set clock DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 266 of 548

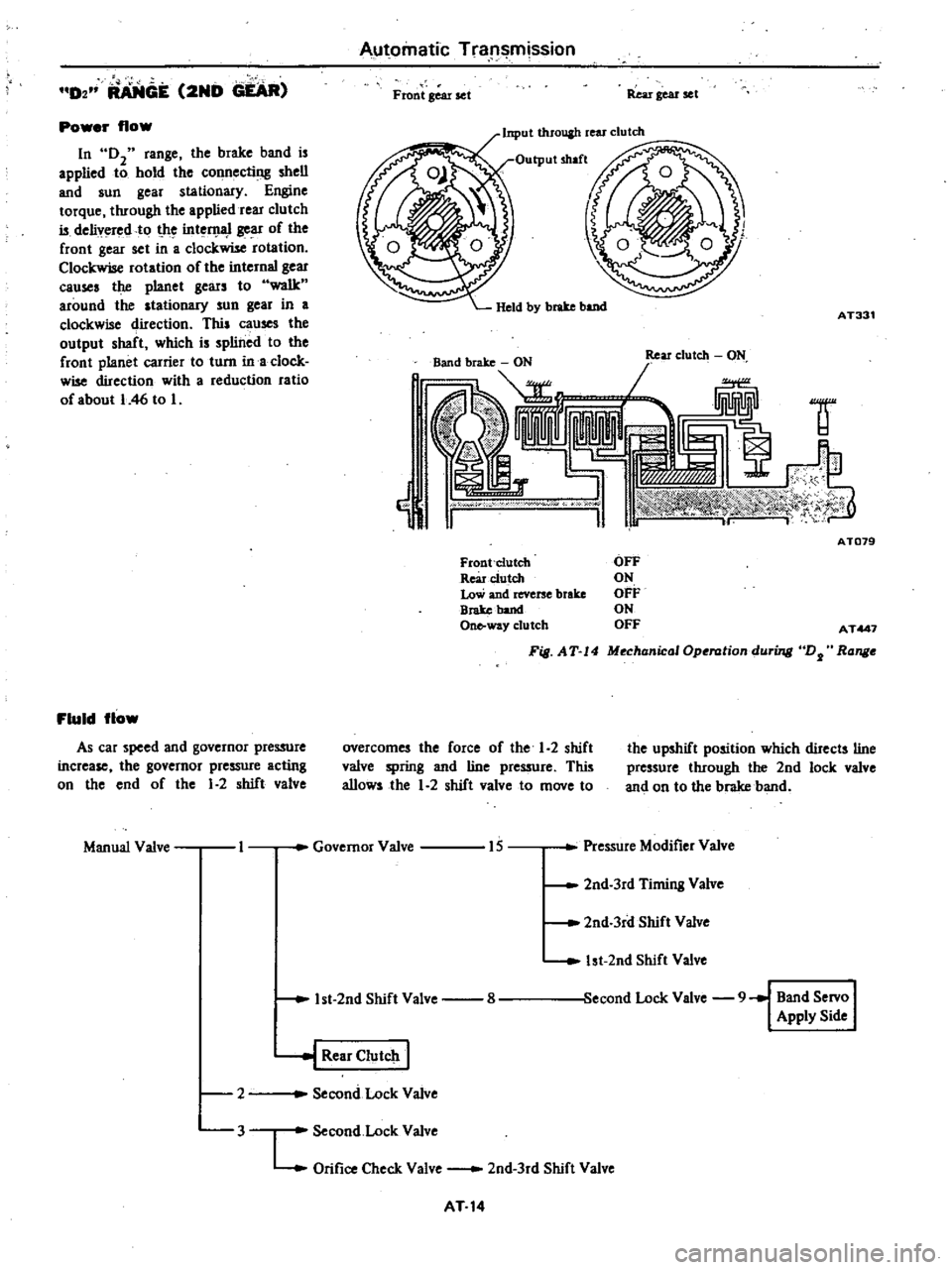

D2

RA

NGE

2ND

GEAR

Power

flow

In

02

range

the

brake

band

is

applied

to

hold

the

connecting

shell

and

sun

gear

stationary

Engine

torque

through

the

applied

rear

clutch

is

delivered

to

t

he

int

D

1l

1

gear

of

the

front

gear

set

in

a

clockwise

rotation

Clockwise

rotation

of

the

internal

gear

causes

the

planet

gears

to

walk

around

the

stationary

sun

gear

in

a

clockwise

direction

This

causes

the

output

shaft

which

is

splined

to

the

front

planet

carrier

to

turn

ina

clock

wise

direction

with

a

reduction

ratio

of

about

I

46

to

I

Fluid

flow

As

car

speed

and

governor

pressure

increase

the

governor

pressure

acting

on

the

end

of

the

1

2

shift

valve

Manual

Valve

I

Automatic

Tra

l

mission

Front

Bear

set

Rear

gear

set

Input

throuah

rear

clutch

AT331

1f

j

cW

oo

w

I

ATD79

Front

Clutch

Rearc1utch

Low

and

reverse

brake

Broke

band

One

way

clutch

OFF

ON

OFF

ON

OFF

AT447

F

S

AT

14

MechanicalOperation

during

DJ

Range

overcomes

the

force

of

the

1

2

shift

valve

spring

and

line

pressure

This

allows

the

1

