length DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 42 of 548

CYLINDER

HEAD

I

Using

Valve

lifter

STl2070000

compress

valve

spring

and

remove

valve

collet

2

Release

Valve

Lifter

and

remove

spring

retainer

spring

oil

seal

spring

seat

and

valve

PREPARATION

FOR

INSPECTION

I

8efore

cleaning

check

for

signs

of

water

and

oille

s

2

Clean

oil

and

carbon

deposits

from

all

parts

They

should

be

clean

from

gaskets

and

sealant

3

Clean

all

oil

holes

with

solvent

and

dry

with

compressed

air

Make

sure

that

they

are

not

restricted

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

I

Make

a

visual

check

for

cracks

and

flaws

2

Measure

surface

of

cylinder

head

on

cylinder

block

sid

for

warpage

If

beyond

designated

limit

correct

s

rface

with

a

surface

grinder

Warpage

of

urfece

Less

than

0

1

mm

0

004

in

EM108

Fig

EM

IS

Checking

Cylinder

Head

Surface

Engine

Mechanical

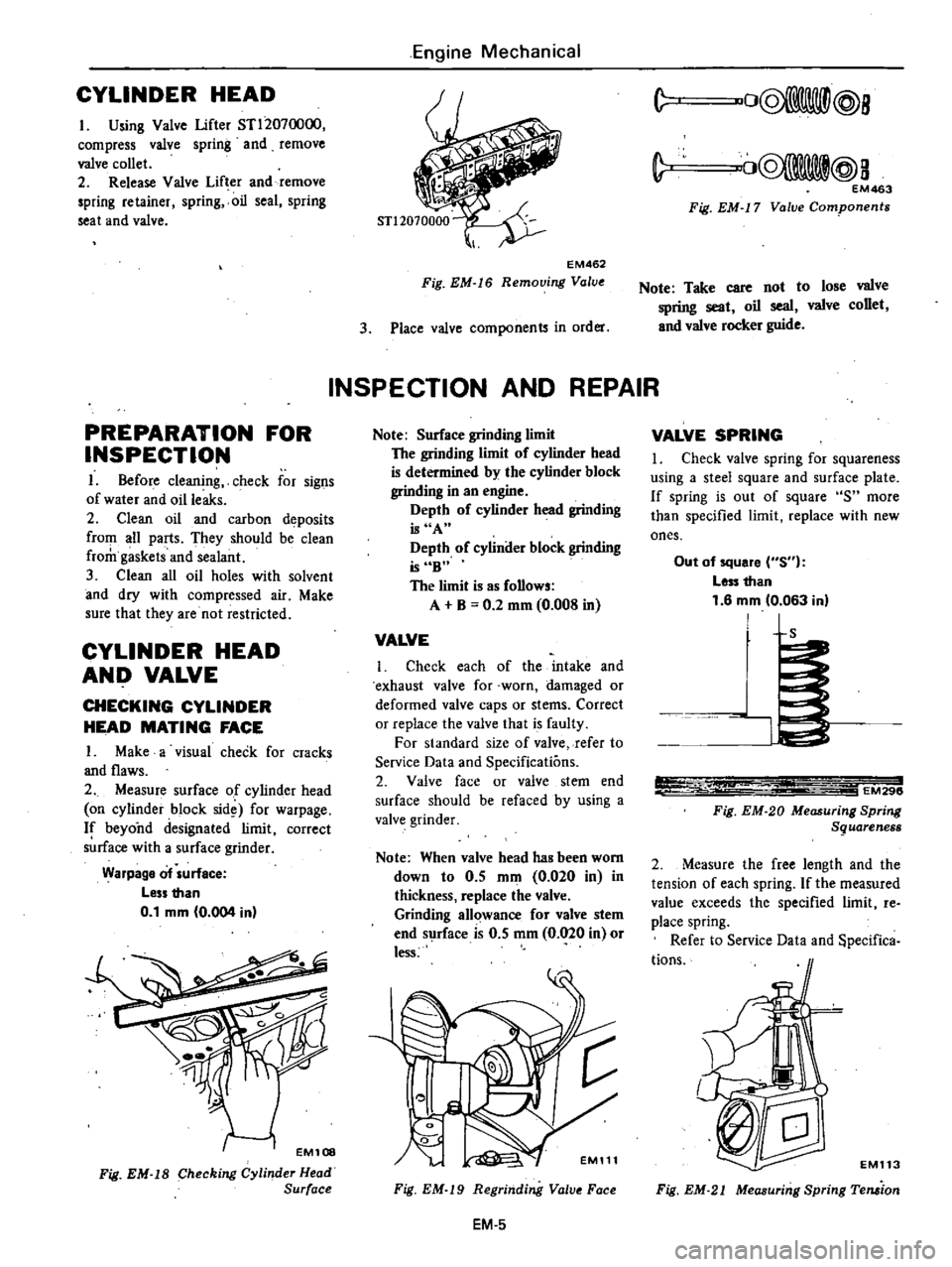

EM462

Fig

EM

16

Removing

Value

3

Place

valve

components

in

order

INSPECTION

AND

REPAIR

Note

Surface

grinding

limit

The

grinding

limit

of

cylinder

head

is

determined

by

the

cylinder

block

grinding

in

an

engine

Depth

of

cylinder

head

grinding

is

A

Depth

of

cylinder

block

grinding

is

6B

The

limit

is

as

follows

A

B

0

2

mm

0

008

in

VALVE

i

Check

each

of

the

intake

and

exhaust

valve

for

worn

damaged

or

deformed

valve

caps

or

stems

Correct

or

replace

the

valve

that

is

faulty

For

standard

size

of

valve

refer

to

Service

Data

and

Specifications

2

Valve

face

or

valve

stem

end

surface

should

be

refaced

by

using

a

valve

grinder

Note

When

valve

head

has

been

worn

down

to

0

5

mm

0

020

in

in

thickness

replace

the

valve

Grinding

allowance

for

valve

stem

end

surface

is

0

5

mm

0

020

in

or

less

c

EM111

Fig

EM

19

Regrinding

Valve

Face

EM

5

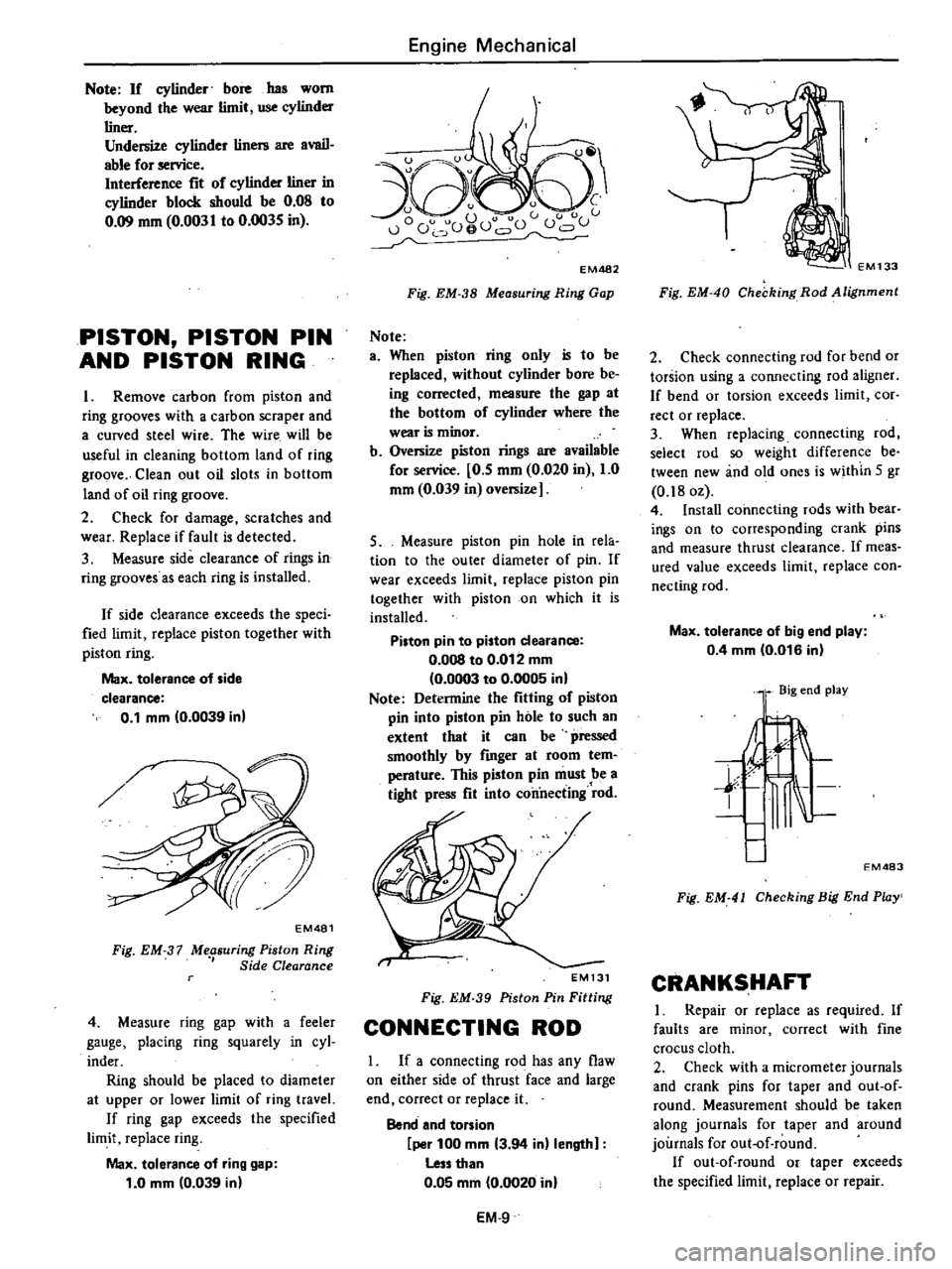

C

vO@

lll@8

C

CQ8@

a

EM463

Fig

EM

17

Valve

Components

Note

Take

care

not

to

lose

valve

spring

seat

oil

seal

valve

