clock DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 22 of 548

SO

B

T

D

C

650

rpm

Non

California

models

except

Canada

100

B

T

0

C

650

rpm

Canada

models

Note

On

FU

models

ignition

timing

t

under

a

con4ition

where

distnoutor

vacuum

hose

is

discon

nected

9

On

FU

models

proceed

as

fol

lows

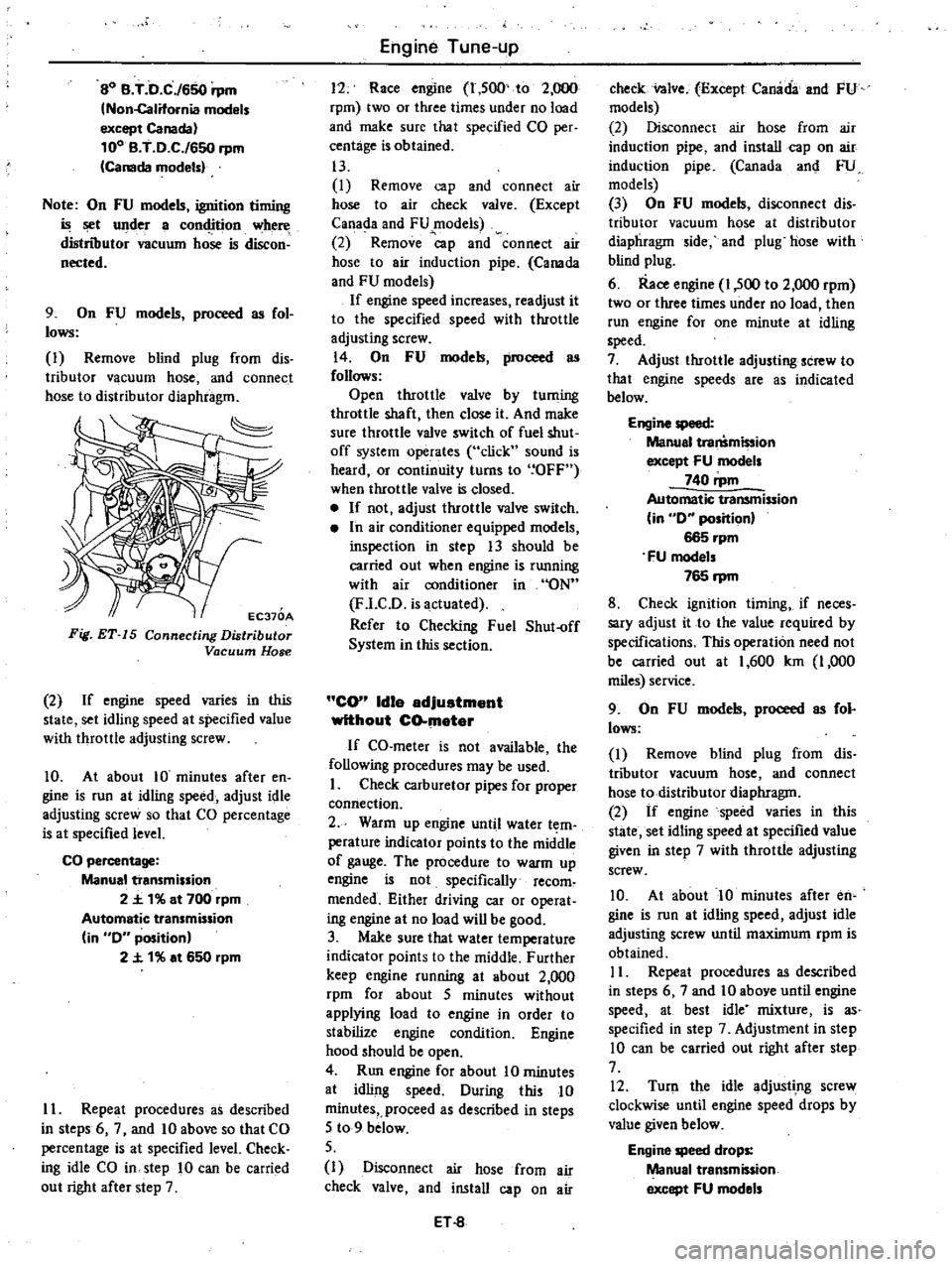

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

EC370A

Fig

ET

15

Connecting

Distributor

Vacuum

Hose

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

1

at

700

rpm

Automatic

transmission

in

0

position

2

t

1

at

650

rpm

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

10

can

be

carried

out

right

after

step

7

Engine

Tune

up

11

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

13

I

Remove

cap

and

connect

air

hose

to

air

check

valve

Except

Canada

and

FU

models

2

Remove

p

and

connect

air

hose

to

air

induction

pipe

Canada

and

FU

models

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

14

On

FU

models

proceed

as

follows

Open

throttle

valve

by

tuming

throttle

shaft

then

close

it

And

make

sure

throttle

valve

switch

of

fuel

shut

off

system

operates

click

sound

is

heard

or

continuity

turns

to

OFF

when

throttle

valve

is

closed

If

not

adjust

throttle

valve

switch

In

air

conditioner

equipped

models

inspection

in

step

13

should

be

carried

out

when

engine

is

running

with

air

conditioner

in

ON

F

l

CD

is

actuated

Refer

to

Checking

Fuel

Shut

off

System

in

this

section

CO

Idle

adjuatment

without

CO

mater

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

comiection

2

Warm

up

engine

until

water

t

m

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

car

or

operat

ing

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

I

Disconnect

air

hose

from

air

check

valve

and

install

cap

on

air

ET

8

check

nlve

Except

Canada

and

FU

models

2

Disconnect

air

hose

from

air

induction

pipe

and

install

cap

on

air

induction

pipe

Canada

an

FU

models

3

On

FU

models

disconnect

dis

tributor

vacuum

hose

at

distributor

diaphragm

ide

and

plug

hose

with

blind

plug

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

to

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

tra

mi

ion

except

FU

models

740

rpm

Automatic

transmission

in

0

position

665

rpm

FU

models

765

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

given

in

step

7

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

until

engine

speed

at

best

idle

