remove seats DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 44 of 548

5

Fit

insert

ensuring

that

it

seats

on

bottom

face

of

its

recess

6

Newly

fitted

valve

seat

should

be

cut

or

ground

with

suitable

seat

cutter

or

grinding

stone

7

Apply

smalliunount

of

fine

grind

ing

compound

to

valve

contacting

face

and

put

valve

into

guide

Lap

valve

against

its

seat

ntil

proper

valve

seat

ing

is

obtained

Remove

valve

and

clean

valve

and

valve

seat

VALVE

ROCKER

ARM

1

AND

SHAFT

I

Check

rocker

arm

bore

and

shaft

for

scores

or

scuffs

2

Check

clearance

between

each

rocker

arm

and

shaft

by

measuring

inner

diameter

of

rocker

arm

bore

and

outer

diameter

of

shaft

If

either

clearance

is

not

within

spec

ification

replace

rocker

arm

and

or

shaft

3

Check

valve

end

contact

surface

of

rocker

arm

for

abnormal

wear

or

scuffs

VALVE

LIFTER

AND

PUSH

ROD

I

Check

valve

lifter

for

wear

or

scuffs

Check

bottom

end

of

valve

lifter

to

make

sure

it

has

a

slight

convex

Replace

valve

lifters

that

are

scored

worn

or

have

unsmooth

bot

tom

2

Check

clearance

between

lifter

hole

on

cylinder

block

and

valve

lifter

Replace

valve

lifter

if

clearance

ex

ceeds

wear

limit

3

Check

push

rod

for

bending

and

damage

Check

end

of

push

rod

for

rough

ness

or

excessive

wear

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAFT

BEARING

CLEARANCE

Journal

diameters

should

be

check

ed

with

a

micrometer

and

bearings

with

an

inside

dial

gauge

Measure

ments

should

then

be

compared

to

Engine

Mechanical

determine

whether

bearings

are

worn

If

worn

beyond

0

15

mm

0

0059

in

replace

using

Camshaft

Bearing

Drift

STl6Il0000

In

press

fitting

a

new

bearing

make

certain

that

oil

holes

in

block

and

bearing

are

properly

aligned

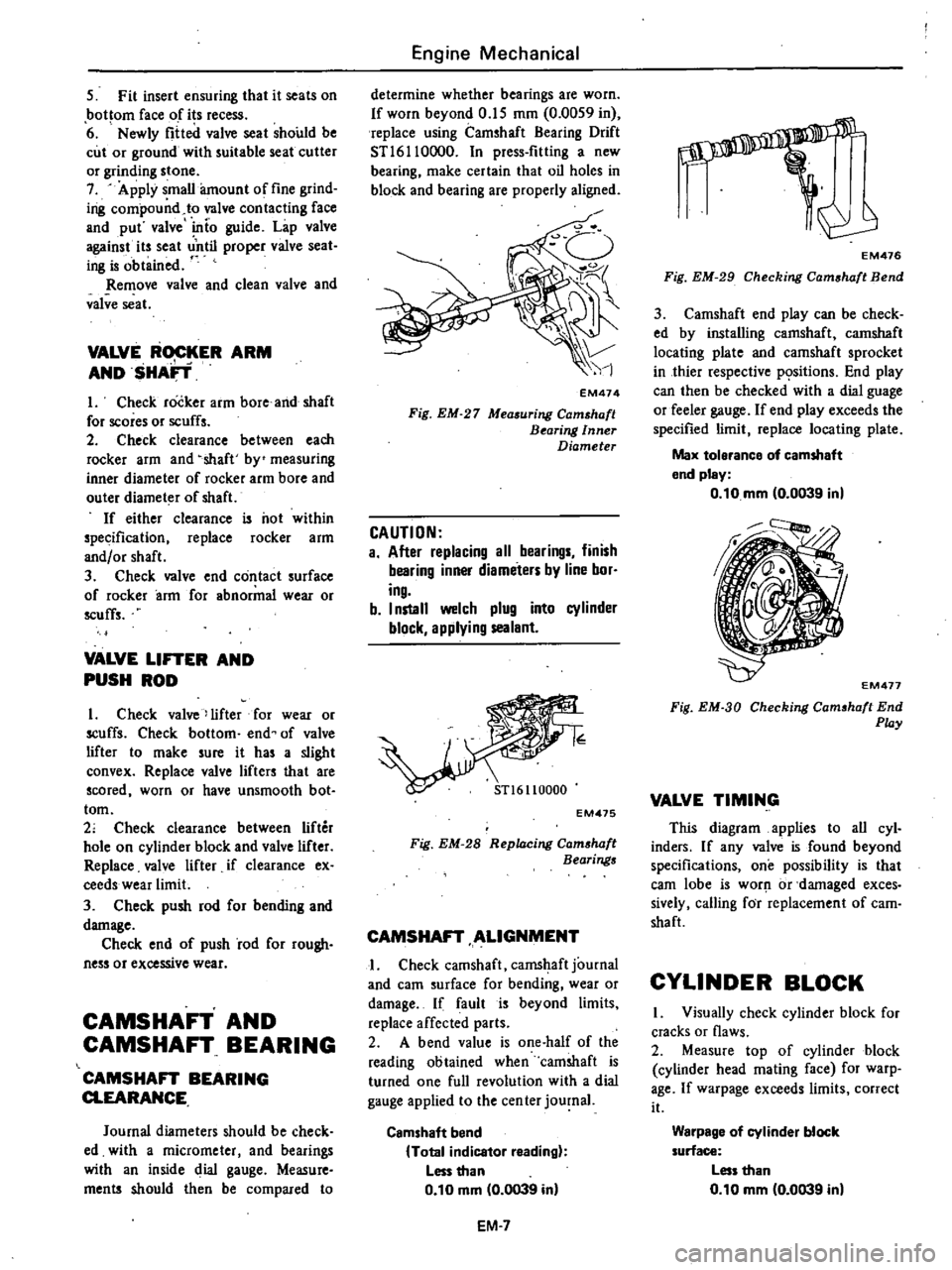

EM474

Fig

EM

27

Measuring

Camshaft

Bearing

Inner

Diameter

CAUTION

a

After

replacing

all

bearings

finish

bearing

