check engine DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 107 of 548

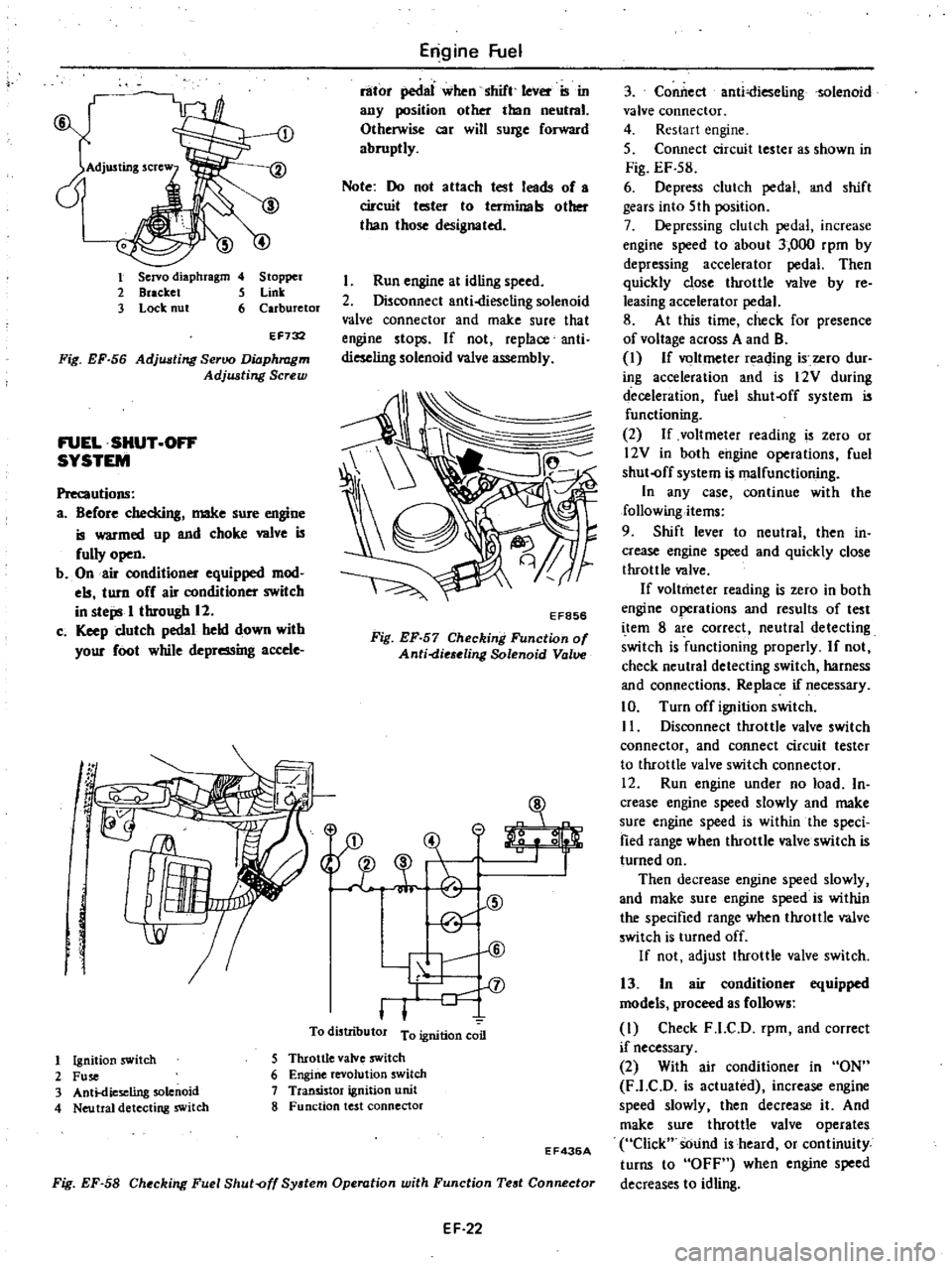

1

Servo

diaphragm

4

Stopper

2

Bracket

5

Link

3

Lock

nut

6

Carburetor

EF732

Fig

EF

56

Adjusting

Seroo

Diaphragm

Adjwting

Screw

FUEL

SHUT

OFF

SYSTEM

Precautions

a

Before

checking

make

sure

engine

is

warmed

up

and

choke

wive

is

fully

open

b

On

air

conditioner

equipped

mod

els

turn

off

air

conditioner

switch

in

steps

I

through

12

c

Keep

clutch

pedal

held

down

with

your

foot

while

depressing

accele

g

f

J

1

Engine

Fuel

rator

pedllI

when

shift

leVer

ISm

any

position

other

than

neutral

Otherwise

car

will

surge

forward

abruptly

Note

Do

not

attach

test

leads

of

a

circuit

tester

to

terminals

other

than

those

designated

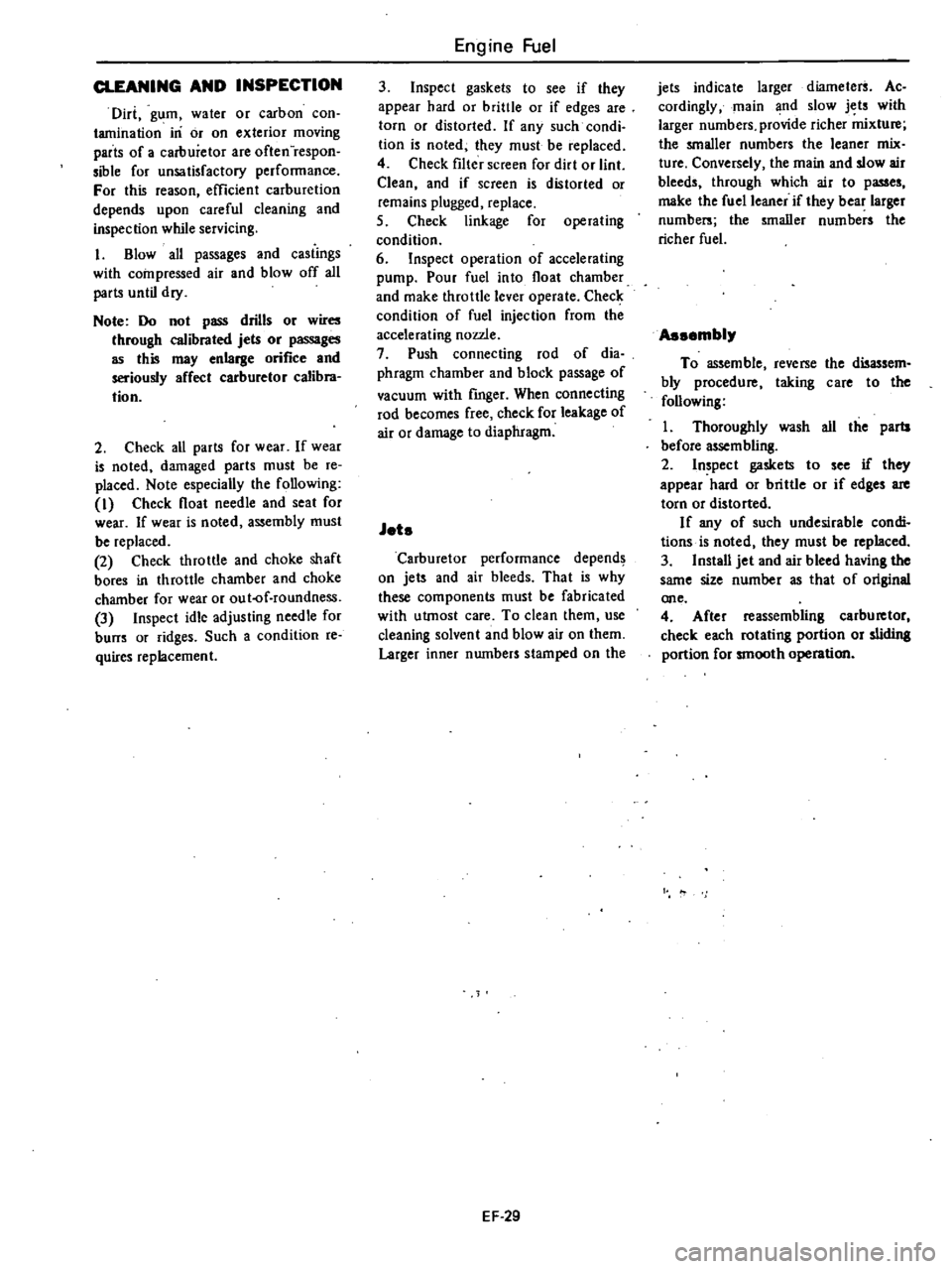

Run

engine

at

idling

speed

2

Disconnect

anti

dieseling

solenoid

valve

connector

and

make

sure

that

engine

stops

If

not

replace

anti

dieseling

solenoid

valve

assembly

EF856

Fig

EF

57

Checking

Function

of

Anti

die

eling

Solenoid

Valve

31

A

t

CID

@

V

II

l

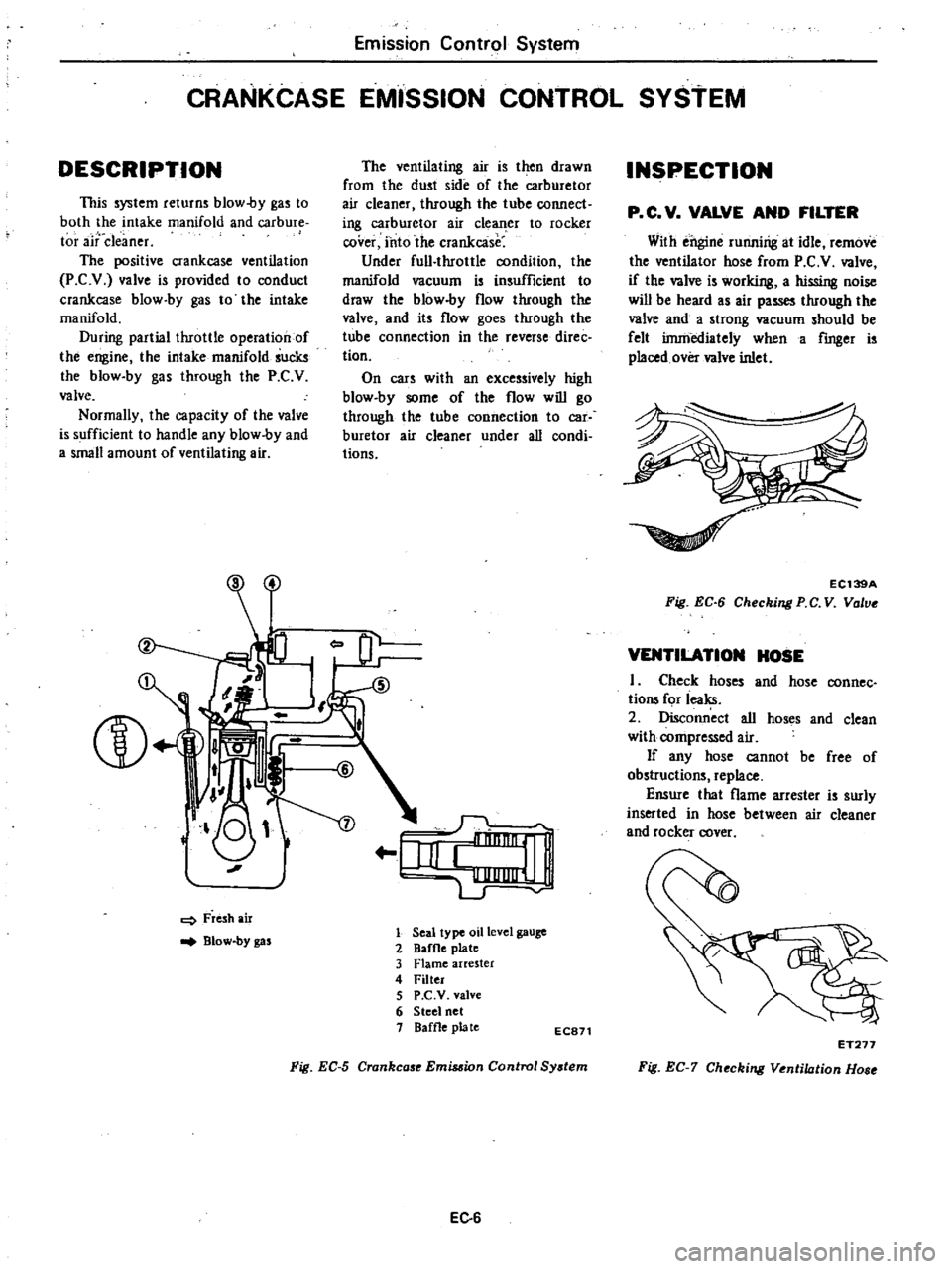

To

distributor

T

n

l1on

coon

o

1

Ignition

switch

2

Fuse

3

Anti

dieseling

solenoid

4

Neu

tral

detecting

switch

5

Throttle

valve

swltch

6

Engine

revolution

switch

7

Transistor

ignition

unit

8

Function

test

connector

Fig

EF

58

Checking

Fuel

Shut

off

System

Operation

with

Function

Test

Connector

EF436A

EF

22

3

Conilect

anti

ieselingsolenoid

valve

connector

4

Restart

engine

5

Connect

circuit

tester

as

shown

in

Fig

EF

S8

6

Depress

clutch

pedal

and

shift

gears

into

5th

position

7

Depressing

clutch

pedal

increase

engine

speed

to

about

3

000

rpm

by

depressing

accelerator

pedal

Then

quickly

close

throttle

wIve

by

re

leasing

accelerator

pedal

8

At

this

time

check

for

presence

of

voltage

across

A

and

B

I

If

voltmeter

reading

i

ero

dur

ing

acceleration

and

is

12V

during

deceleration

fuel

shut

off

system

is

functioning

2

If

voltmeter

reading

is

zero

or

l2V

in

both

engine

operations

fuel

shut

off

system

is

malfunctioning

In

any

case

continue

with

the

following

items

9

Shift

lever

to

neutral

then

in

crease

engine

speed

and

quickly

close

throttle

valve

If

voltmeter

reading

is

zero

in

both

engine

operations

and

results

of

test

i

tern

8

are

correct

neutral

detecting

switch

is

functioning

properly

If

not

check

neutral

detecting

switch

harness

and

connections

Replace

if

necessary

10

Turn

off

ignition

switch

II

Disconnect

throttle

