lock DATSUN 510 1968 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 4 of 252

II

CHAPTER

SIX

ENGINE

Cylmder

block

Crankshaft

PistOns

and

connectmg

rods

Cyhnder

head

Camshaft

Valve

mechamsm

Camshaft

dnve

Mamfolds

011

pump

Fuel

pump

Carburetor

Emission

control

devIces

Engme

removal

Engme

dISassembly

Pistons

and

connectmg

rods

Cyhnder

head

Engme

mspectIon

and

replllr

Engme

reassembly

Service

data

and

speCifications

CHAPTER

SEVEN

FUEL

SYSTEM

Air

cleaner

Fuel

strlllner

Fuel

pump

Carburetor

Fuel

tank

1

CHAPTER

EIGHT

COOLING

SYSTEM

DescnptIon

Water

pump

Fan

clutch

Thermostat

Radiator

CHAPTER

NINE

ENGINE

ELECTRICAL

SYSTEM

Starter

Overrunmng

clutch

assembly

ChargIng

ClrcUlt

Alternator

Alternator

output

Voltage

regulator

DIstrIbutor

Condenser

Igrntlon

cod

SpeCifications

Spark

plugs

CHAPTER

TEN

EMISSION

CONTROL

SYSTEM

Exhaust

emiSSIOn

control

Crankcase

emission

control

Air

mJectlon

system

Engme

modifications

Evaporative

emiSSion

control

Exhaust

system

CHAPTER

ELEVEN

CLUTCH

TRANSMISSION

AND

DRIVESHAFT

Clutch

TransmissIon

Master

cyhnder

TransmissIon

data

and

speCIfications

Operating

cyhnder

Dnveshaft

Withdrawal

lever

adjustment

Dnveshaft

data

and

speCIfications

Clutch

system

bleedmg

Automatic

transmIssIon

checks

Clutch

data

and

speCIfications

31

62

84

91

114

127

Page 5 of 252

CHAPTER

TWELVE

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

149

DIfferentIal

Rear

axle

and

suspension

Codspnng

Shock

absorber

Rear

suspensIOn

arm

Rear

axle

shaft

Wheel

beanngs

Seals

Rear

spnng

Axle

case

SpecificatIons

CHAPTER

THIRTEEN

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

168

Wheel

hub

and

bearmg

StabilIzer

TenSion

rod

Spnng

and

strut

assembly

Transverse

lInk

Lower

ball

Jomt

Front

suspension

adjustment

Wheel

alignment

Posture

adJustment

Steenng

system

SpeCificatIons

CHAPTER

FOURTEEN

BRAKES

187

Brake

pedal

Master

cylInder

Front

diSC

brakes

Rear

brakes

Front

drum

brakes

Wheel

cylInders

Brake

system

bleedIng

Handbrake

Service

data

and

speCificatIons

CHAPTER

FIFTEEN

BODY

ELECTRICAL

SYSTEM

Wmng

SWitches

and

fuses

Instrument

meters

and

panels

Heater

205

Wmdshleld

wipers

Wmdslueld

washers

Headlamps

WIrIng

diagrams

CHAPTER

SIXTEEN

BODY

223

Front

body

trIm

Bumpers

Hood

lock

control

Doors

Door

locks

and

regulators

Trunk

lId

and

rear

bumper

Seats

Tad

gate

INDEX

235

I

Page 6 of 252

CHAPTER

ONE

GENERAL

INFORMATION

This

manual

provides

maintenance

informa

tIon

on

the

Datsun

510

Series

and

521

Series

of

vehlcles

The

510

Series

includes

the

two

door

sedan

four

door

sedan

and

station

wagon

The

521

Senes

IS

the

pIck

up

truck

Coverage

is

from

1968

through

1972

models

All

models

use

the

L16

engme

a

96

horse

power

four

cylmder

overhead

camshaft

design

The

510

has

a

fully

synchronized

four

speed

manual

or

three

speed

automatic

transmisSIon

The

521

has

a

four

speed

manual

transmission

only

In

1972

horsepower

ratIng

was

lowered

to

92

horsepower

due

to

changes

m

emission

control

device

requirements

Figure

1

is

an

over

all

view

of

the

four

door

sedan

Figure

2

shows

the

station

wagon

and

Figure

3

illustrates

the

pick

up

truck

Over

the

years

the

510

and

521

series

have

remained

essentIally

the

same

with

the

excep

tion

of

changes

to

the

emISsion

control

systems

and

overall

body

stylmg

In

this

manual

every

effort

has

been

made

to

pinpoint

