boot DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 187 of 548

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

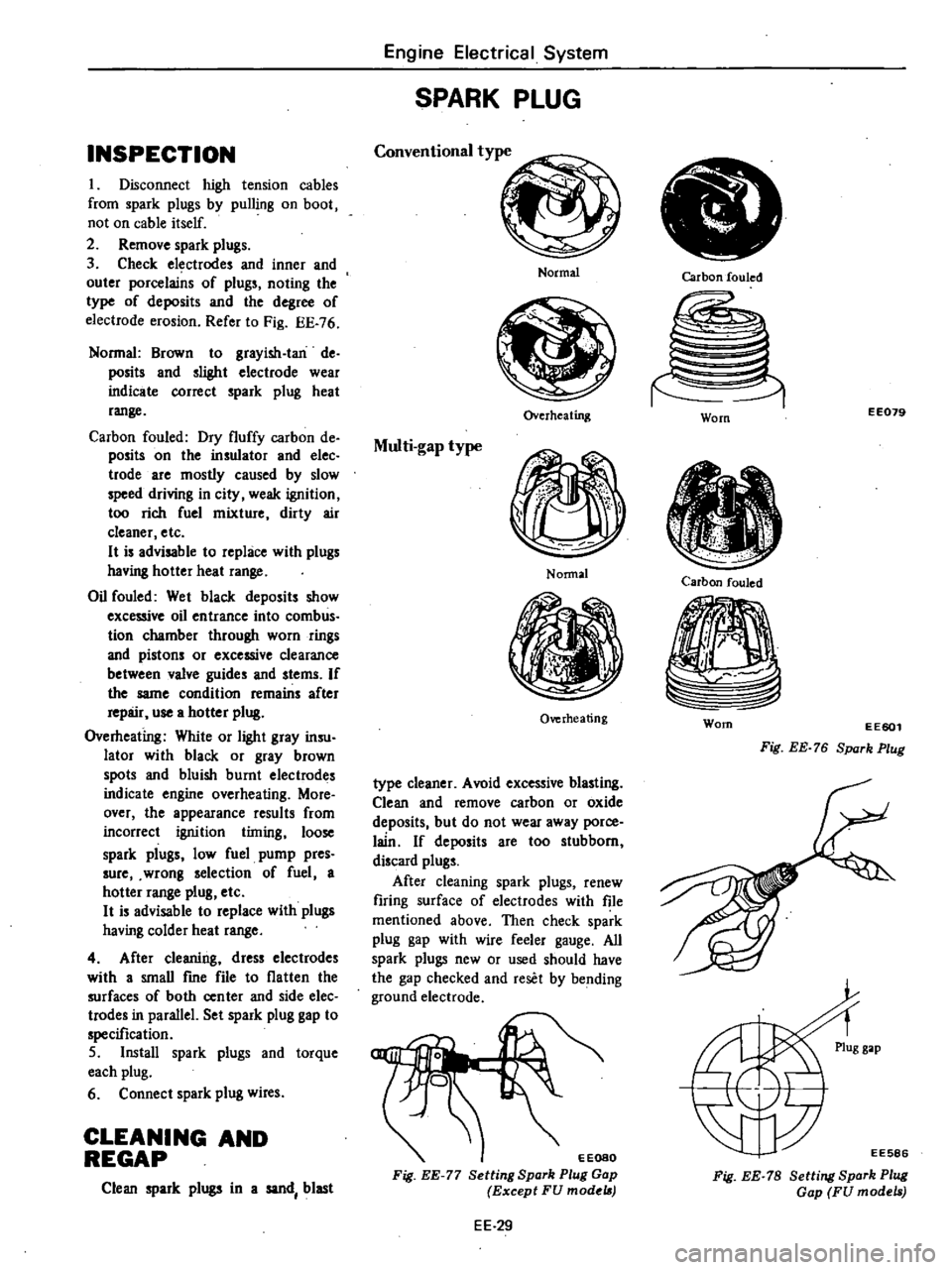

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 219 of 548

I

ht

2nd

fork

r

2

3rd

top

fork

rod

3

Reverse

fork

rod

4

Retaining

pin

5

I

t

2nd

shift

fork

6

3rd

top

shift

fork

7

Checking

ball

plug

8

Check

ban

spring

9

Check

ball

10

Interlock

plunger

11

S

topper

ring

12

Shift

rod

A

bracket

13

Reverse

shift

fork

14

Lock

pin

15

Striking

lever

Manual

Transmission

16

Striking

rod

17

Return

spring

plug

18

Reverse

check

spring

19

Return

pring

20

Plunger

21

D

ring

22

Stopper

pin

bolt

23

Striking

guide

assembly

24

Striking

guide

oil

seal

REMOVAL

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

m

TM781

Fig

MT

4

Removing

Control

Lever

@

@

25

Control

lever

bushing

26

Expansion

plug

27

Control

pin

bushing

28

Control

arm

pin

29

Control

lever

o

Tightening

torque

kg

m

ft

lb

@

0

5

to

0

8

3

6

tn

5

8

@

1

3

to

1

7

9

to

12

Fig

MT

3

F4W60L

Tra11lmiBSion

Shift

Control

Components

TM094A

4

Jack

up

the

car

and

support

its

weight

on

safety

stands

Use

a

hy

draulic

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

5

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

removey

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PO

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

MT

3

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

00

not

place

the

jack

under

the

oil

pan

drain

plug

11

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

V

Page 233 of 548

Manual

Transmission