collet

and

valve

rocker

guide

VALVE

SPRING

I

Check

valve

spring

for

squareness

using

a

steel

square

and

surface

plate

If

spring

is

out

of

square

S

more

than

specified

limit

replace

with

new

ones

Out

of

square

S

Less

than

1

6

mm

0

063

inl

L

1

EM296

Fig

EM

20

Measuring

Spring

Sguareness

2

Measure

the

free

length

and

the

tension

of

each

spring

If

the

measured

value

exceeds

the

specified

limit

re

place

spring

Refer

to

Service

Data

and

pecifica

tions

EMl13

Fig

EM

21

Measuring

Spring

Teruion

Page 46 of 548

Note

If

cylinder

bore

has

worn

beyond

the

wear

limit

use

cylinder

liner

Undersize

cylinder

liners

are

avail

able

for

service

Interference

fit

of

cylinder

liner

in

cylinder

block

ahould

be

0

08

to

0

09

mm

0

003

I

to

0

0035

in

PISTON

PISTON

PIN

AND

PISTON

RING

I

Remove

carbon

from

piston

and

ring

grooves

with

a

carbon

scraper

and

a

curved

steel

wire

The

wire

will

be

useful

in

cleaning

bottom

land

of

ring

groove

Clean

out

oil

slots

in

bottom

land

of

oil

ring

groove

2

Check

for

damage

scratches

and

wear

Replace

if

fault

is

detected

3

Measure

side

clearance

of

rings

in

ring

grooves

as

each

ring

is

installed

If

side

clearance

exceeds

the

speci

fied

limit

replace

piston

together

with

piston

ring

Max

tolerance

of

side

clearance

0

1

mm

0

0039

in

Engine

Mechanical

u

EM482

Fig

EM

38

Measuring

Ring

Gap

Note

a

When

piston

ring

only

is

to

be

replaced

without

cylinder

bore

be

ing

corrected

measure

the

gap

at

the

bottom

of

cylinder

where

the

wear

is

minor

b

Oversize

piston

rings

are

available

for

service

0

5

mm

0

020

in

1

0

mm

0

039

in

oversize

5

Measure

piston

pin

hole

in

rela

tion

to

the

outer

diameter

of

pin

If

wear

exceeds

limit

replace

piston

pin

together

with

piston

on

which

it

is

installed

Piston

pin

to

piston

clearance

O

OOS

to

0

012

mm

0

0003

to

0

0005

in

Note

Determine

the

fitting

of

piston

pin

into

piston

pin

hole

to

such

an

extent

that

it

can