mixture

is

as

specified

in

step

7

Adjustment

in

step

10

can

be

carried

out

right

after

step

7

12

Turn

the

idle

adjustIng

screw

clockwise

until

engine

speed

drops

by

value

given

below

Engine

speed

drops

Manual

transmission

except

FU

models

Page 80 of 548

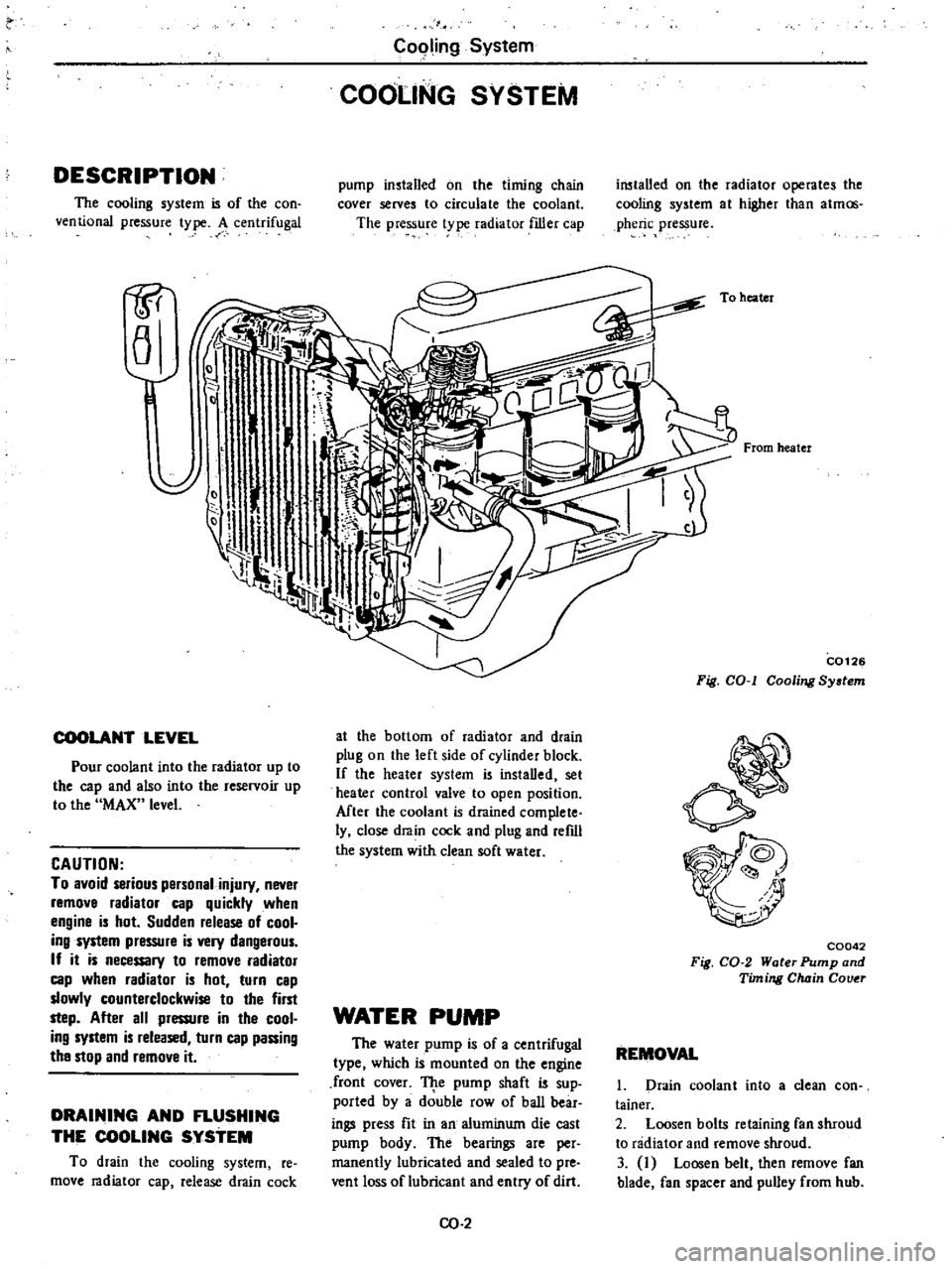

DESCRIPTION

The

cooling

system

is

of

the

con

ventional

pressure

type

A

centrifugal

1P

a

COOLANT

LEVEL

Pour

coolant

into

the

radiator

up

to

the

cap

and

also

into

the

reservoir

up

to

the

MAX

level

CAUTION

To

avoid

serious

personal

injury

never

remove

radiator

cap

quickly

when

engine

is

hot

Sudden

release

of

cool

ing

system

pressure

is

very

dangerous

If

it

is

necessary

to

remove

radiator

cap

when

radiator

is

hot

turn

cap

slowly

counterclockwise

to

the

first

step

After

all

pressure

in

the

cool

ing

system

is

released

turn

cap

passing

the

stop

and

remove

it

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

To

drain

the

cooling

system

re

move

radiator

cap

release

drain

cock

C09ling

System

COOLING

SYSTEM

pump

installed

on

the

timing

chain

cover

serves

to

circulate

the

coolant

The

pressure

t

pe

radiator

filler

cap

at

the

bottom

of

radiator

and

drain

plug

on

the

left

side

of

cylinder

block

If

the

heater

system

is

instaDed

set

heater

control

valve

to

open

position

Mter

the

coolant

is

drained

complete

ly

close

drain

cock

and

plug

and

refdl

the

system

with

clean

soft

water

WATER

PUMP

The

water

pump

is

of

a

centrifugal

type

which

is

mounted

on

the

engine

front

cover

TJ

te

pump

shaft

is

sup

ported

by

a

double

row

of

baD

bear

ings

press

fit

in

an

aluminum

die

cast

pump

body

The

bearings

are

per

manently

lubricated

and

sealed

to

pre

vent

loss

of

lubricant

and

entry

of

dirt

CO

2

installed

on

the

radiator

operates

the

cooling

system

at

higher

than

atmos

pheric

pressure

To

heater

From

heater

C0126

Fig

COol

Cooling

System

C0042

Fig

CO

2

Water

Pump

and

Timing

Chain

Couer

REMOVAL

1

Drain

coolant

into

a

clean

con

tainer

2

Loosen

bolts

retaining

fan

shroud

to

radiator

and

remove

shroud

3

I

Loosen

belt

then

remove

fan

blade

fan

spacer

and

pulley

from

hub

Page 105 of 548

EF053A

Fig

EF

50

Removing

JWrneu

of

Solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

Note

A

quick

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

3

Warm

up

engine

until

it

reaches

operating

temperature

Then

confirm

that

engine

