glove box DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 441 of 548

CLUSTER

I

IDA

Removal

and

installation

I

Disconnect

batterv

ground

cable

2

Remove

steering

column

cover

3

Remove

illumination

control

rhe

ostat

4

Pull

out

heater

control

knob

and

remove

heater

c

ntrol

finisher

5

Remove

screw

attaching

heater

control

assembly

to

cluster

lid

A

nQ

lQ

Ii

tl

rffmfLu

O

r

BF783B

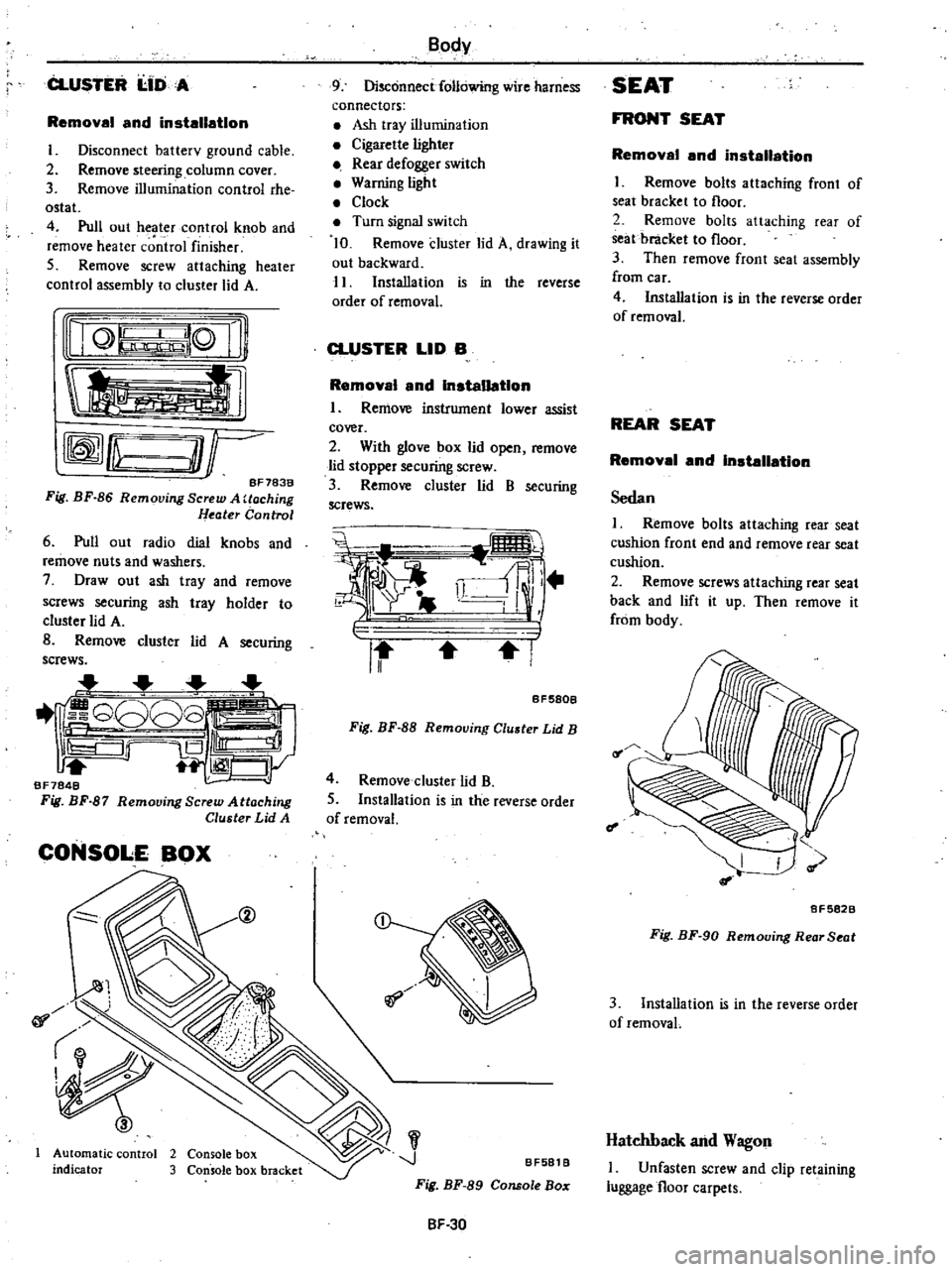

Fig

BF

86

Removing

Screw

A

Uoching

Heater

Control

6

Pull

out

radio

dial

knobs

and

remove

nuts

and

washers

7

Draw

out

ash

tray

and

remove

screws

securing

ash

tray

holder

to

cluster

lid

A

B

Remove

cluster

lid

A

securing

screws

1

G808

iS

Ill

1

CJy

BF7848

Fig

BF

87

Remooing

Screw

Attaching

Cluster

Lid

A

CONSOLE

BOX

@

01

Automatic

control

2

Console

box

indicator

3

Console

box

bracket

Body

9

Disconnect

following

wire

harness

connectors

Ash

tray

illumination

Cigarette

lighter

Rear

defogger

switch

Warning

light

Clock

Turn

signal

switch

10

Remove

cluster

lid

A

drawing

it

out

backward

11

Installation

is

in

the

reverse

order

of

removal

CLUSTER

LID

B

Removal

and

Installation

I

Remove

instrument

lower

assist

cover

2

With

glove

box

lid

open

remove

lid

stopper

securing

screw

3

Remove

cluster