be

pressed

smoothly

by

fmger

at

room

tem

perature

This

piston

pin

must

be

a

tight

press

fit

into

connecting

rod

EM481

Fig

EM

37

Me

suring

Piston

Ring

Side

Clearance

4

Measure

ring

gap

with

a

feeler

gauge

placing

ring

squarely

in

cyl

inder

Ring

should

be

placed

to

diameter

at

upper

or

lower

limit

of

ring

travel

If

ring

gap

exceeds

the

specified

limit

replace

ring

Max

tolerance

of

ring

gap

1

0

mm

0

039

in

EM131

Fig

EM

39

Piston

Pin

Fitting

CONNECTING

ROD

1

If

a

connecting

rod

has

any

flaw

on

either

side

of

thrust

face

and

large

end

correct

or

replace

it

Bend

and

torsion

per

100

mm

3

94

in

length

Less

than

0

05

mm

0

0020

in

EM

9

EM133

Fig

EM

40

Checking

Rod

Alignment

2

Check

connecting

rod

for

bend

or

torsion

using

a

connecting

rod

aligner

If

bend

or

torsion

exceeds

limit

cor

rect

or

replace

3

When

replacing

connecting

rod

select

rod

so

weight

difference

be

tween

new

and

old

ones

is

within

5

gr

0

180z

4

Install

connecting

rods

with

bear

iogs

on

to

corresponding

crank

pins

and

measure

thrust

clearance

If

meas

ured

value

exceeds

limit

replace

con

necting

rod

Max

tolerance

of

big

end

play

0

4

mm

0

016

in

l

Big

end

play

l

t

t

EM483

Fig

EM

41

Checking

Big

End

Pwy

CRANKSHAFT

I

Repair

or

replace

as

required

If

faults

are

minor

correct

with

fine

crocus

cloth

2

Check

with

a

micrometer

journals

and

crank

pins

for

taper

and

out

of

round

Measurement

should

be

taken

along

journals

for

taper

and

around

journals

for

out

of

round

If

out

of

round

or

taper

exceeds

the

specified

limit

replace

or

repair

Page 56 of 548

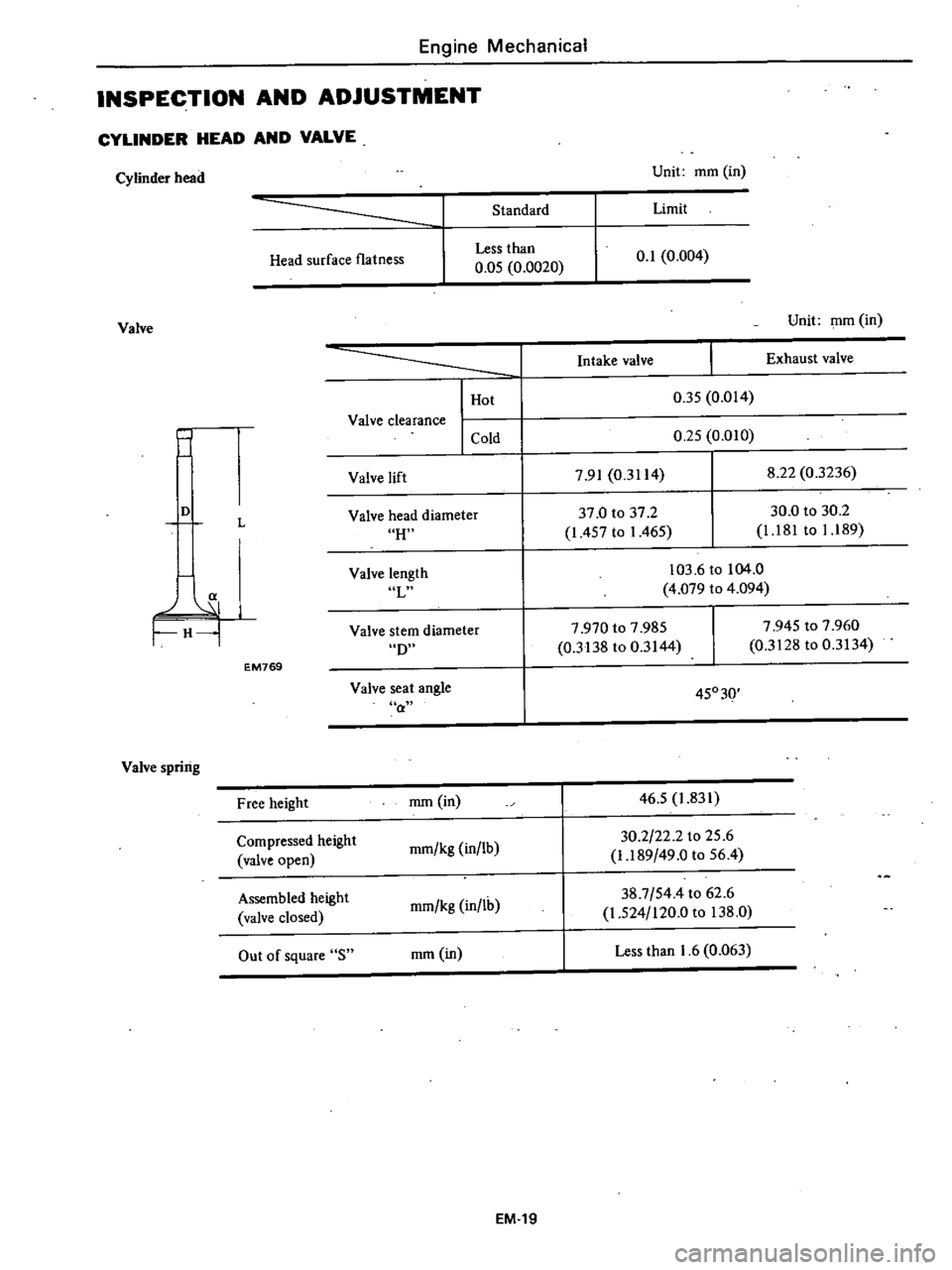

Engine

Mechanical

INSPECTION

AND

ADJUSTMENT

CYLINDER

HEAD

AND

VALVE

Cylinder

head

Unit

mm

in

Standard

Limit

Head

surface

flatness

Less

than

0

05

0

0020

0

1

0

004

Valve

Unit

mm

in

j

I

Hot

Valve

clearance

I

Cold

Intake

valve

Exhaust

valve

0

35

0

014

0

25

0

010

Valve

lift

7

91

0

3114

8

22

0

3236

H

37

0

