spark plugs replace DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 18 of 548

pl

ice

mter

as

an

assembly

2

When

installing

oil

mter

tighten

by

hand

Note

Do

not

overtighten

oil

filter

lest

leakage

shoUld

occur

CHANGING

ENGINE

COOLANT

PERMANENT

ANTI

FREEZE

COOLANT

Note

The

permanent

anti

freeze

coolant

is

an

ethylene

glya

l

base

product

containing

chemical

in

hibitors

to

protect

the

cooling

system

from

rusting

and

corrosion

The

anti

freeze

does

not

cOntain

any

glycerine

or

ethyl

alcohol

It

will

not

evaporate

or

boil

a

ay

and

can

be

ilsed

with

either

high

or

low

temperature

thermostats

It

flows

freely

transfers

heat

efficiently

and

will

not

clog

the

passages

in

the

cooling

system

The

anti

freeze

must

not

be

mixed

with

other

product

This

coolant

can

be

used

throughout

the

seasons

of

the

year

Whenever

coolant

is

changed

the

cooling

system

must

be

flushed

and

refilled

with

a

new

coolant

Check

the

coolant

level

See

instructions

attached

to

the

anti

freeze

container

for

mixing

ratio

of

anti

freeze

to

water

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

Check

hoses

and

fittings

for

loose

connections

or

deterioration

Re

tighten

or

replace

if

necessary

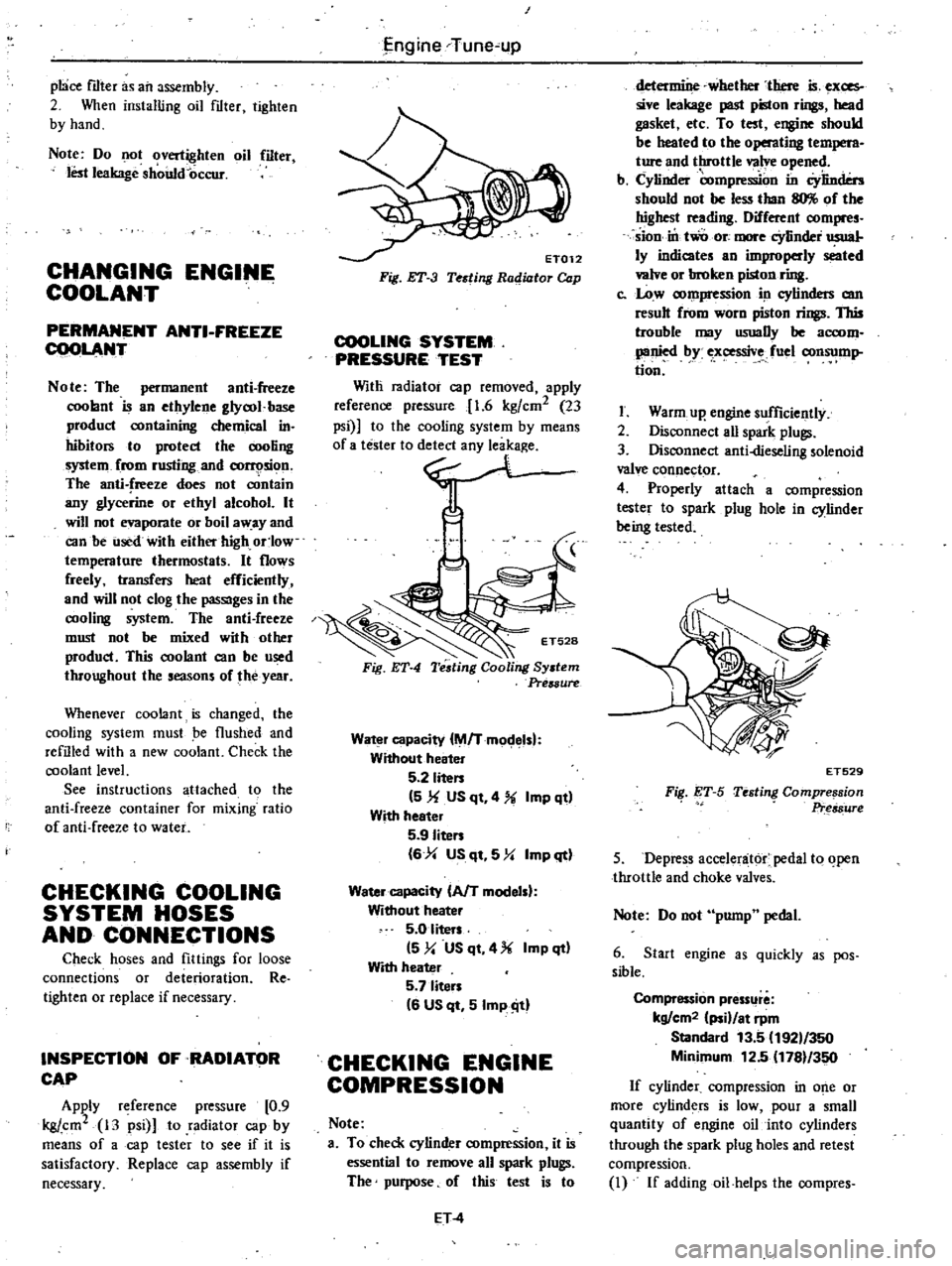

INSPECTION

OF

RADIATOR

CAP

Apply

reference

pressure

0

9

kgj

cm2

13

psi

to

radiator

cap

by

means

of

a

cap

tester

to

see

if

it

is

satisfactory

Replace

cap

assembly

if

necessary

I

j

ngine

Tune

up

ET012

Fig

ET

3

Testing

Radiator

Cap

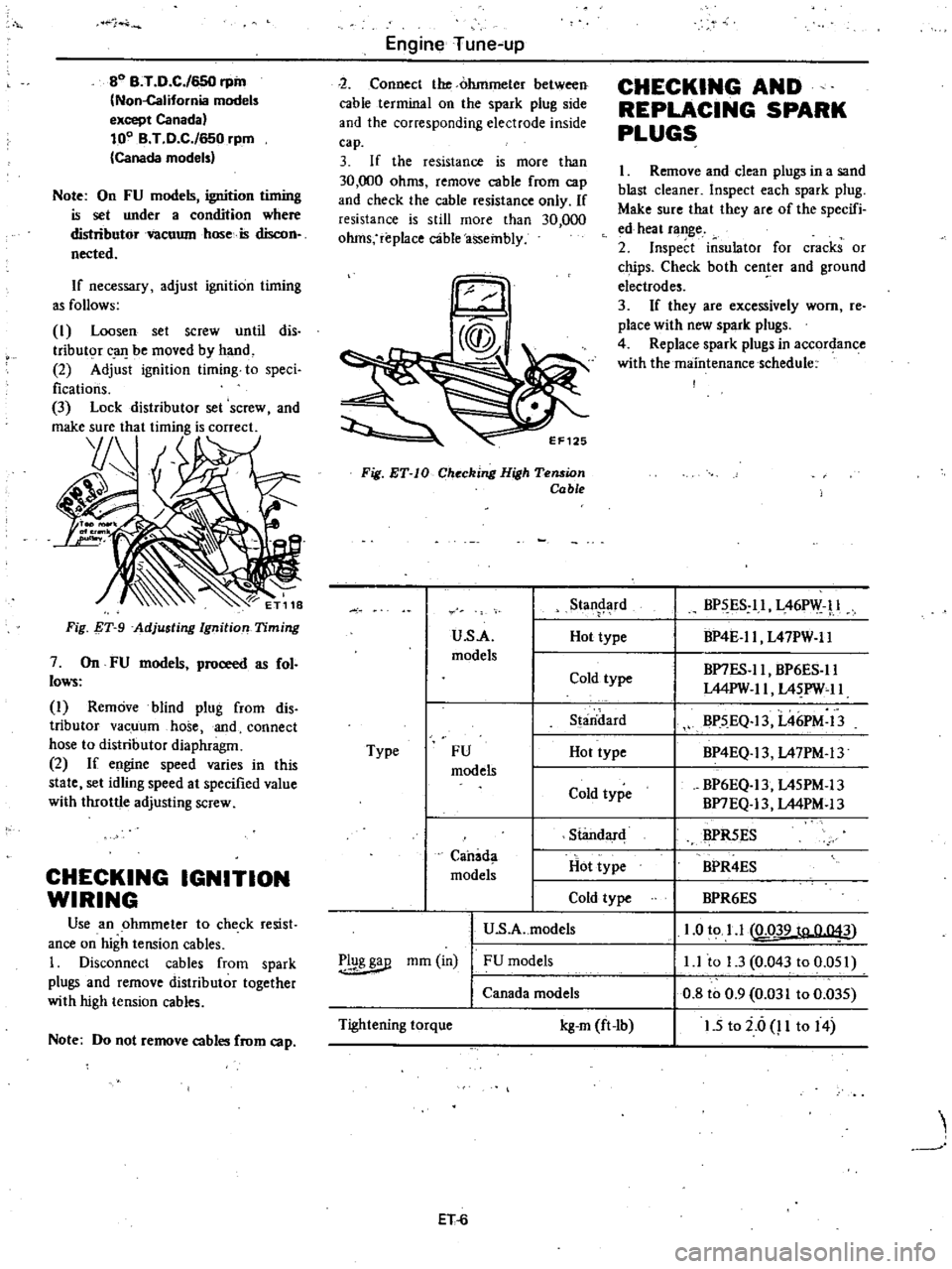

COOLING

SYSTEM

PRESSURE

TEST

Witli

radiator

cap

removed

apply

reference

pressure

1

6

kgfcm2

23

psi

to

the

cooling

system

by

means

0

no

Fig

ET

4

Water

capacity

M

Tmodelsl

Without

heater

5

2

liten

5

1f

US

qt

4

Imp

qt

With

