heater DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 473 of 548

Body

Electdcal

System

INSPECTION

Check

the

following

items

if

blower

motor

fails

to

rotate

FUSE

To

check

for

burned

out

fuse

use

the

same

procedure

as

that

for

ordina

ry

fuses

with

a

circuit

tester

or

test

lamp

BLOWER

MOTOR

POWER

SUPPLY

Disconnect

blower

motor

harness

to

connect

main

harness

2

Connect

one

test

lamp

lead

wire

i

I

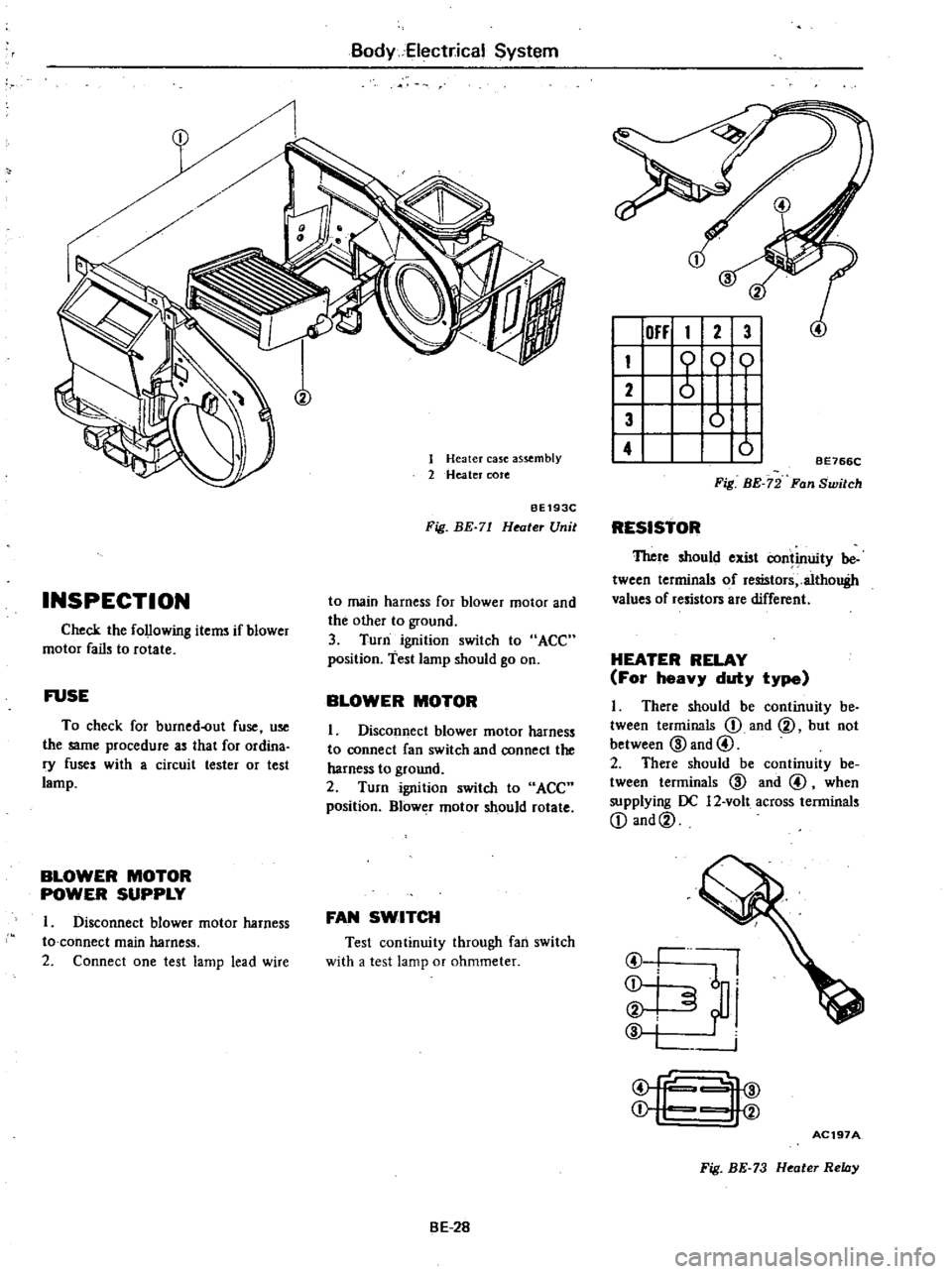

Heater

case

as

mbly

2

Heater

cote

BE193C

Fig

BE

71

Heater

Unit

to

main

harness

for

blower

motor

and

the

other

to

ground

3

Turn

ignition

switch

to

ACC

position

test

lamp

should

go

on

BLOWER

MOTOR

1

Disconnect

blower

motor

harness

to

connect

fan

switch

and

connect

the

harness

to

ground

2

Turn

ignition

switch

to

ACC

position

Blower

motor

should

rotate

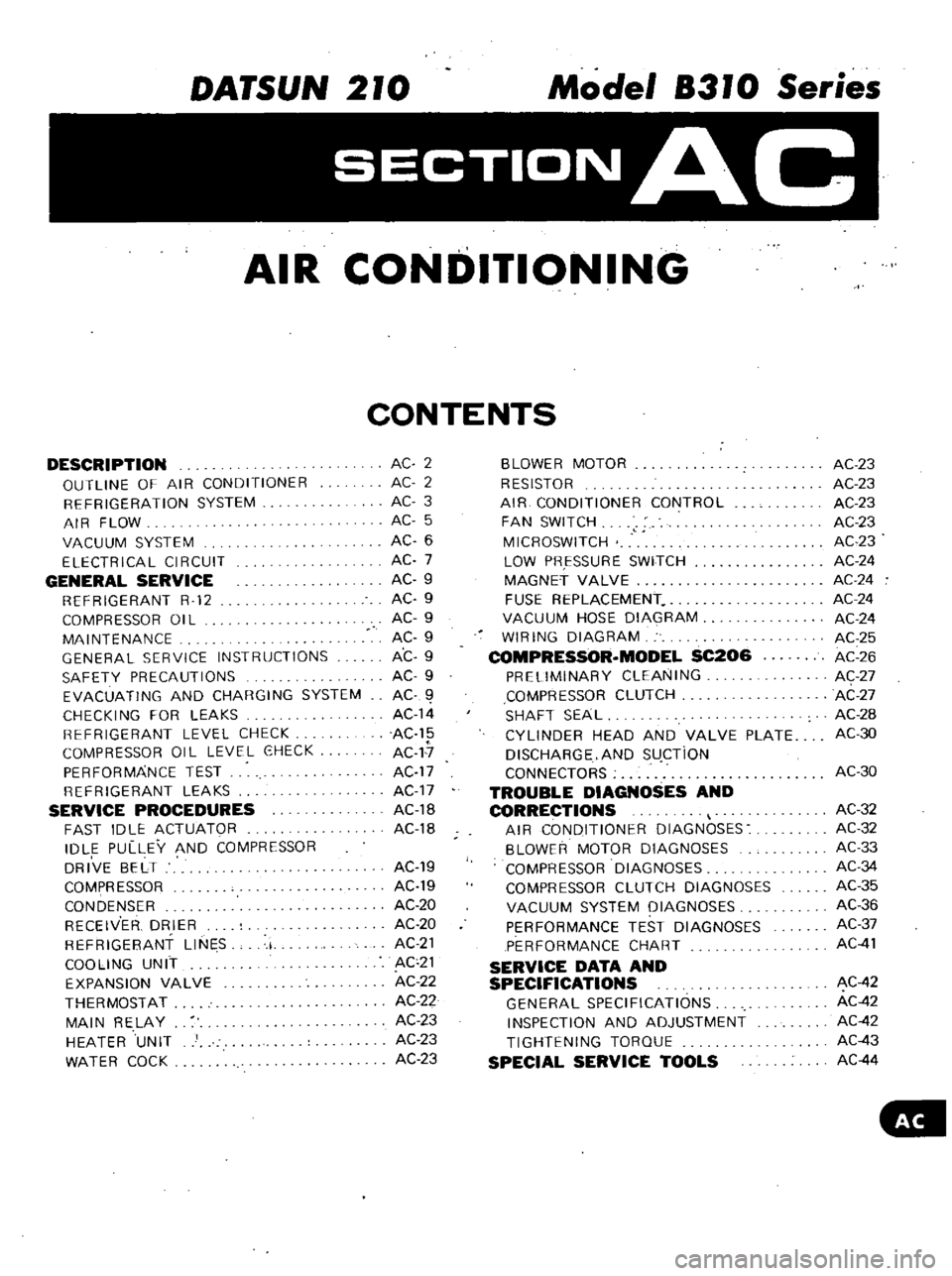

FAN

SWITCH

Test

continuity

through

fan

switch

with

a

test

lamp

or

ohmmeter

BE

2B

OFF

1

2

3

I

1

0

01

2

I

3

0

I

4

01

BE766C

Fig

BE

72

Fan

Switch

RESISTOR

TItere

should

exist

continuity

be

tween

terminals

of

resistors

althouBh

values

of

resistors

are

different

HEATER

RELAY

For

heavy

duty

type

I

There

should

be

continuity

be

tween

terminals

D

and

@

but

not

between

@

and

@

2

There

should

be

continuity

be

tween

terminals

@

and

@

when

supplying

OC

12

volt

across

terminals

D

and@

I

@

I

I

j

i

i

@

fc

4@

j

I

V

AC197A

Fig

BE

73

Heater

Relay

Page 475 of 548

WIPER

MOTOR

WINDSHIELD

WASHER

MOTOR

REAR

WIPER

MOTOR

REAR

WINDOW

WASHER

MOTOR

m

w

o

HORN

CIGARETTE

LIGHTER

CLOCK

HAZARD

FLASHER

LAMP

STOP

LAMP

ROOM

LAMP

LUGGAGE

ROOM

LAMP

TAIL

LAMP

CLEARANCE

LAMP

LICENSE

PLATE

LAMP

COMBINATION