valve

switch

connector

and

connect

circuit

tester

to

throttle

valve

switch

connector

12

Run

engine

under

no

load

In

crease

engine

speed

slowly

and

make

sure

engine

speed

is

within

the

speci

fied

range

when

throttle

valve

switch

is

turned

on

Then

decrease

engine

speed

slowly

and

make

sure

engine

speed

is

within

the

specified

range

when

throttle

valve

switch

is

turned

off

If

not

adjust

throttle

valve

switch

13

In

air

conditioner

equipped

models

proceed

as

follows

I

Check

F

l

C

D

rpm

and

correct

if

necessary

2

With

air

conditioner

in

ON

F

l

C

D

is

actuated

increase

engine

speed

slowly

then

decrease

it

And

make

sure

throttle

valve

operates

Click

sOund

is

heard

or

continuity

turns

to

OFF

when

engine

speed

decreases

to

idling

Page 108 of 548

If

not

adjust

throttle

valve

switch

Fig

EF

59

Adjusting

Throttle

Valve

Switch

Eng

ine

Fuel

If

throttle

valve

switch

cannot

be

adjusted

to

specification

replace

Engine

operation

Throttle

valve

switch

continuity

Engine

speed

rpm

When

engine

speed

increases

OFF

ON

1

150

t200

When

engine

speed

decreases

ON

OFF

I

000

t

200

Inspecting

engine

revolution

switch

Note

Before

checking

the

engine

revolution

switch

make

sure

the

functions

of

other

components

are

correct

in

accordance

with

the

items

described

above

Disconnect

throttle

valve

switch

connector

2

Connect

circuit

tester

3

Run

engine

at

idling

speed

4

Depress

clutch

pedal

and

shift

gear

into

5th

position

5

Depressing

clutch

pedal

increase

engine

speed

slowly

Make

sure

engine

speed

is

within

the

specified

range

when

voltmeter

goes

from

OV

to

l2V

Then

decrease

engine

speed

slowly

and

make

sure

engine

speed

is

within

the

specified

range

when

voltmeter

goes

from

12V

to

OV

EF

23

MAJOR

SERVICE

OPERATION

The

perfectly

adjusted

carburetor

deliver

the

proper

fuel

and

air

ratios

at

aD

speeds

for

the

particular

engine

for

which

it

was

designed

By

com

pletely

disassembling

at

re

ular

inter

vals

which

will

allow

cleaning

of

all

parts

and

passages

the

carburetor

can

be

maintained

in

its

original

condition

and

will

continue

to

deliver

the

proper

ratios

To

maintain

accurate

carburetion

of

passages

and

discharge

holes

ex

treme

care

must

be

taken

in

cleaning

Use

only

carburetor

solvent

and

compressed

air

to

clean

all

passages

and

discharge

holes

Never

use

wire

or

other

pointed

instrument

to

clean

or

carburetor

calibration

will

be

affected

REMOVAL

Remove

carburetor

from

engine

taking

sufficient

