belt DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 84 of 548

u

V

O

I

MAX

Ii

1i

i

iT

1

I

I

11

1

i

MINij

o

f

G

p

rl

MAX

ii

i

p

It

ot

MINi

II

L

Cooling

System

l

CQ074

Pressure

relief

valve

opens

f

C007S

Vacuum

valve

opens

INSPECTION

1

Check

the

amount

of

coolant

in

the

reservoir

tank

If

the

coolant

level

is

below

the

MIN

level

remove

the

re

servoirtank

ruler

cap

and

add

enough

oolant

to

reach

MAX

level

If

the

reservoir

tank

is

empty

check

the

coolantlevel

in

the

radiator

If

the

coolant

in

the

radiator

is

insuf

ficient

pour

it

into

radiator

up

to

the

radiator

cap

and

also

pour

it

into

the

reservoir

tank

until

MAX

level

If

the

coolant

in

the

reservoir

tank

d

ecreases

abnormally

rapid

check

for

a

leak

in

the

cooling

system

REMOVAL

AND

INSTALLATION

1

Reservoir

tank

is

only

inserted

to

reservoir

tank

bracket

and

can

be

easily

removed

To

install

reservoir

tank

reverse

the

order

of

remova

Fig

CO

12

Opefation

of

ReserVoir

Tank

SERVICE

DATA

AND

SPECIFICATIONS

Thermostat

Valve

opening

temperature

Oc

OF

Maximum

valve

lift

mmjOC

in

oF

Radiator

Type

Manual

transmission

Automatic

tralUJ1lission

Cap

relief

pressure

kg

cm2

psi

Testing

pressure

kg

cm

2

psi

Fan

Fan

belt

deflection

mm

in

cO

6

Temperate

type

Frigid

type

Tropical

type

82

180

88

190

76

5

I

70

8

95

8

loo

8

90

0

3

I

203

0

31j2

i

2

0

31

194

Corrugated

fm

type

Corrugated

fm

type

equipped

with

oil

cooler

0

9

I

3

1

6

23

8

to

12

0

31

to

0

47

Page 85 of 548

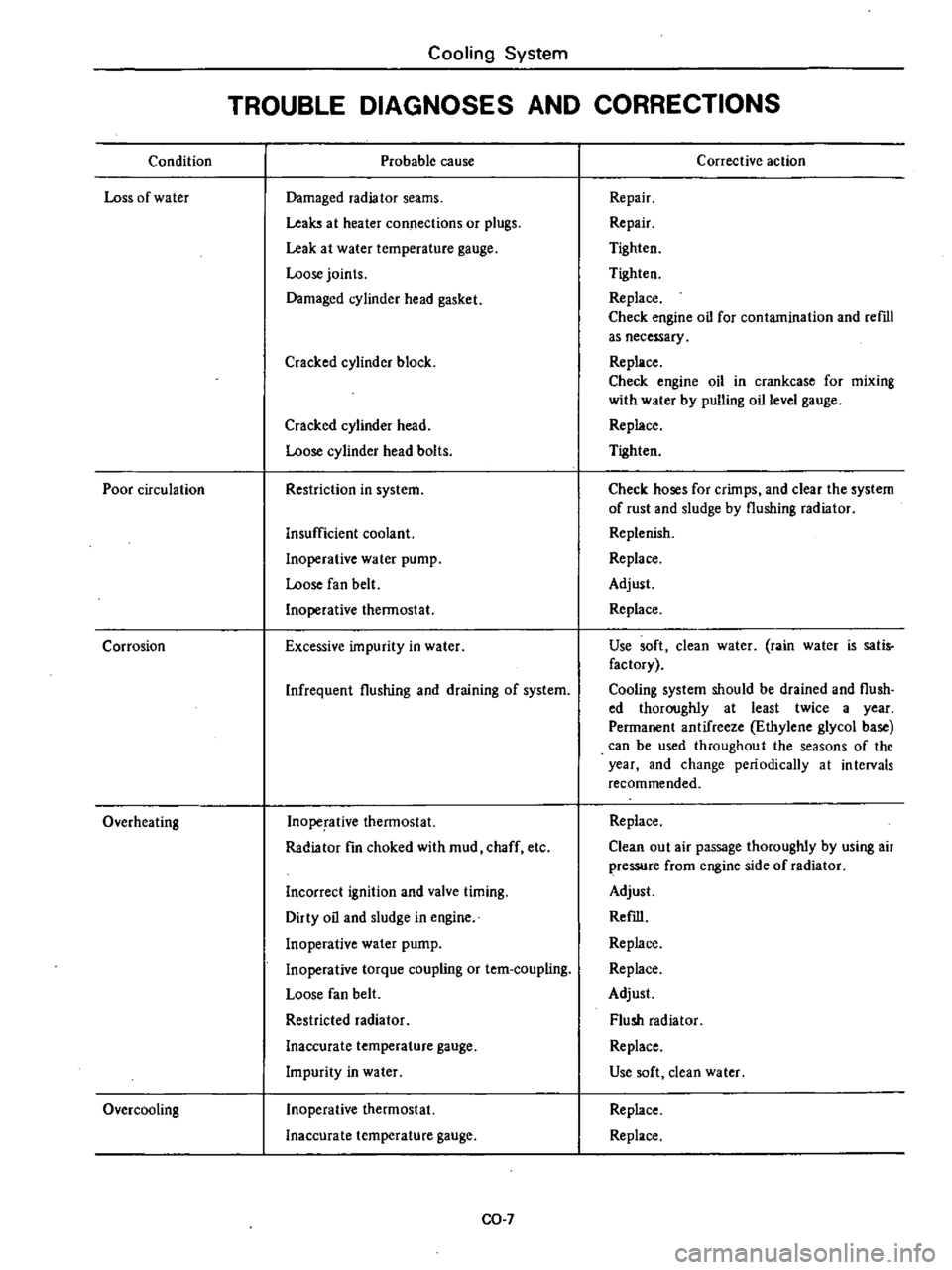

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Over

cooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Inoperative

torque

coupling

or

tem

coupling

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tighten

Tighten

Replace

Check

engine

oil

for

contamination

and

reml

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flush

ed

thoroughly

at

least

twice

a

year

Permanent

antifreeze

Ethylene

glycol

base

can

be

used

throughout

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Replace