METER

LAMP

l

I

ll

6

C

l

ii

en

g

0

o

m

till

oill

l

I

t1

l

CO

l

m

l

m

0

z

t

15A

10A

14

fA

20A

16

T

r

t1

l

t1

l

CO

CO

CJ

CJ

1

1

m

m

0

0

z

z

HEATER

lAIR

CONDITIONER

ENGINE

REVOLUTION

SWITCH

FUEL

CUT

SOLENOID

VACUUM

CUT

SOLENOID

AUTO

CHOKE

HEATER

THROTTLE

OPENER

SOLENOID

TURN

SIGNAL

LAMP

GAUGE

I

FUEL

L

WATER

TEMPERATURE

WARNING

LAMP

BRAKE

CHARGE

OIL

PRESSURE

SEAT

BELT

WARNING

BUZZER

BACK

UP

LAMP

KICKDOWN

SOLENOID

TACHOMETER

REAR

DEFOGGER

f

c

It

1

1

m

g

II

n

a

n

c

It

c

1J

c

CIl

z

G

S

3

OJ

o

Cl

m

CD

In

Ql

Page 478 of 548

m

W

w

t

e

CALIFORNIA

ANO

BATTERY

FU

MOOELS

g

G

II

V

FUSIBLE

LINK

G

uQ

t

WR

NON

cALlFORNIA

ANO

CANAOA

MOOELS

FUSE

BLOCK

ii

I

ll

l

er

0

er

15A

RG

r

I

W

I

0

0

0

0

tl

ij

a

3

Cl

E

0

too

m

a

f

0

II

OFf

I

IST

2ND

I

IAIBICIAIBlc

liB

C

1

I

101

1

10

10

0

5

11101

116

OI66

I

I

I

I

I

I

6

1

0

I

H

I

101010

2

2

12

8

1161616

LIGHTING

SWITCH

rtt

I

Q

l

B

B

I

I

I

8

00

100

2

2

GW

G

y

jl

I

I

g

fi

GY

GY

Ot

I

GW

RG

GW

T

R

cON

INOICATOR

LAMP

IA

TI

r

H

Jl

L

t1

j

GW

RAOIO

ILLUMINATION

LAMP

IrGW

GI

to

GY

r

l

I

3

I

L

HEATER

CONTROL

PANEL

ILLUMINATION

LAMP

I

GWCJ

lOr

GYO

c

I

ASH

TRAY

ILLUMINATION

CJ

LAMP

CLOCK

H

Gya

3

C3

L

INATION

G

J

J

Y

l

B

I

ILLUMINATION

I

CONTROL

UNIT

G

W

INSTRUMENT

HARNESS

COMBINATION

LAMP

r

r

e

i

o

z

lI

OJ

o

Cl

m

CD

0

Ql

CIl

en

l

3

Page 500 of 548

m

ii

I

ll

ic

i

tl

Cl

Ul

0

is

B

w

ii

W

oa

LW

L

CALIFORNIA

ANO

I

d

S

R

FUSIBLE

LINK

o

BATTERY

S

JSt

wGLQ

gWR

NON

GALIFORNIA

ANO

CANAOA

MOOELS

LOC

Off

Ace

ON

Sf

o

0

i

IGNITION

SWITCH

L

B

LN

I

15A

0

0

0

0

o

v

E

FUSE

BLOCK

M

F

i

L