significant

c

if

ferences

between

model

years

The

use

of

SpecIal

tools

and

test

equipment

has

been

avoided

wherever

possible

When

necessary

special

tools

and

test

equipment

are

illustrated

either

in

actual

use

or

alone

A

well

equipped

mecharuc

may

find

he

can

substitute

similar

tools

or

make

his

own

to

fulfill

a

e

Ii

ment

Recommendations

are

occasionally

made

to

refer

servIce

or

mamtenance

to

a

Datsun

dealer

or

a

SpecIaliSt

in

a

specIfied

field

In

these

cases

work

WIll

probably

be

done

more

qUlckly

and

economIcally

than

if

the

mecharuc

performs

them

himself

MODEL

IDENTIFICATION

Body

Number

Plate

The

body

number

IS

stamped

on

the

fire

wall

in

the

engine

compartment

The

numbers

give

the

chasSIS

model

and

serial

number

Model

Identification

Plate

The

model

Identification

plate

Figure

4

is

mounted

WIthin

the

engine

compartment

TIns

plate

gIves

engine

number

and

veh1cle

number

Engine

Identification

The

engine

identrlicatlon

marking

is

stamped

on

the

right

hand

SIde

of

the

cylinder

block

just

below

the

third

and

fourth

sp8l

k

plugs

Model

Identification

Numbel

ll

The

following

numbers

have

been

assigned

to

the

510

and

52

I

Series

vehicles

oj

Page 15 of 252

10

CHAPTER

THREE

pressure

bUllt

up

In

each

cylInder

The

readIngs

when

properly

Interpreted

IndIcate

general

cyl

Inder

and

valve

condltlOn

Vacuum

Gauge

The

vacuum

gauge

IS

easy

to

use

but

dIfficult

for

an

Inexpenenced

mechanIC

to

Interpret

The

results

when

conSIdered

WIth

other

findIngs

can

prOVIde

valuable

clues

to

pOSSIble

trouble

Connect

the

vacuum

gauge

WIth

a

T

connec

tIon

In

the

hose

from

the

carburetor

to

the

vacuum

advance

on

the

dIstnbutor

Start

the

engme

and

let

It

warm

up

thoroughly

Vacuum

readIng

should

be

steady

at

18

22

Inches

NOTE

Subtract

1

Inch

from

reading

for

every

1000

feet

of

altitude

Figure

1

shows

numerous

tYPical

readIngs

WIth

InterpretatIons

Results

are

not

conclusive

WIthout

companng

to

other

tests

such

as

com

preSSIOn

readIngs

Fuel

Pressure

Gauge

ThIS

Instrument

IS

VItal

for

evaluatIng

fuel

pump

performance

Often

a

vacuum

gauge

and

fuel

pressure

gauge

are

combIned

Dwell

Meter

A

dwell

meter

measures

the

dIstance

In

de

grees

of

cam

rotatIon

that

the

breaker

pOInts

remaIn

closed

while

the

engme

IS

runnIng

SInce

thIS

angle

IS

determmed

by

breaker

pOInt

gap

the

dwell

angle

IS

an

accurate

IndIcatIon

of

pOInt

gap

Many

tachometers

Intended

for

tunIng

and

testIng

Incorporate

a

dwell

meter

as

well

Follow

the

manufacturer

s

InstructIon

to

measure

dwell

on

the

Datsun

Tachometer

A

tachometer

IS

essential

for

tunIng

Datsuns

WIth

exhaust

emission

control

deVices

IgmtIOn

turung

and

carburetor

adjustments

must

be

per

formed

at

the

specified

Idle

speed

The

best

In

strument

for

thIS

purpose

IS

one

WIth

a

range

of

0

1

000

or

0

2

000

rpm

Extended

range

0

6

000

or

8

000

Instruments

lack

accuracy

at

lower

speeds

The

InStrument

should

be

capable

of

detecting

changes

of

25

rpm

Stroboscopic

Timing

Light

ThIS

Instrument

pernuts

accurate

IgnitIon

tImIng

By

f1ashmg

a

bght

at

the

preCISe

Instant

cylInder

No

1

fires

the

posItIon

of

the

crank

shaft

pulley

at

that

Instant

can

be

seen

Marks

on

the

pulley

bne

up

With

a

reference

pOInter

on

the

block

dunng

the

tIming

procedure

SUltable

bghts

are

