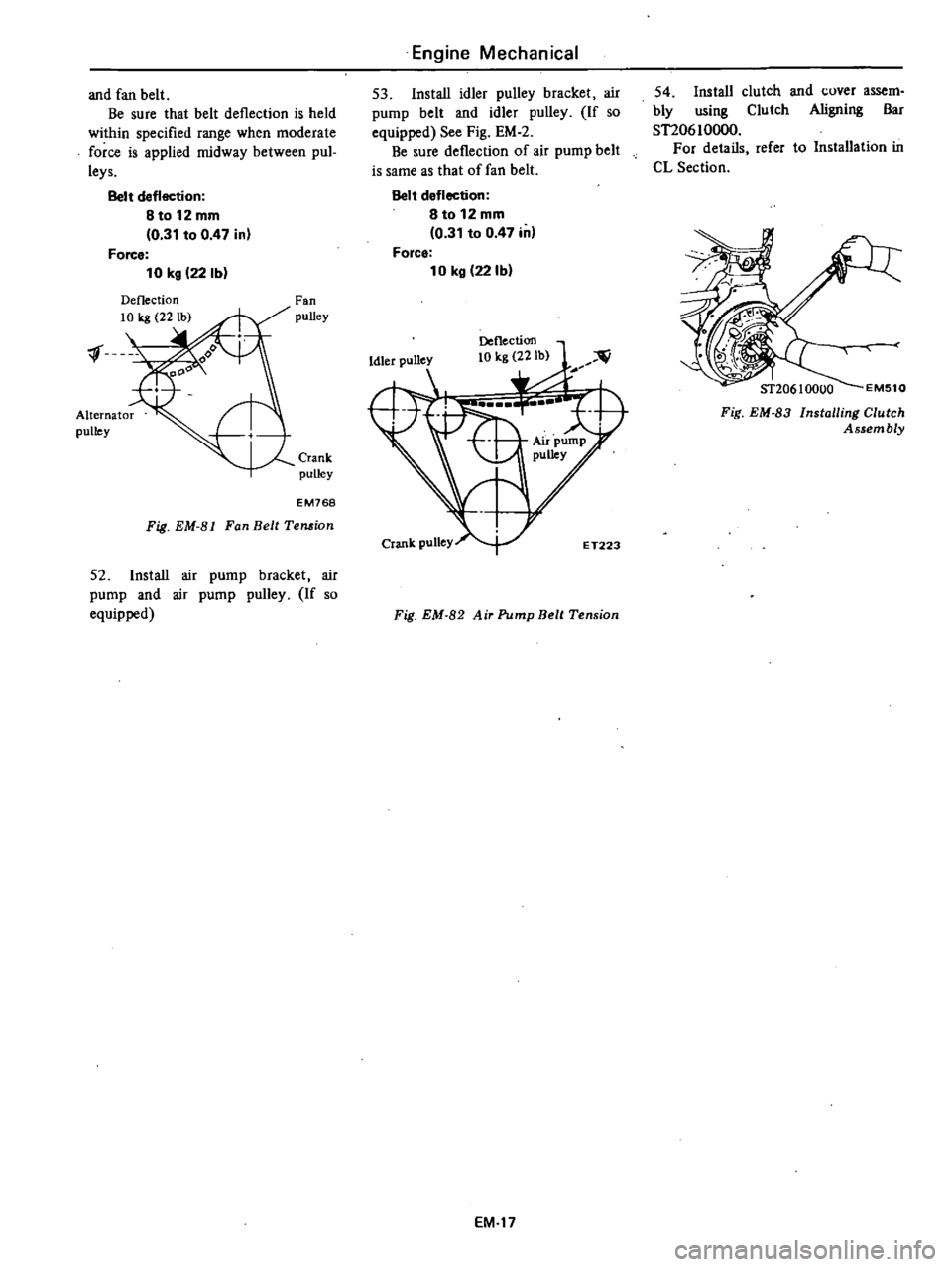

and

fan

belt

Be

sure

that

belt

deflection

is

held

within

specified

range

when

moderate

force

is

applied

midway

between

pul

leys

Belt

deflection

8t012mm

0

31

to

0

47

in

Force

10

kg

22Ib

Deflection

Fan

pulley

f

Crank

pulley

Alternator

pulley

EM768

Fig

EM

81

Fan

Belt

Temion

52

Install

air

pump

bracket

air

pump

and

air

pump

pulley

If

so

equipped

Engine

Mechanical

53

Install

idler

pulley

bracket

air

pump

belt

and

idler

pulley

If

so

equipped

See

Fig

EM

2

Be

sure

deflection

of

air

pump

belt

is

same

as

that

of

fan

belt

Belt

deflection

8

to

12

mm

0

31

to

0

47

in

Force

10

kg

22Ib

Deflection

10

kg

22Ib

Fig

EM

82

Air

Pump

Belt

Tension

EM

17

54

Install

clutch

and

cover

assem

bly

using

Clutch

Aligning

Bar

STI0610000

For

details

refer

to

Installation

in

CL

Section

Fig

EM

83

Installing

Clutch

Assembly

Page 80 of 548

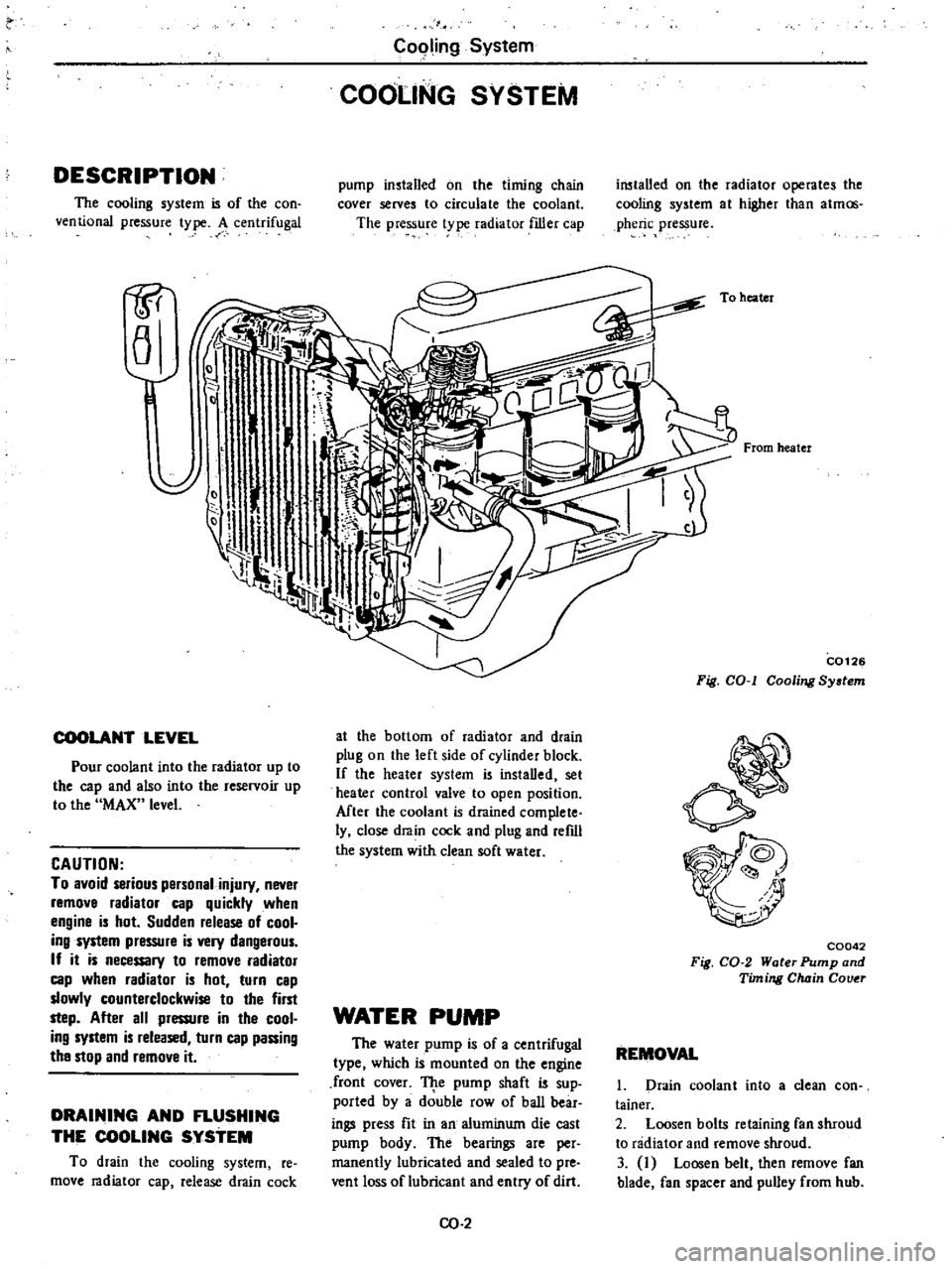

DESCRIPTION

The

cooling

system

is

of

the

con

ventional

pressure

type

A

centrifugal

1P

a

COOLANT

LEVEL

Pour

coolant

into

the

radiator

up

to

the

cap

and

also

into

the

reservoir

up

to

the

MAX

level

CAUTION

To

avoid

serious

personal

injury

never

remove

radiator

cap

quickly

when

engine

is

hot

Sudden

release

of

cool

ing

system

pressure

is

very

dangerous

If

it

is

necessary

to

remove

radiator

cap

when

radiator

is

hot

turn

cap

slowly

counterclockwise

