belt DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 454 of 548

Body

Electrical

System

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

CAUTION

Before

starting

to

work

on

any

part

of

electrical

system

disconnect

battery

ground

cable

BULB

SPECIFICATIONS

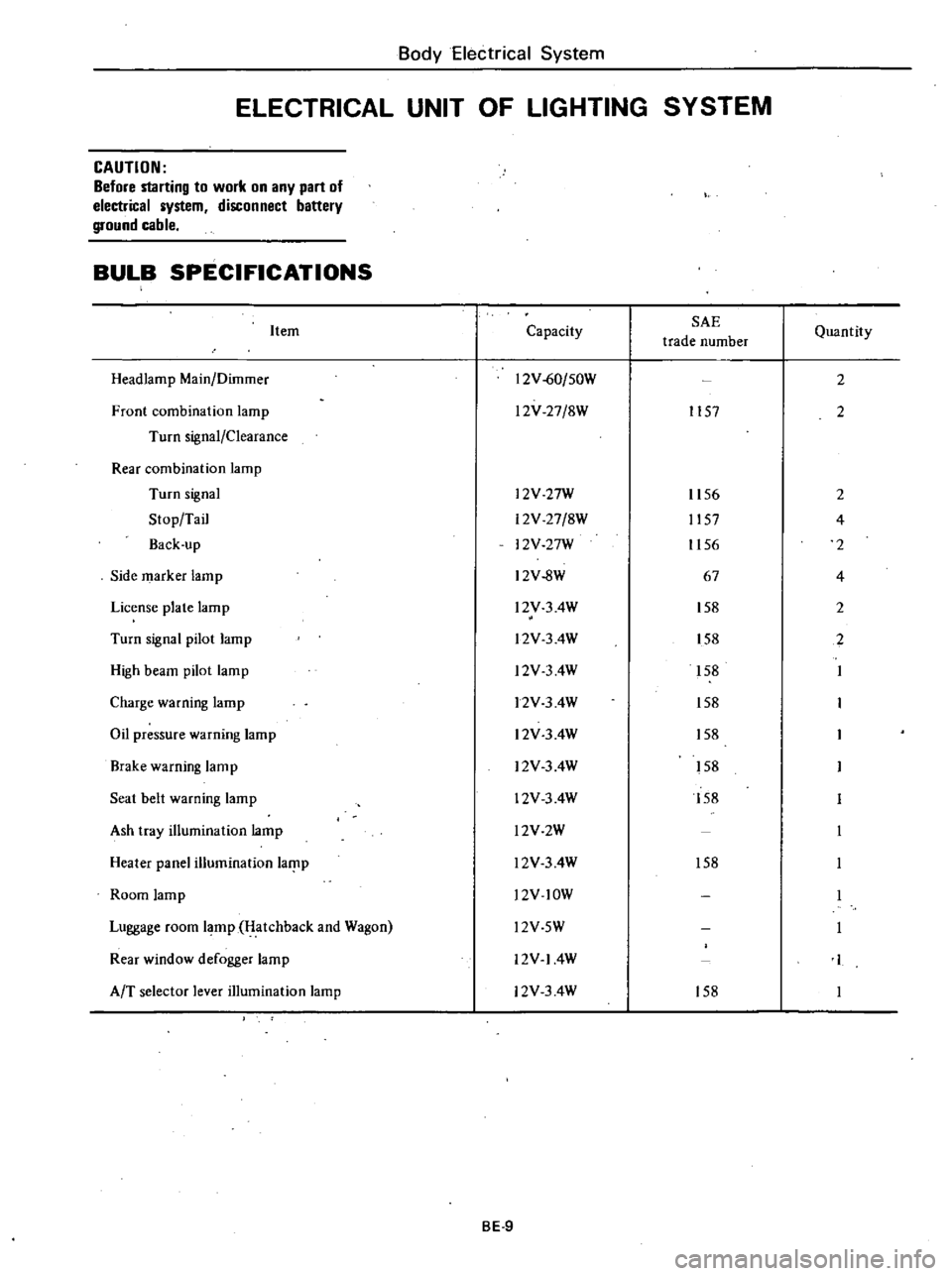

Item

Headlamp

Main

Dilnmer

Front

combination

lamp

Turn

signal

Clearance

Rear

combination

lamp

Turn

signal

Stop

Tail

Back

up

Side

marker

lamp

License

plate

lamp

Turn

signal

pilot

lamp

High

beam

pilot

lamp

Charge

warning

lamp

Oil

pressure

warning

lamp

Brake

warning

lamp

Seat

belt

warning

lamp

Ash

tray

illumination

lamp

Heater

panel

illumination

laf

lp

Room

lamp

Luggage

room

lamp

Hatchback

and

Wagon

Rear

window

defogger

lamp

AfT

selector

lever

illumination

lamp

Capacity

SAE

trade

number

12V

60

50W

l2V

27

8W

1157

l2V

27W

12V

27

8W

12V

27W

12V

8W

l2V

3

4W

l2V

3

4W

l2V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

l2V2W

l2V

3

4W

l2V

lOW

Quantity

2

2

1156

2

1157

4

1156

2

67

4

158

2

158

2

158

158

158

158

158

158

l2V

5W

12V

14W

12V

3

4W

158

BE

9

Page 460 of 548

CHARGE

WARNING

SYSTEM

Refer

to

Section

EE

BRAKE

WARNING

SYSTEM

REPLACEMENT

Hand

brake

switch

I

Disconnect

battery

ground

cable

2

Remove

console

box

if

equipped

3

Disconnect

hand

brake

switch

lead

wire

at

connector

4

Remove

switch

from

switch

bracket

by

pulling

it

5

Install

new

switch

in

the

reverse

order

of

removal

BE

177C

Fig

BE

23

Hand

Brake

Switch

Brake

fluid

level

switch

Brake

fluid

level

switch

is

buiit

into

brake

master

cylinder

cap

The

cap

can

be

easily

removed

by

twisting

it

after

disconnecting

lead

wire

terminals

Then

replace

it

OIL

PRESSURE

WARNING

SYSTEM

REPLACEMENT

011

pressure

switch

To

replace

oil

pressure

switch

dis

Body

Electrical

System

WARNING

SYSTEM

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

Oil

pressureswltch

BE247

Fig

BE

24

Oil

Pres5ure

Switch

@

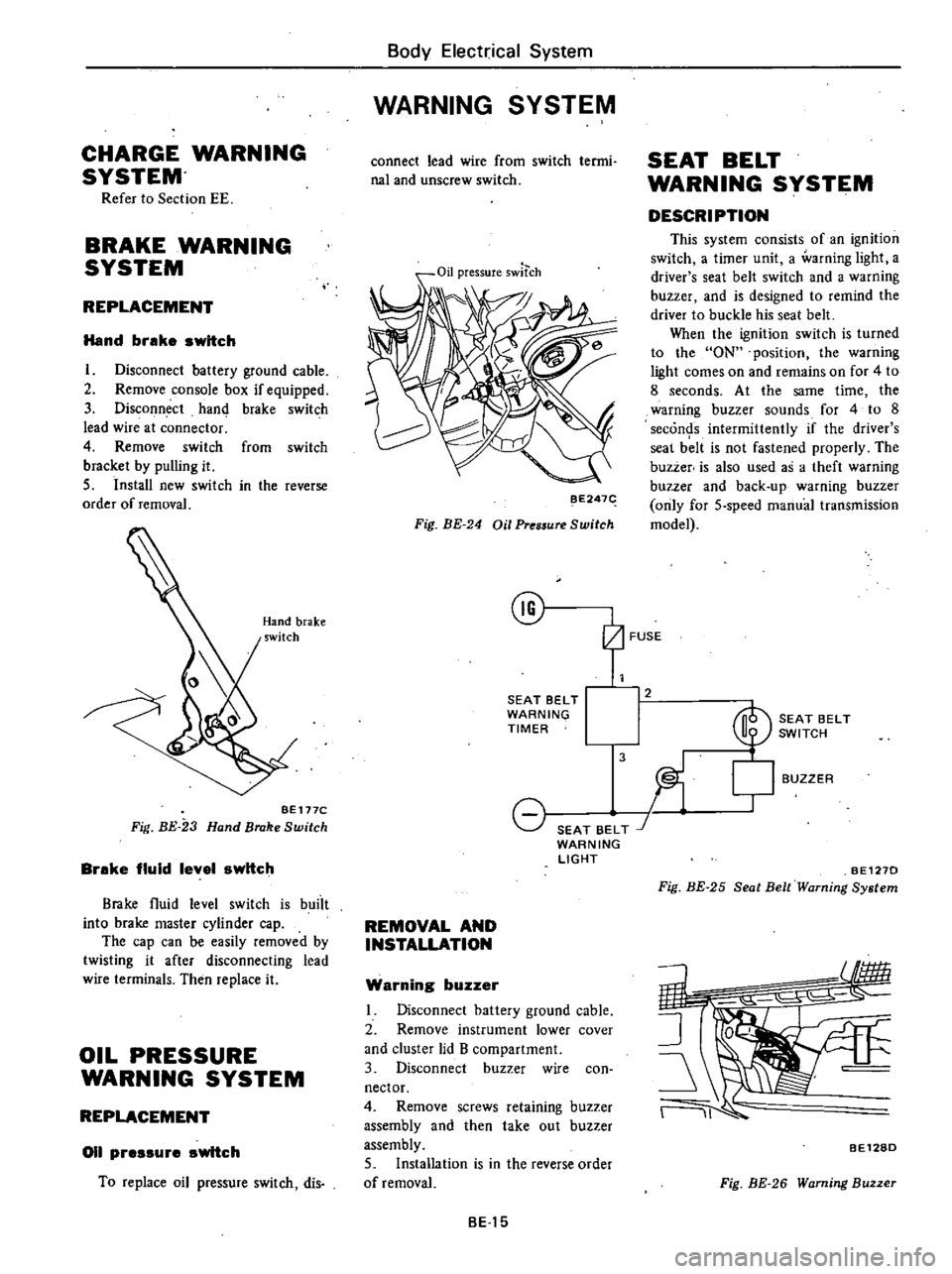

SEAT

BELT

WARNING

TIMER

8

SEAT

BELT

J

WARNING

LIGHT

REMOVAL

AND

INSTALLATION

Warning

buzzer

Disconnect

battery

