fuel type DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 9 of 548

Erigine

crankcase

EI

gine

cooling

system

Transmission

case

Final

drive

case

housing

Steering

gear

box

Fuel

tank

Air

conditioning

system

Refrigerant

Compressor

oil

f

tl

It

J

4

i

1

protect

the

catalytic

cop

verter

froitr

contamination

t

n

General

Information

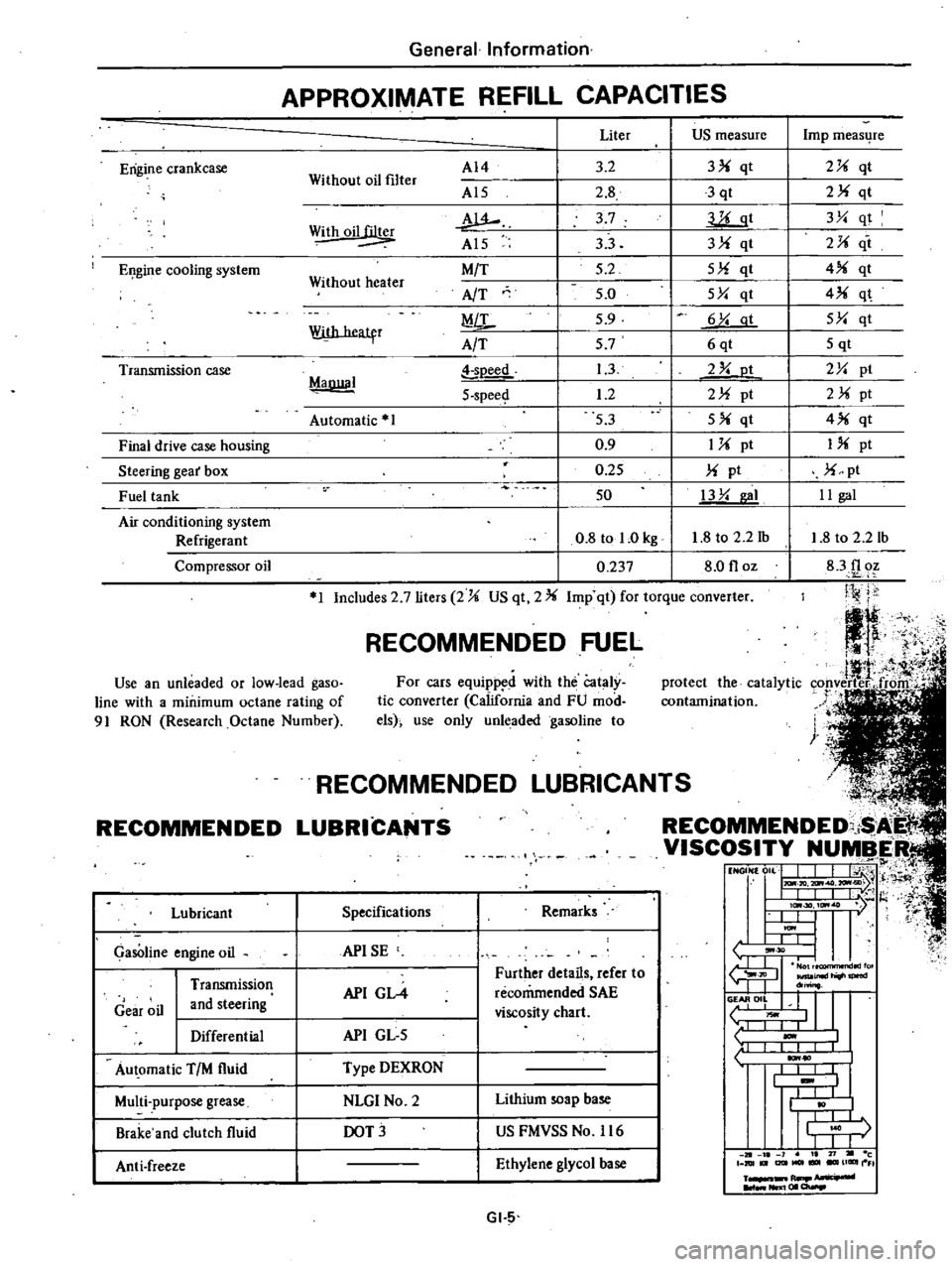

APPROXIMATE

REFILL

CAPACITIES

Without

oil

filter

AI4

Al5

w

Al5

M

T

AfT

MiL

A

T

Liter

US

measure

3

2

3

qt

2

8

3

qt

3

7

llLgt

33

3

qt

5

2

5

qt

5

0

5Y

qt

5

9

6

Y

at

57

6qt

1

3

2

Y

ot

1

2

2

pt

53

5

qt

0

9

1

pt

0

25

pt

50

13

Y

I

0

8

tol

Okg

1

8

to

2

2

1b

0

237

8

0

floz

Withoil

Without

heater

With

heatfr

MaDllal

soeed

5

spee

Automatic

1

1

Includes

2

7

liters

2

US

qt

2

Imp

qt

for

torque

converter

RECOMMENDED

FUEL

Use

an

unleaded

or

low

lead

gaso

line

with

a

minimum

octane

rating

of

91

RON

Research

Octane

Number

For

cars

equipp

d

with

the

Cataly

tic

converter

California

and

FU

mod

els

use

only

unleaded

gasoline

to

RECOMMENDED

Lubricant

GasOline

engine

oil

Gear

oil

Transmission

and

steering

Differential

Au

omatic

TIM

fluid

Multi

purpose

grease

Brake

and

clutch

fluid

Anti

freeze

L

NDED

LUBRICAN

COMMENDED

i

I

VISCOSITY

NUMBER

t1

NGON

0

L

J

I

j

H

I

IlL

I

t

l

I

lc

30

ItM

7

l

t

U

I

ItM

I

L

L

tJ

30

I

I

fu

JIl

inld

do

o

II

L

liOwl

1

I

I

1

10

I

I

I

I

t

I

I

j

r

I

I

J

1

21

l

1

I

71

c

DIUt

I2lItMOl

UGIIII

FI

R

NIl

I

01

a

Specifications

Remarks

APISE

API

GL4

Further

details

refer

to

recommended

SAE

viscosity

chart

API

GL

5

Type

DEXRON

NLGI

No

2

Lithium

soap

base

DOT

US

FMVSS

No

116

Ethylene

glycol

base

GI

5

Imp

meas4re

2

qt

2

qt

3Y

qt

2

it

4

qt

4

q

5Y

qt

5

qt

2Y

pt

2

pt

4

qt

I

pt

pt

II

gal

1

8

to

2

2

lb

83f1

oz

Ji

j

j

Page 16 of 548

f

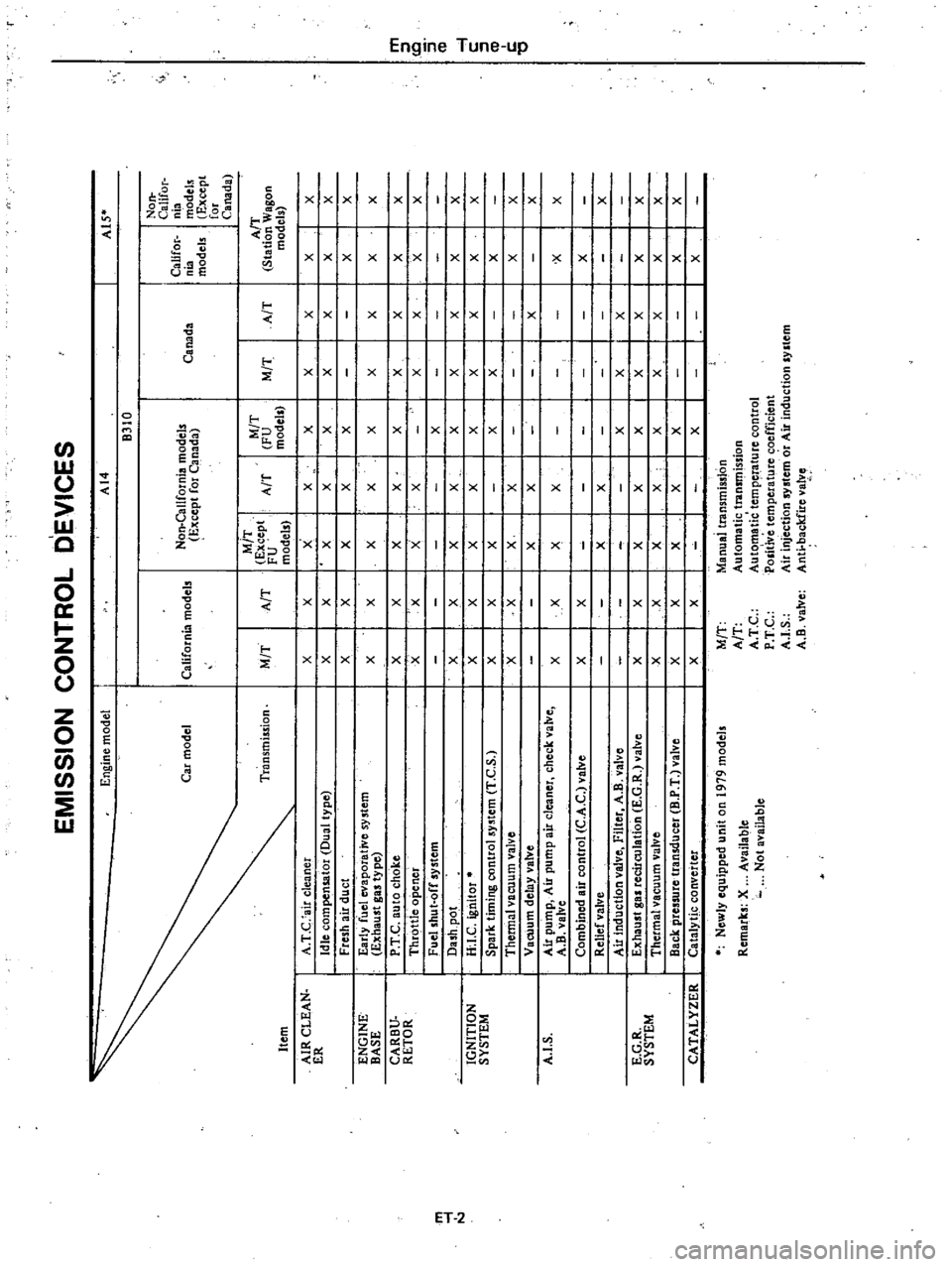

EMISSION

CONTROL

DEVICES

En

ine

model

I

AI4

I

A1S

B310

Non

CaliCor

Non

California

models

Califor

nia

Car

model

California

models

E

cept

for

C

nada

Canada

nia

modeb

models

Except

for

Canada

M

T

M

T

A

T

Ti

ansmiuion

M

T

A

T

Except

A

T

FU

M

T

A

T

Station

Wagon

FU

models

models

models

AIR

CLEAN

I

A

T

C

air

cleaner

I

X

I

X

X

I

X

I

X

I

X

I

X

I

X

X

ER

Idle

compensator

Dual

type

X

I

X

X

I

X

I

X

I

X

I

X

I

X

X

Fresh

air

duct

X

I

X

X

I

X

I

X

I

I

I

X

X

ENGINE

I

Early

fuel

evaporative

system

X

I

X

X

xl

X

I

X

I

X

I

X

X

BASE

Exhaust

gas

type

CARBV

I

P

T

C

auto

choke

X

I

X

X

X

I

X

I

X

I

X

I

X

X

m

RETOR

I

l

Thr

ttle

opener

X

X

X

X

I

I

X

I

X

I

X

X

Q

I

Fuel

shut

off

system

I

X

I

I

I

3

m

ll

i

Dash

po

t

X

X

X

X

I

X

I

X

I

X

I

X

X

N

l

IGNITION

I

H

I

C

ignitor

X

X

X

X

I

X

I

X

I

X

I

X

X

c

SYSTEM

Spark

timing

contra

system

T

e

S

X

X

X

I

I

I

I

l

X

X

I

X

ll

Thermal

vacuum

valve

X

X

X

I

X

I

I

I

I

X

X

c

Vacuum

delay

valve

X

I

X

I

I

I

X

I

0

X

A

I

S

I

Air

pump

Air

pump

air

cleaner

check

valve

I

X

X

I

X

I

X

I

I

I

I

x

X

A

B

valve

Combined

air

control

C

A

C

valve

I

X

X

I

I

I

I

I

I

X

Relief

valve

I

I

