check engine DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 37 of 548

Engine

Tune

up

Condition

Probable

cause

Overheat

Improper

fuel

mixture

Floor

temp

ture

too

high

California

and

FU

model

Problem

in

fuel

system

Refer

to

Inspec

tion

of

Fuel

System

Problem

in

ignition

system

Refer

to

In

spection

oflgnition

System

Corrective

action

Previously

mentioned

Check

the

fuel

system

Check

and

repair

Check

and

repair

SPECIAL

SERVICE

TOOL

Kent

Moore

No

Tool

number

tool

name

Reference

page

or

Fig

No

STl9320000

Oil

filter

wrench

125664

Page

ET

3

ET

23

Kent

Moore

No

Tool

number

tool

name

Reference

page

or

Fig

No

Page 40 of 548

PRELIMINARY

CLEANING

AND

INSPECTION

Before

disassembling

engine

ob

serve

the

following

items

I

Prior

to

disassembling

check

outer

parts

for

sign

of

leak

past

their

gasketed

surfaces

2

Check

carburetor

and

fuel

pump

for

condition

fuel

hoses

for

deteriora

t

ion

cracks

or

otherwise

leakage

of

fuel

past

their

jointed

or

connected

surfaces

3

Wipe

dust

and

mud

off

engine

4

Inspect

outer

parts

for

visual

faults

and

broken

or

missing

parts

such

as

bolts

and

nuts

5

Check

piping

and

electrical

cir

cuits

for

deterioration

breakage

fittings

discontinuity

or

insulation

DISASSEMBLY

To

remove

engine

from

car

refer

to

Section

ER

for

Removal

1

Remove

starting

motor

then

re

move

transmission

from

engine

2

Remove

clutch

assembly

3

Remove

alternator

fan

belt

alter

nator

bracket

and

alternator

adjusting

bar

4

Remove

idler

pulley

air

pump

belt

and

idier

pulley

bracket

If

so

equipped

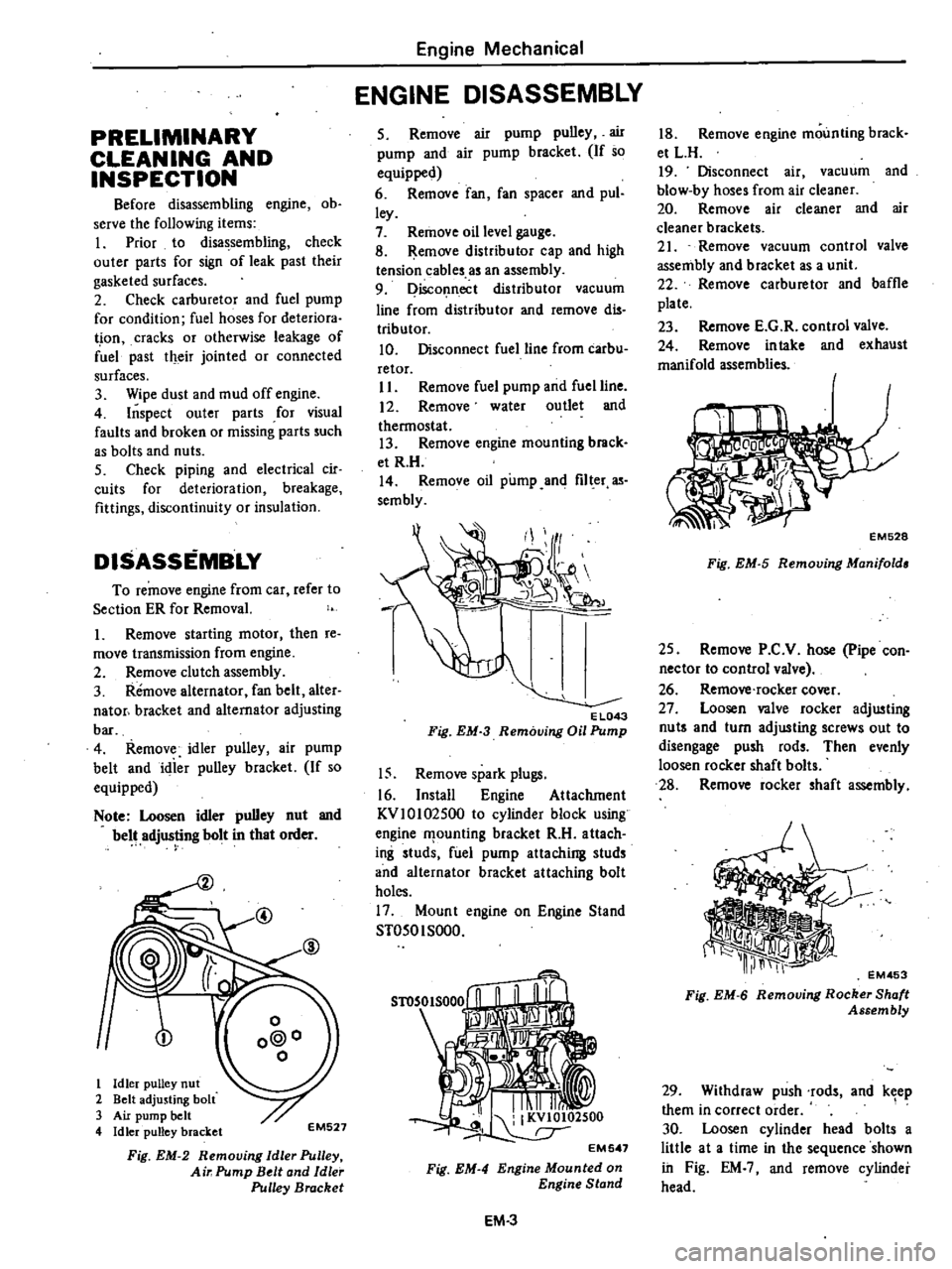

Note

Loosen

idler

pulley

nut

and

belt

adjusting

bolt

in

that

order

@

1

Idler

pulley

nut

2

Belt

adjusting

bolt

3

Air

pump

belt

4

Idler

pulley

bracket

EM527

Fig

EM

2

Removing

Idle

Pulley

Air

Pump

Belt

and

Idle

Pulley

Bracket

Engine

Mechanical

ENGINE

DISASSEMBLY

5

Remove

air

pump

pulley

air

pump

and

air

pump

bracket

If

so

equipped

6

Remove

fan

fan

spacer

and

pul

ley

7

Remove

oil

level

gauge

8

Remove

distributor

cap

and

high

tension

cables

as

an

assembly

9

Disconnect

distributor

vacuum

line

from

distributor

and

remove

dis

tributor

10

Disconnect

fuel

line

from

carbu

retor

II

Remove

fuel

pump

and

fuel

line

12

Remove

water

outlet

and

thermostat

13

Remove

engine

mounting

brack

et

R

H

14

Remove

oil

pump

and

filter

as

sembly

EL043

Fig

EM

3

Removing

Oil

Pump

15

Remove

spark

plugs

16

Install

Engine

Attachment

KVlOI02500

to

cylinder

block

using

engine

f1

ounling

bracket

R

H

attach

ing

studs

fuel

pump

attaching

studs

and

alternator

bracket

attaching

bolt

holes

17

Mount

engine

on

Engine

Stand

ST050I

SOOO

Fig

EM

4

EM

3

18

Remove

engine

mounting

brack

et

L

H

19

Disconnect

air

vacuum

and

blow

by

hoses

from

air

cleaner

20

Remove

air

cleaner

and

air

cleaner

brackets

21

Remove

vacuum

control

valve

assembly

and

bracket

as

a

unit

22

Remove

carburetor

and

baffle

plate

23

Remove

E

G

R

control

valve

24

Remove

intake

and

exhaust

manifold

assemblies

EM528

Fig

EM

5

Removing

Manifold

25

Remove

P

C

V

hose

pipe

con

nector

to

control

valve

26

Remove

rocker

cover

27

Loosen

valve

rocker

adjusting

nut

and

turn

adjusting

screws

out

to

disengage

push

rods

Then

evenly

loosen

rocker

shaft

bolts

28

Remove

rocker

shaft

assembly

EM453

Fig

EM

6

Removing

Rocker

Shaft