heeter

5

9

Iiten

6

4

US

qt

5

Y

Imp

qt

Water

capacity

AfT

modelsl

Without

heater

5

0

liters

5

y

US

qt

4

Imp

qt

With

heater

5

7

liten

6

US

qt

5

Imp

ill

CHECKING

ENGINE

COMPRESSION

Note

a

To

check

cylinder

compression

it

is

essential

to

remove

all

spark

plugs

The

purpose

of

this

test

is

to

ET

4

determine

whether

there

is

exces

sive

leakage

past

piston

rings

head

gasket

etc

To

test

engine

should

be

heated

to

the

operating

t

M

ture

and

throttle

valve

opened

b

Cylinder

compre

on

in

Cylinders

should

not

be

less

than

llO

of

the

highest

reading

Different

compres

sion

in

two

ore

more

cYlinder

usual

ly

indicates

an

improperly

seated

valve

or

broken

piston

ring

c

Low

compression

in

cylinders

am

result

from

worn

piston

rings

This

trouble

may

usuaDy

be

accom

panied

by

ex

ssive

fuel

consump

tion

I

Warm

up

engine

sufficiently

2

Disconnect

aU

spark

plugs

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Properly

attach

a

compression

tester

to

spark

plug

hole

in

cylinder

being

tested

FiI

ET

S

ET529

Testing

Compre

sion

Pr

s8ure

5

Depress

accelenit6r

pedal

to

open

throttle

and

choke

valves

Note

Do

not

pump

pedal

6

Start

engine

as

quickly

as

pos

sible

Compression

pressllre

kg

cm2

ii

at

rpm

Standard

13

5

192

350

Minimum

12

5

1781

350

If

cylinder

compression

in

o

e

or

more

cylinders

is

low

pour

a

small

quantity

of

engine

oil

into

cylinders

through

the

spark

plug

holes

and

retest

compression

I

If

addingoil

helps

the

compres

Page 20 of 548

SO

B

T

D

C

l650

rpm

Non

California

models

except

Canada

100

B

T

D

C

650

rpm

Canada

models

Note

On

FU

models

ignition

timing

is

set

under

a

condition

where

distributor

vacuum

hose

is

discon

nected

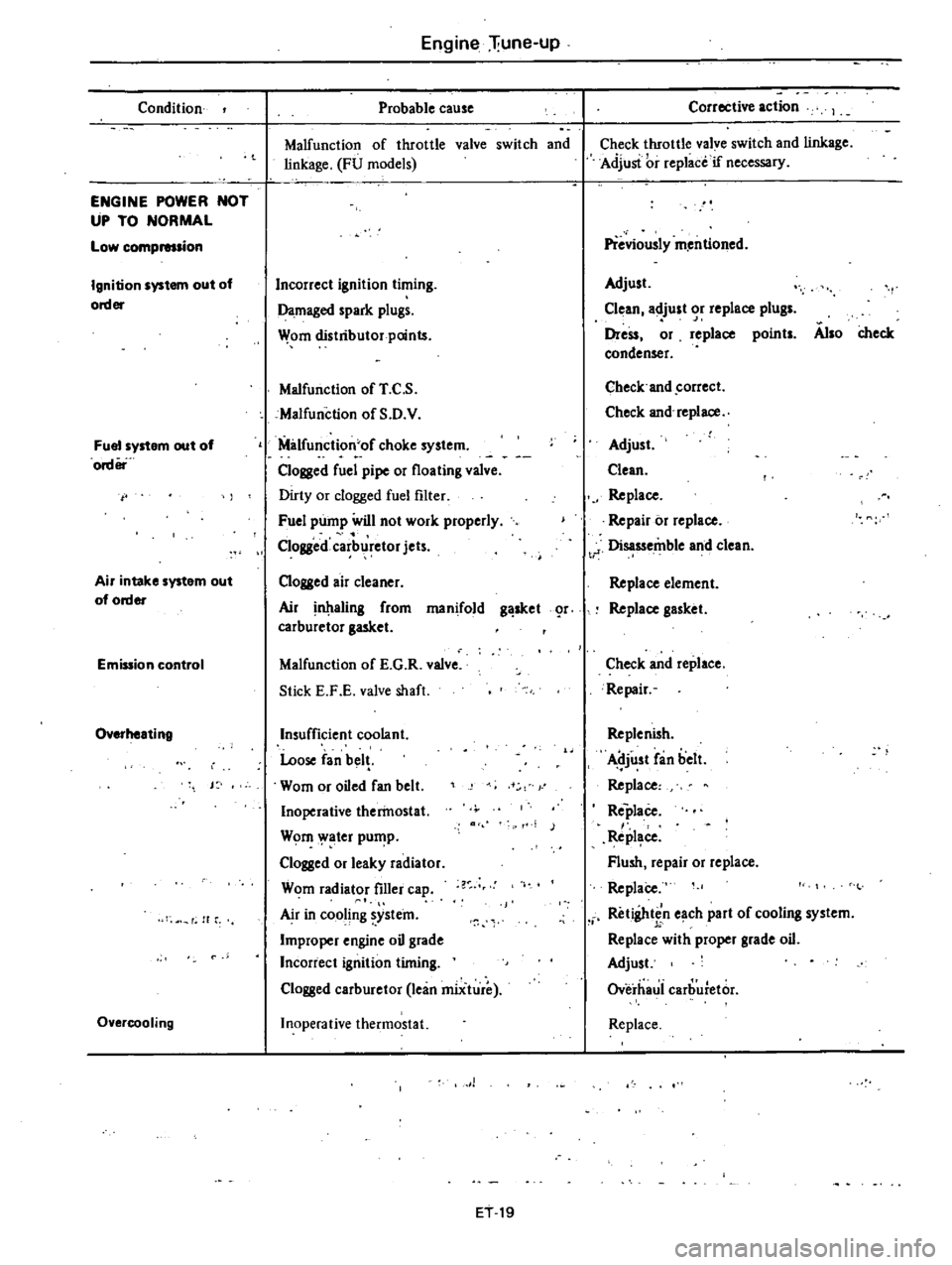