X

I

X

I

I

I

I

X

Air

induction

valve

Filter

A

B

valve

I

I

I

I

X

I

X

I

X

E

G

R

I

Exhaust

gas

recirculation

E

G

R

valve

I

X

I

X

I

X

I

X

I

X

I

X

I

X

I

X

X

SYSTEM

Thetmalvacuum

valve

I

X

I

X

I

X

I

X

I

X

I

X

I

X

I

X

X

Back

pressure

transducer

B

P

T

valve

I

X

I

X

I

X

I

X

I

X

I

I

I

X

X

CATALYZER

I

CatalytJc

converter

I

X

I

X

I

I

I

X

I

I

I

X

Newly

equipped

unit

on

1979

models

M

T

Manual

transmission

Remarks

X

Available

A

T

Automatic

transmission

Not

available

A

T

C

Aute

matic

tempeJ

ature

control

P

T

C

POlitive

temperature

coefficient

A

I

S

Air

injection

system

or

Air

induction

system

A

B

valve

Anti

backfire

valve

Page 24 of 548

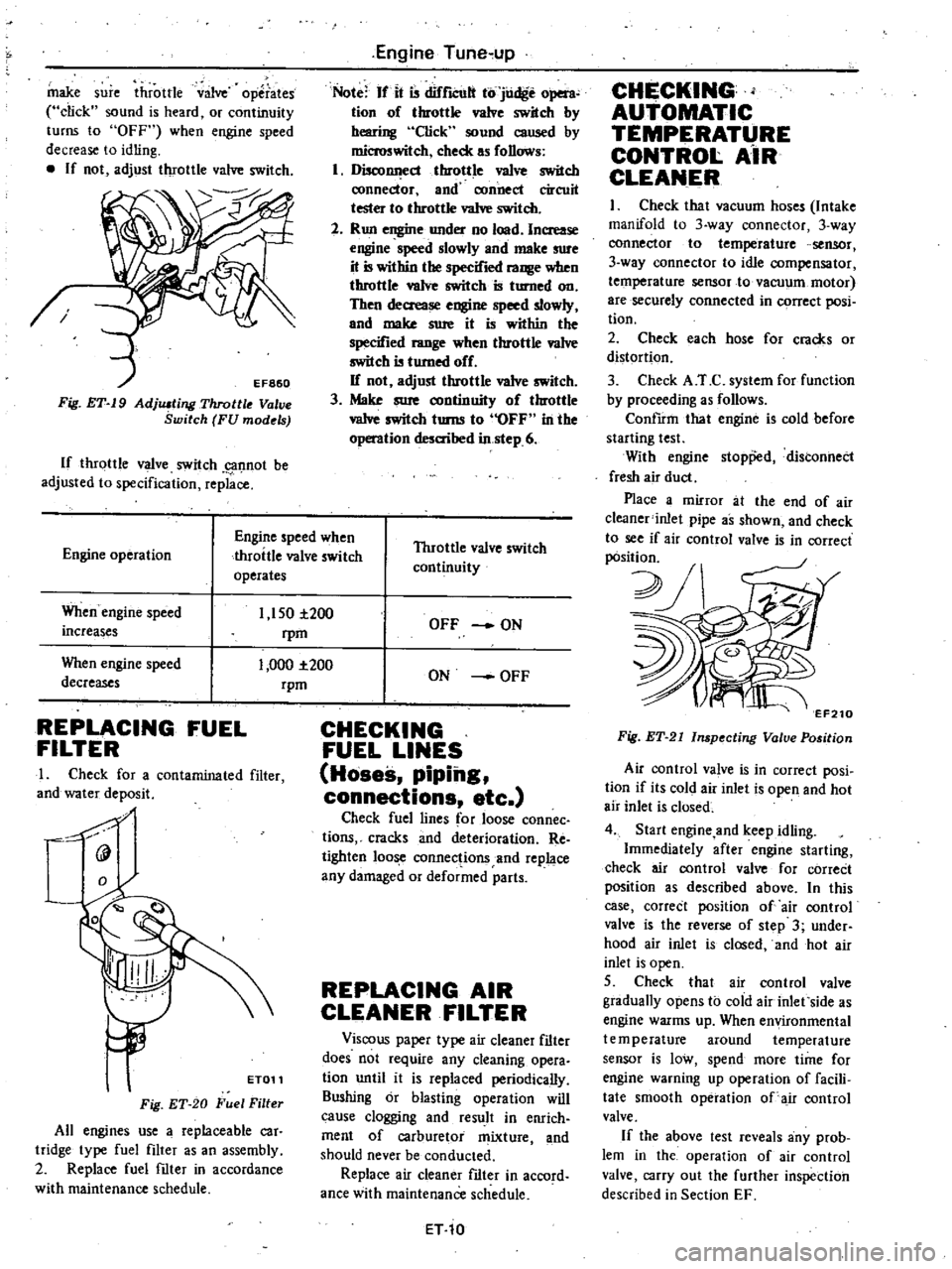

make

sure

throttle

valve

operates

click

sound

is

heard

or

continuity

turns

to

OFF

when

engine

speed

decrease

to

idling

If

not

adjust

throttle

valve

switch

Fig

ET

19

AdjlUting

Throttle

V

ve

Switch

FU

models

If

throttle

valve

switch

g1f1not

be

adjusted

to

specification

replace

Engine

Tune

up

Note

If

it

is

difrlCUlt

to

judge

open

tion

of

throttle

valve

switch

by

hearing

Click

sound

caused

by

microswitch

check

as

follows

1

DiscollI

ecl

throttle

va1ve

switch

ronnector

and

connect

circuit

tester

to

throttle

va1ve

switch

2

Run

engine

under

no

load

Increase

engine

speed

slowly

and

make

sure

it

is

within

the

specified

range

when

throttle

valve

switch

is

turned

on

Then

decrease

engine

speed

slowly

and

make

sure

it

is

within

the

specified

range

when

throttle

va1ve

switch

is

turned

off

If

not

adjust

throttle

valve

switch

3

Make

sure

continuity

of

throttle

vaIve

switch

turns

to

OFF

in

the

operation

desaihed

in

step

6

Engine

operation

Engine

speed

when

throttle

valve

switch

operates

Throttle

valve

switch

continuity

When

engine

speed

increases

1

150

i200

rpm

1

000

1

200

rpm

When

engine

speed

decreases

REPLACING

FUEL

FILTER

I

Check

for

a

contaminated

filter

and

water

deposit

0

9

ET011

Fig

ET

20

Fuel

Filter

All

engines

use

a

replaceable

car

tridge

type

fuel

filter

as

an

assembly

2

Replace

fuel

filter

in

accordance

with

maintenance

schedule

OFF

ON

ON

OFF

CHECKING

FUEL

LINES

Hoses

piping

connections

etc

Check

fuel

lines

for

loose

connec

tions

cracks

and

deterioration

Re

tighten

loose

connections

and

replace

any

damaged

or

deformed

parts

REPLACING

AIR

CLEANER

FILTER

Viscous

paper

type

air

cleaner

filter

does

not

require

any

cleaning

opera

tion

until

it

is

replaced

periodically

Sushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

Replace

air

cleaner

filter

in

accord

ance

with

maintenance

schedule

ET

10

CHECKING

AUTOMATIC

TEMPERATURE

CONTROl

AiR

CLEANER

I

Check

that

vacuum

hoses

Intake

manifold

to

3

way

connector

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

compensator

temperature

sensor

to

vacuum

motor

are

securely

connected

in

C9rrect

posi

tion

2

Check

each

hose

for

cracks

or

distortion

3

Check

A

T

C

system

for

function

by

proceeding

as

follows

ConfIrm

that

engine

is

cold

before

starting

test

With

engine

stopp

d

distonnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

c1eaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

