tires DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 382 of 548

Wheel

and

Tire

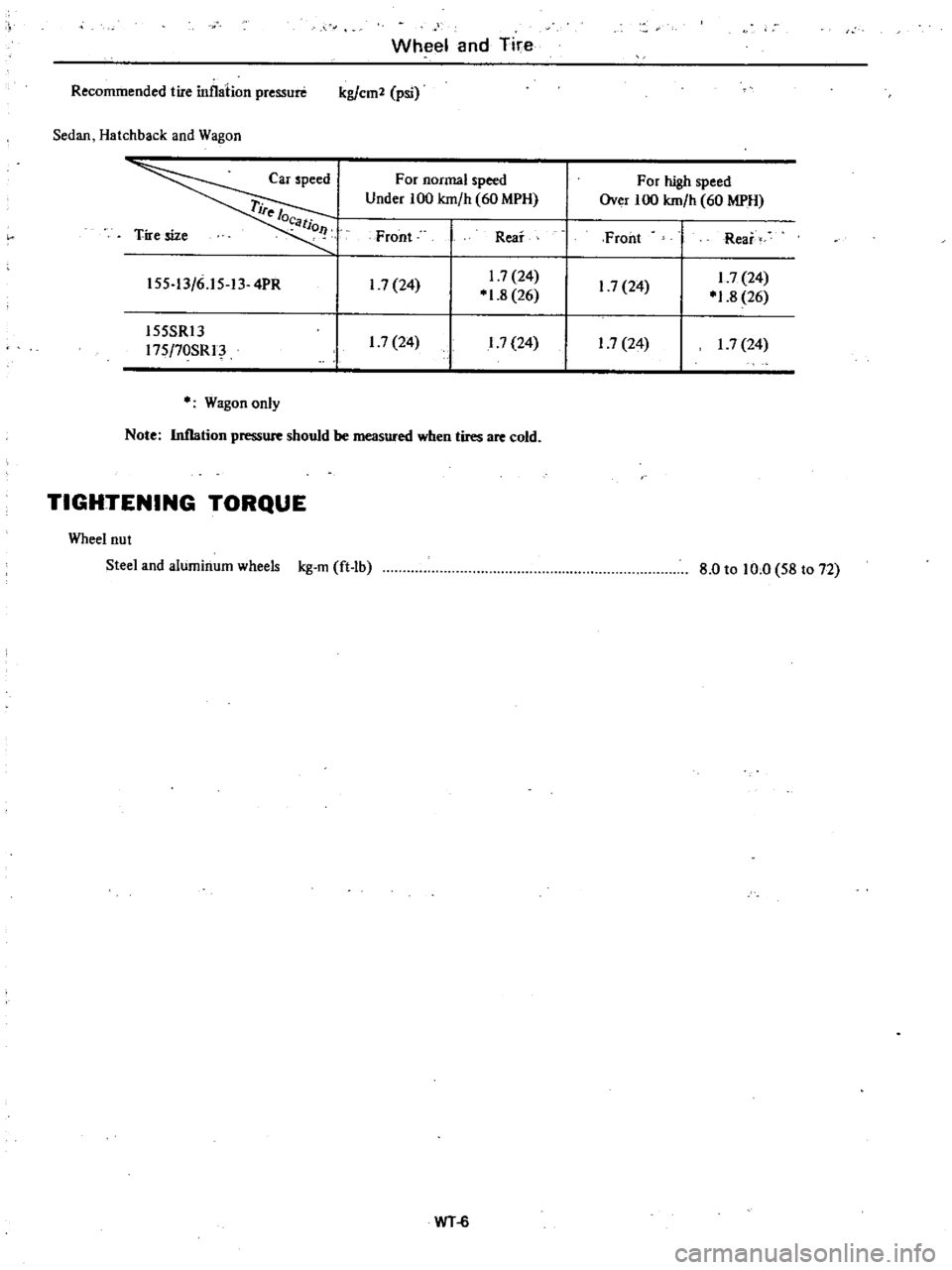

Recommended

tire

inflation

pressure

kg

em

psi

Sedan

Hatchback

and

Wagon

Tire

size

Car

speed

rife

l

o

tio

l

For

normal

speed

For

high

speed

Under

100

km

h

60

MPH

Over

100

km

h

60

MPH

Front

Rear

Front

Rear

I

7

24

1

7

24

1

7

24

1

7

24

01

8

26

01

8

26

17

24

1

7

24

1

7

24

17

24

155

13

6

15

13

4PR

155SRl3

175

70SRI

o

Wagon

only

Note

Inflation

pressure

should

be

measured

when

tires

are

cold

TIGHTENING

TORQUE

Wheel

nut

Steel

and

aluminum

wheels

kg

m

ft

lb

8

0

to

10

0

58

to

72

WT

6

Page 383 of 548

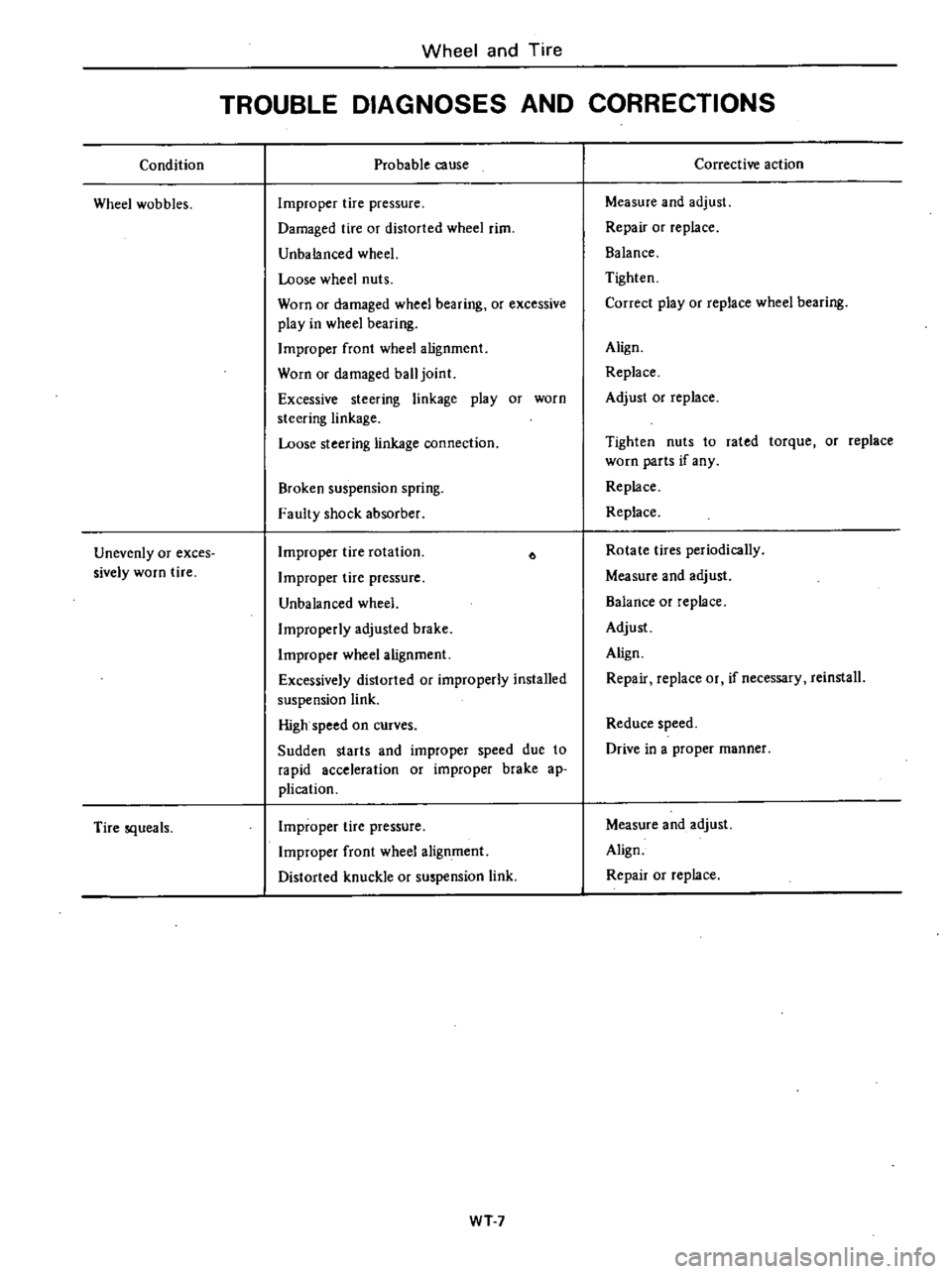

Condition

Wheel

wobbles

Unevenly

or

exces

sively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

in

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Faulty

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

starts

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT7

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Rotate

tires

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Drive

in

a

proper

manner

Measure

and

adjust

Align

Repair

or

replace

Page 418 of 548

Bumper

height

I

Place

car

on

a

flat

surface

under

curb

weight

condition

Tires

must

be

inflated

to

rated

pressure

2

Measure

height

above