lid

B

securing

screws

i

i

ll

r

II

I

BF580B

Fig

BF

88

Removing

Cluster

Lid

B

4

Remove

cluster

lid

B

5

Installation

is

in

the

reverse

order

of

removal

J

BF581

B

Fig

BF

89

Console

Bo

SF

30

SEAT

FRONT

SEAT

Removal

and

installation

I

Remove

bolts

attaching

front

of

seat

bracket

to

floor

2

Remove

bolts

attaching

rear

of

seat

bracket

to

floor

3

Then

remove

front

seat

assembly

from

car

4

Installation

is

in

the

reverse

order

of

removal

REAR

SEAT

Removal

and

Installation

Sedan

I

Remove

bolts

attaching

rear

seat

cushion

front

end

and

remove

rear

seat

cushion

2

Remove

screws

attaching

rear

seat

back

and

lift

it

up

Then

remove

it

from

body

f

I

8F5828

Fig

BF

90

Removing

Rear

Seat

3

Installation

is

in

the

reverse

order

of

removaL

Hatchback

and

Wagon

I

Unfasten

screw

and

clip

retaining

luggage

floor

carpets

Page 522 of 548

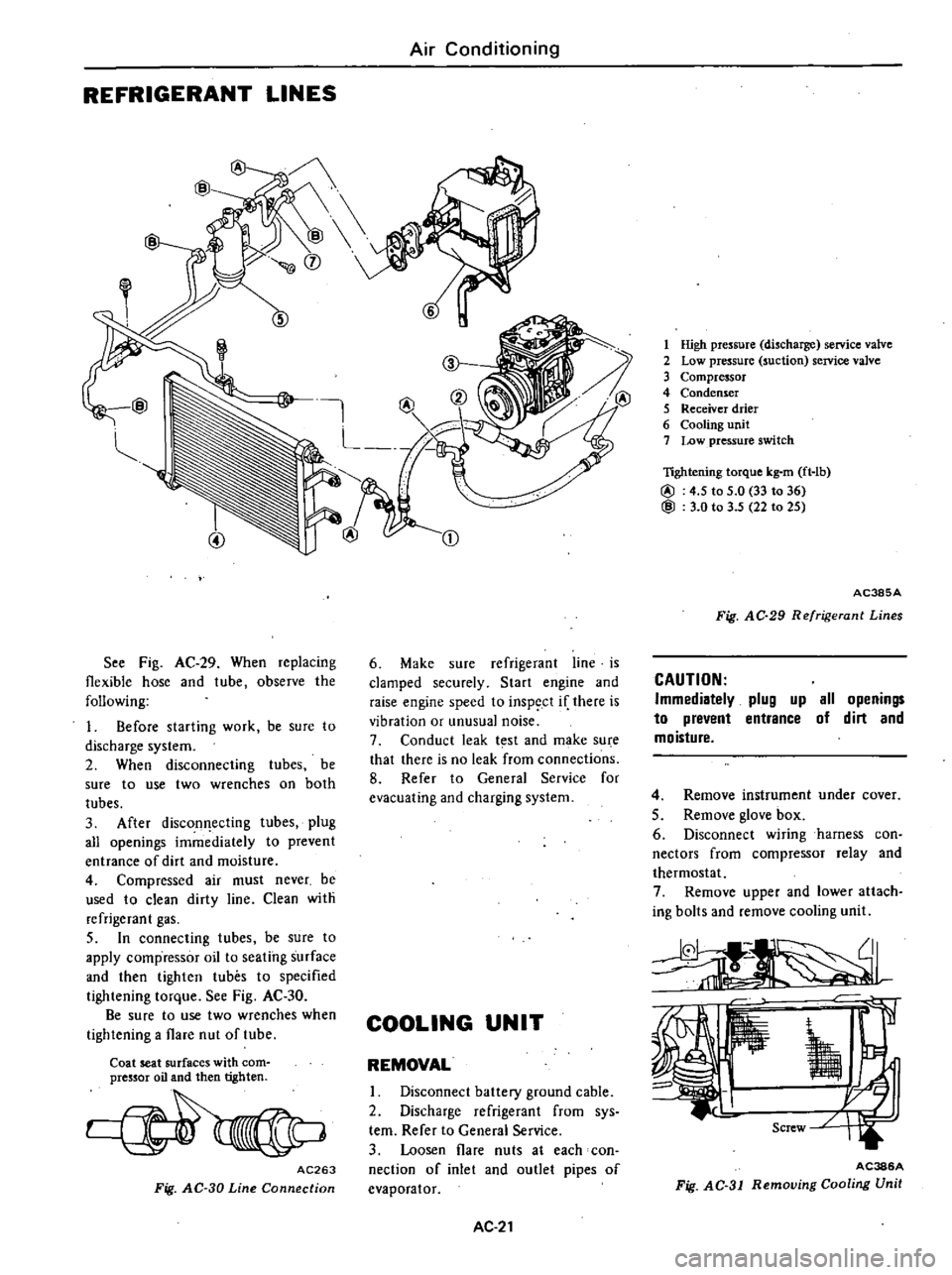

REFRIGERANT

LINES

Air

Conditioning

@

I

J

L

S

r

Z

S

t

@

See

Fig

AC

29

When

replacing

flexible

hose

and

tube

observe

the

following

1

Before

starting

work

be

sure

to

discharge

system

2

When

disconnecting

tubes

be

sure

to

use

two

wrenches

on

both

tubes

3

After

discon

ecting

tubes

plug

all

openings

immediately

to

prevent

entrance

of