pOsition

2J

v

7

EF210

Fig

ET

21

Inspecting

Valve

Position

Air

control

va

ve

is

in

correct

posi

tion

if

its

cold

air

inlet

is

open

and

hot

air

inlet

is

closed

4

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correCt

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

step

3

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

5

Check

that

air

control

valve

gradually

opens

to

cold

air

inlet

side

as

engine

warms

up

When

environmental

temperature

around

temperature

sensor

is

low

spend

more

time

for

engine

warning

up

operation

of

facili

tate

smooth

operation

of

air

control

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

further

inspection

described

in

Section

EF

Page 89 of 548

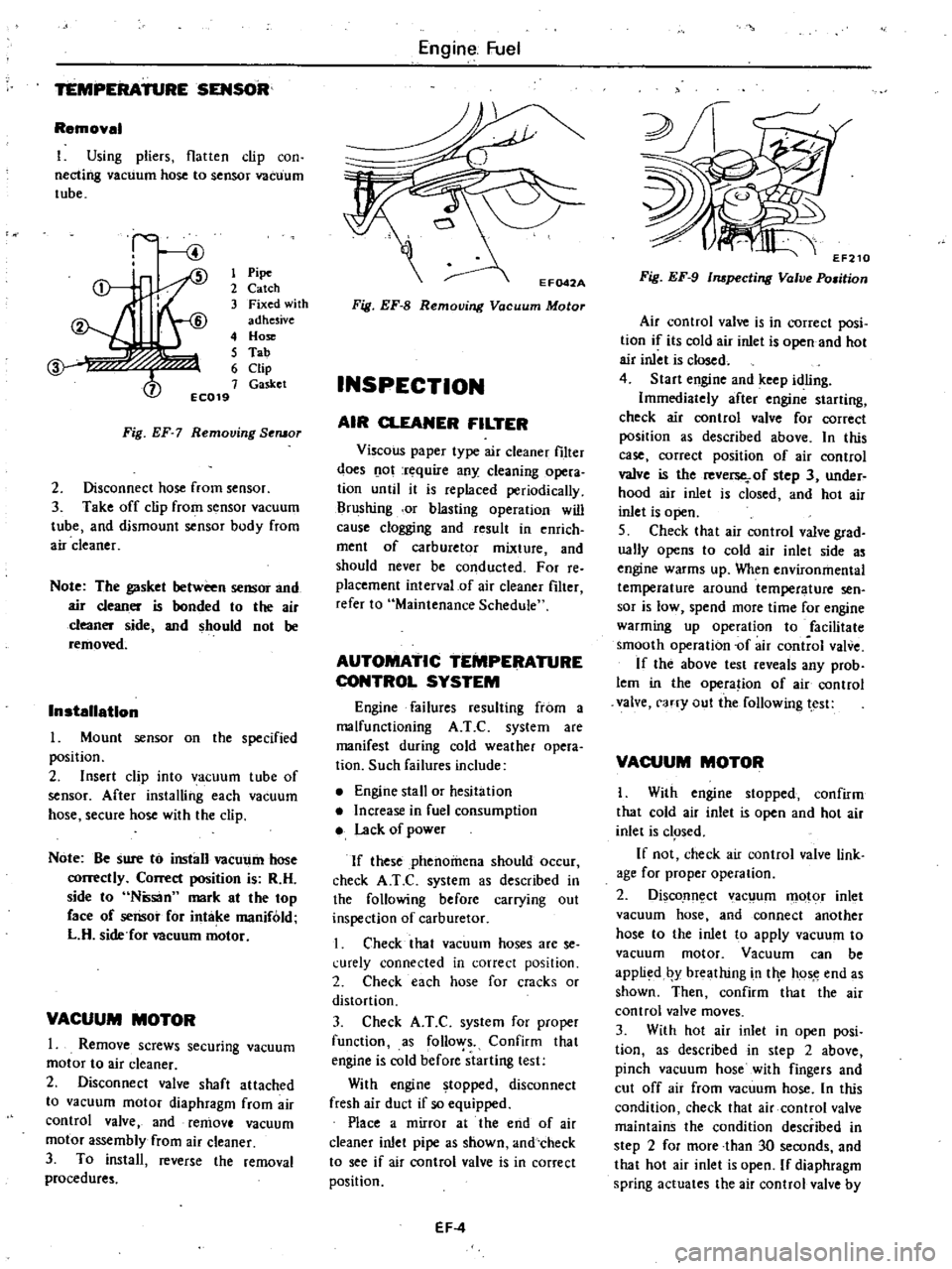

TEMPERATURE

SENSOR

Removal

I

Using

pliers

flatten

clip

con

necting

vacuum

hose

to

sensor

vacuum

tube

1

Pipe

2

Catch

3

Fixed

with

adhesive

4

Hose

5

Tab

6

Clip

7

Gasket

EC019

Fig

EF

7

Removing

Seruor

2

Disconnect

hose

from

sensor

3

Take

off

clip

from

sensor

vacuum

tube

and

dismount

sensor

body

from

air

cleaner

Note

The

gasket

between

sensor

and

air

cleaner

is

bonded

to

the

air

cleaner

side

and

should

not

be

removed

Installation

Mount

sensor

on

the

specified

position

2

Insert

clip

into

vacuum

tube

of

sensor

After

installing

each

vacuum

hose

secure

hose

with

the

clip

Note

Be

sure

to

install

vacUl

11n

hose

correctly

Correct

position

is

R

H

side

to

Ntisan

mark

at

the

top

face

of

sensor

for

intake

manifold

L

H

side

for

Deuum

motor

VACUUM

MOTOR

1

Remove

screws

securing

vacuum

motor

to

air

cleaner

2

Disconnect

valve

shaft

attached

to

vacuum

motor

diaphragm

from

air

control

valve

and

remove

vacuum

motor

assembly

from

air

cleaner

3

To

install

reverse

the

removal

procedures

Engine

Fuel

Fig

EF

8

Removing

Vacuum

Motor

INSPECTION

AIR

CLEANER

FILTER

Viscous

paper

type

air

cleaner

filter

does

o

ot

rt

quire

any

cleaning

opera

tion

until

it

is

replaced

periodically

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

filter

refer

to

Maintenance

Schedule

AUTOMATIC

TEMPERATURE

CONTROL

SYSTEM

Engine

failures

resulting

from

a

malfunctioning

A

T

C

system

are

manifest

during

cold

weather

opera

tion

Such

failures

include

Engine

stall

or

hesitation

Increase

in

fuel

consumption

Lack

of

power

If

these

phenomena

should

occur

check

A

T

e

system

as

described

in

the

following

before

carrying

out

inspection

of

carburetor

I

Check

that

vacuum

hoses

are

se

l

urely

connected

in

correct

position

2

Check

each

hose

for

cracks

or

distortion

3

Check

A

T

C

system

for

proper

function

as

follo

ys

Confirm

that

engine

is

cold

before

starting

test

With

engine

topped

disconnect

fresh

air

duct

if

so

equipped

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

position

EF

4

Fig

EF

9

Inspecting

Valve

Po

man

Air

control

valve

is

in

correct

posi

tion

if

its

cold

air

inlet

is

open

and

hot

air

inlet

is

closed

4

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

step

3

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

S

Check

that

air

control

valve

grad

ually

opens

to

cold

air

inlet

side

as

engine

warms

up

When

environmental