to

the

first

step

After

all

pressure

in

the

cool

ing

system

is

released

turn

cap

passing

the

stop

and

remove

it

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

To

drain

the

cooling

system

re

move

radiator

cap

release

drain

cock

C09ling

System

COOLING

SYSTEM

pump

installed

on

the

timing

chain

cover

serves

to

circulate

the

coolant

The

pressure

t

pe

radiator

filler

cap

at

the

bottom

of

radiator

and

drain

plug

on

the

left

side

of

cylinder

block

If

the

heater

system

is

instaDed

set

heater

control

valve

to

open

position

Mter

the

coolant

is

drained

complete

ly

close

drain

cock

and

plug

and

refdl

the

system

with

clean

soft

water

WATER

PUMP

The

water

pump

is

of

a

centrifugal

type

which

is

mounted

on

the

engine

front

cover

TJ

te

pump

shaft

is

sup

ported

by

a

double

row

of

baD

bear

ings

press

fit

in

an

aluminum

die

cast

pump

body

The

bearings

are

per

manently

lubricated

and

sealed

to

pre

vent

loss

of

lubricant

and

entry

of

dirt

CO

2

installed

on

the

radiator

operates

the

cooling

system

at

higher

than

atmos

pheric

pressure

To

heater

From

heater

C0126

Fig

COol

Cooling

System

C0042

Fig

CO

2

Water

Pump

and

Timing

Chain

Couer

REMOVAL

1

Drain

coolant

into

a

clean

con

tainer

2

Loosen

bolts

retaining

fan

shroud

to

radiator

and

remove

shroud

3

I

Loosen

belt

then

remove

fan

blade

fan

spacer

and

pulley

from

hub