to

37

2

1

457

to

1

465

30

0

to

30

2

1

181

to

1

189

D

L

Valve

head

diameter

a

H

Valve

length

L

103

6

to

104

0

4

079

to

4

094

D

7

970

to

7

985

0

3138

to

0

3144

7

945

to

7

960

0

3128

to

0

3134

Valve

stem

diameter

EM769

Valve

seat

angle

a

45030

Valve

spring

Free

height

mm

in

46

5

1

831

Compressed

height

mm

kg

in

lb

30

2

22

2

to

25

6

valve

open

1

189

49

0

to

56

4

Assembled

height

mm

kg

in

lh

38

7

544

to

62

6

valve

closed

1

524

120

0

to

138

0

Out

of

square

S

mm

in

Less

than

1

6

0

063

EM

19

Page 57 of 548

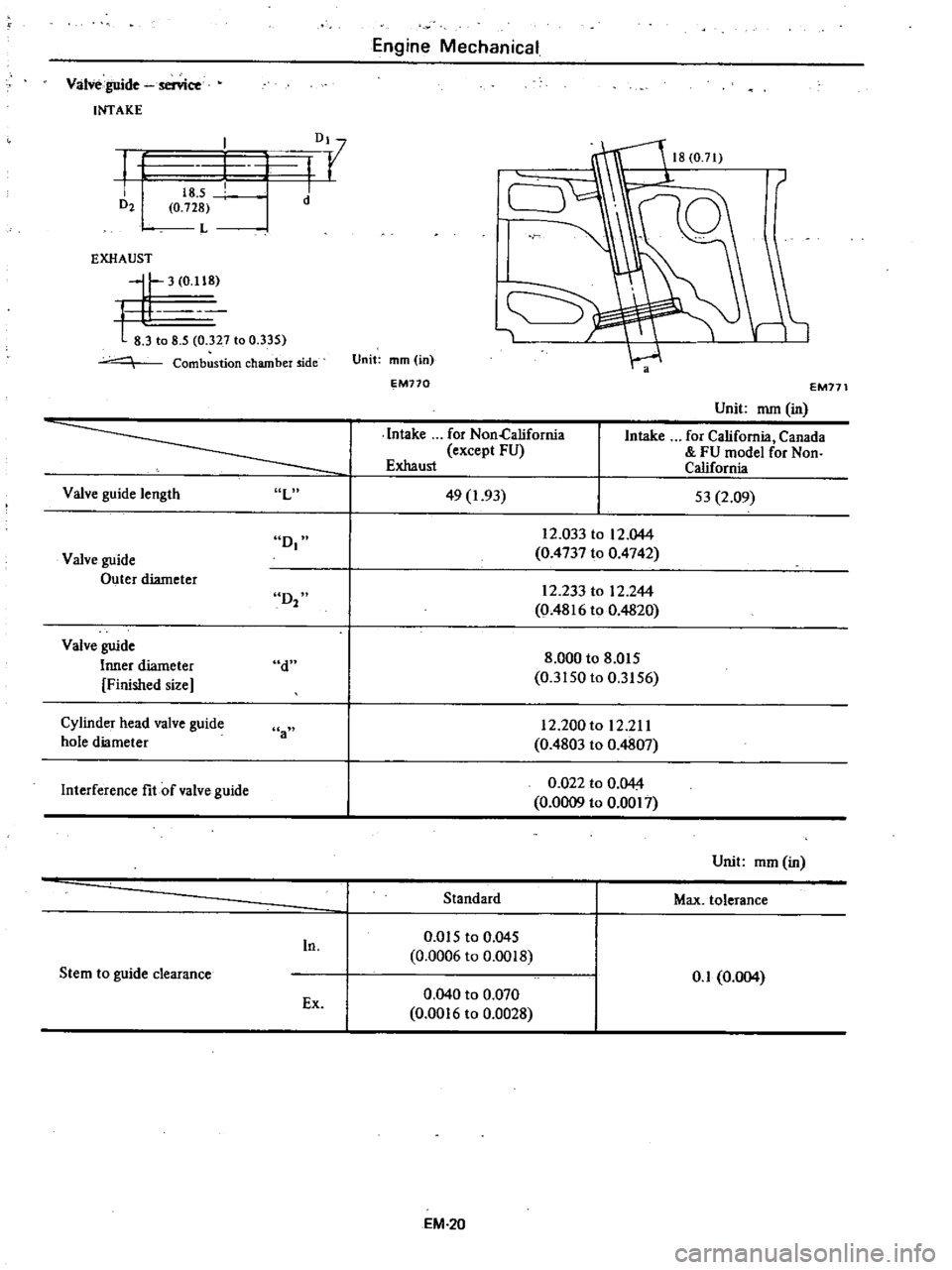

Valve

guide

senice

INTAKE

f

D21

Dl

I

r

I

I

I

d

18

5

0

728

L

EXHAUST

II

3

0

118

t

81

o

8

5

327

to

0

335

Combustion

chamber

ide

Valve

guide

length

L

D

Valve

guide

Outer

diameter

D2

Valve

guide

Inner

diameter

Finished

size

d

Cylinder

head

valve

guide

hole

diameter

a

Interference

fit

of

valve

guide

In

Stem

to

guide

clearance

Ex

Engine

Mechanical

1

Unit

mm

in

EM770

Intake

for

Non

California

except

FU

Exhaust

49

1

93

EM171

Unit

mm

in

Intake

for

California

Canada

FU

model

for

Non

California

53

2

09

12

0331012

044

0

4737

to

0

4742

12

233

to

12

244

0

4816

to

0

4820

8

000

to

8

015

0

3150

to

0

3156

12

200

to

12

211

0

4803

to

0

4807

0

022

to

0

044

0

0009

to

0

0017

Standard

0

Q15

to

0

045

0

0006

to

0

0018

0

040

to

0

070

0

0016

to

0

0028

EM

20

Unit

mm

in

Max

tolerance

0

1

0

004

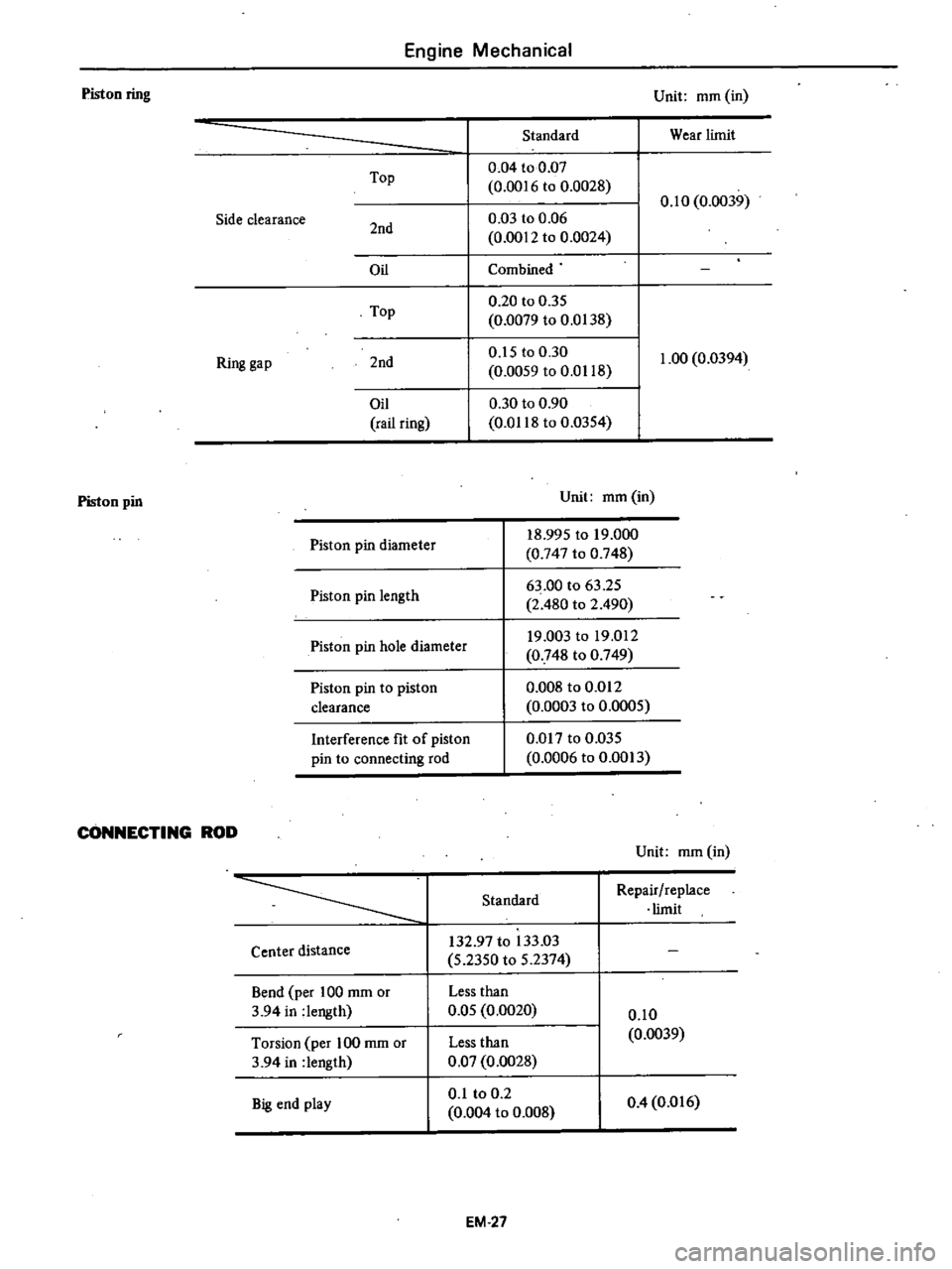

Page 64 of 548

Engine

Mechanical

Piston

ring

Unit

mm

in

Standard

Wear

limit

Top

0

04

to

0

07

0

0016

to

0

0028

0

10

0

0039

Side

clearance

2nd

0

03

to

0

06

0

0012

to

0

0024

Oil

Combined

Top

0

20

to

0

35

0

0079

to

0

0138

Ring

gap

2nd

0

15

to

0

30

1

00

0

0394

0

0059

to

0

0118

Oil

0

30

to

0

90

rail

ring

0

0118

to

0

0354

Piston

pin

Unit

mm

in

Interference

fit

of

piston

pin

to

connecting

rod

18

995

to

19

000

0

747

to

0

748

63

00

to

63