temperature

around

temperature

sen

sor

is

low

spend

more

time

for

engine

warming

up

operation

to

facilitate

smooth

operation

of

air

control

valve

If

the

above

test

reveals

any

prob

lem

in

the

opera

ion

of

air

control

valve

carry

out

the

following

test

VACUUM

MOTOR

I

With

engine

stopped

confirm

that

cold

air

inlet

is

open

and

hot

air

inlet

is

c1

Sed

If

not

check

air

control

valve

link

age

for

proper

operation

2

DiscoJln

ct

ac

um

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

appli

d

by

breathing

in

tile

hos

e

end

as

shown

Then

confirm

that

the

air

control

valve

moves

3

With

hot

air

inlet

in

open

posi

tion

as

described

in

step

2

above

pinch

vacuum

hose

with

fingers

and

cut

off

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

described

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

Page 91 of 548

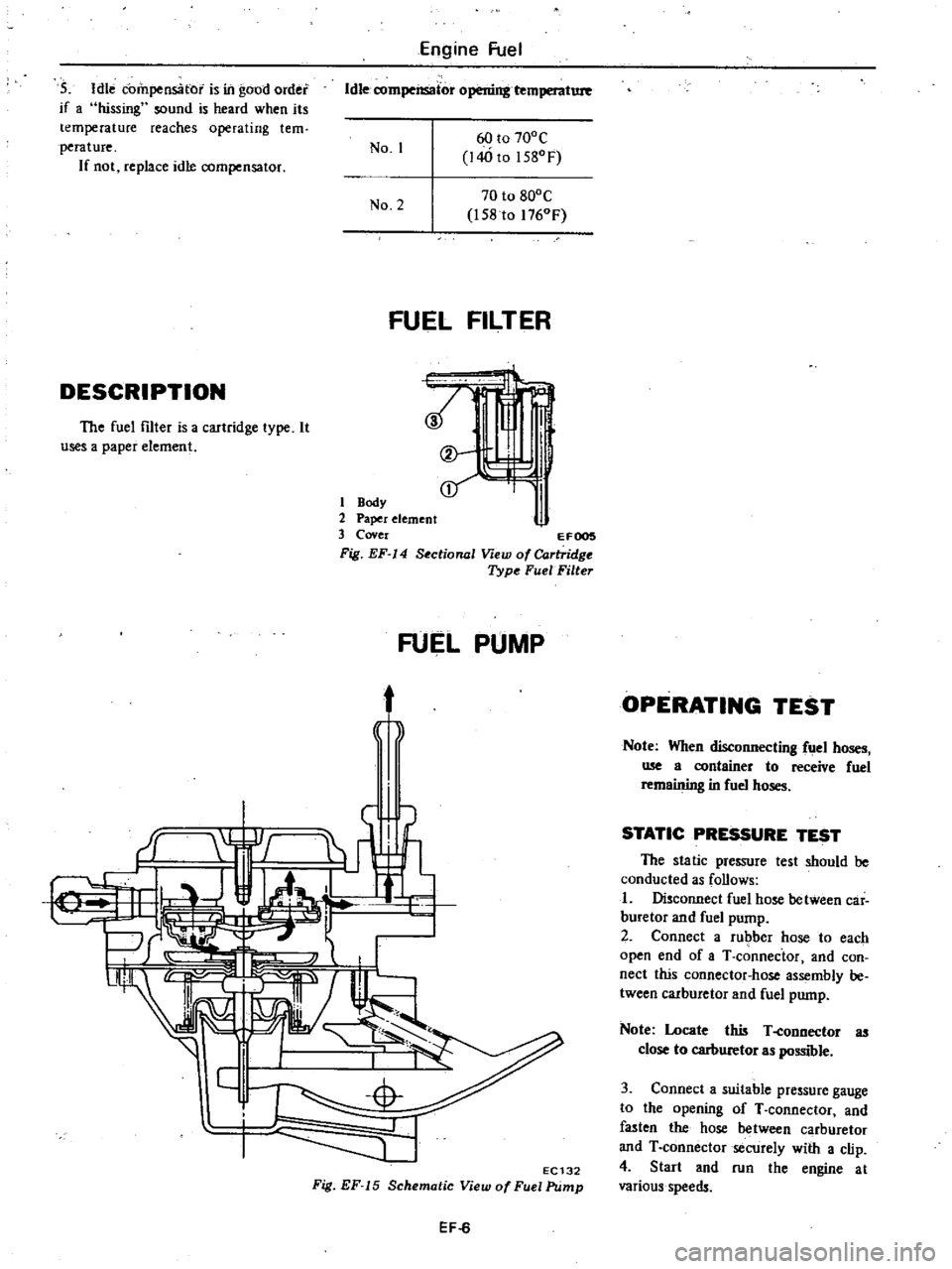

Engine

Fuel

S

Idle

compensator

is

ill

good

order

if

a

hissing

sound

is

heard

when

its

temperature

reaches

operating

tern

perature

If

not

replace

idle

compensator

ldlerompensator

l

b

l

r

I

No

1

60

to

700C

140

to

15

Of

No

2

70

to

800C

158

to

1760F

FUEL

FILTER

DESCRIPTION

t

t

I

J

i

l

The

fuel

filter

is

a

cartridge

type

It

useS

a

paper

element

1

Body

2

Paper

element

3

Cover

EFOOS

Fig

EF

14

Sectional

View

of

Cartridge

Type

FuelFilte

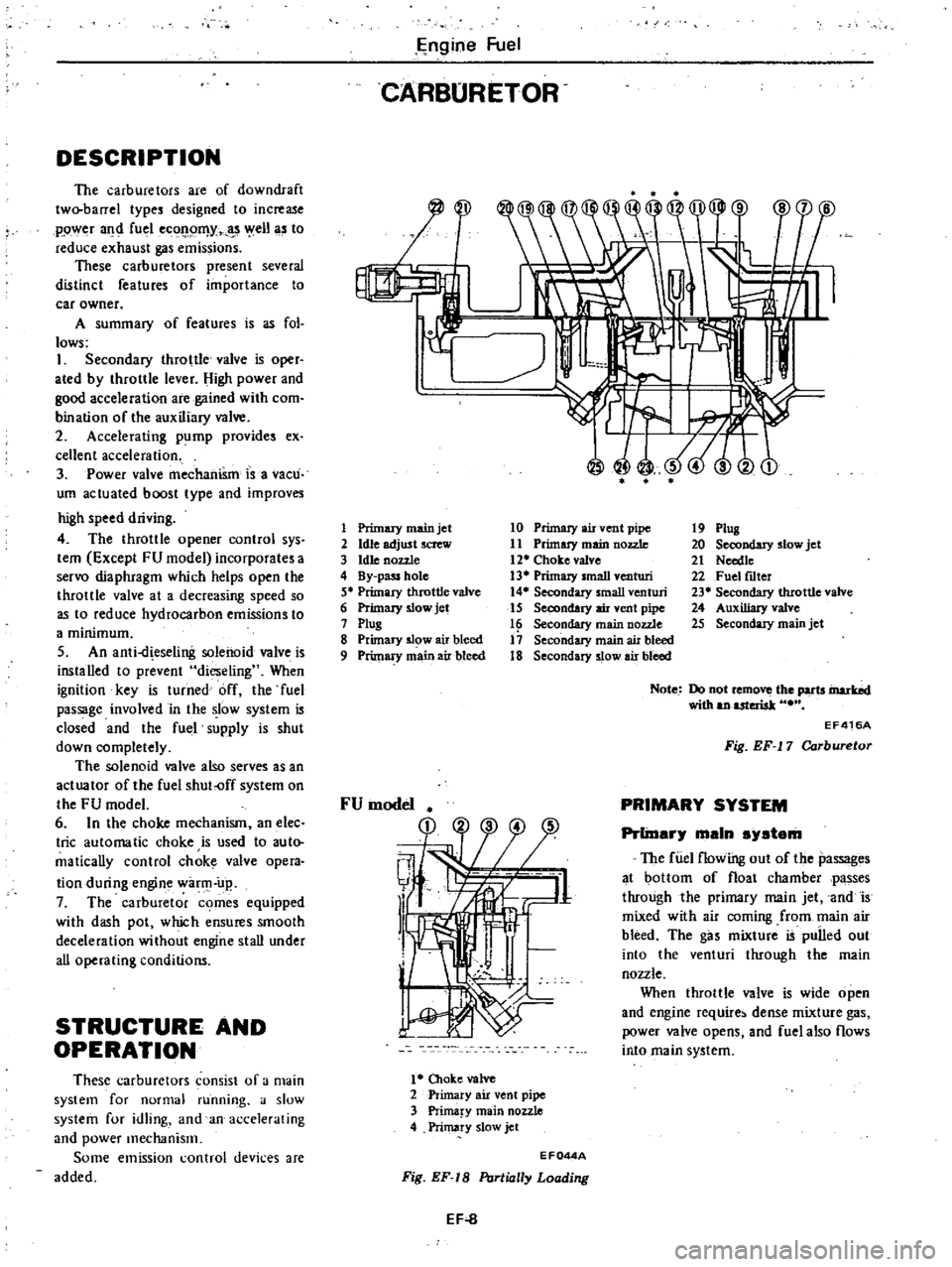

FUEL

PUMP

t

j

f

EC132

Fig

EF

15

Schematic

View

of

Fuel

Pump

EF

6

OPERATING

TEST

Note

When

disconnecting

fuel

hoses

me

a

container

to

receive

fuel

remaining

in

fuel

hoses

STATIC

PRESSURE

TEST

The

static

pressure

test

should

be

conducted

as

follows

I

Disconnect

fuel

hose

between

car

buretor

and

fuel

pump

2

Connect

a

rubber

hose

to

each

open

end

of

aT

connector

and

con

nect

this

connector

hose

assembly

be

tween

carburetor

and

fuel

pump

Note

Locate

this

T

eonnector

as

close

to

carburetor

as

possible

3

Connect

a

suitable

pressure

gauge

to

the

opening

of

T

connector

and

fasten

the

hose

between

carburetor

and

T

connector

secUrely

with

a

clip

4

Start

and

run

the

engine

at

various

speeds

Page 93 of 548

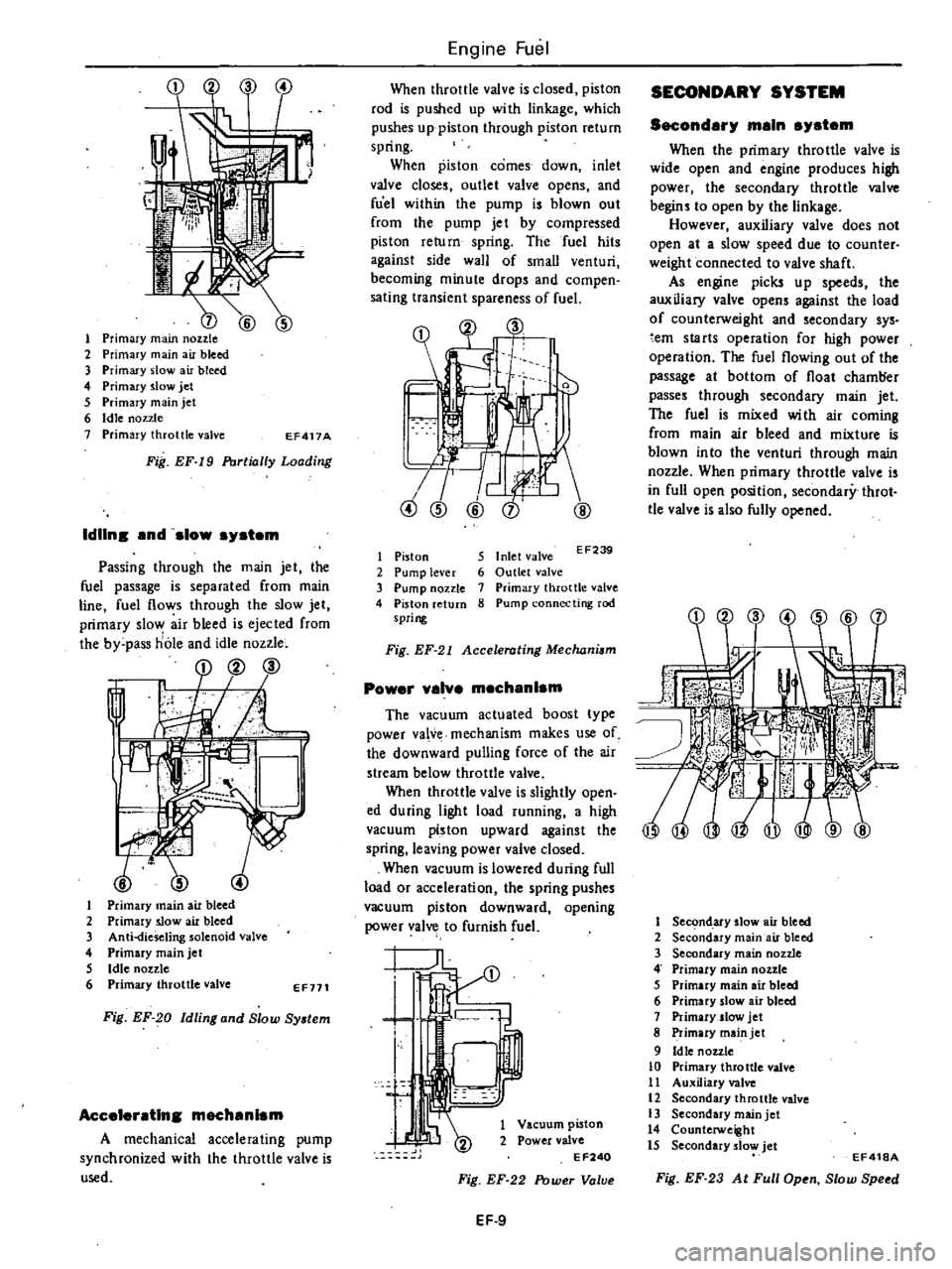

DESCRIPTION

The

carburetors

are

of

downdraft

two

barrel

type

designed

to

increase

ppwe

r

a

fu

l

eC

l

Il

Y

t

3

ell

a

to

reduce

exhaust

gas

emissions

These

carburetors

present

several

distinct

features

of

importance

to

car

owner

A

summary

of

features

is

as

fol

lows

1

Secondary

throttle

valve

is

oper

ated

by

throttle

lever

High

power

and

good

acceleration

are

gained

with

com

bination

of

the

auxiliary

valve

2

Accelerating

pump

provide

ex

cellent

acceleration

3

Power

valve

mechanism

is

a

vacuo

urn

actuated

boost

type

and

improves

high

speed

driving

4

The

throttle

opener

control

sys

tem

Except

FU

model

incorporates

a

servo

diaphragm

which

helps

open

the

throttle

valve

at

a

decreasing

speed

so

as

to

reduce

hydrocarbon

emissions

to

a

minimum

5

An

anti

d

eseling

solenoid

valve

is

installed

to

prevent

dieseling

When

ignition

key

is

turned

off

the

fuel

passage

involved

in

the

ow

system

is

closed

and

the

fuel

supply

is

shut

down

completely

The