Page 81 of 548

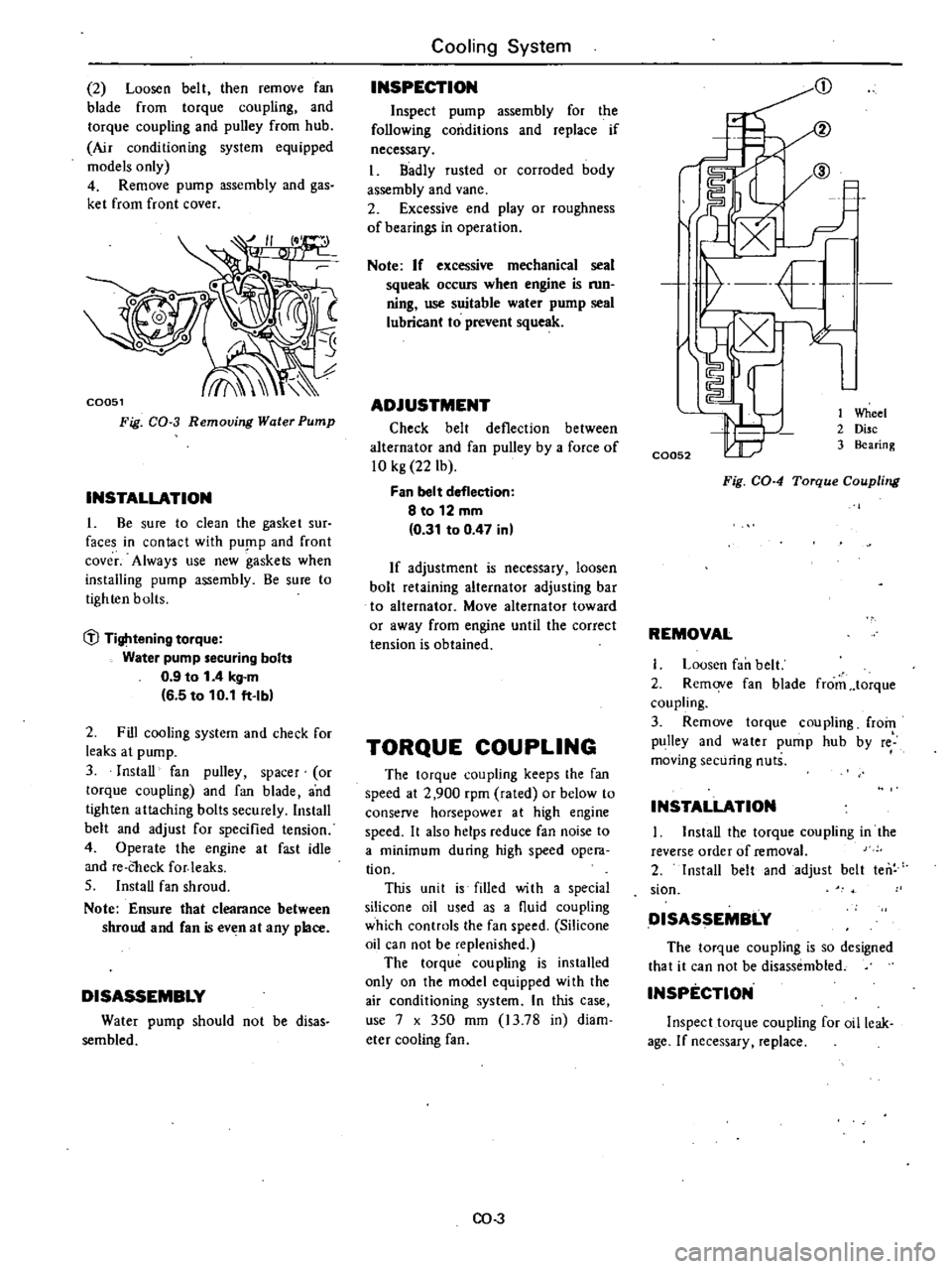

2

Loosen

belt

then

remove

fan

blade

from

torque

coupling

and

torque

coupling

and

pulley

from

hub

Air

conditioning

system

equipped

models

only

4

Remove

pump

assembly

and

gas

ket

from

front

cover

C0051

Fig

CO

3

Removing

Water

Pump

INSTALLATION

1

Be

sure

to

clean

the

gasket

sur

faces

in

contact

with

pU

flP

and

front

cover

Always

use

new

gaskets

when

installing

pump

assembly

Be

sure

to

tighten

bolts

i

l

Tightening

torque

Water

pump

securing

bolts

0

9

to

1

4

kg

m

6

5

to

10

1

ft

Ib

2

Fill

cooling

system

and

check

for

leaks

at

pump

3

InstaD

fan

pulley

spacer

or

torque

coupling

and

fan

blade

and

tighten

attaching

bolts

securely

Install

belt

and

adjust

for

specified

tension

4

Operate

the

engine

at

fast

idle

and

re

Check

for

leaks

S

Install

fan

shroud

Note

Ensure

that

clearance

between

shroud

and

fan

even

at

any

place

DISASSEMBLY

Water

pump

should

not

be

disas

sembled

Cooling

System

INSPECTION

Inspect

pump

assembly

for

the

following

conditions

and

replace

if

necessary

I

Badly

rusted

or

corroded

body

assembly

and

vane

2

Excessive

end

play

or

roughness

of

bearings

in

operation

Note

If

excessive

mechanical

seal

squeak

occurs

when

engine

is

mn

ning

use

suitable

water

pump

seal

lubricant

to

prevent

squeak

ADJUSTMENT

Check

belt

deflection

between

alternator

and

fan

pulley

by

a

