manual transmission DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 84 of 548

u

V

O

I

MAX

Ii

1i

i

iT

1

I

I

11

1

i

MINij

o

f

G

p

rl

MAX

ii

i

p

It

ot

MINi

II

L

Cooling

System

l

CQ074

Pressure

relief

valve

opens

f

C007S

Vacuum

valve

opens

INSPECTION

1

Check

the

amount

of

coolant

in

the

reservoir

tank

If

the

coolant

level

is

below

the

MIN

level

remove

the

re

servoirtank

ruler

cap

and

add

enough

oolant

to

reach

MAX

level

If

the

reservoir

tank

is

empty

check

the

coolantlevel

in

the

radiator

If

the

coolant

in

the

radiator

is

insuf

ficient

pour

it

into

radiator

up

to

the

radiator

cap

and

also

pour

it

into

the

reservoir

tank

until

MAX

level

If

the

coolant

in

the

reservoir

tank

d

ecreases

abnormally

rapid

check

for

a

leak

in

the

cooling

system

REMOVAL

AND

INSTALLATION

1

Reservoir

tank

is

only

inserted

to

reservoir

tank

bracket

and

can

be

easily

removed

To

install

reservoir

tank

reverse

the

order

of

remova

Fig

CO

12

Opefation

of

ReserVoir

Tank

SERVICE

DATA

AND

SPECIFICATIONS

Thermostat

Valve

opening

temperature

Oc

OF

Maximum

valve

lift

mmjOC

in

oF

Radiator

Type

Manual

transmission

Automatic

tralUJ1lission

Cap

relief

pressure

kg

cm2

psi

Testing

pressure

kg

cm

2

psi

Fan

Fan

belt

deflection

mm

in

cO

6

Temperate

type

Frigid

type

Tropical

type

82

180

88

190

76

5

I

70

8

95

8

loo

8

90

0

3

I

203

0

31j2

i

2

0

31

194

Corrugated

fm

type

Corrugated

fm

type

equipped

with

oil

cooler

0

9

I

3

1

6

23

8

to

12

0

31

to

0

47

Page 95 of 548

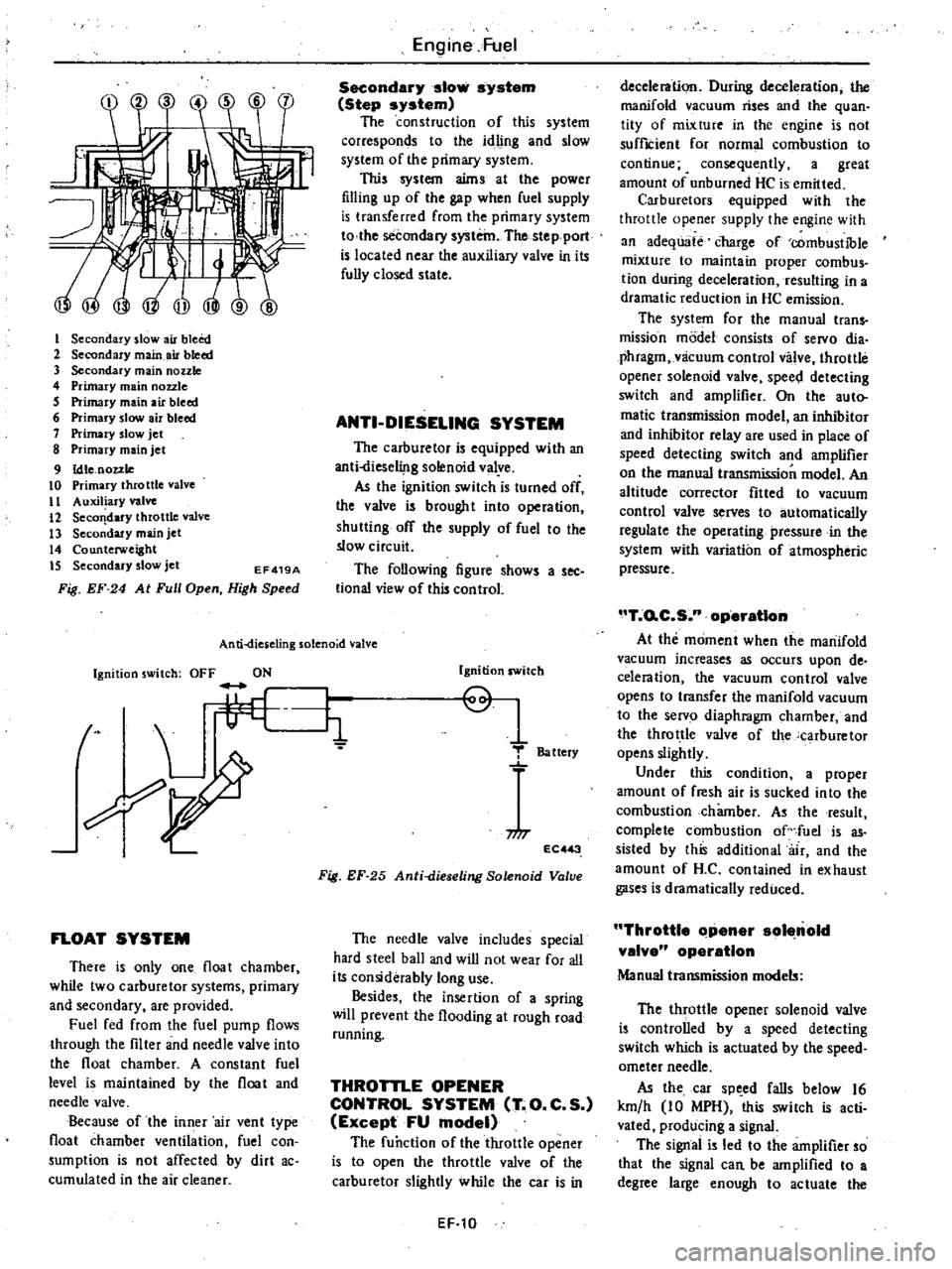

I

Secondary

slow

air

bleed

2

Secondary

main

air

bleed

3

Secondary

main

nozzle

4

Primary

main

nozzle

5

Primary

main

air

bleed

6

Primary

slow

air

bleed

7

Primary

slow

jet

8

Primary

main

jet

9

Idle

nozzle

10

Primary

throttle

valve

II

Auxiliary

valve

12

Seco

dary

throttle

valve

13

Secondary

main

jet

14

Counterweight

IS

Secondary

slow

jet

EF419A

Fig

EF

24

At

Full

Open

High

Speed

Engine

Fuel

Secondary

slow

system

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

stepport

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

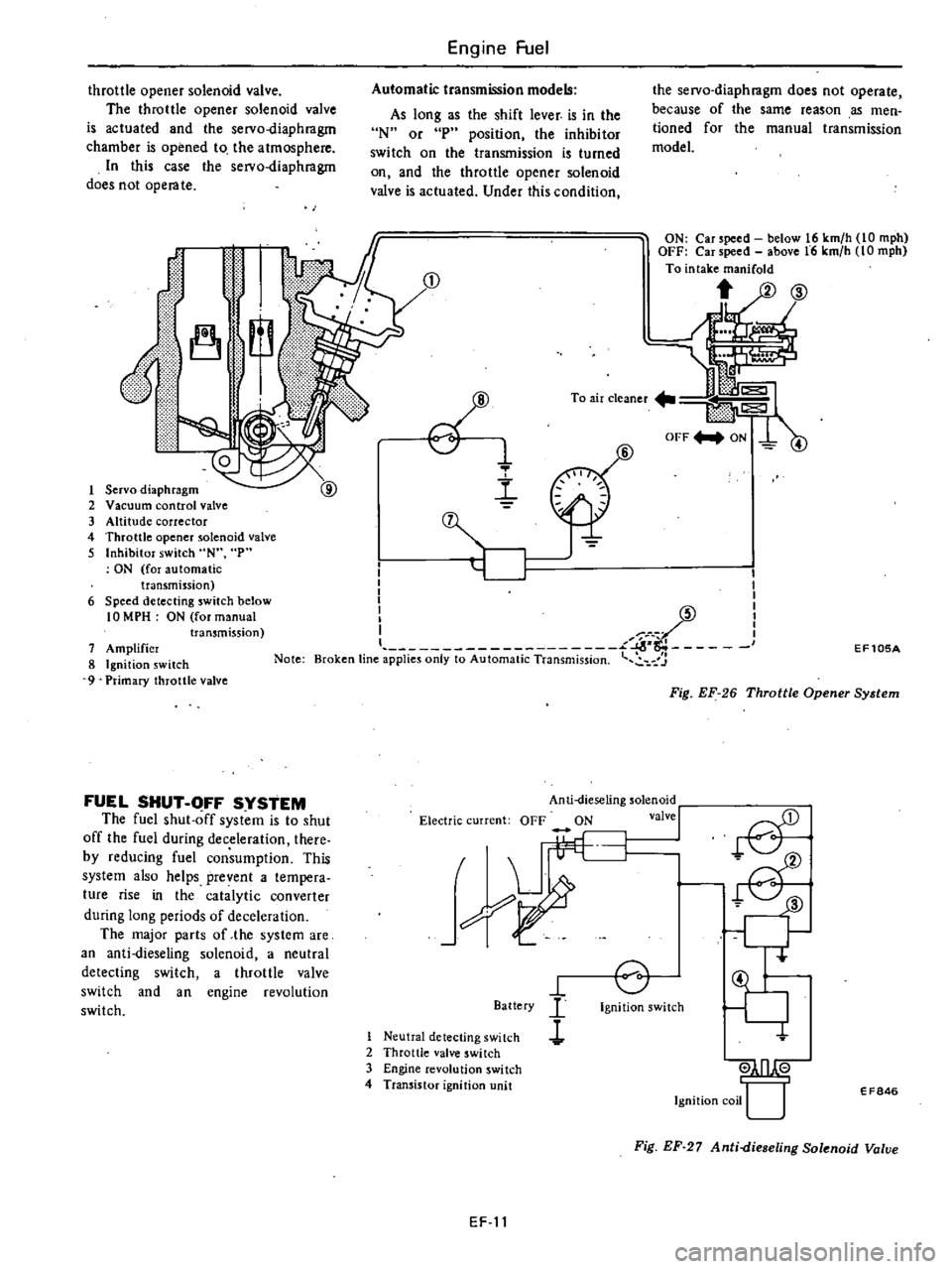

ANTI

DIESELING

SYSTEM

The

carburetor

is

equipped

with

an

anti

liese1i

lg

solenoid

valye

As

the

ignition

switch

is

turned

off

the

valve

is

brought

