lock DATSUN 510 1968 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 35 of 252

30

CHAPTER

FIVE

should

be

1

54

m

39mm

If

the

spnng

tension

is

accurate

the

rehef

valve

should

open

at

54

0

to

59

7

lb

1m

3

8

to

4

2

kg

cm

6

Reassemble

the

oil

pump

Make

certain

all

gaskets

are

mounted

flat

to

avoid

leaks

7

Install

the

dnve

spindle

and

the

oil

pump

to

the

front

cover

8

Install

the

distnbutor

in

the

same

relative

locallon

from

which

it

was

removed

If

the

num

ber

1

cyhnder

was

at

top

dead

center

on

the

compression

stroke

the

punch

mark

on

the

dnve

spindle

should

face

toward

the

front

of

the

engine

9

Install

the

front

splash

shield

and

the

front

stablhzer

10

Insert

the

drain

plug

in

the

pan

and

refill

the

engme

11

Oil

pressure

at

idle

should

be

142

to

17

1

lb

lin

1

0

to

1

2

kg

cm

12

Tlghtenmg

torque

values

for

the

oil

pump

mounting

bolts

is

10

8

to

152ft

lb

1

5

to

2

1

kg

m

and

21

69

to

25

31

ft

lb

3

0

to

25

kg

m

for

the

release

valve

cap

nut

Oil

Filter

The

oil

filter

is

mounted

on

the

nght

hand

side

of

the

cyhnder

block

It

IS

a

cartndge

type

with

built

m

gasket

and

threads

onto

the

mounting

spindle

The

filter

should

be

replaced

every

6

000

miles

as

follows

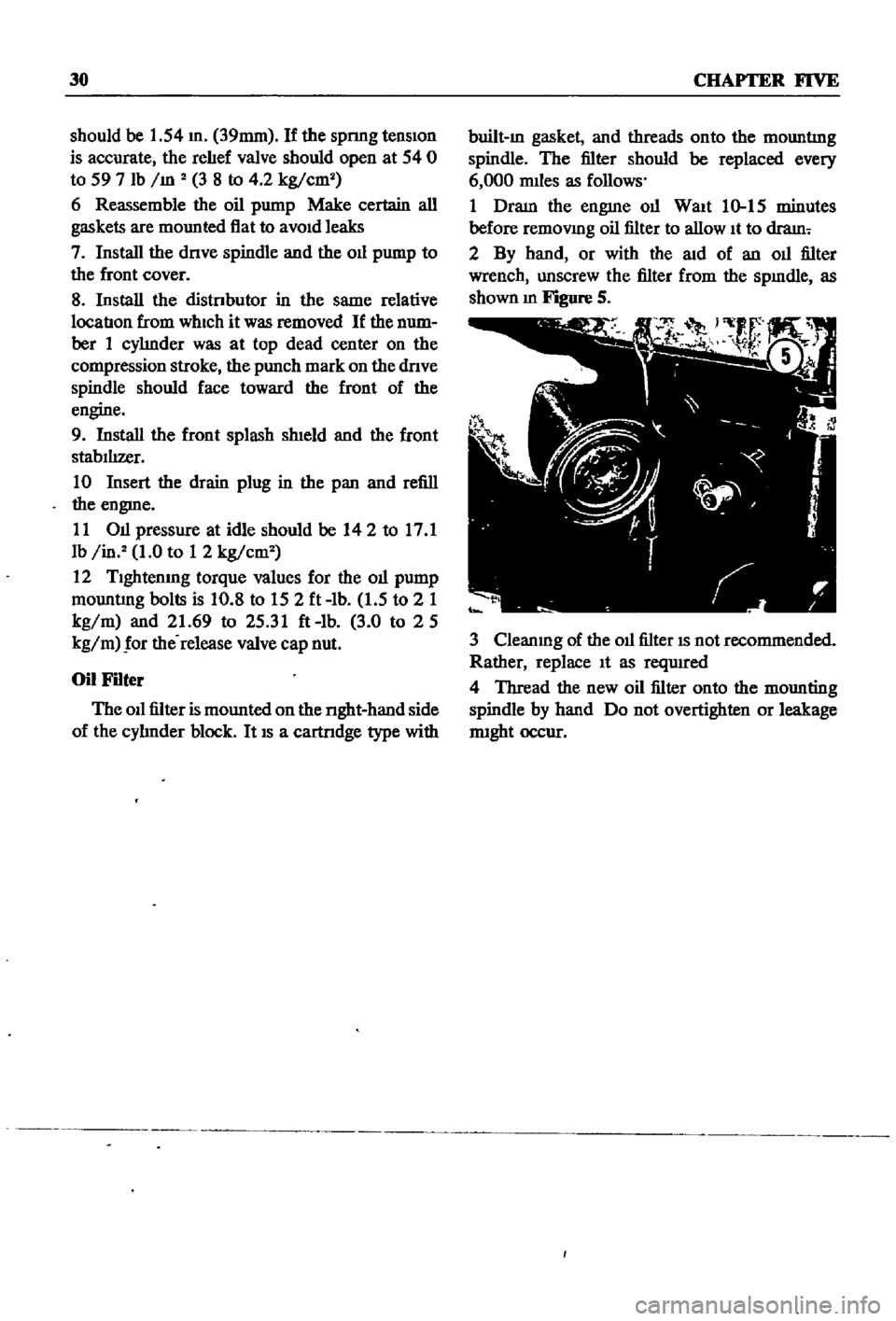

1

Dram

the

engme

oil

Walt

10

15

minutes

before

removmg

oil

filter

to

allow

It

to

dram

2

By

hand

or

with

the

aid

of

an

oil

filter

wrench

unscrew

the

filter

from

the

spmdle

as

shown

m

Figure

S

3

Cleanmg

of

the

oil

filter

IS

not

recommended

Rather

replace

It

as

reqUIred

4

Thread

the

new

oil

filter

onto

the

mounting

spindle

by

hand

Do

not

overtighten

or

leakage

nught

occur

Page 36 of 252

CHAPTER

SIX

ENGINE

Datsun

510

and

521

veJucles

use

the

L16

engme

Over

the

years

the

deSign

remamed

essentIally

the

same

with

nunor

changes

made

to

accommodate

drlIerent

elIDSSlon

control

de

VIces

The

Ll6

IS

a

four

cylmder

overhead

cam

shaft

engme

With

a

97

3

cubic

mch

1595cc

dISplacement

Cylmder

bore

IS

3

2677

in

83mm

stroke

IS

2

9016

m

73

7mm

Output

IS

96

horsepower

1972

mode1s

92

horse

power

at

5

600

rpm

Compression

ratIo

is

8

5

to

1

Equipment

includes

a

single

two

barrel

Hltaclu

carburetor

an

HItachi

alternator