ground

of

bumper

at

two

mounting

locations

as

shown

in

Figs

BF

7

and

BF

8

3

If

bumper

height

is

not

within

the

specification

loosen

shock

ab

sorber

attaching

bolts

and

nuts

Then

adjust

bumper

height

After

adjust

ment

tighten

bolts

and

nuts

securely

Front

bumper

height

H

360

to

408

mm

14

17

to

16

06

in

Rear

bumper

height

H

Sedan

and

Hatchback

391

to

433

mm

15

39

to

17

05

in

Wagon

376

to

418

mm

14

BO

to

16

46

in

Sedan

and

Hatchback

Body

I

J

S

H

I

BF740B

Fig

BF

7

Front

Bumper

Height

Wagon

O

J

H

j

BF741B

Fig

BF

8

Rear

Bumper

Height

BF

7

Page 436 of 548

r

t

s7

Glm

I

6

0

24

k

IJ

4

0

16

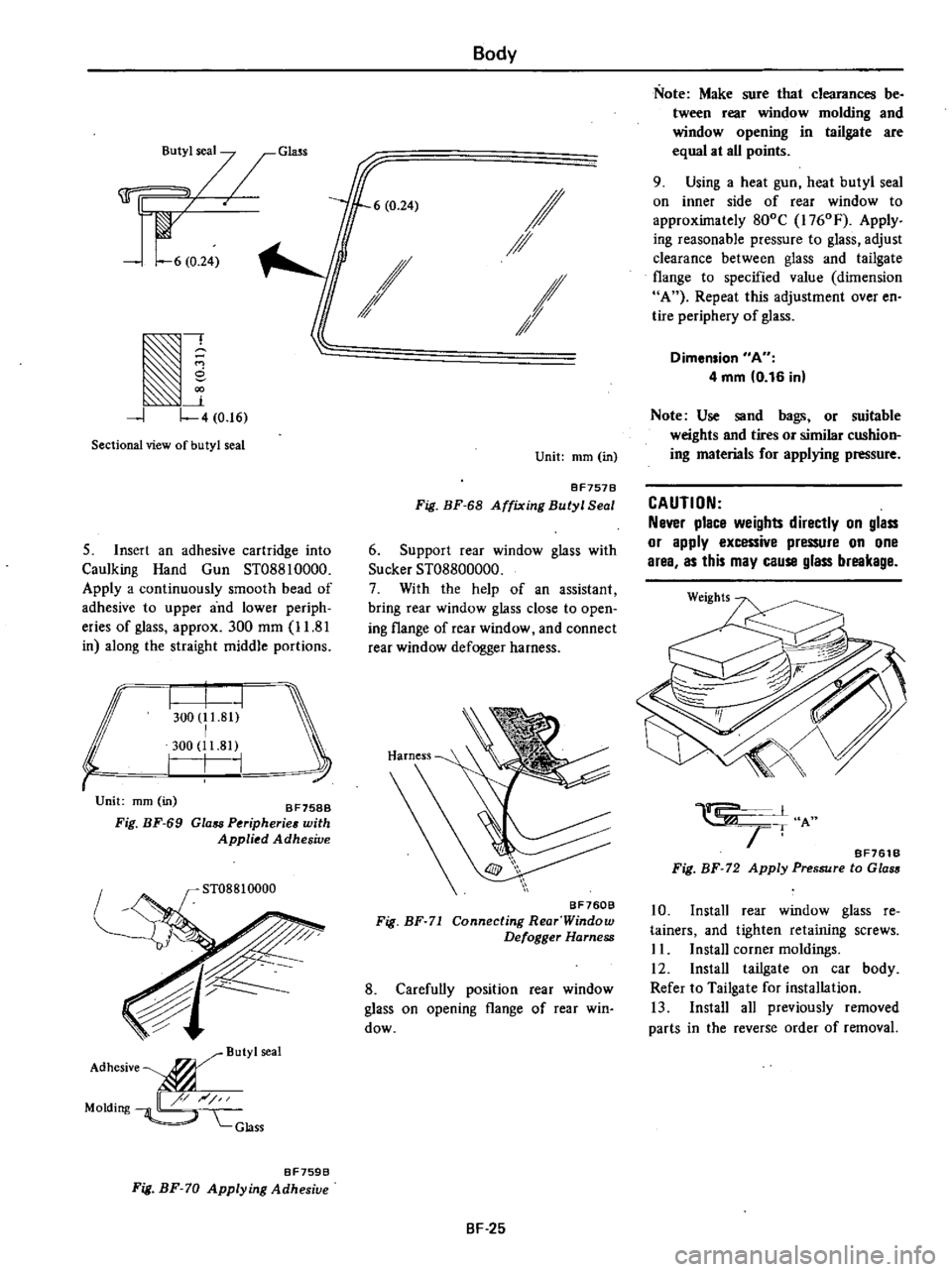

Sectional

view

of

butyl

seal

5

Insert

an

adhesive

cartridge

into

Caulking

Hand

Gun

ST08810000

Apply

a

continuously

smooth

bead

of

adhesive

to

upper

and

lower

periph

eries

of

glass

approx

300

mm

11

81

in

along

the

straight

middle

portions

r

300

1

S

300

11

81

I

I

Unit

mm

in

Fig

BF

69

aF7SaB

Glass

Puipherie

with

Applied

Adhesive

ST08810000

ButYlseal

Adhesive

P

Molding

GlaSS

BF759B

Fig

BF

70

Applying

Adhesiue

Body

6

0

24

If

I

Unit

mm

in

BF7578

Fig

BF

68

Affixing

Butyl

Seal

6

Support

rear

window

glass

with

SuckerST08800000

7

With

the

help

of

an

assistant

bring

rear

window

glass

close

