fuel type DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 117 of 548

Engine

Fuel

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

CARBURETOR

California

models

Non

caJ

ifornia

model

Manual

tranlDlWion

Automatic

transmission

Manual

transmission

FU

model

utomatic

transmission

Type

DCH306

6t

DCH306

63

DCH306

60E

DCH306

67

DCH306

68

3

DCH306

69

1

DCH306

60

2

DCH306

12

4

Primary

Secondary

Primary

Secondary

Primuy

Secondary

Primary

Secondary

Primary

Secondary

Outer

diameter

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

26

1

02

30

1

18

mm

in

Venturi

diameter

23

0

9t

27

1

06

23

0

91

27

1

06

23

0

91

27

1

06

22

0

87

27

1

06

23

0

91

27

1

06

mm

in

Main

jet

107

145

107

1145

106

145

1107

145

105

1145

104

2

t04

4

Main

air

bleed

95

180

95

180

1110

80

65

1M

195

80

Slow

jet

1145

150

145

150

145

150

146

150

45

150

Powerjet

143

43

140

148

2

48

138

140

4

1

With

A15

engine

2

4

For

Canada

models

3

Common

to

models

with

A14

and

AlS

engines

except

Canada

INSPECTION

AND

ADJUSTMENT

A

T

C

AIR

CLEANER

Air

con

trol

valve

partially

opens

Air

control

valve

fully

opens

Oc

OF

Oc

F

38

to

54

100

to

129

Above

55

131

IDLE

COMPENSATOR

Idle

compensator

partially

opens

Bi