solenoid

valve

also

serves

as

an

actuator

of

the

fuel

shut

off

system

on

the

FU

model

6

In

the

choke

mechanism

an

elec

trie

automatic

choke

is

used

to

auto

maticaDy

control

chok

valve

opera

tion

during

engin

war

up

7

The

carburetor

comes

equipped

with

dash

pot

which

ensures

smooth

deceleration

without

engine

stall

under

aU

operating

conditions

STRUCTURE

AND

OPERATION

These

carburetors

consist

of

a

main

system

for

normal

running

a

slow

system

for

idling

and

an

accelerating

and

power

mechanisIll

Some

emission

control

devices

are

added

E

ngine

Fuel

CARBURETOR

I

J

1

Primary

main

jet

2

Idle

adjust

screw

3

hUe

nozzle

4

By

pass

hole

5

Primary

throttle

valve

6

Primary

slow

jet

7

ptug

8

Primary

5l

w

air

bleed

9

Primary

main

air

bleed

10

Primary

air

vent

pipe

11

Primuy

main

nozzle

12

Choke

valve

13

Primary

small

venturi

14

Secondary

small

venturi

15

Secondary

air

vent

pipe

16

Secondary

main

nozzle

17

Secondary

main

air

bleed

18

Secondary

slow

air

bleed

1

Oloke

valve

2

Primary

air

vent

pipe

3

Prima

y

main

nozzle

4

Primary

slow

jet

19

Plug

20

Secondary

slow

jet

21

Needte

22

Fuel

fLlter

23

Secondary

tIuottle

valve

24

Auxiliary

valve

25

Secondary

main

jet

Note

Do

not

remo

the

parts

inarbd

with

anuteriak

EF416A

Fig

EF

17

Carburetor

PRIMARY

SYSTEM

PrlinarJ

main

sJstam

The

fUel

flowing

out

of

the

passages

at

bottom

of

float

chamber

passes

through

the

primary

main

jet

and

is

mixed

with

air

coming

from

main

air

bleed

The

gas

mixture

is

pulled

out

into

the

venturi

through

the

main

nozzle

When

throttle

valve

is

wide

open

and

engine

require

dense

mixture

gas

power

valve

opens

and

fuel

also

flows

into

main

system

EF044A

Fig

EF

18

PtJrlially

Loading

EF

8

Page 94 of 548

t

1

Primary

main

nozzle

2

Primary

main

air

bleed

3

Primary

slow

air

bleed

4

Primary

slow

jet

5

Primary

main

jet

6

Idle

nozzle

7

Primary

throttle

valve

EF417A

Fig

EF

I9

Portially

Loading

IdUns

nd

slow

system

Passing

through

the

main

jet

the

fuel

passage

is

separated

from

main

line

fuel

flows

through

the

slow

jet

primary

slow

air

bleed

is

ejected

from

the

by

pass

hole

and

idle

nozzle

cp

v

Ii

l

1

Primary

main

air

bleed

2

Primary

slow

air

bleed

3

Anti

fieseling

solenoid

valve

4

Primary

main

jet

5

Idle

nozzle

6

Primary

throttle

valve

EF711

Fig

EF

20

Idling

and

Slow

System

Aceeler

tlns

meeh

nlsm

A

mechanical

accelerating

pump

synchronized

with

the

throttle

valve

is

used

Engine

Fuel

When

throttle

valve

is

closed

piston

rod

is

pushed

up

wi

th

linkage

which

pushes

up

piston

through

piston

return

spring

When

piston

comes

down

inlet

valve

closes

outlet

valve

opens

and

fuel

within

the

pump

is

blown

out

from

the

pump

je

t

by

compressed

piston

return

spring

The

fuel

hits

against

side

wall

of

small

venturi

becoming

minute

drops

and

compen

sating

transient

spareness

of

fuel

1

r

@

CD

V

1

Piston

2

Pump

lever

3

Pump

nozzle

4

Piston

return

spring

5

Inlet

valve

EF239

6

Outlet

valve

7

Primary

throttle

valve

8

Pump

connecting

rod

Fig

EF

21

Accelerating

Mechani

m

Power

v

lve

meeh

nlsm

The

vacuum

actuated

boost

type

power

va