25

2

480

to

2

490

19

003

to

19

012

0

748

to

0

749

0

008

to

0

012

0

0003

to

0

0005

0

017

to

0

035

0

0006

to

0

0013

Piston

pin

diameter

Piston

pin

length

Piston

pin

hole

diameter

Piston

pin

to

piston

clearance

CONNECTING

ROD

Unit

mm

in

Standard

Repair

replace

limit

Center

distance

132

97

to

133

03

5

2350

to

5

2374

Bend

per

100

mm

or

3

94

in

length

Less

than

0

05

0

0020

0

10

0

0039

Torsion

per

100

mm

or

3

94

in

length

Big

end

play

Less

than

0

07

0

0028

0

1

to

0

2

0

004

to

0

008

0

4

0

016

EM

27

Page 76 of 548

Not

Pump

rotors

and

body

are

not

serv

iced

separatdy

If

pump

rotors

or

body

are

damaged

or

worn

replace

ment

of

the

entire

oil

pump

assembly

isnecessary

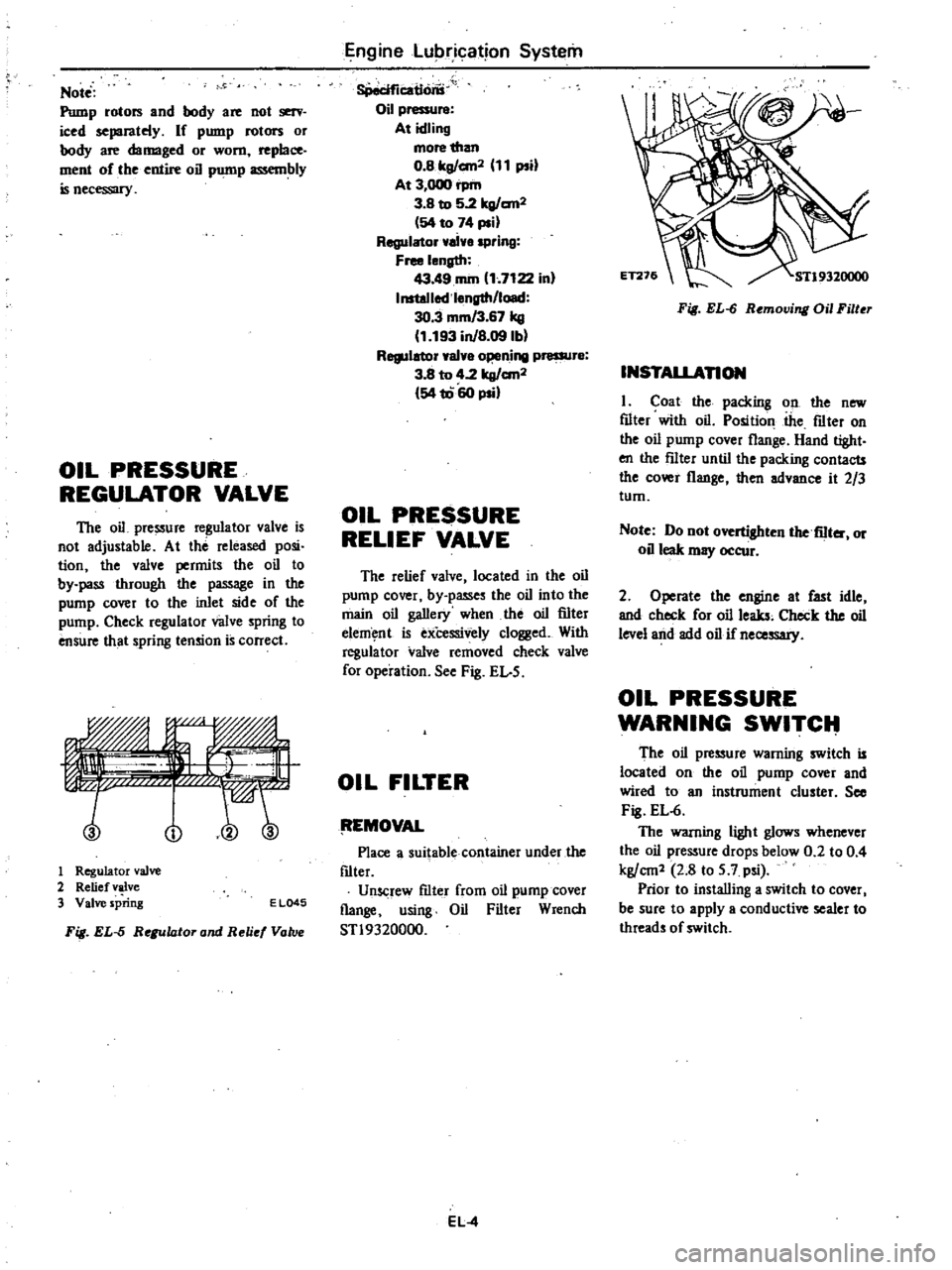

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

posi

tion

the

valve

permits

the

oil

to

by

pass

through

the

passage

in

the

pump

cover

to

the

inlet

side

of

the

pump

Check

regulator

valve

spring

to

ensure

that

spring

tension

is

correct

no

1

Regulator

valve

2

Relief

valve

3

Valve

spring

E

L045

Fig

EL

5

Regulator

and

Reli

Vatv

Engine

Lubrication

System

8Peciflcatlons

Oil

pressure

At

idling

more

than

O

Blrg

an2

11

psi

At

3

000

rpm

3

B

to

5

2lrg

an2

54

to

74

psi

Regulator

ai

spring

Free

length

43

49

rom

1

7122

in

InstoJlod

l

ngth

load

30

3

mm

3

67

kg

1

193

inJB

09lbl

Regulator

val

o

ning

pressur

3

8

to

4

2

lrg

an2

54

1060

psi

OIL

PRESSURE

RELIEF

VALVE

The

relief

valve

located

in

the

oil

pump

cover

by

passes

the

oil

into

the

main

oil

gallery

when

the

oil

filter

elem

nt

is

exCessively

clogged

With

regula

tor

valve

removed

check

valve

for

operation

See

Fig

EL

5

OIL

FILTER

tEMOVAL

Place

a

suitable

container

under

the

f1lter

Unscrew

f1lter

from

oil

pump

cover

flange

using

Oil

Filter

Wrench

STl9320000

EL

4

Fig

EL

6

Removing

Oil

Filter

INSTALLAnON

I

Coat

the

packing

on

the

new

f1lter

with

oil

Position

the

f1lter

on

the

oil

pump

cover