S

R

o

o

D

l

@

@

l

@

l

25

Control

lever

boot

26

Control

pin

bushing

27

Control

arm

pin

28

Control

lever

29

Control

lever

knob

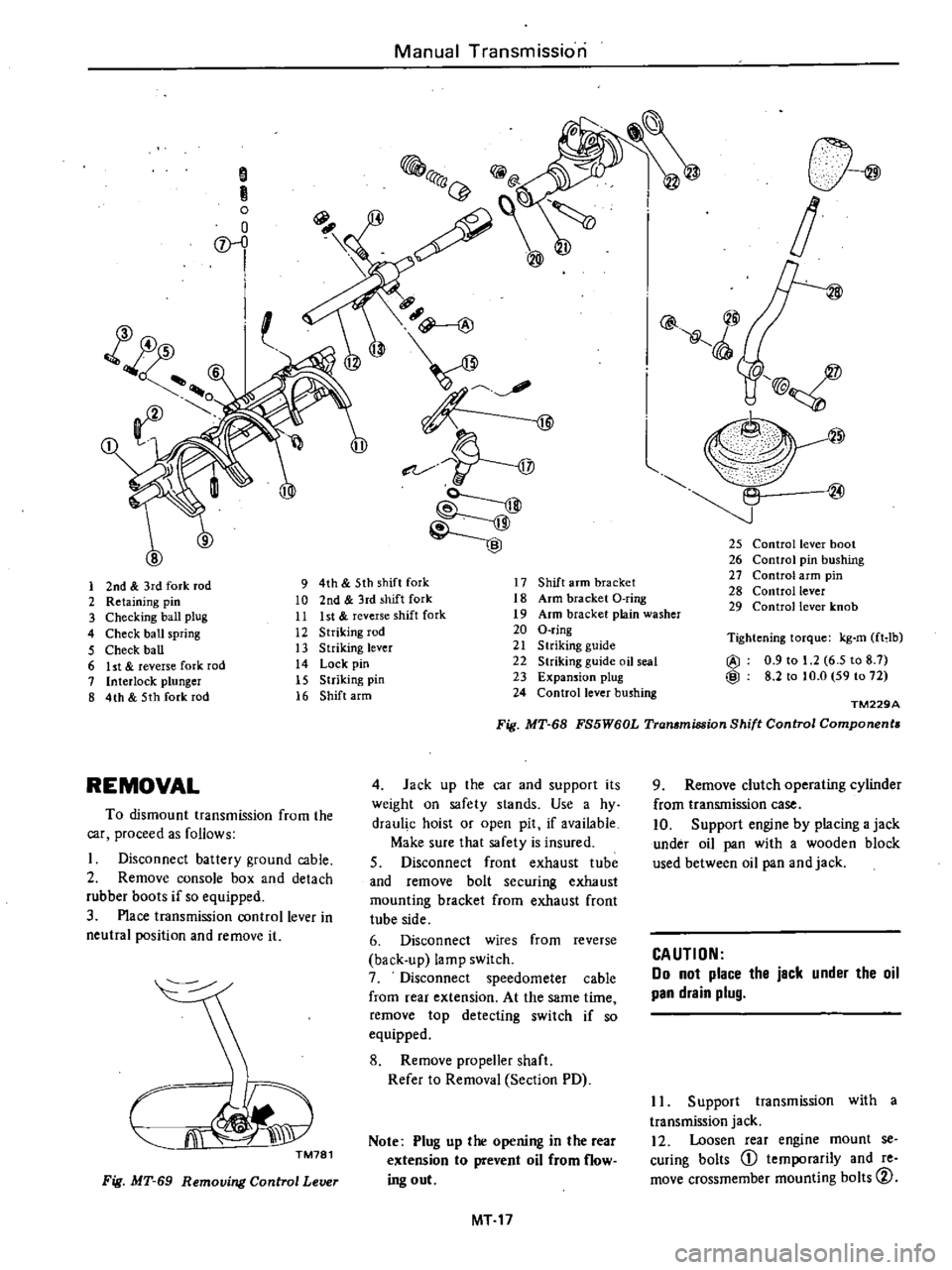

1

2nd

3rd

fork

rod

9

4th

5th

shift

fork

17

Shift

arm

bracket

2

Retaining

pin

10

2nd

3rd

shift

fork

18

Arm

bracket

O

ring

3

Checking

ball

plug

11

Ist

reverse

shift

fork

19

Arm

bracket

plain

washer

4

Check

ball

spring

12

Striking

rod

20

O

ring

5

Check

ball

13

Striking

lever

21

S

lriking

guide

6

ht

reverse

fork

rod

14

Lock

pin

22

Striking

guide

oil

seal

7

Interlock

plunger

15

Striking

pin

23

Expansion

plug

8

4th

5th

fork

rod

16

Shift

arm

24

Control

lever

bushing

Tightening

torque

kg

m

fHb

@

0

9

to

1

2

6

5

to

8

7

@

8

2

to

to

O

59

to

72

TM229A

Fig

MT

68

FS5W60L

Transmission

Shift

Control

Components

REMOVAL

4

Jack

up

the

car

and

supporl

its

weight

on

safety

slands

Use

a

hy

draul

c

hoist

or

open

pit

if

available

Make

sure

that

safety

is

insured

S

Disconnect

front

exhaust

tube

and

remove

bolt

securing

exhaust

mounting

bracket

from

exhaust

front

tube

side

6

Disconnect

wires

from

reverse

back

up

lamp

switch

7

Disconnect

speedometer

cable

from

rear

extension

At

the

same

time

remove

top

detecting

switch

if

so

equipped

8

Remove

propeller

shaft

Refer

to

Removal

Section

PD

To

dismount

transmission

from

the

car

proceed

as

follows

Disconnect

battery

ground

cable

2

Remove

console

box

and

detach

rubber

boots

if

so

equipped

3

Place

transmission

control

lever

in

neutral

position

and

remove

it

CJi

J

TM781

