belt DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 330 of 548

Note

CbedI

dust

seal

forsaatcbes

or

aacb

on

lips

end

replace

if

neces

sary

ASSEMBLY

When

assembling

strut

be

careful

not

to

drop

or

scratch

parts

since

they

are

precisely

machined

to

very

close

tolerances

Before

assembly

clean

away

all

dirt

to

prevent

any

possible

entry

of

dirt

into

strut

Note

If

replacement

of

any

strut

compooent

parts

is

found

to

be

neoesaery

make

sure

tlllt

parta

ere

the

same

brand

as

thoee

used

in

the

strot

essemhly

I

Install

strut

outer

casing

on

Strut

Steering

Gear

Housing

Attachment

KV48

100300

See

Fig

FA

20

2

Install

cylinder

and

piston

rod

assembly

shock

absorber

kit

in

outer

casing

3

Remove

pistoo

rod

guide

from

cylinder

and

Pour

correct

amount

of

new

fluid

into

ylinder

and

strut

outer

casing

Amount

of

oil

325

cc

19

83

cu

in

1

FA065

Fig

FA

22

FillingShoelt

Absorber

Fluid

Note

e

It

i

important

that

correct

emount

of

fluid

be

poured

into

strut

to

assure

correct

damping

force

of

Front

Axle

Front

Suspension

mock

absorber

b

U

GENUINE

NISSAN

STRUT

OIL

or

equivalent

every

after

over

11101

4

Securely

install

piston

rod

guide

in

cylinder

Note

Be

c

aref

1l

t

to

damage

gujde

with

thread

portion

of

pistoo

rod

5

Install

new

O

ring

over

rod

guide

6

Lubricate

sealing

lips

of

gland

packing

uterisked

in

Fig

F

A

23

with

lithium

base

grease

containing

molyb

denum

disulphide

and

install

gland

packing

with

Gland

Packing

Guide

KV40101900

FA659

Grease

V

1

1

0

I

FA464

Fig

FA

23

Grea

ing

Point

of

Gland

lbelting

KV40101900

F

A276

Fig

F

A

24

t

lung

Gland

lbelting

FA

8

7

Tighten

gland

packing

fl

Tightening

torque

8

0

to

11

0

kg

m

58

to

80

ft

lb

Note

a

When

tightening

gland

packing

it

i

POrl

t

J

It

d

he

ttJI

teoded

epproximately

120

IDID

4

72

in

from

upper

surfece

of

gland

packing

to

faclli18te

spring

iosteIlatioo

b

Gland

packing

should

be

tighteoed

to

specified

torque

with

the

aid

of

Gland

Packing

Wreoch

ST35500001

When

doing

so

the

amouot

of

torque

to

be

read

be

neath

wrench

oeedle

should

be

modified

eccording

to

the

following

formula

L

Ckg

m

8x

L

O

IO

or

L

Cft

Ib

58x

L

0

33

where

C

Value

to

he

reed

on

the