metal

No

I

Bi

metal

No

2

Idle

compensator

fully

opens

Bi

metal

No

I

Bi

metal

No

2

Oc

OF

60

to

70

140

to

158

70

to

80

158

to

176

Oc

OF

Above

70

158

Above

80

176

FUEL

PUMP

Fuel

pressure

Fuel

pump

capacity

kgfcm2

psi

cc

cu

in

min

at

rpm

0

27

3

8

450

27

46

1

000

EF

32

Page 126 of 548

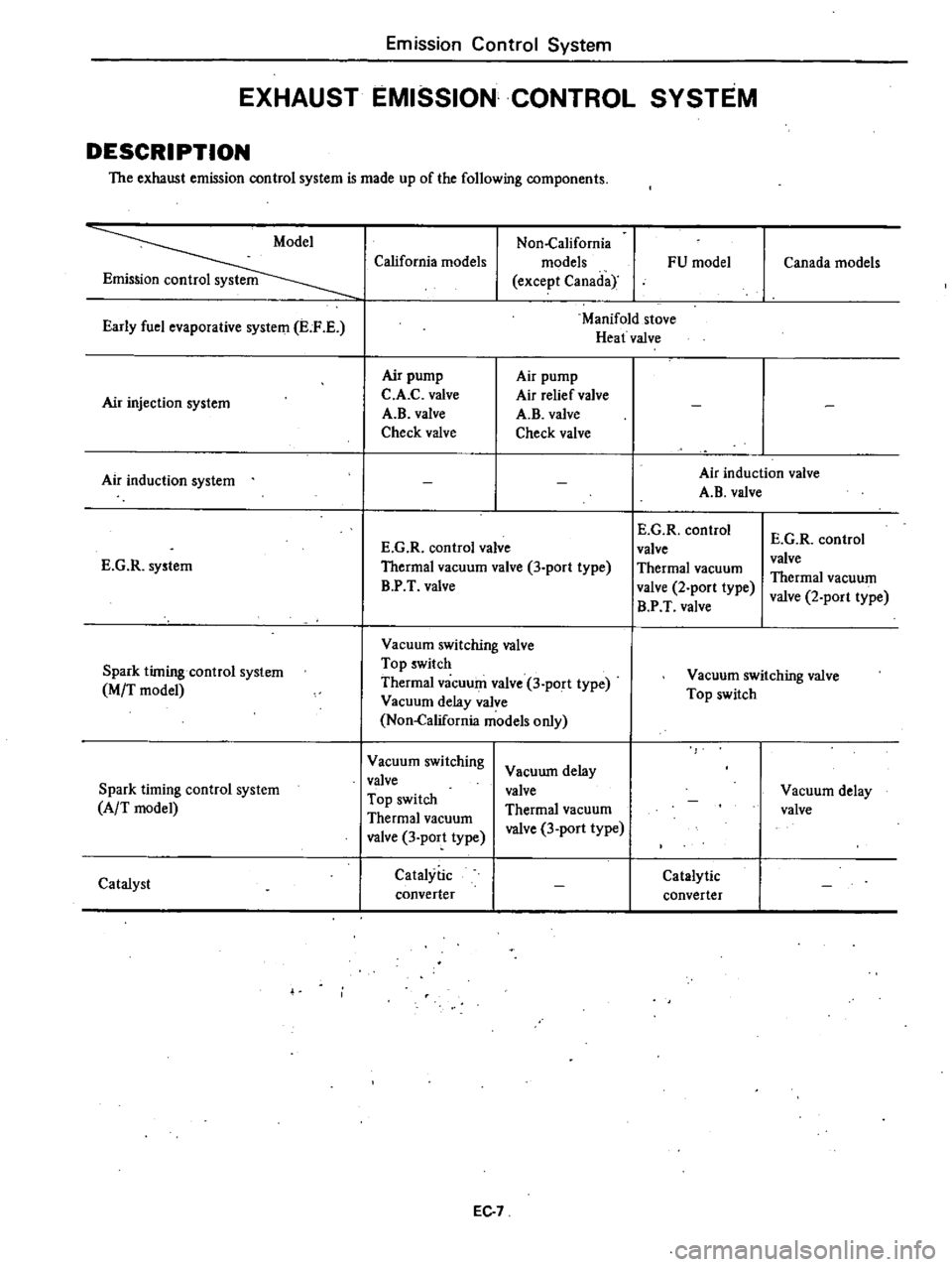

Emission

Control

System

EXHAUST

EMISSION

CONTROL

SYSTEM

DESCRIPTION

The

exhaust

emission

control

system

is

made

up

of

the

following

components

Early

fuel

evaporative

system

E

F

E

Air

injection

system

Air

induction

system

E

G

R

system

Spark

tirningcontrol

system

M

T

model

Spark

timing

control

system

A

T

model

Catalyst

Non

California

California

models

models

except

CanadaY

FU

model

Manifold

stove

Heat

valve

Air

pump

C

A

C

valve

A

B

valve

Check

valve

Air

pump

Air

relief

valve

A

B

valve

Check

valve

E

G

R

control

valve

Thermal

vacuum

valve

3

port

type

B

P

T

valve

Vacuum

switching

valve

Top

switch

Thermal

vacuum

valve

3

port

type

Vacuum

delay

valve

Non

California

models

only

Vacuum

switching

valve

Top

switch

Thermal

vacuum

valve

3

port

type

Vacuum

delay

valve

Thermal

vacuum

valve

3

port

type

Catalytic

converter

EC

7

Canada

models

