diagram DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 44 of 548

5

Fit

insert

ensuring

that

it

seats

on

bottom

face

of

its

recess

6

Newly

fitted

valve

seat

should

be

cut

or

ground

with

suitable

seat

cutter

or

grinding

stone

7

Apply

smalliunount

of

fine

grind

ing

compound

to

valve

contacting

face

and

put

valve

into

guide

Lap

valve

against

its

seat

ntil

proper

valve

seat

ing

is

obtained

Remove

valve

and

clean

valve

and

valve

seat

VALVE

ROCKER

ARM

1

AND

SHAFT

I

Check

rocker

arm

bore

and

shaft

for

scores

or

scuffs

2

Check

clearance

between

each

rocker

arm

and

shaft

by

measuring

inner

diameter

of

rocker

arm

bore

and

outer

diameter

of

shaft

If

either

clearance

is

not

within

spec

ification

replace

rocker

arm

and

or

shaft

3

Check

valve

end

contact

surface

of

rocker

arm

for

abnormal

wear

or

scuffs

VALVE

LIFTER

AND

PUSH

ROD

I

Check

valve

lifter

for

wear

or

scuffs

Check

bottom

end

of

valve

lifter

to

make

sure

it

has

a

slight

convex

Replace

valve

lifters

that

are

scored

worn

or

have

unsmooth

bot

tom

2

Check

clearance

between

lifter

hole

on

cylinder

block

and

valve

lifter

Replace

valve

lifter

if

clearance

ex

ceeds

wear

limit

3

Check

push

rod

for

bending

and

damage

Check

end

of

push

rod

for

rough

ness

or

excessive

wear

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAFT

BEARING

CLEARANCE

Journal

diameters

should

be

check

ed

with

a

micrometer

and

bearings

with

an

inside

dial

gauge

Measure

ments

should

then

be

compared

to

Engine

Mechanical

determine

whether

bearings

are

worn

If

worn

beyond

0

15

mm

0

0059

in

replace

using

Camshaft

Bearing

Drift

STl6Il0000

In

press

fitting

a

new