idling

speed

is

specified

valve

Engine

idling

speed

Manual

transmission

700

rpm

Engine

Fuel

Automatic

transmission

in

0

position

650rpm

Note

On

automatic

transmission

models

never

race

engine

when

gearshift

lever

is

in

0

position

4

Run

engine

under

no

load

In

crease

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

S

At

the

time

manifold

vacuum

pressure

increases

abruptly

to

600

rnmHg

23

6

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

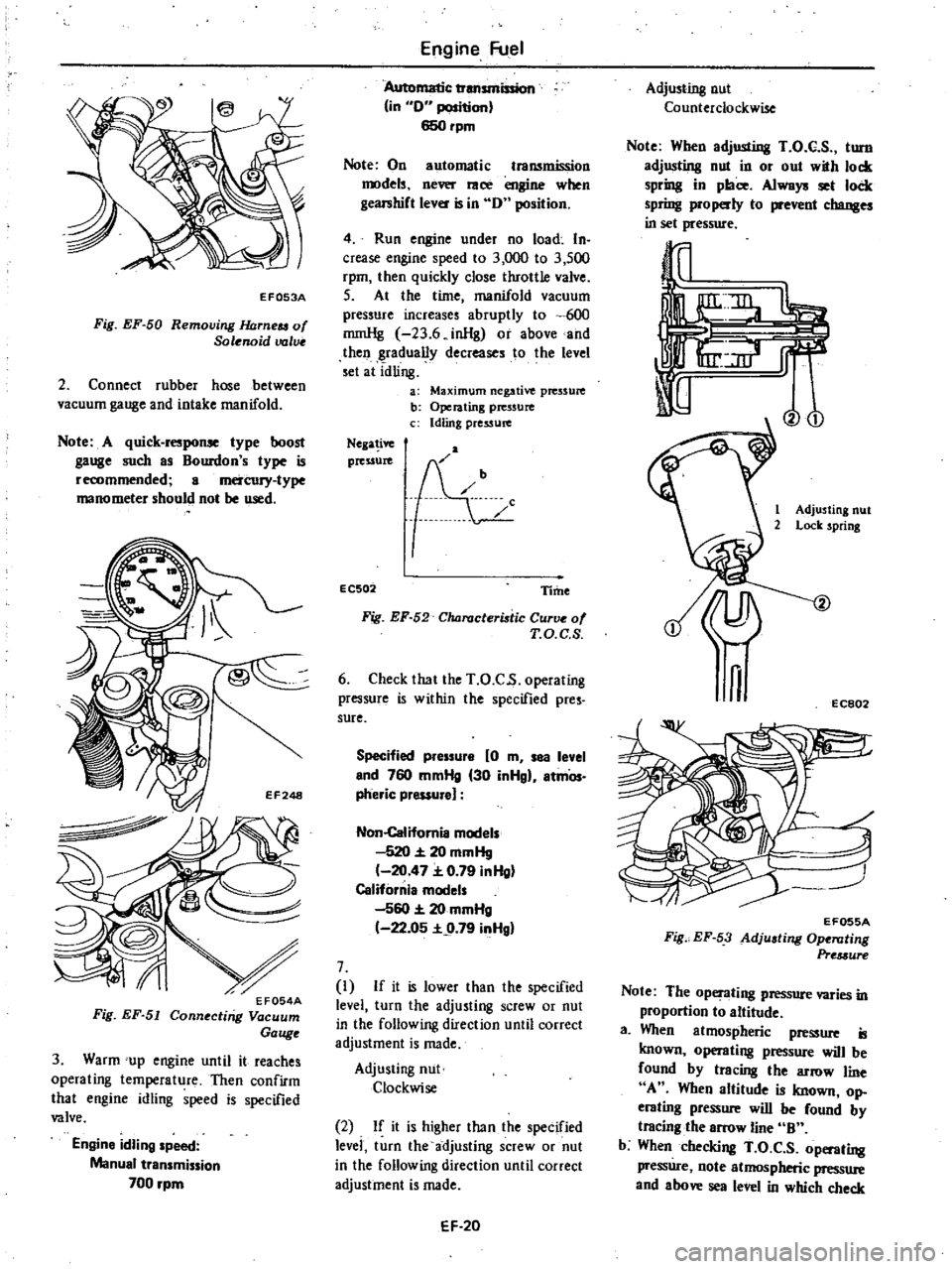

a

Maximum

negative

pressure

b

Operating

pressure

c

Idling

pressure

Nega

ive

pressure

EC502

Time

Fig

EF

52

Characteristic

Curve

of

T

O

C

S

6

Check

that

the

T

O

C

s

operating

pressure

is

within

the

specified

pres

sure

Specified

pressure

0

m

sea

level

end

760

mmHg

30

inHgl

atmOs

pheric

pressure

Non

Califomia

models

520

20

mmHg

20

47

0

79

inHg

California

models

560

20

mmHg

22

05

9

79

inHgl

7

I

If

it

is

lower

than

the

specified

level

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

Adjusting

nut

Clockwise

2

If

it

is

higher

than

the

specified

levei

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

EF

20

Adjusting

nut

Counterclockwise

Note

When

adjusting

T

O

C

S

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

properly

to

prevent

changes

in

set

pressure

Vo

1

Adjusting

nut

2

Lock

spring

n

EC802

EF055A

Fig

EF

53

Adjusting

Ope

llting

Pre

3ure

Note

The

operating

pressure

varies

in

proportion

to

altitude

a

When

atmospheric

pressure

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

A

When

altitude

is

known

op

erating

pressure

will

be

found

by

tracing

the

arrow

line

B

b

When

checking

T

O

C

S

operating

pressure

note

atmospheric

pressure

and

above

sea

level

in

which

check

Page 106 of 548

is

to

be

made

and

determine

set

pressure

by

the

information

fur

nished

For

example

if

above

sea

level

is

1

000

m

3

280

ft

operating

pres

sure

will

then

be

475

mmHg

18

7

inHg

on

non

California

models

or

495

mmHg

19

5

inHg

on

California

models

In

other

words

T

O

C

S

operates

at

475

mmHg

18

7

inHg

or

490

mmHg

19

3

inHg

8

Race

engine

and

check

for

adjust

ment

9

If

engine

speed

will

not

drop

to

idling

speed

when

checking

throttle

opener

operating

pressure

proceed

as

follows

I

Turn

adjusting

screw

counter

clockwise

so

that

throttle

opener

oper

ating

pressure

is

on

high

vacuum

side

Engine

Fuel

25

mmHg

0

98

inHg

away