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

Fig

MT

69

Removing

Control

Lever

MT

17

9

Remove

clutch

operating

cylinder

from

transmission

case

10

Support

engine

by

placing

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

CAUTION

Do

not

place

the

jack

under

the

oil

pan

drain

plug

II

Support

transmission

with

a

transmission

jack

12

Loosen

rear

engine

mount

se

curing

bolts

CD

temporarily

and

re

move

crossmember

mounting

bolts

CV

Page 358 of 548

If

leakage

oCcurs

at

end

around

joints

re

tighten

Of

if

necessary

re

place

faulty

parts

INSTALLATION

Pay

particular

attention

to

follow

ing

instructions

when

installing

brake

lines

I

Leave

a

sulfident

space

between

brake

lines

and

adjacent

parts

so

that

brake

lines

are

completely

free

from

vibration

during

driving

2

Be

careful

not

to

warp

or

twist

brake

lines

3

When

installing

brake

tube

keep

a

certain

distance

between

tube

and

adjacent

parts

as

follows

Tube

to

rotating

parts

30

mm

1

18

in

Tube

to

moving

parts

10

mm

10

39

in

Tube

to

other

palls

5

mm

10

20

in

4

Always

fasten

brake

tubes

with

mounting

clips

where

necessary

On

rear

axle

case

are

two

double

dips

which

should

be

used

to

secure

brake

tubes

in

manner

described

be

low

Bend

short

clip

straight

up

With

brake

tube

on

long

clip

bend

clip

up

and

around

tube

Finally

wrap

short

clip

around

tube

to

secure

the

in

slallation

f

J

i

2

BA141

Fig

BR

7

Fastening

Brake

Tube

Securely

with

Double

Clip

5

Do

not

tighten

brake

line

mount

ing

flare

nut

excessively

CAUTION

When

installing

Fla

e

Nut

6694310000