Assembly

29

Withdraw

push

rods

and

keep

them

in

correct

order

1

30

Loosen

cylinder

head

bolts

a

little

at

a

time

in

the

sequence

shown

in

Fig

EM

and

remove

cylinder

head

Page 42 of 548

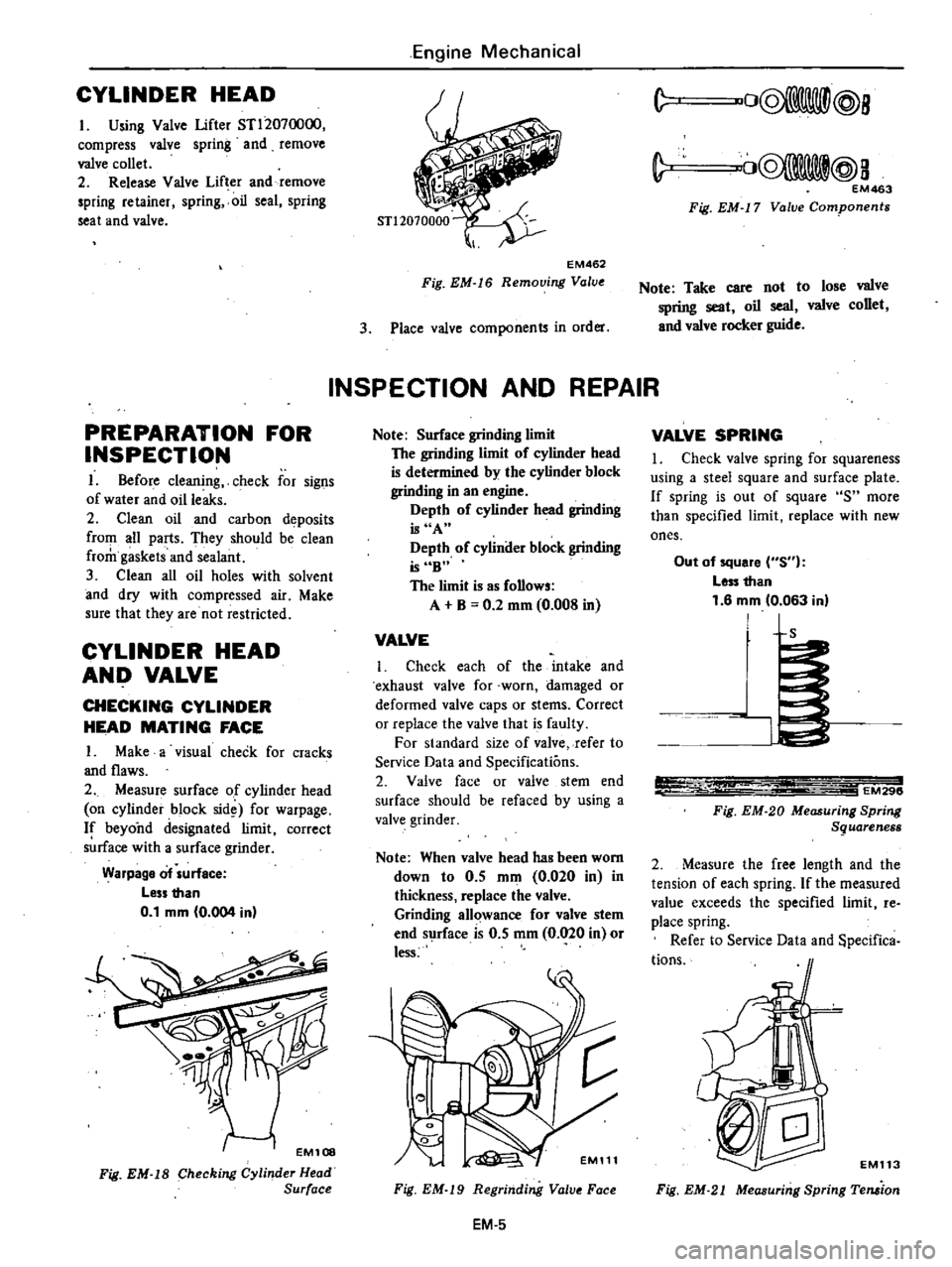

CYLINDER

HEAD

I

Using

Valve

lifter

STl2070000

compress

valve

spring

and

remove

valve

collet

2

Release

Valve

Lifter

and

remove

spring

retainer

spring

oil

seal

spring

seat

and

valve

PREPARATION

FOR

INSPECTION

I

8efore

cleaning

check

for

signs

of

water

and

oille

s

2

Clean

oil

and

carbon

deposits

from

all

parts

They

should

be

clean

from

gaskets

and

sealant

3

Clean

all

oil

holes

with

solvent

and

dry

with

compressed

air

Make

sure

that

they

are

not

restricted

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

I

Make

a

visual

check

for

cracks

and

flaws

2

Measure

surface

of

cylinder

head

on

cylinder

block

sid

for

warpage

If

beyond

designated

limit

correct

s

rface

with

a

surface

grinder

Warpage

of

urfece

Less

than

0

1

mm

0

004

in

EM108

Fig

EM

IS

Checking

Cylinder

Head

Surface

Engine

Mechanical

EM462

Fig

EM

16

Removing

Value

3

Place

valve

components

in

order

INSPECTION

AND

REPAIR

Note

Surface

grinding

limit

The

grinding

limit

of

cylinder

head

is

determined

by

the

cylinder

block

grinding

in

an

engine

Depth

of

cylinder

head

grinding

is

A

Depth

of

cylinder

block

grinding

is

6B

The

limit

is

as

follows

A

B

0

2

mm

0

008

in

VALVE

i

Check

each

of

the

intake

and

exhaust

valve

for

worn

damaged

or

deformed

valve

caps

or

stems

Correct

or

replace

the

valve

that

is

faulty

For

standard

size

of

valve

refer

to

Service

Data

and

Specifications

2

Valve

face

or

valve

stem

end

surface

should

be

refaced

by

using

a

valve

grinder

Note

When

valve

head

has

been

worn

down

to

0

5

mm

0

020

in

in

thickness

replace

the

valve

Grinding

allowance

for

valve

stem

end

surface

is

0

5

mm

0

020

in

or

less

c

EM111

Fig

EM

19

Regrinding

Valve

Face

EM

5

C

vO@

lll@8

C

CQ8@

a

EM463

Fig

EM

17

Valve

Components

Note

Take

care

not

to

lose

valve

spring

seat

oil

seal

valve

collet

and

valve

rocker

guide

VALVE

SPRING

I

Check

valve

spring

for

squareness

using

a

steel

square

and

surface

plate

If

spring

is

out

of

square

S

more

than

specified

limit

replace

with

new

ones

Out

of

square

S

Less

than

1

6

mm

0

063

inl

L

1

EM296

Fig

EM

20

Measuring

Spring

Sguareness

2

Measure

the

free

length

and

the

tension

of

each

spring

If

the

measured

value

exceeds

the

specified

limit

re

place

spring

Refer

to

Service

Data

and

pecifica

tions

EMl13

Fig

EM

21

Measuring

Spring

Teruion

Page 43 of 548

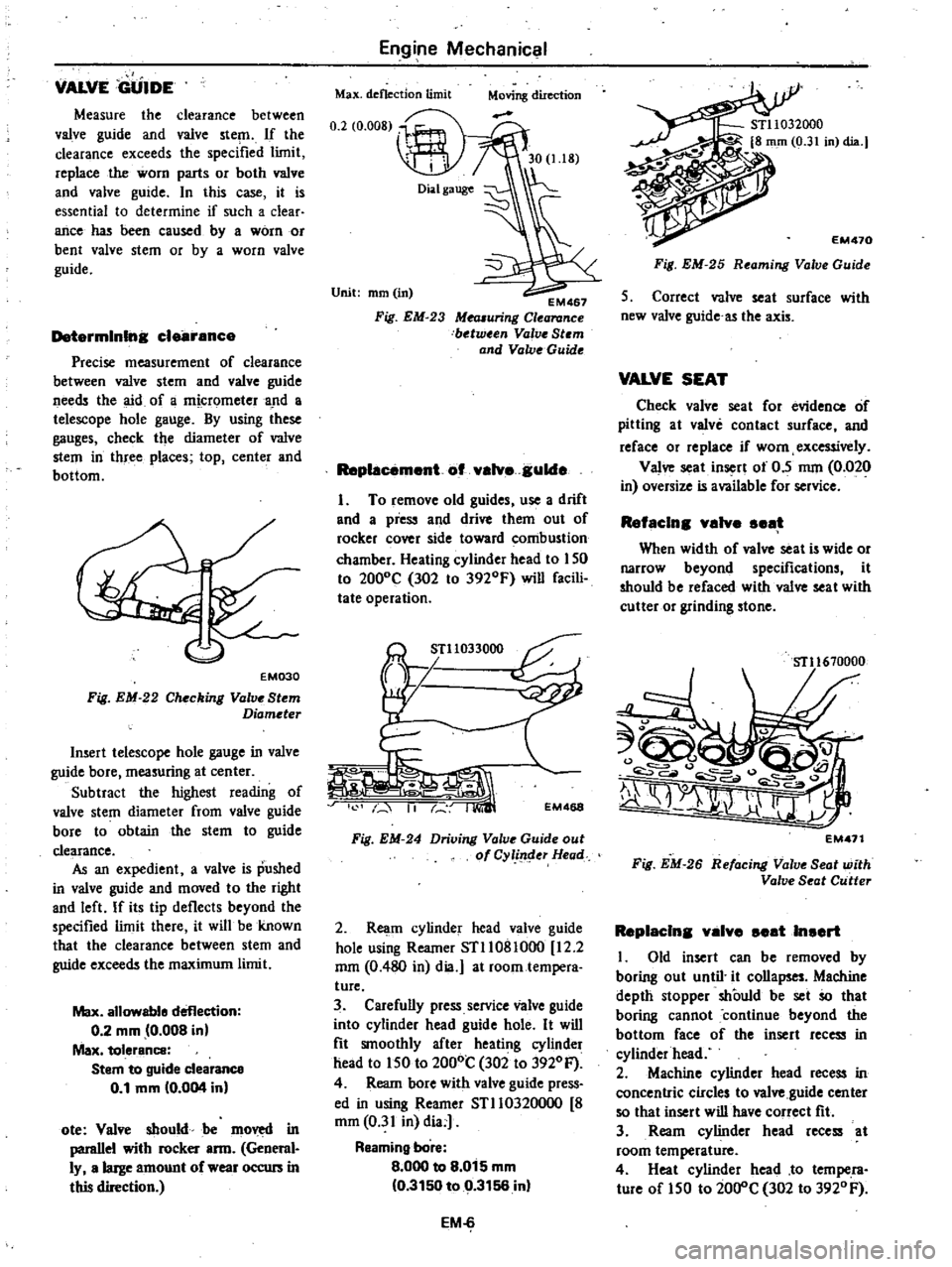

VALVE

GUIDE

Measure

the

clearance

between

valve

guide

and

valve

stern

If

the

clearance

exceeds

the

specified

limit

replace

the

worn

parts

or

both

valve

and

valve

guide

In

this

case

it

is

essential

to

determine

if

such

a

clear

ance

has

been

caused

by

a

worn

or

bent

valve

stem

or

by

a

worn

valve

guide

Determining

clearance

Precise

measurement

of

clearance

between

valve

stem

and

valve

guide

needs

the

aid

of

a

micrometer

and

a

telescope

hole

gauge

By

using

these

gauges

check

the

diameter

of

valve

stem

in

three

places

top

center

and

bottom

EM030

Fig

EM

22

Checking

Valve

Stem

Diameter

Insert

telescope

hole

gauge

in

valve

guide

bore

measuring

at

center