care

to

the

following

Precautions

a

When

disconnecting

fuel

lines

do

not

spill

fuel

from

fuel

pipe

b

When

removing

carburetor

do

not

drop

any

nut

or

bolt

into

intake

manifold

c

Be

careful

not

to

bend

or

scr

tch

any

part

d

Link

system

of

carburetor

differ

between

models

for

U

S

A

and

Canada

For

details

see

Figure

EF

60

which

is

based

on

Canadian

models

Page 114 of 548

CLEANING

AND

INSPECTION

Dirt

gum

water

or

carbon

con

tamination

in

or

on

exterior

moving

parts

of

a

carburetor

are

often

respon

sible

for

unsatisfactory

performance

For

this

reason

efficient

carhuretion

depends

upon

careful

cleaning

and

inspection

while

servicing

Blow

all

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

passages

as

this

may

enlarge

orifice

and

seriously

affect

carburetor

calibra

tion

2

Check

all

parts

for

wear

If

wear

is

noted

damaged

parts

must

be

re

placed

Note

especially

the

following

I

Check

float

needle

and

seat

for

wear

If

wear

is

noted

assembly

must

be

replaced

2

Check

throttle

and

choke

shaft

bores

in

throttle

chamber

and

choke

chamber

for

wear

or

out

of

roundness

3

Inspect

idle

adjusting

needle

for

hurrs

or

ridges

Such

a

condition

re

quires

replacement

Engine

Fuel

3

Inspect

gaskets

to

see

if

they

appear

hard

or

brittle

or

if

edges

are

torn

or

distorted

If

any

such

condi

tion

is

noted

they

must

be

replaced

4

Check

filter

screen

for

dirt

or

lint

Clean

and

if

screen

is

distorted

or

remains

plugged

replace

5

Check

linkage

for

operating

condition

6

Inspect

operation

of

accelerating

pump

Pour

fuel

into

float

chamber

and

make

throttle

lever

operate

Check

condition

of

fuel

injection

from

the

accelerating

nome

7

Push

connecting

rod

of

dia

phragm

chamber

and

block

passage

of

vacuum

with

finger

When

connecting

rod

becomes

free

check

for

leakage

of

air

or

damage

to

diaphragm

Jets

Carburetor

performance

depend

on

jets

and

air

bleeds

That

is

why

these

components

must

be

fabricated

with

utmost

care

To

clean

them

use

cleaning

solvent

and

blow

air

on

them

Larger

inner

nwnbers

stamped

on

the

EF

29

jets

indicate

larger

diameters

Ac

cordingIy

main

and

slow

jets

with

larger

numbers

provide

richer

mixture

the

smaller

numbers

the

leaner

mix

ture

Conversely

the

main

and

slow

air

bleeds

through

which

air

to

passes

make

the

fuel

leaner

if

they

bear

larger

numbers

the

smaller

numbers

the

richer

fuel

Assembly

To

assemble

reverse

the

disassem

bly

procedure

taking

care

to

the