torque

wrench

kg

m

ft

Ib

L

Effective

length

of

torque

wrench

m

ft

Gland

packing

WIcoch

Torque

C

Lm

ft

I

0

1

m

0

33

ft

FA278

Fig

FA

25

Gland

lbeltill

l

Wrench

8

Bleed

air

out

of

shock

absorber

as

follows

I

Holding

strut

by

hand

with

its

spindle

side

facing

down

pull

out

piston

f

d

completely

Then

turn

strut

upside

down

so

that

spindle

side

is

now

facing

up

Under

this

condition

retract

piston

rod

all

the

way

in

2

Repeat

the

above

procedure

several

times

so

that

air

will

be

bled

out

from

strut

th

oroughiy

3

If

during

the

above

step

en

equal

pressure

is

felt

through

the

hand

grippitig

piston

rod

on

both

strokes

it

is

an

indication

that

air

is

expelled

from

strut

thoroughly

Page 378 of 548

t

MAINTEN

NCE

TIRE

INFLATION

Correct

tire

pressure

is

very

impor

tant

for

steering

ease

and

riding

com

fort

Correct

pressure

also

makes

for

a

quieter

ride

and

extends

tire

life

If

all

tires

are

inspected

frequently

and

maintained

at

correct

pressure

any

sharp

objects

in

tread

can

be

quickiy

detected

nd

abnormal

wear

which

invites

serious

problems

can

be

avoided

After

inflating

tires

valves

should

be

checked

for

leakage

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

vaive

caps

firmly

by

hand

JW

Sri

in

1

II

I

i

I

1

I

1

1

I

I

I

II

I

I

I

i

M

I

l

1

14

nl

01

I

II

Toe

in

or

toe

out

wear

I

J

I

I

p

rt

i

Ilnl

lll

11111

IllIlI

Shoulder

wear

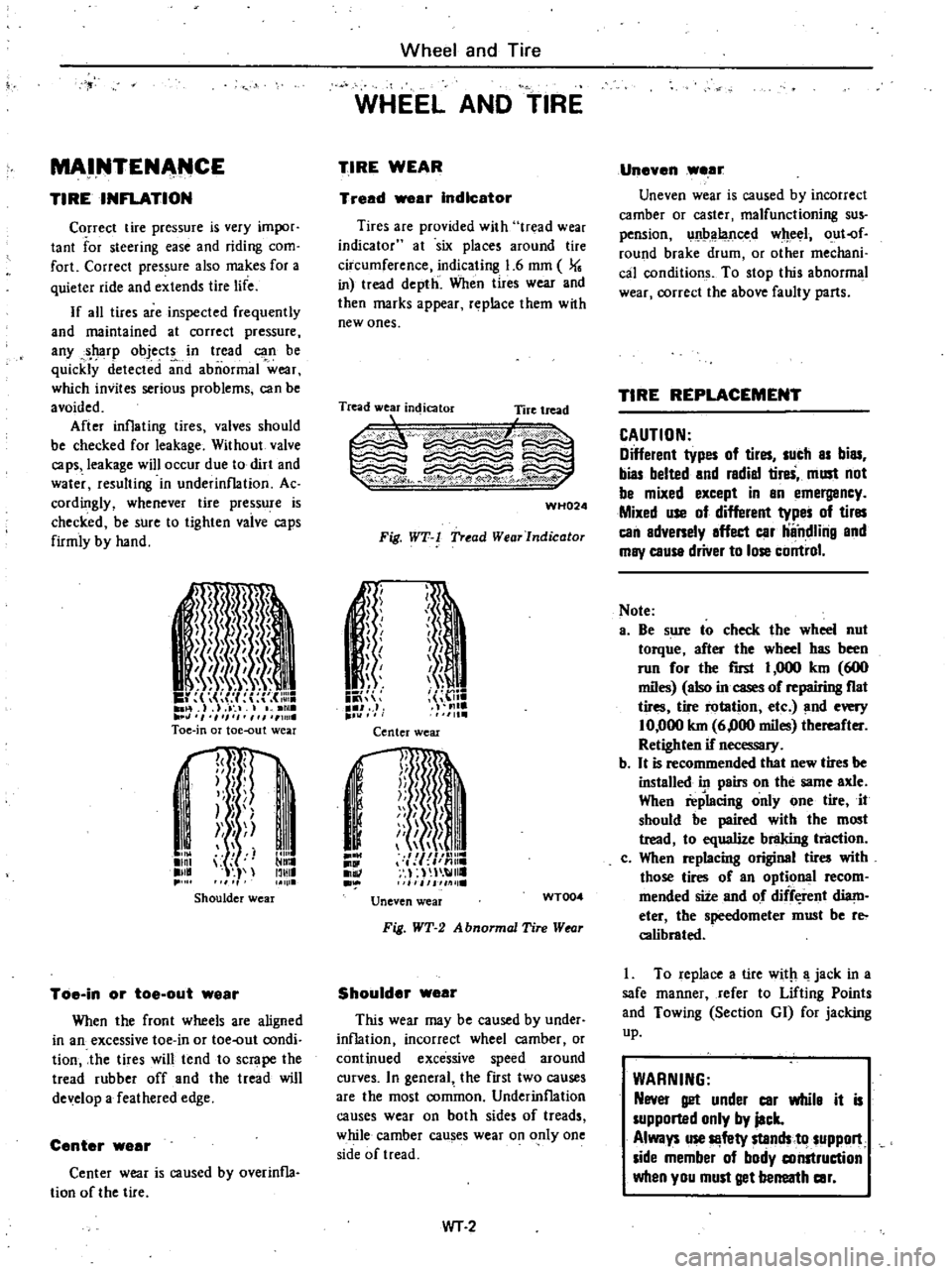

Toe

in

or

toe

out

wear

When

the

front

wheels

are

aligned

in

an

excessive

toe

in

or

toe

out

condi

tion

the

tires

will

tend

to

scrape

the

tread

rubber

off

and

the

tread

will

de

elop

a

feathered

edge

Center

wear

Center

wear

is

caused

by

overinfla

tion

of

the

tire

Wheel

and

Tire

WHEEL

AND

TIRE

TIRE

WEAR

Tread

ar

Indicator

Tires

are

provided

with

tr

lad

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

tires

wear

and

then

marks

appear

replace

them

wtth

new

ones

Tread

wear

indicator

Tire

tread

L

1

c

WH024

Fig

WT

l

Tread

WearJndicator

n

1

ii

J

J

f

J

I

h

I

me

1111

Center

wear

j

I

1II

mnr

I

j

n

Ii

Ii

i

I

Jil

111

lie

Uneven

wear

WT004

Fig

WT

2

A

bnormal

Tire

Wtor

Shoulder

wear

This

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continued