Adjust

Flush

radiator

Replace

Use

soft

dean

water

Replace

Replace

Page 130 of 548

Emission

Control

System

r

@

@

CD

L

I

1

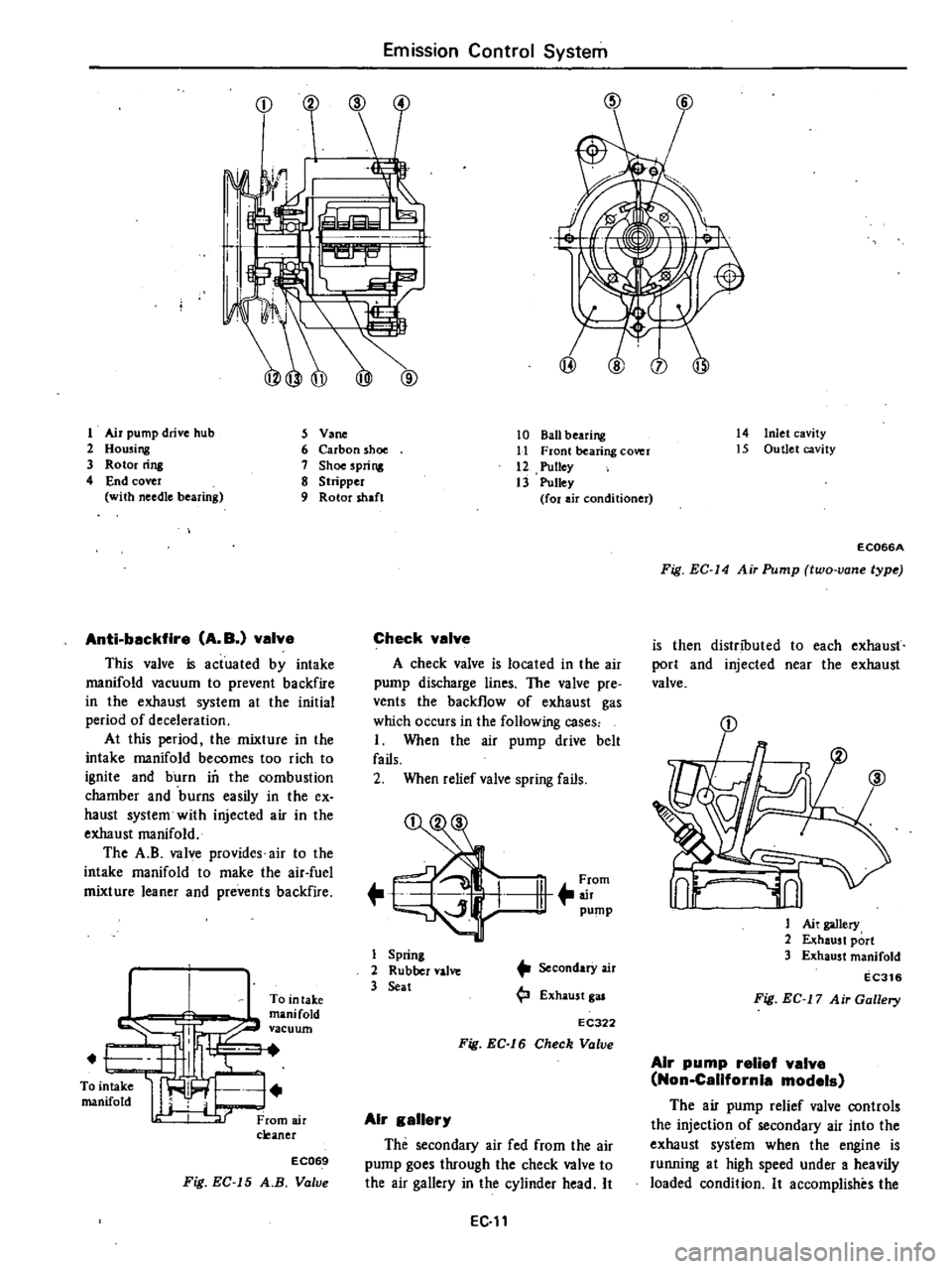

Air

pump

drive

hub

5

V

ne

2

Housing

6

Carbon

shoe

3

Rotor

rins

7

Shoe

spri

ng

4

End

cover

8

Stripper

with

needle

bearing

9

Rotor

shaft

Anti

backfire

A

B

valve

This

valve

is

actuated

by

intake

manifold

vacuum

to

prevent

backfire

in

the

exhaust

system

at

the

initial

period

of

deceleration

At

this

period

the

mixture

in

the

intake

manifold

becomes

too

rich

to

ignite

and

burn

in

the

combustion

chamber

and

burns

easily

in

the

ex

haust

system

with

injected

air

in

the

exhaust

manifold

The

A

B

valve

provides

air

to

the

intake

manifold

to

make

the

air

fuel

mixture

leaner

and

prevents

backfire

To

in

take

manifold

vacuum

EC069

Fig

EC

15

A

B

Valve

10

Ball

bearing

11

Front

bearing

cOYer

12

Pulley

13

Pulley

for

air

conditioner

Check

valve

A

check

valve

is

located

in

the

air

pump

discharge

lines

The

valve

pre

vents

the

backflow

of

exhaust

gas

which

occurs

in

the

following

cases

I

When

the

air

pump

drive

belt

fails

2

When

relief

valve

spring

fails

1

11

rom

pump

1

Spring

2

Rubber

valve

3

Seat

SecondarY

air

4

J

Exhaust

gas

EC322

Fig

EC

16

Check

Valve

Air

gallery

The

secondary

air

fed

from

the

air

pump

goes

through

the

check

valve

to

the

air

gallery

in

the

cylinder

head

It

EC

lt

14

Inlet

cavity

15

Outlet

cavity

EC066A

Fig

EC

14

Air

Pump

two

vane

lype

is

then

distributed

to

each

exhaust

port

and

injected

near

the

exhaust

valve

0

iJl

Ai

gallery

2

Exhaust

port

3

Exhaust

manifold

EC316

Fig

EC

17

Air

Gallery

Air

pump

relief

valve

Non

California

models

The

air

pump

relief

valve

controls

the

injection

of

secondary

air

into

the

exhaust

system

when

the

engine

is

running

at

high

speed

under

a

heavily

loaded

condition

It

accomplishes

the

Page 132 of 548

EC149A

Fig

EC

23

Removing

Air

Cleaner

Filter

Air

pump

1

Remove

air

hoses

from

air

pump

2

Remove

air

pump

pulley