flange

Hand

tight

en

the

f11ter

until

the

packing

contacts

the

cover

flange

then

advance

it

2

3

tum

Note

Do

not

overtighten

the

fiIter

or

oil

leak

may

occur

2

Operate

the

engine

at

fast

idle

and

check

for

oil

leaks

Check

the

oil

level

and

add

oil

if

necessary

OIL

PRESSURE

WARNING

SWITCIt

The

oil

pressure

warning

switch

is

located

on

the

oil

pump

cover

and

wired

to

an

instrument

cluster

See

Fig

EL

6

The

warning

light

glows

whenever

the

oil

pressure

drops

below

0

2

to

0

4

kg

cm1

2

8

to

5

7

psi

Prior

to

installing

a

switch

to

cover

I

be

sure

to

apply

a

conductive

sealer

to

threads

of

switch

Page 77 of 548

Engine

Lubrication

System

SERVICE

DATA

AND

SPECIFICATIONS

Oil

pump

Standard

Wear

limit

Rotor

side

clearance

nun

in

0

04

to

0

08

0

20

0

0079

Rotor

to

bottom

cover

0

0016

to

0

0031

Rotor

tip

clearance

mm

in

less

than

0

20

0

0079

0

12

0

0047

Outer

rotor

to

body

clearance

nun

in

0

15

to

0

21

0

50

0

0197

0

0059

to

0

0083

Oil

pressure

regulator

valve

Oil

pressure

a

t

idling

Oil

pressure

at

3

000

rpm

Regulator

valve

spring

Free

length

Installed

length

load

kg

cm2

psi

kg

cm2

psi

more

than

0

8

II

3

8

to

5

2

54

to

74

nun

in

nun

kg

in

lb

43

49

I

7122

30

3

3

67

1

193

8

09

Tightening

torque

Oil

pump

securing

bolts

Oil

pump

cover

bolt

Regulator

valve

cap

nut

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

0

9

to

I

4

6

5

to

10

1

0

39

to

0

52

2

8

to

3

8

4

0

to

5

0

29

to

36

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Oil

leakage

Damaged

or

cracked

body

cover

Oil

leakage

from

gasket

Oil

leakage

from

regulator

valve

Oil

leakage

from

blind

plug

Replace

Replace

Tighten

or

replace

Replace

Decreased

oil

pressure

Leak

of

oil

in

engine

oil

pan

Dirty

oil

strainer

Damaged

or

worn

pump

rotors

Faulty

regulator

Used

of

poor

quality

engine

oil

Correct

Clean

or

replace

Replace

Adjust

or

replace

Replace

Noise

Excessive

backlash

in

pump

rotors

Replace