11L1

u

R

1

i

ri

1

w

RESISTOR

BW

Il

BLj

L

lljlj

U6

1

BWY

W

B

8

HEAVY

OUTY

TYPE

Standard

for

Canada

and

option

for

U

S

A

LW

HEATER

MOtOR

IOffl

I

2

3

Kro

lli

H

FAN

SWITCH

ST

ANOARO

TYPE

Z

II

II

a

OJ

o

Cl

m

CD

n

n

Ql

CIl

CJ

l

3

Page 501 of 548

Condition

Insufficient

heating

performance

No

heated

air

discharged

Insufficient

air

flow

to

floor

Insufficient

defrosting

performance

Cold

air

discharged

Insufficient

air

flow

to

defroster

Heated

air

discharged

with

lever

in

VENT

Blower

motor

does

not

run

Control

lever

drags

Outside

air

comes

in

with

fan

in

OFF

Noise

frol11

blower

motor

Body

Electrical

System

Probable

cause

Cooling

water

temperature

too

low

Heater

core

plugged

Insufficient

cooling

water

level

Malfunctioning

air

mix

door

Malfunctioning

water

cock

Blower

motor

speed

too

low

Malfunctioning

floor

door

Refer

to

No

heated

air

discharged

Malfunctioning

hoor

door

or

faulty

seal

Defroster

nozzle

plugged

Leak

at

defroster

duct

lo

nozzle

connection

Water

cock

not

operating

properly

Mode

door

not

operating

properly

or

seal

damaged

Fuse

melted

MOlor

wire

connector

disconnected

Faulty

switch

Faulty

motor

Faultyblower

control

amplifier

Inner

wire

rubbing

against

outer

case

end

Control

cable

bent

excessively

Malfunctioniilg

doors

door

levers

etc

Air

intake

door

not

operating

properly

Control

cable

out

of

adjustment

Loose

bolt

in

blower

motor

BE

56

Corrective

action

Check

thermostat

Rep1ace

as

nece

ry

Clean

Rem

Adjust

control

cable

Adjust

control

cable

Check

motor

terminal

voltage

Repair

poor

connection

and

discontinuity

Replace

motor

if

necessary

Replace

blower

control

amplifier

if

neces

sary

Adjust

control

cable