an

HItachi

starter

motor

and

either

a

smgle

point

or

dual

pomt

distnbutor

Figure

1

next

page

IS

an

overall

view

of

the

engme

Figure

2

next

page

is

a

sectIonal

view

The

following

para

graphs

describe

and

illustrate

the

major

com

ponents

of

the

engine

and

provide

detaIled

InStructIons

on

the

removal

disassembly

inspec

tIon

reparr

and

reassembly

of

the

engine

CYLINDER

BLOCK

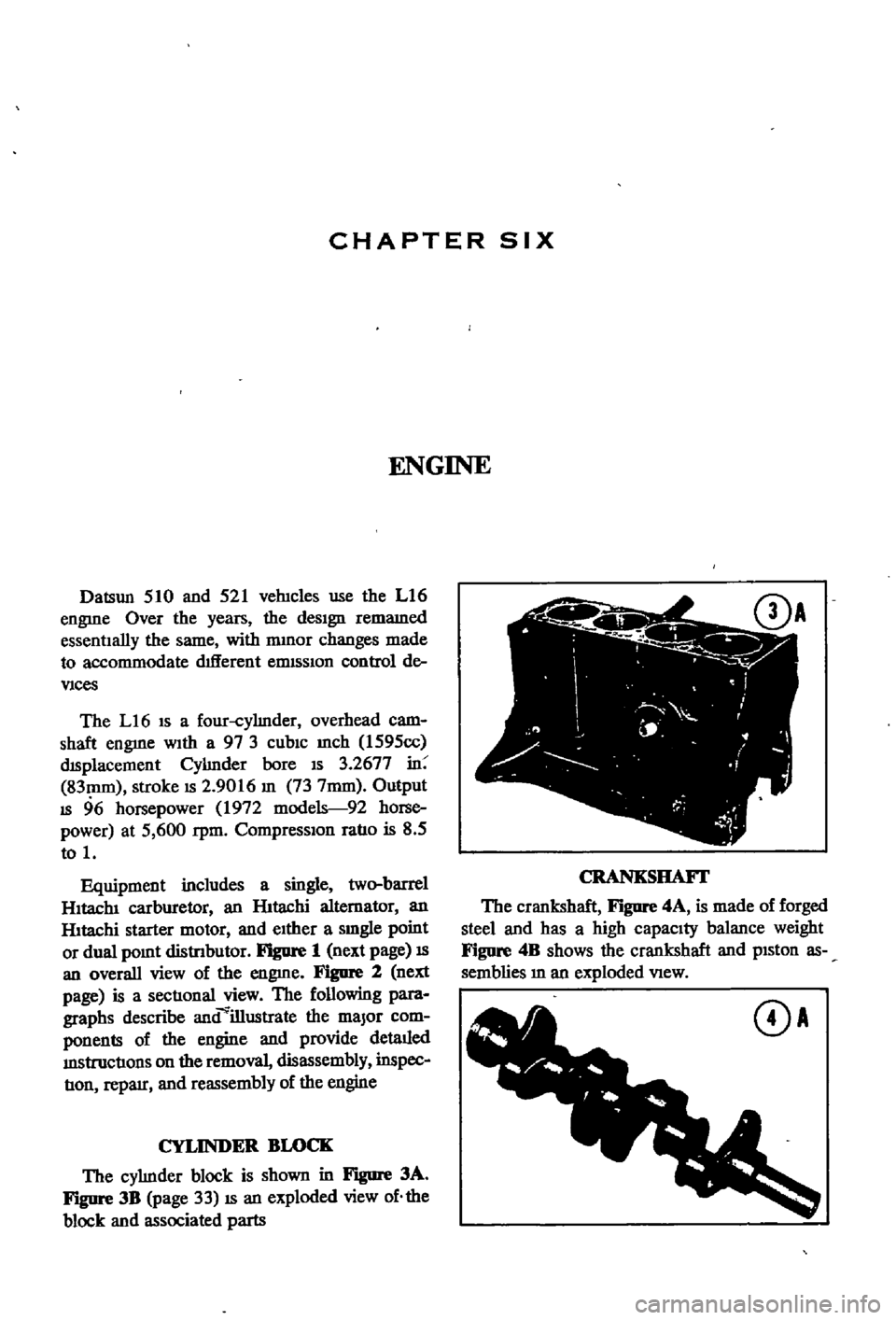

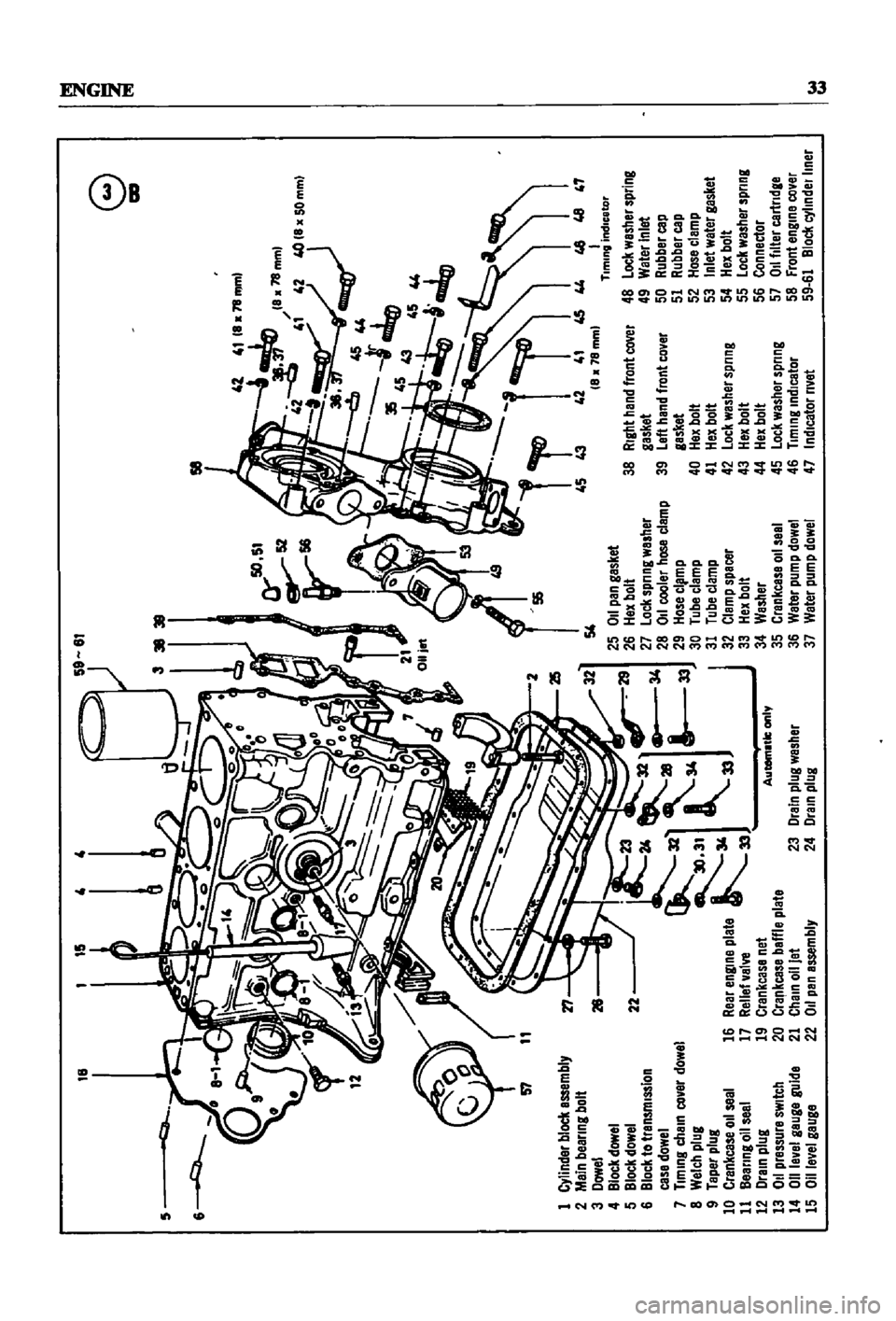

The

cylmder

block

is

shown

in

Figure

3A

Figure

3B

page

33

IS

an

exploded

view

of

the

block

and

associated

parts

CRANKSHAFI

The

crankshaft

F

JgUre

4A

is

made

of

forged

steel

and

has

a

high

capacity

balance

weight

Figure

4B

shows

the

crankshaft

and

pISton

as

semblies

m

an

exploded

VIew

DA

Page 38 of 252

4l

4111a

78

mml

la78mml

42

4

42

4OIla50mml

t

4544

i

35

45

lIq

D

1

43

45

44

6

1i

45

43

42

41

45

44

46

46

47

8

78mml

I

Tlmmg

Indicator

48

lock

washer

spring

49

Water

Inlet

50

Rubber

cap

51

Rubber

cap

52

Hosa

clamp

53

Inlet

watar

gasket

54

Hex

bolt

55

lock

washer

spring

56

Connector

57

011

filter

cartndge

58

front

engme

cover

59

61

Bloel

cyllndelllner

18

15

58

57

1

Cylinder

block

assembly

2

Main

beanng

bolt

3

Dowel

4

Block

dowel

5

Block

dowel

6

Block

to

transmIssIon

case

dowel

7

Tlmmg

chaIn

covar

dowel

8

Welch

plug

9

Taper

plug

10

Crankcase

011

seal

11

Bearing

011

seal

12

Drain

plug

13

011

pressure

sWitch

14

011

level

gauge

guide

15

Oll

evel

gauga

r1

26

54

25

011

pan

gasket

26

Hax

bolt

27

lock

Sprl

ng

washer

28

011

cooler

hose

clamp

29

Hose

cl

mp

30

Tube

clamp

31

Tube

clamp

32

Clamp

spacer

33

Hex

bolt

34

Washer

35

Crankcase

011

seel

36

Waler

pump

dowel

37

Water

pump

dowel

38

RIght

hand

front

caver

gasket

39

left

hand

front

cover

gasket

40

Hex

bolt

41

Hex

bolt

42

lock

washer

spnng

43

Hex

bolt

44

Hex

bolt

45

Lock

washer

spring

46

Tlmmg

Indicator

47

IndIcator

rivet

22

16

23

Drain

plug

washer

24

Dram

plug

e

l

lIlI

1M

1M

Page 41 of 252

36

CHAPTER

SIX

0B

34

35

2224

19

21

p

7

31

13

4

7

O

41

rlj

17

11

lOlL

JET

2

Intake

valve

Insert

3

Exhaust

valve

Insert

4

Intake

valve

guide

5

Exhaust

valve

guide

3

2

7

Od

gallery

taper

plug

I

441

J

8

Cylinder