EL

5

Page 165 of 548

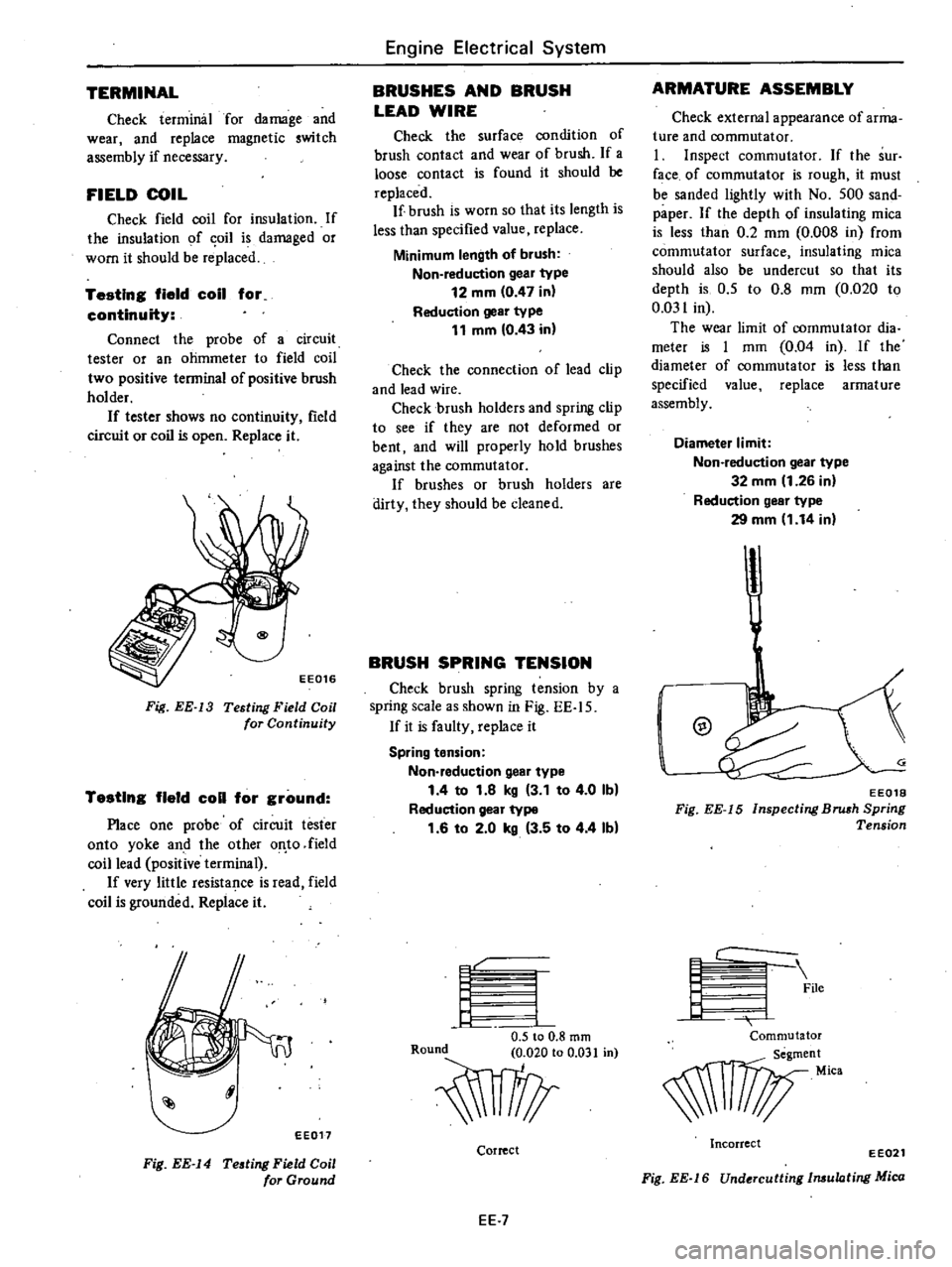

TERMINAL

Check

terminal

for

damage

and

wear

and

replace

magnetic

switch

assembly

if

necessary

FIELD

COIL

Check

field

coil

for

insulation

If

the

insulation

of

oil

is

damaged

or

worn

it

should

be

replaced

Testing

field

coil

for

continuity

Connect

the

probe

of

a

circuit

tester

or

an

ohmmeter

to

field

coil

two

positive

terminal

of

positive

brush

holder

If

tester

shows

no

continuity

field

circuit

or

coil

is

open

Replace

it

Fig

EE

13

Testing

Field

Coil

for

Continuity

Testing

field

coli

for

ground

Place

one

probe

of

circuit

tester

onto

yoke

and

the

other

of

to

field

coil

lead

positive

terminal

If

very

little

resistance

is

read

field

coil

is

grounded

Replace

it

I

EE017

Fig

EE

14

Testing

Field

Coil

for

Ground

Engine

Electrical

System

BRUSHES

AND

BRUSH

LEAD

WIRE

Check

the

surface

condition

of

brush

contact

and

wear

of

brush

If

a

loose

contact

is

found

it

should

be

replaced

If

brush

is

worn

so

that

its

length

is

less

than

specified

value

replace

Minimum

length

of

brush

Non

reduction

gear

type

12

mm

0

47

in

Reduction

gear

type

11

mm

0

43

in

Check

the

connection

of

lead

clip

and

lead

wire

Check

brush

holders

and

spring

clip

to

see

if

they

are

not

deformed

or

bent

and

will

properly

hold

brushes

against

the

commutator

If

brushes

or

brush

holders

are

dirty

they

should

be

cleaned

BRUSH

SPRING

TENSION

Check

brush

spring

tension

by

a

spring

scale

as

shown

in

Fig

EE

l

5

If

it

is

faulty

replace

it

Spring

tension

Non

reduction

geaf

type

1

4

to

1

8

kg

3

1

to

4

0

Ib

Reduction

gear

type

1

6

to

2

0

kg

3

5

to

4

4

Ib

I

r

4

1

0

5

to

0

8

rom

O

iO

Correct

EE

7

ARMATURE

ASSEMBLY

Check

external

appearance

of

arma

ture

and

oommutator

I

Inspect

commutator

If

the

sur

face

of

commutator

is

rough

it

must

be

sanded

lightly

with

No

500

sand

paper

If

the

depth

of

insulating

mica

is

less

than

0

2

mm

0

008

in

from