following

I

Thoroughly

wash

all

the

parts

before

assembling

2

Inspect

gaskets

to

see

if

they

appear

hard

or

brittle

or

if

edges

are

torn

or

distorted

If

any

of

such

undesirable

condi

tions

is

noted

they

must

be

replaced

3

Install

jet

and

air

bleed

having

the

Same

size

number

as

that

of

original

one

4

After

reassembling

carburetor

check

each

rotating

portion

or

sliding

portion

for

smooth

operation

Page 115 of 548

Engine

fuel

TROUBLE

DIAGNOSES

AND

CORRECTIONS

In

the

following

table

the

symp

toms

and

causes

of

carburetor

troubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

There

are

various

causes

of

engine

malfunctions

It

sometimes

happens

that

a

carburetor

which

has

no

fault

appears

to

have

some

problems

when

Condition

Probable

cause

Overflow

Dirt

accumulated

on

needle

valve

Fuel

pump

pressure

too

high

Needle

valve

improperly

seated

Excessive

fuel

consumption

Fuel

overflow

Slow

jet

too

large

on

each

main

jet

Main

air

bleed

clogged

Choke

valve

does

not

open

fully

Outlet

valve

seat

of

accelerator

pump

improper

Unked

opening

of

secondary

throttle

valve

opens

ioo

early

Power

shortage

Mainjels

clogged

Every

throttle

valve

Joes

not

open

fully

Idling

adjustment

incorrect

Fuel

filter

clo

ll

ed

Vacuum

jet

clogged

Air

cleaner

clogged

Diaphragm

damaged

Power

valve

operating

improperly

Improper

idling

Slow

jet

clogged

Every

throttle

valve

does

not

close

Secondary

throttle

valve

operating

im

properly

Throttle

valve

shafts

wom

Packing

between

manifold

carburetor

faulty

Manifold

carburetor

tightening

improper

Fuel

overflow

T

O

C

S

adjustment

incorrect

Vacuum

control

solenoid

damaged

Stuck

dash

pot

EF

30

acfuaJIy

theelectric

syslem

i

at

fatilt

Therefore

whenever

the

engine

is

mal

functioning

the

electrical

system

should

be

checked

fust

before

adjust

ing

carburetor

Corrective

action

Clean

needle

valve

Repair

pump

Replace

See

above

item

Replace

Clean

Adjust

Lap

Adjust

Clean

Adjust

Repair

Repair

Clean

Clean

Replace

Adjust

Clean

Adjust

Overhaul

and

clean

Replace

Replace

packing

Correct

tightening

See

the

first

item

Adjust

Replace

Replace

Page 116 of 548

Condition

Engine

hesitation

Engine

does

not

start

Engine

Fuel

Probable

cause

Main

jet

or

low

jet

clogged

By

pass

hole

idle

passage

clogged

Emulsion

tube

clogged

Incorrect

idling

adjustment

Secondary

throttle

valve

operating

improp

erly

Fuel

overflows

No

fuel

Idling

adjustment

incorrect

Fast

idle

adjustment

incorrect

Damaged

anti

dieseling

solenoid

EF

31