into

operation

shutting

off

the

supply

of

fuel

to

the

slow

circuit

The

following

figure

shows

a

see

tional

view

of

this

control

An

ti

dies

eling

solenoid

valve

Ignition

switch

OFF

ON

t

L

li

FLOAT

SYSTEM

There

is

only

one

float

chamber

while

two

carburetor

systems

primary

and

secondary

are

provided

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

Because

of

the

inner

air

vent

type

float

chamber

ventilation

fuel

con

sumption

is

not

affected

by

dirt

ac

cumulated

in

the

air

cleaner

Ignition

switch

Q

1

T

Battery

niT

EC

3

Fig

EF

25

Anti

dieseling

Solenoid

Valve

The

needle

valve

includes

special

hard

steel

ball

and

wiD

not

wear

for

all

its

considerably

long

use

Besides

the

insertion

of

a

spring

will

prevent

the

flooding

at

rough

road

running

THROTTLE

OPENER

CONTROL

SYSTEM

T

O

C

S

Except

FU

model

The

function

of

the

throttle

opener

is

to

open

the

throttle

valve

of

the

carburetor

slightly

while

the

car

is

in

EF

10

deceleration

During

deceleration

the

manifold

vacuum

rises

and

the

quan

tity

of

mixture

in

the

engine

is

not

suffICient

for

normal

combustion

to

continue

4

consequently

a

great

amount

of

unburned

HC

is

emitted

Carburetors

equipped

with

the

throttle

opener

supply

the

engine

with

an

adequate

charge

of

combustible

mixture

to

maintain

proper

combus

tion

during

deceleration

resulting

in

a

dramatic

reduction

in

HC

emission

The

system

for

the

manual

trans

mission

model

consists

of

servo

dia

phragm

vlicuum

control

valve

throttle

opener

solenoid

valve

spee

l

detecting

switch

and

amplifier

On

the

auto

matic

transmission

model

an

inhibitor

and

inhibitor

relay

are

used

in

place

of

speed

detecting

switch

and

amplifier

on

the

manual

transmission

model

An

altitude

corrector

fitted

to

vacuum

control

valve

serves

to

automatically

regulate

the

operating

pressure

in

the

system

with

variation

of

atmospheric

pressure

T

o

C

S

n

operatIon

At

the

moment

when

the

manifold

vacuum

increases

as

occurs

upon

de

celeration

the

vacuum

control

valve

opens

to

transfer

the

manifold

vacuum

to

the

servo

diaphragm

chamber

and

the

throttle

valve

of

the

carburetor

opens

slightly

Under

this

condition

a

proper

amount

of

fresh

air

is

sucked

into

the

combustion

chamber

As

the

result

complete

combustion

of