excessive

speed

around

curves

In

general

the

first

two

causes

are

the

most

common

Underinflation

causes

wear

on

both

sides

of

treads

while

camber

causes

wear

on

only

one

side

of

tread

WT

2

Uneven

wear

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

stop

this

abnormal

wear

correct

the

above

faulty

parts

TIRE

REPLACEMENT

CAUTION

Different

types

of

tires

sucb

as

bias

bias

belted

and

radial

tireS

must

not

be

mixed

except

in

an

emergancy

Mixed

use

of

different

types

of

tires

can

adversely

affect

car

ilndlilig

and

may

cause

driver

to

lose

control

Note

a

Be

sure

to

check

the

wheel

nut

torque

after

the

wheel

has

been

run

for

the

rust

I

000

km

600

miles

also

in

cases

of

repairing

fiat

tires

tire

rotation

etc

and

every

10

000

km

6

000

miles

thereafter

Retighten

if

necessary

b

It

is

recommended

that

new

tires

be

installed

in

pairs

on

the

same

axle

When

replacing

only

one

tire

it

should

be

paired

with

the

most

tread

to

equalize

braking

tl1lction

c

When

replacing

original

tires

with

those

tires

of

an

optional

recom

mended

site

and

of

diff

rent

diam

eter

the

speedometer

must

be

reo

calibrated

I

To

replace

a

tire

with

a

jack

in

a

safe

manner

refer

to

Lifting

Points

and

Towing

Section

GI

for

jacking

up

WARNING

Never

get

under

car

whila

it

is

supported

only

by

jack

Always

use

Il

fety

stands

to

suppon

side

member

of

body

construction

when

you

must

get

berreatb

car

Page 379 of 548

2

To

install

wheel

tighten

wheel

nuts

in

criss

cross

fashion

As

for

aluminum

wheels

proceed

as

follows

I

Snugly

tighten

four

nuts

after

wheel

is

positioned

See

Fig

WT

3

Iil

Tightening

torque

Wheel

nut

Steel

and

aluminum

wheels

8

0

to

10

0

kg

m

58

to

72

ft

Ibl

CAUTION

Two

types

of

wheel

nuts

Bre

used

one

is

designed

for

use

with

steel

wheel

Bnd

the

other

for

use

with

aluminum

wheel

Do

not

mix

different

types

of

wheel

nuts

p

WT020

For

aluminum

wheels

only

c

WH246

For

teel

wheels

only

Fig

WT

4

Wheel

Nut

Wheel

and

Tire

2

Slightly

pull

wheel

back

to

prop

erly

align

nuts

with

bolt

holes

in

wheel

and

tighten

nuts

as

much

as

possible

with

your

fingers

3

Tighten

four

nuts

evenly

with

a

wheel

wrench

in

criss