ground

cable

2

Remove

instrument

lower

cover

and

cluster

lid

B

compartment

3

Disconnect

buzzer

wire

con

nector

4

Remove

screws

retaining

buzzer

assembly

and

then

take

out

buzzer

assembly

5

Installation

is

in

the

reverse

order

of

removal

BE15

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

This

system

consists

of

an

ignition

switch

a

timer

unit

a

warning

light

a

driver

s

seat

belt

switch

and

a

warning

buzzer

and

is

designed

to

remind

the

driver

to

buckle

his

seat

belt

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

light

comes

on

and

remains

on

for

4

to

8

seconds

At

the

same

time

the

warning

buzzer

sounds

for

4

to

8

seconds

intermittently

if

the

driver

s

seal

b

lt

is

not

fastened

properly

The

buzzer

is

also

used

as

a

theft

warning

buzzer

and

back

up

warning

buzzer

only

for

5

speed

manual

transmission

model

2

3

BUZZER

SEAT

BELT

SWITCH

l

BE1270

Fig

BE

25

Seat

Belt

Warning

System

11

BE128D

Fig

BE

26

Warning

Buzzer

Page 461 of 548

Seat

belt

wammg

timer

unit

1

Disconnect

battery

ground

cable

2

Remove

L

A

dash

side

finisher

3

Disconnect

b

arness

conn

ctor

4

Remove

timer

unit

attaching

screw

S

Install

timer

unit

in

the

everse

order

of

removal

BE1290

Fig

BE

27

Seat

Belt

Warning

Timer

Unit

Seat

belt

switch

I

Disconnect

battery

ground

cable

2

Slide

seat

all

the

way

forward

3

Disconnect

harness

connector

4

Remove

inner

seat

belt

by

re

moving

securing

bolt

5

Install

inner

seat

belt

in

the

re

verse

order

of

removal

BE31QC

Fig

BE

28

Driver

s

Inner

Seat

Belt

Body

Electrical

System

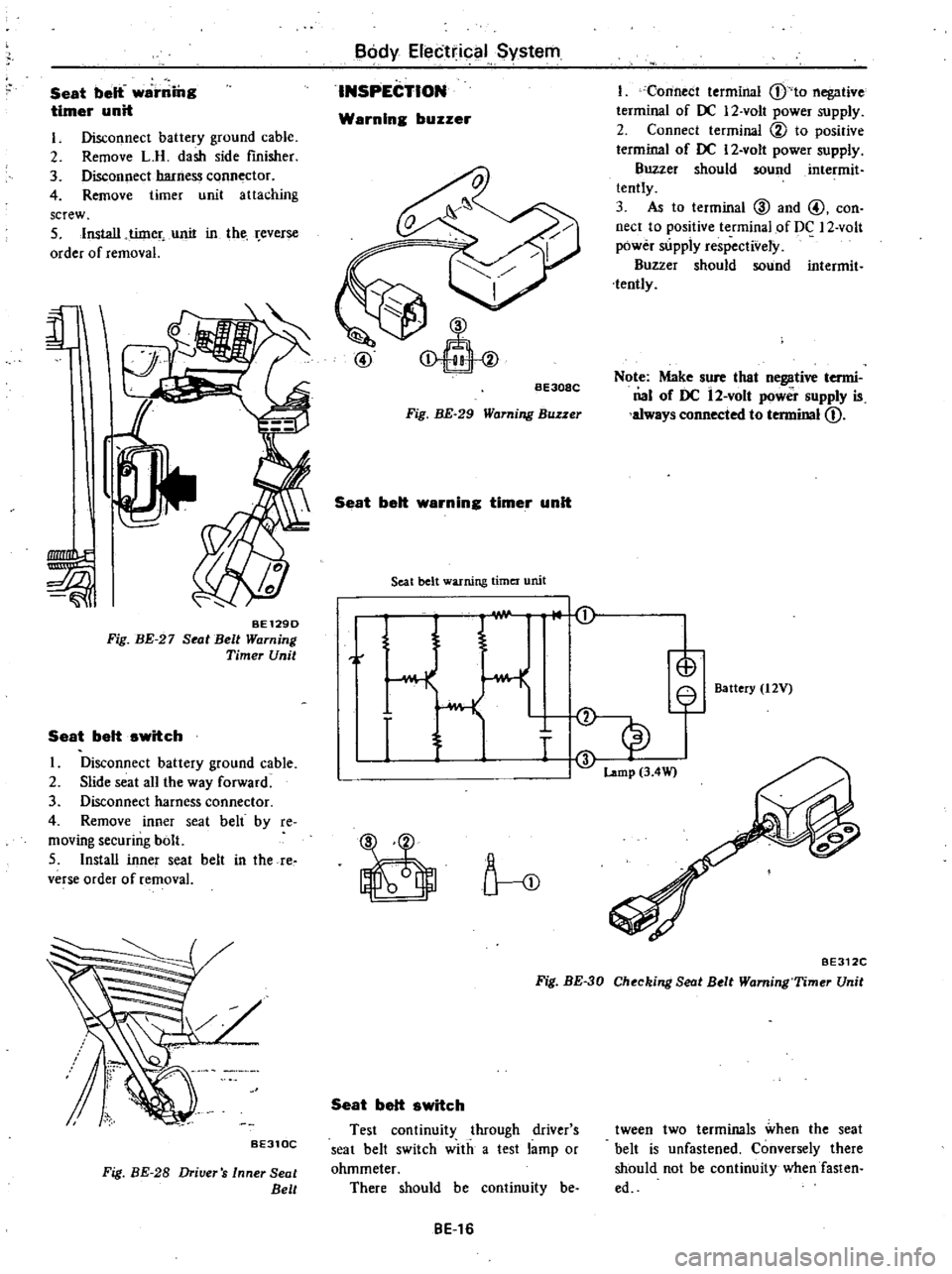

INSPECTION

Warning

buzzer

BE308C

Fig

BE

29

Warning

Buzzer

Seat

belt

warning

timer

unit

Seat

belt

warning

timer

unit

I

Y

o

j

r

tIT

I

Connect

terminal

j

to

negative

terminaI

of

DC

12

volt

power

supply

2

Connect

terminal

to

positive

terminal

of

DC

12

volt

power

supply

Buzzer

should

sound

intermit

tent

y

3

As

to

terminal

@

and

@

con

nect

to

positive

terminal

of

DC

12

volt

power

supply

respectively

Buzzer

should

sound

intermit

tently

Note