bearing

make

certain

that

oil

holes

in

block

and

bearing

are

properly

aligned

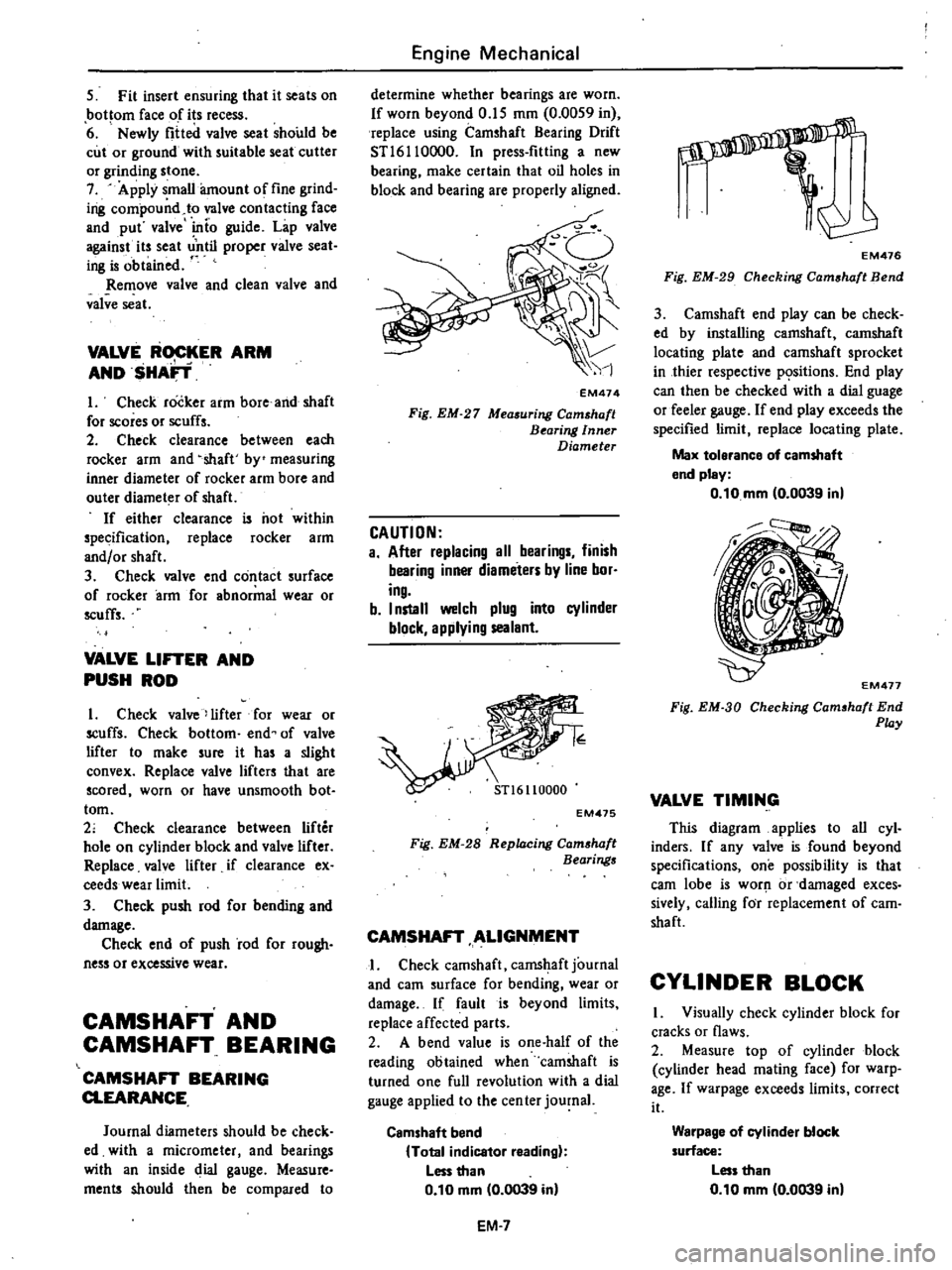

EM474

Fig

EM

27

Measuring

Camshaft

Bearing

Inner

Diameter

CAUTION

a

After

replacing

all

bearings

finish

bearing

inner

diameters

by

line

bor

ing

b

I

nstall

welch

plug

into

cylinder

block

applying

sealant

EM475

Fig

EM

28

Replacing

Cam

haft

Bearings

CAMSHAFT

ALIGNMENT

I

Check

camshaft

camshaft

journal

and

earn

surface

for

bending

wear

or

damage

If

fault

is

beyond

limits

replace

affected

parts

2

A

bend

value

is

one

half

of

the

reading

obtained

when

camshaft

is

turned

one

full

revolution

with

a

dial

gauge

applied

to

the

cen

ter

journal

Camshaft

bend

Total

indicator

reading

Less

than

0

10

mm

0

0039

in

EM

7

s

EM476

Fig

EM

29

Checking

Cam

haft

Bend

3

Camshaft

end

play

can

be

check

ed

by

installing

camshaft

camshaft

locating

plate

and

camshaft

sprocket

in

thier

respective

p

sitions

End

play

can

then

be

checked

with

a

dial

guage

or

feeler

gauge

If

end

play

exceeds

the

specified

limit

replace

locating

plate

Max

tolerance

of

camshaft

end

pley

0

10

mm

0

0039

in

EM477

Fig

EM

3D

Checking

Cam

haft

End

Play

VALVE

TIMING

This

diagram

applies

to

all

cyl

inders

If

any

valve

is

found

beyond

specifications

one

possibility

is

that

earn

lobe

is

worJ

1

or

damaged

exces

sively

calling

for

replacement

of

cam

shaft

CYLINDER

BLOCK

I

Visually

check

cylinder

block

for

cracks

or

flaws

2

Measure

top

of

cylinder

block

cylinder

head

mating

face

for

warp

age

If

warpage

exceeds

limits

correct

it

Warpage

of

cylinder

block

surface

Less

than

0

10

mm

0

0039

in

Page 104 of 548

1

Ignition