from

the

specified

value

2

Turn

adjusting

screw

l

O

of

a

turn

clockwise

so

that

throttle

opener

oper

ating

pressure

drops

by

25

mmHg

0

98

inHg

10

If

throttle

opener

operating

pressure

cannot

be

observed

clearly

even

in

step

9

proceed

as

follows

I

Turn

adjusting

screw

counter

clockwise

so

that

tluottle

opener

oper

ating

pressure

is

on

high

vacuum

side

50

mmHg

1

97

inHg

away

from

mid

point

of

the

specified

range

2

Turn

adjusting

screw

l

of

a

turn

clockwise

Note

The

throttle

opener

operating

pressure

should

be

correctly

set

within

the

specified

range

after

the

above

adju

stments

even

if

the

en

gine

speed

cannot

be

decreased

to

idling

inHg

mmHg

30

750

29

28

24

A

600

700

23

27

560

26

22

550

650

21

25

0

0

20

24

500

600

0

0

19

23

c

o

c

22

ii

18

0

0

450

550

E

c

0

17

2

16

20

400

500

15

B

Non

California

model

350

14

California

model

13

300

5

000

6

000

1ft

0

1

000

2

000

3

001

4

000

0

0

5

1

5

2

km

Altitude

EF056A

Fig

EF

54

Clumges

in

Operating

Pressure

Versus

Changes

in

Atmospheric

Pressure

EF

21

SERVO

DIAPHRAGM

STROKE

I

Connect

engine

tachometer

2

Warm

up

engine

until

it

reaches

operating

temperature

3

Disconnect

rubber

hose

between

servo

diaphragm

and

vacuum

control

valve

Then

connect

rubber

hose

to

in

take

manifold

Servo

diaphragm

Rubber

hose

T

O

C

S

solenoid

valve

T

O

C

S

control

valve

EF250

EF057A

Fig

EF

55

Connecting

Rubber

Hose

to

Intake

Manifold

4

Servo

diaphragm

is

functioning

properly

if

engine

speed

comes

into

the

specified

range

Specified

engine

speed

1

650

to

1

850

rpm

except

Californial

1

900

to

2

100

rpm

for

California

5

If

necessary

adjust

engine

speed

until

it

is

in

the

specified

range

using

servo

diaphragm

adjusting

screw

When

engine

speed

is

lower

than

the

prescribed

range

Turn

adjusting

screw

clockwise

When

engine

speed

is

higher

than

the

prescribed

range

Turn

adjusting

screw

counterclockwise

Page 127 of 548

Emission

Control

System

EARLY

FUEL

EVAPORATIVE

E

FE

SYSTEM

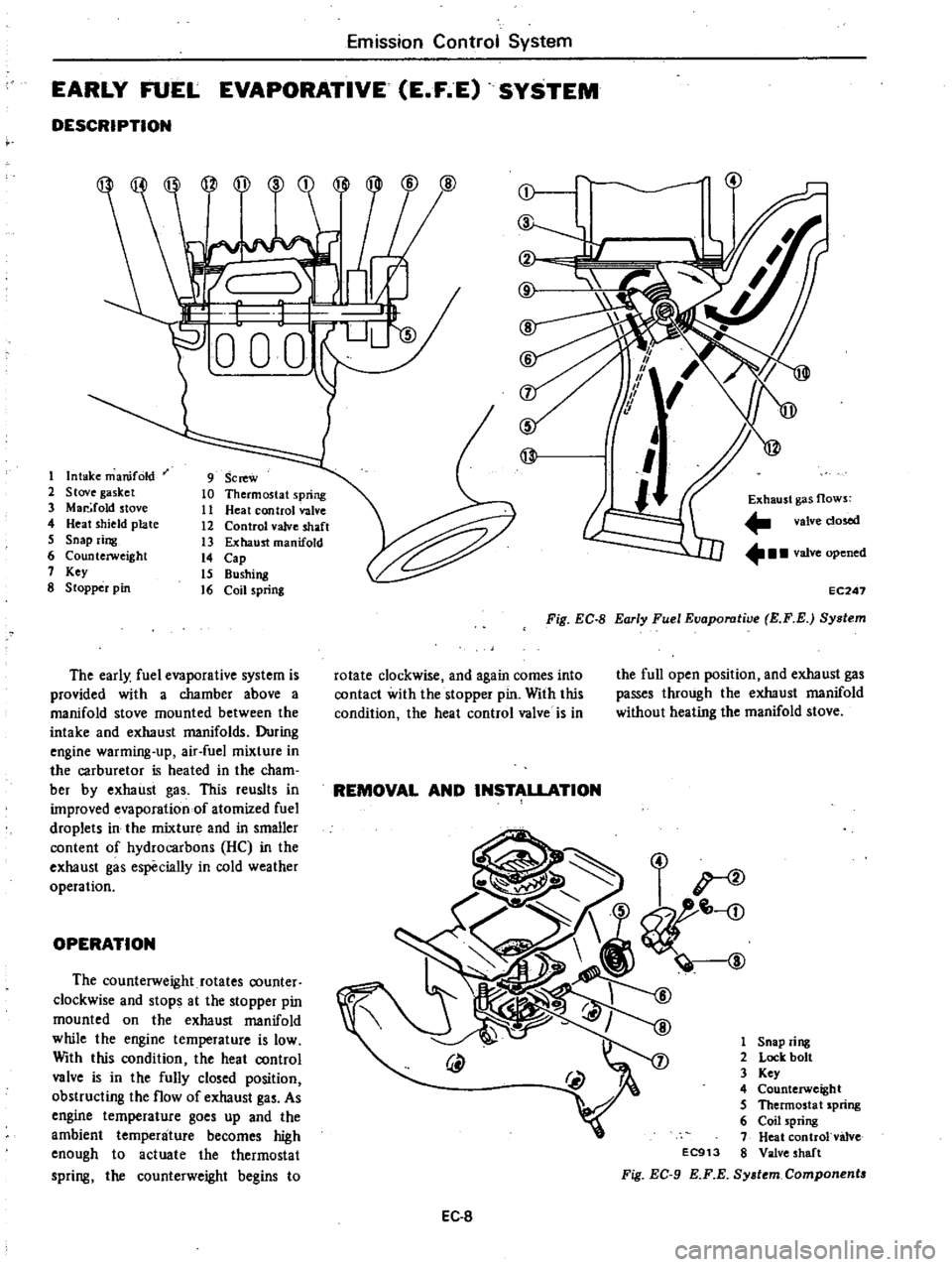

DESCRIPTION

@

jl

D

W

o

0

0

UL

@

1

Intake

manifold

9

Screw

2

Stove

gasket

10

Thermostat

spring

3

Mar

fold

stove

11

Heat

control

valve

4

Heat

shield

plate

12

Control

valve

shaft

5

Snap

ring

13

Exhaust

manifold

6

Countczwcight

14

Cap

7

Key

15

Bushing

8

Stopper

pin

16

Coil

spring

The

early

fuel

evaporative

system

is

provided