Make

sure

that

negative

termi

nal

of

DC

12

volt

power

supply

is

a1ways

connected

to

tenninal

CD

Q

e

Battery

t2V

Lamp

3

4W

BE312C

Fig

BE

30

Checking

Seat

Belt

Warning

Timer

Unit

Seat

belt

switch

Test

continuity

through

driver

s

seat

belt

switch

with

a

test

lamp

or

ohmmeter

There

should

be

continuity

be

BE

16

tween

two

terminals

when

the

seat

belt

is

unfastened

Conversely

there

should

not

be

continuity

when

fasten

ed

Page 475 of 548

WIPER

MOTOR

WINDSHIELD

WASHER

MOTOR

REAR

WIPER

MOTOR

REAR

WINDOW

WASHER

MOTOR

m

w

o

HORN

CIGARETTE

LIGHTER

CLOCK

HAZARD

FLASHER

LAMP

STOP

LAMP

ROOM

LAMP

LUGGAGE

ROOM

LAMP

TAIL

LAMP

CLEARANCE

LAMP

LICENSE

PLATE

LAMP

COMBINATION

METER

LAMP

l

I

ll

6

C

l

ii

en

g

0

o

m

till

oill

l

I

t1

l

CO

l

m

l

m

0

z

t

15A

10A

14

fA

20A

16

T

r

t1

l

t1

l

CO

CO

CJ

CJ

1

1

m

m

0

0

z

z

HEATER

lAIR

CONDITIONER

ENGINE

REVOLUTION

SWITCH

FUEL

CUT

SOLENOID

VACUUM

CUT

SOLENOID

AUTO

CHOKE

HEATER

THROTTLE

OPENER

SOLENOID

TURN

SIGNAL

LAMP

GAUGE

I

FUEL

L

WATER

TEMPERATURE

WARNING

LAMP

BRAKE

CHARGE

OIL

PRESSURE

SEAT

BELT

WARNING

BUZZER

BACK

UP

LAMP

KICKDOWN

SOLENOID

TACHOMETER

REAR

DEFOGGER

f

c

It

1

1

m

g

II

n

a

n

c

It

c

1J

c

CIl

z

G

S

3

OJ

o

Cl

m

CD

In

Ql

Page 490 of 548

m

l

U1

ii

I

ll

cio

i

t

s

a

Cl

t

m

l

e

BATTERY

8

GtG

ug

ew

FUSIBLE

LINK

BELT

TIMER

I

i

DD

l

J

G

if

I

lOCI

OffIACCI

aNI

Sf

I

0

0

8

i

i

16

I

S

IGNITION

SWITCH

FUSE

BLOCK

B

0

lOA

G

L

BL

ORIVER

S

BELT

SWITCH

tl

WARNING

LAMP

iP

aB

ij

II

VB

L

I

81

WB

I

t

OI

00

00

0

0

B

B

B

B

feB

WARNING

BUZZER

III

e

IIll

a

I

III

Z

i

C

OJ

o

Cl

m

CD

n

o

Q

CIl

en

l

3

Page 492 of 548

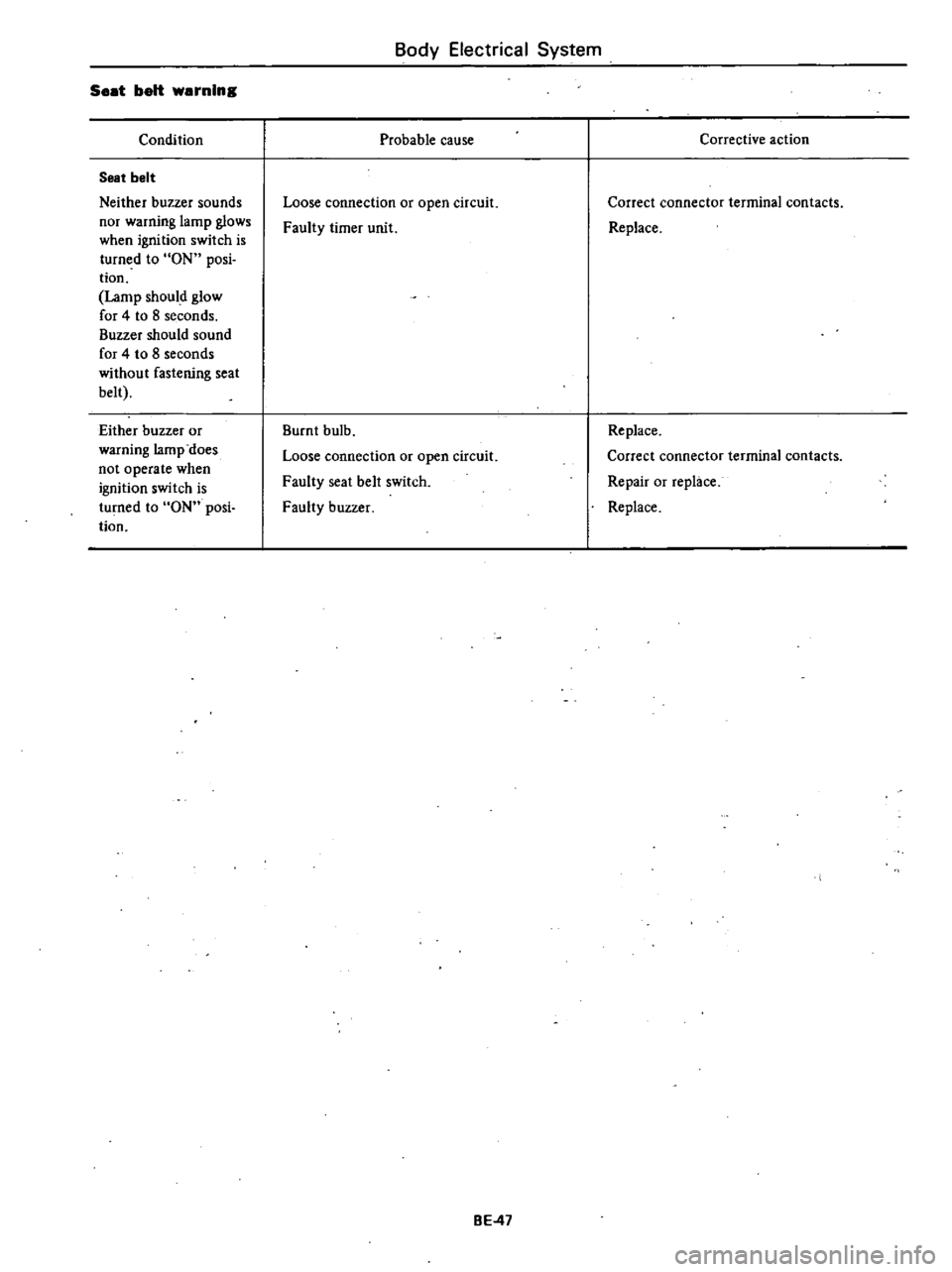

Seat

belt

warning

Condition

Seat

belt

Neither

buzzer

sounds

nor

warning

lamp

glows

when

ignition

switch

is

turned

to

ON

posi

tion

Lamp

should

glow

for

4

to

8

seconds

Buzzer

should

sound

for

4

to

8

seconds

without

fastening

seat

belt

Either

buzzer

or

warning

lamp

does

not

operate

when

ignition

switch

is

turned

to

ON

posi

tion