fuel

is

as

sisted

by

this

additional

air

and

the

amount

of

H

C

contained

in

exhaust

gases

is

dramatically

reduced

Throttle

Clpener

sol

nold

valve

operation

Manual

transmission

models

The

throttle

opener

solenoid

valve

is

controlled

by

a

speed

detecting

switch

which

is

actuated

by

the

speed

ometer

needle

As

the

car

sp

ed

falls

below

16

km

h

10

MPH

this

switch

is

acti

vated

producing

a

signal

The

signal

is

led

to

the

amplifier

so

that

the

signal

can

be

amplified

to

a

degree

large

enough

to

actuate

the

Page 96 of 548

throttle

opener

solenoid

valve

The

throttle

opener

solenoid

valve

is

actuated

and

the

servo

diaphragm

chamber

is

opened

to

the

atmosphere

In

this

case

the

seIVo

diaphragm

does

not

opera

te

Engine

Fuel

Automatic

transmission

models

As

long

as

the

shift

lever

is

in

the

N

or

p

position

the

inhibitor

switch

on

the

transmission

is

turned

on

and

the

throttle

opener

solenoid

valve

is

actuated

Under

this

condition

the

seIVo

diaphragm

does

not

operate

because

of

the

same

reason

as

men

tioned

for

the

manual

transmission

model

ON

Car

peed

betow

t6

km

h

to

mph

OFF

Car

peed

above

16

km

h

to

mph

To

intake

manifold

j

lJl

11

1

ti

i

ljn

L

o

1

Servo

diaphragm

2

Vacuum

control

valve

3

Altitude

corrector

4

Throttle

opener

solenoid

valve

5

Inhibitor

switch

N

p

ON

for

automatic

transmission

6

Speed

detecting

switch

below

10

MPH

ON

for

manual

transmission

7

Amplifier

8

Ignition

switch

9

Primary

throttle

valve

Note

FUEL

SHUT

OFF

SYSTEM

The

fuel

shut

off

system

is

to

shut

off

the

fuel

during

deceleration

there

by

reducing

fuel

consumption

This

system

also

helps

prevent

a

tempera

ture

rise

in

the

catalytic

converter

during

long

periods

of

deceleration

The

major

parts

of

the

system

are

an

anti

dieseling

solenoid

a

neutral

detecting

switch

a

throttle

valve

switch

and

an

engine

revolution

switch

e

1

l

6

I

I

I

I

I

I

I

I

I

l

L

I

Broken

tine

applies

only

to

Automatic

Transmission

7

Anti

dieseling

solenoid

Electric

current

OFF

ON

valve

I

I

h

L

Battery

I

Neutral

detecting

switch

l

2

Throttle

valve

switch

3

Engine

revolution

switch

4

Transistor

ignition

unit

o

Ignition

switch

EF105A

Fig

EF

26

Throttle

Opener

System

ill

Ignition

coil

U

EF846

Fig

EF

27

Anti

dieseling