3

Loosen

air

pump

adjusting

bar

mounting

bolts

and

air

pump

mount

ing

bolts

then

remove

air

pump

drive

belt

4

Air

pump

assembly

can

be

taken

out

from

bracket

5

Installation

is

in

the

reverse

se

quence

of

removal

Fig

EC

24

Removing

Air

Pump

Check

valve

1

Disconnect

air

hose

from

check

valve

2

Remove

check

valve

from

engine

cylinder

head

3

Installation

is

in

the

reverse

se

fluence

of

removal

Emission

Control

System

EC151A

Fig

EC

25

Removing

Check

Valve

A

B

valve

A

B

valve

is

located

at

the

rear

side

of

air

cleaner

Remove

air

hoses

and

vacuum

tube

A

B

valve

can

then

be

taken

out

EC152A

Fig

EC

26

Removing

A

B

Valve

Air

pump

relief

valve

Non

California

models

I

Loosen

clamp

of

air

hose

and

disconnect

air

hose

from

relief

valve

EC

13

2

Remove

screws

securing

relief

valve

to

air

cleaner

Relief

valve

can

then

be

taken

out

easily

3

Installation

is

in

the

reverse

se

quence

of

removal

EC153A

Fig

EC

27

Removing

Air

Pump

Relief

Valve

C

A

C

valve

California

models

C

A

C

valve

is

located

beneath

con

trol

device

bracket

Remove

clamps

and

disconnect

air

hoses

and

vacuum

tube

2

Remove

screws

securing

C

A

C

valve

Air

control

valve

can

then

be

taken

out

easily

3

Installation

is

in

the

reverse

se

quence

of

removal

EC154A

Fig

EC

28

Removing

C

A

C

Volvo

Page 136 of 548

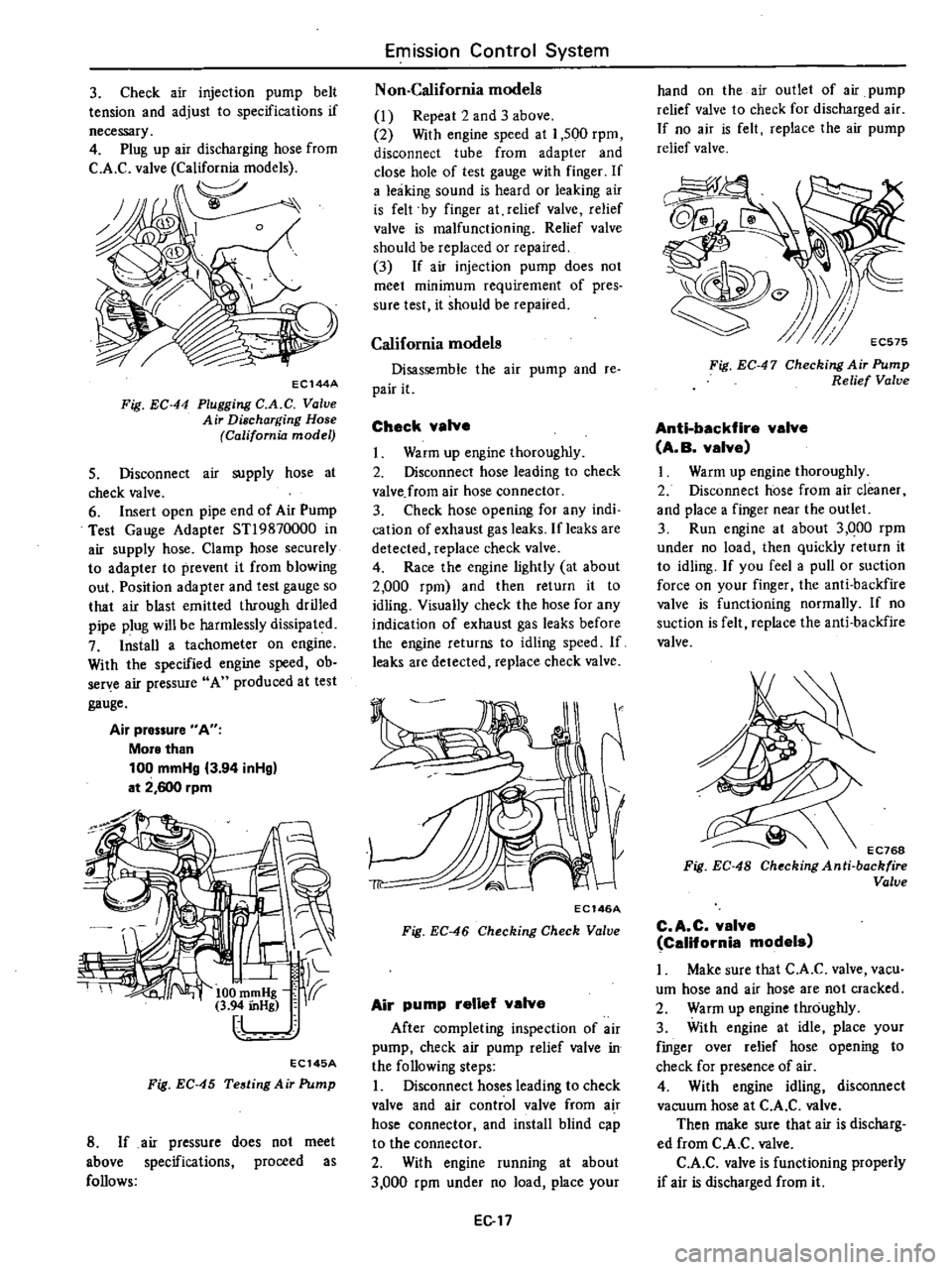

3

Check

air

injection

pump

belt

tension

and

adjust

to

specifications

if

necessary

4

Plug

up

air

discharging

hose

from

C

A

C

valve

California

models

y

o

EC144A

Fig

EC

44

Plugging

C

A

C

Value

Air

Discharging

Hose

California

model

S

Disconnect

air

supply

hose

at

check

valve

6

Insert

open

pipe

end

of

Air

Pump

Test

Gauge

Adapter

STl9870000

in

air

supply

hose

Clamp

hose

securely

to

adapter

to

prevent

it

from

blowing

out

Position

adapter

and

test

gauge

so

that

air

blast

emitted

through

drilled

pipe

plug

will

be

harmlessly

dissipated

7

Install

a

tachometer

on

engine

With

the

specified

engine

speed

ob

serye

air