to

open

iog

flange

of

rear

window

and

connect

rear

window

defogger

harness

BF760B

Fig

BF

71

Connecting

Rear

Window

Defogger

Harness

8

Carefully

position

rear

window

glass

on

opening

flange

of

rear

win

dow

BF

25

Note

Make

sure

that

clearances

be

tween

rear

window

molding

and

window

opening

in

tailgate

are

equal

at

all

points

9

Using

a

heat

gun

heat

butyl

seal

on

inner

side

of

rear

window

to

approxilnately

800C

l760F

Apply

ing

reasonable

pressure

to

glass

adjust

clearance

between

glass

and

tailgate

flange

to

specified

value

dimension

A

Repeat

this

adjustment

over

en

tire

periphery

of

glass

Dimension

A

4

mm

0

16

in

Note

Use

sand

bags

or

suitable

weights

and

tires

or

similar

cushion

ing

materials

for

applying

pressure

CAUTION

Never

place

weights

directly

on

glass

or

apply

excessive

pressure

on

one

area

as

this

may

cause

glass

breakage

1

I

I

A

1T

BF761B

Fig

BF

72

Apply

Pressure

to

Glass

10

Install

rear

window

glass

re

tainers

and

tighten

retaining

screws

II

Install

corner

moldings

12

Install

tailgate

on

car

body

Refer

to

Tailgate

for

installation

13

Install

all

previously

removed

parts

in

the

reverse

order

of

removal

Page 456 of 548

ILLUMINATION

CONTROL

UNIT

Body

Electrical

System

8

GY

GW

AIMING

ADJUSTMENT