Adjust

control

cable

Clean

Correcl

Adjust

control

cable

Adjust

control

cable

Correct

cause

and

replace

qrrect

Replace

Check

and

correct

Replace

Adjust

control

cable

Correct

Ch

ck

and

COrrect

Repair

or

replace

Adjust

control

cable

Check

and

tighten

loose

bolts

Page 502 of 548

DATSUN

210

Model

8310

Series

SECTIONAC

AIR

CONDITIONING

CONTENTS

DESCRIPTION

OUTLINE

OF

AIR

CONDITIONER

REFRIGERATION

SYSTEM

AIR

FLOW

VACUUM

SYSTEM

ELECTRICAL

CIRCUIT

GENERAL

SERVICE

REFRIGERANT

R

12

COMPRESSOR

OIL

MAINTENANCE

GENERAL

SERVICE

INSTRUCTIONS

SAFETY

PRECAUTIONS

EVACUATING

AND

CHARGING

SYSTEM

CHECKI

NG

FOR

LEAKS

REFRIGERANT

LEVEL

CHECK

COMPRESSOR

OIL

LEVEL

OHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

SERVICE

PROCEDURES

FAST

IDLE

ACTUATOR

IDL

E

PULLEY

AND

COMPRESSOR

DRIVE

BELT

COMPR

ESSOR

CONDENSER

RECEIV

ER

DRIER

REFRIGERANT

LINES

I

COOLING

UNIT

EXPANSION

VALVE

THERMOSTAT

MAIN

RELAY

HEATER

UNIT

WATER

COCK

AC

2

AC

2

AC

3

AC

5

AC

6

AC

7

AC

9

AC

9

AC

9

AC

9

AC

9

AC

9

AC

1

AC14

AC15

AC

17

AC17

AC17

AC18

AC1B

AC19

AC19

AC

20

AC

20

AC

21

ACc21

AC

22

AC

22

AC

23

AC

23

AC

23

BLOWER

MOTOR

RESISTOR

AIR

CONDITIONER

CONTROL

FAN

SWITCH

MICROSWITCH

LOW

PRESSURE

SWITCH

MAGNET

VALVE

FUSE

REPLACEMENT

VACUUM

HOSE

DIAGRAM

WIRING

DIAGRAM

COMPRESSOR

MODEL

SC206

PRELIMINARY

CLEANING

COMPRESSOR

CLUTCH

SHAFT

SEAL

CYLINDER

HEAD

AND

VALVE

PLATE

DISCHARGE

AND

sU

CTiON

CONNECTORS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

AIR

CONDITIONER

DIAGNOSES

BLOWER

MOTOR

DIAGNOSES

COMPRESSOR

DIAGNOSES

COMPRESSOR

CLUTCH

DIAGNOSES

VACUUM

SYSTEM

DIAGNOSES

PERFORMANCE

TEST

DIAGNOSES

PERFORMANCE

CHART

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

SPECIAL

SERVICE