blind

plug

9

Cylinder

blind

plug

10

Taper

plug

21

Washer

34

Rocker

cover

44

Spnng

washer

11

Cylinder

head

011

jet

22

Front

head

cover

35

Rocker

cover

gasket

45

Water

outlet

12

stud

23

Bolt

36

Od

filler

cap

46

JOint

washer

13

stud

24

Front

cover

head

gasket

37

011

cap

paclung

47

stud

14

stud

28

Hex

bolt

38

Rocker

cover

bolt

48

Hex

nut

15

Stud

29

lock

washer

spring

39

Thennostat

a5sem

bly

49

Spring

washer

17

Cylinder

head

gasket

30

Engine

front

Slinger

40

Thennostat

hOUSing

50

Water

temperature

gauge

18

Cylinder

head

bolt

31

Engine

rear

slinger

41

Thennostat

gasket

51

Water

temperature

ground

nut

19

Cylinder

head

bolt

32

Spnng

washer

42

Hex

bolt

53

Cam

bracket

bolt

20

Cylinder

head

bolt

33

Hex

nut

43

Hex

bolt

54

Cam

bracket

bolt

shoe

type

of

tensIOner

reduces

vibration

and

controls

overall

cham

tenSIOn

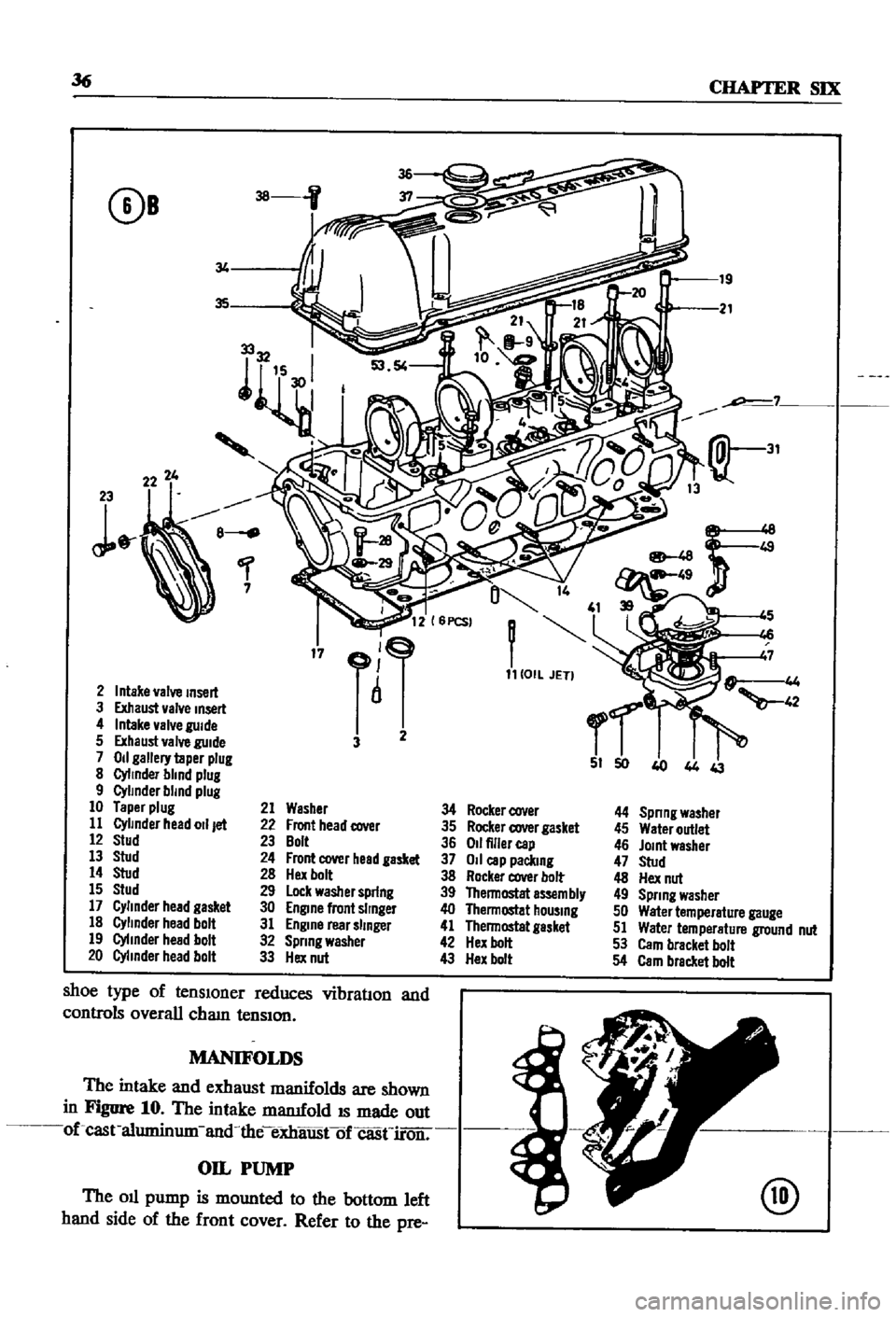

MANIFOLDS

The

intake

and

exhaust

manifolds

are

shown

in

Figure

10

The

intake

mamfold

IS

made

out

of

cast

aluminum

and

the

eXhaustof

casn

roir

OIL

PUMP

The

oil

pump

is

mounted

to

the

bottom

left

hand

side

of

the

front

cover

Refer

to

the

pre

@

Page 43 of 252

38

CHAPTER

SIX

EMISSION

CONTROL

DEVICES

All

Datsuns

have

a

sealed

type

of

crankcase

emISSion

control

device

and

an

exhaust

emISsion

control

deVice

Models

sold

m

Cahfornla

smce

1970

also

have

an

evaporative

emisSion

control

deVice

An

rmportant

part

of

the

exhaust

control

device

is

the

air

pump

located

at

the

bottom

left

hand

side

of

the

engme

It

IS

dnven

by

a

belt

off

of

the

crankshaft

pulley

and

supphes

air

to

the

exhaust

system

In

1972

an

electric

blower

in

corporated

m

the

air

cleaner

replaced

the

mechanical

pumI

ENGINE

REMOVAL

Expenence

has

shown

It

IS

easier

to

remove

the

engine

and

the

transmission

as

a

smgle

UnIt

than

to

remove

the

engme

alone

Once

the

en

gine

and

transmiSSIon

are

out

of

the

vehIcle

the

tranSmIssion

can

be

detached

from

the

engme

To

remove

the

engme

transmISsion

proceed

as

follows

1

Scribe

ahgnment

marks

on

the

hood

around

the

hmges

ThIS

will

make

remstallatlon

eaSIer

2

Remove

the

two

bolts

that

secure

each

hInge

and

remove

the

hood

It

is

not

necessary

to

re

move

the

hood

support

from

the

engme