Solenoid

Valve

EF

11

Page 100 of 548

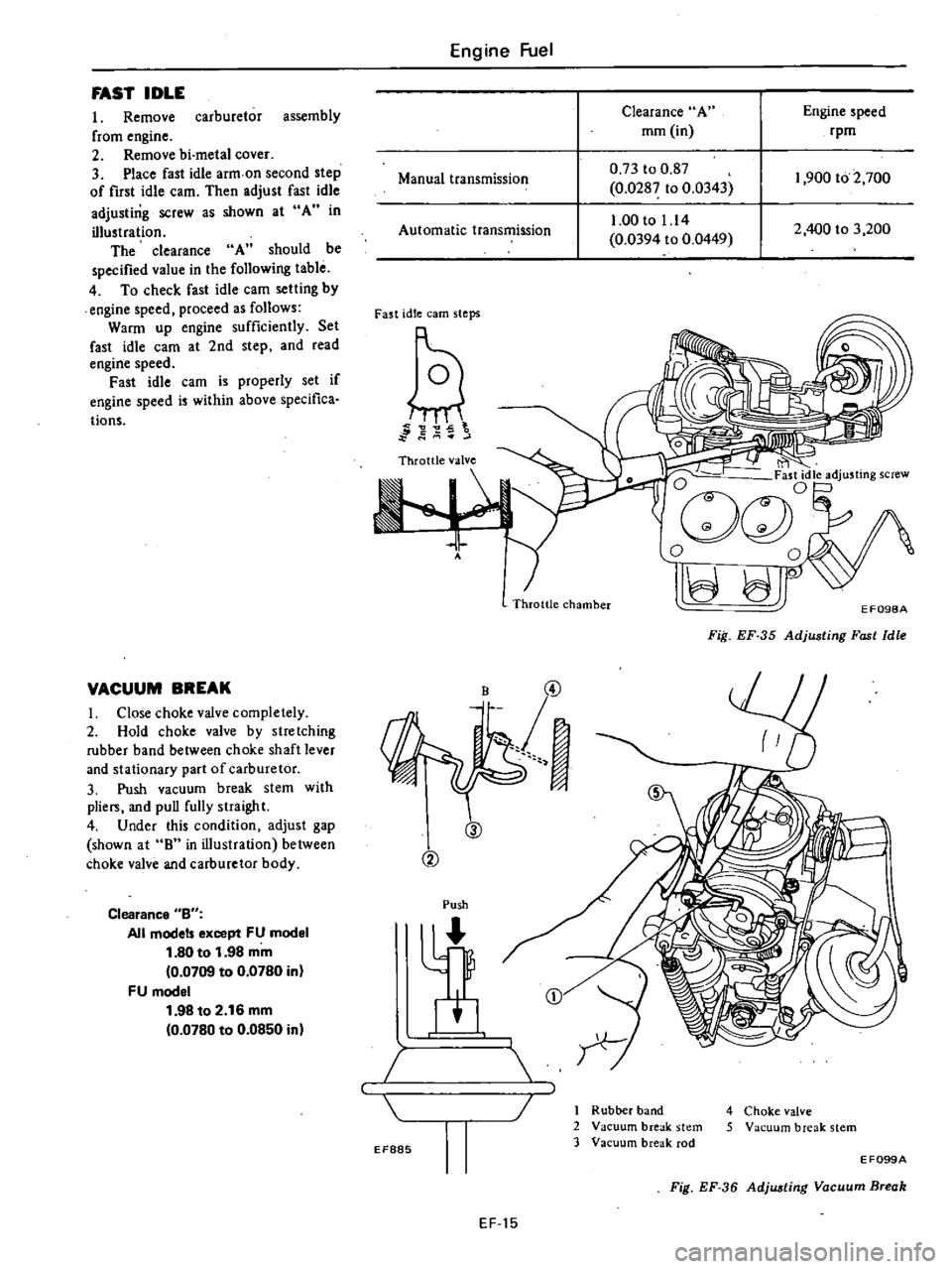

FAST

IDLE

I

Remove

carburetor

assembly

from

engine

2

Remove

bi

metal

cover

3

Place

fast

idle

arm

on

second

step

of

first

idle

cam

Then

adjust

fast

idle

adjusting

screw

as

shown

at

A

in

illustration

The

clearance

A

should

be

specified

value

in

the

following

table

4

To

check

fast

idle

cam

setting

by

engine

speed

proceed

as

follows

Warm

up

engine

sufficiently

Set

fast

idle

cam

at

2nd

step

and

read

engine

speed

Fast

idle

cam

is

properly

set

if

engine

speed

is

within

above

specifica

Hons

VACUUM

BREAK

I

Close

choke

valve

completely

2

Hold

choke

valve

by

stretching

rubber

band

between

choke

shaft

lever

and

stationary

part

of

carburetor

3

Push

vacuum

break

stem

with

plie

and

puD

fully

straight

4

Under

this

condition

adjust

gap

shown

at

8

in

illustration

between

choke

valve

and

carburetor

body

Clearance

Bu

All

model

except

FU

model

1

80

to

1

98

mm

0

0709

to

0

0780

in

FU

model

1

98

to

2

16

mm

0

0780

to

0

0850

in

Engine

Fuel

Clearance

A

mm

in

Engine

speed

rpm

Manual

transmission

0

73

to

0

87

0

0287

to

0

0343

1

00

to

1

14

0

0394

to

0

0449

2

400

to

3

200

1

900

to

2

700

Automatic

transmission

Fast

idle

earn

steps

g

g

2

5

t

to

J

A

ti

Ogc

j

jdle

adjusting

screw

o

0

II

r

Throttle

chamber

EF098A

Fiil

EF

35

Adjusting

Fast

Idle

@

B

@

cv

Push

I

4

Choke

valve

5

Vacuum

break

stem

EF885

1

Rubber

band

2

Vacuum

break

stem

3

Vacuum

break

rod

E

F099A

Fig

EF

36

Adjwtirig

Vacuum

Break

EF

15

Page 103 of 548

Engine

Fuel

Upon

completion

of

adjustment

make

sure

that

link

system

opera

tes

smoothly

It

is

necessary

to

remove

Carburetor

from

engine

in

adjusting

this

accelera

tor

pump

stroke

limiter

1

Remove

carburetor

from

engine

2

Insert

a

l

l

to

I

S

mm

0

043

to

0

059

in

feeler

gauge

a

piece

of

round

stock

of

proper

thickness

is

best

betwee

l

primary

ca

buretor

throat

and

throtile

valve

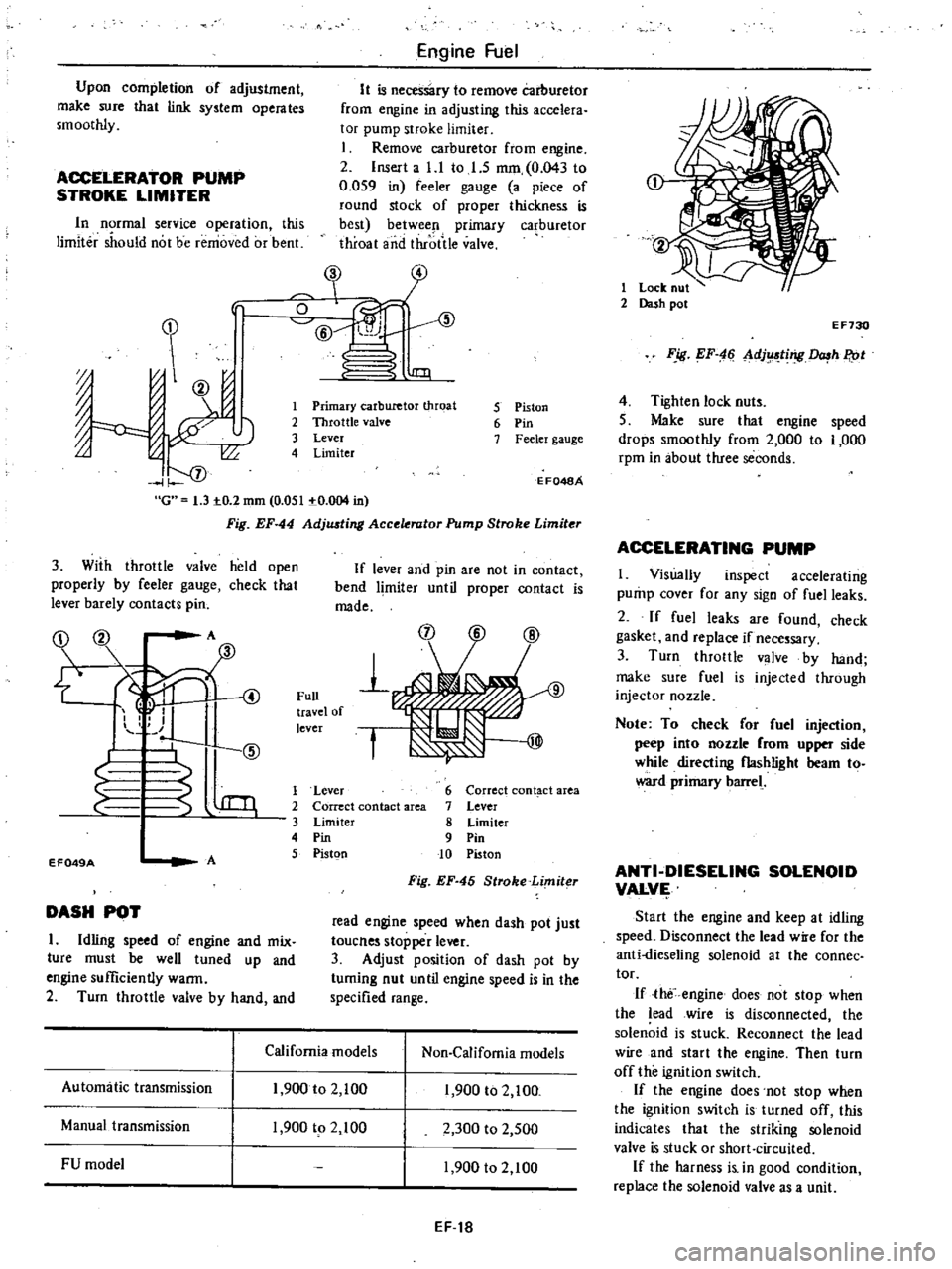

ACCELERATOR

PUMP

STROKE

LIMITER

In

rmal

service

operation

this

limiter

should

not

be

removed

or

bent

In

J

0

ID

@

l

1IJl

J

J

00

I

f

oj

G

1

3

IO

2

mm

0

051

IO

004

in

Fig

EF

44

AdjlUting

Acce

rator

Pump

Stroke

Limiter

1

Primary

carburetor

throat

2

Throttle