TOOLS

AC

23

AC

23

AC

23

AC

23

AC23

AC

24

AC

24

AC24

AC

24

AC

25

AC

26

AC

27

AC

27

AC

28

AC30

AC30

AC32

AC

32

AC

33

AC34

AC35

AC36

AC37

AC

41

AC

42

AC

42

AC

42

AC

43

AC

44

Page 503 of 548

Air

Conditioning

DESCRIPTION

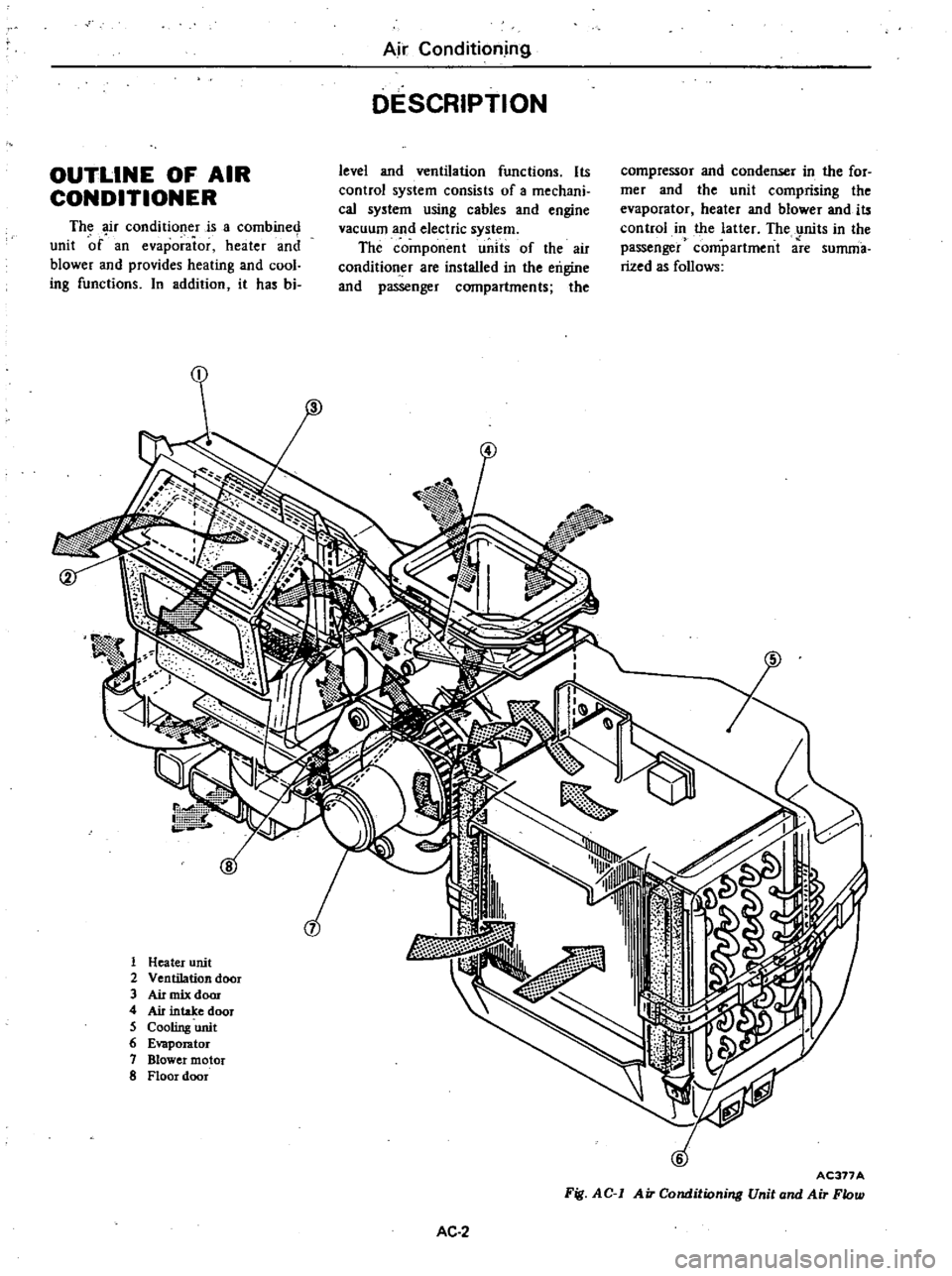

OUTLINE

OF

AIR

CONDITIONER

level

and

ventilation

functions

Its

control

system

consists

of

a

mechani

cal

system

using

cables

and

engine

vacuum

and

electric

system

The

component

units

of

the

air

conditioner

are

installed

in

the

engine

and

passenger

compartments

the

compressor

and

condenser

in

the

for

mer

and

the

unit

comprising

the

evaporator

heater

and

blower

and

i

Is

control

in

the

latter

The

units

in

the

passenger

compartment

aTe

summa

rized

as

foUows

Th

ipr

conditio

er

isa

combine4

unit

of

an

evaporator

heater

and

blower

and

provides

heating

and

cool

lng

functions

In

addition

it

has

hi

I

1

Heater

unit

2

Ventilation

door

3

Air

mix

dom

4

Air

intake

door

5

Cooling

unit

6

E

r

or

7

Blower

motor

8

Floor

door

AC377A

Fig

AC

1

Air

Conditioning

Unit

and

Air

Flow

AC

2

Page 506 of 548

Air

Conditioning

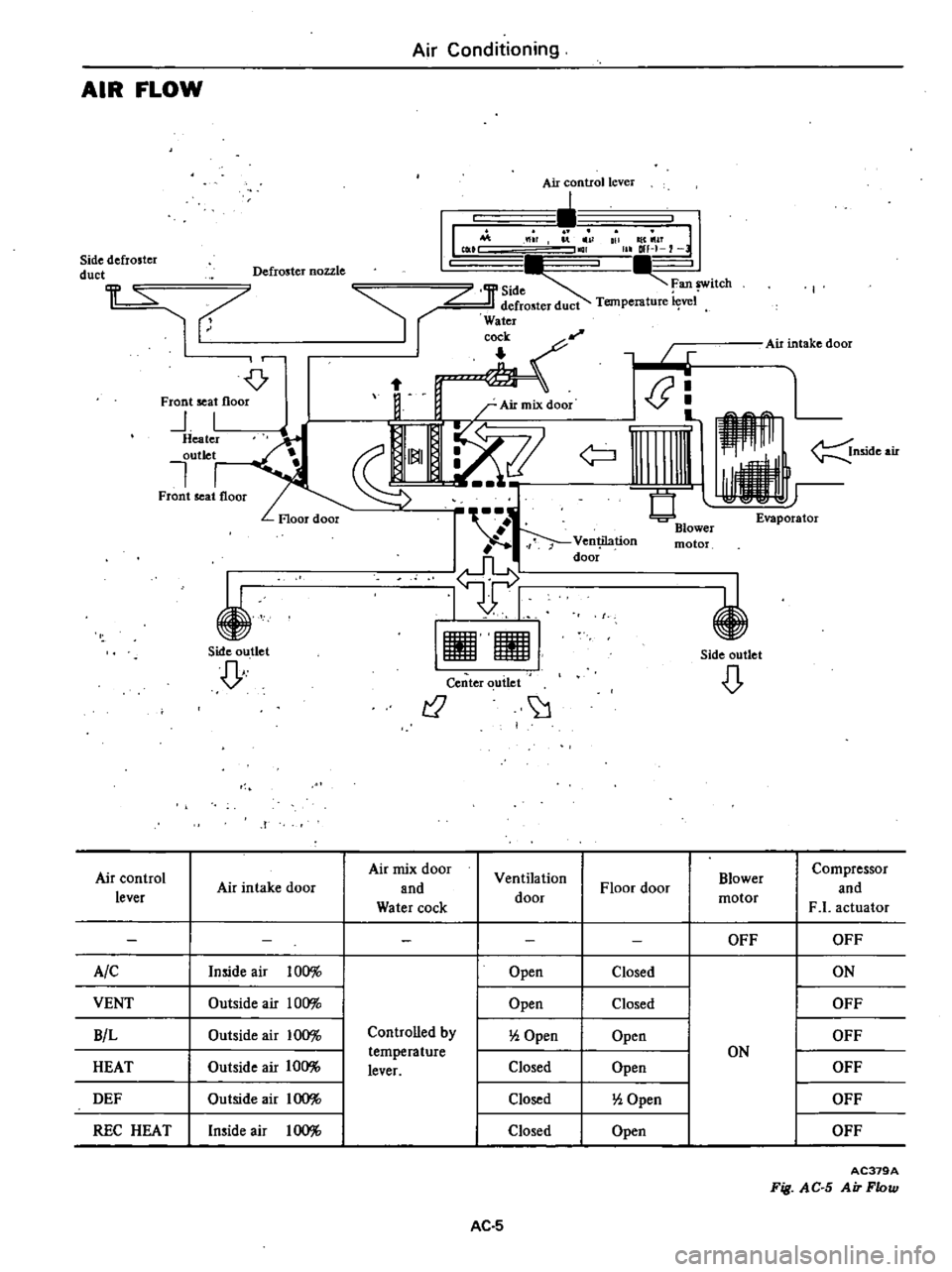

AIR

FLOW

Air

control

lever

1M

l

r

I

1

all

IC

1T

I

tCliO

ar

afH

7

Sidedefrostcr

duct

Defroster

nozzle

L

Jf

SOd

Fan

switch

1

7

l

t

I

Air

intake

door

r

If

Ftont

seat

flOO

i

f

t

I

J

Heater

outlet

nside

air

l

Front

seat

floor

Evaporator

i

Side

outlet

D

I

I

IIll

91

i

Side

outlet

Center

udet

r2

D

I

Air

control

Air

mix

door

Ventilation

Blower

Compressor

Air

intake

door

and

Floor

door

and

lever

Water

cock

door

motor

F

1

actuator

OFF

OFF

AIC

Inside

air

100

Open

Closed

ON

VENT

Outside

air

100

Open