dirt

and

moisture

4

Compressed

air

must

never

be

used

to

clean

dirty

line

Clean

with

refrigerant

gas

5

In

connecting

tubes

be

sure

to

apply

compressor

oil

to

seating

surface

and

then

tighten

tubes

to

specified

tightening

torque

See

Fig

AC

30

Be

sure

to

use

two

wrenches

when

tightening

a

flare

nut

of

tube

Coat

seat

surfaces

with

com

pressor

oil

and

then

tighten

AC263

Fig

AC

30

Line

Connection

CD

6

Make

sure

refrigerant

line

is

clamped

securely

Start

engine

and

raise

engine

speed

to

inspect

if

there

is

vibration

or

unusual

noise

7

Conduct

leak

t

st

and

make

su

e

that

there

is

no

leak

from

connections

8

Refer

to

General

Service

for

evacuating

and

charging

system

COOLING

UNIT

REMOVAL

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tern

Refer

to

General

Service

3

Loosen

flare

nuts

at

each

con

nection

of

inlet

and

outlet

pipes

of

evaporator

AC

21

1

High

pressure

discharge

service

valve

2

Low

pressure

suction

service

valve

3

Compressor

4

Condenser

5

Receiver

drier

6

Cooling

unit

7

Low

pressure

switch

lightening

torque

kg

m

ft

lb

@

4

5

to

5

0

33

to

36

@

3

0

to

3

5

22

to

25

AC385A

Fig

AC

29

Refrigerant

Lines

CAUTION

Immediatelv

plug

up

all

openings

to

prevent

entrance

of

dirt

and