2

shift

valve

to

move

to

the

upshift

position

which

directs

line

pressure

through

the

2nd

lock

valve

and

on

to

the

brake

band

Governor

Valve

15

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

econd

Lock

Valve

9

Band

Servo

I

Apply

Side

1st

2nd

Shift

Valve

8

l

Rear

CIutclt

I

Second

Lock

Valve

2

3

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

AT

14

Page 268 of 548

Automatic

Transmission

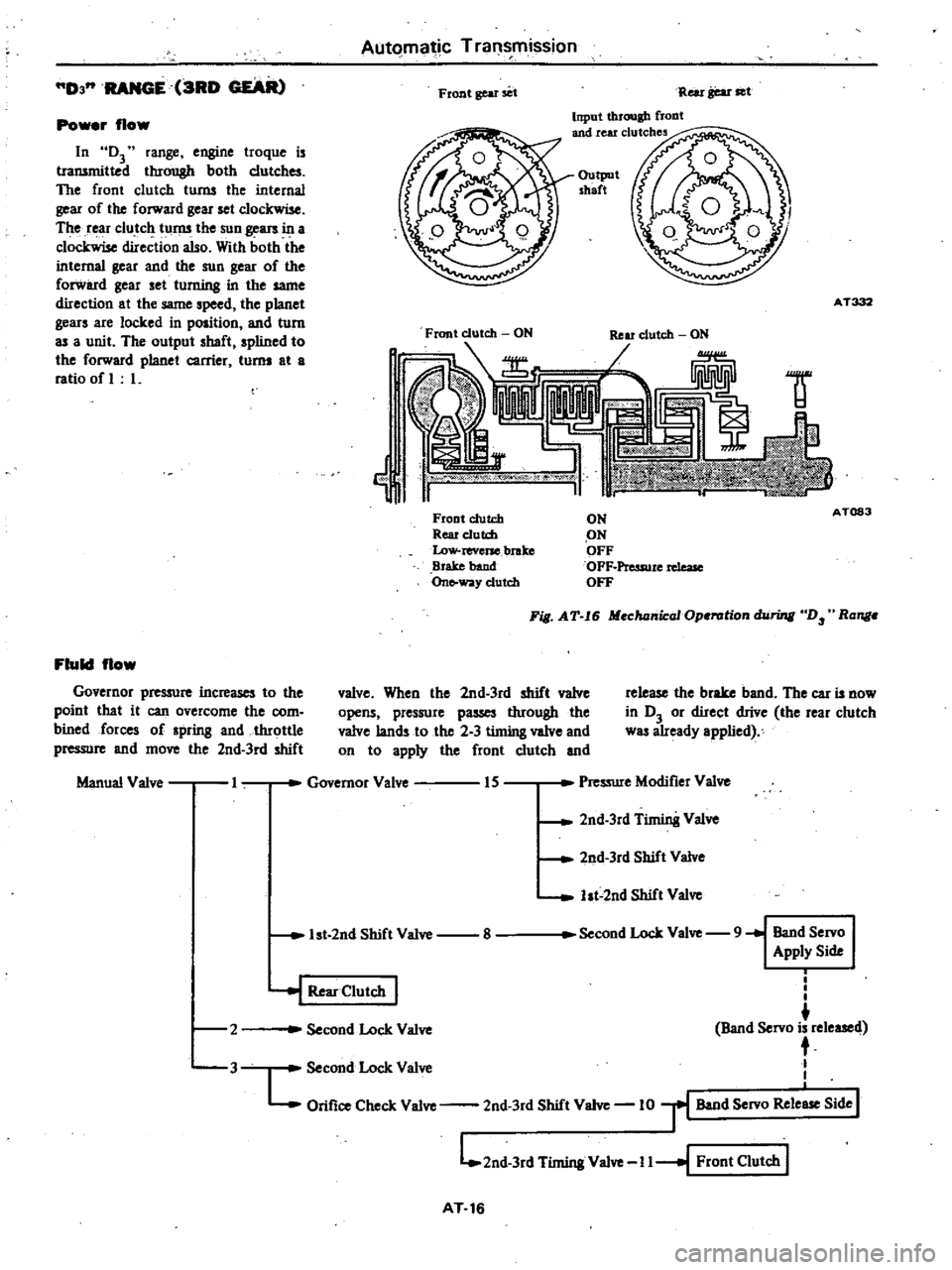

D3

RANGE

3RD

GEAR

Front

gear

set

Rei

r

gear

set

Input

through

flODt

and

rear

clutches

Power

flow

In

D3

range

engine

troque

is

transmitted

through

both

clutches

The

front

clutch

turns

the

internal

gear

of

the

forward

gear

set

clockwise

The

rear

clutch

turns

the

sun

gears

in

a

clockwise

direction

also

With

both

the

internal

gear

and

the

sun

gear

of

the

forward

gear

set

turning

in

the

same

direction

at

the

same

speed

the

planet

gears

are

locked

in

position

and

turn

as

a

unit

The

output

shaft

spIined

to

the

forward

planet

carrier

turns

at

a

ratio

of

L

Output

shaft

AT332

Front

clutch

ON

Ij

1f

Front

clutch

Rear

e1utd

Low

reverse

brake

Brake

band

On

way

clutch

ON

ON

OFF

OFF