commutator

surface

insulating

mica

should

also

be

undercut

so

that

its

depth

is

0

5

to

0

8

mm

0

020

to

0

031

in

The

wear

limit

of

commutator

dia

meter

is

I

mm

0

04

in

If

the

diameter

of

commutator

is

less

than

specified

value

replace

armature

assembly

Diameter

limit

Non

reduction

gear

type

32

mm

1

26

in

Reduction

gear

type

29

mm

1

14

in

I

@

EE018

Fig

EE

15

Inspecting

Bnah

Spring

Tension

c

I

File

Commutator

nt

I

1

11

Mica

Incorrect

EE021

Fig

EE

16

Undercutting

Imulating

Mica

Page 190 of 548

Engine

Electrical

System

STARTING

MOTOR

Type

S1I4

160B

I

Sl14

163E

S114

253

Outer

diameter

of

commutator

mm

in

More

than

32

1

26

More

than

29

L14

Minimum

length

of

brush

mm

in

12

0

47

II

0

43

Brush

spring

tension

kg

Ib

1

4

to

1

8

3

1

to

4

0

1

6to

2

0

3

5

to

4

4

Clearance

between

bearing

metal

and

armature

shaft

mm

in

Less

than

0

2

0

008

Clearance

R

between

pinion

front

edge

and

pinioIl

stopper

mm

in

0

3

to

2

5

0

012

to

0

098

Difference

T

in

height

of

pinion

nun

in

0

3

to

1

5

0

012

to

0

059

ALTERNATOR

Type

LRI5049

Minimum

length

of

brush

mm

in

More

than

7

5

0

295

Brush

spring

pressure

gr

oz

255

to

345

8

99

to

12

17

Slip

ring

outer

diameter

nun

in

More

than

30

1

18

DISTRIBUTOR

Air

gap

mm

in

D4K8

19

I

D4K8

l3

I

D4K8

18

I

D4K8

02

D4K8

15

I

D4K8

16

0

3

to

0

5

0

012

to

0

020

Type

Cap

il1s

ation

resistance

M

1

More

than

50

Rotor

head

insulation

resistance

Mil

More

than

50

Cap

carbon

point

length

mm

in

10

0

39

Vacuum

advance

0

105

4

13

0

170

6

69

0

80

3

15

0

105

4

13

0

70

2

76

0

170

6

69

Distributor

degree

distributor

9

250

3

225

12

265

9

300

15

300

6

5

300

mmHg

inHg

9

84

8

86

10

43

11

81

11

81

11

81

Centrifugal

advance

0

550

6

550

0

550

0

550

0

750

0

750

Distributor

degree

distributor

14

2

300

14

2

300

13

5

2

400

13

5

2

400

10

2

400

10

2

400

rpm

EE

32

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37