brake

tubes

use

Torque

Wrench

Brake

System

t

D

Tightening

torque

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

Brake

hose

connector

1

7

to

2

0

kg

m

112

to

14

ft

lb

J

way

connector

bolt

0

8

to

1

1

kltm

5

8

to

8

0

ft

Ib

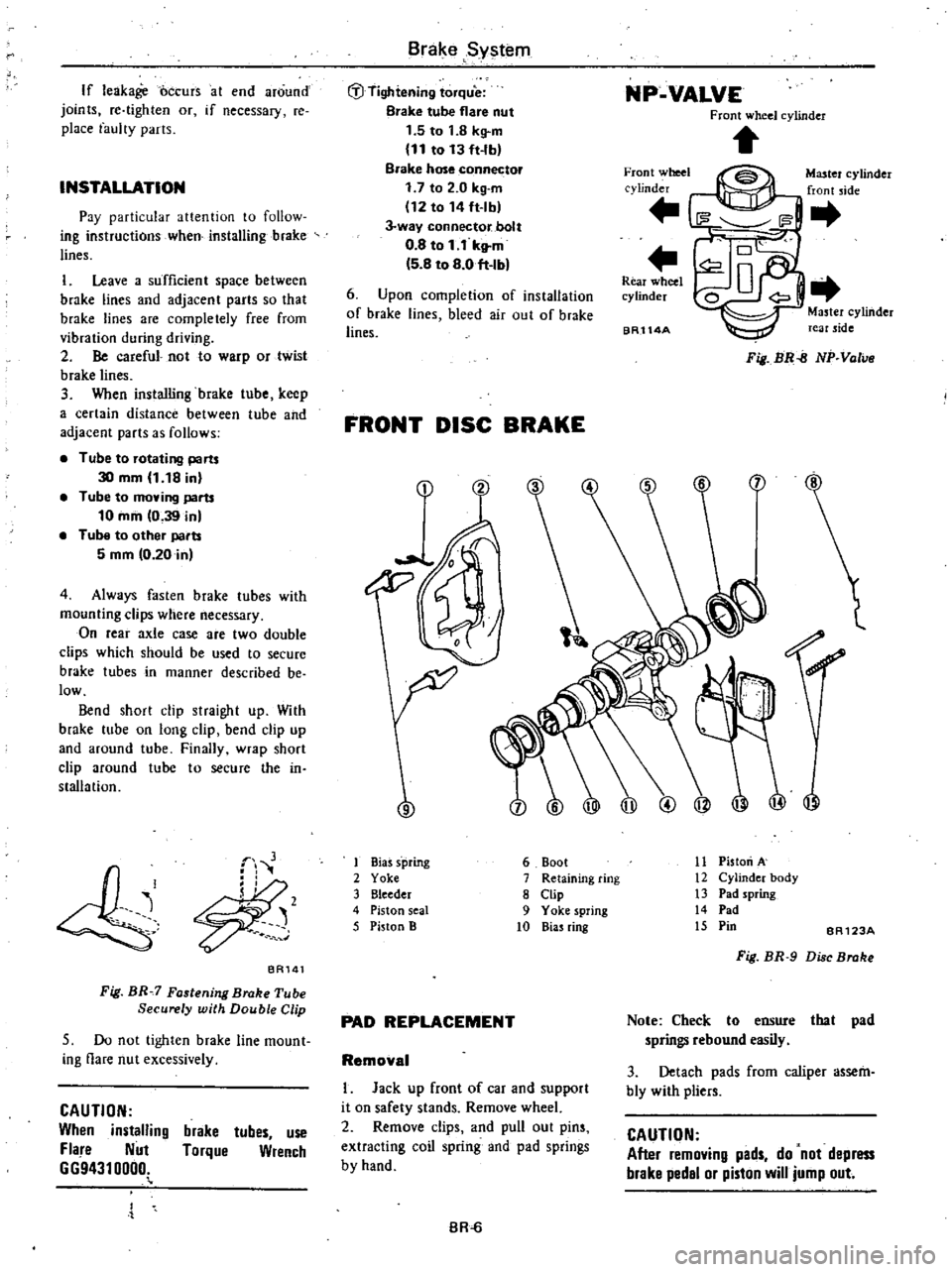

NP

VALVE

Front

wheel

cylinder

Front

wheel

cylinder

Master

cylinder

front

jde

6

Upon

completion

of

installation

of

brake

lines

bleed

air

out

of

brake

lines

Rear

wheel

cylinder

BR114A

Master

cylinder

rear

side

Fig

BR

B

NP

Valve

FRONT

DISC

BRAKE

9

ilJ

I

Bias

s

pring

2

Yoke

3

Bleeder

4

Piston

seal

5

Piston

B

11

Piston

A

12

Cylinder

body

13

Pad

spring

14

Pad

15

Pin

6

Boot

7

Retaining

ring

8

Clip

9

Yoke

spring

10

Bias

ring

BR123A

Fig

BR

9

Di

c

Broke

PAD

REPLACEMENT

Note

Check

to

ensure

that

pad

springs

rebound

easily

3

Detach

pads

from

caliper

assem

bly

with

pliers

Removal

I

Jack

up

front

of

car

and

support

it

on

safety

stands

Remove

wheel

2

Remove

clips

and

pull

out

pins

extracting

coil

spring

and

pad

springs

by

hand

CAUTION

After

removing

pads

do

not

depress

brake

pedal

or

piston

will

jump

out

BR

Page 361 of 548

BR563

Fig

BR

10

Removing

Pad

Inspection

Clean

pads

with

cleaning

solvent

CAUTION

Use

brake

fluid

to

clean

Never

use

mineral

oil

2

When

pads

are

heavily

fouled

with

oil

or

grease

or

when

pad

is

deteriorated

or

deformed

replace

it

3

If

pad

is

worn

to

less

than

the

specified

value

replace

Pad

wear

limit

Minimum

thickness

t

6

mm

0

063

in

Note

Always

replace

pads

in

pad

kit

four

pads

two

clips