pressure

A

produced

at

test

gauge

Air

pressure

A

More

than

100

mmHg

3

94

inHg

at

2

600

rpm

I

jff

100

m

Hg

f1

3

94

mHg

I

EC145A

Fig

EC

45

Testing

Air

Pump

8

If

air

pressure

does

not

meet

above

specifications

proceed

as

follows

Emission

Control

System

Non

California

models

1

Repeat

2

and

3

above

2

With

engine

speed

at

1

500

rpm

disconnect

tube

from

adapter

and

close

hole

of

test

gauge

with

finger

If

a

leaking

sound

is

heard

or

leaking

air

is

felt

by

finger

at

relief

valve

relief

valve

is

malfunctioning

Relief

valve

should

be

replaced

or

repaired

3

If

air

injection

pump

does

not

meet

minimum

requirement

of

pres

sure

test

it

should

be

repaired

California

models

Disassemble

the

air

pump

and

re

pair

it

Check

valve

Warm

up

engine

thoroughiy

2

Disconnect

hose

leading

to

check

valve

from

air

hose

connector

3

Check

hose

opening

for

any

indi

cation

of

exhaust

gas

leaks

If

leaks

are

detected

replace

check

valve

4

Race

the

engine

lightly

at

about

2

000

rpm

and

then

return

it

to

idling

Visually

check

the

hose

for

any

indication

of

exhaust

gas

leaks

before

the

engine

returns

to

idling

speed

If

leaks

are

detected

replace

check

valve

EC146A

Fig

EC

46

Checking

Check

Valve

Air

pump

relief

valve

After

completing

inspection

of

air

pump

check

air

pump

relief

valve

in

the

following

steps

I

Disconnect

hoses

leading

to

check

valve

and

air

control

valve

from

air

hose

connector

and

install

blind

c

p

to

the

connector

2

With

engine

running

at

about

3

000

rpm

under

no

load

place

your

EG

7

hand

on

the

air

outlet

of

air

pump

relief

valve

to

check

for

discharged

air

If

no

air

is

felt

replace

the

air

pump

relief

valve

G

EC575

Fig

EC

47

Checking

Air

Pump

Relief

Valve

Anti

backfire

valve

A

B

valve

I

Warm

up

engine

thoroughly

2

Disconnect

hose

from

air

cleaner

and

place

a

finger

near

the

outlet

3

Run

engine

at

about

3

QOO

rpm

under

no

load

then

quickly

return

it

to

idling

If

you

feel

a

pull

or

suction

force

on

your