Corrective

action

Clean

Clean

tube

Clean

Correct

adjustment

Overhaul

and

clean

See

the

first

item

Check

pump

fuel

pipe

and

needle

valve

Adjust

Adju

t

Replace

Page 125 of 548

Emission

Control

System

CRANKCASE

EMISSION

CONTROL

SYSTEM

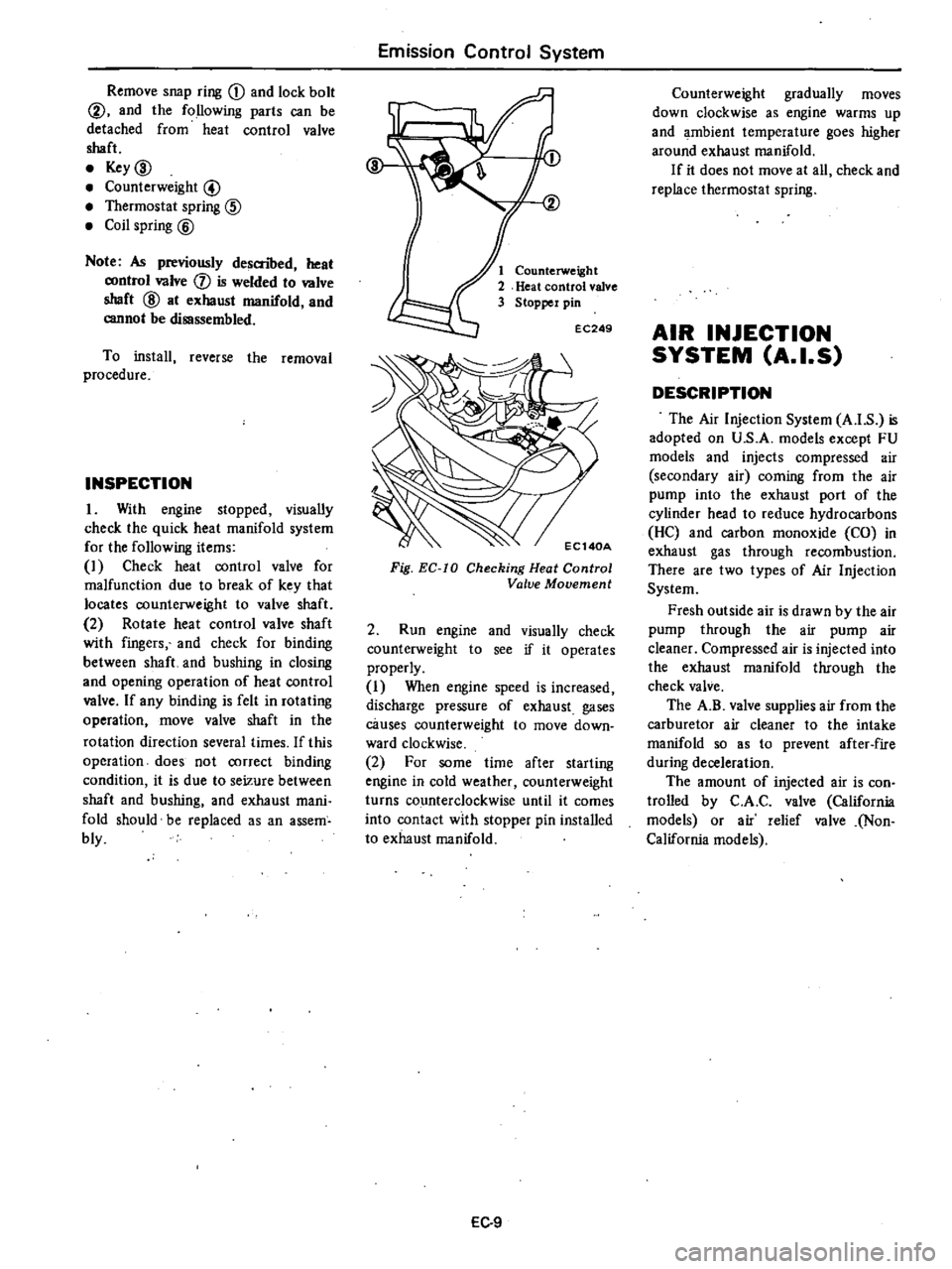

DESCRIPTION

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carbure

tor

aitdeaner

The

positive

crankcase

ventilation

P

C

v

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

During

partial

throttle

operation

of

the

engine

the

intake

manifold

sucks

the

blow

by

gas

through

the

P

C

V

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

L

J

J

o

I

Fresh

air

Blow

by

gas

The

ventilating

air

is

then

drawn

from

the

dust

side

of

the

carburetor

air

cleaner

through

the

tube

connect

ing

carburetor

air

cle

er

to

rocker

cover

into

the

crankcase

Under

full

throttle

condition

the

manifold

vacuum

is

insufficient

to

draw

the

blow

by

flow

through

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

direc

tion

On

cars

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

car

buretor

air

cleaner

under

all

condi

tions

r

IiI

e

1

LJ

1

Seal

type

oil

level

gauge

2

DafOe

plate

3

Flame

arrester

4

Filter

5

P

C

V

valve

6

Steel

net

1

Baffle

plate

EC871

Fig

EC

5

Crankcase

Emis

ion

Control

Sy

tem

EC

6

INSPECTION

p

C

V

VALVE

AND

FILTER

With

ei

gine

runnirig

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

wiD

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

irnniediately

when

a

fmger

is

placed

over

valve

inlet

EC139A

Fig

EC

6

Checking

PC

V

Vo

ve

VENTILATION

HOSE

I

Check

hoses

and

hose

connec

tions

for

ieaks

2

oisconn

ct

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surly

inserted

in

hose

between

air

cleaner

and

rocker

rover

ET277

Fig

EC

7

Checking

Ventilation

Hose

Page 128 of 548

Remove

snap

ring

CD

and

lock

bolt

@

and

the

following

parts

can

be

detached

from

heat

control

valve

shaft

Key

ID

Counterweight

@

Thermostat

spring

@

Coil

spring

@

Note

As

previously

descnbed

heat

control

valve

j

is

welded

to

valve

shaft

@

at

exhaust

manifold

and

cannot

be

disassembled

To

install

reverse

the

removal

procedure

INSPECTION

1

With

engine

stopped

visually

check

the

quick

heat

manifold

system

for

the

following

items

I

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

2

Rotate

heat

control

valve

shaft

with

fingers

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

Emission

Control

System

Counterweight

Heat

control

valve

Stopper

pin

EC249

Fig

EC

IO

Checking