firewall

3

DISconnect

the

lower

radIator

hose

from

the

right

hand

SIde

of

the

engine

and

at

the

bottom

of

the

radIator

ThIS

will

pernnt

coolant

to

dram

from

the

engme

and

the

radIator

4

Remove

the

draIn

plugs

from

the

engine

pan

and

translIDSsIon

and

completely

dram

lubn

cants

Into

suitable

contamers

5

DISconnect

the

battery

cables

from

the

bat

tery

loosen

the

two

hold

down

clamps

and

re

move

the

battery

NOTE

The

location

and

number

of

hoses

to

be

removed

from

the

air

cleaner

varies

from

model

to

model

It

IS

normally

easier

to

remove

the

hoses

from

the

sources

rather

than

try

to

dISconnect

them

from

yndemeath

the

air

cleaner

The

1972

model

Will

requlre

dlsconnectlOn

of

the

electrica1

cirCUit

In

the

air

cleaner

system

wing

nut

from

the

top

of

the

air

cleaner

and

remove

the

aIr

cleaner

7

DIsconnect

the

upper

radiator

hose

from

the

radiator

and

the

thermostat

housmg

Remove

the

hose

8

Disconnect

the

two

heater

hoses

from

the

nght

hand

side

of

the

engme

TIe

these

bac

so

they

won

t

interfere

with

removal

of

the

engme

9

Remove

the

radIator

grille

by

unscrewing

all

mountmg

screws

10

Remove

the

four

mounting

screws

holding

the

fan

shield

to

the

backside

of

the

radiator

11

Remove

the

four

mountmg

bolts

holdIng

the

radiator

In

place

In

automatic

tranSmISsion

models

dISconnect

the

two

transnnsslOn

oIl

cooler

lInes

from

the

bottom

of

the

radiator

Pull

the

radiator

straight

up

to

remove

Remove

the

fan

shield

12

Loosen

the

adjustment

and

mounting

bolts

from

the

retamIng

brackets

on

the

alternator

and

air

pump

If

so

eqwpped

The

alternator

is

lo

cated

at

the

bottom

nght

hand

Side

of

the

engme

and

the

air

pump

on

the

lower

left

hand

Side

13

Loosen

tenSIon

on

the

two

dnve

belts

re

move

the

belts

from

the

alternator

and

air

pump

and

then

from

the

fan

pulleys

14

Remove

the

bolts

holdIng

the

fan

and

pulley

to

the

water

pump

assembly

and

remove

the

fan

and

pulley

15

DISconnect

the

fuel

hne

from

the

fuel

pump

16

DIsco

ect

accelerator

control

linkage

and

choke

WIre

at

the

carburetor

17

Disconnect

the

wiring

from

the

starter

motor

alternator

Ignition

coIl

oIl

pressure

switch

and

temperature

transmItting

unit

NOTE

The

following

steps