inner

diameters

by

line

bor

ing

b

I

nstall

welch

plug

into

cylinder

block

applying

sealant

EM475

Fig

EM

28

Replacing

Cam

haft

Bearings

CAMSHAFT

ALIGNMENT

I

Check

camshaft

camshaft

journal

and

earn

surface

for

bending

wear

or

damage

If

fault

is

beyond

limits

replace

affected

parts

2

A

bend

value

is

one

half

of

the

reading

obtained

when

camshaft

is

turned

one

full

revolution

with

a

dial

gauge

applied

to

the

cen

ter

journal

Camshaft

bend

Total

indicator

reading

Less

than

0

10

mm

0

0039

in

EM

7

s

EM476

Fig

EM

29

Checking

Cam

haft

Bend

3

Camshaft

end

play

can

be

check

ed

by

installing

camshaft

camshaft

locating

plate

and

camshaft

sprocket

in

thier

respective

p

sitions

End

play

can

then

be

checked

with

a

dial

guage

or

feeler

gauge

If

end

play

exceeds

the

specified

limit

replace

locating

plate

Max

tolerance

of

camshaft

end

pley

0

10

mm

0

0039

in

EM477

Fig

EM

3D

Checking

Cam

haft

End

Play

VALVE

TIMING

This

diagram

applies

to

all

cyl

inders

If

any

valve

is

found

beyond

specifications

one

possibility

is

that

earn

lobe

is

worJ

1

or

damaged

exces

sively

calling

for

replacement

of

cam

shaft

CYLINDER

BLOCK

I

Visually

check

cylinder

block

for

cracks

or

flaws

2

Measure

top

of

cylinder

block

cylinder

head

mating

face

for

warp

age

If

warpage

exceeds

limits

correct

it

Warpage

of

cylinder

block

surface

Less

than

0

10

mm

0

0039

in

Page 49 of 548

PRECAUTION

Before

assembling

engine

observe

following

precautions

I

Clean

all

disass

mbled

parts

with

clean

solvent

All

611

holes

in

crank

shaft

camshaft

valve

rocker

shaft

etc

should

be

thoroughly

cleaned

to

re

move

all

traces

of

grinding

chips

or

lint

Always

use

clean

solvent

2

In

general

used

gaskets

packings

and

oil

seals

should

be

replaced

3

Under

no

circumstances

should

lockwashers

be

reuse

d

4

Place

bolts

nuts

and

woshers

back

in

their

original

parts

or