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

ailn

use

adjusting

screw

on

side

of

headlamp

BE1200

Fig

BE

I3

Illumination

Control

Unit

1

Vertical

adjustment

2

Horizontal

adjustment

BE1210

Fig

BE

14

Aiming

Ad

iusting

Screws

Note

Before

makiiIg

headlamp

aim

ing

adjustment

observe

the

follow

ing

instructions

a

Keep

all

tires

inflated

to

correct

pressures

b

Place

car

and

tester

on

one

and

BE

11

same

flat

surface

c

See

that

there

is

no

load

in

car

coolant

engine

oil

fIlled

up

to

correct

level

and

full

fuel

tank

other

than

the

driver

or

equivalent

weight

placed

in

driver

s

position

d

For

details

refer

to

SAE

J599d

When

performing

headlamp

aiming

adjustment

use

an

aiming

machine

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

almer

it

should

be

in

good

repair

calibrated

and

used

accordi

g

to

respective

operation

manuals

supplied

with

the

unit

If

any

aimer

is

not

available

aiming

adjustment

can

be

done

as

follqws

Turn

headlamp

low

beam

on

H

Horizontal

center

line

of

headlamps

BE297D

Fig

BE

I5

Aiming

Adjustment

Unit

mm

in

Note

a

Adjust

headlamps

so

that

upper

edge

of

hot

spot

is

equal

in

height

to

headlamp

height

and

left

edge

of

hot

spot

is

equal

in

height

to

each

center

line

of

headlamps

b

Dotted

lines

in

illustration

show

center

of

headlamp