are

per

formed

from

under

the

car

lack

up

the

front

of

the

car

and

position

stands

under

the

front

support

points

to

proVide

working

room

under

the

vehicle

WARNING

Never

climb

under

a

vehicle

that

is

supported

by

the

lack

only

If

stands

are

not

avflllable

sturdy

wooden

blocks

can

be

U3ed

6

Disconnect

all

hoses

that

lead

to

the

air

cleaner

remove

two

bolts

that

hold

the

air

cleaner

to

its

mountmg

bracket

unscrew

the

18

Remove

two

bolts

holdIng

the

clutch

operat

Ing

cylInder

to

the

flywheel

hOUSIng

shown

m

Page 44 of 252

ENGINE

39

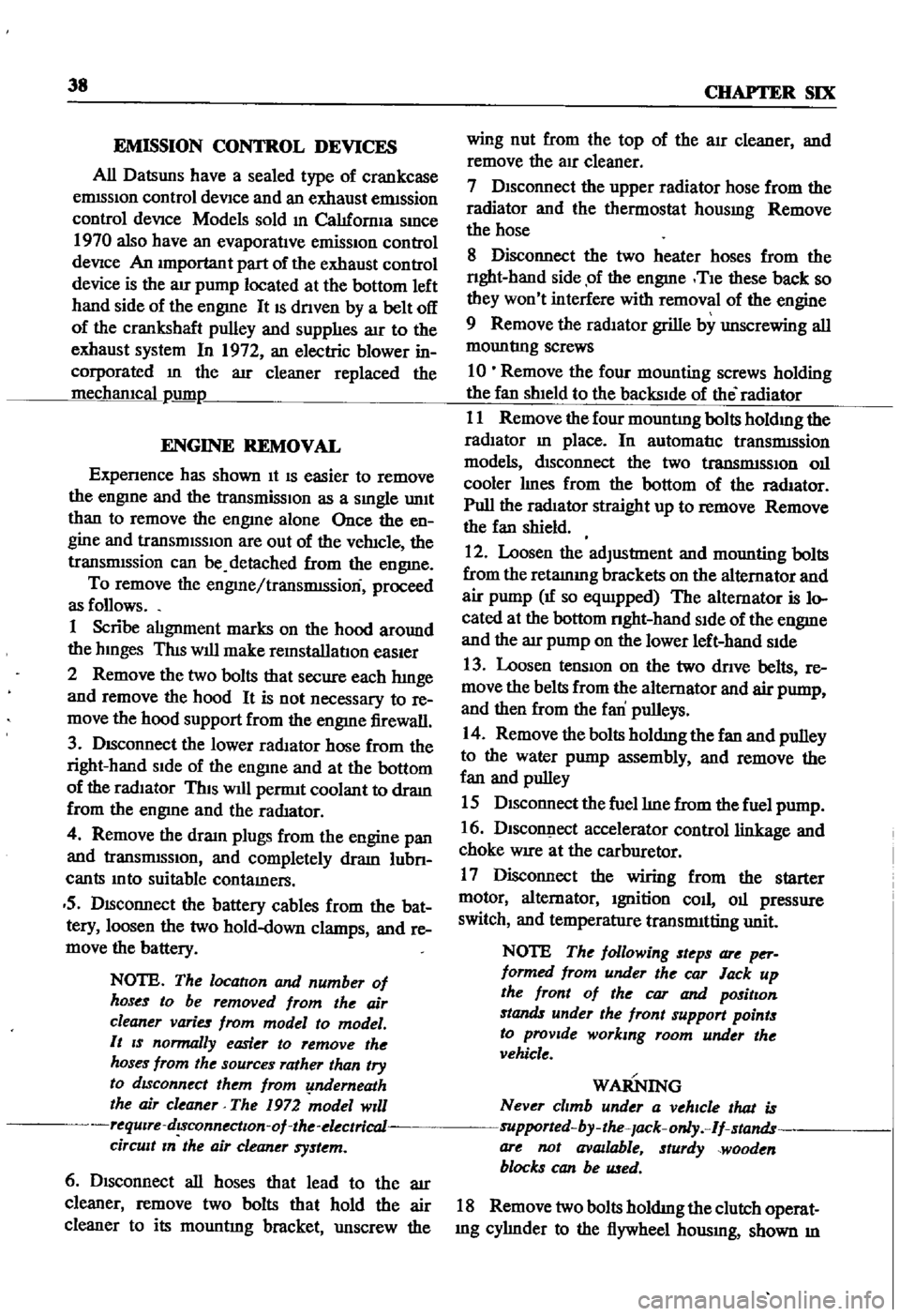

Figure

11

Remove

the

clutch

return

spnng

from

Its

holdmg

bracket

and

the

clutch

operatmg

cylmder

from

the

clutch

withdrawal

lever

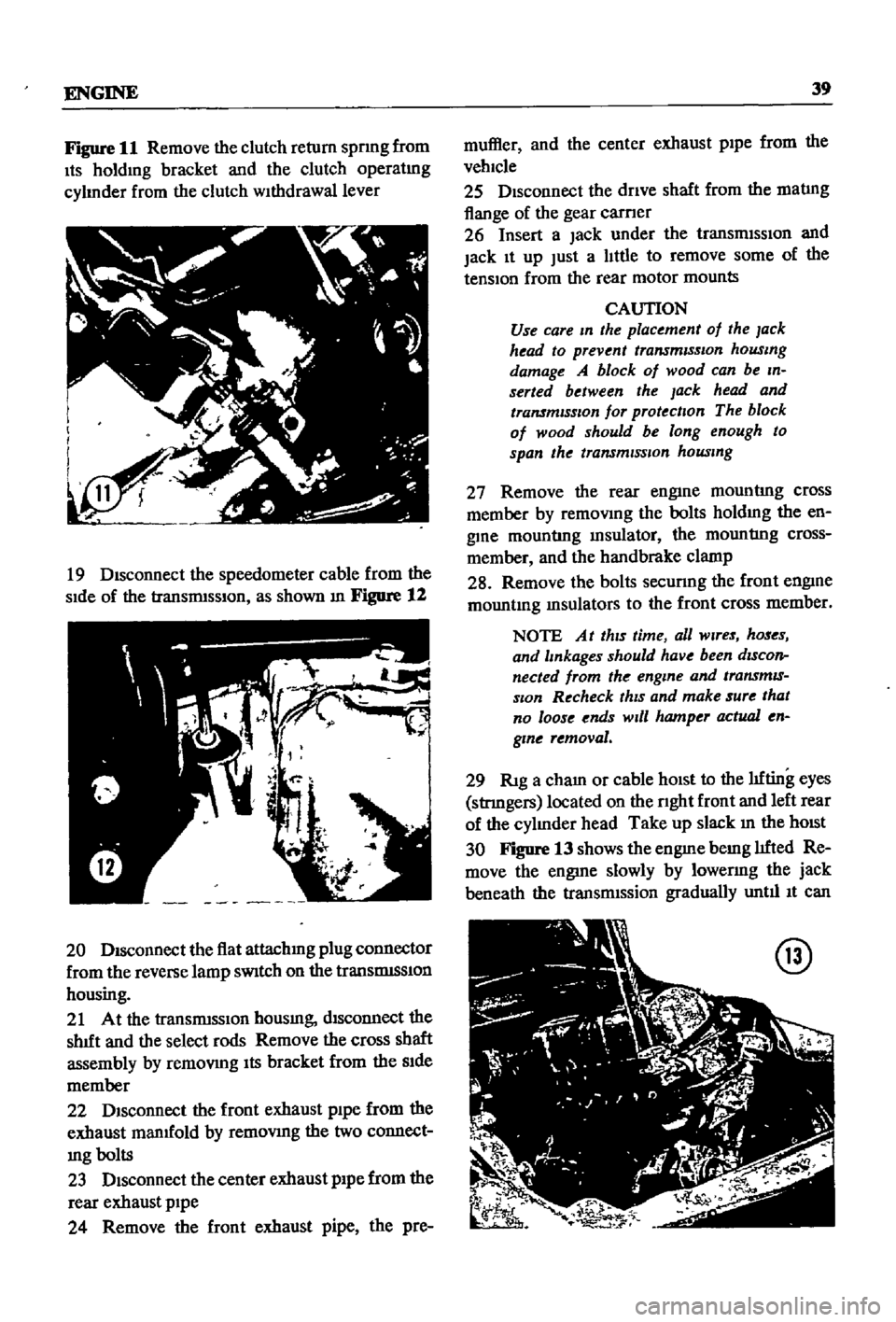

19

Disconnect

the

speedometer

cable

from

the

side

of

the

transnnsslOn

as

shown

m

Figure

12

20

Disconnect

the

flat

attachmg

plug

connector

from

the

reverse

lamp

sWitch

on

the

translDlSSlon

housing

21

At

the

transnnsslOn

housmg

disconnect

the

shIft

and

the

select

rods

Remove

the

cross

shaft

assembly

by

remOVIng

Its

bracket

from

the

Side

member

22

DISconnect

the

front

exhaust

pipe

from

the

exhaust

manIfold

by

remoVing

the

two

connect

mg

bolts

23

Disconnect

the

center

exhaust

pipe

from

the

rear

exhaust

pipe

24

Remove

the

front

exhaust

pipe

the

pre

muffler

and

the

center

exhaust

pipe

from

the

vehicle

25

Disconnect

the

dnve

shaft

from

the

matIng

flange

of

the

gear

carner

26

Insert

a

Jack

under

the

transmiSSIOn

and

jack

It

up

Just

a

little

to

remove

some

of

the

tension

from

the

rear

motor

mounts

CAUTION

Use

care

m

the

placement

of

the

lack

head

to

prevent

transmiSSIOn

housmg

damage

A

block

of

wood

can

be

m

serted

between

the

Jack

head

and

transmISSIOn

for

protection

The

block

of

wood

should

be

long

enough

to

span

the

transmiSSion

housmg

27

Remove

the

rear

engine

mountIng

cross

member

by

remoVing

the

bolts

holdmg

the

en

gine

mountIng

msulator

the

mountIng

cross

member

and

the

handbrake

clamp

28

Remove

the

bolts

secunng

the

front

engine

mountmg

msulators

to

the

front

cross

member

NOTE

At

thiS

time

all

Wires

hoses

and

lmkages

should

have

been

dIScon

nected

from

the

engme

and

transmIS

sIOn

Recheck