valve

3

Lever

4

Limiter

5

Piston

6

Pin

7

Feeler

gauge

E

F048A

3

With

throttle

valve

held

open

properly

by

feeler

gauge

check

that

lever

barely

contacts

pin

If

lever

and

pin

are

not

in

contact

bend

limiter

until

proper

contact

is

made

OZ

00

A

fID

1

S

@

4

1

Full

travel

of

lever

f

EF049A

A

1

Lever

2

Correct

contact

area

3

Limiter

4

Pin

5

Pistgn

6

Correct

cont

ct

area

7

Lever

8

Limiter

9

Pin

10

Piston

Fig

EF

45

Stroke

Limiter

DASH

POT

I

Idling

speed

of

engine

and

mix

ture

must

be

well

tuned

up

and

engine

sufficiently

warm

2

Turn

throttle

valve

by

hand

and

read

engine

speed

when

dash

pot

just

toucnes

stopper

lever

3

Adjust

position

of

dash

pot

by

tuming

nut

until

engine

speed

is

in

the

specified

range

California

models

Non

Califomia

models

Automatic

transmission

1

900

to

2

100

1

900

to

2

100

Manual

transmission

1

900

tp

2

100

2

300

to

2

500

FU

model

1

900

to

2

100

EF

t8

1

Lock

nut

2

Dash

pot

E

F730

F

ig

EF

4

Ll

dj

ting

h

P

ot

4

Tighten

lock

nuts

5

Make

sure

that

engine

speed

drops

smoothly

from

2

000

to

1

000

rpm

in

about

three

seconds

ACCELERATING

PUMP

I

Visually

inspect

accelerating

pump

cover

for

any

sign

of

fuel

leaks

2

If

fuel

leaks

are

found

check

gasket

and

replace

if

necessary

3

Turn

throttle

valve

by

hand

make

sure

fuel

is

injected

through

injector

nozzle

Note

To

check

or

fuel

injection

peep

into

nozzle

rom

upper

side

while

directing

flashlight

beam

to

ward

primary

barrel

ANTI

DIESELING

SOLENOID

VALVI

Start

the

engine

and

keep

at

idling

speed

Disconnect

the

lead

w

e

for

the

anti

dieseling

solenoid

at

the

connec

tor

If

the

engine

does

not

stop

when

the

lead

wire

is

disconnected

the

solenoid

is

stuck

Reconnect

the

lead

wire

and

start

the

engine

Then

turn

off

the

ignition

switch

If

the

engine

does

not

stop

when

the

ignition

switch

is

turned

off

this

indicates

that

the

striking

solenoid

valve

is

stuck

or

short

circuited

If

the

harness

i

in

good

condition

replace

the

solenoid

valve

as

a

unit

Page 104 of 548

1

Ignition

switch

2

Amplifier

3

Speed

switch

Note

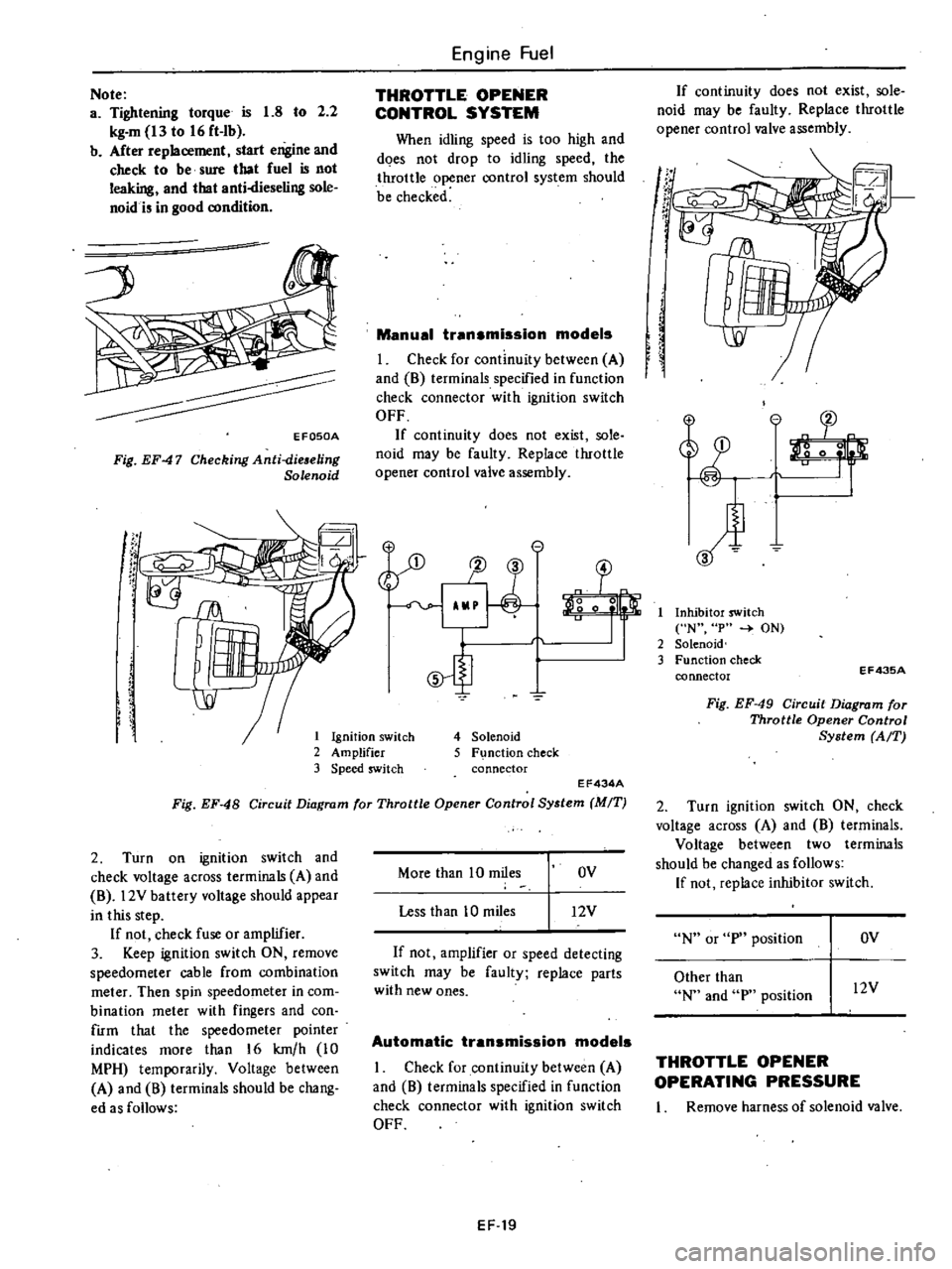

a

Tightening

torque

is

1

8

to

2

2

kg

m

13

to

16

ft

Ib

b

After

replacement

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

sole