four

pad

pins

and

four

pad

springs

4

Check

rotor

referring

to

Rotor

for

inspection

Installetlon

I

Clean

and

apply

P

RC

grease

on

yoke

guide

groove

of

cylinder

body

sliding

contact

portions

of

yoke

and

end

surface

of

piston

Note

a

Do

not

use

common

brake

grease

b

Be

careful

not

to

get

brake

grease

on

rotor

and

pads

2

Loosen

air

bleeder

and

push

pis

ton

B

outer

piston

in

cylinder

until

end

surface

of

piston

B

coincides

with

end

surface

of

retaining

ring

on

boot

Then

inner

pad

can

be

installed

Brake

System

BR564

Fig

BR

11

Pushing

Piston

CAUTION

Piston

can

be

easily

pushed

in

by

hand

but

if

pushed

too

far

groove

of

piston

will

go

inside

of

piston

seal

as

shown

in

Fig

BR

12

At

this

point

if

piston

is

pressured

or

moved

piston

seal

will

be

damaged

If

piston

has

been

pushed

in

too

far

remove

brake

assembly

and

disassemble

it

Then

push

piston

out

in

the

direction

shown

by

arrow

Assemble

it

again

referring

to

follow

ing

section

00

I

Normal

I

position

L

BR409

Fig

BR

12

Position

for

Pushing

Piston

3

Push

piston

A

inner

piston

in

cylinder

by

pulling

yoke

as

shown

The

outer

pad

can

then

be

installed

BRS6S

Fig

BR

13

Pulling

in

Piston

A

BR

7

4

After

installing

pads

depress

brake

pedal

several

times

and

pads

will

settle

into

proper

position

Note

When

worn

out

pads

are

re

placed

with

new

ones

brake

fluid

may

overflow

reservoir

While

re

placing

pads

keep

loosening

bleeder

to

release

brake

fluid

5

Install

wheels

and

lower

car

to

ground

REMOVAL

I

Remove

pads

Refer

to

Pad

Re