cross

fashion

f

WT016

Align

nuti

with

bolt

holes

in

wheel

and

evenly

tighten

nuts

each

one

a

little

at

a

time

Fig

WT

3

Installing

Aluminum

Wheel

Note

Be

careful

not

to

smear

thread

ed

portion

of

bolt

and

nut

and

seat

of

nut

with

oil

or

grease

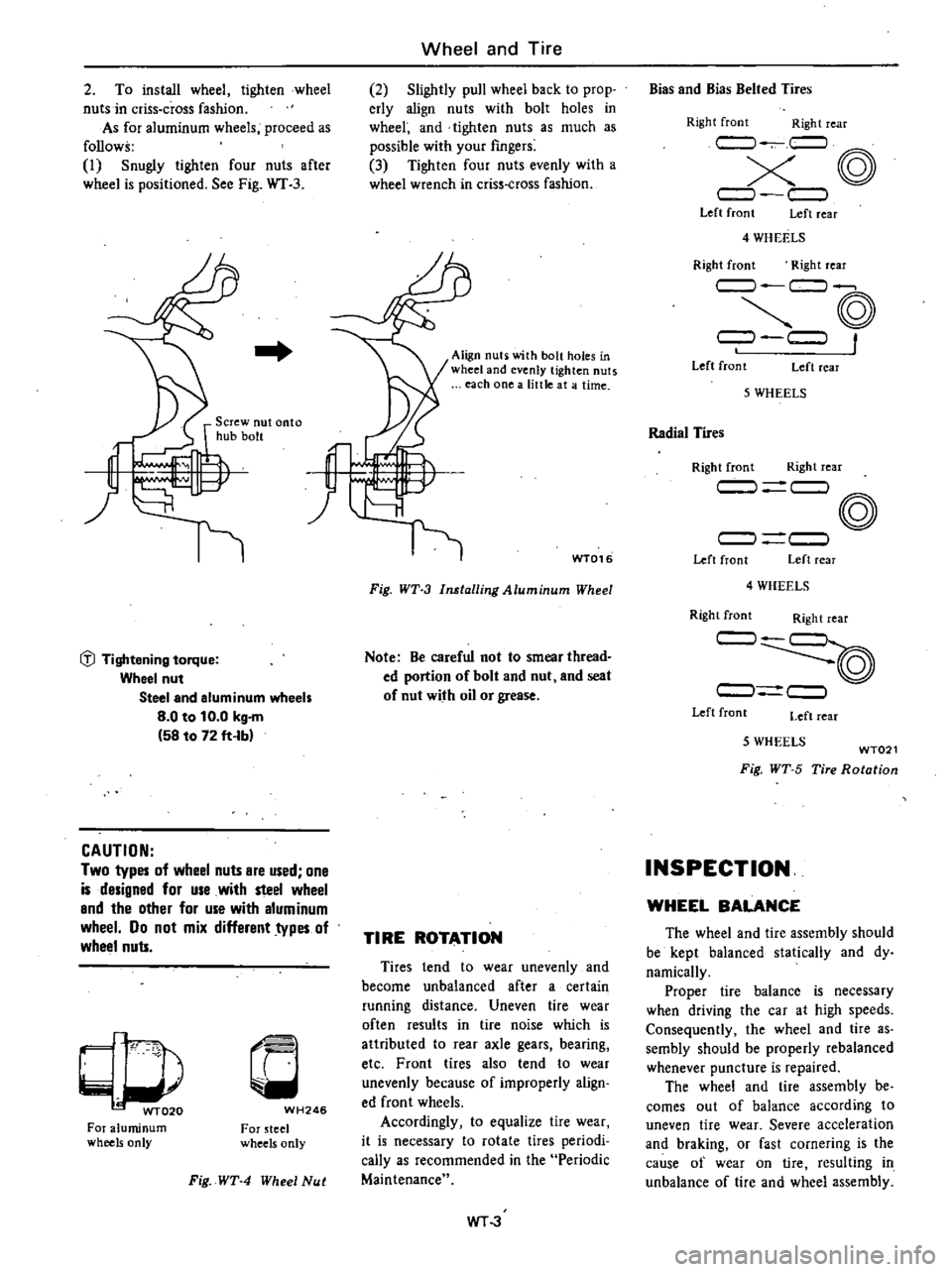

TIRE

ROTATION

Tires

tend

to

wear

unevenly

and

become

unbalanced

after

a

certain

running

distance

Uneven

tire

wear

often

results

in

tire

noise

which

is

attributed

to

rear

axle

gears

bearing

etc

Front

tires

also

tend

to

wear

unevenly

because

of

improperly

align

ed

front

wheels

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

periodi

cally

as

recommended

in

the

Periodic

Maintenance

WT

3

Bias

and

Bias

Belted

Tires

Right

front

Right

rear

c

J

c

l

X@

c

l

c

J

Left

front

Left

rear

4

WH

EELS

Right

front

Right

rear

c

J

c

l

@

9

c

J

Left

front

Left

rear

5

WHEELS

Radial

Tires

Right

front

Right

rear

c

J

c

l

@

c

l

c

J

Left

front

Left

rear

4

WHEELS

Right

front

Right

rear

c

J

c

J

c

l

Left

front

Left

rear

5

WHEELS

WT021

Fig

WT

5

Tire

Rotation

INSPECTION

WHEEL

BALANCE

The

wheel

and

tire

assembly

should

be

kept

balanced

statically

and

dy

namically

Proper

tire

balance

is

necessary

when

driving

the

car

at

high

speeds

Consequently

the

wheel

and

tire

as

sembly

should

be

properly

rebalanced

whenever

puncture

is

repaired

The

wheel

and

tire

assembly

be

comes

out

of

balance

according

to

uneven

tire

wear

Severe

acceleration

and

braking

or

fast

cornering

is

the

cause

of

wear

on

tire

resulting

in

unbalance

of

tire

and

wheel

assembly

Page 412 of 548

DATSUN

210

Model

8310

Series

F

BODY

CONSTRUCTION

BODY

ALIGNMENT

BUMPER

DESCRIPTION

INSPECTION

FRONT

BUMPER

REAR

BUMPER

BODY

FRONT

END

RADIATOR

GRILLE

FRONT

APRON

COWL

TOP

GRILLE

FRONT

FENDER

FENDER

PROTECTOR

HOOD

HOOD

LOCK

CONTROL

DOORS

FRONT

DOOR

REAR

DOOR

4

door

Sedan

and

Wagon

BODY

REAR

END

TRUNK

LID

Sedan

SAC

K

000

R

Hatchabck

BODY

CONTENTS

BF

2

BF

4

BF

5

BF

5

BF

6

BF

8

SF

8

BF

9

BF

9

BF

9

BF

10

BF

10

BF

10

BF

11

BF

11

BF

12

BF

12

BF

15

BF

16

BF

16

BF

18

TAILGATE

Wagon

WINDSHIELD

AND

WINDOW

GLASS

WINDSHIELD

GLASS

REAR

WINDOW

GLASS

Sedan

and

Hatchback

REAR

WINDOW

GLASS

Wagon