with

a

chamber

above

a

manifold

stove

mounted

between

the

intake

and

exhaust

manifolds

During

engine

warming

up

air

fuel

mixture

in

the

carburetor

is

heated

in

the

cham

ber

by

exhaust

gas

This

reuslts

in

improved

evaporation

of

atomized

fuel

droplets

in

the

mixture

and

in

smaller

content

of

hydrocarbons

HC

in

the

exhaust

gas

especially

in

cold

weather

operation

OPERATION

The

counterweight

rotates

counter

clockwise

and

stops

at

the

stopper

pin

mounted

on

the

exhaust

manifold

while

the

engine

temperature

is

low

With

this

condition

the

heat

control

valve

is

in

the

fully

closed

position

obstructing

the

flow

of

exhaust

gas

As

engine

temperature

goes

up

and

the

ambient

temperature

becomes

high

enough

to

actuate

the

thermostat

spring

the

counterweight

begins

to

j

@

l

7

1

1

5

If

@

I

Exhaust

gas

flows

valve

dosed

valve

opened

EC247

Fig

EC

8

Early

Fuel

Eaaporatiae

E

F

E

System

rotate

clockwise

and

again

comes

into

contact

with

the

stopper

pin

With

this

condition

the

heat

control

valve

is

in

the

full

open

position

and

exhaust

gas

passes

through

the

exhaust

manifold

without

heating

the

manifold

stove

REMOVAL

AND

INSTALLATION

1

Snap

ring

2

Lock

bolt

3

Key

4

Counterweight

5

Thermosta

t

spring

6

Coil

spring

7

Heat

controlvalve

EC913

8

Valve

shaft

Fig

EC

9

KF

E

Sy

tem

Component

EC

8

Page 128 of 548

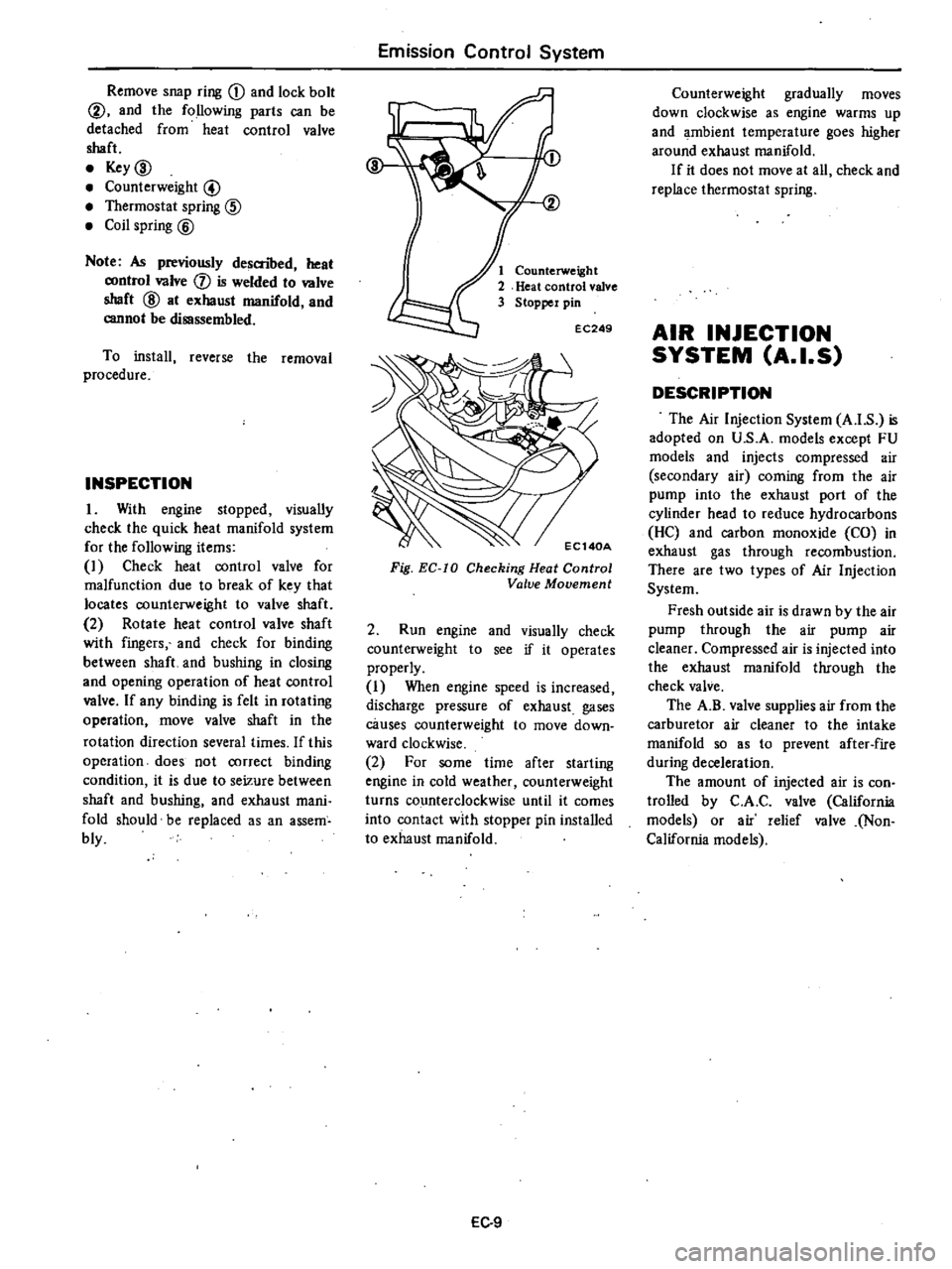

Remove

snap

ring

CD

and

lock

bolt

@

and

the

following

parts

can

be

detached

from

heat

control

valve

shaft

Key

ID

Counterweight

@

Thermostat

spring

@

Coil

spring

@

Note

As

previously

descnbed

heat

control

valve

j

is

welded

to

valve

shaft

@

at

exhaust

manifold

and

cannot

be

disassembled

To

install

reverse

the

removal

procedure

INSPECTION

1

With

engine

stopped

visually

check

the

quick

heat

manifold

system

for

the

following

items

I

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

2

Rotate

heat

control

valve

shaft

with

fingers

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

Emission

Control

System

Counterweight

Heat

control

valve

Stopper

pin

EC249

Fig

EC

IO

Checking

Heat

Control

Valve

Movement

2

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

2

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

EC

9

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

If

it

does

not

move

at

all

check

and

replace

thermostat

spring

AIR

INJECTION

SYSTEM

A

I

S

DESCRIPTION

The

Air