finger

the

anti

backfire

valve

is

functioning

normally

If

no

suction

is

felt

replace

the

anti

backfire

valve

EC768

Fig

EC

48

Chocking

Anti

backfire

Valve

C

A

C

valve

California

models

I

Make

sure

that

C

A

C

valve

vacu

um

hose

and

air

hose

are

not

cracked

2

Warm

up

engine

throughly

3

With

engine

at

idle

place

your

fmger

over

relief

hose

opening

to

check

for

presence

of

air

4

With

engine

idling

disconnect

vacuum

hose

at

C

A

C

valve

Then

make

sure

that

air

is

discharg

ed

from

C

A

C

valve

C

A

C

valve

is

functioning

properly

if

air

is

discharged

from

it

Page 172 of 548

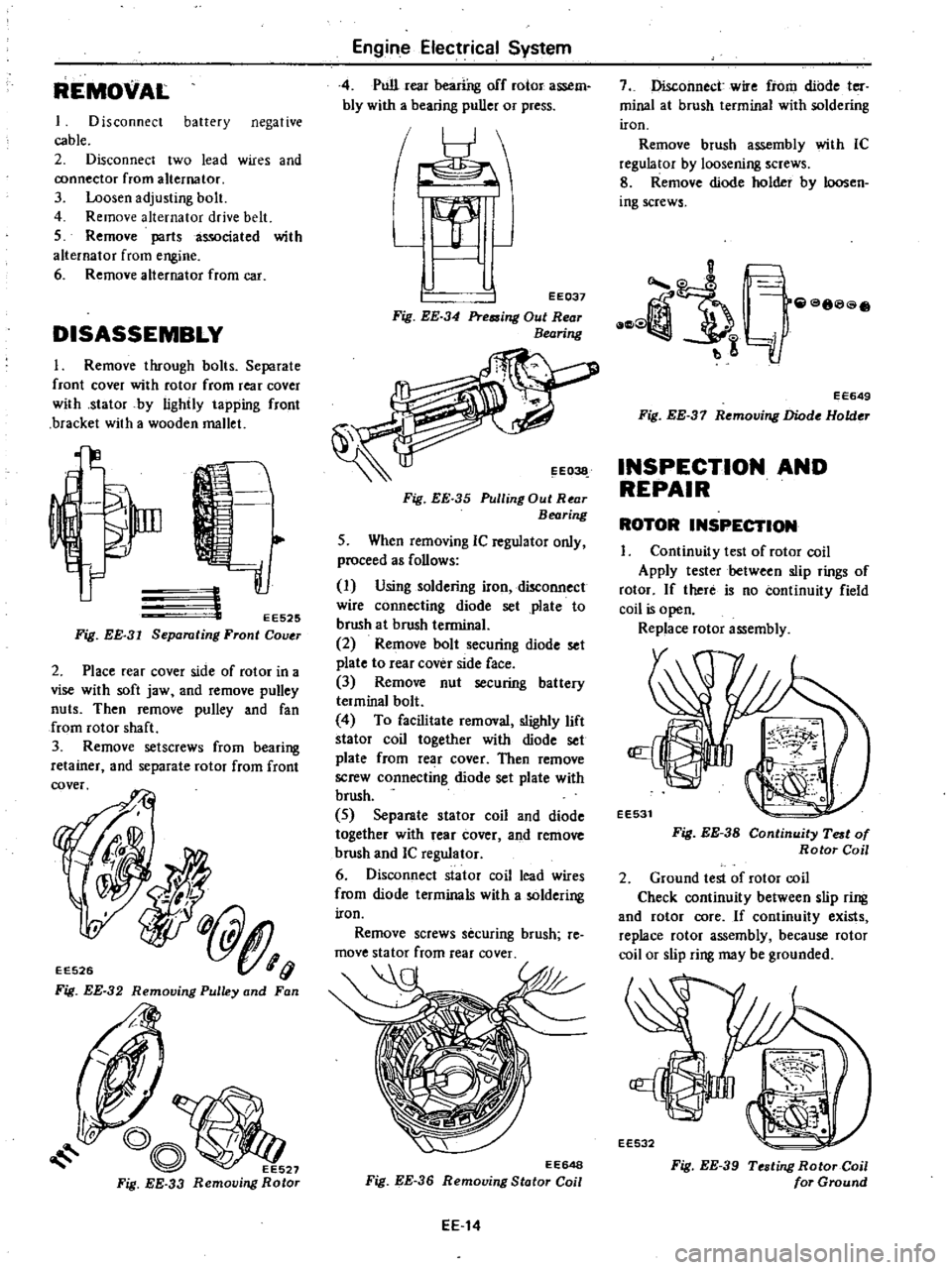

REMOVAL

1

Disconnect

battery

negative

cable

2

Disconnect

two

lead

wires

and

oonnector

from

alternator

3

Loosen

adjusting

bolt

4

Remove

alternator

drive

belt

5

Remove

parts

associated

with

alternator

from

engine

6

Remove

alternator

from

car

DISASSEMBLY

I

Remove

through

bolts

Separate

front

cover

with

rotor

from

rear

cover

with

stator

by

lightly

tapping

front

bracket

with

a

wooden

mallet

rnJ

J

i

EE525

Separating

Front

COI

T

Fig

EE

31

2

Place

rear

cover

side

of

rotor

in

a

vise

with

soft

jaw

and

remove

pulley

nuts

Then

remove

pulley

and

fan

from

rotor

shaft

3

Remove

setscrews

from

bearing

retainer

and

separate

rotor

from

front

EE526

Fig

EE

32

Removing

Pulley

and

Fan

tr

s

0

27

Fig

EE

33

Removing

Rotor

Engine

Electrical

System

4

Pull

rear

bearfug

off

rotor

assem

bly

with

a

bearing

puller

or

press

EE037

Fig

EE

34

Pressing

Out

Rear

Bearing

I

EO

Fig

EE

35

Pulling

Out

Rear

Bearing

5

When

removing

IC

regulator

only

proceed

as

follows

I

Using

soldering

iron

disconnect

wire

connecting

diode

set

plate

to

brush

at

brush

terminal

2

Remove

bolt

securing

diode

set

plate

to

rear

cover

side

face

3

Remove

nut

securing

battery

terminal

bolt

4

To

facilitate

removal

s1ighly

lift

stator

coil

together

with

diode

set

plate

from

re

r

cover

Then

remove

screw

connecting

diode

set

plate

with

brush

5

Separate

stator

coil

and