Pressure

rdeaJe

OFF

A

T083

Fill

AT

I6

Mechanical

Operation

hiring

D

Ronge

Fluid

flow

Governor

pre

ure

increases

to

the

poinl

that

it

can

overcome

the

com

bined

forces

of

spring

and

throttle

pressure

and

move

the

2nd

3rd

shift

valve

When

the

2nd

3rd

shift

valve

opens

pressure

passes

through

the

valve

lands

to

the

2

3

timing

valve

and

on

to

apply

the

front

clutch

and

release

the

brake

band

The

car

is

now

in

D3

or

direct

drive

the

rear

clutch

was

already

applied

Manual

Valve

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timin8

Valve

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

1st

2nd

Shift

Valve

8

Second

Lock

Valve

9

Band

Servo

Apply

Side

2

i

I

I

Band

Servo

is

released

t

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

10

r

Band

Servo

Rele

Side

I

L

2nd

3rd

Timing

Valve

I

I

I

Front

Clutch

I

J

Second

Lock

Valve

I

Rear

Clutch

I

3

AT

16

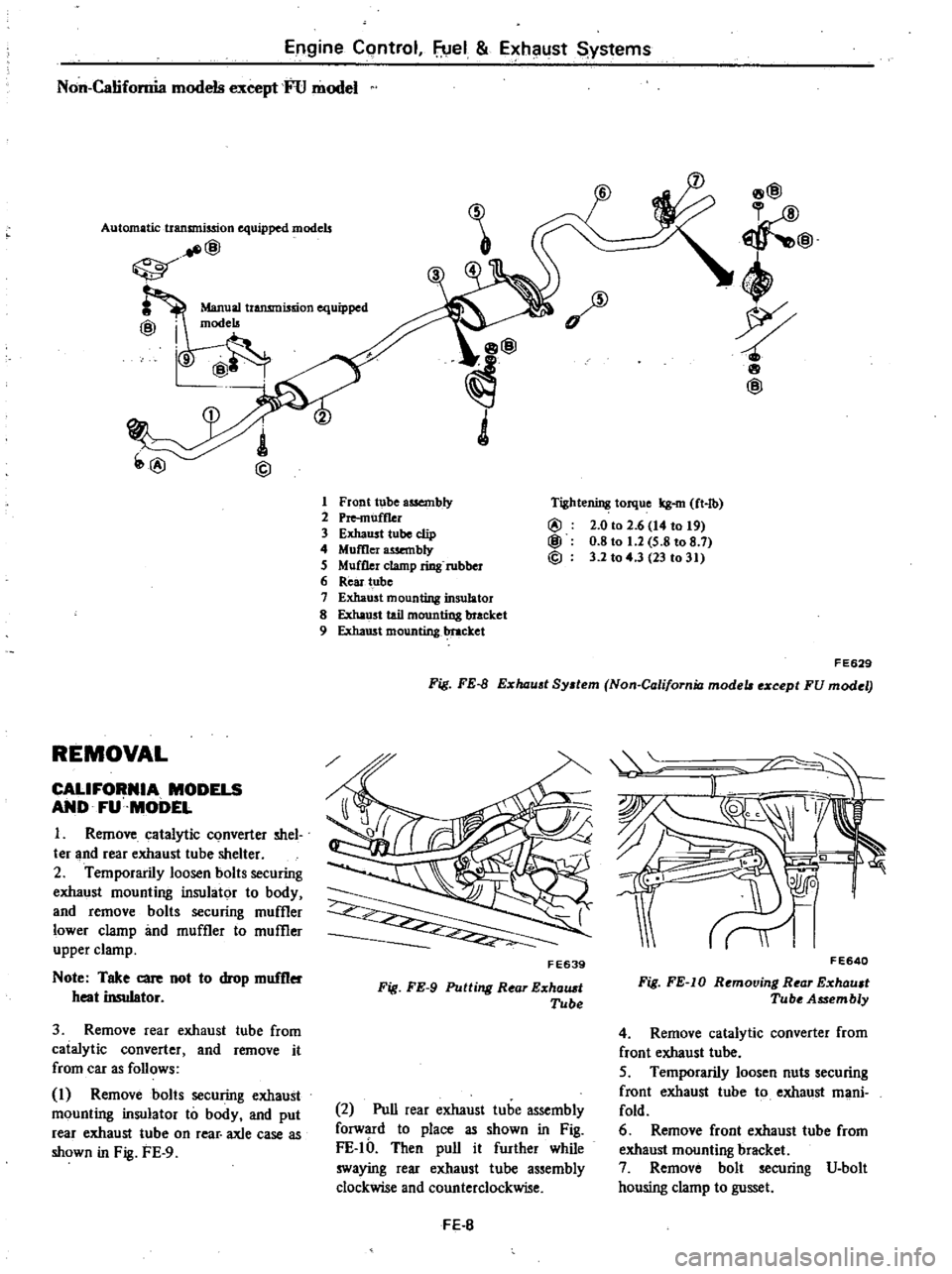

Page 406 of 548

Engine

Control

fuel

Exhaust

Systems

Non

California

models

except

FU

model

Automatic

transmission

equipped

models

@

REMOVAL

CALIFORNIA

MODELS

AND

FU

MODEL

I

Remove

catalytic

converter

shel

ter

and

rear

exhaust