Air

induction

valve

A

B

valve

E

G

R

control

valve

Thermal

vacuum

valve

2

port

type

B

P

T

valve

E

G

R

control

valve

Thermal

vacuum

valve

2

port

type

Vacuum

switching

valve

Top

switch

Catalytic

converter

Vacuum

delay

valve

Page 187 of 548

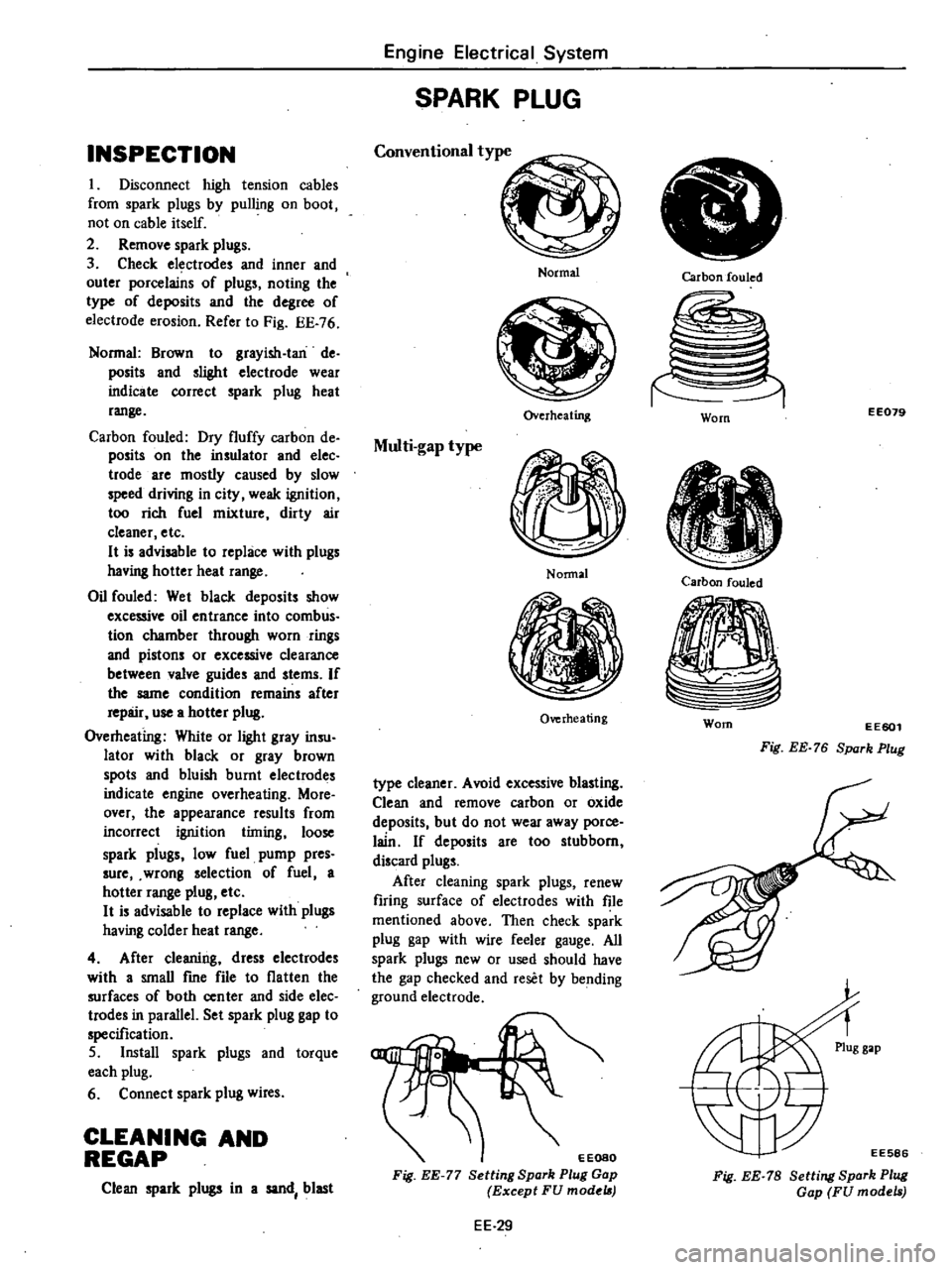

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 335 of 548

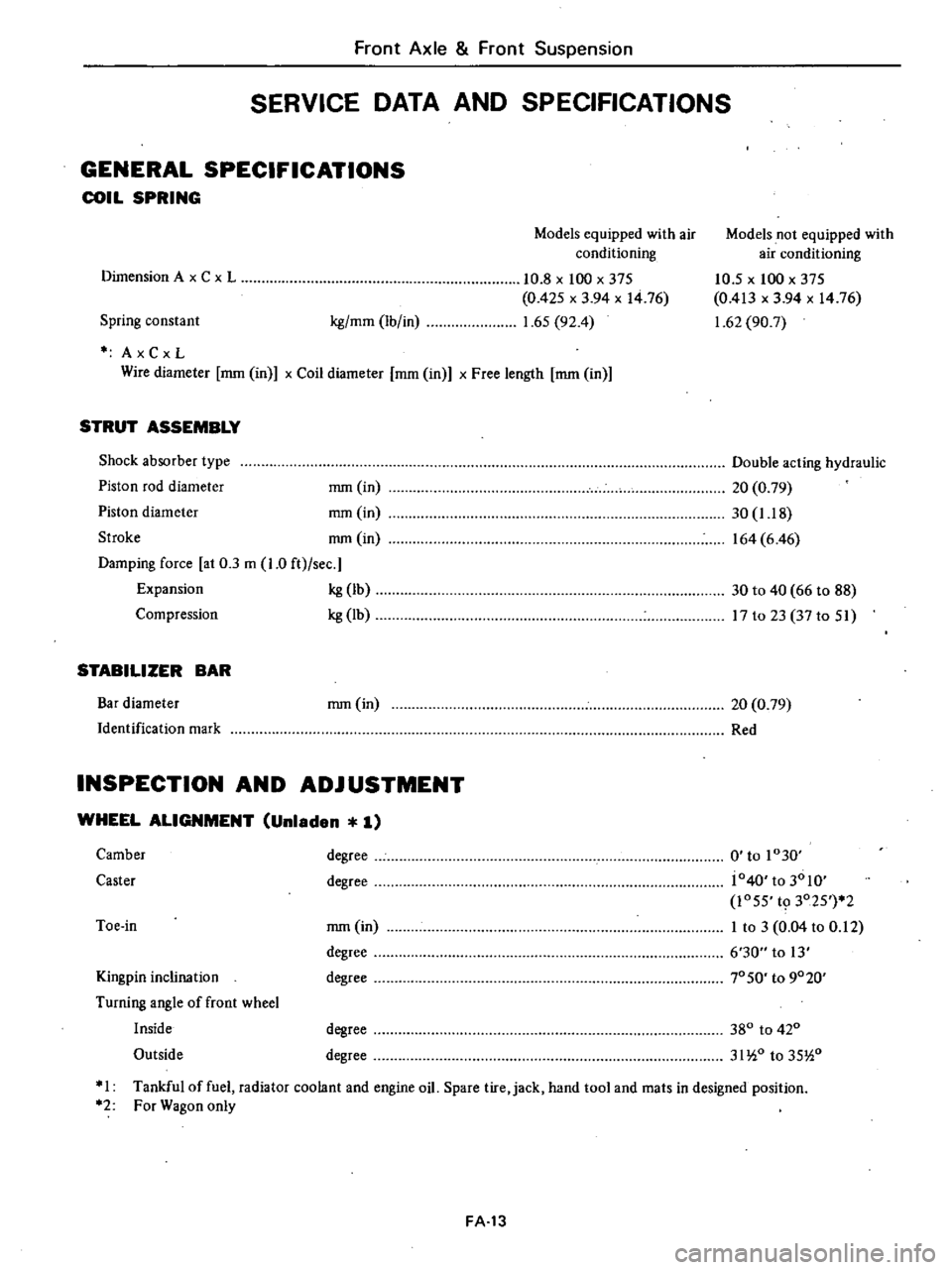

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

COIL

SPRING

Models

equipped

with

air

conditioning

Models

not

equipped

with

air

conditioning

10

5

x

100

x

375

0

413

x

3

94

x

1476

1

62

90

7

Spring

constant

kg

mm

Ib

in

10

8

x

100

x

375

0

425

x

3

94

x

1476

1

65

92

4

Dimension

A

x

C

x

L

AxCxL

Wire

diameter

mm

in

x

Coil

diameter

mm

in

x

Free

length

mm

in

STRUT

ASSEMBLY

Shock

absorber

type

Piston

rod

diameter

mm

in

Piston

diameter

mm

in

Stroke

nun

in

Damping

force

at

0

3

m

1

0

ft

sec

Expansion

kg

Ib

Compression

kg

Ib

Double

acting

hydraulic

20

0

79

30

1

18

164

6

46

30

to

40

66

to

88

17

to

23

37

to

51

STABILIZER

BAR

Bar

diameter

Identification

mark

mm

in

20

0

79

Red

INSPECTION

AND

ADJUSTMENT

WHEEL

ALIGNMENT

Unladen

1

Kingpin

inclination

Turning

angle

of

front

wheel

Inside

Outside