Subtract

the

highest

reading

of

valve

stem

diameter

from

valve

guide

bore

to

obtain

the

stem

to

guide

clearance

As

an

expedient

a

valve

is

pushed

in

valve

guide

and

moved

to

the

right

and

left

If

its

tip

deflects

beyond

the

specified

limit

there

it

will

be

known

that

the

clearance

between

stem

and

guide

exceeds

the

maximum

limit

Max

allowabl

deflection

0

2

mm

0

008

in

Max

tolerance

Stem

to

guide

clearance

0

1

mm

10

004

in

ote

Valve

sbould

be

moved

in

paraIlel

with

rocker

ann

General

ly

a

large

amount

of

wear

occurs

in

this

direction

Engine

Mechanical

Max

deflection

limit

Unit

mm

in

EM467

Mea6uring

Clearance

between

Valve

Stem

and

Valve

Guide

Fig

EM

23

Replacement

of

valve

julde

I

To

remove

old

guides

use

a

drift

and

a

pie

and

drive

them

out

of

rocker

cover

side

toward

combustion

chamber

Heating

cylinder

head

to

I

SO

to

200

C

302

to

392

F

will

facili

tate

operation

T11033000

EM468

1

II

Fig

EM

24

Driving

Valve

Guide

out

of

Cylinder

Head

2

Ream

cylinder

head

valve

guide

hole

using

Reamer

STlI081000

12

2

mrn

0

480

in

dia

at

room

tempera

ture

3

Carefully

press

service

Valve

guide

into

cylinder

head

guide

hole

It

will

fit

smoothly

after

heating

cylinder

head

to

ISO

to

200

302

to

392

F

4

Ream

bore

with

valve

guide

press

ed

in

using

Reamer

STll0320000

8

mm

0

31

in

dia

Reaming

bore

8

000

to

8

015

mm

0

3150

to

0

3156

in

EM

6

EM470

Fig

EM

25

Reaming

Valve

Guide

5

Correct

va1ve

seat

surface

with

new

valve

guide

as

the

axis

VALVE

SEAT

Check

valve

seat

for

evidence

of

pitting

at

valve

contact

surface

and

reface

or

replace

if

worn

excessively

Valve

seat

insert

of

0

5

mm

0

020

in

oversize

is

available

for

service

Refaclng

valve

seat

When

width

of

valve

seat

is

wide

or

narrow

beyond

specifications

it

should

be

refaced

with

valve

seat

with

cutter

or

grinding

stone

iIT11670000

EM411

Fig

EM

26

Refacing

Valve

Seat

with

Valve

Seat

Cutter

Replaclna

valve

seat

Insert

I

Old

insert

can

be

removed

by

boring

out

until

it

collapses

Machine

depth

stopper

should

be

set

So

that

boring

cannot

continue

beyond

the

bottom

face

of

the

insert

recess

in

cylinderhead

2

Machine

cylinder

head

recess

in

concentric

circles

to

valve

guide

center

so

that

insert

will

have

correct

fit

3

Ream

cylinder

head

recess

at

room

temperature

4

Heat

cylinder

head

to

tempera

ture

of

150

to

200

C

302

to

3920F

Page 44 of 548

5

Fit

insert

ensuring

that

it

seats

on

bottom

face

of

its

recess

6

Newly

fitted

valve

seat

should

be

cut

or

ground

with

suitable

seat

cutter

or

grinding

stone

7

Apply

smalliunount

of

fine

grind

ing

compound

to

valve

contacting

face

and

put

valve

into

guide

Lap

valve

against

its

seat

ntil

proper

valve

seat

ing

is

obtained

Remove

valve

and

clean

valve

and

valve

seat

VALVE

ROCKER

ARM

1

AND

SHAFT

I

Check

rocker

arm

bore

and

shaft

for

scores

or

scuffs

2

Check

clearance

between

each

rocker

arm

and

shaft

by

measuring

inner

diameter

of

rocker

arm

bore

and

outer

diameter

of

shaft

If

either

clearance

is

not

within

spec

ification

replace

rocker

arm

and

or

shaft

3

Check

valve

end

contact

surface

of

rocker

arm

for

abnormal

wear

or

scuffs

VALVE

LIFTER

AND

PUSH

ROD

I

Check

valve

lifter

for

wear

or

scuffs

Check

bottom

end

of

valve

lifter

to

make