tube

shelter

2

Temporarily

loosen

bolts

securing

exhaust

mounting

insulator

to

body

and

remove

bolts

securing

muffler

lower

clamp

imd

muffler

to

muffler

upper

clamp

Note

Take

care

Dot

to

drop

muffler

heat

insulator

3

Remove

rear

exhaust

tube

from

catalytic

converter

and

remove

it

from

car

as

follows

I

Remove

bolts

securing

exhaust

mounting

insulator

to

body

and

put

rear

exhaust

tube

on

rear

axle

case

as

shown

in

Fig

FE

9

1

Front

tube

assembly

2

Pre

muff1er

3

Exhaust

tube

clip

4

Momer

wembly

5

Muffler

clamp

ring

rubber

6

Rear

tube

7

Exhaust

mounting

insulator

8

Exha

st

tail

mounting

bracket

9

Exhaust

mounting

1

ttacket

8@

@

4

wp

8

@

Tightening

torque

kg

m

ft

lb

@

2

0

to

2

6

14

to

t9

@

0

8

to

1

2

5

8

to

8

7

@

3

2

to

4

3

23

to

31

FE629

Fig

FE

B

E

haust

System

Non

California

mode

e

cept

FU

modet

FE639

Fig

FE

9

Putting

Rear

E

halUt

Tube

2

Pull

rear

exhaust

tube

assembly

forward

to

place

as

shown

in

Fig

FE

IO

Then

pull

it

further

while

swaying

rear

exhaust

tube

assembly

clockwise

and

counterclockwise

FE

B

II

F

E640

Fig

FE

IO

Removing

Rear

E

xhault

Tube

Assembly

4

Remove