Body

Electrical

System

Probable

cause

Loose

connection

or

open

circuit

Faulty

timer

unit

Burnt

bulb

Loose

connection

or

open

circuit

Faulty

seat

belt

switch

Faulty

buzzer

BE

47

Corrective

action

Correct

connector

terminal

contacts

Replace

Replace

Correct

connector

terminal

contacts

Repair

or

replace

Replace

Page 502 of 548

DATSUN

210

Model

8310

Series

SECTIONAC

AIR

CONDITIONING

CONTENTS

DESCRIPTION

OUTLINE

OF

AIR

CONDITIONER

REFRIGERATION

SYSTEM

AIR

FLOW

VACUUM

SYSTEM

ELECTRICAL

CIRCUIT

GENERAL

SERVICE

REFRIGERANT

R

12

COMPRESSOR

OIL

MAINTENANCE

GENERAL

SERVICE

INSTRUCTIONS

SAFETY

PRECAUTIONS

EVACUATING

AND

CHARGING

SYSTEM

CHECKI

NG

FOR

LEAKS

REFRIGERANT

LEVEL

CHECK

COMPRESSOR

OIL

LEVEL

OHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

SERVICE

PROCEDURES

FAST

IDLE

ACTUATOR

IDL

E

PULLEY

AND

COMPRESSOR

DRIVE

BELT

COMPR

ESSOR

CONDENSER

RECEIV

ER

DRIER

REFRIGERANT

LINES

I

COOLING

UNIT

EXPANSION

VALVE

THERMOSTAT

MAIN

RELAY

HEATER

UNIT

WATER

COCK

AC

2

AC

2

AC

3

AC

5

AC

6

AC

7

AC

9

AC

9

AC

9

AC

9

AC

9

AC

9

AC

1

AC14

AC15

AC

17

AC17

AC17

AC18

AC1B

AC19

AC19

AC

20

AC

20

AC

21

ACc21

AC

22

AC

22

AC

23

AC

23

AC

23

BLOWER

MOTOR

RESISTOR

AIR

CONDITIONER

CONTROL

FAN

SWITCH

MICROSWITCH

LOW

PRESSURE

SWITCH

MAGNET

VALVE

FUSE

REPLACEMENT

VACUUM

HOSE

DIAGRAM

WIRING

DIAGRAM

COMPRESSOR

MODEL

SC206

PRELIMINARY

CLEANING

COMPRESSOR

CLUTCH

SHAFT

SEAL

CYLINDER

HEAD

AND

VALVE

PLATE

DISCHARGE

AND

sU

CTiON

CONNECTORS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

AIR

CONDITIONER

DIAGNOSES

BLOWER

MOTOR

DIAGNOSES

COMPRESSOR

DIAGNOSES

COMPRESSOR

CLUTCH

DIAGNOSES

VACUUM

SYSTEM

DIAGNOSES

PERFORMANCE

TEST

DIAGNOSES

PERFORMANCE

CHART

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

SPECIAL

SERVICE

TOOLS

AC

23

AC

23

AC

23

AC

23

AC23

AC

24

AC

24

AC24

AC

24

AC

25

AC

26

AC

27

AC

27

AC

28

AC30

AC30

AC32

AC

32

AC

33

AC34

AC35

AC36

AC37

AC

41

AC

42

AC

42

AC

42

AC

43

AC

44

Page 504 of 548

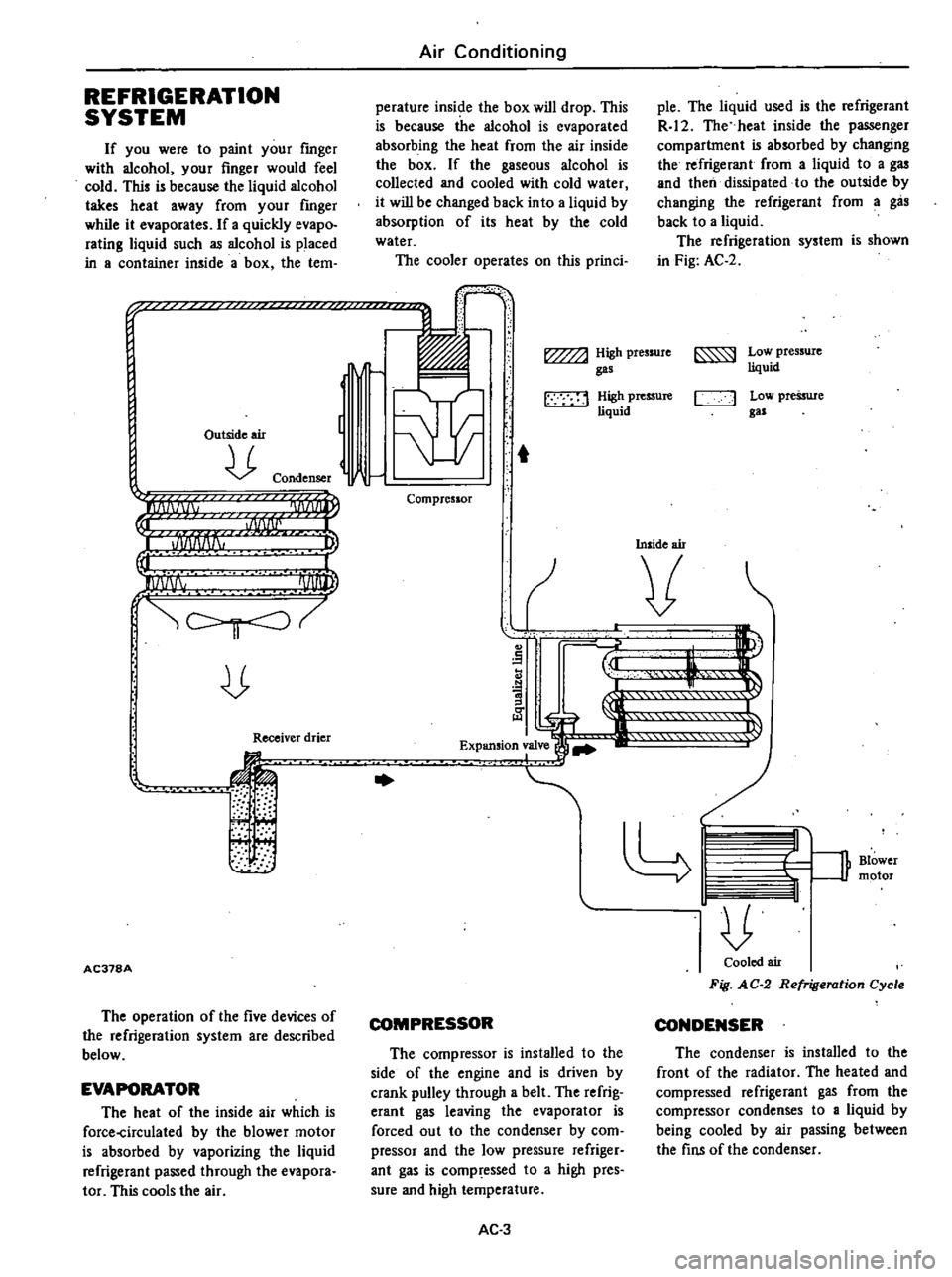

REFRIGERATION

SYSTEM

If

you

were

to

paint

your

rmger

with

alcohol

your

finger