sure

it

has

a

slight

convex

Replace

valve

lifters

that

are

scored

worn

or

have

unsmooth

bot

tom

2

Check

clearance

between

lifter

hole

on

cylinder

block

and

valve

lifter

Replace

valve

lifter

if

clearance

ex

ceeds

wear

limit

3

Check

push

rod

for

bending

and

damage

Check

end

of

push

rod

for

rough

ness

or

excessive

wear

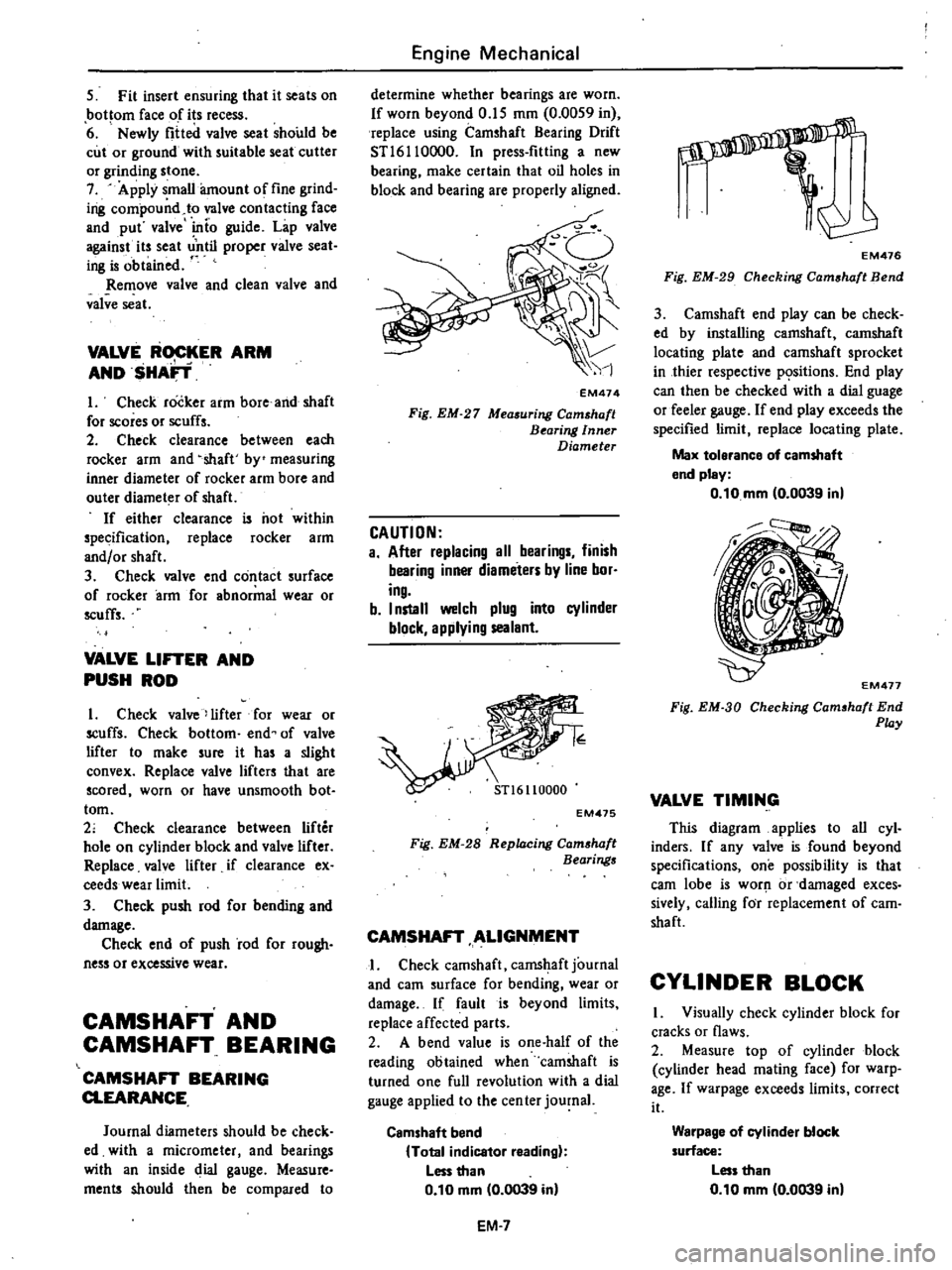

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAFT

BEARING

CLEARANCE

Journal

diameters

should

be

check

ed

with

a

micrometer

and

bearings

with

an

inside

dial

gauge

Measure

ments

should

then

be

compared

to

Engine

Mechanical

determine

whether

bearings

are

worn

If

worn

beyond

0

15

mm

0

0059

in

replace

using

Camshaft

Bearing

Drift

STl6Il0000

In

press

fitting

a

new

bearing

make

certain

that

oil

holes

in

block

and

bearing

are

properly

aligned

EM474

Fig

EM

27

Measuring

Camshaft

Bearing

Inner

Diameter

CAUTION

a

After

replacing

all

bearings

finish

bearing

inner

diameters

by

line

bor

ing

b

I

nstall

welch

plug

into

cylinder

block

applying

sealant

EM475

Fig

EM

28

Replacing

Cam

haft

Bearings

CAMSHAFT

ALIGNMENT

I

Check

camshaft

camshaft

journal

and

earn

surface

for

bending

wear

or

damage

If

fault

is

beyond

limits

replace

affected

parts

2

A

bend

value

is

one

half

of

the

reading

obtained

when

camshaft

is

turned

one

full

revolution

with

a

dial

gauge

applied

to

the

cen

ter

journal

Camshaft

bend

Total

indicator

reading

Less

than

0

10

mm

0

0039

in

EM

7

s

EM476

Fig

EM

29

Checking

Cam

haft

Bend

3

Camshaft

end

play

can

be

check

ed

by

installing

camshaft

camshaft

locating

plate

and

camshaft

sprocket

in

thier

respective

p

sitions

End

play

can

then

be

checked

with

a

dial

guage

or

feeler

gauge

If

end

play

exceeds

the

specified

limit

replace

locating

plate

Max

tolerance

of

camshaft

end

pley

0

10

mm

0

0039

in

EM477

Fig

EM

3D

Checking

Cam

haft

End

Play

VALVE

TIMING

This

diagram

applies

to

all

cyl

inders

If

any

valve

is

found

beyond

specifications

one

possibility

is

that

earn

lobe

is

worJ

1

or

damaged

exces

sively

calling

for

replacement

of

cam

shaft

CYLINDER

BLOCK

I

Visually

check

cylinder

block

for

cracks

or

flaws

2

Measure

top

of

cylinder

block

cylinder

head

mating

face

for

warp

age

If

warpage

exceeds

limits

correct

it

Warpage

of

cylinder

block

surface

Less

than

0

10

mm

0

0039

in

Page 45 of 548

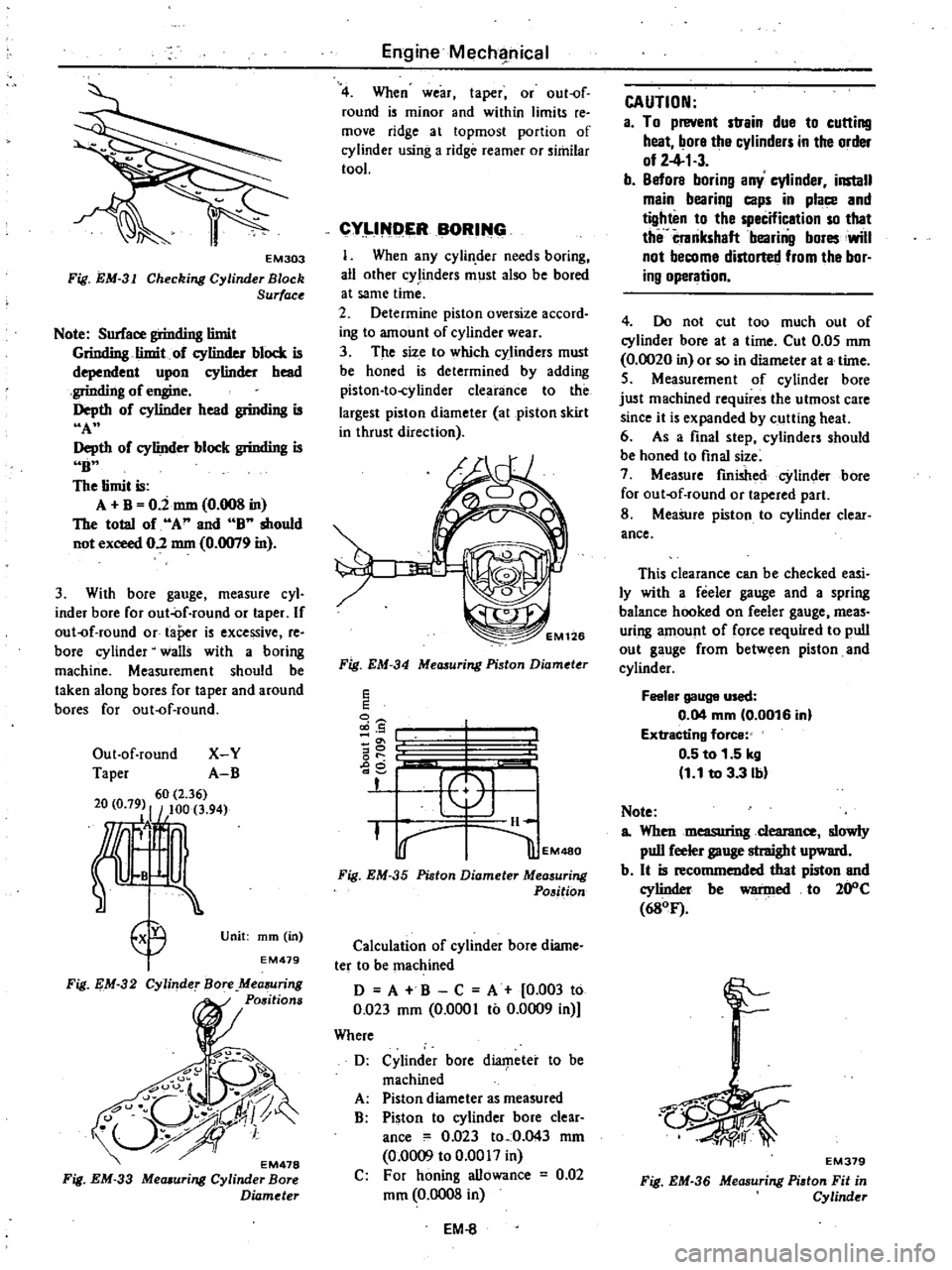

EM303

Fig

EM

31

Checking

Cylinder

Block

Surface

Note

Surface

grinding

6mit

Grinding

limit

of

cylinder

block

is

dependent

upon

cylinder

bead

grinding

of

engjne

Depth

of

cylinder

head

grinding

is

A

Depth

of

cylinder

block

b

1

b

is

U

The

limit

is

A

B

O

imm

0

008

in

The

total

of

A

and

B

should

not

exceed

0

2

mm

0

0079

in

3

With

bore

gauge

measure

cyl

inder

bore

for

out

of

round

or

taper

If

out

f

round

or

taPer

is

excessive

re

bore

cylinder

walls

with

a

boring

machine

Measurement

should

be

taken

along

bores

for

taper

and

around

bores

for

out

f

round

Out

of

round

X

Y

Taper

A

B

60

2

36

20

0

79

I

100

3

94

Ii

B

E9

I

Unit

mm

in

EM479

Fig

EM

32

Cylinder

Bore

Mea

uring

Positions

EM478

Fig

EM

33

Mecuuring

Cylinder

Bore

Diameter

Engine

Mecha

hical

4

When

wear

taper

or

out

of

round

is

minor

and

within

limits

re

move

ridge

at

topmost

portion

of

cylinder

using

a