from

which

they

were

removed

5

MOst

packing

Serve

best

when

liquid

packing

is

applied

to

sealing

surfaces

When

desigiiated

use

suitable

liquid

packing

to

eliminate

possibility

of

water

oil

and

gas

leak

6

Prior

to

assemQling

all

sliding

surfaces

should

be

lioerally

oiled

7

Proper

tightening

is

essential

to

successful

performanCe

of

all

car

re

pairs

It

is

also

important

to

follow

correct

tightenig

sequence

in

pulling

up

cylinder

head

Be

on

alert

at

all

times

to

amount

of

clearance

per

mitted

8

Cleanliness

of

tools

or

parts

such

as

work

bench

used

jn

making

a

repai

is

essential

When

setting

up

a

job

every

precaution

should

be

taken

that

tools

or

parts

are

free

of

dirt

mud

and

oil

Do

not

work

in

dust

and

grit

for

they

are

primary

cause

of

wear

in

any

engine

CYLINDER

HEAD

I

Install

valve

spring

seat

Install

valve

oil

seal

by

lightly

tapping

its

head

with

a

plastic

hammer

through

Valve

Lip

Seal

Drift

KVI0104800

Engine

Mechanical

ENGINE

ASSEMBLY

m

f

if

@

@

4

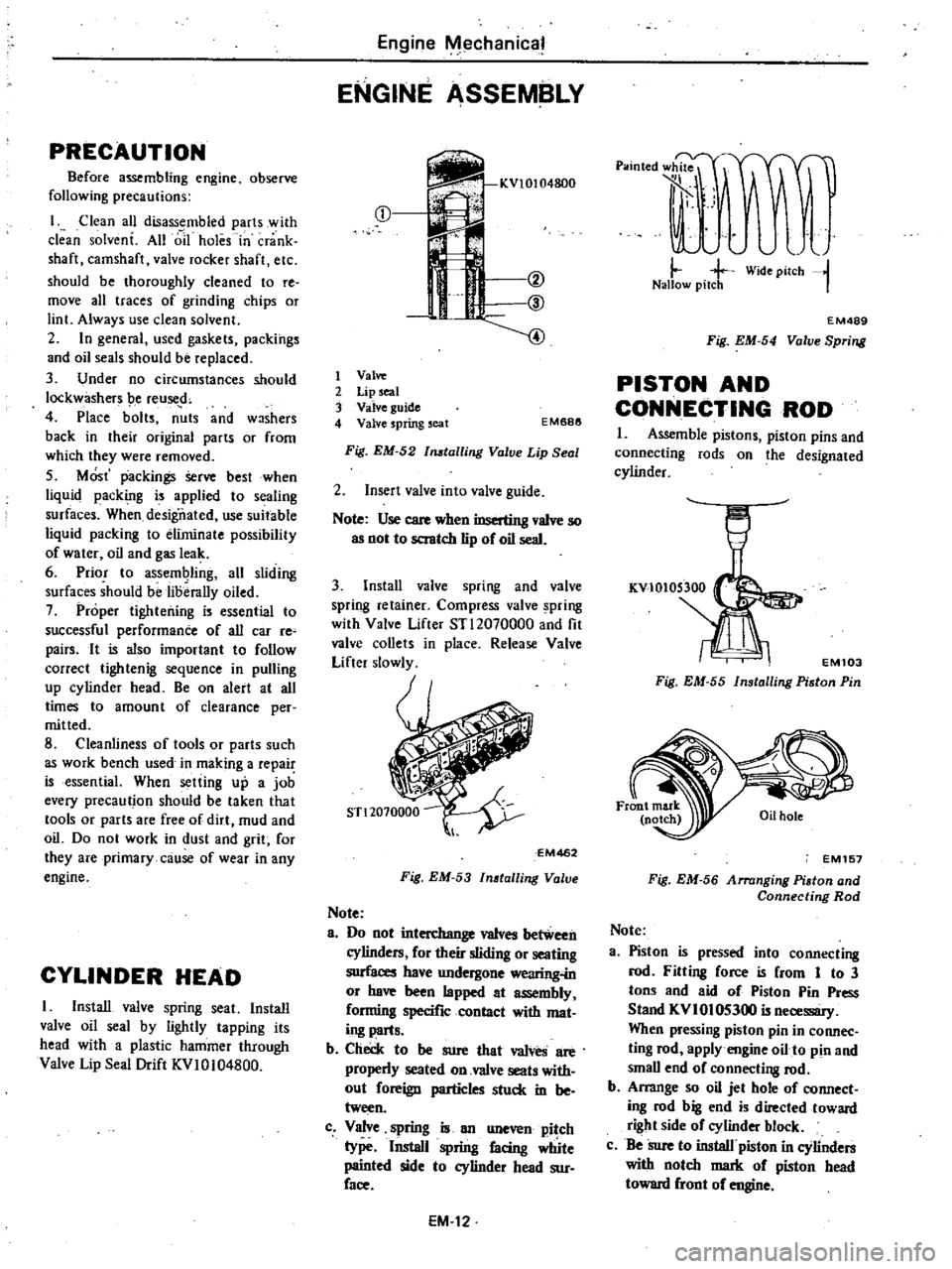

1

Valve

2

Lip

seal

3

Valve

guide

4

Valve

spring

seat

EM688

Fig

EM

52

tailing

Valve

Lip

Seal

2

Insert

valve

into

valve

guide

Note

Use

care

when

inserting

valve

so

as

not

to

scratch

lip

of

oil

seal

3

Install

valve

spring

and

valve

spring

retainer

Compress

valve

pring

with

Valve

Lifter

STl2070000

and

fit

valve

collets

in

place

Release

Valve

Lifter

slowly

EM462

Fig

EM

53

Inatalling

Valve

Note

8

Do

not

interchange

valves

between

cylinders

for

their

sliding

or

seating

surfaces

have

undergone

wearing

in

or

have

been

lapped

at

assembly

forming

specific

contact

with

mat

ing

parts

b

Check

to

be

sure

that

valves

are

properly

seated

on

valve

seats

with

out

foreign

particles

stuck

in

be

tween

c

Valve

spring

is

an

uneven

pitch

type

Install

spring

facing

Wte

painted

side

to

cylinder

head

sur

face

EM

12

p

lOted