Heat

Control

Valve

Movement

2

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

2

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

EC

9

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

If

it

does

not

move

at

all

check

and

replace

thermostat

spring

AIR

INJECTION

SYSTEM

A

I

S

DESCRIPTION

The

Air

Injection

System

A

I

S

is

adopted

on

U

S

A

models

except

FU

models

and

injects

compressed

air

secondary

air

coming

from

the

air

pump

into

the

exhaust

port

of

the

cylinder

head

to

reduce

hydrocarbons

He

and

carbon

monoxide

CO

in

exhaust

gas

through

recombustion

There

are

two

types

of

Air

Injection

System

Fresh

outside

air

is

drawn

by

the

air

pump

through

the

air

pump

air

cleaner

Compressed

air

is

injected

into

the

exhaust

manifold

through

the

check

valve

The

A

B

valve

supplies

air

from

the

carburetor

air

cleaner

to

the

intake

manifold

so

as

to

prevent

after

fire

during

deceleration

The

amount

of

injected

air

is

con

trolled

by

C

A

C

valve

California

models

or

air

relief

valve

Non

California

models

Page 130 of 548

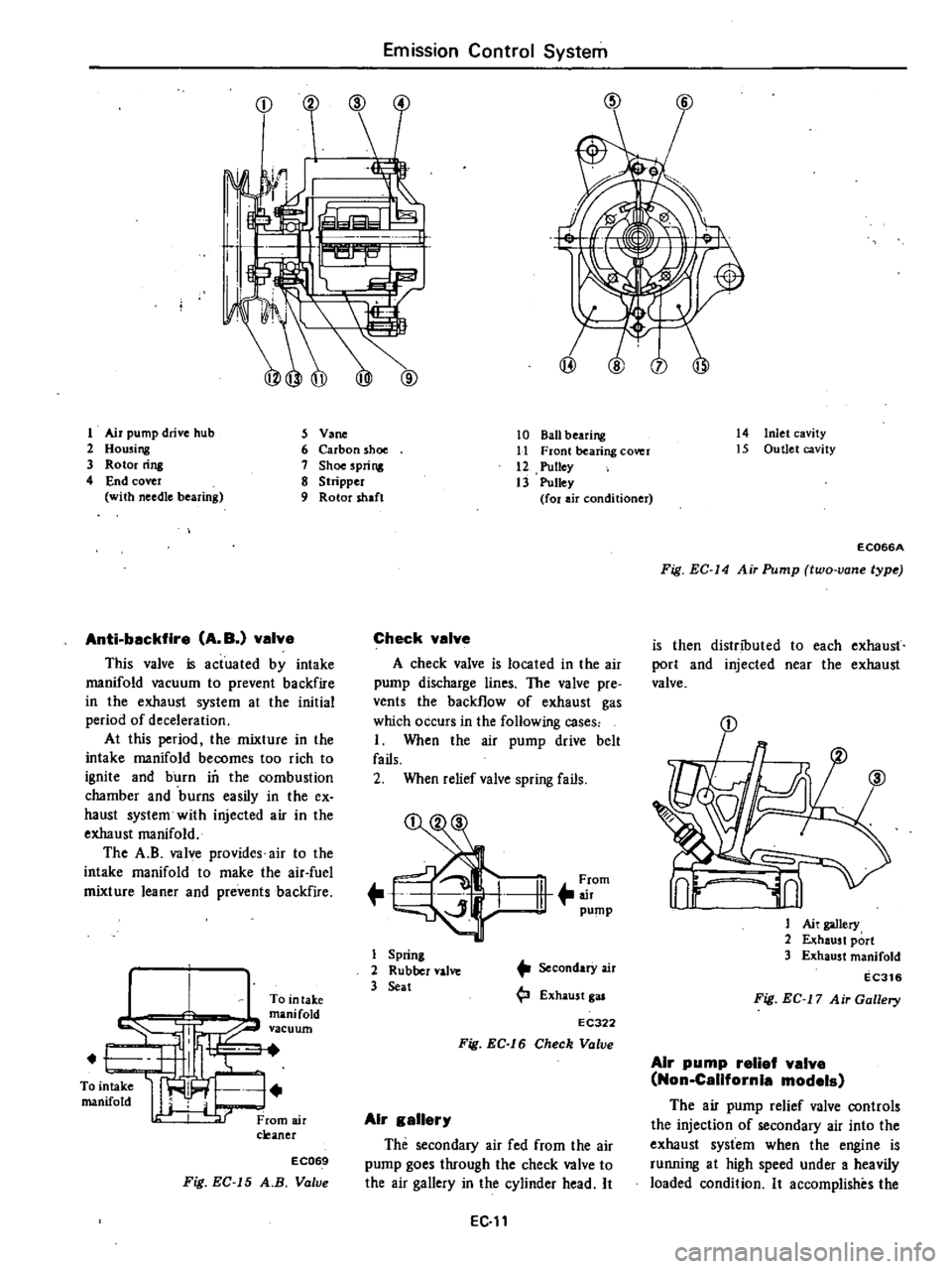

Emission

Control

System

r

@

@

CD

L

I

1

Air

pump

drive

hub

5

V

ne

2

Housing

6

Carbon

shoe

3

Rotor

rins

7

Shoe

spri

ng

4

End

cover

8

Stripper

with

needle

bearing

9

Rotor

shaft

Anti

backfire

A

B

valve

This

valve

is

actuated

by

intake

manifold

vacuum

to

prevent

backfire

in

the

exhaust

system

at

the

initial

period

of

deceleration

At

this

period

the

mixture

in

the

intake

manifold

becomes

too

rich

to

ignite

and

burn

in

the

combustion

chamber

and

burns

easily

in

the

ex

haust

system

with

injected

air

in

the

exhaust

manifold

The

A

B

valve

provides

air

to

the

intake

manifold

to

make

the

air

fuel

mixture

leaner

and

prevents

backfire

To

in

take

manifold

vacuum

EC069

Fig

EC

15

A

B

Valve

10

Ball

bearing

11

Front

bearing

cOYer

12

Pulley

13

Pulley

for

air

conditioner

Check

valve

A

check

valve

is

located

in

the

air

pump

discharge

lines

The

valve

pre

vents

the

backflow

of

exhaust

gas

which

occurs

in

the

following

cases

I

When

the

air

pump

drive

belt

fails

2

When

relief

valve

spring

fails

1

11

rom

pump

1

Spring

2

Rubber

valve

3

Seat

SecondarY

air

4

J

Exhaust

gas

EC322

Fig

EC

16

Check

Valve

Air

gallery

The

secondary

air

fed

from

the

air

pump

goes

through

the

check

valve

to

the

air

gallery

in

the

cylinder

head

It

EC

lt

14

Inlet

cavity

15

Outlet

cavity

EC066A

Fig

EC

14

Air

Pump

two

vane

lype

is

then