SIDE

WINDOW

GLASS

2

Door

Sedan

and

Hatchback

REAR

QUARTER

WINDOW

GLASS

Hatchback

REAR

SIDE

WINDOW

GLASS

Wagon

INTERIOR

INSTRUMENT

PANEL

CONSOLE

BOX

SEAT

SEAT

BELT

TRIM

AND

MOLDING

ROOF

TRIMMING

BODY

SIDE

TRIM

AND

MOLDING

SPECIAL

SERVICE

TOOLS

BF

20

8F

21

SF

21

BF

22

SF

23

BF

26

BF

26

BF

27

SF

29

BF

29

SF

30

BF

30

BF

31

SF

32

BF

32

BF

32

BF

34

Page 442 of 548

Z

jJ

BF769B

Fig

BF

91

Removing

Screws

Attaching

Floor

Carpet

and

Clip

2

Release

lock

on

rear

seat

back

and

tilt

seat

back

approx

600

for

ward

3

Slide

rear

seat

back

backwards

and

draw

out

outside

seat

back

hinge

pin

from

bracket

on

car

body

BF770B

Fig

BF

92

Removing

Rear

Seat

Back

4

Slide

rear

seat

back

outwards

and

draw

out

inside

seat

back

hinge

from

bracket

on

car

body

and

remove

seat

back

S

Installation

is

in

the

reverse

order

of

removal

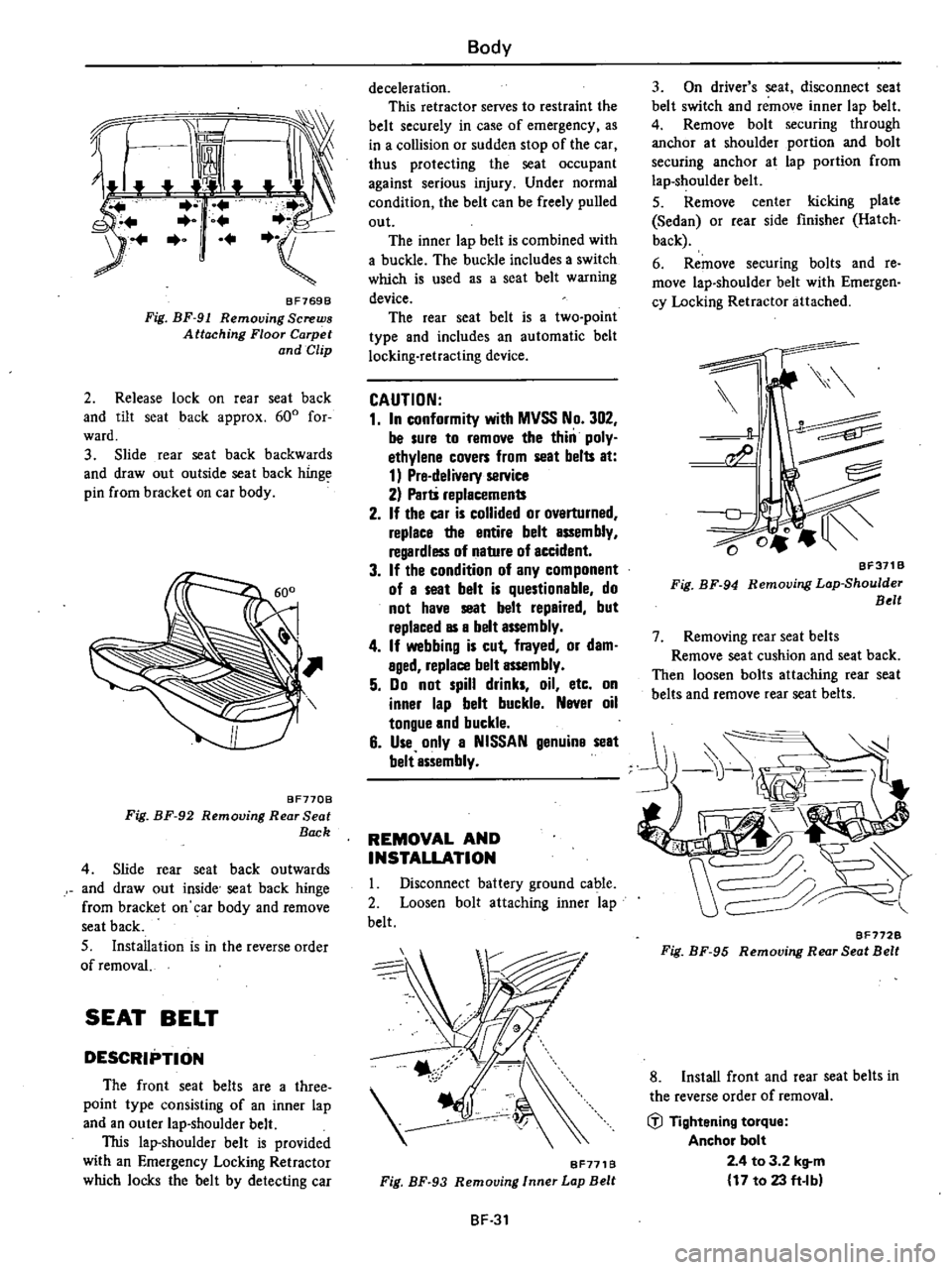

SEAT

BELT

DESCRIPTION

The

front

seat

belts

are

a

three

point

type

consisting

of

an

inner

lap

and

an

outer

lap

shoulder

belt

This

lap

shoulder

belt

is

provided

with

an

Emergency

Locking

Retractor

which

locks

the

belt

by

detecting

car

Body

deceleration

This

retractor

serves

to

restraint

the

belt

securely

in

case

of

emergency

as

in

a

collision

or

sudden

stop

of

the

car

thus

protecting

the

seat

occupant

against

serious

injury

Under

normal

condition

the

belt

can

be

freely

pulled

out

The

inner

lap

belt

is

combined

with

a

buckle

The

buckle

includes

a

switch

which

is

used

as

a

seat

belt

warning

device

The

rear

seat

belt

is

a

two

point

type

and

includes

an

automatic

belt

locking

retracting

device

CAUTION

1

In

conformity

with

MVSS

No

302

be

sure

to

remove

the

thin

poly

ethylene

covers

from

seat

belts

at

1

Pre

delivery

service

2

Parti

replacements

2

If

the

car

is

collided

or

ovarturned

replace

the

entire

belt

assembly

regardless

of

nature

of

accident

3

If

the

condition

of

any

component

of

a

seat

belt

is

questionable

do

not

have

seat

belt

repaired

but

raplaced

as

a

belt

assembly

4

If

webbing

is

cut

frayed

or

dam

aged

replace

belt

assembly

5

Do

not

spill

drinks

oil

etc

on

inner

lap

belt

buckla

Naver

oil

tongue

and

buckle

6

Use

only

a

NISSAN

genuina

seat

belt