thiS

and

make

sure

that

no

loose

ends

Will

hamper

actual

en

gme

removal

29

RIg

a

cham

or

cable

hOist

to

the

lifting

eyes

stnngers

located

on

the

nght

front

and

left

rear

of

the

cylmder

head

Take

up

slack

m

the

hOist

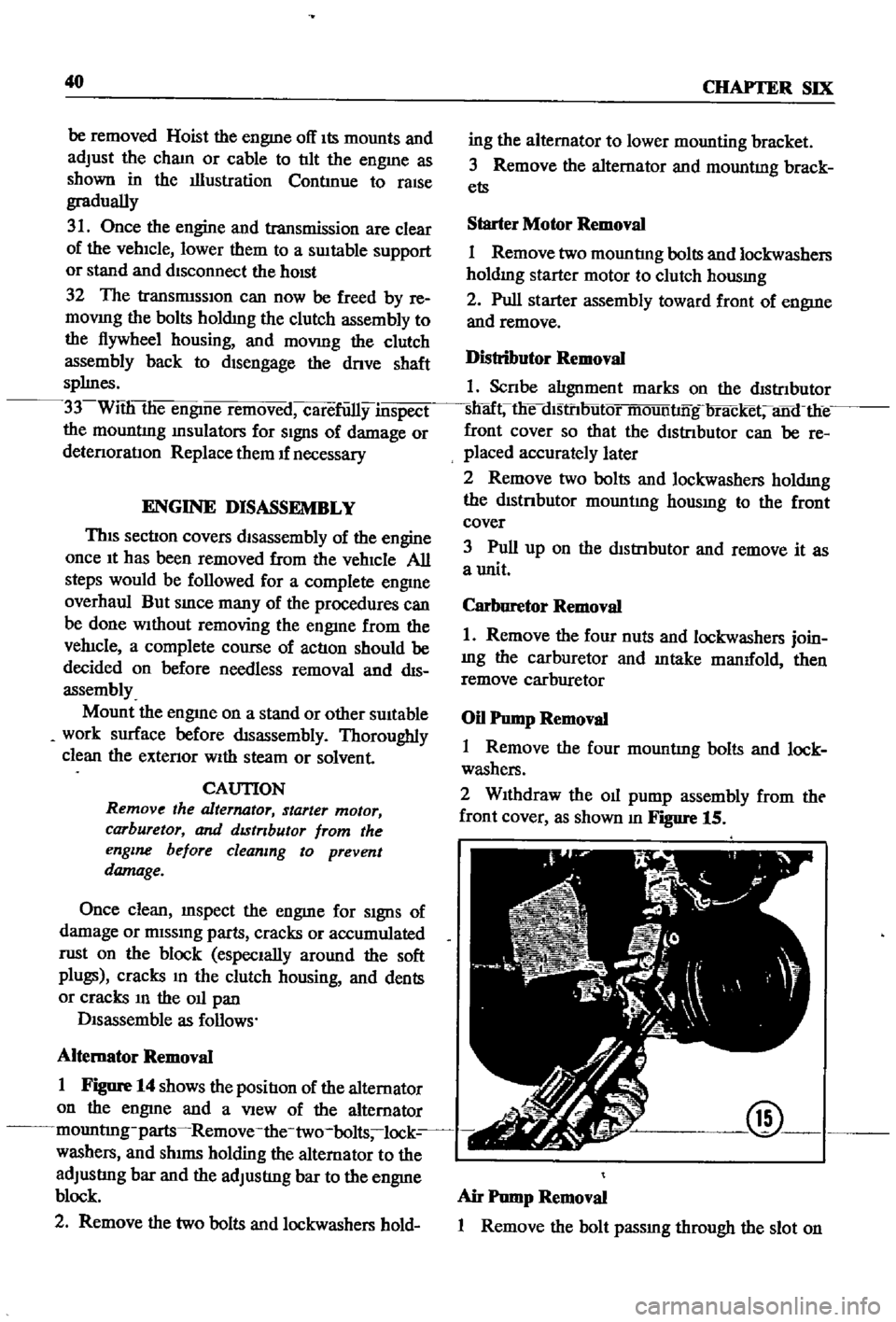

30

Figure

13

shows

the

engme

bemg

lifted

Re

move

the

engine

slowly

by

lowenng

the

jack

beneath

the

transnnssion

gradually

until

It

can

@

Page 45 of 252

40

CHAPTER

SIX

be

removed

Hoist

the

engme

off

Its

mounts

and

adjust

the

cham

or

cable

to

tIlt

the

engme

as

shown

in

the

illustration

ContInue

to

raIse

gradually

31

Once

the

engine

and

transmission

are

clear

of

the

vehIcle

lower

them

to

a

swtable

support

or

stand

and

dIsconnect

the

hOISt

32

The

transmISSIon

can

now

be

freed

by

re

movmg

the

bolts

holdIng

the

clutch

assembly

to

the

flywheel

housing

and

movmg

the

clutch

assembly

back

to

dIsengage

the

dnve

shaft

splmes

33

Witlltlie

engIne

removed

carefiillyinspect

the

mountIng

Insulators

for

SIgnS

of

damage

or

detenoratIon

Replace

them

1f

necessary

ENGINE

DISASSEMBLY

ThIS

sectIon

covers

dIsassembly

of

the

engine

once

It

has

been

removed

from

the

vehIcle

All

steps

would

be

followed

for

a

complete

engme

overhaul

But

smce

many

of

the

procedures

can

be

done

WIthout

removing

the

engIne

from

the

velucle

a

complete

course

of

actIon

should

be

decided

on

before

needless

removal

and

ms

assembly

Mount

the

engme

on

a

stand

or

other

sUItable

work

surface

before

msassembly

Thoroughly

clean

the

extenor

WIth

steam

or

solvent

CAUTION

Remove

the

alternator

starter

motor

carburetor

and

dIStributor

from

the

engine

before

cleaning

to

prevent

damage

Once

clean

mspect

the

engme

for

SIgnS

of

damage

or

mlssmg

parts

cracks

or

accumulated

rust

on

the

block

especIally

around

the

soft

plugs

cracks

In

the

clutch

housing

and

dents

or

cracks

In

the

oil

pan

DISassemble

as

follows

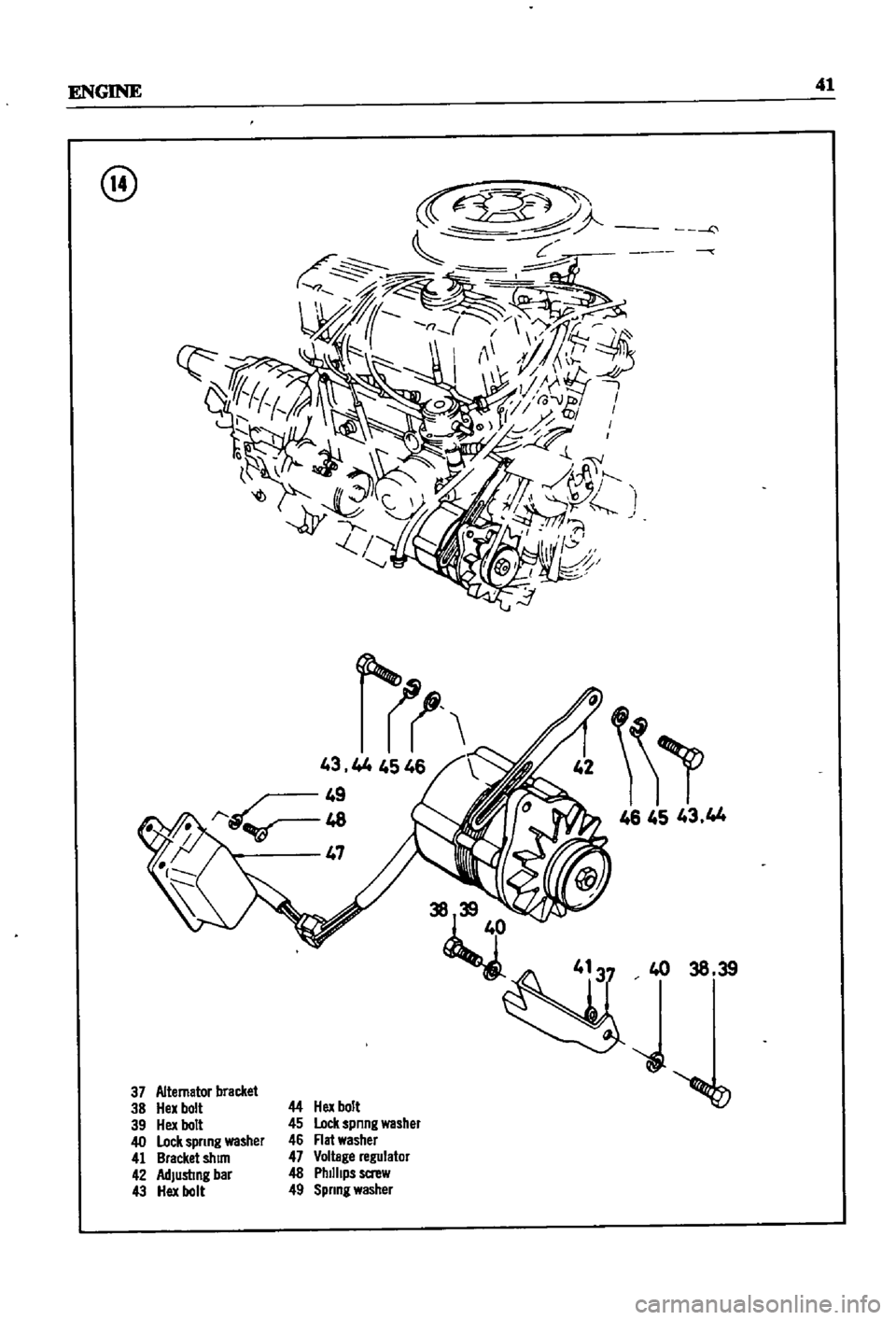

Alternator

Removal

1

Figure

14

shows

the

positIon

of

the

alternator

on

the

engme

and

a

VIew

of

the

alternator

mountIng

parts

Remove

the

two

bolts

lock

washers

and

shmls

holding

the

alternator

to

the

adjustIng

bar

and

the

adjustIng

bar

to

the

engme

block

2

Remove

the

two

bolts

and

lockwashers

hold