If

necessary

adjust

ignition

timing

as

follows

I

Loosen

set

screw

until

dis

tributor

c

uJ

be

moved

by

hand

2

Adjust

ignition

timing

to

speci

fications

3

Lock

distributor

set

screw

and

make

sure

that

timing

is

correct

YJ

Fig

T

9

Adjusting

Ignition

Timing

7

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

with

throttle

adjusting

screw

CHECKING

IGNITION

WIRING

Use

an

ohmmeter

to

check

resist

ance

on

high

tension

cables

1

Disconnect

cables

from

spark

plugs

and

remove

distributor

together

with

high

tension

cables

Note

Do

not

remove

cables

from

cap

Engine

Tune

up

2

Connect

the

ohmmeter

between

cable

terminal

on

the

spark

plug

side

and

the

corresponding

electrode

inside

cap

3

If

the

resistance

is

more

than

30

000

ohms

remove

cable

from

cap

and

check

the

cable

resistance

only

If

resistance

is

still

more

than

30

000

ohms

replace

c3ble

assembly

Fig

ET

IO

Checking

High

Tension

Cable

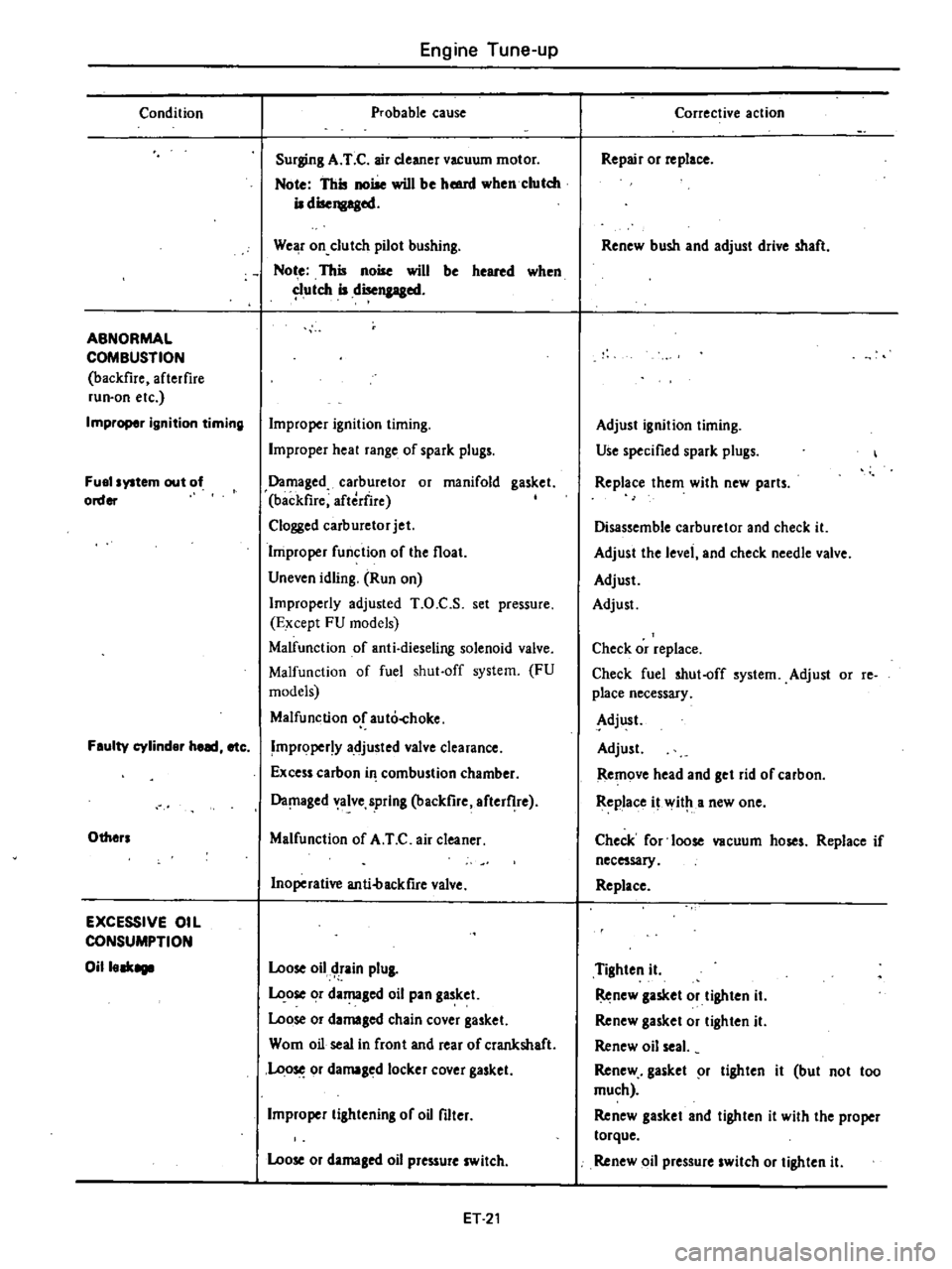

u

s

A

models

Type

FU

models

Standard

Hot

type

Cold

type

U

S

A

models

Canada

models

r

1g

mm

in

FU

models

Canada

models

Tightening

torque

kg

m

ft

lb

ET

6

Stan

rd

Hot

type

Cold

type

S

aridard

Hot

type

Cold

type

CHECKING

AND

REPLACING

SPARK

PLUGS

I

Remove

and

clean

plugs

in

a

sand

blast

cleaner

Inspect

each

spark

plug

Make

sure

that

they

are

of

the

specifi

ed

heat

range

2

Inspect

insulator

for

cracks

or

chips

Check

both

center

and

ground

electrodes

3

If

they

are

excessively

worn

re

place

with

new

spark

plugs

4

Replace

spark

plugs

in

accordance

with

the

maintenance

schedule

BP

ES

ll

L46PW

l

BP4E

ll

L47PW

ll

BP7ES

ll

BP6ES

ll

L44PW

II

L4

PW

11

BP5

EQ

13

L46PM

13

BP4EQ

13

L47PM

13

BP6EQ

13

L45PM

13

BP7EQ

13

L44PM

13

BPR5ES

BPR4ES

BPR6ES