switch

2

Amplifier

3

Speed

switch

Note

a

Tightening

torque

is

1

8

to

2

2

kg

m

13

to

16

ft

Ib

b

After

replacement

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

sole

noid

i

in

good

condition

EFOSOA

Fig

EF47

Checking

Anti

dieaeling

Solenoid

l

SJ

Engine

Fuel

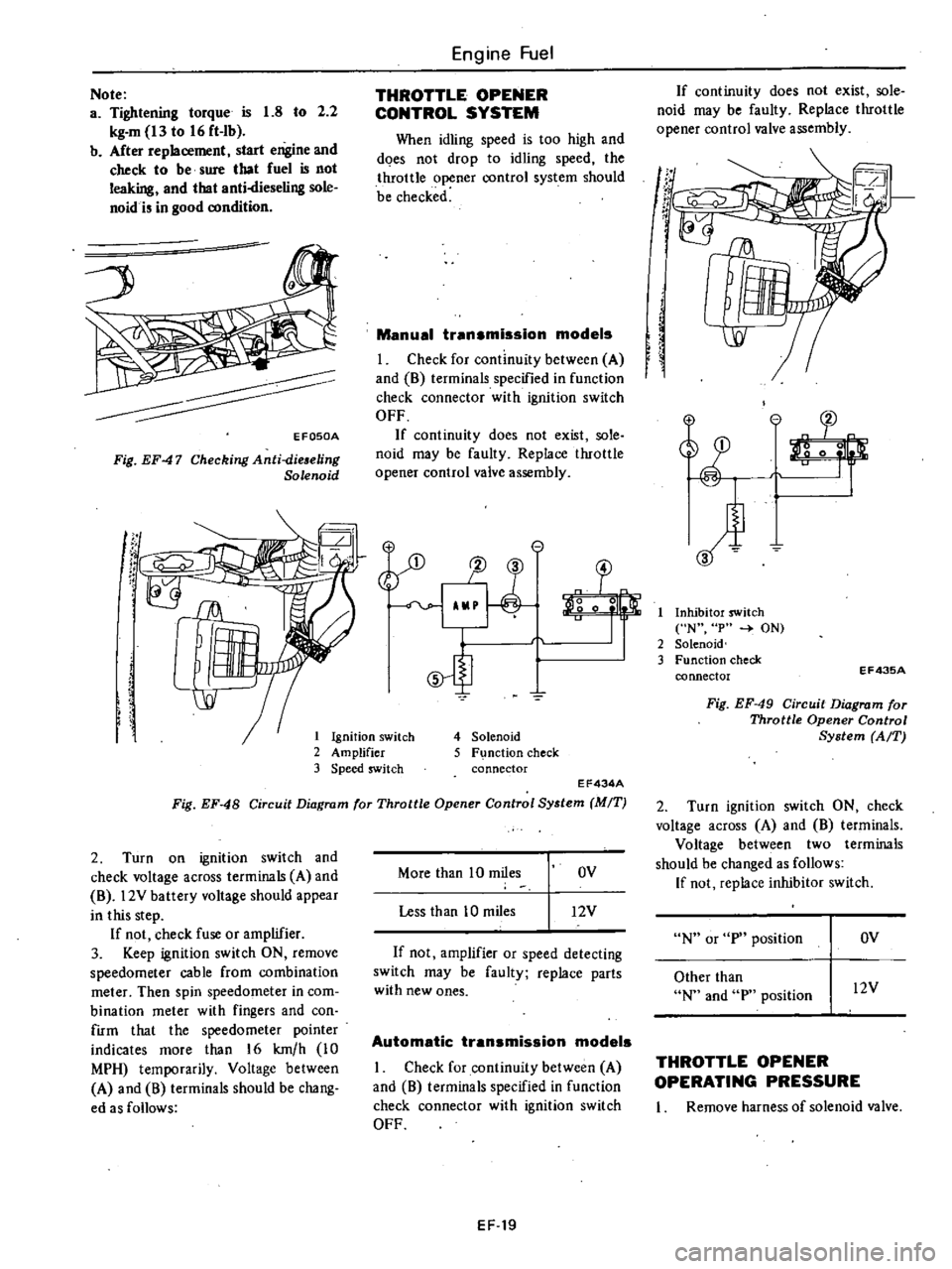

THROTTLE

OPENER

CONTROL

SYSTEM

When

idling

speed

is

too

high

and

does

not

drop

to

idling

speed

the

throttle

opener

control

system

should

be

checked

Manual

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

e

1J

3

o

0

5

4

Solenoid

5

F

nction

check

connector

EF434A

Fig

EF

48

Circuit

Diagram

for

Throttle

Opener

Control

System

MIT

2

Turn

on

ignition

switch

and

check

voltage

across

terminals

A

and

8

l2V

battery

voltage

should

appear

in

this

step

If

not

check

fuse

or

amplifier

3

Keep

ignition

switch

ON

remove

speedometer

cable

from

combination

meter

Then

spin

speedometer

in

com

bination

meter

with

fingers

and

con

firm

that

the

speedometer

pointer

indicates

more

than

16

km

h

10

MPH

temporarily

Voltage

between

A

and

8

terminals

should

be

chang

ed

as

follows

More

than

10

miles

OV

Less

than

10

miles

12V

If

not

amplifier

or

speed

detecting

switch

may

be

faulty

replace

parts

with

new

ones

Automatic

transmission

models

I

Check

for

continuity

between

A

and

8

terminals

specified

in

function

check

connector

with

ignition

switch

OFF

EF

19

If

continuity

does

not

exist

sole

noid

may

be

faulty

Replace

throttle

opener

control

valve

assembly

If

t

r

If

I

Inhibitor

switch

N

p

ON

2

Solenoid

3

Function

check

connector

EF43SA

Fig

EF

49

Circuit

Diagram

for

Throttle

Opener

Control

System

AfT

2

Turn

ignition

switch

ON

check

voltage

across

A

and

8

terminals

Voltage

between

two

terminals

should

be

changed

as

follows

If

not

replace

inhibitor

switch

N

or

p

position

OV

Other

than

N

and

p

position

l2V

THROTTLE

OPENER

OPERATING

PRESSURE

I

Remove

harness

of

solenoid

valve

Page 178 of 548

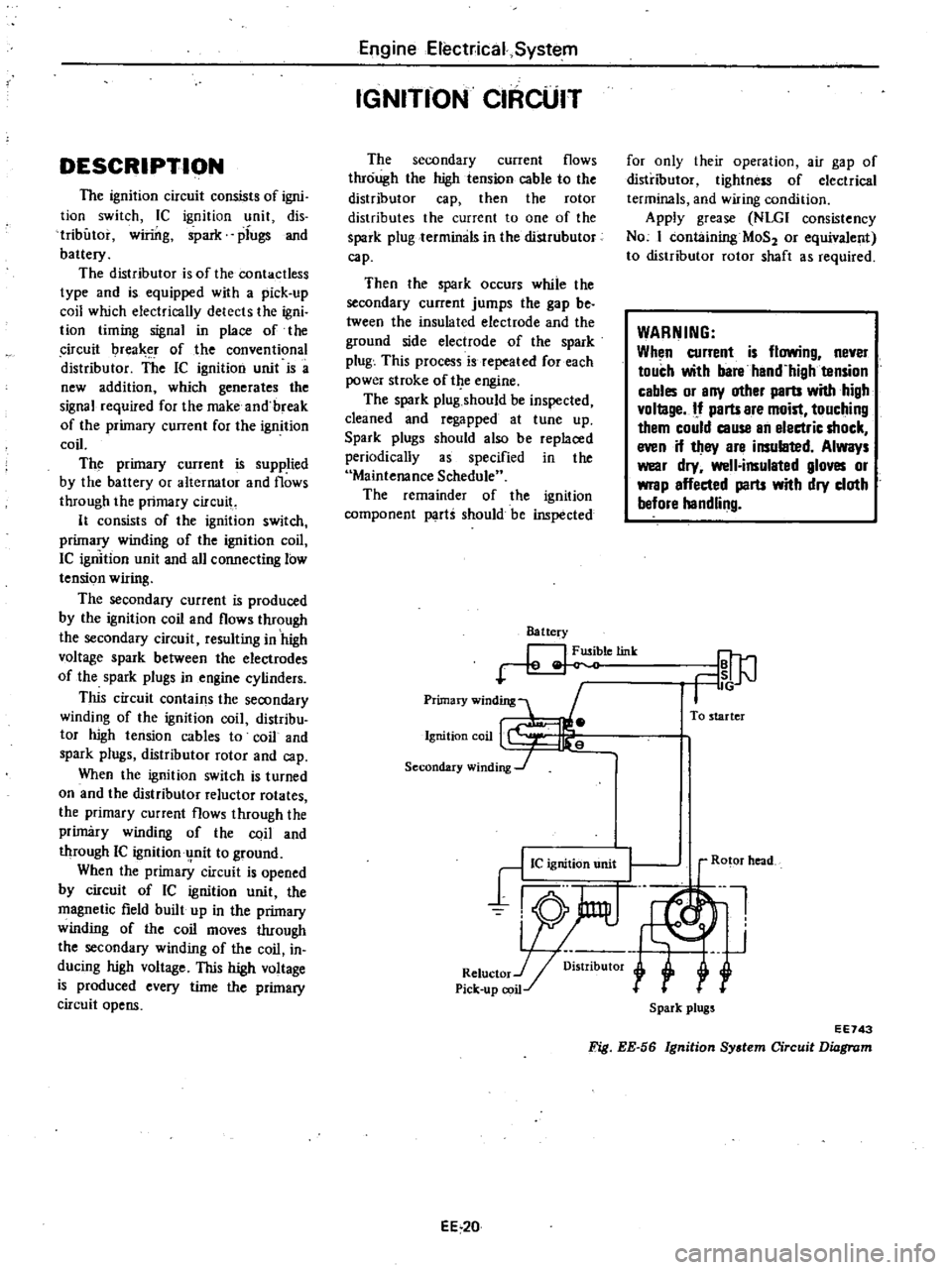

DESCRIPTION

The

ignition

circuit

consists

of

igni

tion

switch

Ie

ignition

unit

dis

tributor

winng

ipark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

ircuit

I

rea

r

of

the

conventional

distributor

The

IC

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

current

for

the

ignition

coil

The

primary

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

primary

winding

of

the

ignition

coil

IC

ignition

unit

and

all

connecting

low

tension

wiring

The

secondary

current

is

produced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

resulting

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

cables

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

IC

ignitionu

nit

to

ground

When

the

primary

circuit

is

opened

by

circuit

of

IC

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

in

ducing

high

voltage

This

high

voltage

is

produced

every

time

the

primary

circuit

opens

EngineElect

ical

System

IGNITfON

CIRCUIT

The

secondary

current

flows

through

the

high

tension

cable

to

the

distributor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distrubutor

cap

Then

the

spark

occurs

while

the

secondary

current

jumps

the

gap

be

tween

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

t

e

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Schedule

The

remainder

of

the

ignition

component

parti

should

be

inspected

Battery

letink

Primary

winding

1

Ignition

coil

Secondary

winding

J

for

only

their

operation

air

gap

of

distributor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MaS

or

equivalent

to

distributor

rotor

shaft

as

required

WARNING

When

current

is

flowing

never

touch

with

bare

hand

high

tension

cables

or

any

other

parts

with

high

vollage

If

parts

are

moist

touching

them

could

cause

an

electric

shock

even

if

they

are

insulated

Always

wear

dry

well

insulated

gloves

or

wrap

affected

parts

with

dry

cloth

before

handling

To

starter

EE

20

Ro

or

head

Ul

J

r

Spark

plugs

EE743

Fig

EE

56

Ignition

System

Circuit

Diagram

Page 183 of 548

Engine

Electrical

System

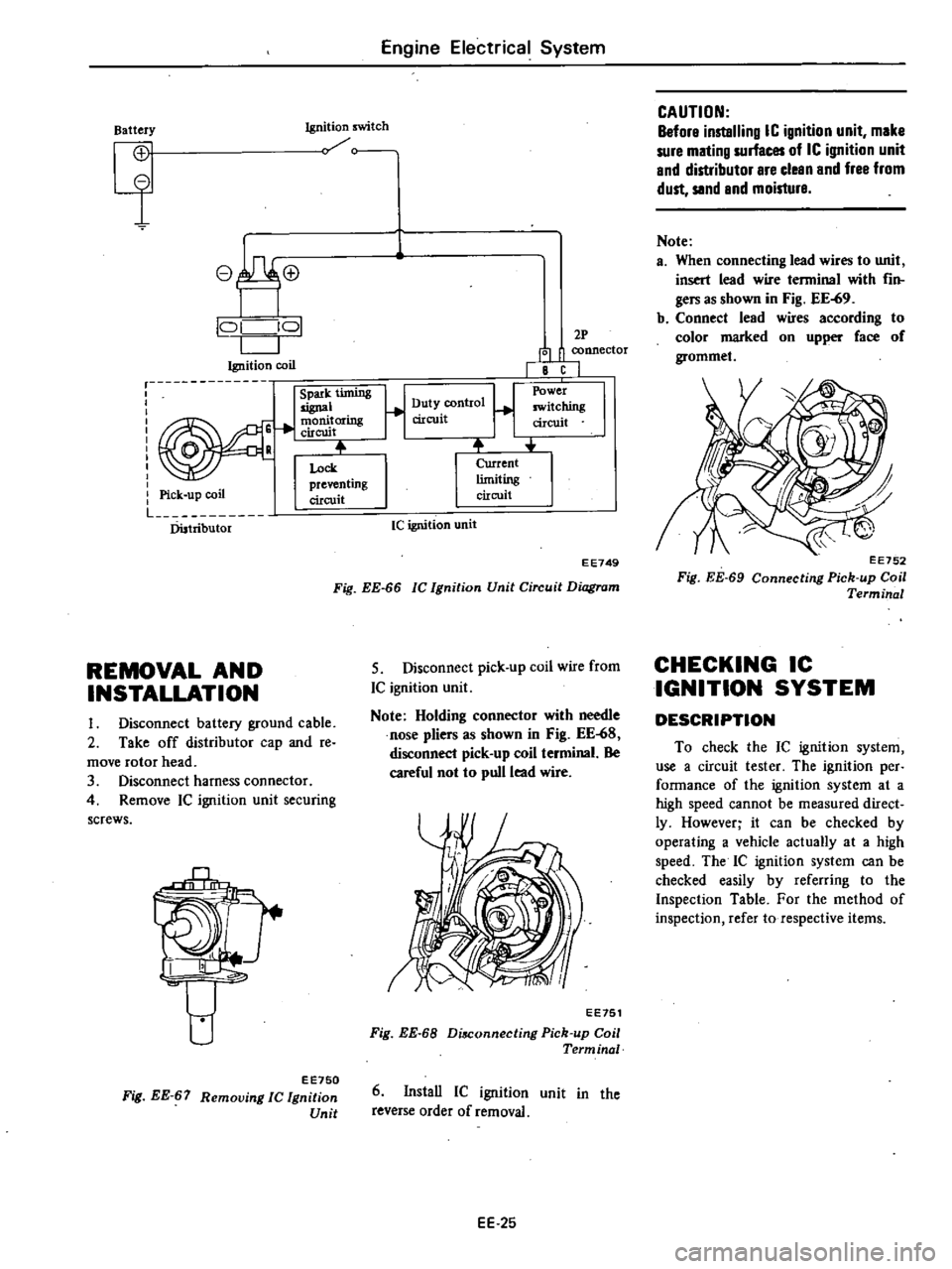

Battery

Ignition

switch

CG

1

e

@

P

L

JO

L

J

Ignition

coil

r

Spark

timing

signal

I

oni

1oring

Clfcwt

0

R

Lock

Pi

k

il

preventing

c

up

co

circuit

Ln

n

Distributor

2P

fJ

1I

connector

8C

H

uty

control

ClICUlt

Power

switching

circuit

Current

limiting

circuit

Ie

ignition

unit

EE749

Fig

EE

66

Ie

Ignition

Unit

Circuit

Diagram

REMOVAL

AND

INSTALLATION

5

Disconnect

pick

up

coil

wire

from

IC

ignition

unit

Note

Holding

connector

with

needle

nose

pliers

as

shown

in

Fig

EE

68

disconnect

pick

up

coil

terminal

Be

careful

not

to

pull

lead

wire

I

Disconnect

battery

ground

cable

2

Take

off

distributor

cap

and

re

move

rotor

head

3

Disconnect

harness

connector

4

Remove

Ie

ignition

unit

securing

screws

rf

I

I

EE751

Fig

EE

68

Di

Connecting

Pick

up

Coil

Term

inal

eE750

Fig

EE

67

Removing

Ie

Ignition

Unit

6

InstaU

IC

ignition

unit

in

the

reverse

order

of

removal

EE

25

CAUTION

Before

instelling

IC

ignition

unit

mike

sure

mlting

surfaces

of

IC

ignition

unit

end

distributor

Ire

cleen

and

free

from

dust

sand

and

moisture

Note

a

When

connecting

lead

wires

to

unit

insert

lead

wire

terminal

with

fin

ger

as

shown

in

Fig

EE

69

b

Connect

lead

wires

according

to

color

marked

on

upper

face

of

grommet

EE752

Fig

EE

69

Connecting

Pick

up

Coil

Terminal

CHECKING

IC

IGNITION

SYSTEM

DESCRIPTION

To

check

the

IC

ignition

system

use

a

circuit

tester

The

ignition

per

fannance

of

the

ignition

system

at

a

high

speed

cannot

be

measured

direct

ly

However

it

can

be

checked

by

operating

a

vehicle

actually

at

a

high

speed

The

IC

ignition

system

can

be

checked

easily

by

referring

to

the

Inspection

Table

For

the

method

of

inspection

refer

to

respective

items

Page 259 of 548

P

r

n

P

rk

Torqu

con

r1lr

011

cool

Drain

volv

r

Front

lubricatic

Ora

1

x

j

L

u

2

6

CD

pr

u

II

ator

Automatic

Transmission

Lawand

b

r

kr

Brah

bond

f

12@

J

f

di

X

Ivacuum

r

11

throttl

Throttl

lenOI

I

I

yo

lv

e

f

k

UP

j

o

n

1

I

s

I

j

I

c

u

u

00

0

I

1

2

@

r

13

@2nd

3rdShlft

10

lv

In

Jl

Si

R

or

clutch

x

Otific

chick

volv

Throttl

drain

01

x

II

5

I

J

1

11

II

2

@l

2

dl

r

Shift

u

I

I

j2

II

Xu

J

I

f1

11

U

2

n

Ol

l

I

I

X

X

Secondary

Primary

90

rn01

101

90

nor

01

Not

Mark

d

X

ore

drain

lint

pru

r

Go

nor

f

d

p

u

ur

Govtrnor

prusu

r

r

cl

Torqu

convert

p

ur

TI

I

ratt

prUlur

AT455

Fig

A

T

B

Oil

Pre

re

Circuit

Diagram

P

rang

Par

AT7

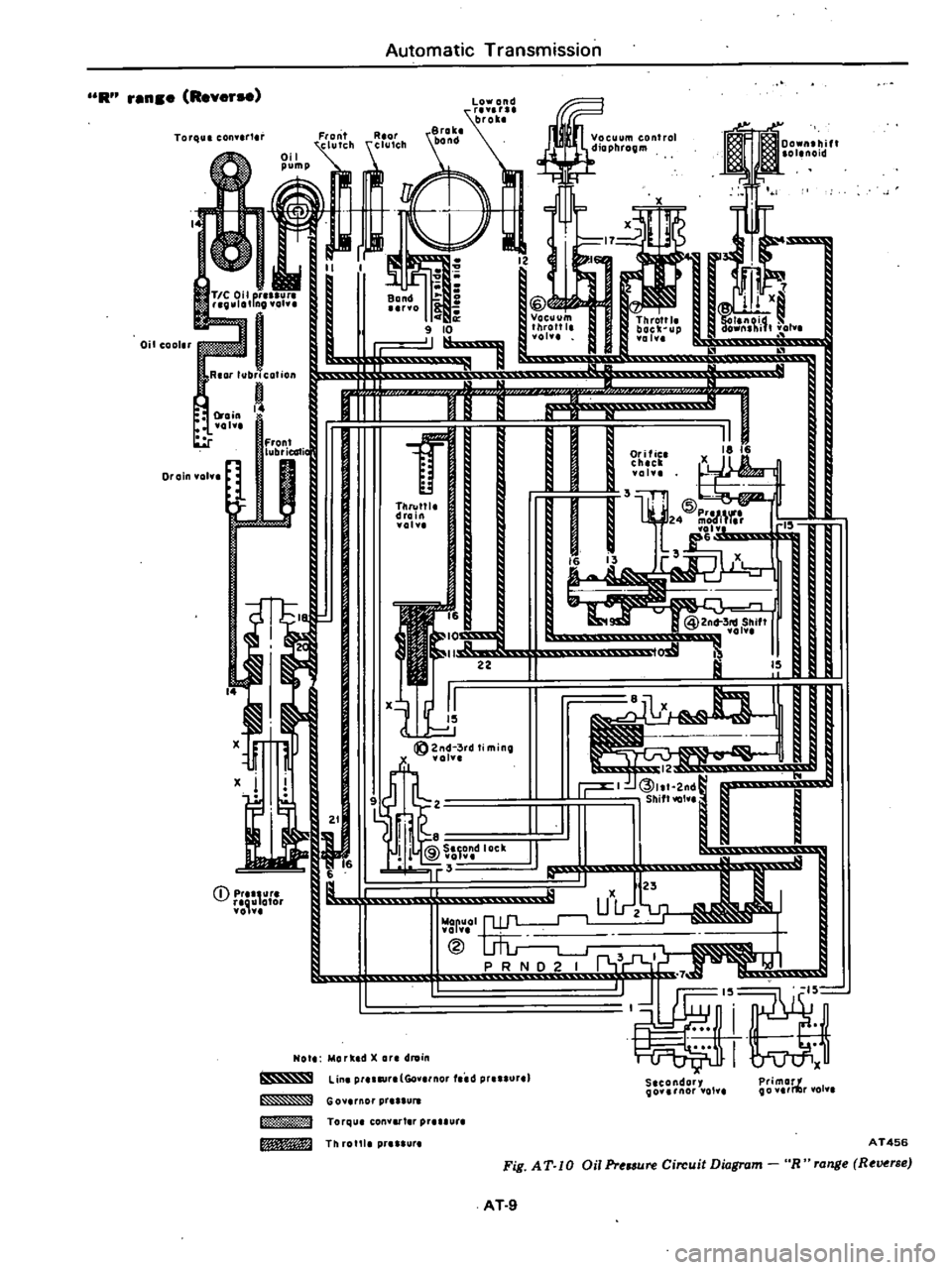

Page 261 of 548

Automatic

Transmission

R

ren

e

Rever

Torque

con

r1

ril

j

j

I

f

I

12

C

I

J

111

x

J

0

8

Q

I

II

lr

Vacuum

Throttl

I

old