would

feel

cold

This

is

because

the

liquid

alcohol

takes

heat

away

from

your

rmger

while

it

evaporates

If

a

quickly

evapo

rating

liquid

such

as

alcohol

is

placed

in

a

container

inside

a

box

the

tern

Air

Conditioning

perature

inside

the

box

will

drop

This

is

because

the

alcohol

is

evaporated

absorbing

the

heat

from

the

air

inside

the

box

If

the

gaseous

alcohol

is

collected

and

cooled

with

cold

water

it

will

be

changed

back

into

a

liquid

by

absorption

of

its

heat

by

the

cold

water

The

cooler

operates

on

this

princi

1

r

I

Outside

air

U

Condenser

r

lf

P

9

n

U

Receiver

drier

AC378A

The

operation

of

the

five

devices

of

the

refrigeration

system

are

described

below

EVAPORATOR

The

heat

of

the

inside

air

which

is

force

irculated

by

the

blower

motor

is

absorbed

by

vaporizing

the

liquid

refrigerant

passed

through

the

evapora

tor

This

cools

the

air

l

t

High

pressure

gas

I

High

pressure

liquid

Compressor

Jj

COMPRESSOR

The

compressor

is

installed

to

the

side

of

the

engine

and

is

driven

by

crank

pulley

through

a

belt

The

refrig

erant

gas

leaving

the

evaporator

is

forced

out

to

the

condenser

by

com

pressor

and

the

low

pressure

refriger

ant

gas

is

compressed

to

a

high

pres

sure

and

high

temperature

AC3

pie

The

liquid

used

is

the

refrigerant

R

12

The

heat

inside

the

passenger

compartment

is

absorbed

by

changing

the

refrigerant

from

a

liquid

to

a

gas

and

then

dissipated

to

the

outside

by

changing

the

refrigerant

from

a

gas

back

to

a

liquid

The

refrigeration

system

is

shown

in

Fig

AC

2

Low

pressure

liquid

C

J

Low

pressure

gas

Inside

air

v

n

Blower

1f

motor

Cooled

air

Fig

AC

2

Refrigeration

Cycle

CONDENSER

The

condenser

is

installed

to

the

front

of

the

radiator

The

heated

and

compressed

refrigerant

gas

from

the

compressor

condenses

to

a

liquid

by

being

cooled

by

air

passing

between

the

fins

of

the

condenser

Page 510 of 548

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

Note

Exercise

care

when

handling

re

frigerant

as

it

is

stored

under

high

pressure