neon

bulb

types

and

xenon

strobe

hghts

Neon

tunmg

bghts

are

ddticult

to

see

and

must

be

used

in

dImly

bt

areas

Xenon

strobe

bghts

can

be

used

In

bnght

sunbght

Use

the

bght

accordIng

to

the

manufacturer

s

InStruC

tIons

Exhaust

Analyzer

Of

all

Instruments

descnbed

here

this

IS

the

least

bkely

to

be

owned

by

a

home

mechanic

One

Instrument

samples

the

exhaust

gases

from

the

taIlpIpe

and

measures

the

thermal

conduc

tIVIty

of

the

exhaust

gas

SInce

different

gases

conduct

heat

at

varYIng

rates

thermal

conduc

tIVIty

of

the

exhaust

IS

a

good

IndIcatIon

of

gases

present

This

Instrument

IS

VItal

for

accurately

checkIng

the

effectIveness

of

exhaust

emIssion

control

adjustments

but

IS

too

expenSIve

for

an

amateur

mechanIC

to

conSIder

buying

STARTER

Starter

system

troubles

are

relatIvely

easy

to

ISolate

The

followmg

are

common

symptoms

and

cures

1

Engme

cranks

very

slowly

or

not

at

all

Turn

on

the

headhghts

If

the

bghts

are

very

dun

most

likely

the

battery

or

the

connecting

WireS

are

at

fault

Check

the

battery

using

the

pro

cedures

descnbed

in

the

Tune

up

chapter

Check

wmmgfur

e

s

wom

andd

connectIom

H

the

battery

and

connectIng

WIres

check

good

turn

the

headlIghts

on

and

try

to

crank

the

engIne

H

the

lIghts

dIDl

drastIcally

the

starter

is

probably

shorted

to

ground

Remove

the

starter

and

test

it

usmg

the

procedures

gIven

in

Chapter

NIne

If

the

lights

remain

bnght

or

dun

slIghtly

when

crankIng

the

engme

the

trouble

may

be

in

the

starter

solenOId

or

wmng

To

ISolate

the

trouble

short

the

two

large

solenoid

ternunals

together

not

to

ground

if

the

starter

cranks

normally

check

the

solenoid

and

wmng

up

to

the

Page 18 of 252

TROUBLESHOOTING

13

trouble

may

also

be

worn

bearings

Remove

the

alternator

and

repair

ENGINE

These

procedures

assume

the

starter

cranks

the

engme

over

normally

If

not

refer

to

Starter

section

m

this

chapter

1

Engme

won

t

start

Could

be

caused

by

the

IgOltlon

or

fuel

problems

First

determine

If

high

voltage

to

spark

plug

occurs

To

do

thiS

dISconnect

one

of

the

spark

plug

wires

Hold

the

exposed

wrre

termlOal

y

to

Y2

lOch

from

ground

any

metal

in

engine

com

partment

With

an

msulated

screwdriver

Crank

the

engme

over

If

sparks

do

not

Jump

to

ground

or

the

sparks

are

very

weak

the

trouble

may

be

10

the

IgnitIOn

system

See

Ignition

System

Trou

bleshootmg

to

further

check

If

sparks

occur

properly

the

trouble

may

be

10

the

fuel

system

See

Fuel

System

Troubleshootmg

2

Engme

misses

steadily

Remove

one

spark

plug

wrre

at

a

tune

and

ground

the

wrre

If

engme

mISs

increases

that

cyhnder

was

work

109

properly

Reconnect

the

wire

and

check

the

others

When

a

wire

IS

dIs

connected

and

engme

miss

remams

the

same

that

cylinder

IS

not

finng

Check

spark

as

descnbed

10

Step

1

If

no

spark

occurs

for

one

cyhnder

only

check

dlStnbutor

cap

wrre

and

spark

plug

If

spark

occurs

prop

erly

check

compressIOn

and

mtake

maOlfold

vacuum

to

ISolate

the

trouble

3

Engme

misses

erratlcally

at

all

speeds

Interrmttent

trouble

can

be

difficult

to

find

It

could

be

ill

the

Ignition

system

exhaust

system

or

fuel

system

Follow

troubleshooting

proce

dures

for

these

systems

carefully

to

isolate

the

trouble

4

Engme

misses

at

Idle

only

Trouble

could

exist