ing

the

alternator

to

lower

mounting

bracket

3

Remove

the

alternator

and

mountmg

brack

ets

Starter

Motor

Removal

1

Remove

two

mountIng

bolts

and

lockwashers

holdmg

starter

motor

to

clutch

housmg

2

Pull

starter

assembly

toward

front

of

engme

and

remove

Distributor

Removal

1

Scnbe

ahgnment

marks

on

the

mstrlbutor

shaft

tl

ie

ihsthDutor

mountmg

oracket

anihlfe

front

cover

so

that

the

dIStnbutor

can

be

re

placed

accurately

later

2

Remove

two

bolts

and

lockwashers

holdIng

the

dlstnbutor

mountmg

housmg

to

the

front

cover

3

Pull

up

on

the

dlstnbutor

and

remove

it

as

a

unit

Carburetor

Removal

1

Remove

the

four

nuts

and

lockwashers

join

mg

the

carburetor

and

mtake

manifold

then

remove

carburetor

Oil

Pump

Removal

1

Remove

the

four

mountIng

bolts

and

lock

washers

2

WIthdraw

the

011

pump

assembly

from

tht

front

cover

as

shown

m

Figure

15

@

Air

Pump

Removal

1

Remove

the

bolt

passmg

through

the

slot

on

Page 46 of 252

ENGINE

@

41

I

t

43

44

45

46

49

48

47

46

45

43

44

38

39

37

Alternator

bracket

38

Hex

bolt

39

Hex

bolt

40

Lock

spring

washer

41

Bracket

shim

42

Adjusbng

bar

43

Hex

bolt

44

Hex

bolt

45

Lock

spnng

washer

46

Rat

washer

47

Voltage

regulator

48

Phillips

screw

49

Spring

washer

Page 47 of 252

4Z

CHAPTER

SIX

the

adJustmg

bar

mto

the

mountmg

flange

of

the

arr

pump

2

Remove

the

bolt

lInking

the

arr

pump

to

the

mountmg

bracket

and

remove

pump

3

The

bracket

has

four

bolts

to

the

engme

the

adJustmg

bar

mounts

on

the

front

cover

WIth

two

bolts

Remove

these

to

free

the

front

cover

Water

Pump

Removal

I

Remove

the

bolts

and

lockwashers

Jommg

the

water

pump

to

the

front

cover

The

number

of

bolts

vanes

from

year

to

year

due

to

pump

aesign

clianges

Remove

water

pump

Fuel

Pump

Removal

I

Remove

the

two

nuts

and

lockwashers

secur

mg

fuel

pump

to

the

engIne

and

remove

pump

Rocker

Arm

COYer

Removal

I

Remove

SIX

bolts

holdmg

rocker

arm

cover

to

head

and

lIft

off

cover

Intake

and

Exhaust

Manifold

Removal

I

Remove

eleven

nuts

and

lockwashers

that

secure

the

mtake

and

exhaust

manIfolds

2

Remove

mtake

and

exhaust

manIfolds

as

shown

in

Figure

16

Thermostat

and

Water

Inlet

Housings

1

Remove

two

bolts

and

lockwashers

secunng

thermostat