1

0

to

1

1

LQ39

to

0

043

l

l

to

1

3

0

043

to

0

051

0

8

to

0

9

0

031

to

0

035

1

5

to

i

6

P

to

14

Page 33 of 548

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compmsion

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

J

f

H

r

Overcooling

Engine

liune

up

Probable

cause

Malfunction

of

throttle

valve

switch

and

linkage

FU

models

Incorrect

ignition

timing

Damaged

spark

plugs

Wom

distributor

points

Malfunction

of

T

C

S

cMalfunction

of

S

D

V

Milfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

filter

Fuel

pump

will

not

work

properly

Clogged

carb

retor

jets

Clogged

air

cleaner

Air

aling

from

manifold

g

sket

r

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

bel

Wom

or

oiled

fan

belt

Inoperative

therinostat

Wom

ater

pu

p

Clogged

or

leaky

radiator

Wom

radiator

filler

ca

Air

in

cooling

ystein

Improper

engine

oil

grade

Incorrect

ignition

timing

Clogged

carburetor

lean

miiture

Inoperative

thermostat

1

ET

19

Corrective

action

Check

throttle

valve

switch

and

linkage

Adjusi

i

r

replace

if

necessary

Previously

m

entioned

Adjust

Clean

adjust

or

replace

plugs

Dress

or

replace

points

Also

check

condenser

Check

and

correct

Check

and

replace

Adjust

Clean

Replace

Repair

or

replace

t

J

Disassemble

and

clean

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Repl

ce

Flush

repair

or

replace

ReplaCe

Retightin

e

ch

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaui

carburetor

Replace

Page 35 of 548

Condition

ABNORMAL

COMBUSTION

backfire

afterfire

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Feulty

cylinder

heed

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilleek8111

Engine

Tune

up

Probable

cause

Surging

A

T

C

air

cleaner

vacuum

motor

Note

This

noise

will

be

hmnl

when

clutch

iI

disengaged

We

r