assembly

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Loosen

bolt

attaching

inner

lap

belt

BF771B

Fig

BF

93

Removing

Inner

Lap

Belt

BF

31

3

On

driver

s

seat

disconnect

seat

belt

switch

and

remove

inner

lap

belt

4

Remove

bolt

securing

through

anchor

at

shoulder

portion

and

bolt

securing

anchor

at

lap

portion

from

lap

shoulder

belt

5

Remove

center

kicking

plate

Sedan

or

rear

side

finisher

Hatch

back

6

Remove

securing

bolts

and

re

move

lap

shoulder

belt

with

Emergen

cy

Locking

Retractor

attached

BF311B

Fig

BF

94

Removing

Lop

Shoulder

Belt

7

Removing

rear

seat

belts

Remove

seat

cushion

and

seat

back

Then

loosen

bolts

attaching

rear

seat

belts

and

remove

rear

seat

belts

BF772B

Fig

BF

95

Removing

Rear

Seat

Belt

8

Install

front

and

rear

seat

belts

in

the

reverse

order

of

removal

iil

Tightening

torque

Anchor

bolt

2

4

to

3

2

kg

m

17

to

23

ft

Ibl

Page 443 of 548

INSPECTiON

OF

SEAT

BELT

SWITCH

The

contacts

of

seat

belt

switch

are

normally

closed

When

tongue

latches

buckle

the

tip

end

of

tongue

pushes

push

rod

to

open

the

switch

contacts

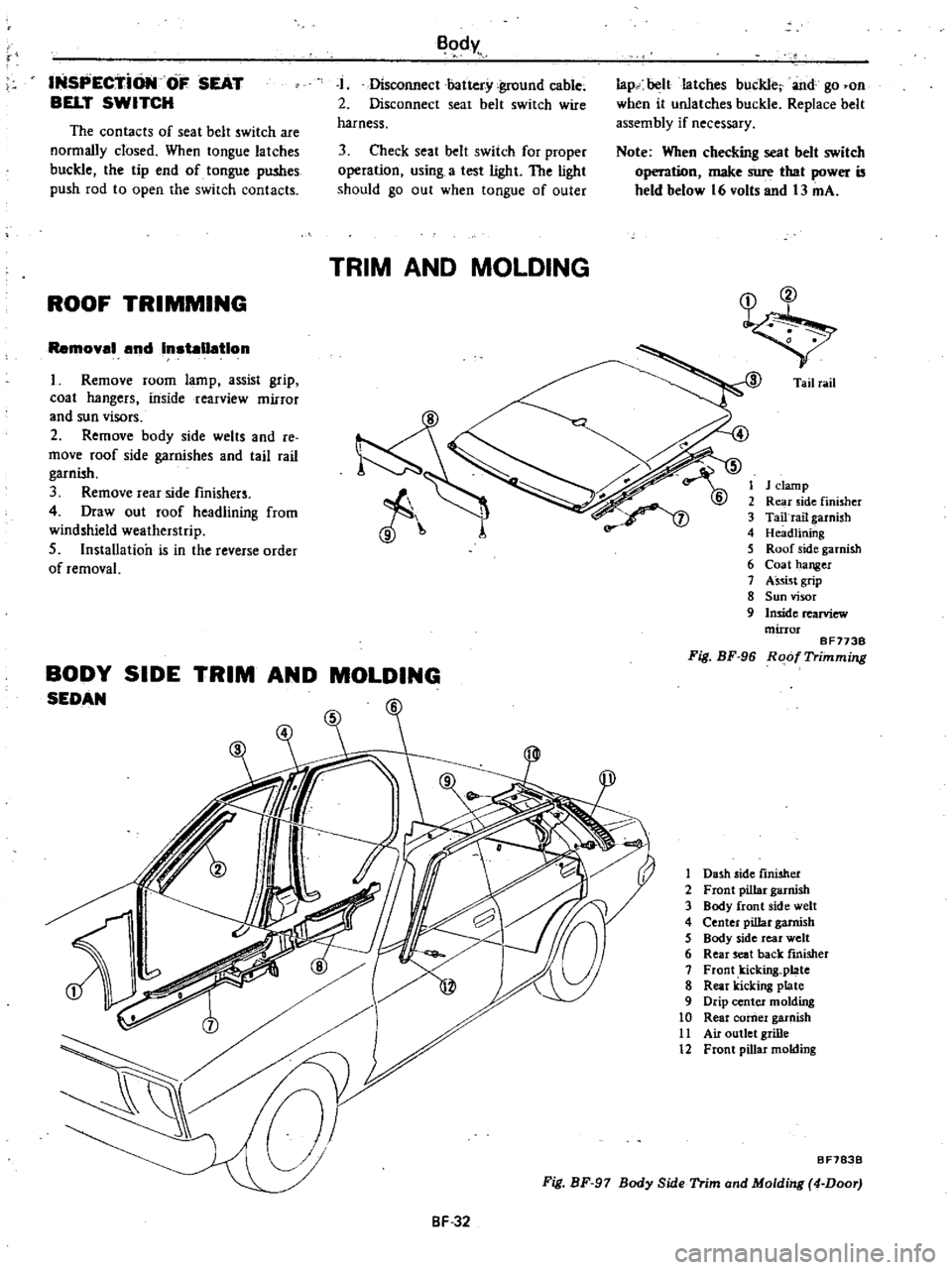

ROOF

TRIMMING

Removel

end

Inetelletlon

l

Remove

room

lamp

assist

grip

coat

hangers

inside

rearview

mirror

and

sun

visors

2

Remove

body

side

welts

and

re

move

roof

side

garnishes

and

tail

rail

garnish

3

Remove

rear

side

finishers

4

Draw

out

roof

headlining

from

windshield

weatherstrip

5

Installation

is

in

the

reverse

order

of

removal

Body

u

I

Disconnectbatter

y

ground

cable

2

Disconnect

seat

belt

switch

wire

harness

lape

belt

latches

buckle

and

go

on

when

it

unlatches

buckle

Replace

belt

assembly

if

necessary

Note

When

checking

seat

belt

switch

operation

make

sure

that

power

held

below

16

volts

and

13

mA

3

Check

seat

belt

switch

for

proper

operation

using

a

test

light

The

light

should

go

out

when

tongue

of

outer

TRIM

AND

MOLDING

f

BODY

SIDE

TRIM

AND

MOLDING

SEDAN

T

S

Tail

rail

1

J

clamp

2

Rear

side

finisher

3

Tailrail

garnish

4

Headlining

5

Roof

side

garnish

6

Coat

hanger

7

Assist

grip

8

Sun

visor

9

Inside

rearview

mirror

BF173B

Fig

BF

96

Roof

Trimming

1

Dash

side

finisher

2

Front

pillar

garnish

3

Body

front

side

welt

4

Center