housmg

to

head

Remove

housmg

as

shown

m

Figure

17

@

2

Remove

two

nuts

and

lockwashers

from

top

of

thermostat

housmg

to

gam

access

to

thermo

stat

3

Remove

two

bolts

and

lockwashers

that

hold

water

mlet

housmg

to

front

cover

and

lIft

off

housing

Front

Cover

Removal

1

Remove

bolt

and

washer

from

center

of

crank

pulley

Pulley

tool

Will

be

necessary

for

removal

from

crankshaft

2

Remove

nme

bolts

and

lockwashers

holdmg

front

cover

to

cylInder

block

then

remove

cover

as

shown

m

Figure

18

@

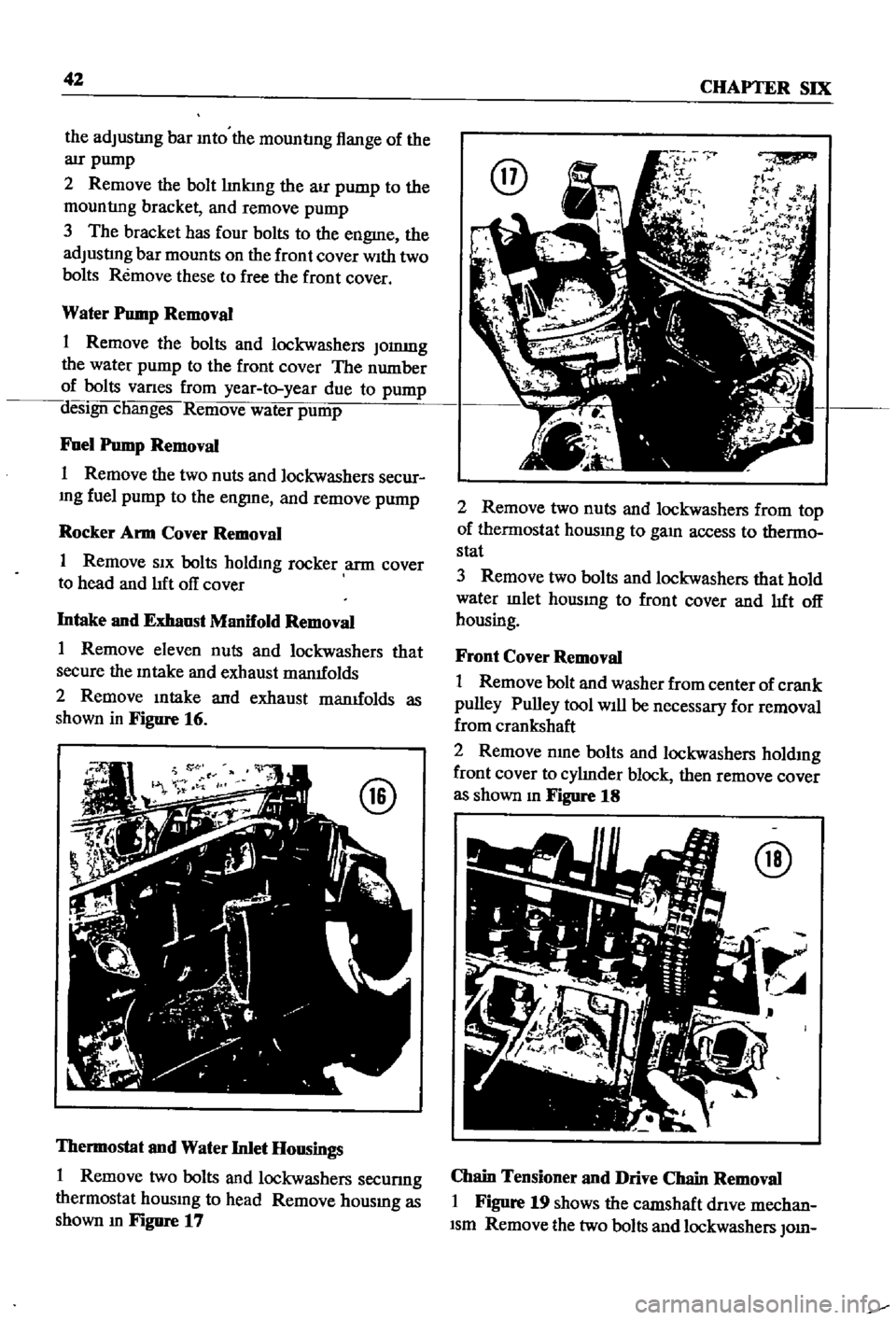

Chain

Tensioner

and

Drive

Chain

Removal

I

Figure

19

shows

the

camshaft

dnve

mechan

Ism

Remove

the

two

bolts

and

lockwashers

010

Page 48 of 252

ENGINE

43

@

0

00

o

mg

the

cham

tenslOner

to

the

block

to

free

the

sprIng

loaded

tenslOner

assembly

2

Remove

the

four

bolts

and

lockwashers

hold

mg

the

left

and

rIght

sIde

cham

guides

to

the

cylmder

block

Remove

the

guIdes

3

On

the

front

of

the

camshaft

remove

the

bolt

and

lockwasher

holdIng

the

fuel

pump

cam

as

sembly

and

the

eam

sprocket

to

the

eam

4

LIft

the

drIve

chaIn

asIde

and

remove

the

earn

sprocket

and

fuel

pump

cam

from

the

cam

shaft

as

shown

In

Figure

20

5

Remove

the

dnve

cham

from

the

crankshaft

drIve

spr6cket

Cylinder

Head

Removal

NOTE

Removal

of

the

cylinder

head

requires

a

special

tool

identified

as

DatsunST49010000

and

is

shown

In

FIGURE

21

@

I

USIng

the

specIal

tool

or

eqUIvalent

remove

ten

bolts

and

washers

holdIng

cylinder

head

to

cyhnder

block

See

Figure

22

2

Remove

head

from

block

and

dtscard

gasket

Oil

Pan

and

Strainer

Removal

I

Invert

the

engme

remove

22

bolts

and

wash

ers

secunng

pan

to

block

and

remove

011

pan

On

automatIc

transmission

models

tpe

pan

bolts

also

hold

the

oIl

cooler

hose

and

tube

clamps

in

place

DISCard

011

pan

gasket

3

Figure

23

shows

the

oIl

stramer

mOlJ

lted

m

the

block

Remove

two

bolts

and

washers

for

dISassembly

Crankshaft

Removal

I

Use

a

gear

puller

as

shown

III

Figure

24

to

pull

the

oIl

thrower

crankshaft

worm

gear

and

drive

cham

sprocket

from

the

crankshaft

The

above

parts

are

held

In

place

by

three

woodruff

keyS

2

DISconnect

the

pIston

and

connectrng

rod

assemblIes

from

the

crankshaft

by

removing

the