Injection

System

A

I

S

is

adopted

on

U

S

A

models

except

FU

models

and

injects

compressed

air

secondary

air

coming

from

the

air

pump

into

the

exhaust

port

of

the

cylinder

head

to

reduce

hydrocarbons

He

and

carbon

monoxide

CO

in

exhaust

gas

through

recombustion

There

are

two

types

of

Air

Injection

System

Fresh

outside

air

is

drawn

by

the

air

pump

through

the

air

pump

air

cleaner

Compressed

air

is

injected

into

the

exhaust

manifold

through

the

check

valve

The

A

B

valve

supplies

air

from

the

carburetor

air

cleaner

to

the

intake

manifold

so

as

to

prevent

after

fire

during

deceleration

The

amount

of

injected

air

is

con

trolled

by

C

A

C

valve

California

models

or

air

relief

valve

Non

California

models

Page 189 of 548

Engine

Electrical

System

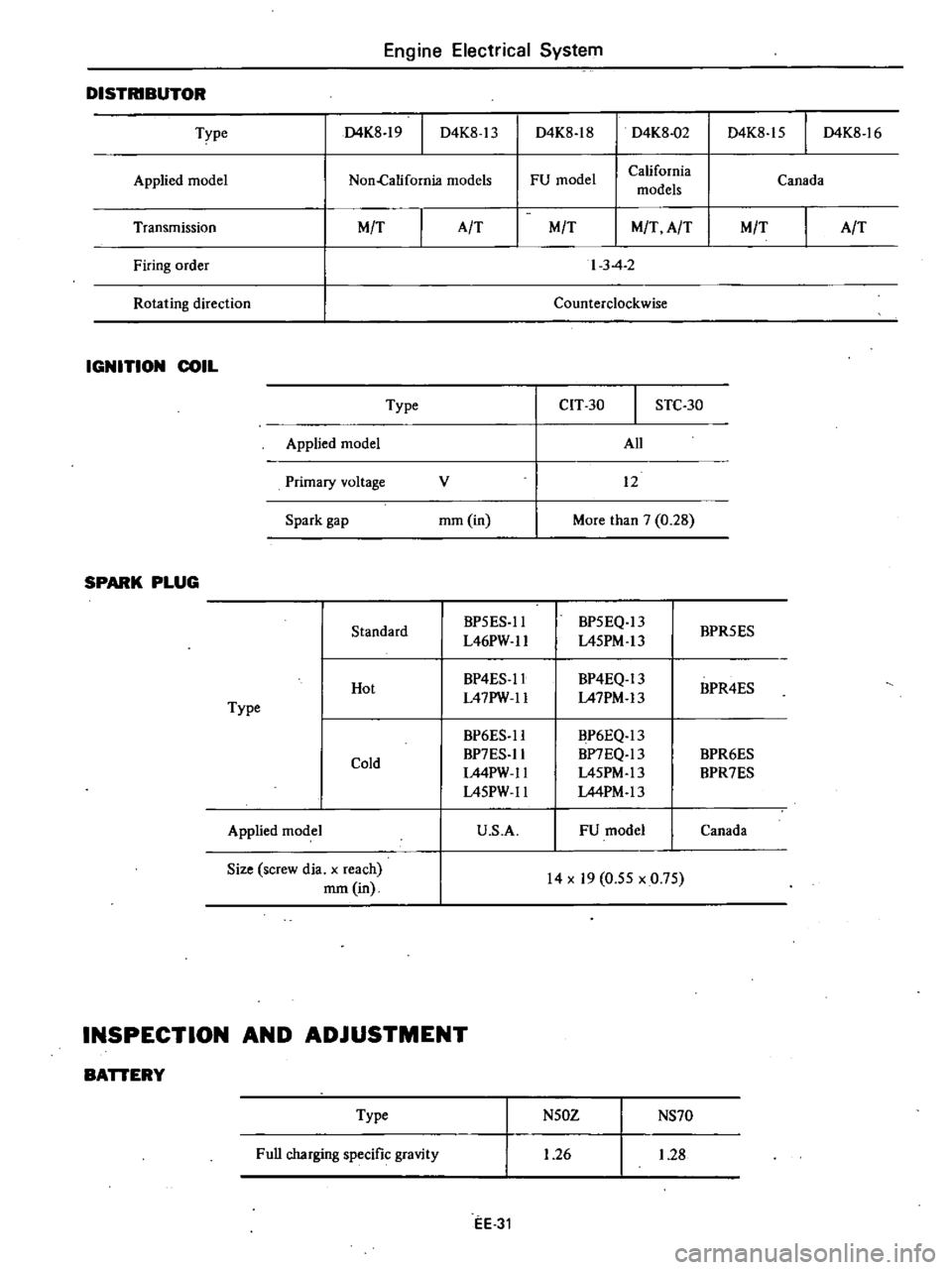

DISTRIBUTOR

D4K8

18

D4K8

15

I

D4K8

16

Type

D4K8

19

I

D4K8

13

D4K8

02

Applied

model

FU

model

California

models

Canada

Non

California

models

Transmission

MfT

Firing

order

Rotating

direction

IGNITION

COIL

Type

Applied

model

Primary

voltage

Spark

gap

SPARK

PLUG

Standard

Hot

Type

Cold

Applied

model

Size

screw

dia

x

reach

mm

in

AfT

MfT

MfT

AfT

MfT

AfT

I

3

4

2

Counterclockwise

cn

30

STC

30

All

v

12

mm

in

More

than

7

0

28

BP5ES

II

BP5EQ

13

BPR5ES

L46PW

1I

L45PM

13

BP4ES

1I

BP4EQ

13

BPR4ES

L47PW

1I

L47PM

13

BP6ES

1I

BP6EQ

13

BP7ES

1I

BP7EQ

13

BPR6ES

L44PW

1I

L45PM

13

BPR7ES

L45PW

1I

L44PM

13

U

S

A

FU

model

Canada

14

x

19

0

55

x

0

75

INSPECTION

AND

ADJUSTMENT

BATTERY

Type

Full

charging

specific

gravity

N50Z

NS70

1

26

1

28

EE

31

Page 221 of 548

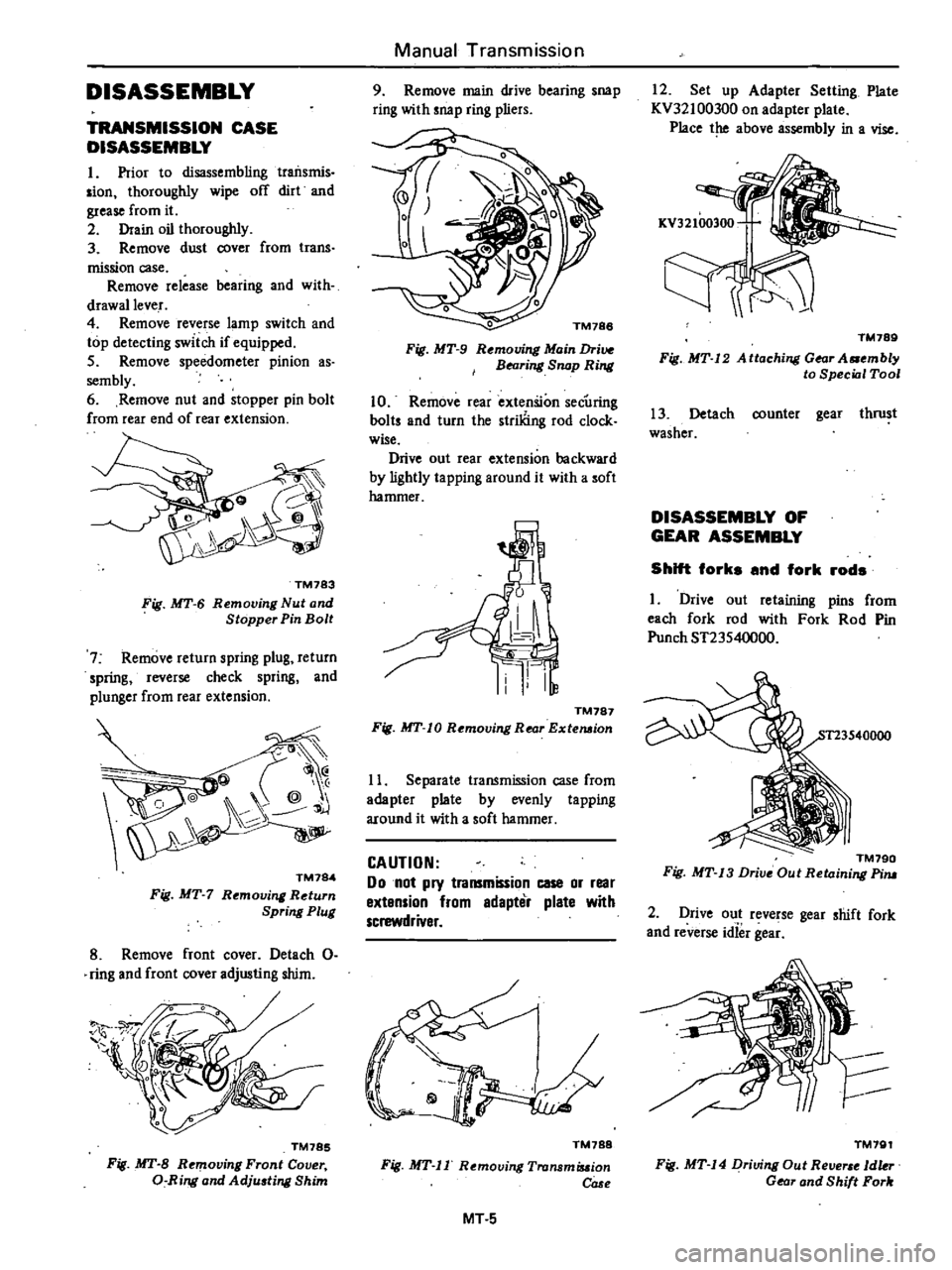

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

I

Prior

to

disassembling

traiIsmis

sian

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

and

top

detecting

switch

if

equipped

5

Remove

speedometer

pinion

as

sembly

6

Remove

nut

and

stopper

pin

bolt

from

rear

end

of

rear

extension

TM783

Fig

MT

6

Removing

Nut

and

Stopper

Pin

Bolt

7

Remove

return

spring

plug

return

spring

reverse

check

spring

and

plunger

from

rear

extension

@

@

j

TM784

Fig

MT

7

Rt

moving

Return

Spring

Plug

8

Remove

front

cover

Detach

0

ring

and

front

cover

adjusting

shim

TM785

Fig

MT

B

Removing

Front

Cover

a

Ring

and

Adju

ting

Shim

Manual

Transmission

9

Remove

main

drive

bearing

snap

ring

with

snap

ring

pliers

o

TM188

Fig

MT

9

Rt

mouing

Main