l

rJF

t

A

J

il

j

j

Wide

pilCh

l

Nallow

pitch

I

EM489

Fig

EM

54

Valve

Spring

PISTON

AND

CONNECTING

ROD

I

Assemble

pistons

piston

pins

and

connecting

rods

on

the

designated

cylinder

EM103

Fig

EM

55

Installing

Piston

Pin

EM157

Fig

EM

56

Arranging

Piaton

and

Connecting

Rod

Note

3

Piston

is

pressed

into

connecting

rod

Fitting

force

is

from

1

to

3

tons

and

aid

of

Piston

Pin

Press

Stand

KVI

01

05300

is

necessary

When

pressing

piston

pin

in

connec

ting

rod

apply

engine

oil

to

pin

and

small

end

of

connecti

8

rod

b

Arrange

so

oil

jet

hole

of

connect

ing

rod

big

end

is

directed

toward

right

side

of

cylinder

block

c

Be

Sure

to

install

piston

in

cylinders

with

notch

mark

of

piston

head

toward

front

of

engine

Page 331 of 548

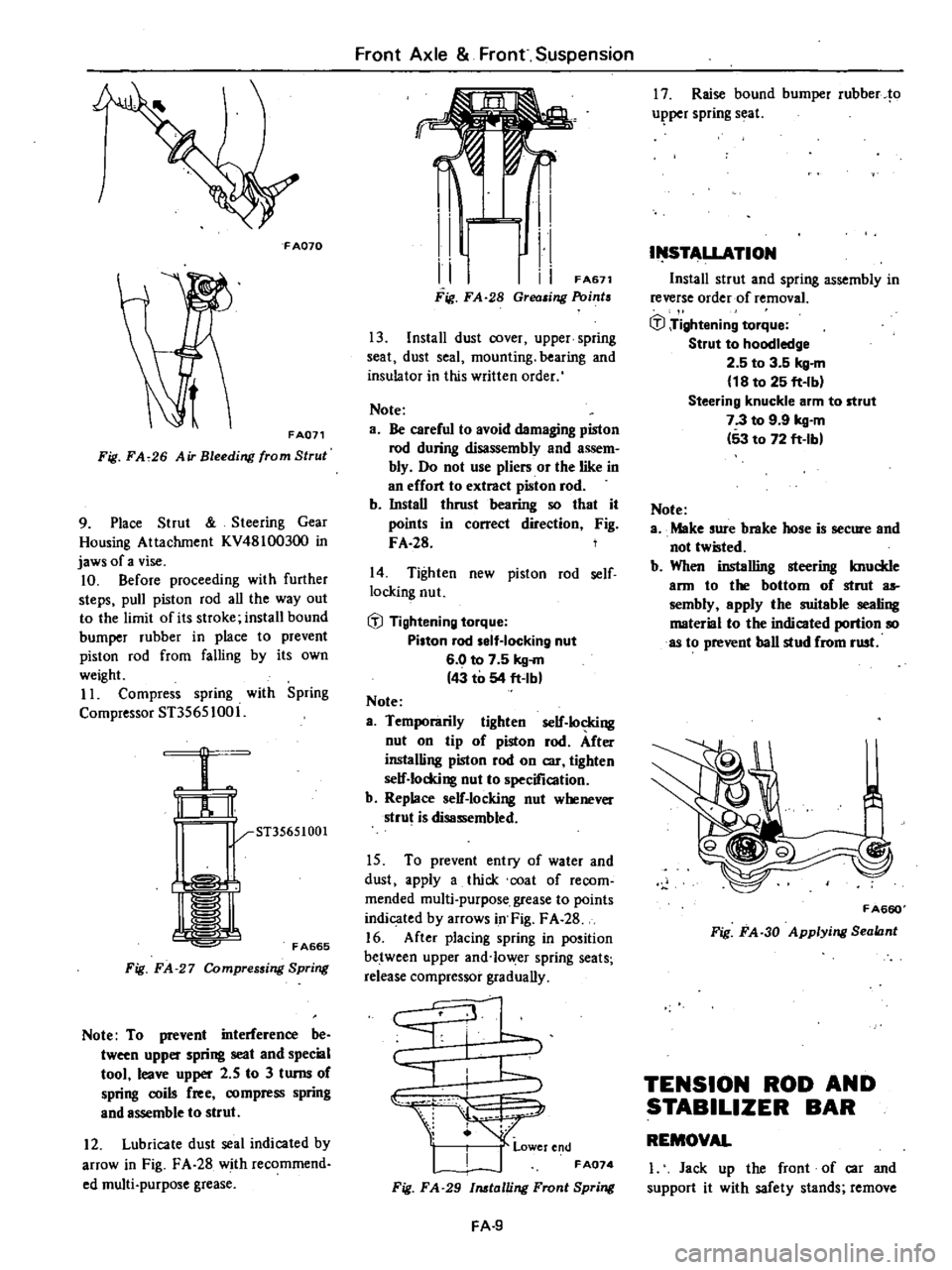

FA070

FA071

Fig

FA

26

Air

Bleeding

from

Strul

9

Place

Strut

Steering

Gear

Housing

Attachment

KV48100300

in

jaws

of

a

vise

10

Before

proceeding

with

further

steps

pull

piston

rod

all

the

way

out

to

the

limit

of

its

stroke

install

bound

bumper

rubber

in

place

to

prevent

piston

rod

from

falling

by

its

own

weight

11

Compress

spring

with

Spring

Compressor

ST35651001

ST35651001

r

l

I

FA665

Fig

FA

27

Compressing

Spring

Note

To

prevent

interference

be

tween

upper

spring

seat

and

special

tool

leave

upper

2

5

to

3

turns

of

spring

coils

free

compress

spring

and

assemble

to

strut

12

Lubricate

dust

seal

indicated

by

arrow

in

Fig

FA

28

with

recommend

ed

multi

purpose

grease

Front

Axle

Front

Suspension

I

1

i

I

FA671

Fig

FA

28

Grea

ing

Point

13

Install

dust

cover

upper

spring

seat

dust

seal

mounting

bearing

and

insulator

in

this

written

order

Note

a

Be

careful

to

avoid

damaging

piston

rod

during

disassembly

and

assem

bly

Do

not

use

pliers

or

the

like

in

an

effort

to

extract

piston

rod

b

InstaU

thrust

bearing

so

that

it

points

in

correct

direction