Closed

OFF

B

L

Outside

air

100

Controlled

by

0

Open

Open

OFF

temperature

ON

HEAT

Outside

air

100

lever

Closed

Open

OFF

DEF

Outside

air

100

Closed

0

Open

OFF

REC

HEAT

Inside

air

100

Closed

Open

OFF

AC379A

Fig

AC

S

Air

Flow

AC

5

Page 523 of 548

to

DISASSEMBLY

AND

ASSEMBLY

y

1

7

1

r

II

l

1

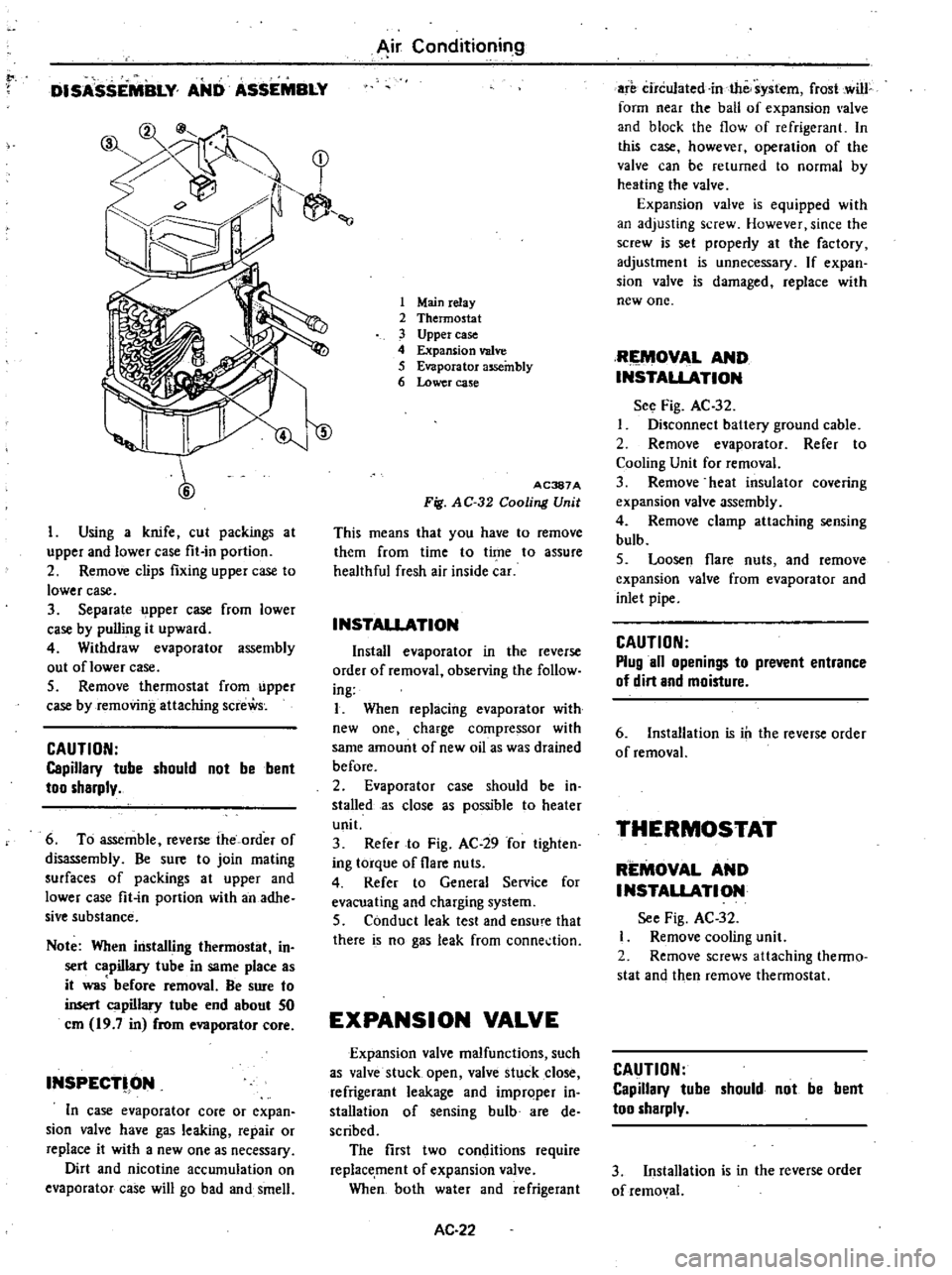

Using

a

knife

cut

packings

at

upper

and

lower

case

fit

in

portion

2

Remove

clips

fixing

upper

case

to

lower

case

3

Separate

upper

case

from

lower

case

by

pulling

it

upward

4

Withdraw

evaporator

assembly

out

oflower

case

5

Remove

thermostat

from

upper

case

by

removing

attaching

screWs

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

6

To

assemble

reverse

the

order

of

disassembly

Be

sure

to

join

mating

surfaces

of

packings

at

upper

and

lower

case

fit

in

portion

with

an

adhe

sive

substance

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

50

em

19

7

in

from

evaporator

core

INSPECT

ON

In

case

evaporator

core

or

expan

sion

valve

have

gas

leaking

repair

or

replace

it

with

a

new

one

as

necessary

Dirt

and

nicotine

accumulation

on

evaporator

case

will

go

b

d

and

smell

Air

Conditioning

1

Mainrelay

2

Thermostat

3

Upper

case

4

Expansion

valve

5

Evaporator

assembly

6

Lower

case

ID

AC387A

Fig

AC

32

Cooling

Unit

This

means

that

you

have

to

remove

them

from

time

to

time

to

assure

healthful

fresh

air

inside

car

INSTAllATION

Install

evaporator

in

the

reverse

order

of

removal

observing

the

follow

ing

I

When

replacing

evaporator

with

new

one

charge

compressor

with

same

amount

of

new

oil

as

was

drained

before

2

Evaporator

case

should

be

in

stalled

as

close

s

possible

to

heater

unit