Drive

BNring

Snap

Ring

10

Remove

rear

extenSion

secUring

baits

and

turn

the

striliing

rod

clock

wise

Drive

out

rear

extension

backward

by

lightly

ta

pping

around

it

with

a

soft

hammer

TM787

Fig

MT

10

Removing

Rear

Extemion

11

Separate

transmission

case

from

adapter

plate

by

evenly

tapping

around

it

with

a

soft

hammer

CAUTION

Do

not

pry

transmission

case

or

rear

extension

from

edapter

plate

with

screwdriver

TM788

Fig

MT

II

Removing

Tronsmiuion

COSf

MT

5

12

Set

up

Adapter

Setting

Plate

KV32100300

on

adapter

plate

Place

the

above

assembly

in

a

vise

TM789

Fig

MT

12

A

ttaching

Gear

A

mbly

to

Special

Tool

13

Detach

counter

gear

thrust

washer

DISASSEMBLY

OF

GEAR

ASSEMBLY

Shift

forks

and

fork

rods

I

Drive

out

retaining

pins

from

each

fork

rod

with

Fork

Rod

Pin

Punch

ST23540000

TM790

Fig

MT

13

Drive

Out

Retaining

Pim

2

Drive

out

reverse

gear

shift

fork

and

reverse

idief

gea

TM791

Fig

MT

14

Driving

Out

Re

1dkr

Gear

and

Shift

Fork

Page 230 of 548

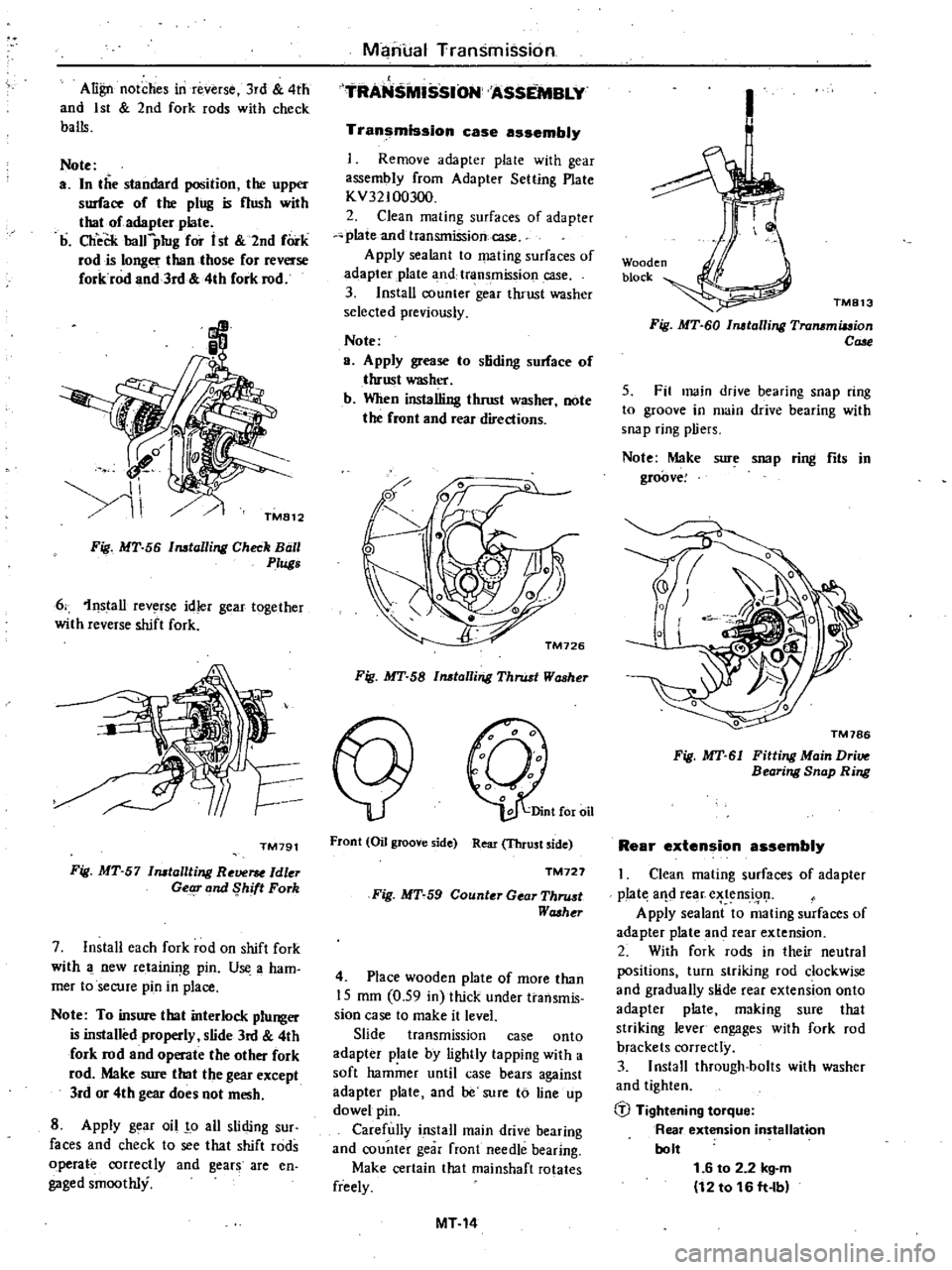

Align

notches

in

reverse

3rd

4th

and

1st

2nd

fork

rods

with

check

balls

Note

a

In

the

standard

position

the

upper

surface

of

the

ping

is

nush

with

thaI

of

adapter

plate

b

CheCk

balfpIug

for

i

st

2nd

fork

rod

is

longer

than

those

for

reverse

forkrod

and

3rd

4th

fork

rod

Manual

Transmission

TRANS

SSION

ASSEMBLY

Transmission

case

assembly

Remove

adapter

plale

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

3

nd

transmission

case

3

Install

counter

gear

thrust

washer

selected

previously

Note

a

Apply

grease

to

stiding

sorface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

rear

directions

Fig

MT

56

Installing

Check

Ball

0

Plugs

6

1nstall

rev

rse

idler

gear

together

with

reverse

shift

fork

TM791

Fig

MT

57

Installting

Re

ldler

Getg

and

Shift

Fork

7

Install

each

fork

rod

on

shift

fork

with

new

retainif

g

pin

U

a

ham

mer

toseCUfe

pin

in

place

Note

To

insure

that

interlock

plunger

is

installed

properly

slide

3rd

4th

fork

rod

and

operate

the

other

fork

rod

Make

sure

that

the

gear

except

lrd

or

4th

gear

does

not

mesh

8

Apply

g

ar

oil

o

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

are

en

gaged

smoothly

Fig

MT

58

Installing

Thrust

Washer

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

59

Counter

Gear

Thru

t

Washt

r

4

Place

wooden

plate

of

more

than

15

mm

0

59

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