Fig

FA

28

14

Tighten

new

piston

rod

self

locking

nut

fil

Tightening

torque

Pi

ton

rod

elf

Iocking

nut

6

0

to

7

5

kg

m

43

to

54

ft

lbl

Note

a

Temporarily

tighten

self

locking

nut

on

tip

of

piston

rod

After

installing

piston

rod

on

car

tighten

self

locking

nut

to

specification

b

Replace

self

locking

nut

whenever

strut

is

disassembled

15

To

prevent

entry

of

water

and

dust

apply

a

thick

coat

of

recom

mended

multi

purpose

grease

to

points

indicated

by

arrows

in

Fig

F

A

28

16

After

placing

spring

in

position

between

upper

and

lo

er

spring

seats

release

compressor

graduaUy

I

J

k

1

jt

r

end

FA074

Fig

FA

29

talling

Front

Spring

FA

9

17

Raise

bound

bumper

rubber

10

u

per

spring

seal

I

STALLATION

Install

strut

and

spring

assembly

in

reverse

order

of

removaL

fil

Tightening

torque

Strut

to

hoodledge

2

5

to

3

5

kg

m

18

to

25

ft

Ib

Steering

knuckle

arm

to

strut

7

3

to

9

9

kg

m

53

to

72

ft

lb

Note

a

Make

sure

brake

hose

is

secure

and

not

tw

ted

b

When

installing

steering

knuckle

ann

to

the

bottom

of

strut

as

sembly

epply

the

suitable

sealing

material

to

the

indicated

portion

so

as

to

prevent

ball

stud

from

rust

FA660

Fig

FA

30

Applying

Sealant

TENSION

ROD

AND

STABILIZER

BAR

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

with

safety

stands

remove

Page 380 of 548

The

symptom

of

unbalance

appears

as

tramps

car

shake

and

steering

mal

function

To

correct

unbalance

use

proper

wheel

balancer

Maximum

allowable

unbalance

at

rim

flange

10

gr

10

35

ozl

Balance

weight

10

to

60

gr

10

35

to

2

12

ozl

at

10

gr

10

35

ozl

interval

Note

a

Be

sure

to

place

correct

balance

weights

on

inner

edge

of

rim

See

Fig

wr

6

b

Do

not

put

mOle

than

two

weights

on

each

side

c

Two

types

of

balance

weights

are

used

one

is

designed

for

use

with

steel

wheel

and

the

other

for

use

with

aluminum

wheel

Do