catalytic

converter

from

front

exhaust

tube

5

Temporarily

loosen

nuts

securing

f

root

exhaust

tube

to

exhaust

mani

fold

6

Remove

front

exhaust

tube

from

exhaust

mounting

bracket

7

Remove

bolt

securing

V

bolt

housing

clamp

to

gusset

Page 466 of 548

t

Fig

BE

45

Speaker

Antenna

Remove

screws

fastening

upper

and

lower

antenna

supports

to

front

pillar

2

Install

antenna

in

the

reverse

order

of

removal

Feeder

cable

I

Disconnect

battery

ground

cable

2

Remove

antenna

3

Remove

front

pillar

molding

4

Remove

cluster

lid

A

5

Disconnect

feeder

cable

from

radio

receiver

6

Pull

out

feeder

cable

through

hole

in

front

pillar

7

Install

feeder

cable

in

the

reverse

order

of

removal

r

BE251C

Fig

BE

46

Antenna

and

Feeder

Cable

ADJUSTING

ANTENNA

TRIMMER

When

a

new

radio

receiver

antenna

or

feeder

cable

is

installed

antenna

trimmer

shoul

be

adjusted

Body

Electrical

System

Extend

antenna

completely

2

Tune

in

to

frequency

of

the

weakest

station

between

12

and

16

I

200

to

1

600

kHz

on

dial

Noise

may

be

generated

but

dis

regard

it

3

Turn

anteiln3

trimmer

to

left

and

right

slowly

and

set

it

at

a

position

where

receiving