moisture

4

Remove

instrument

under

cover

5

Remove

glove

box

6

Disconnect

wiring

harness

con

nectors

from

compressor

relay

and

thermostat

7

Remove

upper

and

lower

attach

ing

bolts

and

remove

cooling

unit

AC386A

Fig

AC

31

Removing

Cooling

Unit

Page 524 of 548

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

SO

em

19

7

in

from

evaporator

core

INSPECTION

1

Test

continuity

between

two

switch

terminals

with

test

lamp

or

ohmmerter

Continuity

should

exist

2

With

capillary

tube

end

dipped

into

ice

salt

water

maintained

to

I

oc

300

F

test

continuity

between

two

switch

terminals

Continuity

should

not

exist

3

If

switch

is

found

damaged

re

place

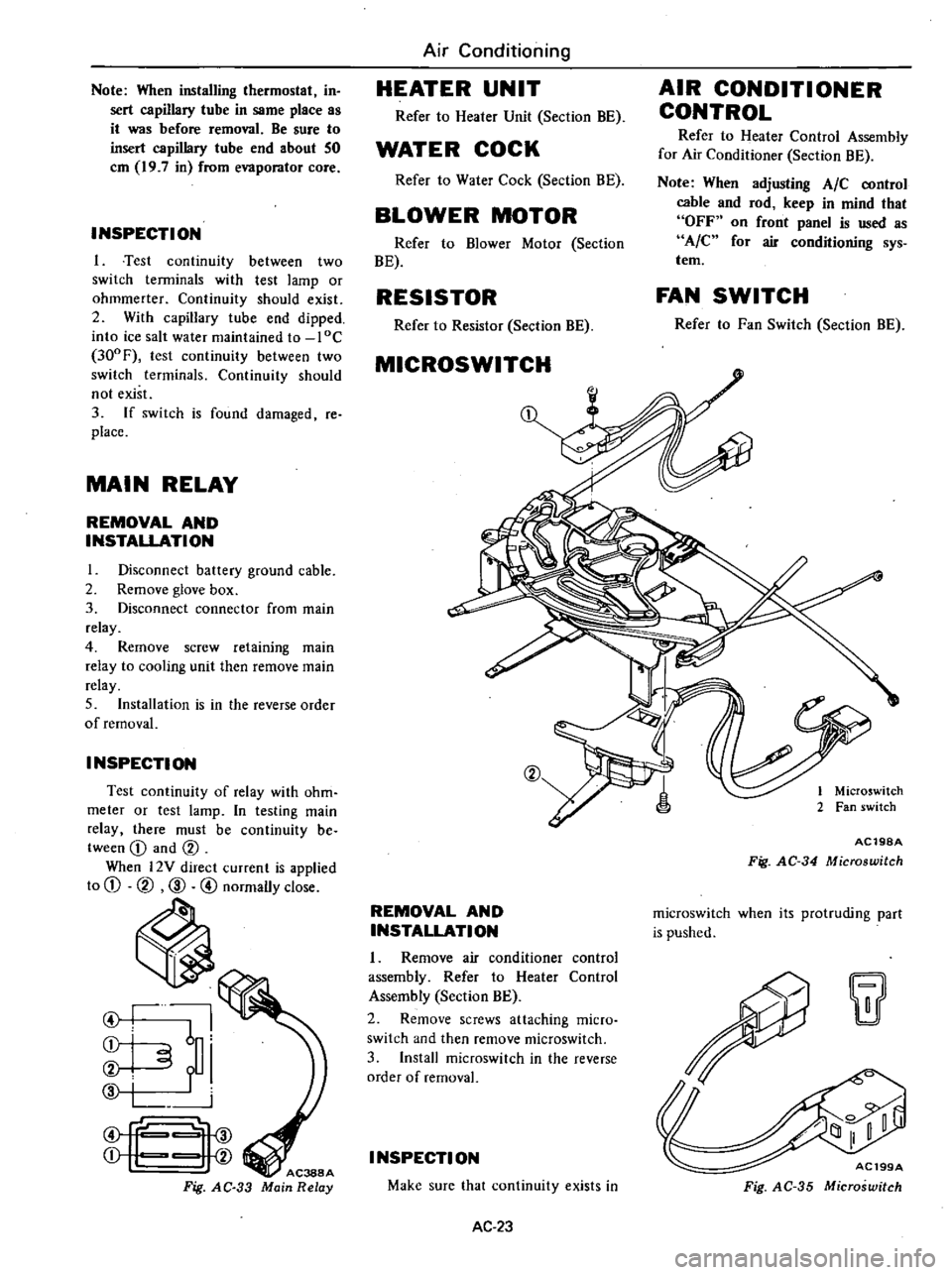

MAIN

RELAY

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

connector

from

main

relay

4

Remove

screw

retaining

main

relay

to

cooling

unit

then

remove

main

relay

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Test

continuity

of

relay

with

ohm

meter

or

test

lamp

In

testing

main

relay

there

must

be

continuity

be

tween

CD

and

CV

When

l2Y

direct

current

is

applied

to

CD

CV

CID

@

normally

close

ti

I

I

6

i

i

f

i

f

Fig

AC

33

Air

Conditioning

HEATER

UNIT

Refer

to

Heater

Unit

Section

BE

WATER

COCK

Refer

to

Water

Cock

Section