placement

2

Remove

brake

tube

from

caliper

assembly

CAUTION

When

removing

brake

tube

use

suit

able

tube

wrench

Never

use

open

end

or

adjustable

wrench

Note

Plug

up

hole

in

caliper

so

that

brake

fluid

does

not

flow

out

from

cylinder

body

3

Loosen

bolts

securing

cylinder

body

to

knuckle

spindle

and

remove

caliper

assembly

from

strut

DISASSEMBLY

I

Drain

brake

fluid

from

top

hole

of

cylinder

body

2

Push

both

pistons

A

and

B

into

cylinder

Refer

to

Pad

Replacement

3

Tap

cylinder

body

lightly

with

a

plastic

hammer

Cylinder

will

then

separate

from

yoke

BR115A

Fig

BR

14

Tapping

Cylinder

Block

Page 362 of 548

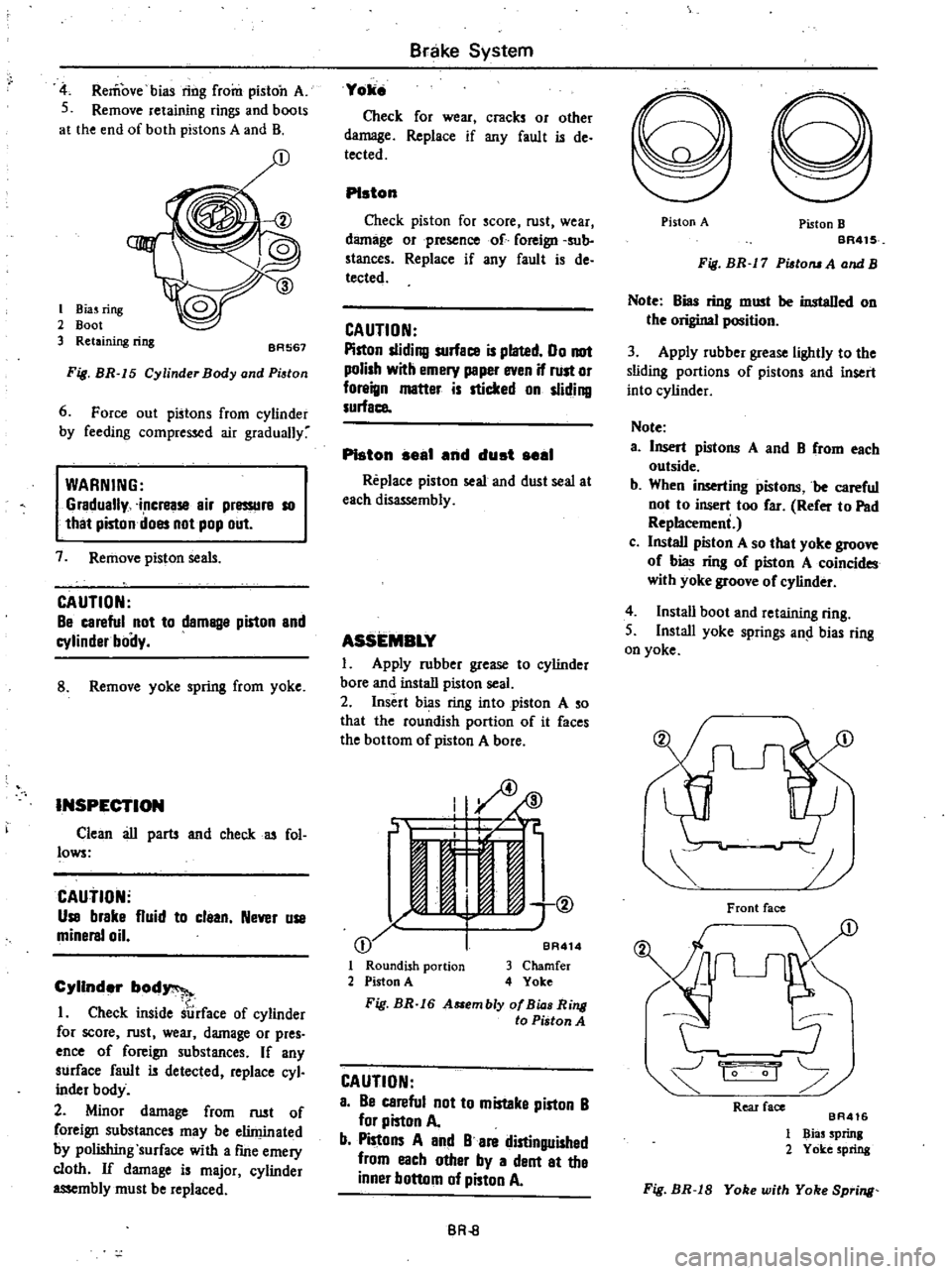

Remove

bias

ring

from

piston

A

S

Remove

retaining

rings

and

boots

at

the

end

of

both

pistons

A

and

B

I

Biuring

2

Boot

3

Retaining

ring

BA567

Fig

BR

15

Cylinder

Body

and

Pi

tan

6

Force

out

pistons

from

cylinder

by

feeding

compressed

air

gradually

WARNING

Gradually

increase

air

pressurs

10

that

piston

does

not

pop

out

7

Remove

piston

seals

CAUTION

Be

careful

not

to

damBlle

piston

and

cylinder

boily

8

Remove

yoke

spring

from

yoke

INSPECTION

Clean

au

parts

and

check

u

fol

lows

CAutiON

Use

brake

fluid

to

claan

Never

use

minersl

oil

Cylinder

bod

1

Check

inside

surface

of

cylinder

for

score

rust

wear

damage

or

pres

ence

of

foreign

substances

If

any

surface

fault

is

detected

replace

cyl

inder

body

2

Minor

damage

from

rust

of

foreign

substances

may

be

eliminated

by

polishing

surface

with

a

fme

emery

cloth

If

damage

is

major

cylinder

assembly

must

be