rnainshaft

rotates

freely

MT14

1

Wooden

block

TM813

Fig

MT

60

Installing

Transmiuion

Cale

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

snap

ring

fits

in

groove

Fig

MT

61

Fitting

Main

Dri

Bearing

Snap

Ring

Rear

extension

assembly

Clean

mating

surfaces

of

adapter

p

Iat

aIld

rear

e

tens

i91

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

rear

extension

2

With

fork

rods

in

their

neutral

positions

turn

striking

rod

clockwise

and

gradually

slide

rear

extension

onto

adapter

plate

making

sure

that

striking

lever

engages

with

fork

rod

brackets

correctly

3

Install

through

bolts

with

washer

and

tighten

b

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb

Page 235 of 548

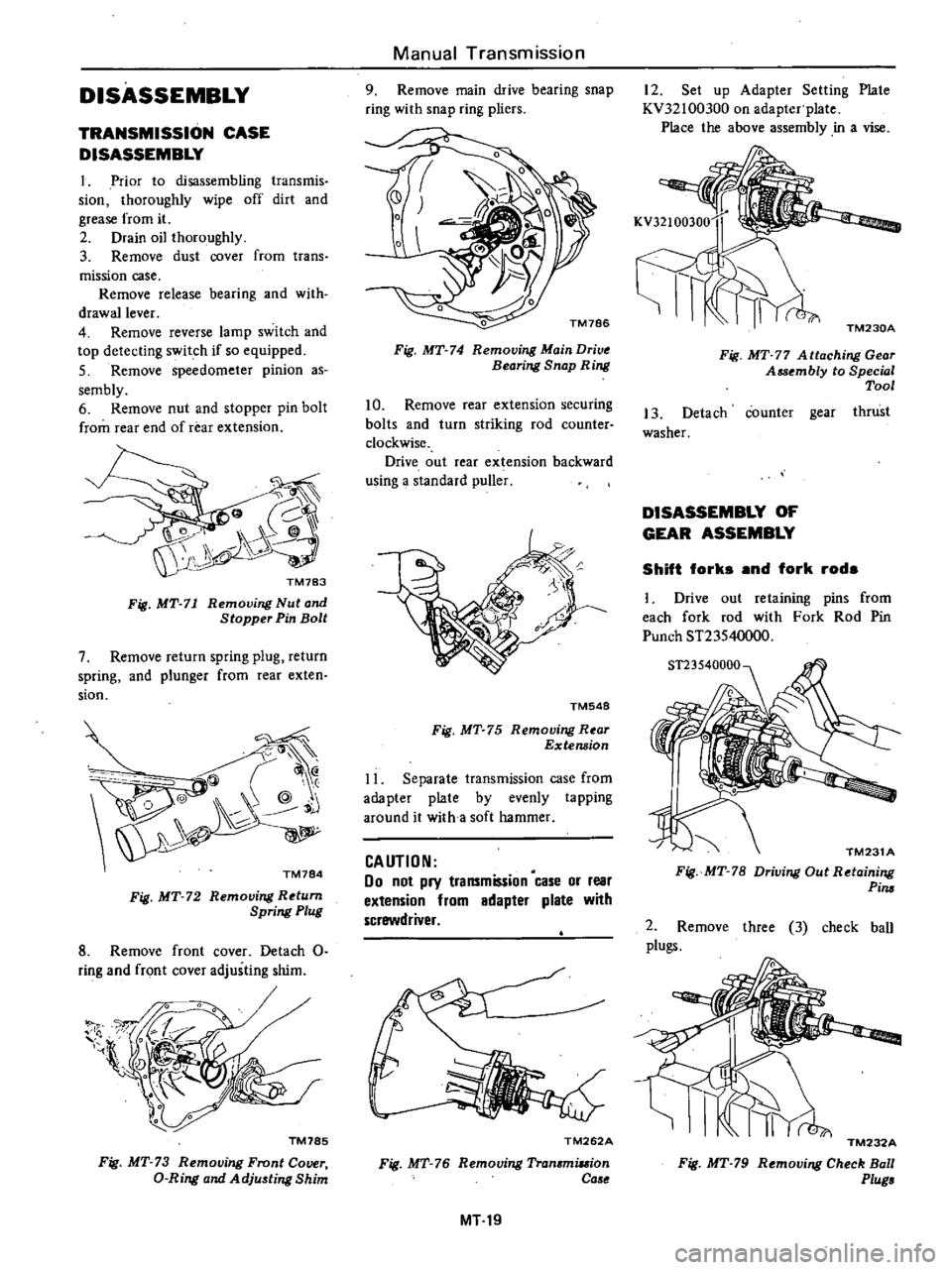

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

1

Prior

to

disassembling

transmis

sion

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

and

top

detecting

switch

if

so

equipped

5

Remove

speedometer

pinion

as

sembly

6

Remove

nut

and

stopper

pin

bolt

from

rear

end

of

rear

extension

Fig

MT

71

Removing

Nut

and

Stopper

Pin

Bolt

7

Remove

return

spring

plug

return

spring

and

plunger

from

rear

exten

sion

@

@

Q

@

j

TM784

Fig

MT

72

Removing

Return

Spring

Plug

8

Remove

front

cover

Detach

0

ring

and

front

cover

adjusting

shim

1l

l

TM785

Fig

MT

73

Removing

Front

Cover

D

Ring

and

Adju

ting

Shim

Manual

Transmission

9

Remove

main

drive

bearing

snap

ring

with

snap

ring

pliers

Fig

MT

74

Removing

Main

Drive

Bearing

Snap

Ring

10

Remove

rear

extension

securing

bolts

and

turn

striking

rod

counter

clockwise

Drive

out

rear

extension

backward

using

a

standard

puller

TM548

Fig

MT

75

Removing

R

ar

Extension

11

Separate

transmission

case

from

adapter

plate

by

evenly

tapping

around

it

with

a

soft

hammer

CAUTION

00

not

pry

transmission

case

or

rear

extension

from

adapter

plate

with

screwdriver

TM262A

Fig

MT

76

Removing

Tran

miuion

Ca

e

MT19

12

Set

up

Adapter

Setting

Plate

KV32100300

on

adapter

plate

Place

the

above

assembly

in

a

vise

TM230A

Fig

MT

77

A

ttaching

Gear

Assembly

to

Special

Tool

13

Detach

counter

gear

thrust

washer

DISASSEMBLY

OF

GEAR

ASSEMBLY

Shift

forks

and

fork

rods

1

Drive

out

retaining

pins

from

each

fork

rod

with

Fork

Rod

Pin

Punch

ST23540000

TM231

A

Fig

MT

78

Driving

Out

Retaining

Pim

2

Remove

three

3

check

ball

plugs

TM232A

Fig

MT

79

Removing

Check

Ball

Plug