v

mechanism

makes

use

of

the

downward

pulling

force

of

the

air

stream

below

throttle

valve

When

throttle

valve

is

slightly

open

ed

during

light

load

running

a

high

vacuum

p

ston

upward

against

the

spring

leaving

power

valve

closed

When

vacuum

is

lowered

during

full

load

or

acceleration

the

spring

pushes

vacuum

piston

downward

opening

power

valve

to

furnish

fuel

I

t

f

i

1

Vacuum

piston

2

Power

valve

EF240

Fig

EF

22

Power

Valve

EF

9

SECONDARY

SYSTEM

Second

ry

m

ln

system

When

the

primary

throttle

valve

is

wide

open

and

engine

produces

high

power

the

secondary

throttle

valve

begins

to

open

by

the

linkage

However

auxiliary

valve

does

not

open

at

a

slow

speed

due

to

counter

weight

connected

to

valve

shaft

As

engine

picks

up

speeds

the

auxiliary

valve

opens

against

the

load

of

counterweight

and

secondary

sys

em

starts

operation

for

high

power

operation

The

fuel

flowing

out

of

the

passage

at

bottom

of

float

chamt

er

passes

through

secondary

main

jet

The

fuel

is

mixed

wi

th

air

coming

from

main

air

bleed

and

mixture

is

blown

in

to

the

venturi

through

main

nozzle

When

primary

throttle

valve

is

in

full

open

position

secondary

throt

tle

valve

is

also

fully

opened

I

Secl

ndary

slow

air

bleed

2

Secondary

main

air

bleed

3

Secondary

main

nozzle

4

Primary

main

nozzle

5

Primary

main

air

bleed

6

Primary

slow

air

bleed

7

Primary

slow

jet

8

Primary

main

jet

9

Idle

nozzle

10

Primary

throttle

valve

11

Auxiliary

valve

12

Secondary

throttle

valve

13

Secondary

main

jet

14

Counterweight

15

Secondary

slow

jet

EF418A

Fig

EF

23

At

Full

Open

Stow

Speed

Page 95 of 548

I

Secondary

slow

air

bleed

2

Secondary

main

air

bleed

3

Secondary

main

nozzle

4

Primary

main

nozzle

5

Primary

main

air

bleed

6

Primary

slow

air

bleed

7

Primary

slow

jet

8

Primary

main

jet

9

Idle

nozzle

10

Primary

throttle

valve

II

Auxiliary

valve

12

Seco

dary

throttle

valve

13

Secondary

main

jet

14

Counterweight

IS

Secondary

slow

jet

EF419A

Fig

EF

24

At

Full

Open

High

Speed

Engine

Fuel

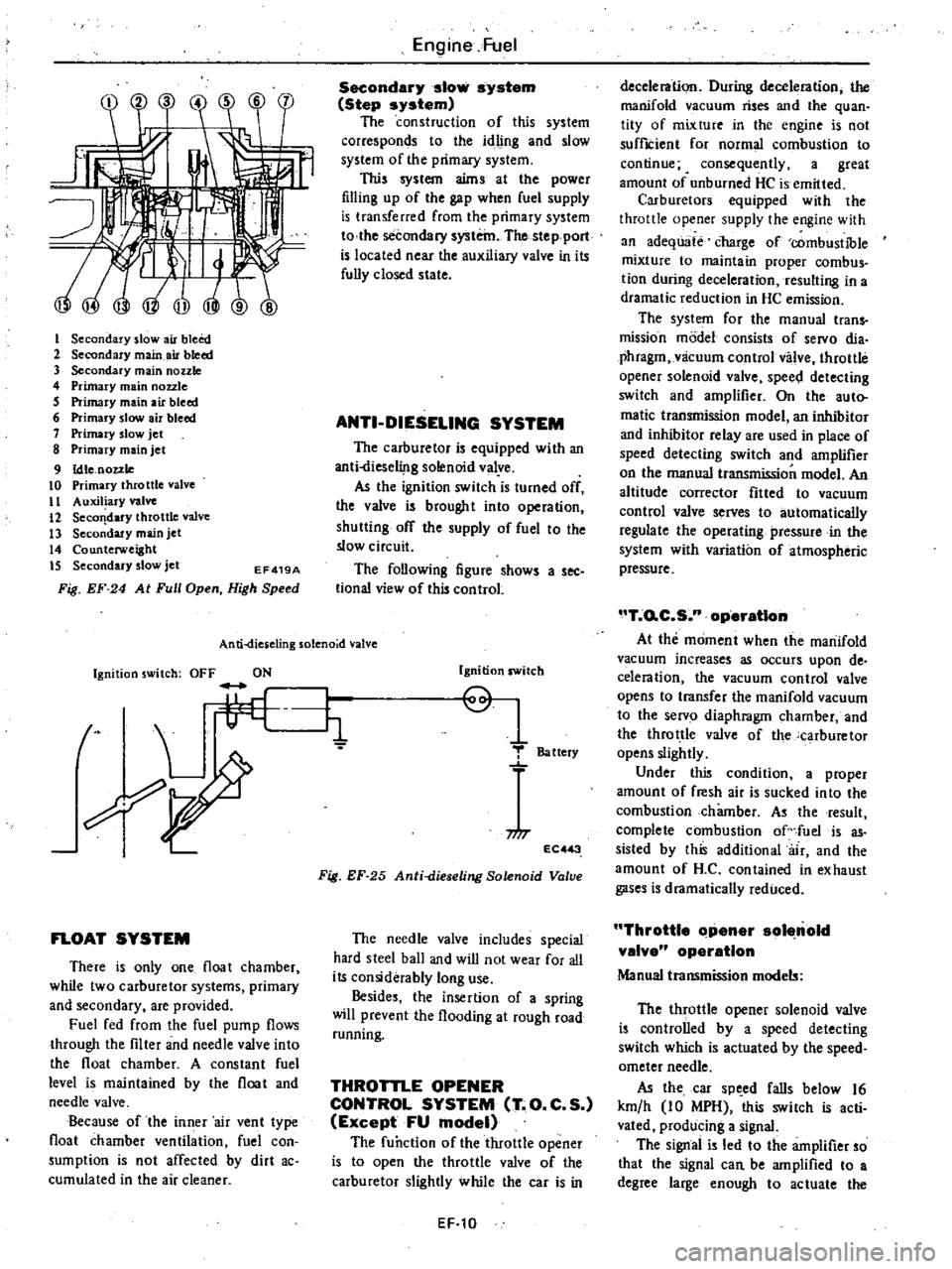

Secondary

slow

system

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

stepport

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

ANTI

DIESELING

SYSTEM

The

carburetor

is

equipped

with

an

anti

liese1i

lg

solenoid

valye

As

the

ignition

switch

is

turned

off

the

valve

is

brought

into

operation

shutting

off

the

supply

of

fuel

to

the

slow

circuit

The

following

figure

shows

a

see

tional

view

of

this

control

An

ti

dies

eling

solenoid

valve

Ignition

switch

OFF

ON

t

L

li

FLOAT

SYSTEM

There

is

only

one

float

chamber

while

two

carburetor

systems

primary

and

secondary

are

provided

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

Because

of

the

inner

air

vent

type

float

chamber

ventilation

fuel

con

sumption

is

not

affected

by

dirt

ac

cumulated

in

the

air

cleaner

Ignition

switch

Q

1

T

Battery

niT

EC

3

Fig

EF

25

Anti

dieseling

Solenoid

Valve

The

needle

valve

includes

special

hard

steel

ball

and

wiD

not

wear

for

all

its

considerably

long

use

Besides

the

insertion

of

a

spring

will

prevent

the

flooding

at

rough

road

running