3

Refer

to

Fig

AC

29

for

tighten

ing

torque

of

flare

nuts

4

Refer

to

General

Service

for

evacuating

and

charging

system

5

Conduct

leak

test

and

ensu

e

that

there

is

no

gas

leak

from

conne

tion

EXPANSION

VALVE

Expansion

valve

malfunctions

such

as

valve

stuck

open

valve

stuck

close

refrigerant

leakage

and

improper

in

stall

tion

of

sensing

bulb

are

de

scribed

The

first

two

conditions

require

replacement

of

expansion

valve

When

both

water

and

refrigerant

AC

22

are

circulated

in

the

system

frost

cwill

form

near

the

ball

of

expansion

alve

and

block

the

flow

of

refrigerant

In

this

case

however

operation

of

the

valve

can

be

returned

to

normal

by

heating

the

valve

Expansion

valve

is

equipped

with

an

adjusting

screw

However

since

the

screw

is

set

properly

at

the

factory

adjustment

is

unnecessary

If

expan

sion

valve

is

damaged

replace

with

new

one

RIEMOV

L

AND

INSTALlATION

See

Fig

AC

32

Disconnect

baltery

ground

cable

2

Remove

ev

porator

Refer

to

Cooling

Unit

for

removal

3

Remove

heat

insulator

covering

expansion

valve

assembly

4

Remove

clamp

attaching

sensing

bulb

5

Loosen

flare

nuts

and

remove

expansion

valve

from

evaporator

and

inlet

pipe

CAUTION

Plug

all

openings

to

prevent

entrance

of

dirt

and

moisture

6

Installation

is

ill

the

reverse

order

of

removal

THERMOSTAT

REMOVAL

AND

INSTALlATION

See

Fig

AC

32

Remove

cooling

unit

2

Remove

screws

attaching

thenno

stat

and

then

remove

thermostat

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

3

Installation

is

in

the

reverse

order

of

removal

Page 524 of 548

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

SO

em

19

7

in

from

evaporator

core

INSPECTION

1

Test