not

mix

different

types

of

balance

weights

WHEEL

In

order

to

ensure

satisfactory

steering

condition

as

well

as

maximum

tire

life

proceed

follows

Check

wheel

rim

especially

rim

flange

and

bead

seat

for

rust

distor

tion

cracks

or

other

faults

which

might

cause

air

leaks

Function

of

tubeless

tire

depends

on

a

good

seal

between

tire

bead

and

wheel

rim

Thoroughly

remove

rust

dust

oxi

dized

rubber

or

sa

nd

from

wheel

rim

Note

Rim

bead

seats

should

be

clean

ed

with

the

following

Steel

wheel

Wile

brush

coone

steel

wool

etc

Aluminum

wheel

Neutral

detergent

cloth

etc

Use

dial

gauge

to

examine

wheel

rim

for

lateral

and

radial

runout

Wheel

and

Tire

Lateral

and

radial

runout

Steel

wheel

less

than

1

2

mm

0

047

in

Aluminumwlte

1

lass

than

0

5

mm

10

020

in

Difference

right

and

left

lateral

runout

Steel

wheel

leu

than

0

5

mm

10

020

in

Aluminum

wheel

less

than

0

2

mm

0

008

in

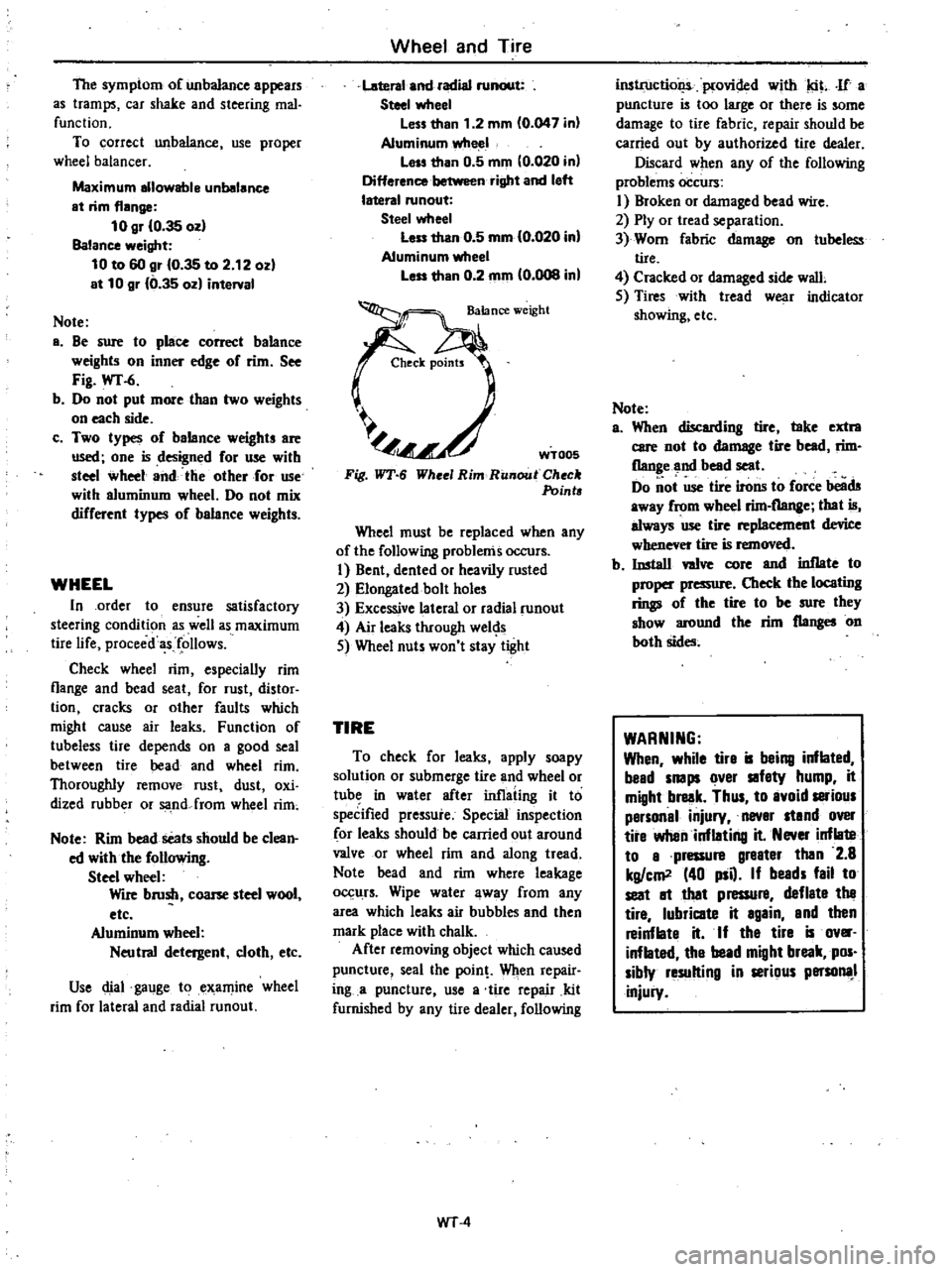

C

JeCk

points

l

Fig

WT

6

WT005

Whee

Rim

RUllout

Check

Points

Wheel

must

be

replaced

when

any

of

the

following

problems

occurs

I

Bent

dented

or

heavily

rusted

2

Elongated

bolt

holes

3

Excessive

lateral

or

radial

runout

4

Air

leaks

through

wel

s

5

Wheel

nuts

won

t

stay

tight

TIRE

To

check

for

leaks

apply

soapy

solution

or

submerge

tire

and

wheel

or

tub

in

water

after

inflating

it

to

speCified

pressure

Special

inspection

for

leaks

should

be

carried

out

around

valve

or

wheel

rim

and

along

tread

Note

bead

and

rim

where

leakage

0

11rs

Wipe

water

away

from

any

area

which

leaks

air

bubbles

and

then

mark

place

with

chalk

After

removing

object

which

caused

puncture

seal

the

pain

Wilen

repair

ing

a

puncture

use

a

tire

repair

kit

furnished

by

any

tire

dealer

following

WT

4

inslrt1ctiol

iplovided

with

tit

If

a

puncture

is

too

large

or

there

is

some

damage

to

tire

fabric

repair

should

be

carried