distributed

to

each

exhaust

port

and

injected

near

the

exhaust

valve

0

iJl

Ai

gallery

2

Exhaust

port

3

Exhaust

manifold

EC316

Fig

EC

17

Air

Gallery

Air

pump

relief

valve

Non

California

models

The

air

pump

relief

valve

controls

the

injection

of

secondary

air

into

the

exhaust

system

when

the

engine

is

running

at

high

speed

under

a

heavily

loaded

condition

It

accomplishes

the

Page 132 of 548

EC149A

Fig

EC

23

Removing

Air

Cleaner

Filter

Air

pump

1

Remove

air

hoses

from

air

pump

2

Remove

air

pump

pulley

3

Loosen

air

pump

adjusting

bar

mounting

bolts

and

air

pump

mount

ing

bolts

then

remove

air

pump

drive

belt

4

Air

pump

assembly

can

be

taken

out

from

bracket

5

Installation

is

in

the

reverse

se

quence

of

removal

Fig

EC

24

Removing

Air

Pump

Check

valve

1

Disconnect

air

hose

from

check

valve

2

Remove

check

valve

from

engine

cylinder

head

3

Installation

is

in

the

reverse

se

fluence

of

removal

Emission

Control

System

EC151A

Fig

EC

25

Removing

Check

Valve

A

B

valve

A

B

valve

is

located

at

the

rear

side

of

air

cleaner

Remove

air

hoses

and

vacuum

tube

A

B

valve

can

then

be

taken

out

EC152A

Fig

EC

26

Removing

A

B

Valve

Air

pump

relief

valve

Non

California

models

I

Loosen

clamp

of

air

hose

and

disconnect

air

hose

from

relief

valve

EC

13

2

Remove

screws

securing

relief

valve

to

air

cleaner

Relief

valve

can

then

be

taken

out

easily

3

Installation

is

in

the

reverse

se

quence

of

removal

EC153A

Fig

EC

27

Removing

Air

Pump

Relief

Valve

C

A

C

valve

California

models

C

A

C

valve

is

located

beneath

con

trol

device

bracket

Remove

clamps

and

disconnect

air

hoses

and

vacuum

tube

2

Remove

screws

securing

C

A

C

valve

Air

control

valve

can

then

be

taken

out

easily

3

Installation

is

in

the

reverse

se

quence

of

removal

EC154A

Fig

EC

28

Removing

C

A

C

Volvo

Page 135 of 548

them

b

If

carbon

shoes

are

exposed

beyond

the

rotor

end

face

remove

carbon

shoes

and

clean

shoe

grooves

Reas

semble

carbon

shoes

6

Vane

1

Pack

vane

bearing

with

high

melting

poinf

grease

MIL

G

3S45

A

Es

o

ANDOK260

or

equivalent

and

insert

dummy

shaft

into

the

vane

bearing

STl9900000

EC563

Fig

EC

40

Va

Assembly

2

Install

vane

in

place

on

rotor

uMng

Dummy

Shaft

STl9900000

as

a

guide

Note

The

woes

may

require

6

to

16

km

4

to

10

miles

wear

in

running

time

In

the

event

a

slight

squeaking

still

remains

drive

the

car

about

64

to

80

km

h

40

to

SO

MPH

In

most

cases

6

to

16

km

4