replaced

Brake

System

Yoke

Check

for

wear

cracks

or

other

damage

Replace

if

any

fault

is

de

tected

PIston

Check

piston

for

score

rust

wear

damage

orpresenco

of

foreign

sub

stances

Replace

if

any

fault

is

de

tected

CAUTION

Piston

sliding

surface

is

plated

00

not

polish

with

emery

peper

even

if

rust

or

foreign

matter

is

sticked

on

sliding

surface

PIston

seal

end

dust

seel

Replace

piston

seal

and

dust

seal

at

each

dis

mbly

ASSEMBLY

1

Apply

rubber

grease

to

cylinder

bore

and

install

piston

seal

2

Insert

bias

ring

into

piston

A

so

that

the

roundish

portion

of

it

faces

the

bottom

of

piston

A

bore

I

ID

J

if

C

jt

11

e

1

@

I

j

BA

I

Roundish

portion

3

Chamfer

2

Piston

A

4

Yoke

Fig

BR

16

A

embly

af

Bia

Ring

to

Piston

A

CAUTION

a

Be

careful

not

to

mistaka

piston

B

for

piston

A

b

Pistons

A

and

B

are

distinguished

from

each

other

by

a

dent

at

the

inner

bottom

of

piston

A

BR

8

Piston

A

Piston

B

BR41S

Fig

BR

17

Pisto

A

and

B

Note

Bias

ring

must

be

instaDed

on

the

original

position

3

Apply

rubber

grease

lightly

to

the

sliding

portions

of

pistons

and

insert

into

cylinder

Note

a

Insert

pistons

A

and

B

from

each

outside

b

When

inserting

pistons

be

careful

not

to

insert

too

far

Refer

to

Pad

Replacemeni

c

Install

piston

A

so

that

yoke

groove

of

bias

ring

of

piston

A

coincides

with

yoke

groove

of

cylinder

4

Instau

boot

and

retaining

ring

S

Install

yoke

springs

an

bias

ring

on

yoke

Front

face

1

1

0

Rear

face

BA416

1

Bias

Sprinl

2

Yoke

spring

Fig

BR

18

Yoke

with

Yoke

Spring