pillar

garnish

5

Body

side

rear

welt

6

Rear

seat

back

finisher

7

Front

kicking

plate

8

Rear

kicking

plate

9

Drip

center

molding

10

Rear

comer

garnish

11

Air

outlet

grille

12

Front

pillar

molding

Fig

BF

97

Body

Side

Trim

ond

Molding

4

Door

BF783B

BF

32

Page 446 of 548

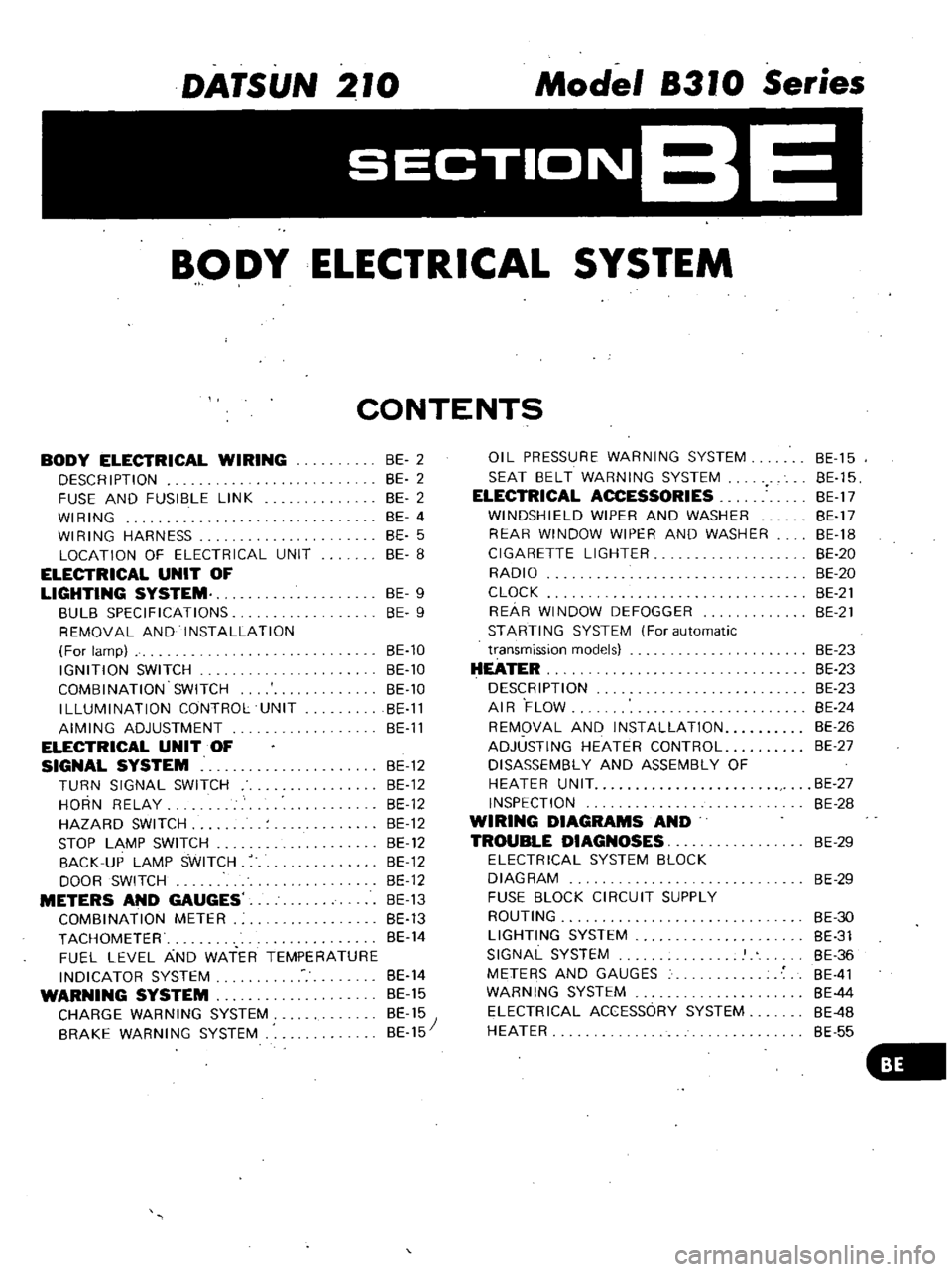

DATSUN

210

Model

8310

Series

SECTIONBE

BODY

ELECTRICAL

SYSTEM

CONTENTS

BODY

ELECTRICAL

WIRING

DESCRIPTION

FUSE

AND

FUSIBLE

LINK

WIRING

WIRING

HARNESS

LOCATION

OF

ELECTRICAL

UNIT

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

BULB

SPECIFICATIONS

REMOVAL

AND

INSTALLATION

For

lamp

IGNITION

SWITCH

COMBINATION

SWITCH

ILLUMINATION

CONTROL

UNIT

AIMING

ADJUSTMENT

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

BE

12

TURN

SIGNAL

SWITCH

BE

12

HORN

RELAY

BE

12

HAZARD

SWITCH

BE

12

STOP

LAMP

SWITCH

BE

12

BACK

UP

LAMP

SWITCH

BE

12

DOOR

SWITCH

BE

12

METERS

AND

GAUGES

BE

13

COMBINATION

METER

BE

13

TACHOMETER

BE

14

FUEL

LEVEL

AND

WATER

TEMPERATURE

INDICATOR

SYSTEM

BE

14

WARNING

SYSTEM

BE

15

CHARGE

WARNING

SYSTEM

BE

15

BRAKE

WARNING

SYSTEM

BE

15

BE

2

BE

2

BE

2

BE

4

BE

5

BE

8

BE

9

BE

9

BE

10

BE

10

BE

10

BE

11

BE

11

OIL

PRESSURE

WARNING

SYSTEM

SEAT

BELT

WARNING

SYSTEM

ELECTRICAL

ACCESSORIES

WINDSHIELD

WIPER

AND

WASHER

REAR

WINDOW

WIPER

AND

WASHER

CIGARETTE

LIGHTER

RADIO

CLOCK

REAR

WINDOW

DEFOGGER

STARTING

SYSTEM

For

automatic

transmission

models

HEATER

DESCRIPTION

AIR

FLOW

REMOVAL

AND

INSTALLATION

ADJUSTING

HEATER

CONTROL

DISASSEMBLY

AND

ASSEMBLY

OF

HEATER

UNIT

INSPECTION

WIRING

DIAGRAMS

AND

TROUBLE

DIAGNOSES

ELECTRICAL

SYSTEM

BLOCK

DIAGRAM

FUSE

BLOCK

CIRCUIT

SUPPLY

ROUTING

LIGHTING

SYSTEM

SIGNAL

SYSTEM

METERS

AND

GAUGES

WARNING

SYSTEM

ELECTRICAL

ACCESSORY

SYSTEM

HEATER

BE

15

BE

15

BE

17

BE

17

BE

18

BE

20

BE

20

BE

21

BE

21

BE

23

BE

23

BE

23

BE

24

BE

26

BE

27

BE

27

BE

28

BE

29

BE

29

BE

30

BE

31

BE

36

BE

41

BE

44

BE

4B

BE

55

Page 447 of 548

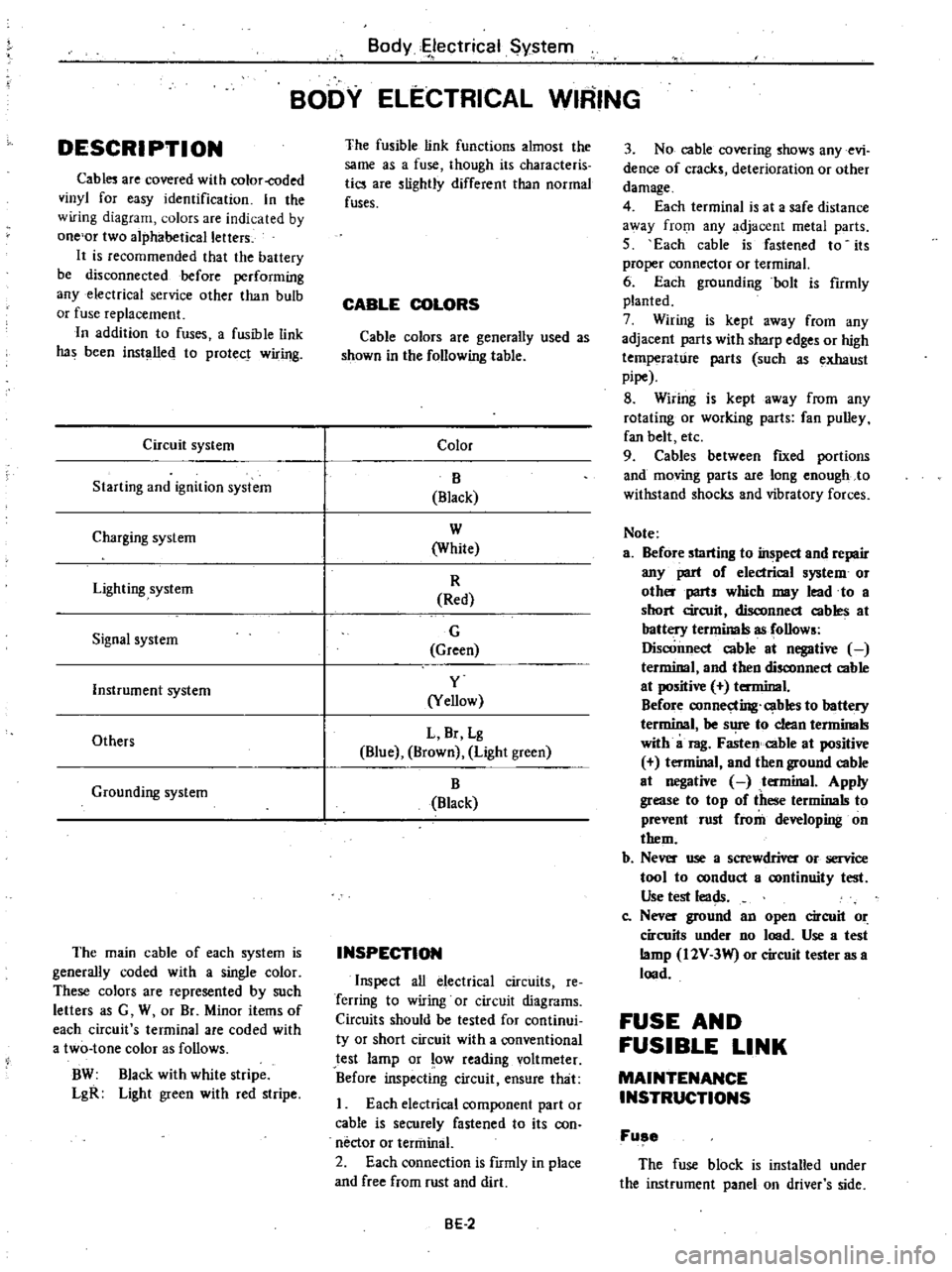

DESCRI

PTI

ON

Cabl

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

olors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

Circuit

system

Starting

and

ignition

system

Charging

system

Lighting

system

Signal

system

Instrument

system

Others

Grounding