to

10

miles

will

be

sufficient

for

wear

in

7

Shoe

spring

Place

shoe

springs

in

deeper

groave

of

shoe

11

I

11

1

EC123

Fig

EC

4I

Ins

tolling

Shoe

Spring

Note

When

installing

a

shoe

spring

make

sure

that

the

outward

bend

ing

side

faces

in

shoe

and

that

both

ends

of

sJlri

face

in

the

wall

of

Emission

Control

System

shoe

groove

6e

Sure

to

push

spring

in

SO

that

spring

end

face

is

flush

with

rotor

8

Rotor

ring

Install

rotor

ring

by

correctly

align

ing

the

rear

end

face

of

rotor

with

the

on

mark

in

rotor

ring

and

tighten

screws

with

Hexagon

Wrench

ST

98

10000

l

l

Tightening

torque

Rotor

ring

screw

0

5

to

0

7

kg

m

13

6

to

5

1

ft

lb

Fig

EC

42

Installing

Rotor

Ring

9

Removal

of

dummy

shaft

CarefuDy

withdraw

dummy

shaft

from

vane

10

Vane

shaft

Pack

rear

bearing

with

high

melting

pain

t

grease

MIL

G

3S45

A

Esso

ANDOK

260

or

equivalent

Apply

thin

coating

of

grease

to

vane

shaft

and

rotor

ring

and

insert

vanf

shafi

into

its

bearing

Note

a

Do

not

apply

an

undue

stress

to

vane

shaft

when

inserting

b

If

two

vanes

are

dislocated

when

inserting

vane

shaft

correctly

align

Yanes

by

inserting

dummy

shaft

Then

draw

out

dummy

shaft

and

insert

vane

shaft

c

When

wear

occurs

on

vane

shaft

or

when

replacement

of

rear

bearing

is

necessary

replace

rear

rover

assem

bly

J

I

End

cover

Position

end

cover

in

place

Snugly

tighten

the

bolt

close

to

the

dowel

Then

tighten

end

cover

bolts

EC

t6

l

l

Tighteningtnrque

End

cover

bolts

0

7

to

0

9

kg

m

5

1

to

6

5

ft

bl

EC302

Fig

EC

43

lnstolling

End

Cover

12

Pulley

Tighten

pulley

securing

bolts

Tightening

torque

Pulley

securing

bolts

0

75

to

0

90

kg

m

5

4

to

6

5

ft

Ib

INSPECTION

The

following

procedures

are

re

commended

for

checking

and

or

as

certaining

that

the

various

components

of

the

exhaust

emission

control

system

are

opera

ting

properly

The

engine

and

all

components

mu

t

be

at

normal

operating

tempera

tures

when

the

tests

are

performed

Prior

to

performing

any

extensive

diag

nosis

of

the

exhaust

control

ystem

h

must

be

determined

that

the

engine

as

a

unit

is

functioning

properly

Air

injection

s

stem

hoses

Check

air

system

hoses

for

loose

connections

cracks

or

deterioration

Retighten

01

replace

if

necessary

Air

pump

I

Operate

engine

until

it

reaches

normal

operating

temperature

2

Inspect

all

hose

hose

connec

tions

and

air

gaDery

for

leaks

and

correct

if

necessary

before

checking

air

injection

pump