diode

together

with

rear

cover

and

remove

brush

and

IC

regulator

6

Disconnect

stator

coil

lead

wires

from

diode

terminals

with

a

soldering

iron

Remove

screws

securing

brush

re

move

stator

from

rear

cover

EE648

Fig

EE

36

Removing

Stator

Coil

EE

14

7

Disconnect

wire

from

diode

tor

minal

at

brush

terminal

with

soldering

iron

Remove

brush

assembly

with

IC

regulator

by

loosening

screws

8

Remove

diode

holder

by

loosen

ing

screws

acefii

li

E

E649

Fig

EE

37

Removing

Diode

Holder

INSPECTION

AND

REPAIR

ROTOR

INSPECTION

I

Continuity

test

of

rotor

coil

Apply

tester

between

slip

rings

of

rotor

If

there

is

no

continuity

field

coil

is

open

Replace

rotor

assembly

Fig

EE

38

Continuity

Test

of

Rotor

Coil

2

Ground

test

of

rotor

coil

Check

continuity

between

slip

ring

and

rotor

core

If

continuity

exists

replace

rotor

assembly

because

rotor

coil

or

slip

ring

may

be

grounded

EE532

Fig

EE

39

Te

ting

Rotor

Coil

for

Ground

Page 192 of 548

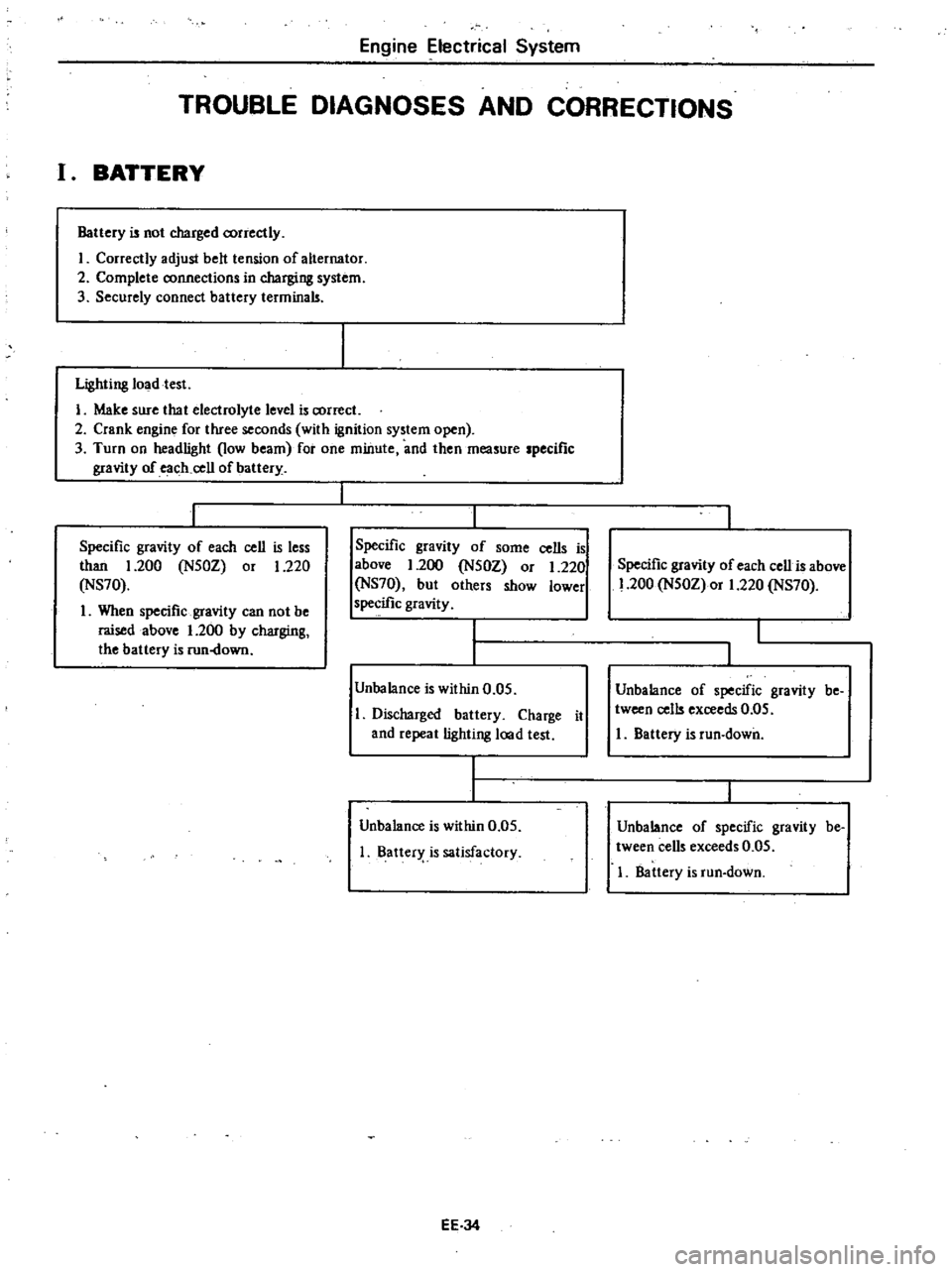

Engine

Electrical

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

I

BATTERY

Battery

is

not

charged

correctly

I

Correctly

adjust

belt

tension

of

alternator

2

Complete

connections

in

charging

system

3

Securely

connect

battery

terminals

Lighting

Joadtest

I

Make

sure

that

electrolyte

level

is

correct

2

Crank

engine

for

three

seconds

with

ignition

system

open

3

Turn

on

headlight

low

beam

for

one

minute

and

then

measure

specific

gravity

of

each

cell

of

battery

Specific

gravity

of

each

cell

is

less

than

1

200

N50Z

or

1

220

NS70

1

When

specific

gravity

can

not

be

raised

above

1

200

by

charging

the

battery

is

run

down

Specific

gravity

of

some

cells

is

above

1

200

N50Z

or

1

220

NS70

but

others

show

lower

specific

gravity

Unbalance

is

within

0

05

Discharged

battery

Charge

it

and

repeat

lighting

lood

test

Unbalance

is

within

0

05

Batter

is

satisfactory

EE

J4

Specific

gravity

of

each

cell

is

above

1

200

N50Z

or

1

220

NS70

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Unbalance