BE

BLOWER

MOTOR

Refer

to

Blower

Motor

Section

BE

RESISTOR

Refer

to

Resistor

Section

BE

MICROSWITCH

CV

REMOVAL

AND

INSTALLATION

1

Remove

air

conditioner

control

assembly

Refer

to

Heater

Control

Assembly

Section

BE

2

Remove

screws

attaching

micro

switch

and

then

remove

rnicroswitch

3

Install

rnicroswitch

in

the

reverse

order

of

removal

I

NSPECTI

ON

Make

sure

that

continuity

exists

in

AC

23

AIR

CONDITIONER

CONTROL

Refer

to

Heater

Control

Assembly

for

Air

Conditioner

Section

BE

Note

When

adjusting

AIC

control

cable

and

rod

keep

in

mind

that

OFF

on

front

panel

is

used

as

A

C

for

air

conditioning

sys

tem

FAN

SWITCH

Refer

to

Fan

Switch

Section

BE

1

Microswitch

2

Fan

switch

AC19SA

Fig

AC

34

Microswitch

rnicroswitch

when

its

protruding

part

is

pushed

w

AC199A

Fig

AC

35

Microswitch

Page 525 of 548

LOW

PRESSURE

SWITCH

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tem

Refer

to

General

Service

3

Disconnect

connector

to

low

pressure

switch

4

Remove

low

pressure

switch

by

turning

the

switch

5

Installation

is

in

the

reverse

order

of

removal

INSPECTION

Using

a

circuit

tester

make

sure

that

low

pressure

switch

exhibits

con

tinuity

when

gas

pressure

of

refriger

ant

in

system

is

normal

and

that

low

pressure