noid

i

in

good

condition

EFOSOA

Fig

EF47

Checking

Anti

dieaeling

Solenoid

l

SJ

Engine

Fuel

THROTTLE

OPENER

CONTROL

SYSTEM

When

idling

speed

is

too

high

and

does

not

drop

to

idling

speed

the

throttle

opener

control

system

should

be

checked

Manual

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

e

1J

3

o

0

5

4

Solenoid

5

F

nction

check

connector

EF434A

Fig

EF

48

Circuit

Diagram

for

Throttle

Opener

Control

System

MIT

2

Turn

on

ignition

switch

and

check

voltage

across

terminals

A

and

8

l2V

battery

voltage

should

appear

in

this

step

If

not

check

fuse

or

amplifier

3

Keep

ignition

switch

ON

remove

speedometer

cable

from

combination

meter

Then

spin

speedometer

in

com

bination

meter

with

fingers

and

con

firm

that

the

speedometer

pointer

indicates

more

than

16

km

h

10

MPH

temporarily

Voltage

between

A

and

8

terminals

should

be

chang

ed

as

follows

More

than

10

miles

OV

Less

than

10

miles

12V

If

not

amplifier

or

speed

detecting

switch

may

be

faulty

replace

parts

with

new

ones

Automatic

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

EF

19

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

If

t

r

If

I

Inhibitor

switch

N

p

ON

2

Solenoid

3

Function

check

connector

EF43SA

Fig

EF

49

Circuit

Diagram

for

Throttle

Opener

Control

System

AfT

2

Turn

ignition

switch

ON

check

voltage

across

A

and

8

terminals

Voltage

between

two

terminals

should

be

changed

as

follows

If

not

replace

inhibitor

switch

N

or

p

position

OV

Other

than

N

and

p

position

l2V

THROTTLE

OPENER

OPERATING

PRESSURE

I

Remove

harness

of

solenoid

valve

Page 105 of 548

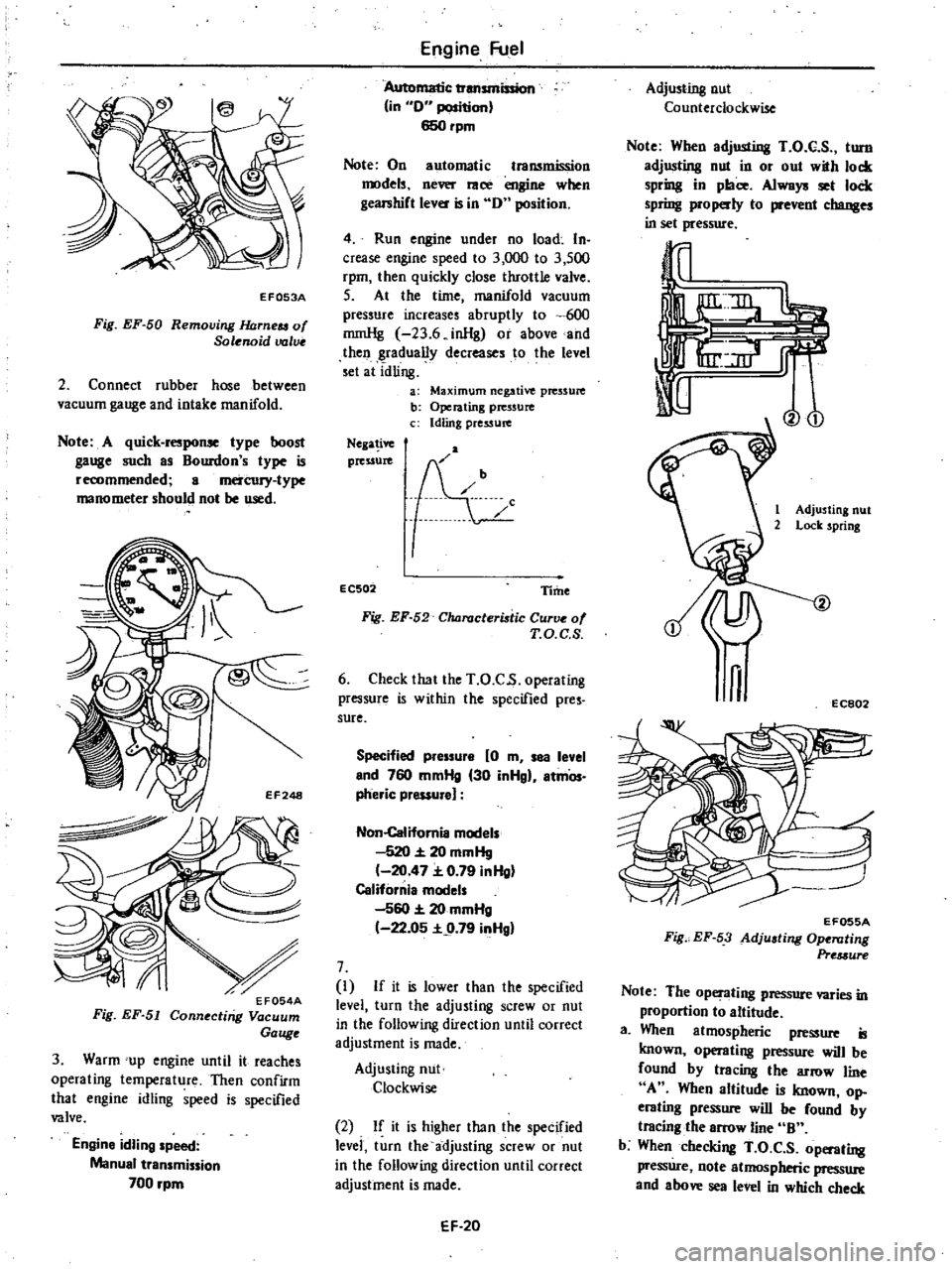

EF053A

Fig

EF

50

Removing

JWrneu

of

Solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

Note

A

quick

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

3

Warm

up

engine

until

it

reaches

operating

temperature

Then

confirm

that

engine

idling

speed

is

specified

valve

Engine

idling

speed

Manual

transmission

700

rpm

Engine

Fuel

Automatic

transmission

in

0

position

650rpm

Note

On

automatic

transmission

models

never

race

engine

when

gearshift

lever

is

in

0

position

4

Run

engine

under

no

load

In

crease

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

S

At

the

time

manifold

vacuum

pressure

increases

abruptly

to

600

rnmHg

23

6