ridge

reamer

or

similar

tool

CYLlND

ER

BORING

I

When

any

cylin

der

needs

boring

all

other

cY

linders

must

also

be

bored

at

same

time

2

Determine

piston

oversize

accord

ing

to

amount

of

cylinder

wear

3

The

size

to

which

c

linders

must

be

honed

is

determined

by

adding

piston

to

cylinder

clearance

to

the

largest

piston

diameter

at

piston

skirt

in

thrust

direction

f

EM126

Fig

EM

34

Measuring

Piston

Diameter

E

E

5

g

or

ge

I

PI

H

i

I

lEM480

Fig

EM

35

Piston

Diameter

Measuring

Position

Calculation

of

cylinder

bore

diame

ter

to

be

machined

D

A

B

C

A

0

003

to

0

023

mm

0

0001

to

0

0009

in

Where

D

Cylinder

bore

diaIpeter

to

be

machined

A

Piston

diameter

as

measured

B

Piston

to

cylinder

bore

clear

ance

0

023

to

0

043

mm

0

0009

to

0

0017

in

C

For

honing

allowance

0

02

mm

0

0008

in

EM

8

CAUTION

a

To

prevent

strain

due

to

cutting

heat

bore

the

cylinders

in

the

order

of

2

4

1

3

b

Before

boring

any

cylinder

install

main

bearing

caps

in

place

and

tighten

to

the

specification

so

that

the

crankshaft

bearing

bores

will

not

become

distorted

from

the

bor

ing

operation

4

Do

not

cut

too

much

out

of

cylinder

bore

at

a

time

Cut

0

05

mm

0

0020

in

or

so

in

diameter

at

a

time

5

Measurement

of

cylinder

bore

just

machined

requires

the

utmost

care

since

it

is

expanded

by

cutting

heal

6

As

a

final

step

cylinders

should

be

honed

to

final

size

7

Measure

finished

cylinder

bore

for

out

of

round

or

tapered

part

8

Measure

piston

to

cylinder

clear

ance

This

clearance

can

be

checked

easi

ly

with

a

feeler

gauge

and

a

spring

balance

hooked

on

feeler

gauge

meas

uring

amount

of

force

required

to

pull

out

gauge

from

between

piston

and

cylinder

Feeler

gauge

used

0

04

mm

0

0016

inl

Extracting

force

0

5

to

1

51rg

1

1

to

3

3

b

Note

a

Whenmeasuringcleanmce

slowly

pull

feeler

gauge

straight

upward

b

It

is

recommended

that

piston

and

cylinder

be

warmed

to

20

C

680F

r

EM379

Fig

EM

36

Measuring

Pi

ton

Fit

in

Cylinder

Page 46 of 548

Note

If

cylinder

bore

has

worn

beyond

the

wear

limit

use

cylinder

liner

Undersize

cylinder

liners

are

avail

able

for

service

Interference

fit

of

cylinder

liner

in

cylinder

block

ahould

be

0

08

to

0

09

mm

0

003

I

to

0

0035

in

PISTON

PISTON

PIN

AND

PISTON

RING

I

Remove

carbon

from

piston

and

ring

grooves

with

a

carbon

scraper

and

a

curved

steel

wire

The

wire

will

be

useful

in

cleaning

bottom

land

of

ring

groove

Clean

out

oil

slots

in

bottom

land

of

oil

ring

groove

2

Check

for

damage

scratches

and

wear

Replace

if

fault

is

detected

3

Measure

side

clearance

of

rings

in

ring

grooves

as

each

ring

is

installed

If

side

clearance

exceeds

the

speci

fied

limit

replace

piston

together

with

piston

ring

Max

tolerance

of

side

clearance

0

1

mm

0

0039

in

Engine

Mechanical

u

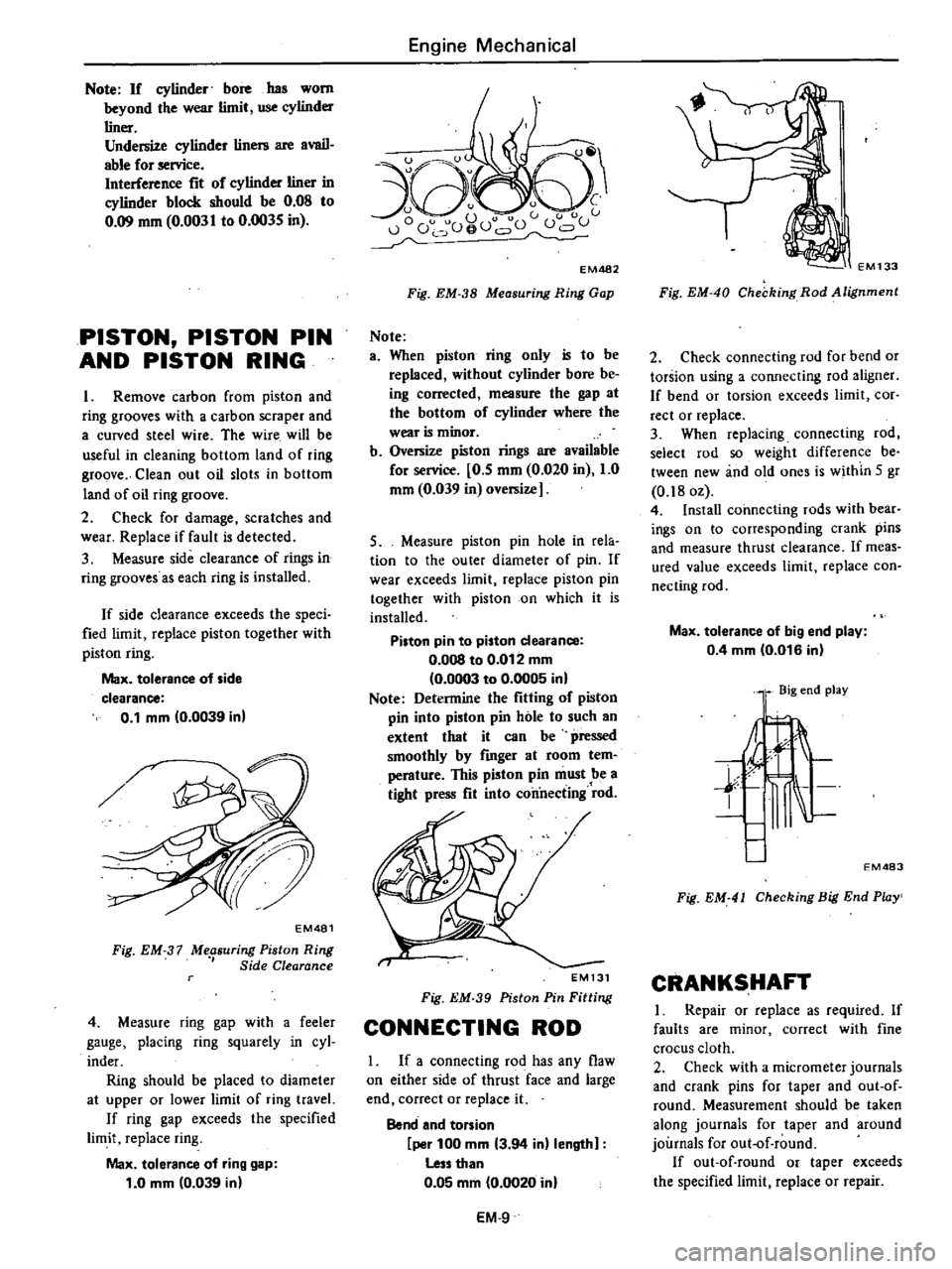

EM482

Fig

EM

38

Measuring

Ring

Gap

Note

a

When

piston

ring

only

is

to

be

replaced

without

cylinder

bore

be

ing

corrected

measure

the

gap

at

the

bottom

of

cylinder

where

the

wear

is

minor

b

Oversize

piston

rings

are

available

for

service

0

5

mm

0

020

in

1

0

mm

0

039

in

oversize

5

Measure

piston

pin

hole

in

rela

tion

to

the

outer

diameter

of

pin

If

wear

exceeds

limit

replace

piston

pin

together

with

piston

on