mm

in

degree

degree

0

to

1030

j040

to

3010

1055

t9

3025

2

I

to

3

0

04

to

0

12

6

30

to

13

70

SO

to

9020

Camber

Caster

degree

degree

Toe

in

degree

degree

380

to

420

31

io

to

35

i0

I

Tankful

of

fuel

radiator

coolant

and

engine

oil

Spare

tire

jack

hand

tool

and

mats

in

designed

position

2

For

Wagon

only

FA

13

Page 403 of 548

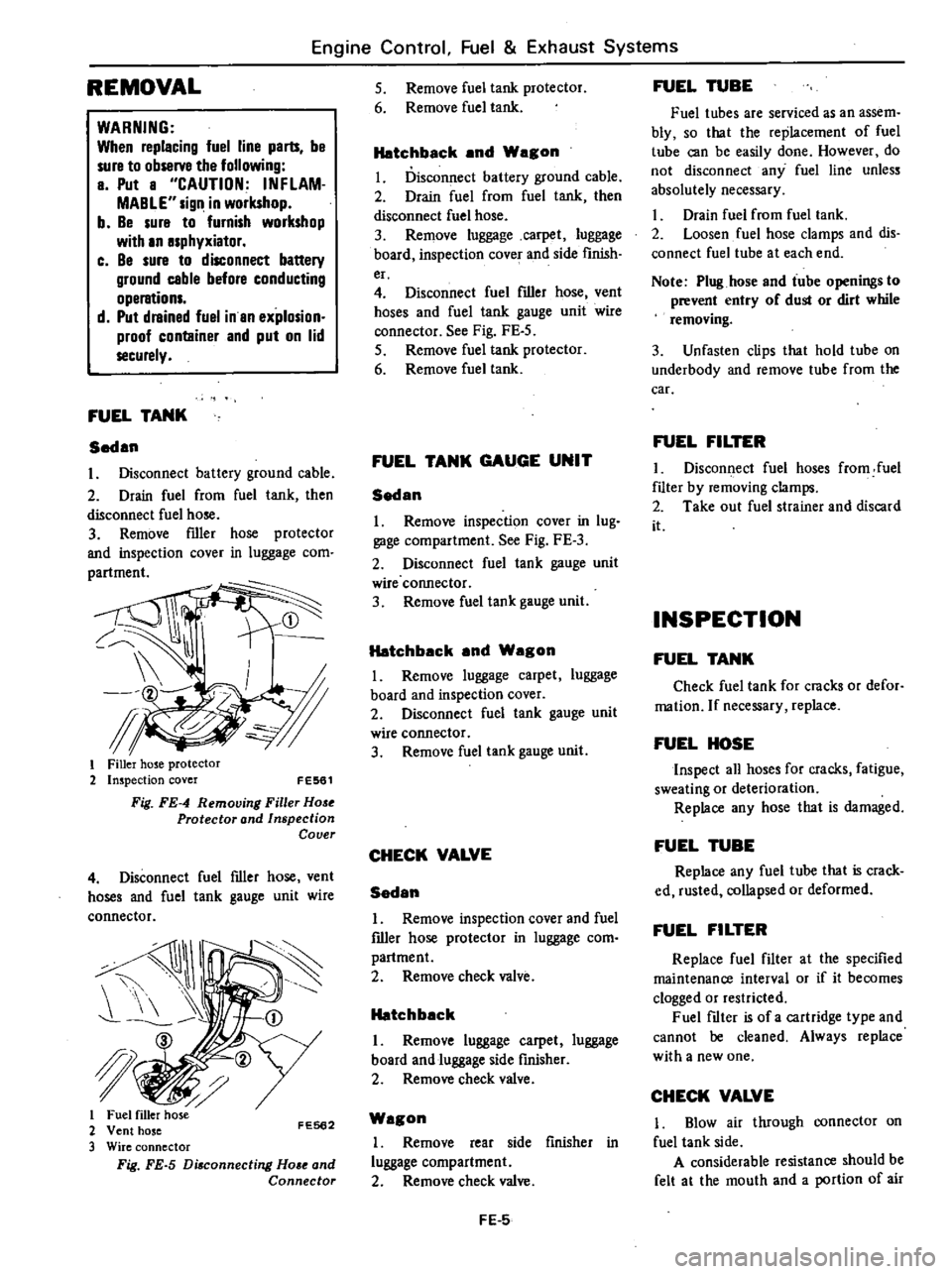

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

WARNING

When

replacing

fuel

line

parts

be

sure

to

observe

the

following

a

Put

a

CAUTION

INFLAM

MABLE

sign

in

workshop

b

Be

sure

to

furnish

workshop

with

In

asphyxiator

c

Be

sure

to

disconnect

battery

ground

cable

before

conducting

operations

d

Put

drained

fuel

in

an

explosion

proof

container

and

put

on

lid

securely

FUEL

TANK

Sedan

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

filler

hose

protector

and

inspection

cover

in

luggage

com

i

tl

f

I

Filler

hose

protector

2

Inspection

cover

FE561

Fig

FE

4

Removing

Filler

Hose

Protector

and

Inspection

Cover

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

I

JI

I

2

FE562

3

Fig

FE

5

Di

connecting

Ho

e

and

Connector

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

Hatchback

and

Wagon