COMPRESSOR

OIL

The

SUNISO

5GS

refrig

ration

lubricant

should

be

used

to

assure

the

successful

compressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrica

tion

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

MAINTENANCE

The

following

checks

and

main

tenance

are

especially

important

to

the

air

conditioner

I

Check

refrigerant

level

2

Check

refrigerant

leaks

3

Check

compressor

drive

belt

for

proper

deflection

4

Even

in

the

off

season

turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

GENERAL

SERVICE

INSTRUCTIONS

If

dirt

water

or

air

enters

the

air

conditioner

system

it

will

be

seriously

affected

Be

sure

to

observe

the

following

I

Always

keep

the

working

place

clean

and

dry

and

free

from

dirt

and

Air

Conditioning

GENERAL

SERVICE

dust

Wipe

water

off

from

the

line

fittings

with

a

clean

cloth

before

dis

connecting

2

Have

all

necessary

tools

in

prepar

ation

beforehand

and

have

tools

clean

and

dry

3

Handling

plug

when

the

system

line

is

disconnected

4

Handling

compressor

oil

For

details

refer

to

each

descrip

tion

in

this

manual

SAFETY

PRECAUTIONS

WARNING

1

Since

direct

contact

of

the

liquid

refrigerant

with

your

skin

will

cause

frostbite

always

be

carelul

when

handling

the

refrigerant

Always

wear

goggles

to

protect

your

eyes

when

working

around

the

system

2

The

refrigerant

service

container

has

a

safe

strength

However

if

handled

incorrectly

it

will

ex

plode

Therelore

always

follow

the

instructions

On

the

label

In

particular

never

store

it

in

a

hot

location

above

520e

1260F

or

drop

it

from

a

high

height

3

The

refrigerant

gas

is

odorless

and

colorless

and

breathing

may

become

difficult

due

to

the

lack

of

oxygen

Since

the

relrigerant

gas

is

heavier

than

air

and

will

lay

close

to

the

floor

be

espe

cially

careful

when

handling

it

in

small

confined

spaces

4

The

refrigerant

itself

is

nonflam

mable

However

a

toxic

gas

phosgene

gas

is

produced

when

it

contacu

fire

and

special

care

is

therefore

required

when

check

ing

for

leaks

in

the

system

with

a

halide

torch

5

Do

not

steam