of

specific

gravity

be

tween

cells

exceeds

0

05

I

Battery

is

run

down

Page 194 of 548

Engine

Electrical

System

III

ALTERNATOR

Including

voltage

regulator

Condition

No

output

Excessive

output

Low

output

Noisy

alternator

Probable

cause

Sticking

brushes

Dirty

brushes

and

slip

rings

Loose

connections

or

broken

leads

Open

stator

winding

Open

rotor

winding

Open

diodes

Shorted

diodes

Shorted

rotor

Shorted

stator

Ground

BAT

terminal

Broken

fan

belt

Voltage

regulator

breakdown

Poor

connection

of

alternator

S

terminal

Open

diode

Loose

or

worn

fan

belt

Slicking

brushes

Low

brush

spring

tension

Voltage

regulator

breakdown

Dirty

slip

ring

Partial

hort

ground

or

open

in

stator

winding

Partially

shorted

or

grounded

rotor

winding

Open

or

damaged

diode

Loose

mounting

Loose

drive

pulley

Broken

ball

bearing

Improperly

seated

brushes

EE

36

Corrective

action

Correct

or

replace

bru

hes

and

brush

springs

Clean

Retigliten

or

older

connection

Replace

leads

if

necessary

Repair

or

replace

stator

Replace

rotor

Replace

Replace

Replace

rotor

Replace

Replace

insulator

Replace

Check

regulator

operation

and

repair

or

replace

a

required

Correct

Replace

Retighten

or

replace

Correct

or

replace

brushes

and

springs

if

necessary

Replace

brush

spring

Check

regulator

operation

and

repair

or

replace

as

required

Clean

Replace

tator

Replace

rotor

Replace

diode

Retighten

bolts

Retighten

Replace

Seat

correctly

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 201 of 548

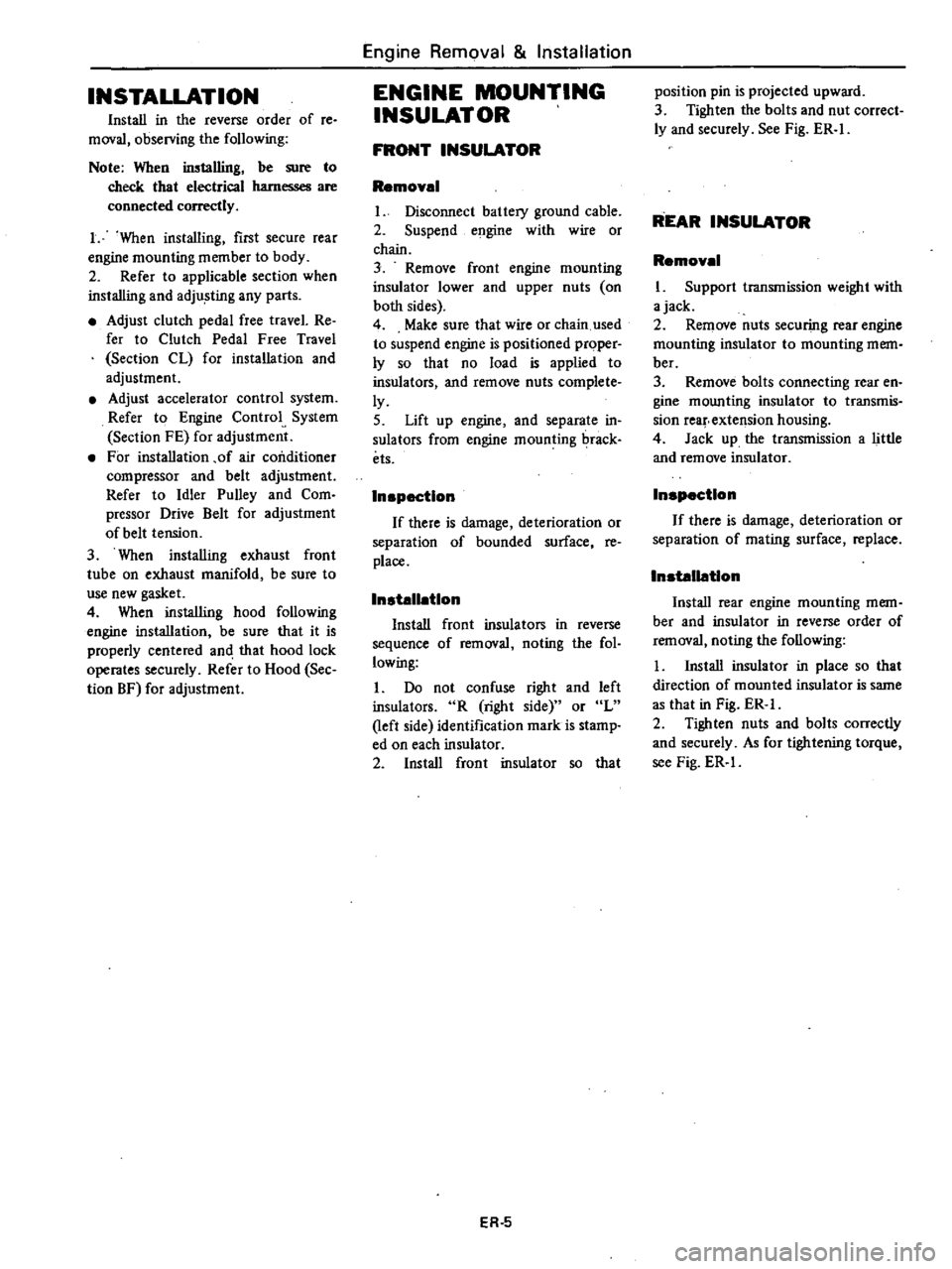

INSTALLATION

Install

in

the

reverse

order

of

re

moval

observing

the

following

Note

When

inslal1ing

be

sure

to

check

thaI

electrical

harnesses

are

connected

ly

1

When

installing

first

secure

rear

engine

mounting

member

to

body

2

Refer

to

applicable

section

when

installing

and

adjusting

any

parts

Adjust

clutch

pedal

free

travel

Re

fer

to

Clutch

Pedal

Free

Travel

Section

CL

for

installation

and

adjustment

Adjust

accelerator

control

system

Refer

to

Engine

Control

System

Section

FE

for