sensitivity

is

highest

BE29SD

Fig

BE

47

Trimmer

Adjusting

Screw

CLOCK

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

combination

meter

3

Disconnect

harness

connector

4

Remove

clock

by

loosening

re

taining

screws

5

Install

clock

in

the

reverse

order

of

removal

r

Jf

rr

i1

b

Ii

f

7

8

eE758C

Fig

BE

48

Clock

BE

21

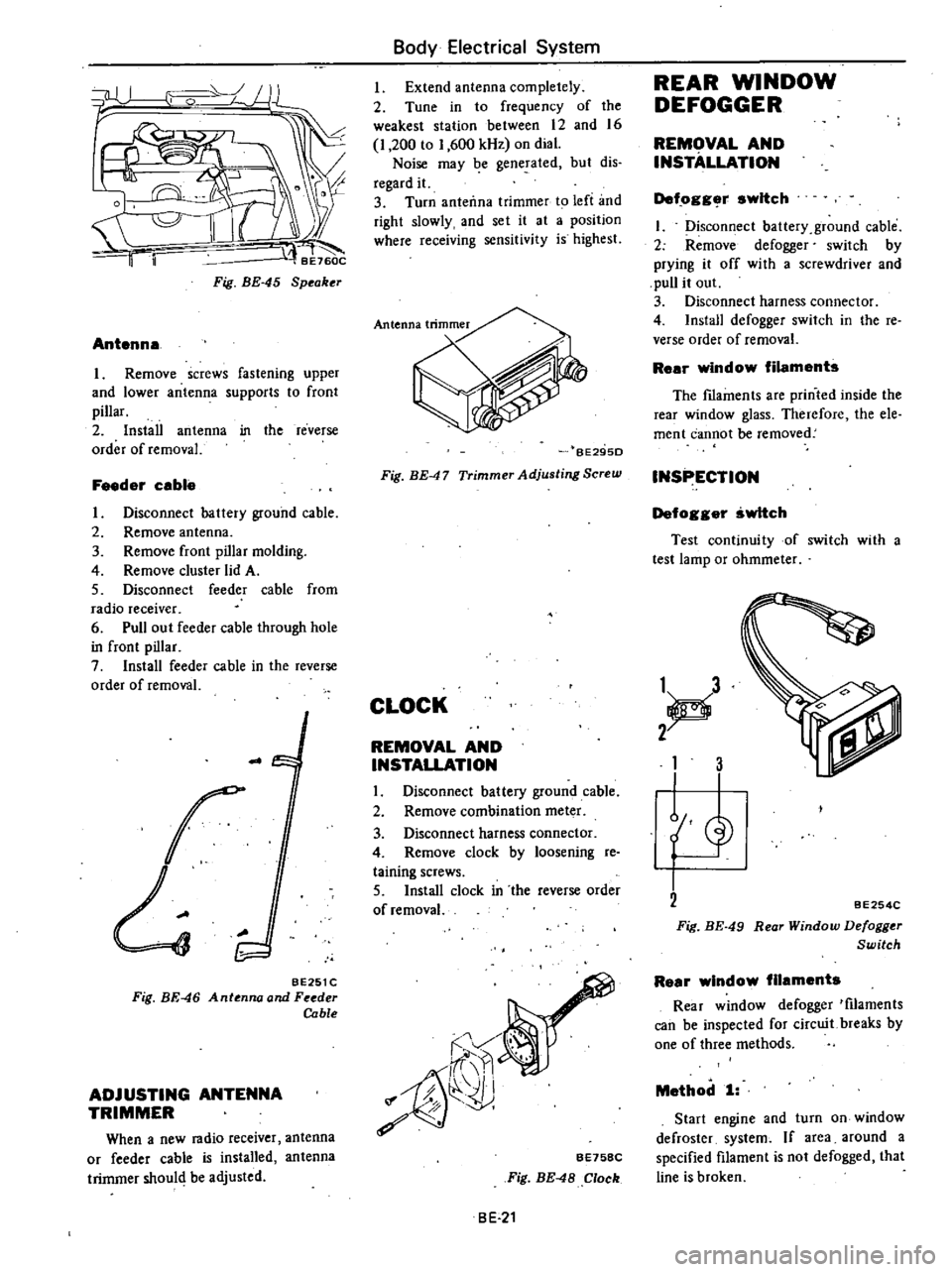

REAR

WINDOW

DEFOGGER

REMOVAL

AND

INSTALLATION

Def

ogg

r

switch

I

Disconfi

ect

battery

ground

cable

2

Remove

defogger

switch

by

prying

it

off

with

a

screwdriver

and

pull

it

out

3

Disconnect

harness

connector

4

Install

defogger

switch

in

the

reo

verse

order

of

removal

Rear

window

filaments

The

fIlaments

are

printed

inside

the

rear

window

glass

Therefore

the

ele

ment

cannot

be

removed

INSPECTION

Defogger

switch

Test

continuity

of

switch

with

a

test

lamp

or

ohmmeter

1

d

2

1

3

L

BE254C

Fig

BE

49

Rear

Window

Defogger

Switch

Rear

window

filaments

Rear

window

defogger

tfilaments

can

be

inspected

for

circuit

breaks

by

one

of

three

methods

Method

1

Start

engine

and

turn

on

window

defroster

system

If

area

around

a

specified

filament

is

not

defogged

that

line

is

broken