clean

On

the

sys

tem

especially

condenser

since

excessively

high

pressure

will

build

up

in

the

system

resulting

in

explosion

of

the

system

The

above

precautions

are

essen

tial

in

handling

of

Refrigerant

12

and

their

strict

observation

AC

9

requires

sufficient

training

Therefore

it

is

of

first

impor

tance

that

any

other

personnel

than

a

well

trained

serviceman

should

not

be

allowed

to

handle

the

refrigerant

EVACUATING

AND

CHARGING

SYSTEM

During

servicing

use

caution

to

keep

air

from

getting

into

refrigerant

When

air

enters

the

system

all

refriger

ant

must

be

evacuated

from

system

prior

to

charging

new

refrigerant

Air

in

refrigerant

has

the

following

delete

rious

effects

1

Since

the

condensation

tempera

ture

of

the

air

is

extremely

low

the

air

will

not

be

condensed

when

refrigerant

gas

is

condensed

in

the

condenser

and

the

air

will

thus

remain

in

gaseous

fonn

Consequently

the

effective

thermal

transmission

area

of

condenser

for

refrigerant

gas

will

be

reduced

and

refrigerant

gas

to

be

condensed

will

be

reduced

The

pressure

rise

will

become

proportional

to

the

volume

of

the

air

in

system

2

When

air

and

refrigerant

are

r

tixed

in

system

a

chemical

reaction

will

be

produced

and

hydrochloric

acid

which

will

adversely

affect

the

aluminum

copper

iron

and

other

materials

in

system

may

be

generated

HANDLING

MANIFOLD

GAUGE

The

pressure

at

the

high

and

low

sides

of

system

should

be

measured

when

evacuating

and

charging

refrig

erant

and

when

diagnosing

trouble

in

the

system

The

manifold

gauge

is

used

for

these

purposes

A

manifold

gauge

has

two

pressure

gauges

a

low

pressure

gauge

and

a

high

pressure

gauge

These

gauges

are

connected

to

the

high

and

low

side

service

valves

of

system

through

flexible

charging

hoses

The

construction

of

manifold

gauge

is

Page 520 of 548

Air

Conditioning

IDLER

PULLEY

AND

COMPRESSOR

DRIVE

BELT

ADJ

USTMENT

OF

BELT

TENSION

Idler

pulley

Alternator

Crankshaft

pulley

Unit

mm

in

Idler

pulley

Fig

AC

25

Belt

Tension

Specified

compressor

belt

tension