on

clutch

pilot

bushing

Not

e

This

noise

will

be

heared

when

utch

iI

disengaged

Improper

ignition

timing

Improper

heal

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfire

aftedire

Clogged

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

T

O

C

S

set

pressure

Except

FU

models

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

fuel

shut

off

system

FU

models

Malfunction

or

auto

hoke

Improper

y

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Da

laged

alve

spring

backfire

after

he

Malfunction

of

A

T

C

air

cleaner

Inoperative

anti4lackfire

valve

Loose

oil

tain

plUI

ose

or

damaged

oil

pan

gasket

Loose

or

damaled

chain

cover

gasket

Wom

oil

seal

in

front

and

rear

of

crankshaft

Loo

or

damaged

locker

cover

gasket

Improper

lilhtening

of

oU

filter

Loose

or

damaled

oil

pressure

switch

ET

21

Corrective

action

Repair

or

replace

Renew

bush

and

adjust

drive

shaft

Adjust

ignition

liming

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Check

fuel

shut

off

system

Adjust

or

re

place

necessary

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

wit

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replace

Tighten

it

Renew

lasket

or

tighten

iI

Renew

gasket

or

lighten

it

Renew

oil

seal

Renew

gasket

r

lighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Page 178 of 548

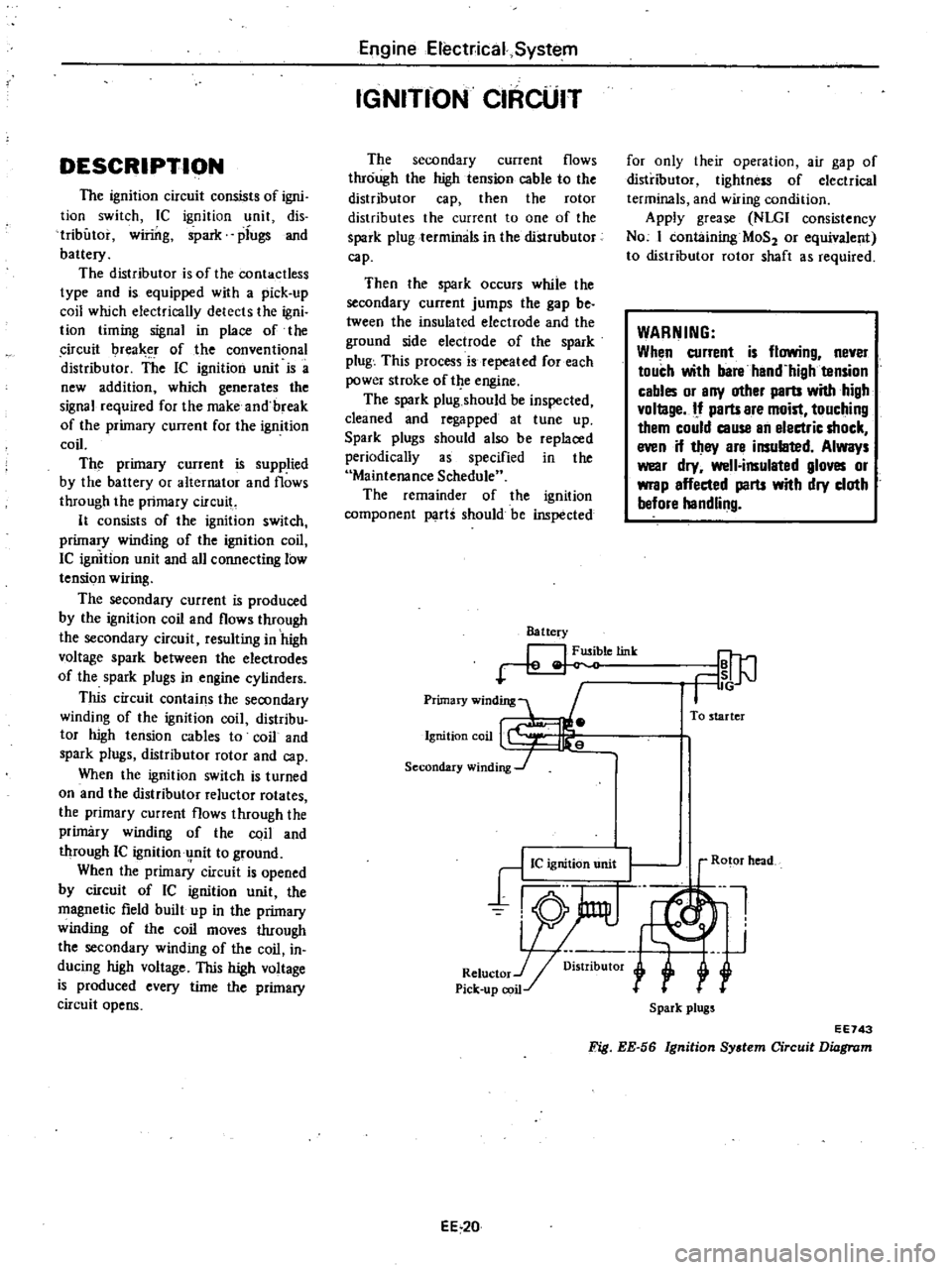

DESCRIPTION

The

ignition

circuit

consists

of

igni

tion

switch

Ie

ignition

unit

dis

tributor

winng

ipark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

ircuit

I

rea

r

of

the

conventional

distributor

The

IC

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

current

for

the

ignition

coil

The

primary

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

primary

winding

of

the

ignition

coil

IC

ignition

unit

and

all

connecting