anywhere

ill

IgOltlon

system

Follow

Ignition

TroubleshootlOg

procedure

care

fully

Trouble

could

also

eXist

10

the

carburetor

Idle

crrcult

Check

Idle

mIXture

adjustment

and

check

for

restnctions

m

the

idle

crrcUlt

5

Engme

misses

at

high

speed

only

Problems

could

be

ill

the

fuel

or

IgOltlon

systems

heck

accelerator

pump

operation

fuel

pump

dehvery

fuel

hnes

etc

as

descnbed

under

Fuel

System

Troubleshootillg

Also

check

spark

plugs

and

wrres

6

Low

performance

at

all

speeds

poor

acceleratIOn

Trouble

usually

ill

IgOltlon

or

fuel

system

Check

each

With

the

appropnate

troubleshooting

pro

cedure

7

ExceSSive

fuel

consumptIOn

Could

be

caused

by

a

Wide

variety

of

seemmgly

unrelated

factors

Check

for

clutch

shppage

brake

drag

defective

wheel

beanngs

or

poor

front

end

alignment

Check

IgOltlOn

system

and

fuel

system

8

011

pressure

lamp

does

not

light

when

IgmtlOn

switch

IS

on

Check

the

alternator

warning

lamp

If

it

ISn

t

on

either

go

to

Step

1

Chargmg

System

Trouble

shootlOg

If

only

the

oil

pressure

lamp

IS

off

open

the

englOe

compartment

hd

and

locate

the

oil

pressure

sender

on

the

block

near

the

oil

filter

Make

sure

the

wrre

is

connected

to

the

sender

and

makmg

good

contact

Pull

the

wrre

off

and

ground

it

If

the

lamp

hghts

replace

the

sender

If

the

lamp

does

not

light

replace

the

lamp

9

011

pressure

lamp

lights

or

flickers

when

engme

IS

runmng

Indicates

low

or

complete

loss

of

oil

pressure

Stop

the

englOe

unmedmtely

coast

to

a

stop

With

the

clutch

dISengaged

Tlus

may

simply

be

caused

by

a

low

oil

level

or

an

overheatmg

en

glOe

Check

the

oil

level

and

fan

belt

tensIOn

Check

for

a

shorted

oil

pressure

sender

with

an

ohmmeter

or

a

contlOulty

tester

Remove

and

clean

the

oil

dipstick

and

check

oil

level

and

condition

RepleOlsh

or

replace

the

oil

as

re

qurred

Listen

for

unusual

nOISes

mdlcatmg

dam

aged

beanngs

etc

Do

not

re

start

the

engine

until

you

know

why

the

hght

went

on

and

are

sure

that

the

problem

has

been

corrected

IGNITION

SYSTEM

This

procedure

assumes

the

battery

IS

ill

good

enough

condition

to

crank

the

engme

at

a

normal

rate

Page 20 of 252

TROUBLESHOOTING

15

5

Stumbling

when

acceleratmg

from

Idle

Check

accelerator

pump

diaphragm

and

Idle

speed

adjustment

6

Engine

mISses

at

hIgh

speed

or

lacks

power

This

mdlcates

pOSSible

fuel

starvatIon

Check

fuel

pump

pressure

and

capacIty

Clean

main

Jet

and

float

needle

valve

7

Black

exhaust

smoke

Black

exhaust

smoke

means

a

badly

ovemch

nuxture

Check

Idle

mIXture

and

Idle

speed

ad

Justment

Check

for

excessive

fuel

pump

pres

sure

or

blocked

return

hne

from

carburetor

to

fuel

tank

Check

for

leaky

float

or

worn

needle

valve

8

ExceSSIve

fuel

consumptIOn

ThIS

may

be

another

mdIcatIon

of

an

ovemch

fuel

mixture

Check

that

automatIc

choke

oper

ates

If

so

eqUIpped

or

that

the

manual

choke

contraIlS

not

being

left

out

Check

Idle

mIXture

and

Idle

speed

Check

for

excessIve

fuel

pump

pressure

leaky

float

or

worn

needle

valve

Make

certam

that

jets

are

the

proper

SIZe

Fuel

Pump

Pressure

Testing

1

Install

a

T

fittmg

m

the

fuel

hue

close

to

the

carburetor

2

Connect

a

fuel

pressure

gauge

to

the

fittmg

WIth

a

short

tube

3

Check

fuel

pump

pressure

as

described

in

the

Fuel

System

chapter

EXHAUST