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

luggage

carpet

luggage

board

inspection

covef

and

side

finish

er

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

See

Fig

FE

5

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

FUEL

TANK

GAUGE

UNIT

Sedan

1

Remove

inspection

cover

in

lug

gage

compartment

See

Fig

FE

3

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

Hatchback

and

Wagon

I

Remove

luggage

carpet

luggage

board

and

inspection

cover

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

CHECK

VALVE

Sedan

I

Remove

inspection

cover

and

fuel

filler

hose

protector

in

luggage

com

partment

2

Remove

check

valve

Hatchback

I

Remove

luggage

carpet

luggage

board

and

luggage

side

finisher

2

Remove

check

valve

Wagon

I

Remove

rear

side

finisher

in

luggage

compartment

2

Remove

check

valve

FE

5

FUEL

TUBE

Fuel

tubes

are

serviced

as

an

assem

bly

so

that

the

replacement

of

fuel

tube

can

be

easily

done

However

do

not

disconnect

any

fuel

line

unless

absolutely

necessary

Drain

fuel

from

fuel

tank

2

Loosen

fuel

hose

clamps

and

dis

connect

fuel

tube

at

each

end

Note

Plug

hose

and

tube

openings

to

prevent

entry

of

dust

or

dirt

while

removing

3

Unfasten

clips

that

hold

tube

on

underbody

and

remove

tube