out

by

authorized

tire

dealer

Discard

when

any

of

the

following

problems

occurs

I

Broken

or

damaged

bead

wire

2

Ply

or

tread

separation

3

Worn

fabric

damage

on

tubeless

tire

4

Cracked

or

damaged

side

wall

5

Tires

with

tread

wear

indicator

showing

etc

Note

a

When

discarding

tire

take

extra

care

not

to

damage

tire

bead

rim

flange

and

bead

seat

Do

ot

use

tire

irons

to

foree

beads

away

from

wbeel

rim

flange

that

is

always

use

tire

replacement

device

whenever

tire

is

removed

b

Install

wive

core

and

inflate

to

proper

pressure

Check

the

locating

rings

of

the

tire

to

be

sure

they

show

around

the

rim

flanges

on

both

sides

WARNING

When

while

tire

is

being

inflated

bead

snaps

over

safety

hump

it

might

break

Thus

to

avoid

satious

personal

injury

never

stand

over

tire

when

inflating

it

Never

inflate

to

a

pressure

greater

then

2

8

kg

em

40

psQ

If

beads

fail

to

seat

It

that

pressure

deflate

the

tire

lubricate

it

again

and

then

reinflate

it

If

the

tire

is

ov

inflated

the

bead

might

break

pos

sibly

resulting

in

serious

persona

injury

Page 432 of 548

Body

WINDSHIELD

AND

WINDOW

GLASS

WINDSHIELD

GLASS

00

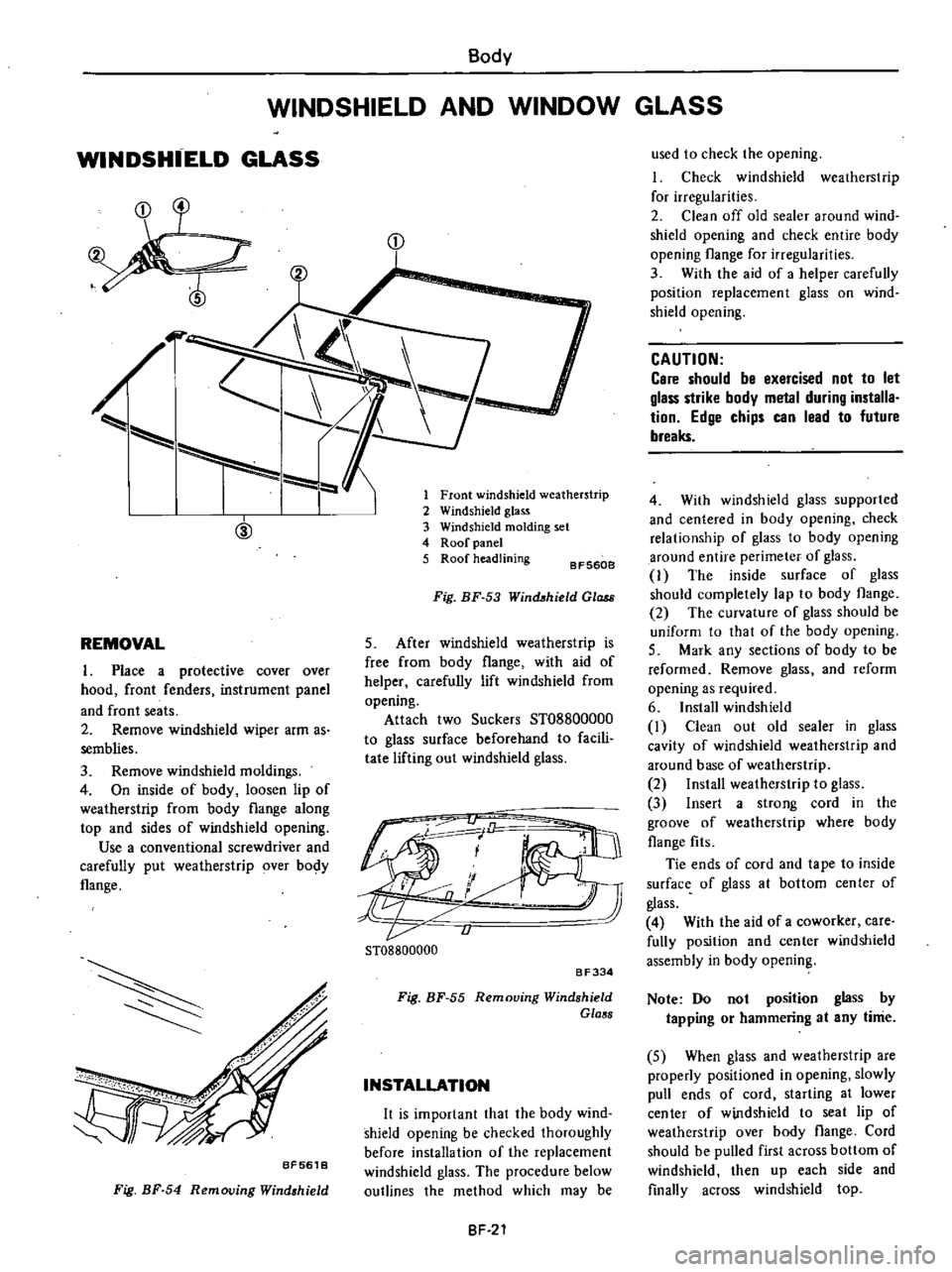

REMOVAL

I

Place

a

protective

cover

over

hood

front

fenders

instrument

panel

and

front

seats

2

Remove

windshield

wiper

arm

as

semblies

3

Remove

windshield

moldings

4

On

inside

of

body

loosen

lip

of

weatherstrip

from

body

flange

along

top

and

sides

of

windshield

opening

Use

a

conventional

screwdriver

and

carefully

put

weatherstrip

over

body

flange

BF5618

Fig

BF

54

Removing

Wind

hield

D

1

Front

windshield

weatherstrip

2

Windshield

glass

3

Windshield

molding

set

4

Roof

panel

5

Roof

headlining

BF5608

Fig

BF

53

Winct

hield

Ol

5

After

windshield

weatherstrip

is

free

from

body

flange

with

aid

of

helper

carefully

lift

windshield

from

opening

Attach

two

Suckers

ST08800000

to

glass