which

it

is

installed

Piston

pin

to

piston

clearance

O

OOS

to

0

012

mm

0

0003

to

0

0005

in

Note

Determine

the

fitting

of

piston

pin

into

piston

pin

hole

to

such

an

extent

that

it

can

be

pressed

smoothly

by

fmger

at

room

tem

perature

This

piston

pin

must

be

a

tight

press

fit

into

connecting

rod

EM481

Fig

EM

37

Me

suring

Piston

Ring

Side

Clearance

4

Measure

ring

gap

with

a

feeler

gauge

placing

ring

squarely

in

cyl

inder

Ring

should

be

placed

to

diameter

at

upper

or

lower

limit

of

ring

travel

If

ring

gap

exceeds

the

specified

limit

replace

ring

Max

tolerance

of

ring

gap

1

0

mm

0

039

in

EM131

Fig

EM

39

Piston

Pin

Fitting

CONNECTING

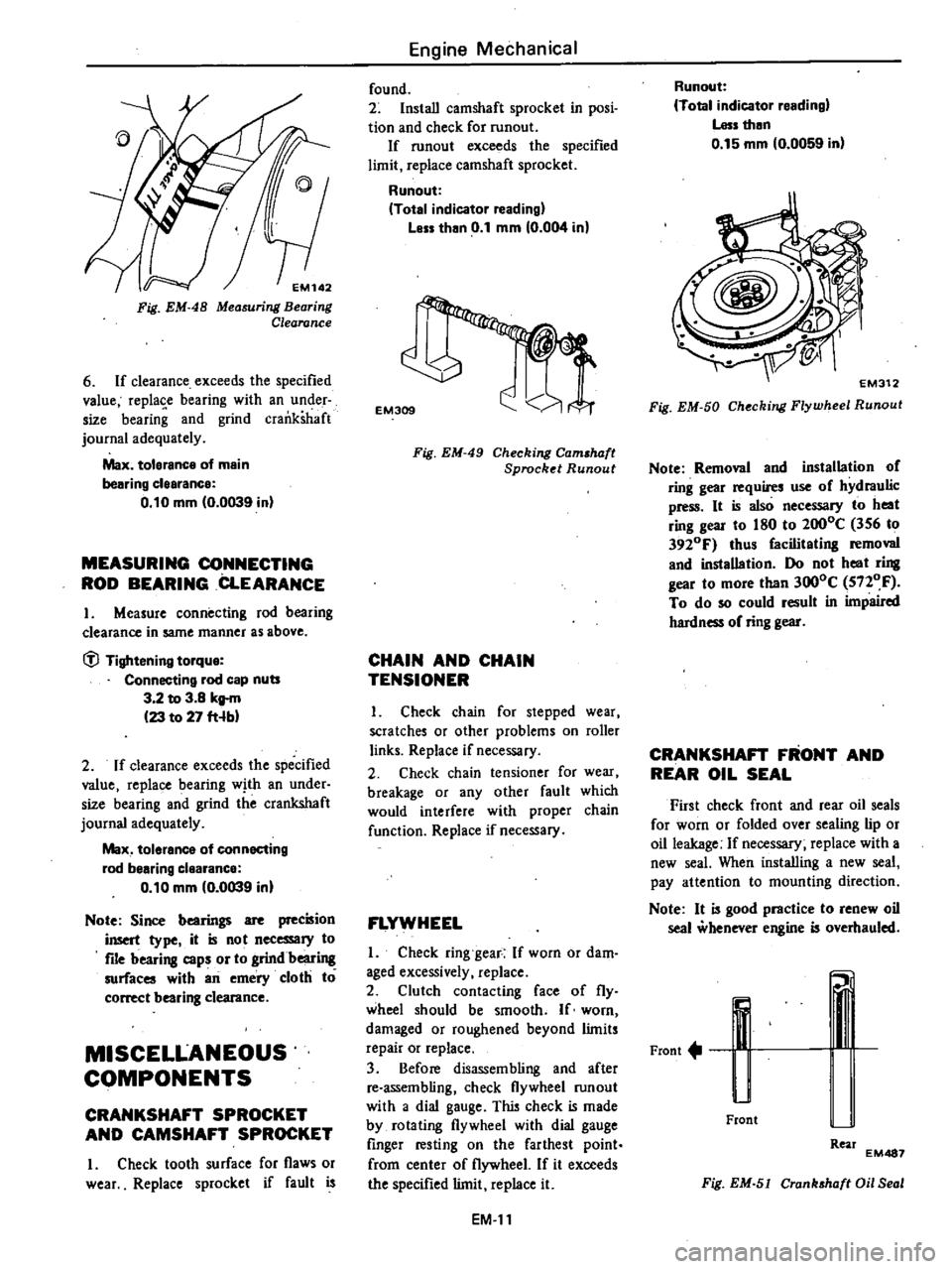

ROD

1

If

a

connecting

rod

has

any

flaw

on

either

side

of

thrust

face

and

large

end

correct

or

replace

it

Bend

and

torsion

per

100

mm

3

94

in

length

Less

than

0

05

mm

0

0020

in

EM

9

EM133

Fig

EM

40

Checking

Rod

Alignment

2

Check

connecting

rod

for

bend

or

torsion

using

a

connecting

rod

aligner

If

bend

or

torsion

exceeds

limit

cor

rect

or

replace

3

When

replacing

connecting

rod

select

rod

so

weight

difference

be

tween

new

and

old

ones

is

within

5

gr

0

180z

4

Install

connecting

rods

with

bear

iogs

on

to

corresponding

crank

pins

and

measure

thrust

clearance

If

meas

ured

value

exceeds

limit

replace

con

necting

rod

Max

tolerance

of

big

end

play

0

4

mm

0

016

in

l

Big

end

play

l

t

t

EM483

Fig

EM

41

Checking

Big

End

Pwy

CRANKSHAFT

I

Repair

or

replace

as

required

If

faults

are

minor

correct

with

fine

crocus

cloth

2

Check

with

a

micrometer

journals

and

crank

pins

for

taper

and

out

of

round

Measurement

should

be

taken

along

journals

for

taper

and

around

journals

for

out

of

round

If

out

of

round

or

taper

exceeds

the

specified

limit

replace

or

repair

Page 48 of 548

EM142

Fig

EM

48

Measuring

Bearing

Clearance

6

If

clearance

exceeds

the

specified

value

replase

bearing

with

an

under

size

bearing

and

grind

crankshaft

journal

adequately

Max

tolerance

of

main

bearing

clearance

0

10

mm

0

0039

in

MEASURING

CONNECTING

ROD

BEARING

CLEARANCE

I

Measure

connecting

rod

bearing

clearance

in

same

manner

as

above

tfl

Tightening

torque

Connecting

rod

cap

nuts

3

2

to

3

8

kg

m

23

to

27

fHb

2

If

clearance

exceeds

the

specified

value

replace

bearing

with

an

under

size

bearing

and

grind

the

crankshaft

journal

adequately

Max

tolerance

of

connecting

rod

bearing

clearance

0

10

mm

0

0039

in

Note

Since

bearings

are

precision

insert

type

it

is

not

necessary

to

file

bearing

caps

or

to

grindbeari

surfaces

with

an

emery

cloth

to

correct

bearing

clearance

MISCELLANEOUS

COMPONENTS

CRANKSHAFT

SPROCKET

AND

CAMSHAFT

SPROCKET

I

Check

tooth

surface

for

flaws

or

wear

Replace

sprocket

if

fault

is

Engine

Mechanical

found

2

Install

camshaft

sprocket

in

posi

tion

and

check

for

runout

If

runout

exceeds

the

specified

limit

replace

camshaft

sprocket

Runout

Total

indicator

reading

Less

than

0

1

mm

0

004

in

EM309

Fig

EM

49

Checking

Cam

haft

Sprocket

Runout

CHAIN

AND

CHAIN

TENSIONER

I

Check

chain

for

stepped

wear

scratches

or

other

problems

on

roller

links

Replace

if

necessary

2

Check

chain

tensioner

for

wear

breakage

or

any

other

fault

which

would

interfere

with

proper

chain

function

Replace

if

necessary