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

a

Maximum

negative

pressure

b

Operating

pressure

c

Idling

pressure

Nega

ive

pressure

EC502

Time

Fig

EF

52

Characteristic

Curve

of

T

O

C

S

6

Check

that

the

T

O

C

s

operating

pressure

is

within

the

specified

pres

sure

Specified

pressure

0

m

sea

level

end

760

mmHg

30

inHgl

atmOs

pheric

pressure

Non

Califomia

models

520

20

mmHg

20

47

0

79

inHg

California

models

560

20

mmHg

22

05

9

79

inHgl

7

I

If

it

is

lower

than

the

specified

level

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

Adjusting

nut

Clockwise

2

If

it

is

higher

than

the

specified

levei

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

EF

20

Adjusting

nut

Counterclockwise

Note

When

adjusting

T

O

C

S

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

properly

to

prevent

changes

in

set

pressure

Vo

1

Adjusting

nut

2

Lock

spring

n

EC802

EF055A

Fig

EF

53

Adjusting

Ope

llting

Pre

3ure

Note

The

operating

pressure

varies

in

proportion

to

altitude

a

When

atmospheric

pressure

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

A

When

altitude

is

known

op

erating

pressure

will

be

found

by

tracing

the

arrow

line

B

b

When

checking

T

O

C

S

operating

pressure

note

atmospheric

pressure

and

above

sea

level

in

which

check

Page 117 of 548

Engine

Fuel

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

CARBURETOR

California

models

Non

caJ

ifornia

model

Manual

tranlDlWion

Automatic

transmission

Manual

transmission

FU

model

utomatic

transmission

Type

DCH306

6t

DCH306

63

DCH306

60E

DCH306

67

DCH306

68

3

DCH306

69

1

DCH306

60

2

DCH306

12

4

Primary

Secondary

Primary

Secondary

Primuy

Secondary

Primary

Secondary

Primary

Secondary

Outer

diameter

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

mm

in

Venturi

diameter

23

0

9t

27

1

06

23

0

91

27

1

06

23

0

91

27

1

06

22

0

87

27

1

06

23

0

91

27

1

06

mm

in

Main

jet

107

145

107

1145

106

145

1107

145

105

1145

104

2

t04

4

Main

air

bleed

95

180

95

180

1110

80

65

1M

195

80

Slow

jet

1145

150

145

150

145

150

146

150

45

150

Powerjet

143

43

140

148

2

48

138

140

4

1

With

A15

engine

2

4

For

Canada

models

3

Common

to

models

with

A14

and

AlS

engines

except

Canada

INSPECTION

AND

ADJUSTMENT

A

T

C

AIR

CLEANER

Air

con

trol

valve

partially

opens

Air