force

of

10

kg

22

Ib

Fan

belt

deflection

8

to

12

mm

0

31

to

0

47

in

If

adjustment

is

necessary

loosen

bolt

retaining

alternator

adjusting

bar

to

alternator

Move

alternator

toward

or

away

from

engine

until

the

correct

tension

is

obtained

TORQUE

COUPLING

The

torque

coupling

keeps

the

fan

speed

at

2

900

rpm

rated

or

below

to

conserve

horsepower

at

high

engine

speed

It

also

helps

reduce

fan

noise

to

a

minimum

during

high

speed

opera

tion

This

unit

is

filled

with

a

special

silicone

oil

used

as

a

fluid

coupling

which

controls

the

fan

speed

Silicone

oil

can

not

be

replenished

The

torque

coupling

is

installed

only

on

the

model

equipped

with

the

air

conditioning

system

In

this

case

use

7

x

350

mm

13

78

in

diam

eter

cooling

fan

CO

3

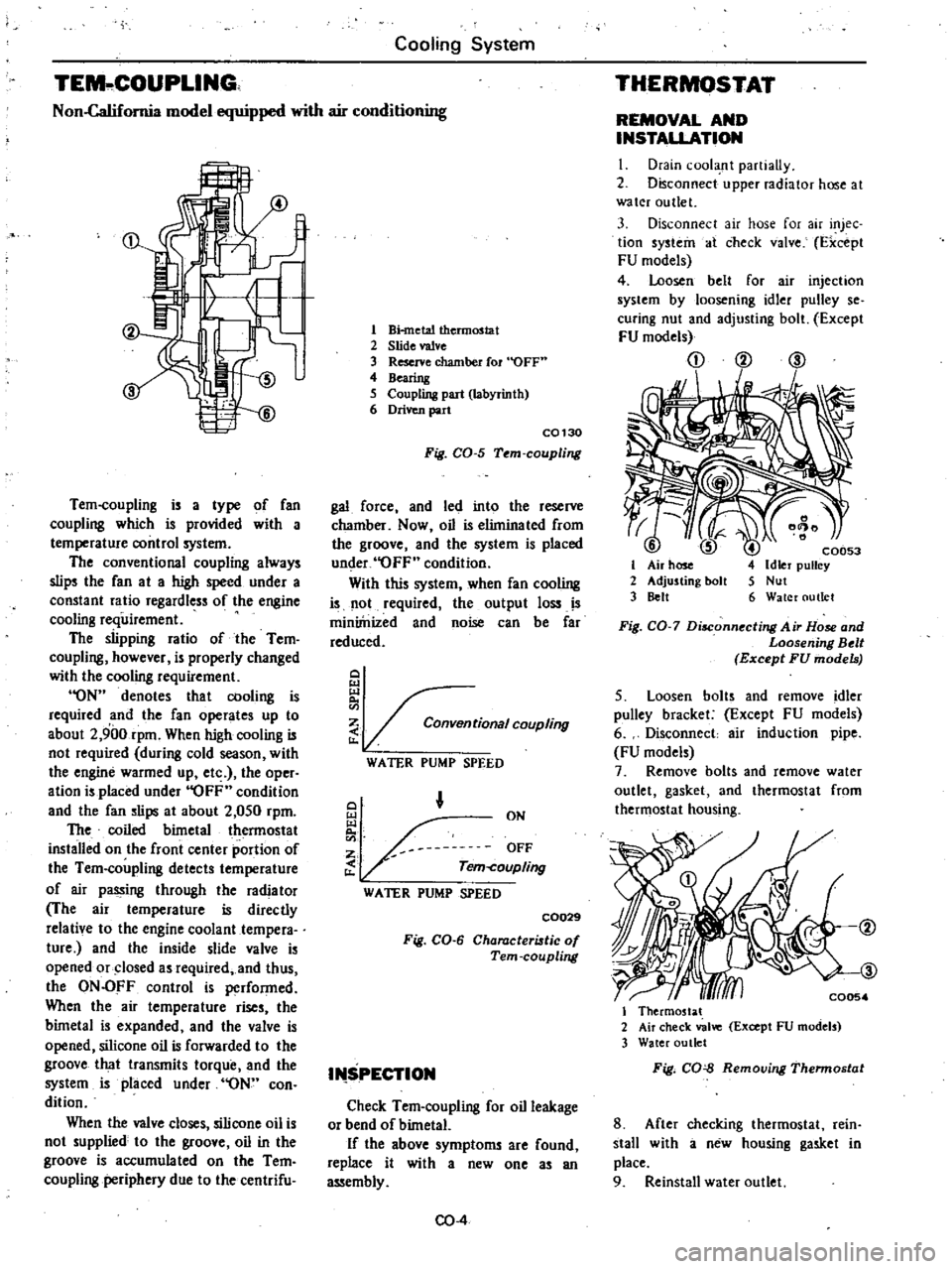

C0052

t

Wheel

2

Disc

3

Bearing

Fig

CO

4

Torque

Coupling

REMOVAL

Lousen

fan

belt

2

Remove

fan

blade

from

torque

coupling

3

Remove

torque

coupling

from

pulley

and

water

pump

hub

by

re

moving

securing

nuts

INSTALLATION

I

InstaD

the

torque

coupling

in

the

reverse

order

of

removal

2

Install

belt

and

adjust

belt

ten

sian

DISASSEMBLY

The

torque

coupling

is

so

designed

that

it

can

not

be

disassembled

INSPECTION

Inspect

torque

coupling

for

oil

leak

age

If

necessary

replace

Page 82 of 548

Cooling

System

TEM

COUPLlNG

Non

Califomia

model

equipped

with

air

conditioning