low

tension

wiring

The

secondary

current

is

produced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

resulting

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

cables

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

IC

ignitionu

nit

to

ground

When

the

primary

circuit

is

opened

by

circuit

of

IC

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

in

ducing

high

voltage

This

high

voltage

is

produced

every

time

the

primary

circuit

opens

EngineElect

ical

System

IGNITfON

CIRCUIT

The

secondary

current

flows

through

the

high

tension

cable

to

the

distributor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distrubutor

cap

Then

the

spark

occurs

while

the

secondary

current

jumps

the

gap

be

tween

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

t

e

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Schedule

The

remainder

of

the

ignition

component

parti

should

be

inspected

Battery

letink

Primary

winding

1

Ignition

coil

Secondary

winding

J

for

only

their

operation

air

gap

of

distributor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MaS

or

equivalent

to

distributor

rotor

shaft

as

required

WARNING

When

current

is

flowing

never

touch

with

bare

hand

high

tension

cables

or

any

other

parts

with

high

vollage

If

parts

are

moist

touching

them

could

cause

an

electric

shock

even

if

they

are

insulated

Always

wear

dry

well

insulated

gloves

or

wrap

affected

parts

with

dry

cloth

before

handling

To

starter

EE

20

Ro

or

head

Ul

J

r

Spark

plugs

EE743

Fig

EE

56

Ignition

System

Circuit

Diagram

Page 186 of 548

JUDGMENT

OV

is

indicated

IC

ignition

unit

NG

But

condition

of

pick

up

coil

can

not

be

judged

Proceed

to

the

item

for

Pick

up

Coil

Check

Bat

tery

voltage

is

indicated

Condition

cannot

be

judged

Proceed

to

item

9

9