is

8

to

12

mm

0

31

to

0

47

in

when

thumb

pressure

of

10

kg

22

Ib

is

applied

midway

between

idler

pulley

and

compressor

pulley

1

Loosen

idler

pulley

lock

nut

and

then

adjust

pulley

by

turning

adjusting

bolt

2

After

adjustment

tighten

idler

pulley

lock

nut

bolt

3

Remove

idler

pulley

4

Install

pulley

in

the

reverse

order

of

removal

5

Adjust

compressor

belt

tension

REMOVAL

AND

INSTALLATION

1

Jack

up

front

of

car

and

remove

under

cover

2

Remove

idler

pulley

lock

nut

and

loosen

belt

tension

adjusting

Fig

AC26

AC382A

Idler

Pulley

TIghtening

torque

@

3

7

to

5

1

kg

m

27

to

37

ft

lb

AC383A

Fig

AC

27

Compressor

and

Bracket

AC

19

REMOVAL

I

Operate

compressor

if

possible

at

engine

idling

speed

with

air

condi

tioner

controls

set

for

maximum

cool

ing

and

high

blower

speed

for20

to

30

minutes

with

all

windows

open

to

return

oil

into

compressor

2

Disconnect

battery

ground

cables

and

compressor

lead

wire

at

con

nector

3

Discharge

refrigerant

from

cool

ing

system

Refer

to

Discharging

Sys

tem

4

Jack

up

front

of

car

and

remove

under

cover

5

Loosen

idler

pulley

lock

nut

and

loosen

tension

adjusting

bolt

fully

Remove

compressor

drive

belt

See

Fig

AC

26

6

Remove

high

and

low

flexible

hoses

from

compressor

WARNING

Gradually

loosen

discharge

side

hose

fitting

and

remove

it

after

remaining

pressure

has

been

re

leased

CAUTION

Be

sure

to

immediately

put

plug

in

flexible

hose

and

compressor

open

ings

7

Remove

bolts

securing

lower

part

of

compressor

8

Remove

bolts

securing

upper

part

of

compressor

Hold

compressor

with

one

hand

when

removing

bolts

and

then

remove

compressor

With

compressor

clutch

up

lift

compressor

out

with

both

hands

CAUTION

00

not

attempt

to

leave

the

com

pressor

on

its

side

or

upside

down

for

more

than

10

minutes

as

the

compressor

oil

will

enter

the

low

pressure

chambers

If

under

that

condition

compressor

should

be

oper

ated

suddenly

internal

damage

would

result

To

expel

oil

from

chambers

hand

crank

compressor

several

times

in

its

installed

condition