from

the

car

FUEL

FILTER

I

Disconnect

fuel

hoses

from

fuel

filter

by

removing

clamps

2

Take

out

fuel

strainer

and

discard

it

INSPECTION

FUEL

TANK

Check

fuel

tank

for

cracks

or

defor

mation

If

necessary

replace

FUEL

HOSE

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

FUEL

TUBE

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

FUEL

FILTER

Replace

fuel

filter

at

the

specified

maintenance

interval

or

if

it

becomes

clogged

or

restricted

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

CHECK

VALVE

1

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air

Page 547 of 548

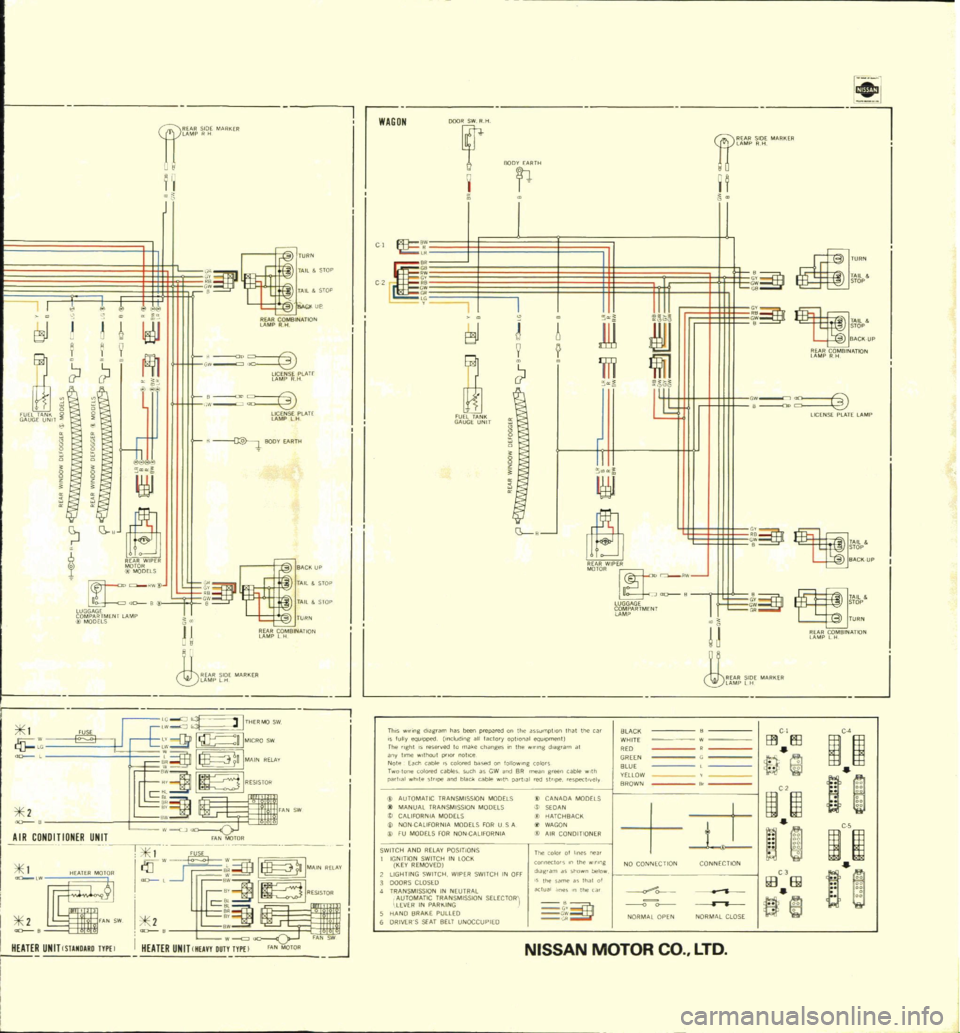

C

E3J

i

I

u

r

o

alNATIO

1

9

fl

l

w

tif

S

lATr

u

N

T

i

0

lf

5f

lAH

8

g

llOOY

AIITI

0

BI

b

RWIPER

IoOODELS

a

RW

LUGGAGf

aD

B

iO

b

n

rNr

lAMP

1

FUSE

1

AIR

CONDnION

R

UNIT

1

lii

I

I

N

UNITCSlAMD

UOTYPEl

I

LAMP

lH

ARKER

Th

ng

diagram

ha

been

fullyeqU1pped

nclod

p

wredontheas

The

ght

IS

e

erv

l

og

all

factory

optIonal

SUmQtron

tllat

the

car

BLACK

any

tme

II

1aut

to

make

chang

s

In

the

eQU

Omefll

Note

EaCh

cao

ro

notICe

l

d

g

am

at

WHITE

D

CI

r

olon

colO

E

d

Ca

Iore

l

ba

ed

on

1011010

ffi

El3

C4

pa

l

a

wh

te

Sl

l

bles

Suel

as

GW

n

8R

g

colors