THROTTLE

OPENER

CONTROL

SYSTEM

T

O

C

S

Except

FU

model

The

function

of

the

throttle

opener

is

to

open

the

throttle

valve

of

the

carburetor

slightly

while

the

car

is

in

EF

10

deceleration

During

deceleration

the

manifold

vacuum

rises

and

the

quan

tity

of

mixture

in

the

engine

is

not

suffICient

for

normal

combustion

to

continue

4

consequently

a

great

amount

of

unburned

HC

is

emitted

Carburetors

equipped

with

the

throttle

opener

supply

the

engine

with

an

adequate

charge

of

combustible

mixture

to

maintain

proper

combus

tion

during

deceleration

resulting

in

a

dramatic

reduction

in

HC

emission

The

system

for

the

manual

trans

mission

model

consists

of

servo

dia

phragm

vlicuum

control

valve

throttle

opener

solenoid

valve

spee

l

detecting

switch

and

amplifier

On

the

auto

matic

transmission

model

an

inhibitor

and

inhibitor

relay

are

used

in

place

of

speed

detecting

switch

and

amplifier

on

the

manual

transmission

model

An

altitude

corrector

fitted

to

vacuum

control

valve

serves

to

automatically

regulate

the

operating

pressure

in

the

system

with

variation

of

atmospheric

pressure

T

o

C

S

n

operatIon

At

the

moment

when

the

manifold

vacuum

increases

as

occurs

upon

de

celeration

the

vacuum

control

valve

opens

to

transfer

the

manifold

vacuum

to

the

servo

diaphragm

chamber

and

the

throttle

valve

of

the

carburetor

opens

slightly

Under

this

condition

a

proper

amount

of

fresh

air

is

sucked

into

the

combustion

chamber

As

the

result

complete

combustion

of

fuel

is

as

sisted

by

this

additional

air

and

the

amount

of

H

C

contained

in

exhaust

gases

is

dramatically

reduced

Throttle

Clpener

sol

nold

valve

operation

Manual

transmission

models

The

throttle

opener

solenoid

valve

is

controlled

by

a

speed

detecting

switch

which

is

actuated

by

the

speed

ometer

needle

As

the

car

sp

ed

falls

below

16

km

h

10

MPH

this

switch

is

acti

vated

producing

a

signal

The

signal

is

led

to

the

amplifier

so

that

the

signal

can

be

amplified

to

a

degree

large

enough

to

actuate

the

Page 98 of 548

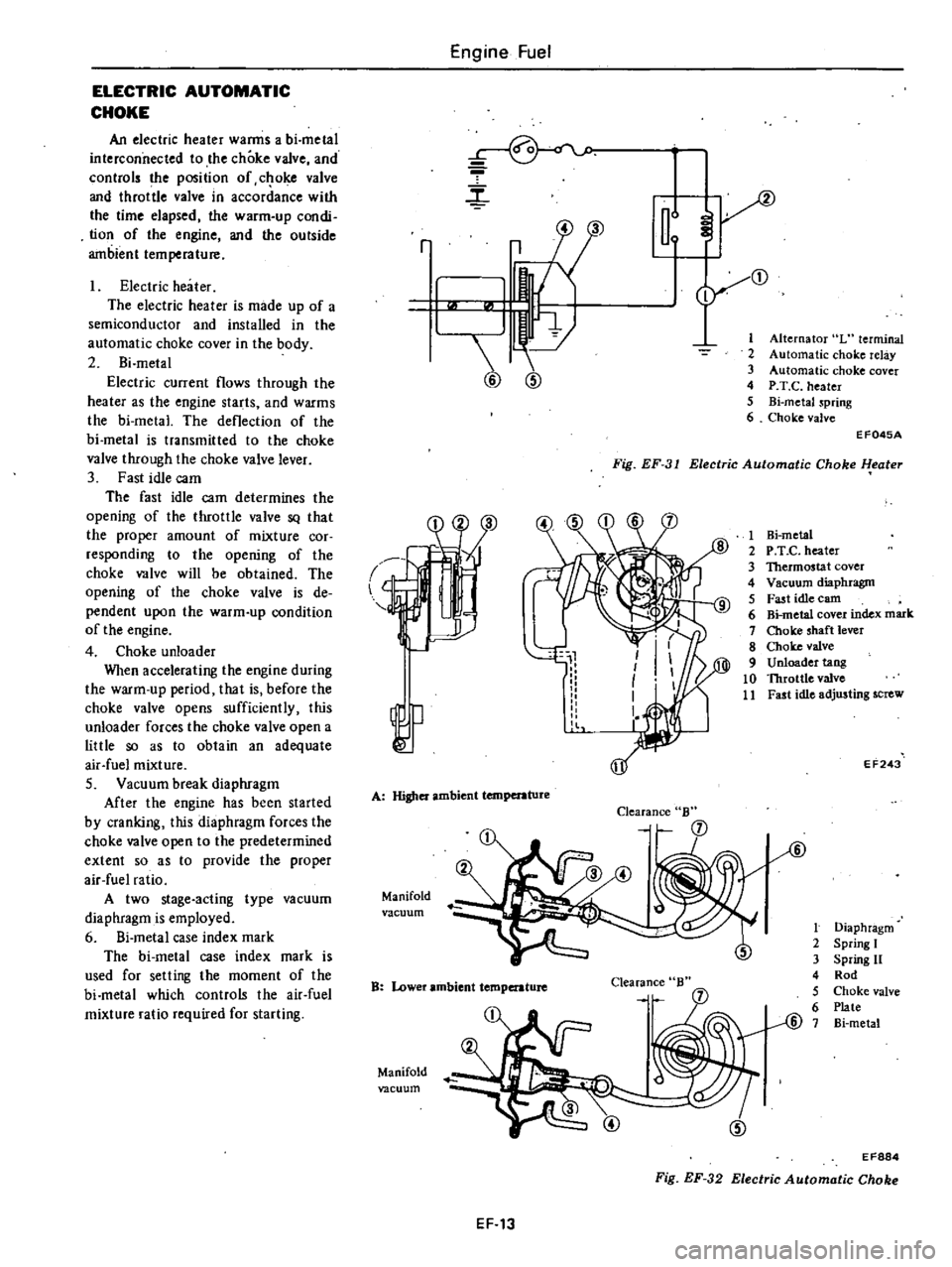

ELECTRIC

AUTOMATIC

CHOKE

An

electric

heater

warms

a

bi

metal

interconnected

to

the

choke

valve

and

controls

the

position

of

c

oke

valve

and

throttle

valve

in

accordance

with

the

time

elapsed

the

warm

up

condi

tion

of

the

engine

and

the

outside

ambient

temperature

Electric

heater

The

electric

heater

is

made

up

of

a

semiconductor

and

installed

in

the

automatic

choke

cover

in

the

body

2

Bi

metal

Electric

current

flows

through

the

heater

as

the

engine

starts

and

warms

the

bi

metal

The

deflection

of

the

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

valve

lever

3

Fast

idle

cam

The

fast

idle

cam

determines

the

opening

of

the

throttle

valve

SQ

that

the

proper

amount

of

mixture

cor

responding

to

the

opening

of

the

choke

valve

will

be

obtained

The

opening

of

the

choke

valve

is

de

pendent

upon

the

warm

up

condition

of

the

engine

4

Choke

unloader

When

accelerating

the

engine

during

the

warm

up

period

that

is

before

the

choke

valve

opens

sufficiently

this

unloader

forces

the

choke

valve

open

a

little

so

as