control

valve

fully

opens

Oc

OF

Oc

F

38

to

54

100

to

129

Above

55

131

IDLE

COMPENSATOR

Idle

compensator

partially

opens

Bi

metal

No

I

Bi

metal

No

2

Idle

compensator

fully

opens

Bi

metal

No

I

Bi

metal

No

2

Oc

OF

60

to

70

140

to

158

70

to

80

158

to

176

Oc

OF

Above

70

158

Above

80

176

FUEL

PUMP

Fuel

pressure

Fuel

pump

capacity

kgfcm2

psi

cc

cu

in

min

at

rpm

0

27

3

8

450

27

46

1

000

EF

32

Page 153 of 548

REMOVAL

AND

INSTALLATION

I

Jack

up

the

car

Note

Apply

parking

brake

and

place

wheel

chocks

2

Remove

screws

securing

lower

shelter

of

catalytic

converter

Loosen

flange

bolt

connecting

catalytic

converter

to

front

and

rear

exhaust

tube

Catalytic

converter

assembly

can

then

be

taken

out

3

Installation

i

in

the

reverse

se

quence

of

removal

CAUTION

a

Be

careful

not

to

damage

catalytic

co

when

handliilg

b

Never

wet

catalyzer

with

water

oil

etc

t

J

Tightening

torque

Catalyti

converter

bolts

2

6

to

3

4

kg

m

19

to

25

ft

lb

Emission

Control

System

EC075A

EC076A

Fig

EC

103

Removing

Catalytic

Converter

INSPECTION

PrelimInary

In

pectlon

Vi

ually

check

condition

of

all

component

parts

including

hose

tubes

and

wires

replace

if

necessary

Refer

to

Air

Injection

System

for

inspection

EC

34

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

e

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmis

sion

and

N

or

P

for

automatic

transmission

position

I

Adjust

engine

idling

speed

and

CO

percentage

Refer

to

Adjusting

Carburetor

Idle

RPM

and

Mixture

Ratio

for

adjustment

2

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

percent

age

obtained

3

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

adjusting

screw

4

Warm

up

engine

for

about

four

minutes

at

2

000

pm

under

no

load

S

Measure

Ci

percentage

at

idling

speed

After

stepAhas

been

complet

ed

wait

for

one

minute

before

making

CO

percentage

measurement

6

If

CO

percentage

measured

in

step

5

is

less

than

0

3

the

catalytic

converter

is

normaL

7

If

CO

percentage

measured

in

step

5

is

over

0

3

recheck

AJ

S

and

1

replace

air

check

valVe

The

perform

inspection

steps

4

and

S

8

If

CO

percentage

is

still

over

0

3

in

step

7

catalyt

iC

converter

i

mal

functioning

Replace

catalytic

con

verter

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder