height DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 419 of 548

Body

2

Length

of

shock

absorber

Front

shock

absorber

I

164

6

46

q

j

0

I

0

0

67

2

64

Rear

shock

absorber

G

riA

l

yll

L

J

J

Unit

mm

in

3

Checking

shock

absorber

I

Place

car

in

front

of

a

wall

Apply

hand

brake

and

place

wheel

chocks

securely

2

Place

a

jack

between

wall

and

extend

jack

approximately

20

mm

0

79

in

The

bumper

should

move

approxilnately

50

mm

I

97

in

back

ward

through

shock

absorber

opera

tion

See

Fig

BF

IO

Note

Use

a

jack

with

y

of

more

than

600

kg

I

3231b

94

3

70

rL

I

i

r

T

l

f

L

W

67

2

64

1

8F742B

Fig

BF

9

Length

of

Shock

Absorber

3

Make

sure

bumper

returns

to

its

original

position

when

jack

is

re

tracted

Note

When

replacing

shock

absorb

ers

make

Sure

they

are

of

the

same

type

and

rating

and

manufactured

by

the

same

maker

4

For

rear

bumper

utilize

the

same

procedures

as

described

for

front

bumper

f

BF7438

1

Front

bumper

2

Jack

3

Wheel

chock

Fig

BF

10

Checking

Shock

Abaorber

Function

BF

8

FRONT

BUMPER

REMOVAL

AND

INSTALLATION

1

Loosen

bolts

attaching

front

bumper

to

shock

absorbers

and

re

move

bumper

See

Fig

BF

5

2

Loosen

bolts

attaching

shock

ab

sorbers

to

radia

tor

core

support

and

side

members

and

remove

shock

absorbers

3

Install

shock

absorbers

and

front

bumper

in

reverse

order

of

removal

and

adjust

bumper

height

as

shown

in

Fig

BF

7

fj

Tightening

torque

Front

bumper

Bumper

to

shock

absorber

attaching

bolt

6

0

to

8

0

kg

m

43

to

58

ft

Ib

Shock

absorber

to

body

attaching

bolt

and

nut

front

0

93

to

1

2

kg

m

6

7

to

B

7

ft

Ibl

attaching

bolt

and

nut

sida

1

9

to

2

5

kg

m

14

to

18

ft

b

REAR

BUMPER

REMOVAL

AND

INSTALLATION

1

Loosen

bolts

attaching

rear

bumper

to

shock

absorbers

and

re

move

rear

bumper

See

Fig

BF

6

2

Loosen

bolts

and

nuts

attaching

shock

absorbers

to

side

members

and

remove

shock

absorbers

3

Install

shock

absorbers

an

rear

bumper

in

reverse

order

of

removal

and

adjust

rear

bumper

height

as

shown

in

Fig

BF

B

fj

Tightening

torque

Rear

bumper

Bumper

to

shock

absorber

attaching

bolt

rear

6

0

to

8

0

kg

m

43

to

58

ft

b

Shock

absorber

to

body

attaching

bolt

and

nut

rear

0

93

to

1

2

kg

m

6

7

to

8

7

ft

b

attaching

bolt

and

nut

side

6

0

to

BoO

kg

m

43

to

58

ft

b

Page 456 of 548

ILLUMINATION

CONTROL

UNIT

Body

Electrical

System

8

GY

GW

AIMING

ADJUSTMENT

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

ailn

use

adjusting

screw

on

side

of

headlamp

BE1200

Fig

BE

I3

Illumination

Control

Unit

1

Vertical

adjustment

2

Horizontal

adjustment

BE1210

Fig

BE

14

Aiming

Ad

iusting

Screws

Note

Before

makiiIg

headlamp

aim

ing

adjustment

observe

the

follow

ing

instructions

a

Keep

all

tires

inflated

to

correct

pressures

b

Place

car

and

tester

on

one

and

BE

11

same

flat

surface

c

See

that

there

is

no

load

in

car

coolant

engine

oil

fIlled

up

to

correct

level

and

full

fuel

tank

other

than

the

driver

or

equivalent

weight

placed

in

driver

s

position

d

For

details

refer

to

SAE

J599d

When

performing

headlamp

aiming

adjustment

use

an

aiming

machine

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

almer

it

should

be

in

good

repair

calibrated

and

used

accordi

g

to

respective

operation

manuals

supplied

with

the

unit

If

any

aimer

is

not

available

aiming

adjustment

can

be

done

as

follqws

Turn

headlamp

low

beam

on

H

Horizontal

center

line

of

headlamps

BE297D

Fig

BE

I5

Aiming

Adjustment

Unit

mm

in

Note

a

Adjust

headlamps

so

that

upper

edge

of

hot

spot

is

equal

in

height

to

headlamp

height

and

left

edge

of

hot

spot

is

equal

in

height

to

each

center

line

of

headlamps

b

Dotted

lines

in

illustration

show

center

of

headlamp

Page 510 of 548

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

Note

Exercise

care

when

handling

re

frigerant

as

it

is

stored

under

high

pressure

COMPRESSOR

OIL

The

SUNISO

5GS

refrig

ration

lubricant

should

be

used

to

assure

the

successful

compressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrica

tion

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

MAINTENANCE

The

following

checks

and

main

tenance

are

especially

important

to

the

air

conditioner

I

Check

refrigerant

level

2

Check

refrigerant

leaks

3

Check

compressor

drive

belt

for

proper

deflection

4

Even

in

the

off

season

turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

GENERAL

SERVICE

INSTRUCTIONS

If

dirt

water

or

air

enters

the

air

conditioner

system

it

will

be

seriously

affected

Be

sure

to

observe

the

following

I

Always

keep

the

working

place

clean

and

dry

and

free

from

dirt

and

Air

Conditioning

GENERAL

SERVICE

dust

Wipe

water

off

from

the

line

fittings

with

a

clean

cloth

before

dis

connecting

2

Have

all

necessary

tools

in

prepar

ation

beforehand

and

have

tools

clean

and

dry

3

Handling

plug

when

the

system

line

is

disconnected

4

Handling

compressor

oil

For

details

refer

to

each

descrip

tion

in

this

manual

SAFETY

PRECAUTIONS

WARNING

1

Since

direct

contact

of

the

liquid

refrigerant

with

your

skin

will

cause

frostbite

always

be

carelul

when

handling

the

refrigerant

Always

wear

goggles

to

protect

your

eyes

when

working

around

the

system

2

The

refrigerant

service

container

has

a

safe

strength

However

if

handled

incorrectly

it

will

ex

plode

Therelore

always

follow

the

instructions

On

the

label

In

particular

never

store

it

in

a

hot

location

above

520e

1260F

or

drop

it

from

a

high

height

3

The

refrigerant

gas

is

odorless

and

colorless

and

breathing

may

become

difficult

due

to

the

lack

of

oxygen

Since

the

relrigerant

gas

is

heavier

than

air

and

will

lay

close

to

the

floor

be

espe

cially

careful

when

handling

it

in

small

confined

spaces

4

The

refrigerant

itself

is

nonflam

mable

However

a

toxic

gas

phosgene

gas

is

produced

when

it

contacu

fire

and

special

care

is

therefore

required

when

check

ing

for

leaks

in

the

system

with

a

halide

torch

5

Do

not

steam

clean

On

the

sys

tem

especially

condenser

since

excessively

high

pressure

will

build

up

in

the

system

resulting

in

explosion

of

the

system

The

above

precautions

are

essen

tial

in

handling

of

Refrigerant

12

and

their

strict

observation

AC

9

requires

sufficient

training

Therefore

it

is

of

first

impor

tance

that

any

other

personnel

than

a

well

trained

serviceman

should

not

be

allowed

to

handle

the

refrigerant

EVACUATING

AND

CHARGING

SYSTEM

During

servicing

use

caution

to

keep

air

from

getting

into

refrigerant

When

air

enters

the

system

all

refriger

ant

must

be

evacuated

from

system

prior

to

charging

new

refrigerant

Air

in

refrigerant

has

the

following

delete

rious

effects

1

Since

the

condensation

tempera

ture

of

the

air

is

extremely

low

the

air

will

not

be

condensed

when

refrigerant

gas

is

condensed

in

the

condenser

and

the

air

will

thus

remain

in

gaseous

fonn

Consequently

the

effective

thermal

transmission

area

of

condenser

for

refrigerant

gas

will

be

reduced

and

refrigerant

gas

to

be

condensed

will

be

reduced

The

pressure

rise

will

become

proportional

to

the

volume

of

the

air

in

system

2

When

air

and

refrigerant

are

r

tixed

in

system

a

chemical

reaction

will

be

produced

and

hydrochloric

acid

which

will

adversely

affect

the

aluminum

copper

iron

and

other

materials

in

system

may

be

generated

HANDLING

MANIFOLD

GAUGE

The

pressure

at

the

high

and

low

sides

of

system

should

be

measured

when

evacuating

and

charging

refrig

erant

and

when

diagnosing

trouble

in

the

system

The

manifold

gauge

is

used

for

these

purposes

A

manifold

gauge

has

two

pressure

gauges

a

low

pressure

gauge

and

a

high

pressure

gauge

These

gauges

are

connected

to

the

high

and

low

side

service

valves

of

system

through

flexible

charging

hoses

The

construction

of

manifold

gauge

is

Page 516 of 548

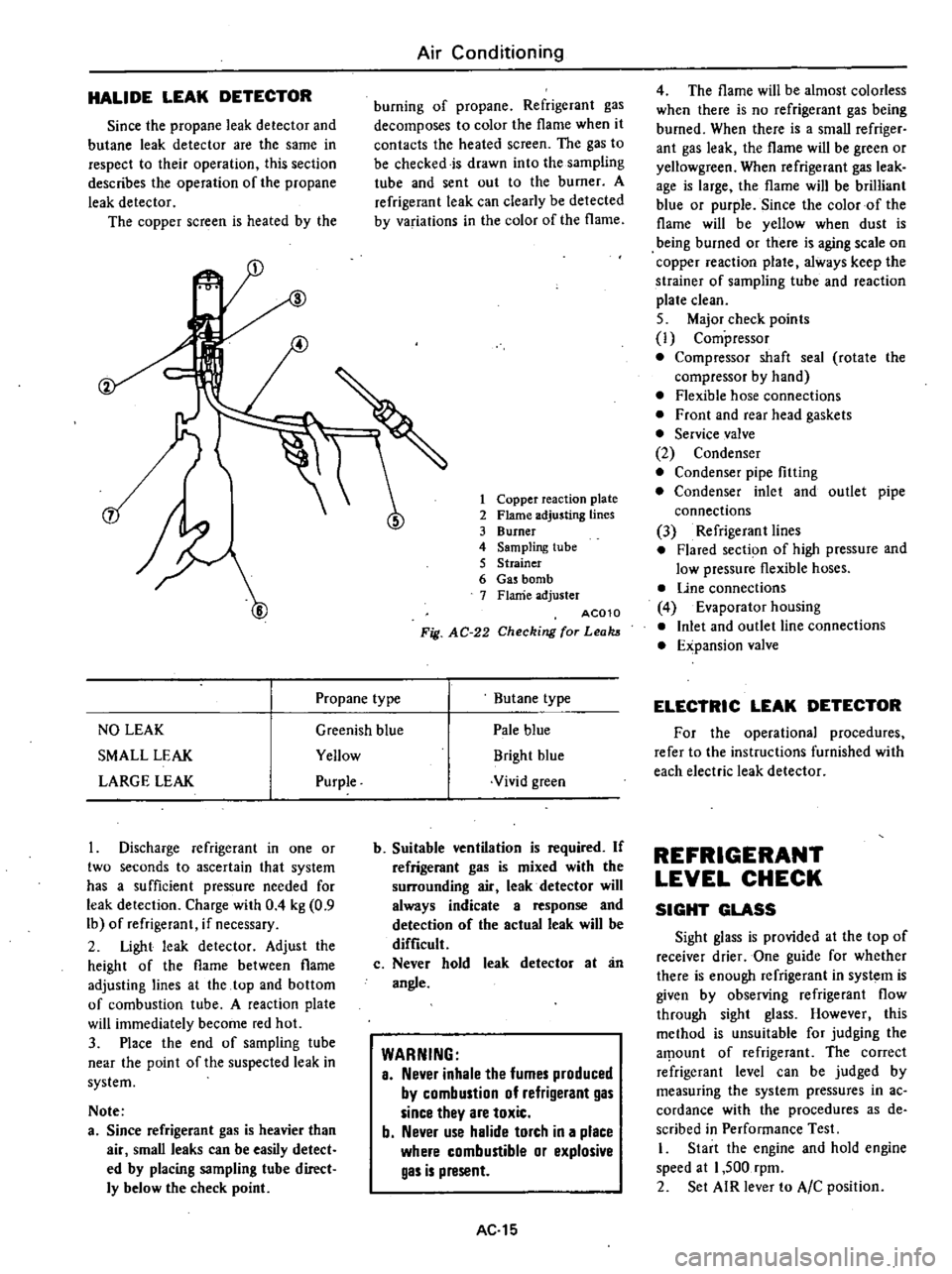

HALIDE

LEAK

DETECTOR

Since

the

propane

leak

detector

and

butane

leak

detector

are

the

same

in

respect

to

their

operation

this

section

describes

the

operation

of

the

propane

leak

detector

The

copper

screen

is

heated

by

the

Air

Conditioning

burning

of

propane

Refrigerant

gas

decomposes

to

color

the

flame

when

it

contacts

the

heated

screen

The

gas

to

be

checked

is

drawn

into

the

sampling

tube

and

sent

out

to

the

burner

A

refrigerant

leak

can

clearly

be

detected

by

variations

in

the

color

of

the

flame

1

Copper

reaction

plate

2

Flame

adjusting

lines

3

Burner

4

Sampling

tube

5

Strainer

6

Gas

bomb

7

Flame

adjuster

AC010

Fig

AC

22

Checking

for

Leaks

4

The

flame

will

be

almost

colorless

when

there

is

no

refrigerant

gas

being

burned

When

there

is

a

small

refriger

ant

gas

leak

the

flame

will

be

green

or

yellowgreen

When

refrigerant

gas

leak

age

is

large

the

flame

will

be

brilliant

blue

or

purple

Since

the

color

of

the

flame

will

be

yellow

when

dust

is

being

burned

or

there

is

aging

scale

on

copper

reaction

plate

always

keep

the

strainer

of

sampling

tube

and

reaction

plate

clean

5

Major

check

points

l

Compressor

Compressor

shaft

seal

rotate

the

compressor

by

hand

Flexible

hose

connections

Front

and

rear

head

gaskets

Service

valve

2

Condenser

Condenser

pipe

fitting

Condenser

inlet

and

outlet

pipe

connections

3

Refrigerant

lines

Flared

section

of

high

pressure

and

low

pressure

flexible

hoses

Une

connections

4

Evaporator

housing

Inlet

and

outlet

line

connections

Expansion

valve

Propane

type

Butane

type

ELECTRIC

LEAK

DETECTOR

NO

LEAK

Greenish

blue

Pale

blue

For

the

operational

procedures

SMALL

LEAK

Yellow

Bright

blue

refer

to

the

instructions

furnished

with

LARGE

LEAK

Purple

Vivid

green

each

electric

leak

detector

Discharge

refrigerant

in

one

or

two

seconds

to

ascertain

that

system

has

a

sufficient

pressure

needed

for

leak

detection

Charge

with

0

4

kg

0

9

Ib

of

refrigeranl

if

necessary

2

Light

leak

detector

Adjust

the

height

of

the

flame

between

flame

adjusting

lines

at

the

top

and

bottom

of

combustion

tube

A

reaction

plate

will

immediately

become

red

hot

3

Place

the

end

of

sampling

tube

near

the

point

of

the

suspected

leak

in

system

Note

a

Since

refrigerant

gas

is

heavier

than

air

small

leaks

can

be

easily

detect

ed

by

placing

sampling

tube

direct

ly

below

the

check

point

b

Suitable

ventilation

is

required

If

refrigerant

gas

is

mixed

with

the

surrounding

air

leak

detector

will

always

indicate

a

response

and

detection

of

the

actual

leak

will

be

difficult

c

Never

hold

leak

detector

at

an

angle

WARNING

a

Never

inhale

the

fumes

produced

by

combustion

of

refrigerant

gas

since

they

are

toxic

b

Never

use

halide

torch

in

a

place

where

combustible

or

explosive

gas

is

present

AC

15

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

Sight

glass

is

provided

at

the

top

of

receiver

drier

One

guide

for

whether

there

is

enough

refrigerant

in

syst

m

is

given

by

observing

refrigerant

flow

through

sight

glass

However

this

method

is

unsuitable

for

judging

the

aJTlount

of

refrigerant

The

correct

refrigeranl

level

can

be

judged

by

measuring

the

system

pressures

in

ac

cordance

with

the

procedures

as

de

scribed

in

Performance

Test

1

Start

the

engine

and

hold

engine

speed

al

1

500

rpm

2

Set

AIR

lever

to

AlC

position