switch

does

not

exhibit

con

tinuity

when

gas

pressure

drops

below

2

2

kg

cm2

31

p

i

MAGNET

VALVE

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Disconnect

magnet

valve

lead

wires

and

vacuum

hoses

3

Remove

magnet

valve

securing

screws

and

then

remove

magnet

valve

i

i

WrE

AC389A

Fig

AC

36

Removjng

Magnet

Valve

4

Installation

is

in

the

reverse

order

of

removal

INSPECTION

I

rest

continuity

with

ohmmeter

2

Apply

D

C

12

volts

across

termi

Air

Conditioning

031

under

this

state

orally

blow

through

one

vacuum

port

to

ensure

that

there

is

air

flow

at

the

other

FUSE

REPLACEMENT

REPLACEMENT

A

20

ampere

in

line

fuse

is

part

of

air

conditioner

harness

located

behind

glove

box

J

Disconnect

batiery

ground

cable

2

Remove

instrument

under

cover

3

Remove

glove

box

4

Take

out

fuse

holder

from

air

conditioner

harness

and

replace

fuse

with

a

new

one

CAUTION

If

fuse

is

blown

be

sure

to

climi

nate

the

cause

befure

installing

new

fuse

in

position

r

AC276A

Fig

AC

37

Fu

e

Replacement

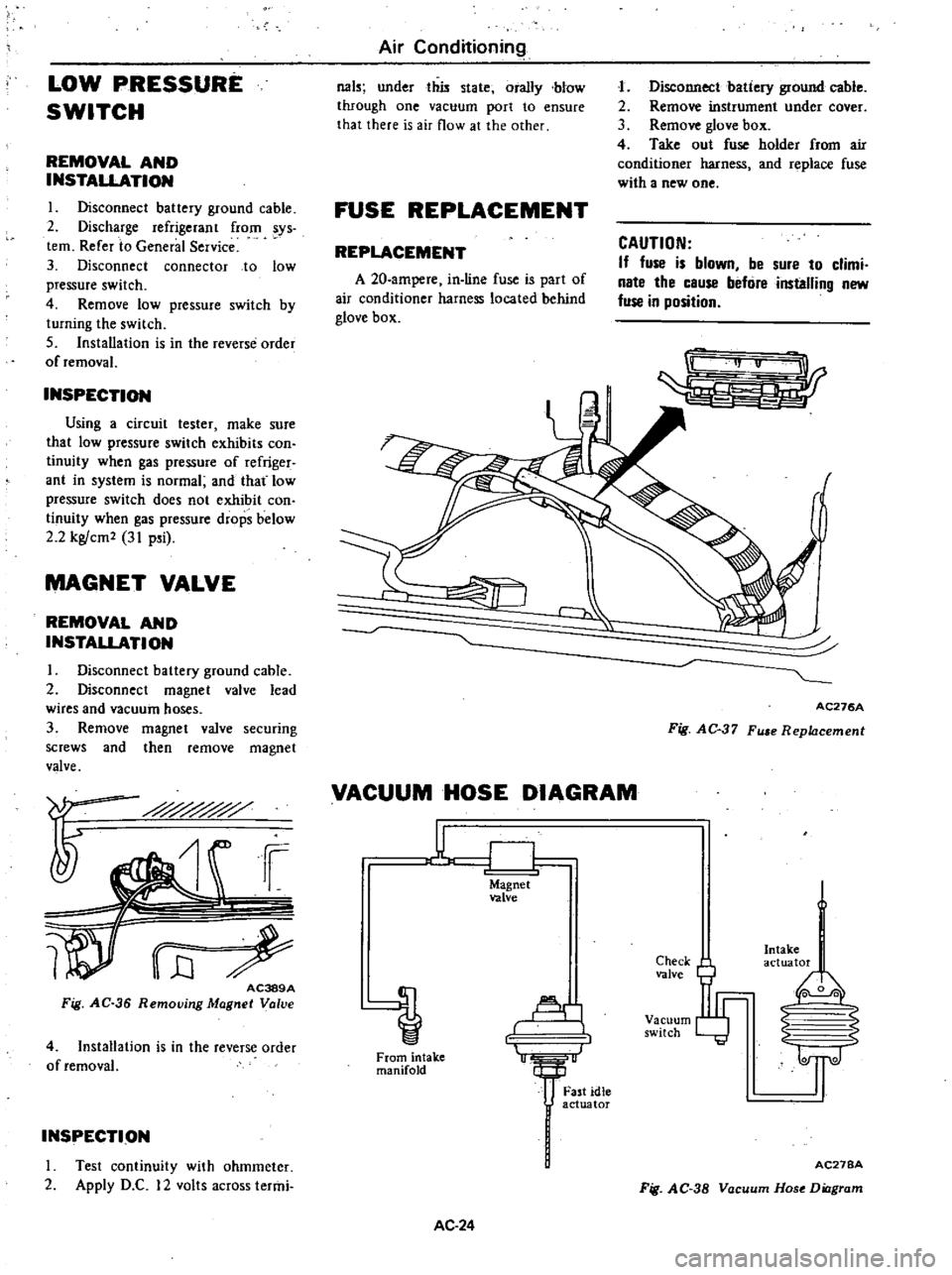

VACUUM

HOSE

DIAGRAM

u

CJ

Magnet

valve

Al

1

From

intake

manifold

AC

24

Fast

idle

actuator

Check

valve

Vacuum

switch

Intake

actuator

I

0

0

2

S

1l

AC27BA

Fig

AC

38

Vacuum

Hose

Diagram