FLYWHEEL

I

Check

ring

gear

If

worn

or

dam

aged

excessively

replace

2

Clutch

contacting

face

of

fly

wheel

should

be

smooth

If

worn

damaged

or

roughened

beyond

limits

repair

or

replace

3

Before

disassembling

and

after

re

assembling

check

flywheel

run

out

with

a

dial

gauge

This

check

is

made

by

rotating

flywheel

with

dial

gauge

finger

resting

on

the

farthest

point

from

center

of

flywheel

If

it

exceeds

the

specified

limit

replace

it

EM

II

Runout

Total

indicator

reading

Less

then

0

15

mm

0

0059

in

Fig

EM

50

Checking

Flywheel

Runout

Note

Removal

and

installation

of

ring

gear

requires

use

of

hydraulic

press

It

is

also

necessary

to

heat

ring

gear

to

180

to

2000C

356

to

3920F

thus

facilitating

removal

and

installation

Do

not

heat

ring

gear

to

more

than

3000C

5nOF

To

do

so

could

result

in

impaired

hardness

of

ring

gear

CRANKSHAFT

FRONT

AND

REAR

OIL

SEAL

First

check

front

and

rear

oil

seals

for

worn

or

folded

over

sealing

lip

or

oil

leakage

If

necessary

replace

with

a

new

seal

When

installing

a

new

seal

pay

attention

to

mounting

direction

Note

It

is

good

practice

to

renew

oil

seal

whenever

engine

is

overhauled

Front

u

Front

Rear

EM487

Fig

EM

51

Cranhhaft

Oil

Seal

Page 49 of 548

PRECAUTION

Before

assembling

engine

observe

following

precautions

I

Clean

all

disass

mbled

parts

with

clean

solvent

All

611

holes

in

crank

shaft

camshaft

valve

rocker

shaft

etc

should

be

thoroughly

cleaned

to

re

move

all

traces

of

grinding

chips

or

lint

Always

use

clean

solvent

2

In

general

used

gaskets

packings

and

oil

seals

should

be

replaced

3

Under

no

circumstances

should

lockwashers

be

reuse

d

4

Place

bolts

nuts

and

woshers

back

in

their

original

parts

or

from

which

they

were

removed

5

MOst

packing

Serve

best

when

liquid

packing

is

applied

to

sealing

surfaces

When

desigiiated

use

suitable

liquid

packing

to

eliminate

possibility

of

water

oil

and

gas

leak

6

Prior

to

assemQling

all

sliding

surfaces

should

be

lioerally

oiled

7

Proper

tightening

is

essential

to

successful

performanCe

of

all

car

re

pairs

It

is

also

important

to

follow

correct

tightenig

sequence

in

pulling

up

cylinder

head

Be

on

alert

at

all

times

to

amount

of

clearance

per

mitted

8

Cleanliness

of

tools

or

parts

such

as

work

bench

used

jn

making

a

repai

is

essential

When

setting

up

a

job

every

precaution

should

be

taken

that

tools

or

parts

are

free

of

dirt

mud

and

oil

Do

not

work

in

dust

and

grit

for

they

are

primary

cause

of

wear

in

any

engine

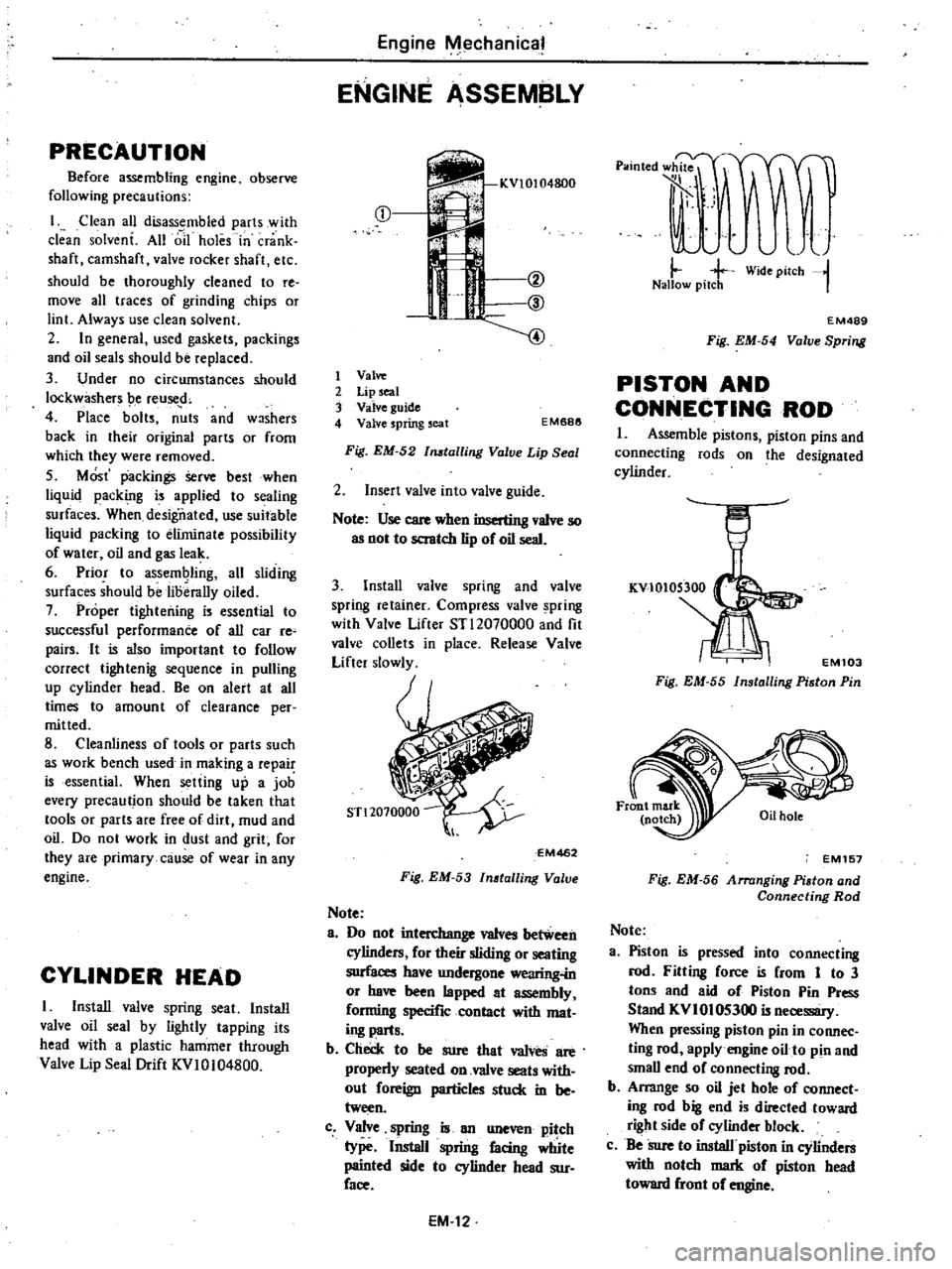

CYLINDER

HEAD

I

Install

valve

spring

seat

Install

valve

oil

seal

by

lightly

tapping

its

head

with

a

plastic

hammer

through

Valve

Lip

Seal

Drift

KVI0104800

Engine

Mechanical

ENGINE

ASSEMBLY

m

f

if

@

@

4

1

Valve

2

Lip

seal

3

Valve

guide

4

Valve

spring

seat

EM688

Fig

EM

52

tailing

Valve

Lip

Seal

2

Insert

valve

into

valve

guide

Note

Use

care

when

inserting

valve

so

as

not

to

scratch

lip

of

oil

seal

3

Install

valve

spring

and

valve

spring

retainer

Compress

valve

pring

with

Valve

Lifter

STl2070000

and

fit

valve

collets

in

place

Release

Valve

Lifter

slowly

EM462

Fig

EM

53

Inatalling

Valve

Note

8

Do

not

interchange

valves

between

cylinders

for

their

sliding

or

seating

surfaces

have

undergone

wearing

in

or

have