to

obtain

an

adequate

air

fuel

mixture

S

Vacuum

break

diaphragm

After

the

engine

has

been

started

by

cranking

this

diaphragm

forces

the

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

the

proper

air

fuel

ratio

A

two

stage

acting

type

vacuum

diaphragm

is

employed

6

Si

metal

case

index

mark

The

bi

metal

case

index

mark

is

used

for

selling

the

moment

of

the

bi

metal

which

controls

the

air

fuel

mixture

ratio

required

for

starting

Engine

Fuel

r

m

2

3

4

5

6

r

3

1

@

@

Alternator

L

terminal

Automatic

choke

relay

Automatic

choke

cover

P

T

C

heater

Bi

metaJ

spring

Choke

valve

Fig

EF

31

Electric

Automatic

Choke

l

eater

EF045A

l

A

Higher

ambient

temperature

Manifold

vacuum

Clearance

B

B

Lower

ambient

temperature

Clearance

Manifold

vacuum

1

Hi

metal

2

P

T

e

heater

3

Thermostat

cover

4

Vacuum

diaphragm

5

Fast

idle

earn

6

Bi

metal

cover

index

mark

7

Choke

shaft

lever

8

Choke

valve

9

Unloader

tang

10

Throttle

valve

11

Fast

idle

adjusting

screw

EF243

t

Diaphragm

2

Spring

I

3

Spring

11

4

Rod

5

Choke

valve

6

Plate

@

7

Bi

metal

EF884

Fig

EF

32

Electric

Automatic

Choke

EF

13

Page 105 of 548

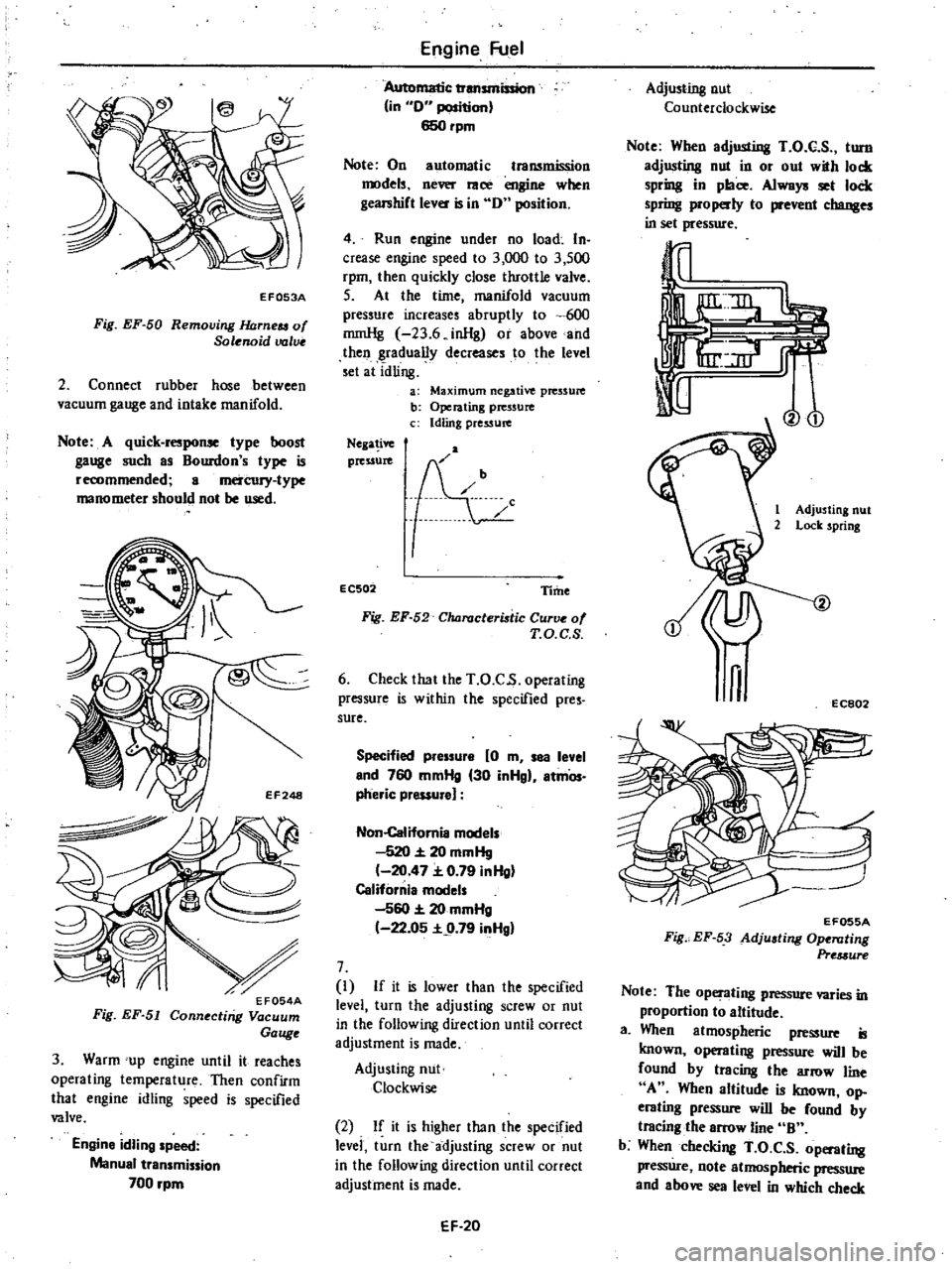

EF053A

Fig

EF

50

Removing

JWrneu

of

Solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

Note

A

quick

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

3

Warm

up

engine

until

it

reaches

operating

temperature

Then

confirm

that

engine

idling

speed

is

specified

valve

Engine

idling

speed

Manual

transmission

700

rpm

Engine

Fuel

Automatic

transmission

in

0

position

650rpm

Note

On

automatic

transmission

models

never

race

engine

when

gearshift

lever

is

in

0

position

4

Run

engine

under

no

load

In

crease

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

S

At

the

time

manifold

vacuum

pressure

increases

abruptly

to

600

rnmHg

23

6

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

a

Maximum

negative

pressure

b

Operating

pressure

c

Idling

pressure

Nega

ive

pressure

EC502

Time

Fig

EF

52

Characteristic

Curve

of

T

O

C

S

6

Check

that

the

T

O

C

s

operating

pressure

is

within

the

specified

pres

sure

Specified

pressure

0

m

sea

level

end

760

mmHg

30

inHgl

atmOs

pheric

pressure

Non

Califomia

models

520

20

mmHg

20

47

0

79

inHg

California

models

560

20

mmHg

22

05

9

79

inHgl

7

I

If

it

is

lower

than

the

specified

level

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

Adjusting

nut

Clockwise

2

If

it

is

higher

than

the

specified

levei

turn

the

adjusting

screw

or

nut

in

the

following

direction

until

correct

adjustment

is

made

EF

20

Adjusting

nut

Counterclockwise

Note

When

adjusting

T

O

C

S

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

properly

to

prevent

changes

in

set

pressure

Vo

1

Adjusting

nut

2

Lock

spring

n

EC802

EF055A

Fig

EF

53

Adjusting

Ope

llting

Pre

3ure

Note

The

operating

pressure

varies

in

proportion

to

altitude

a

When

atmospheric

pressure

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

A

When

altitude

is

known

op

erating

pressure

will

be

found

by

tracing

the

arrow

line

B

b

When

checking

T

O

C

S

operating

pressure

note

atmospheric

pressure

and

above

sea

level

in

which

check