Tem

coupling

is

a

type

of

fan

coupling

which

is

provided

with

a

temperature

control

system

The

conventional

coupling

always

slips

the

fan

at

a

high

speed

under

a

constant

ratio

regardless

of

the

engine

cooling

requirement

The

slipping

ratio

of

the

Tem

coupling

however

is

properly

changed

with

the

cooling

requirement

ON

denotes

that

cooling

is

required

and

the

fan

operates

up

to

about

2

900rpm

When

high

cooling

is

not

required

during

cold

season

with

the

engine

warmed

up

etc

the

oper

ation

is

placed

under

OFF

condition

and

the

fan

slips

at

about

2

050

rpm

The

coiled

bimetal

thermostat

installed

on

the

front

center

portion

of

the

Tem

coupling

detects

temperature

of

air

passing

through

the

radiator

The

air

temperature

is

directly

relative

to

the

engine

coolant

tempera

ture

and

the

inside

slide

valve

is

opened

or

closed

as

required

and

thus

the

ON

OFF

control

is

performed

When

the

air

temperature

rises

the

bimetal

is

expanded

and

the

valve

is

opened

silicone

oil

is

forwarded

to

the

groove

that

transmits

torque

and

the

system

is

placed

under

ON

con

dition

When

the

valve

closes

silicone

oil

is

not

supplied

to

the

groove

oil

in

the

groove

is

accumulated

on

the

Tem

coupling

periphery

due

to

the

centrifu

1

Bi

metal

thermostat

2

Slide

valve

3

Reserve

chamber

fOl

OFF

4

Bearing

5

Coupling

part

labyrinth

6

Driven

part

C0130