I

10

J

f

k

JP

L

u

I

lJ

El

J

U

I

II

O

co

l

chell

01

TO

I

drain

fol

il

Xl

tJj

1

J

l

2nd

3rd

Ii

minQ

x

U1

1

21

1

1C

ll

IIF

li@S

OC

II

to

0

r

6

9r3

Q

rm

g

L

1

u

iii

uLrt

23

r

t

@

PRND2

I

I

x

moo

la

OlenOid

Oil

cooler

1Rear

lubr

c

otion

f

L

ohl

r

Front

u

J

I

@2nd

3

Shift

vol

a

IS

I

12

u

l

r

I

3

w

q

r

4

I

l

Secondory

Qo

rnar

01

Primarf

Qo

i1lr

lol

Note

Mork

d

X

Qr

droin

j

Lin

prUltfrt

Go

nor

tced

r

rr

uur

J

G

0

1

1

101

pr

L

J

3

J

Torqu

can

tar

P

Urt

Tn

rotU

pr

ur

AT456

Fig

AT

10

Oil

Pr

lSure

Circuit

Diagram

R

range

Reverse

AT

9

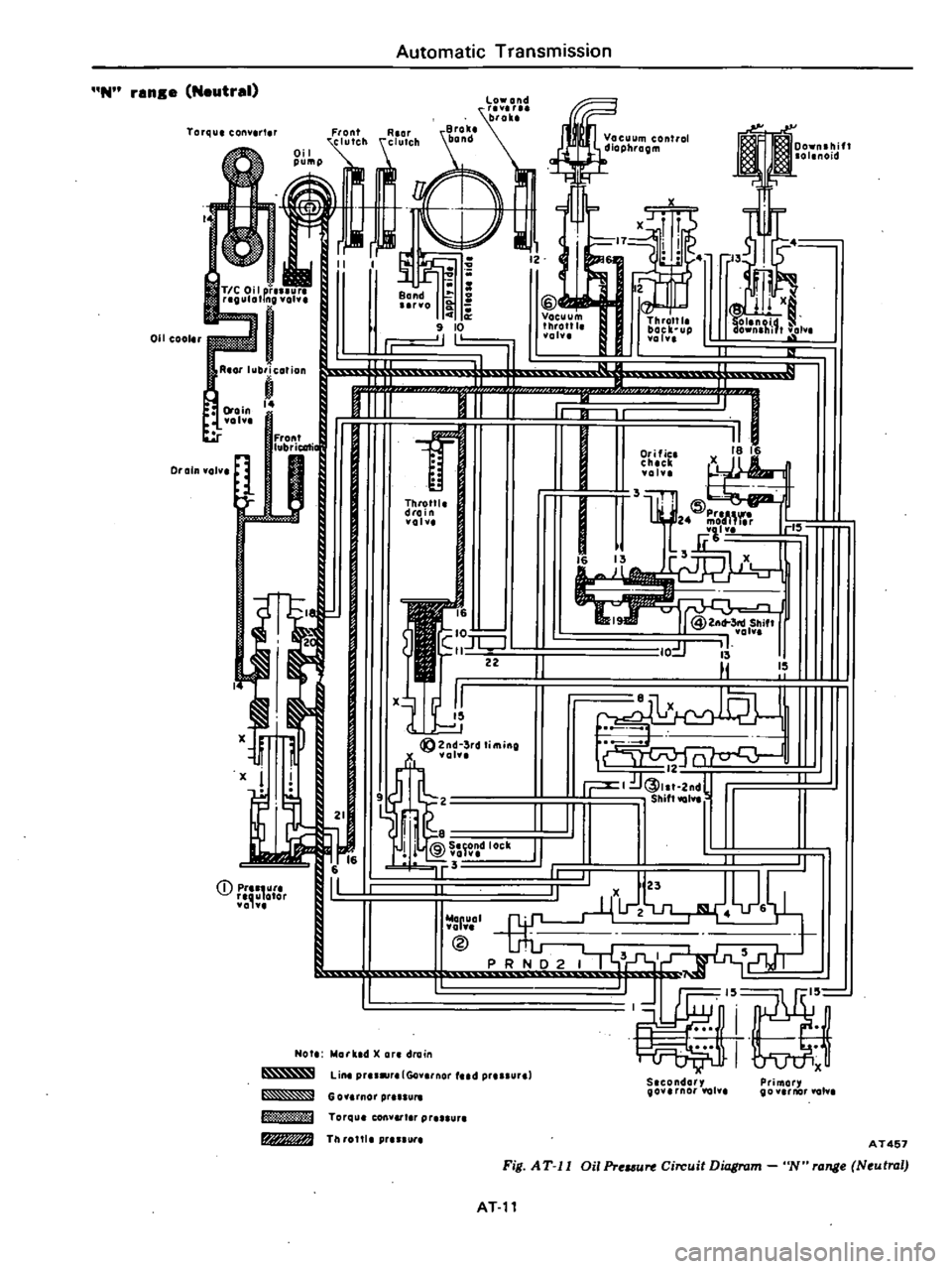

Page 263 of 548

N

ran

e

Neutral

Torqu

conv

rt

r

011

cool

r

TIC

Oil

pillut

i

RlOr

lubricofion

j

l

oin

vo

Drain

volv

Fron

lub

icati

lJ

x

I

U

2

CD

pr

utl

II

o

or

Automatic

Transmission

e

m

eoo

h

m

Band

ii

@

rvo

Vacuum

Thronl

0

throttl

boclt

up

I

I

olu

Yolv

I

r

Throttl

drain

volv

16

IO

S

X

tJ1

1

g

2nd

3rd

timing

oh

8

r

t

@

I

Not

hlorll

td

X

or

drain

Lin

pru

lr

lGo

rnor

d

pr

ur

60

rnol

pr

m

Torqu

convert

r

Plu

ur

W

TI

I

rottl

p

nur

f

r

1

1

18

I

L

O

lie

chick

volv

3lIf

IDpre

l

h

J

24

m

iM

llv

16

3

X

1X

0

jr

i

II

I

II

I

I

I

X

U4lJ

I

3

J

a

i

I

U1J

S

condory

governor

lal

Primor

gov

rnor

tO

AT457

Fig

AT

II

Oil

Pr

u

Circuit

Diagram

N

rang

Neutral

ATll

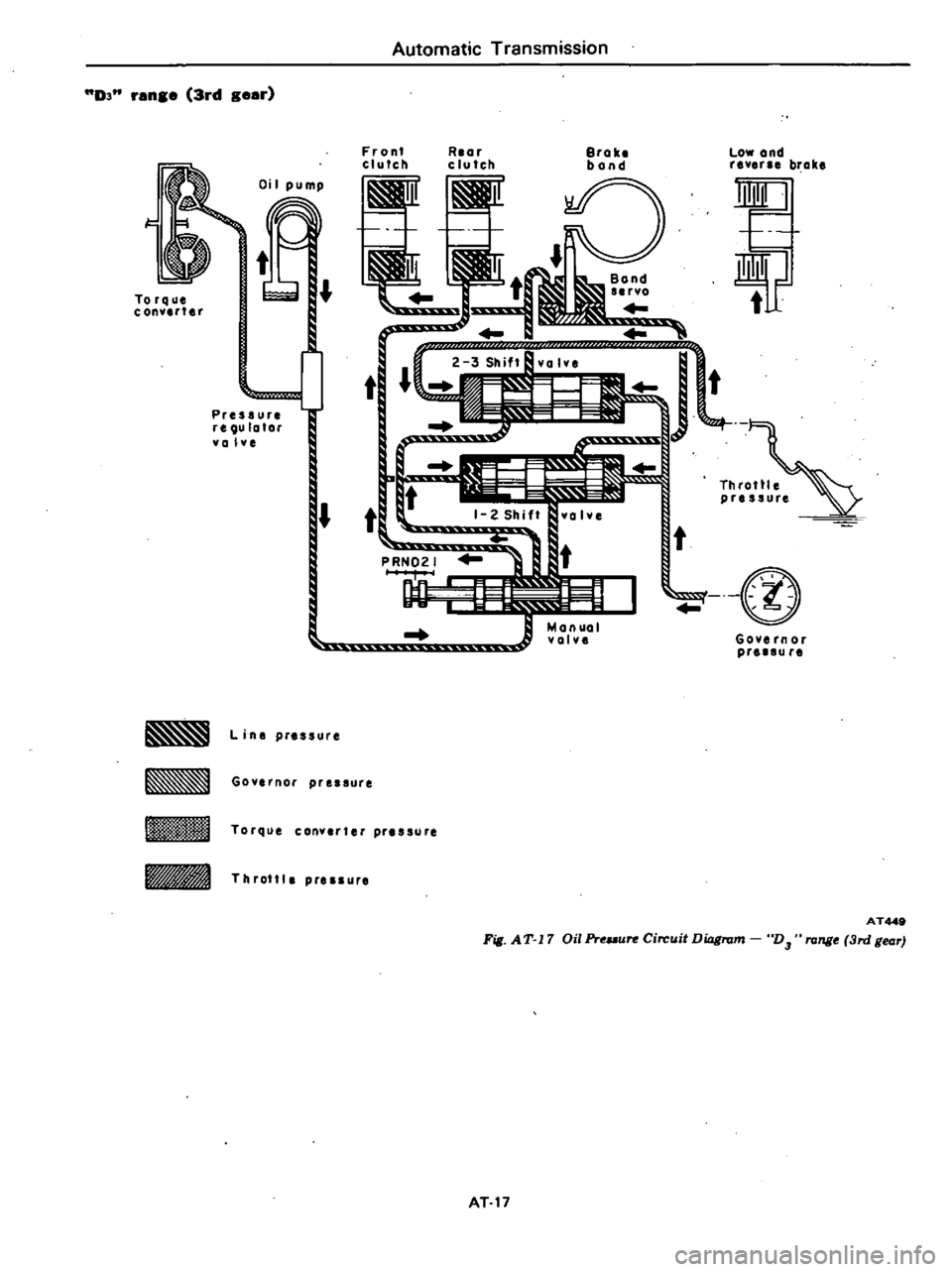

Page 269 of 548

D3

ran

3rd

g

ar

Oi

I

pump

1

t

Torque

J

C

onYlrt

r

I

i

t

t

Pressure

reQula

or

Ya

lye

L

i

ns

pressure

Goyernor

pressure

Automatic

Transmission

Front

clurch

Rlar

clutch

Brake

bond

Low

and

rever

brake

0

thBond

L

B