continuity

between

two

switch

terminals

with

test

lamp

or

ohmmerter

Continuity

should

exist

2

With

capillary

tube

end

dipped

into

ice

salt

water

maintained

to

I

oc

300

F

test

continuity

between

two

switch

terminals

Continuity

should

not

exist

3

If

switch

is

found

damaged

re

place

MAIN

RELAY

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

connector

from

main

relay

4

Remove

screw

retaining

main

relay

to

cooling

unit

then

remove

main

relay

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Test

continuity

of

relay

with

ohm

meter

or

test

lamp

In

testing

main

relay

there

must

be

continuity

be

tween

CD

and

CV

When

l2Y

direct

current

is

applied

to

CD

CV

CID

@

normally

close

ti

I

I

6

i

i

f

i

f

Fig

AC

33

Air

Conditioning

HEATER

UNIT

Refer

to

Heater

Unit

Section

BE

WATER

COCK

Refer

to

Water

Cock

Section

BE

BLOWER

MOTOR

Refer

to

Blower

Motor

Section

BE

RESISTOR

Refer

to

Resistor

Section

BE

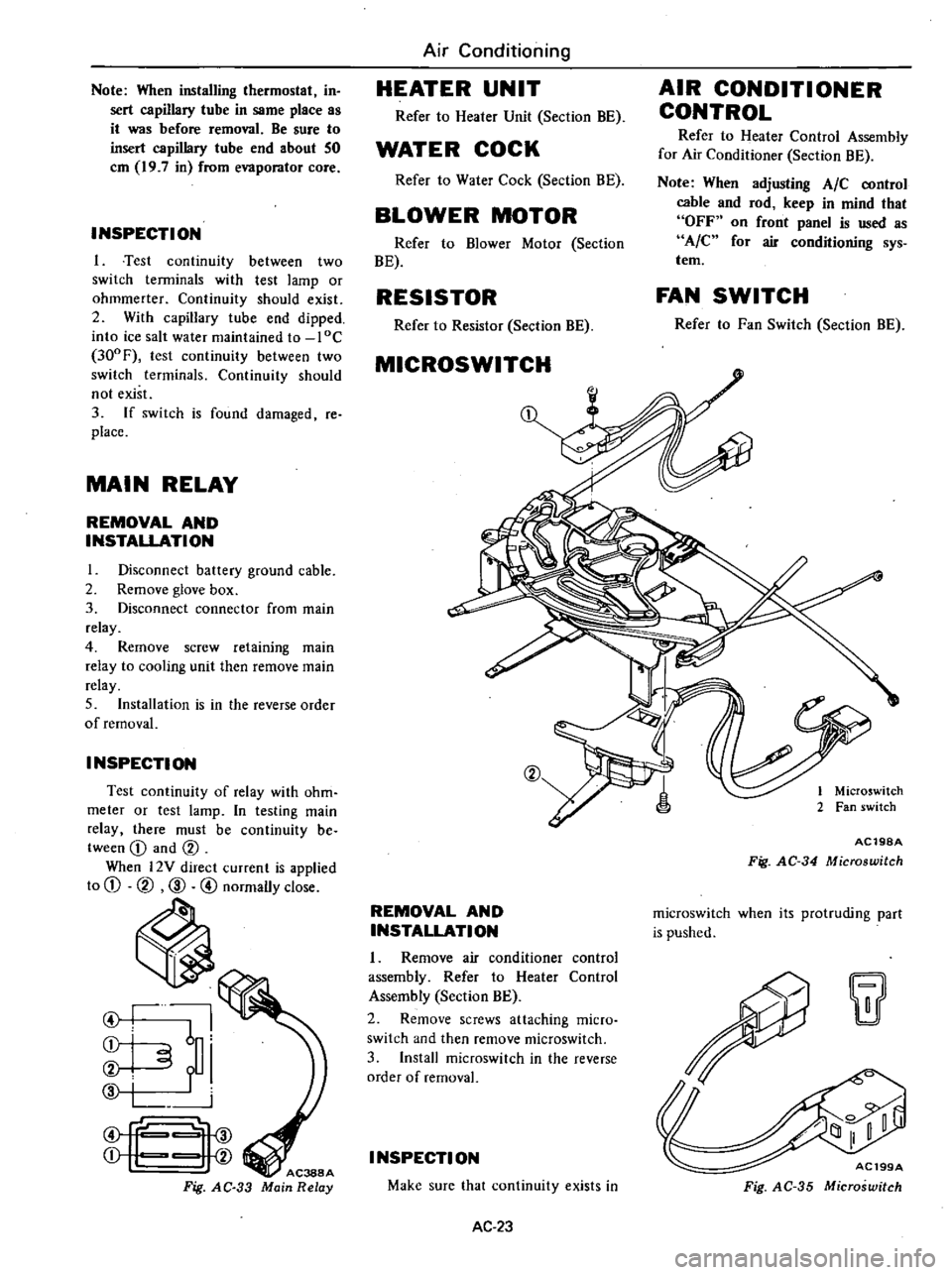

MICROSWITCH

CV

REMOVAL

AND

INSTALLATION

1

Remove

air

conditioner

control

assembly

Refer

to

Heater

Control

Assembly

Section

BE

2

Remove

screws

attaching

micro

switch

and

then

remove

rnicroswitch

3

Install

rnicroswitch

in

the

reverse

order

of

removal

I

NSPECTI

ON

Make

sure

that

continuity

exists

in

AC

23

AIR

CONDITIONER

CONTROL

Refer

to

Heater

Control

Assembly

for

Air

Conditioner

Section

BE

Note

When

adjusting

AIC

control

cable

and

rod

keep

in

mind

that

OFF

on

front

panel

is

used

as

A

C

for

air

conditioning

sys

tem

FAN

SWITCH

Refer

to

Fan

Switch

Section

BE

1

Microswitch

2

Fan

switch

AC19SA

Fig

AC

34

Microswitch

rnicroswitch

when

its

protruding

part

is

pushed

w

AC199A

Fig

AC

35

Microswitch