Fig

CO

5

Tem

coupling

gal

force

and

led

into

the

reserve

chamber

Now

oil

is

eliminated

from

the

groove

and

the

system

is

placed

under

OFF

condition

With

this

system

when

fan

cooling

is

not

required

the

output

loss

IS

miniinized

and

noise

can

be

far

reduced

Q

i

tionalCOUPling

WATER

PUMP

SPEED

Q

ON

OFF

Tem

coupling

WATER

PUMP

SPEED

C0029

Fig

CO

6

Characteristic

of

Tern

coupling

I

SPECTION

Check

Tem

coupling

for

oil

leakage

or

bend

of

bimetaL

If

the

above

symptoms

are

found

replace

it

with

a

new

one

as

an

assembly

CO

4

THERMOSTAT

REMOVAL

AND

INSTALLATION

I

Drain

cool

nt

partiaUy

2

Disconnect

upper

radiator

hose

at

water

outlet

3

Disconnect

air

hose

for

air

injec

tion

systein

at

check

valve

Fxcept

FU

models

4

Loosen

belt

for

air

injechon

system

by

loosening

idler

pulley

se

curing

nut

and

adjusting

bolt

Except

FU

models

CD

@

ID

I

2

3

C0053

Idler

pulley

Nut

Water

outlet

Fig

CO

7

Disconnecting

Air

Hose

and

Loosening

Belt

Except

FU

models

5

Loosen

bolts

and

remove

idler

pulley

bracket

Except

FU

models

6

Disconnect

air

induction

pipe

FU

models

7

Remove

bolts

and

remove

water

outlet

gasket

and

thermostat

from

thermostat

housing

I

Thermostat

2

Air

check

valve

Except

FU

models

3

Water

outlet

Fig

CO

Removing

Thennostat

8

After

checking

thermostat

rein

stall

with

a

new

housing

gasket

in

place

9

Reinstall

water

outlet