so

J

1

1

1

lt

r

T

tr

Throttle

pressure

t

t

I

@

t

Governor

pr

au

r

Torque

canYlr

er

pr

ssure

rIA

Throttle

pressure

AT449

Fill

AT

17

Oil

Pro

ure

Circuit

Diagram

D3

range

3rd

gear

AT

17

Page 271 of 548

Automatic

Transmission

D

nnse

klckdown

Shift

valvas

In

2nd

sear

position

Vacuum

control

dlophroem

r

r

X

I

i

jI

2

dl

2

l

s

o

@

i

i

JJ

1

1

I

N1

1

JJ

r

OI

r

J

@

I

J

ju

n

II

r

1

o

N

m

II

lln

pru

r

Gov

nor

Iud

pr

ssurel

1

x

x

S

condary

Primor

90V

nor

val

00

rnor

olv

Low

ond

brok

Brak

bond

2

Oil

cooler

I

r

J

80nd

no

C

a

i

0

J

P

N

R

ar

lubrication

aJ

8

ll

Ill

f

I

f

j

l

l

0

1

1

Throttl

drain

voh

i

Xl

U

II

CD

r

lIU

afor

volv

I

l

r

Go

rnor

pr

IU

Torqu

conv

t

r

pr

lur

TIl

rotll

p

lure

AT458

Fig

AT

18

Oil

Pr

mn

Circuit

Diagram

D

rong

kickdown

hift

va

v

s

in

2nd

gear

position

AT

19

X

Throttl

back

up

vain

F

w

I

P

b

I

1

Orific

18

16

ch

ck

X

val

1

r

@2n

3n

lShift

01

l

l

I

Page 273 of 548

2

renge

2nd

Beer

Oil

cool

Reor

lubrication

o

4

Drain

oha

Fron

lubricaf

Drain

vol

x

x

I

Ii

6

II

D

r

ou

alar

01

1

4

Automatic

Transmission

J

R

or

j

j

I

r

r

Bond

0

0

41

9

10

Throttl

I

r

lc

uP

a

II

J

I

i

ll

fr

t

rr

1

1

I

i

Throttle

I

drain

ahe

j

01

1816

x

@Zn6

3rd

Shift

101

1

J

is

t1

1x

J

I

I

n

s

t

Z

l

n

S

II

I

1

1

1

II

IS

N

U

g

2nd

3rd

timing

X

vol

I

I

2

S

j

000j

Ul

I1

I

w

X

fo4anuol

P

R

lIo

Not

Morked

X

art

drain

Slcondory

govunor

ViII

Primor

go

nor

vol

line

pr

ur

Go

nor

lid

pr

ure

G

o

rnOI

pr

Torqul

con

r

p

JUri

Th

rotU

p

AT459

Fig

AT

19

Oil

ProIlU

Circuit

Diagram

2

range

2nd

tar

AT

21