GREEN

1m

o11Id

blaCk

cao

th

pa

l

I

n

5

at

l@

Il

BLUE

C

AUTOMATIC

fRAN

pe

l

tely

YlilOW

I

MANUAL

TRAN

M

MISSION

MODUS

BROWN

1

CALIFORNIA

MOD

ION

MODELS

A

MODELS

w

w

B

j

NONCAUroRNIA

I

HATCHBACK

It

it

FU

MODEtS

FOR

tS

FOR

USA

WAGON

AllFORN

A

t

AIR

CONDITIONER

SWITCH

AND

RE

J

IGNITION

SWI

Y

POSITIONS

KEY

REMOVEO

IN

lOCII

n

co

o

011

@

1

1

LIGHTING

SWITCH

W

P

con

10

lhe

w

n

g

DOORS

CtoSlO

ER

SWITCH

IN

OFF

TRANSMISSION

m

hown

be

w

NO

CONNECTION

CONNECTION

AUtOMATIC

T

EUTRAl

I

me

th

of

lEVER

IN

PAIU

IN

SSIDN

SlLECfORi

oKlualhne

nthec

HANOBRAIIEPUllEO

t

ffi

III

fi

ORIVEWS

SEAT

BELT

UNOCCUPIED

@

C

JiOR

lOPEN

NORMAL

CLOSE

NISSAN

MOTOR

tl

J

w

iJ

j

II

C

TA

l

SfOP

t

o

L

SlOP

fUPN

lj

ro

elNA

TI

N

JbtJ

1

G

J

W

1

J

ITHERMO

sw

B

H

IMICRO

sw

1

l

n

MA

IN

RELA

V

c

1W231

rAN

SW

I

A

NMOTOR

of

l

I

rr

I

I

I

c

1m231

i

11

II

i

HEATER

UNIT

Mun

DUT

FA

N

J

WAGON

t

o

a

ijE

c

r

g

E3J

FUEl

Tjl

NII

GA

LJGE

UNIT

JL

OODfi

11

tl

DJ

H

t

ow

J

TA

l

BA

CII

UP

rI

O

BlNjl

TIOf

l

J

9

111

fi

l

JID

l

6

o

o

c

II

LICENSE

PLA

TE

LAMP

ijf

I

LUGGAGE

R

r2

ARTMENI

C

ow

Tjl

ll

STOP

IIA

CIIUP

t

C

co

STOP

fURN

n

ro

fBINA

TION

I

J

CO

LTD