surface

beforehand

to

facili

tate

lifting

out

windshield

glass

Li

ST08800000

BF334

Fig

BF

55

Removing

Windshield

Glass

INSTALLATION

It

is

important

that

the

body

wind

shield

opening

be

checked

thoroughly

before

installation

of

the

replacement

windshield

glass

The

procedure

below

outlines

the

method

which

may

be

BF

21

used

to

check

the

opening

I

Check

windshield

weatherstrip

for

irregularities

2

Clean

off

old

sealer

around

wind

shield

opening

and

check

entire

body

opening

flange

for

irregularities

3

With

the

aid

of

a

helper

carefully

position

replacement

glass

on

wind

shield

opening

CAUTION

Care

should

be

exercised

not

to

let

glass

strike

body

metal

during

installa

tion

Edge

chips

can

lead

to

future

breaks

4

With

windshield

glass

supported

and

centered

in

body

opening

check

relationship

of

glass

to

body

opening

around

entire

perimeter

of

glass

I

The

inside

surface

of

glass

should

completely

lap

to

body

flange

2

The

curvature

of

glass

should

be

uniform

to

that

of

the

body

opening

5

Mark

any

sections

of

body

to

be

reformed

Remove

glass

and

reform

opening

as

required

6

Install

windshield

I

Clean

out

old

sealer

in

glass

cavity

of

windshield

weatherstrip

and

around

base

of

weatherstrip

2

Install

weatherstrip

to

glass

3

Insert

a

strong

cord

in

the

groove

of

weatherstrip

where

body

flange

fits

Tie

ends

of

cord

and

tape

to

inside

surface

of

glass

at

bottom

center

of

glass

4

With

the

aid

of

a

coworker

care

fully

position

and

center

windshield

assembly

in

body

opening

Note

Do

not

position

glass

by

tapping

or

hammering

at

any

time

5

When

glass

and

weatherstrip

are

properly

positioned

in

opening

slowly

pull

ends

of

cord

starting

at

lower

center

of

windshield

to

seat

lip

of

weatherstrip

over

body

flange

Cord

should

be

pulled

first

across

bottom

of

windshield

then

up

each

side

and

finally

across

windshield

top