adjustment

For

installation

of

air

conditioner

compressor

and

belt

adjustment

Refer

to

Idler

Pulley

and

Com

pressor

Drive

Belt

for

adjustment

of

belt

tension

3

When

installing

exhaust

front

tube

on

exhaust

manifold

be

sure

to

use

new

gasket

4

When

installing

hood

following

engine

installation

be

sure

that

it

is

properly

centered

and

that

hood

lock

operates

securely

Refer

to

Hood

See

tion

BF

for

adjustment

Engine

Removal

Installation

ENGINE

MOUNTING

INSULATOR

FRONT

INSULATOR

Removal

Disconnect

battery

ground

cable

2

Suspend

engine

with

wire

or

chain

3

Remove

front

engine

mounting

insulator

lower

and

upper

nuts

on

both

sides

4

Make

sure

that

wire

or

chain

used

to

suspend

engine

is

positioned

prqper

ly

so

that

no

load

is

applied

to

insulators

and

remove

nuts

complete

ly

5

Lift

up

engine

and

separate

in

sulators

from

engine

mounting

rack

ets

Inspection

If

there

is

damage

deterioration

or

separation

of

bounded

surface

re

place

Installation

Install

front

insulators

in

reverse

sequence

of

removal

noting

the

fol

lowing

1

Do

not

confuse

right

and

left

insulators

R

right

side

or

L

left

side

identification

mark

is

stamp

ed

on

each

insulator

2

Install

front

insulator

so

that

ER

5

position

pin

is

projected

upward

3

Tighten

the

bolts

and

nut

correct

ly

and

securely

See

Fig

ER

I

REAR

INSULATOR

Removal

l

Support

transmission

weight

with

ajack

2

Remove

nuts

securing

rear

engine

mounting

insulator

to

mounting

mem

ber

3

Remove

bolts

connecting

rear

en

gine

mounting

insulator

to

transmis

sion

reaf

extension

housing

4

Jack

up

the

transmission

a

little

and

remove

insulator

Inspection

If

there

is

damage

deterioration

or

separation

of

mating

surface

replace

Installation

Install

rear

engine

mounting

mem

ber

and

insulator

in

reverse

order

of

removal

noting

the

following

I

Install

insulator

in

place

so

that

direction

of

mounted

insulator

is

same

as

that

in

Fig

ER

2

Tighten

nuts

and

bolts

correctly

and

securely

As

for

tightening

torque

see

Fig

ER

l