Remove

IC

ignition

unit

Refer

to

IC

ignition

Unit

for

re

moval

10

Measure

resistance

between

two

terminals

of

pick

up

coil

JUDGMENT

Approx

40011

are

indicated

The

ignition

coil

is

an

oil

filled

type

The

ignition

coil

case

is

filled

with

oil

which

has

good

insulating

and

heat

radiating

characteristics

The

ignition

coil

has

a

greater

ratio

between

the

primary

and

secondary

windings

to

step

up

battery

voltage

to

high

voltage

This

causes

stronger

sparks

to

jump

the

spark

plug

gap

The

cap

is

made

of

alkyd

resin

which

offers

high

resistance

to

electric

arc

and

increased

insulation

When

high

tension

cable

is

installed

to

ignition

coil

there

should

be

no

clearance

between

their

caps

Note

Do

not

disconnect

high

tension

cables

from

spark

plugs

during

en

gine

running

r

EE354

1

High

tension

cable

2

Rubber

cap

Fig

EE

74

Correct

Instalhltion

of

High

Tension

Cable

Engine

Electrical

System

Pick

up

coil

OK

IC

ignition

unit

NG

Approx

40011

are

not

indicated

Pick

up

coil

NG

Condition

of

IC

ignition

unit

can

not

be

judged

Proceed

to

item

11

II

Replace

faulty

pick

up

coil

with

new

one

12

Install

original

IC

ignition

unit

13

Check

parking

performance

JUDGMENT

Sparks

occur

IC

ignition

system

IC

ignition

unit

OK

No

spark

OCCUrs

IC

ignition

unit

NG

IGNITION

COIL

If

NG

replace

faulty

IC

ignition

unit

with

new

one

P1ck

up

coil

check

I

Make

sure

that

ignition

switch

is

in

OFF

position

2

Remove

IC

ignition

unit

Refer

to

IC

Ignition

Unit

for

removal

3

Measure

resistance

between

two

terminals

of

pick

up

coil

JUDGMENT

Approx

40011

are

indicated

OK

Approx

40011

are

not

indicated

NG

If

NG

replace

faulty

pick

up

coil

with

new

one

1

@

I

rJ

1

C

I

I

i

jllll

1

t

1

Rubber

cap

for