system

The

main

cable

of

each

system

is

generally

coded

with

a

single

color

These

colors

are

represented

by

such

letters

as

G

W

or

Br

Minor

items

of

each

circuit

s

terminal

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

Body

ectrical

System

BODY

ELECTRICAL

WIRING

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

characteris

tics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

generally

used

as

shown

in

the

following

table

Color

B

Black

W

White

R

Red

G

Green

y

Yellow

L

Br

Lg

Blue

Brown

Light

green

B

Black

INSPECTION

Inspect

all

electrical

circuits

Ie

Terring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

continui

ty

or

short

circuit

with

a

conventional

test

lamp

or

low

reading

voltmeter

Before

inspecting

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

tenninal

2

Each

connection

is

fIrmly

in

place

and

free

from

rust

and

dirt

BE

2

3

No

cable

covering

shows

any

evi

dence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

3

Vay

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

6

Each

grounding

bolt

is

fumly

planted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

fIXed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Note

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

oth

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

s

1

to

clean

tenninals

with

a

rag

Fasten

cable

at

positive

t

minal

and

then

ground

cable

at

negative

tenninal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Ne

use

a

screwdriver

or

service

tool

to

oonduct

a

oontinuity

test

Use

test

leads

Co

Nev

ground

an

open

circuit

or

circuits

under

no

lood

Use

a

test

lamp

I2V

3W

or

circuit

tester

as

a

lood

FUSE

AND

FUSIBLE

LINK

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

driver

s

side

Page 450 of 548

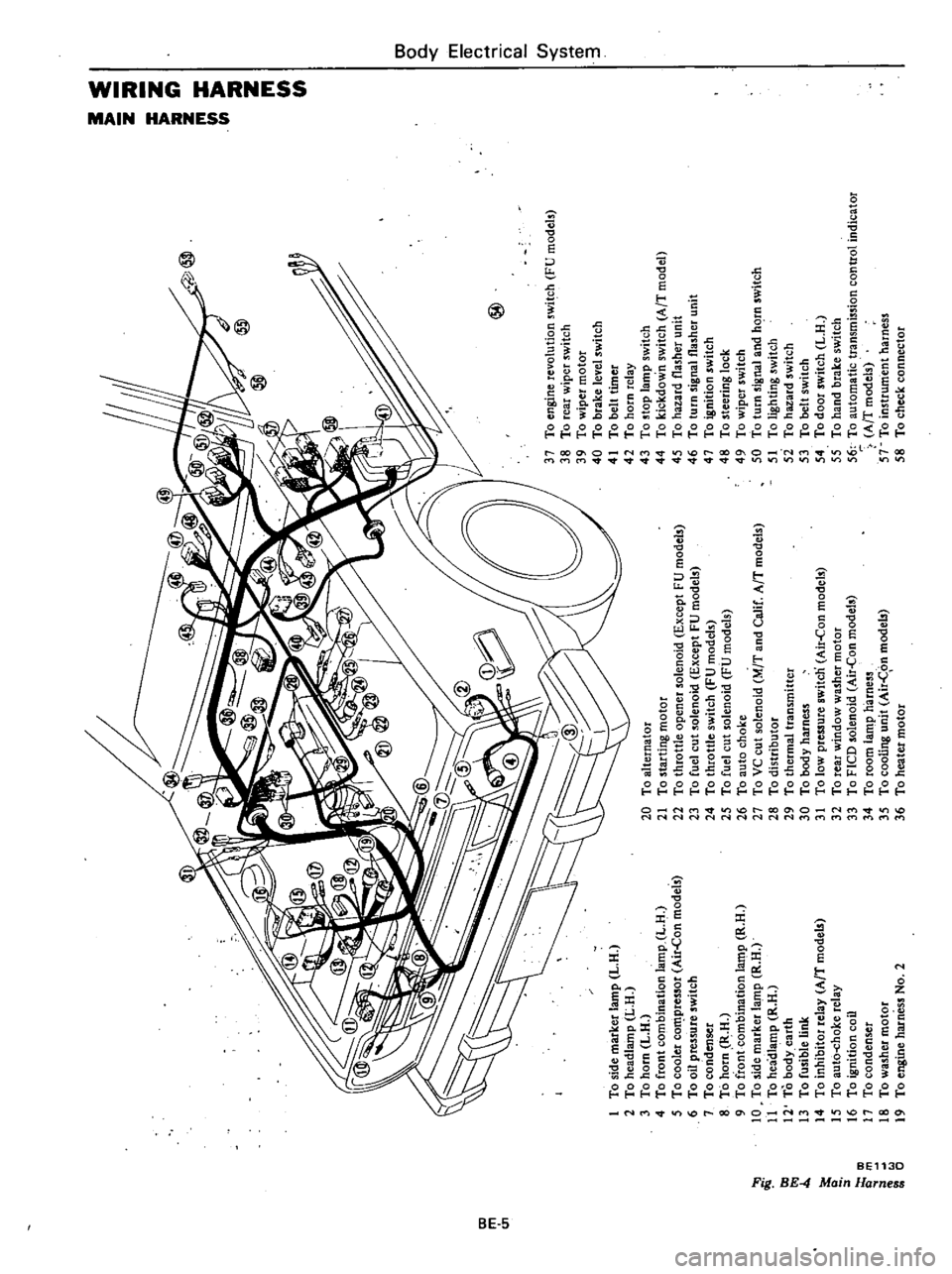

m

c

n

to

l

l

I

g

iF

0

1

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 453 of 548

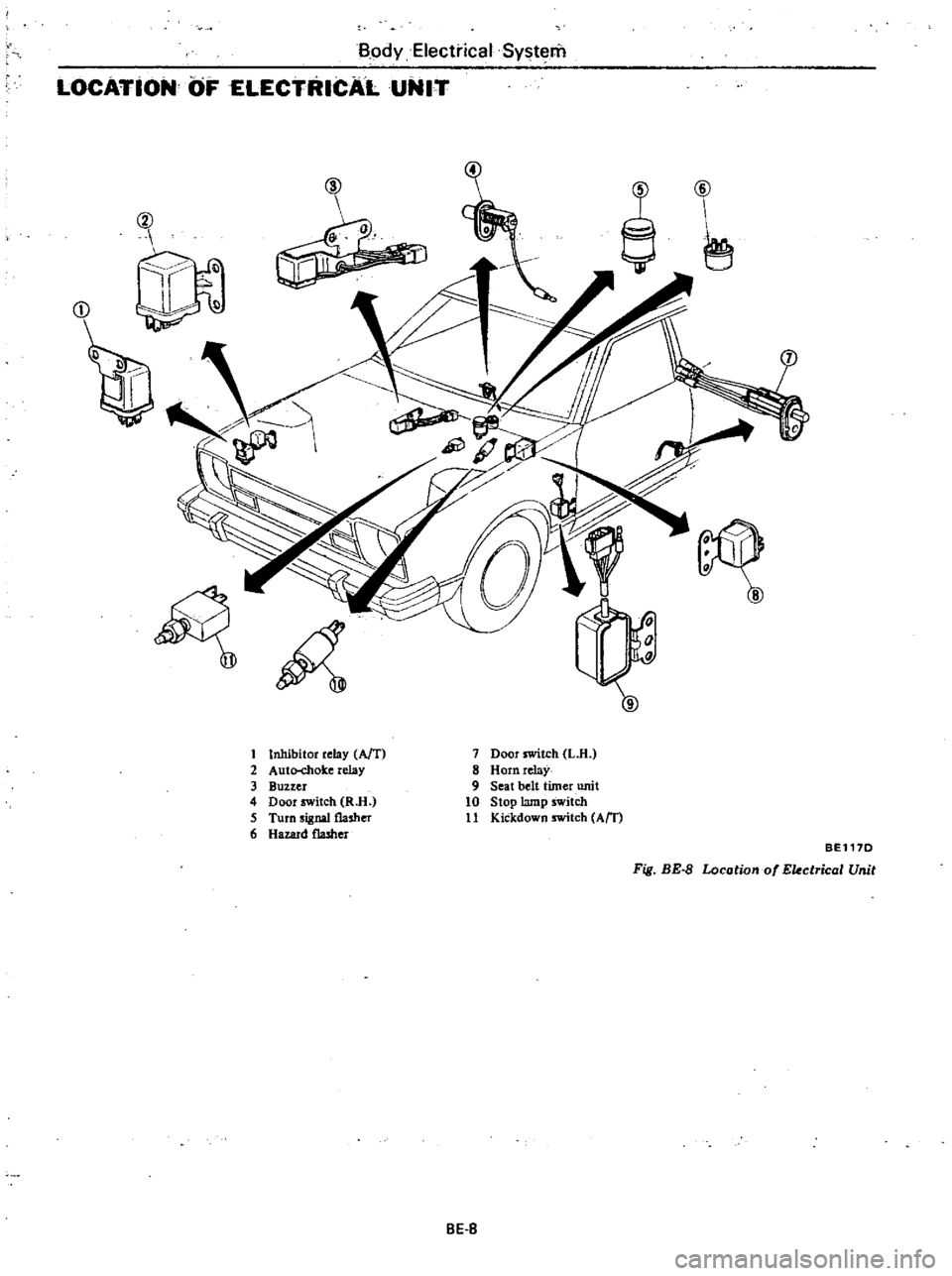

BodyElecti

ical

System

LOCATiON

OF

ELECTRICAL

UNIT

@

Q

J

r

J

D

t

Inhibitor

relay

AfT

2

Auto

chok

e

relay

3

Buzzer

4

Door

switch

RlI

5

Turn

signal

flasher

6

Hazard

flasher

7

Door

switch

L

H

8

Horn

relaY

9

Seat

belt

timer

unit

10

Stop

lamp

switch

11

Kickdown

switch

Am

BEl17D

Fig

BE

8

Locotiono

Ekctricol

Unit

BE

S