been

lapped

at

assembly

forming

specific

contact

with

mat

ing

parts

b

Check

to

be

sure

that

valves

are

properly

seated

on

valve

seats

with

out

foreign

particles

stuck

in

be

tween

c

Valve

spring

is

an

uneven

pitch

type

Install

spring

facing

Wte

painted

side

to

cylinder

head

sur

face

EM

12

p

lOted

l

rJF

t

A

J

il

j

j

Wide

pilCh

l

Nallow

pitch

I

EM489

Fig

EM

54

Valve

Spring

PISTON

AND

CONNECTING

ROD

I

Assemble

pistons

piston

pins

and

connecting

rods

on

the

designated

cylinder

EM103

Fig

EM

55

Installing

Piston

Pin

EM157

Fig

EM

56

Arranging

Piaton

and

Connecting

Rod

Note

3

Piston

is

pressed

into

connecting

rod

Fitting

force

is

from

1

to

3

tons

and

aid

of

Piston

Pin

Press

Stand

KVI

01

05300

is

necessary

When

pressing

piston

pin

in

connec

ting

rod

apply

engine

oil

to

pin

and

small

end

of

connecti

8

rod

b

Arrange

so

oil

jet

hole

of

connect

ing

rod

big

end

is

directed

toward

right

side

of

cylinder

block

c

Be

Sure

to

install

piston

in

cylinders

with

notch

mark

of

piston

head

toward

front

of

engine

Page 51 of 548

9

Make

SUre

there

is

proper

end

play

at

crankshaft

Crankshaft

end

play

0

05toO

15mm

0

OO20

to

0

0059

in

laJlk

h

end

play

J

EM486

Fig

EM

63

Checking

Crank

luJft

End

Play

10

Install

rear

oil

seal

using

suitable

drift

Fig

EM

64

n

talling

Rear

Oil

Seal

II

Install

rear

plate

12

Install

flywh

el

secwely

and

tighten

bolts

to

specified

torque

dl

Tightening

torque

Flywheel

and

drive

plate

A

14

engine

fixing

bolts

8

0

to

9

0

kg

m

58

to

65

ft

Ib

Drive

plate

A

15

engine

fixing

bolts

8

5

to

9

5

kg

m

61

to

69

ft

b

Fig

EM

65

n

talling

Flywheel

13

Rotate

engine

quarter

turn

and

install

piston

rod

assembly

using

Pis

Engine

Mechanical

ton

Ring

Compressor

EM03470000

EM497

Fig

EM

66

tolling

Platon

Rod

Assem

bly

Note

a

Insert

pistons

in

L

r

nding

cyl

inders

b

Apply

engine

oil

to

sliding

parts

c

Arrange

pistons

so

number

stamped

on

piston

head

faces

to

front

of

engine

d

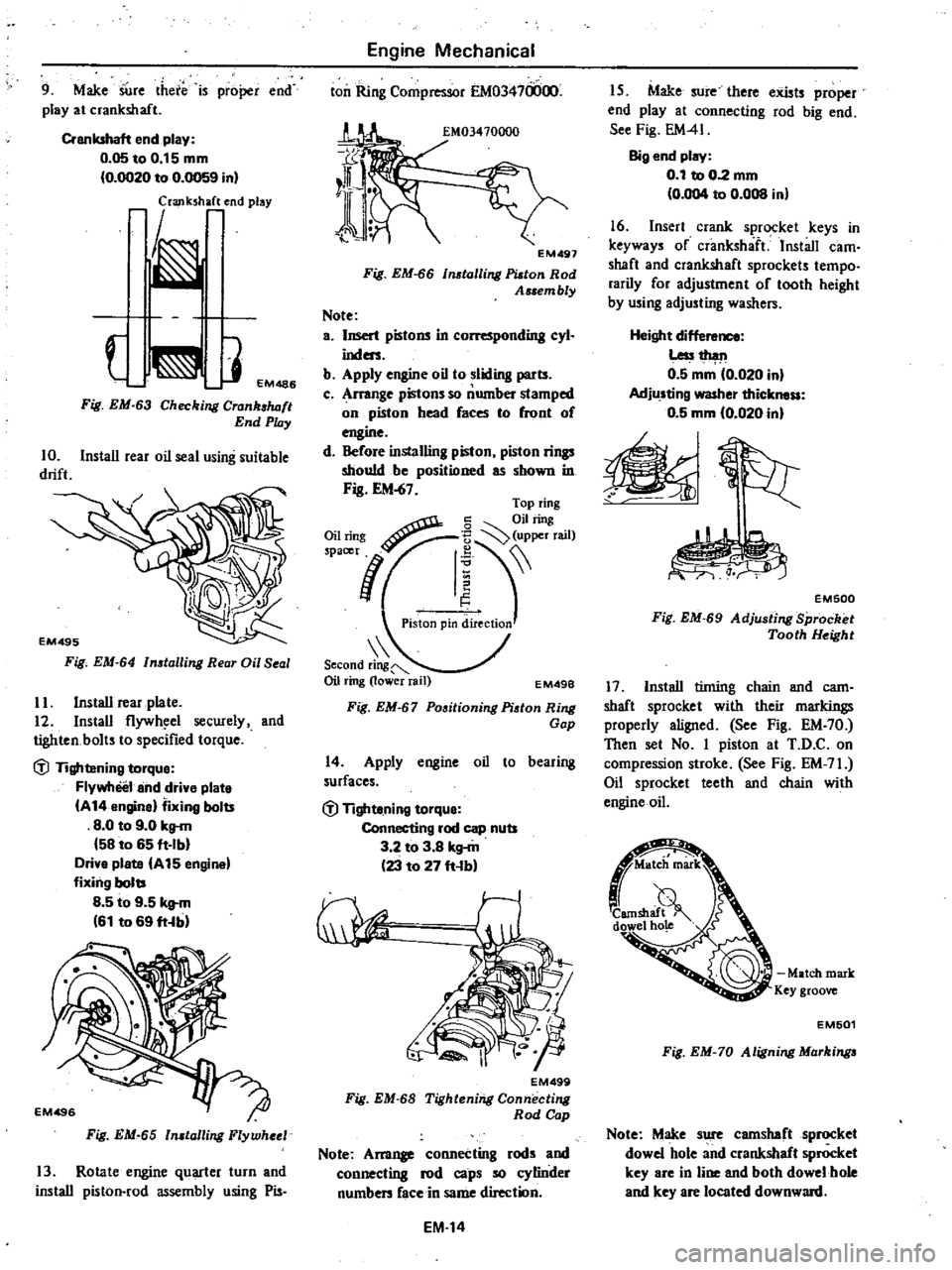

Before

installing

piston

piston

rings

should

be

positioned

as

shown

in

Fig

EM

67

Second

ring

Oil

ring

lower

rail

EM49B

Fig

EM

67

Positioning

Piston

Ring

Gap

14

Apply

engine

oil

to

bearing

surfaces

dl

Tighte

ning

torque

Connecting

rod

cap

nuts

3

2

to

3

8

kg

m

23

to

27

ft

b

EM499

Fig

EM

68

Tightening

Connecting

Rod

Cap

Note

Am11

connecting

rods

and

connecting

rod

caps

so

cylinder

numben

face

in

same

direction

EM

14

I

S

Make

sure

there

exists

proper

end

play

at

connecting

rod

big

end

See

Fig

EM41

Big

end

play

0

1

to

0

2

mm

0

004

to

0

008

in

16

Insert

crank

sprocket

keys

in

keyways

of

crankshaft

Install

cam

shaft

and

crankshaft

sprockets

tempo

rarily

for

adjustment

of

tooth

height

by

using

adjusting

washers

Height

dif

Less1

h

l11

0

5

mm

0

020

in

Adjusting

washer

thickness

0

5

mm

10

020

in

EM500

Fig

EM

69

Adju

ting

Sprocket

Tooth

Height

17

Install

tinting

chain

and

cam

shaft

sprocket

with

their

markings

properly

aligned

See

Fig

EM

70

Then

set

No

I

piston

at

T

D

C

on

compression

stroke

See

Fig

EM

71

Oil

sprocket

teeth

and

chain

with

engine

oil

Match

mark

Key

groove

EM501

Fig

EM

70

Aligning

Markinga

Note

Make

sure

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

dowel

hole

and

key

are

located

downward