ignition

coil

2

Secondary

tenninal

3

Cap

4

Primary

terminal

5

Spring

6

Secondary

winding

EE

28

EE578

7

Primary

winding

8

Side

core

9

Insulator

10

Center

core

11

Segment

12

Case

Fig

EE

75

Ignition

Coit

Page 187 of 548

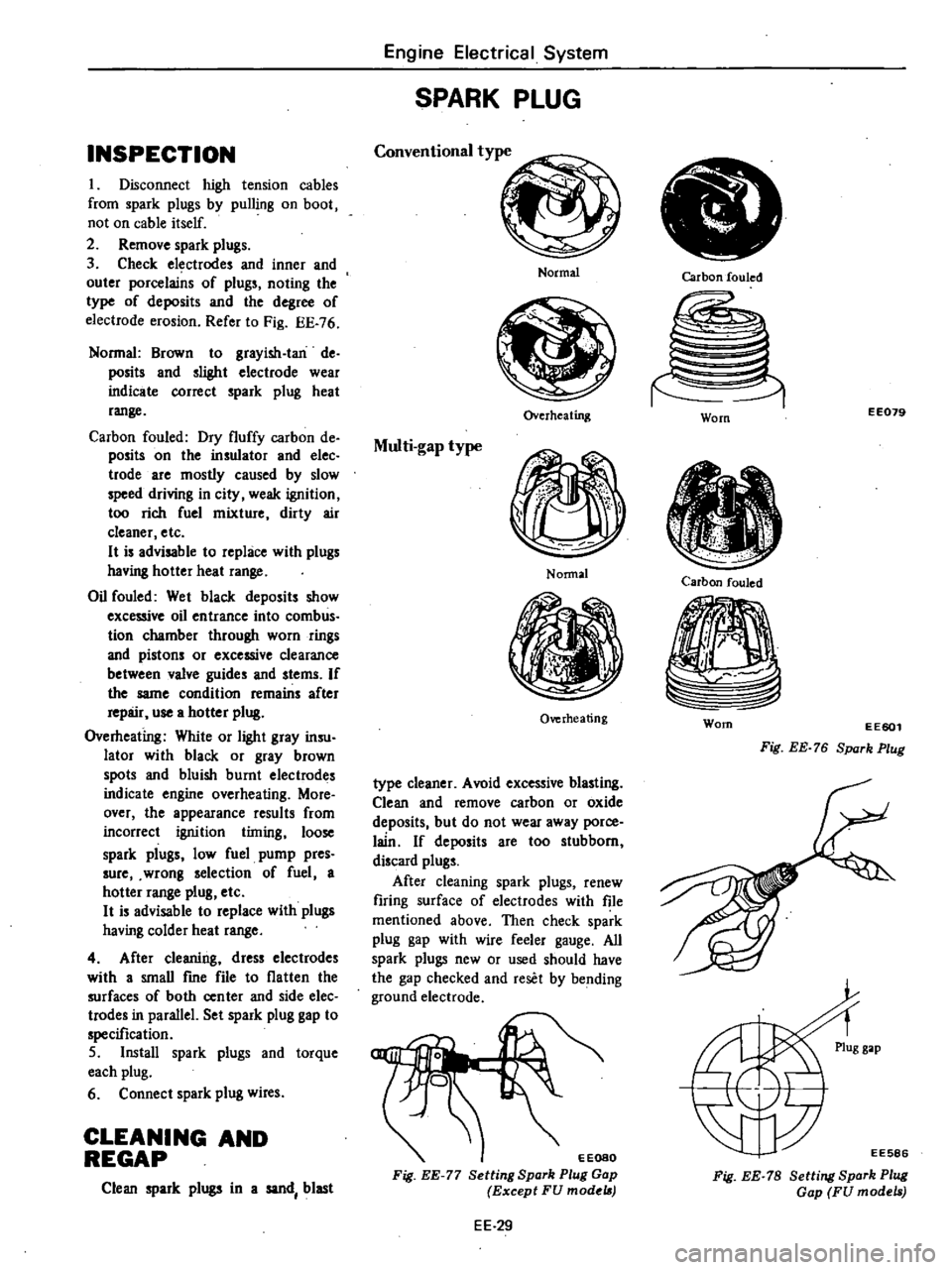

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37

Page 196 of 548

2

Engine

rotates

but

does

not

run

smoothly

This

may

be

caused

by

the

ignition

Condition

Location

Engine

misses

Distributor

Ignition

coil

High

tension

cable

Spark

plugs

IC

ignition

unit

Engine

causes

knocking

very

often

Distributor

Spark

plugs

Engine

does

not

deliver

enough

power

Distributor

Spark

plugs

Engine

Electrical

System

system

or

other

engine

conditions

not

related

to

ignition

system

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

Probable

cause

Foreign

matter

onpicl

up

coil

Improper

air

gap

Leak

of

electricity

at

cap

and

rotor

head

Breakage

of

pick

up

coil

lead

wire

Worn

or

shaky

breaker

plate

Worn

or

shaky

distributor

driVing

shaft

Layer

short

circuit

or

inferior

quality

coil

Deterioration

of

insulation

with

cense

quenlleak

of

electricity

Fouled

Leak

of

electricity

at

upper

porcelain

insulator

Spark

plug

gap

too

narrow

Faulty

IC

ignition

unit

Breakage

of

circuit

Detached

connection

Improper

ignition

timing

too

advanced

Coming

off

or

breakage

of

governor

spring

Worn

pin

or

hole

of

governor

Burnt

too

much

Improper

ignition

timing

too

retarded

Improper

functioning

governor

Foreign

particles

stuck

in

air

gap

Fouled

EE

38

Corrective

action

Clean

Correct

Repair

or

replace

Replace

Replace

assembly

Replace

aSsembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

or

replace

Replace

Replace

Repair

Correct

Correct

or

replace

Replace

Replace

Correct

Replace

assembly

Clean

Clean