EMISSION

CONTROL

The

followmg

symptoms

as

ume

you

have

ad

justed

the

Ignition

and

carburetor

to

specdicatIon

and

that

you

have

checked

the

results

on

an

accurate

exhaust

gas

anajyzer

1

CO

content

too

low

Make

sure

Idle

speed

IS

not

too

low

Check

Idle

mIXture

adjustment

too

lean

Check

carbu

retor

Jets

and

channels

Clean

and

or

replace

as

necessary

Check

engme

condition

With

a

com

pressIOn

and

vacuum

test

2

CO

content

too

hIgh

Check

Idle

mixture

adjustment

too

nch

Check

for

dIrty

air

cleaner

and

defectIve

automatIc

choke

If

so

equipped

Check

carburetor

Jets

and

channels

Clean

and

or

replace

as

necessary

Check

engme

condItIon

WIth

compression

and

vacuum

test

3

Hydrocarbon

level

too

hIgh

Check

that

Idle

speed

and

mIXture

adjustments

are

to

specIfication

Check

spark

plug

condItIon

and

gap

Check

breaker

pomts

Check

IgnItIon

tnumg

too

early

Check

mtake

mamfold

for

leaks

Check

valve

clearance

too

small

Check

condItIon

of

valves

With

compressIOn

test

MANUAL

CLUTCH

1

SlIppage

ThiS

is

most

noticeable

when

acceleratIng

m

a

hIgh

gear

at

relatIvely

slow

speed

To

check

slip

page

park

the

car

on

a

level

surface

WIth

the

handbrake

set

ShIft

to

2nd

gear

and

release

the

clutch

as

If

drlVing

off

If

the

clutch

is

good

the

engme

will

slow

and

stall

If

the

clutch

shps

con

tInued

engme

speed

will

gIve

It

away

CAUTION

ThIS

IS

a

severe

test

Perform

only

when

slippage

IS

suspected

not

penodlcally

Shppage

results

from

IDSufliclent

clutch

pedal

free

play

all

or

grease

on

the

clutch

disc

worn

pressure

plate

or

weak

sprmgs

Also

check

for

bIndIng

m

the

clutch

cable

and

lever

arm

which

may

prevent

full

engagement

2

Drag

or

failure

to

release

ThIS

problem

usually

causes

dIfficult

shIftIng

and

gear

clash

espeCially

when

downshIftmg

The

causes

may

be

excessive

clutch

pedal

free

play

warped

or

bent

pressure

plate

or

clutch

dISC

ex

cessive

clutch

cable

guide

sag

and

broken

or

loose

clutch

lmings

Check

conditIOn

of

mam

shaft

splines

3

Chatter

or

grabbing

A

number

of

thmgs

can

cause

tIns

Check

cable

gUIde

sag

and

tIghtness

of

transnusslOn

to

frame

and

engme

to

transmlSslon

mountIng

bolts

Check

for

worn

or

mISaligned

pressure

plate

and

misalIgned

release

plate

4

Other

nOIses

NOISe

usually

mdlcates

a

dry

or

defective

release

bearIng

Check

the

beanng

and

replace

If

neces

Page 21 of 252

16

CHAPTER

TIlREE

sary

Also

check

all

parts

for

mlSaltgnment

and

uneven

wear

TRANSMISSION

1

Difficult

to

mesh

gears

Make

certam

the

clutch

pressure

plate

and

re

lease

beanng

are

m

good

condItion

The

trouble

can

be

caused

by

worn

gears

shaft

and

or

bear

mgs

DISassemble

and

repaIr

as

requIred

Also

can

be

caused

by

msufficlent

operatmg

stroke

due

to

worn

or

loose

sltdmg

parts

or

a

defective

synchronIZer

DIsassemble

carefully

InSpect

and

replace

as

requIred

2

Gears

slip

out

of

mesh

Generally

thIS

trouble

occurs

when

the

mterlock

plunger

check

ball

and

or

spnng

IS

weakened

or

worn

The

trouble

can

also

be

caused

by

worn

fork

rod

ball

groove

damaged

bearings

or

dam

aged

gears

DIsassemble

carefully

mspect

and

replace

as

required

3

NOIse

If

nOISes

are

heard

wIth

the

engme

idlmg

and

the

clutch

disengaged

the

nOIse

IS

probably

conung

from

the

transmISSIOn

Several

Items

can

cause

nOISes

either

smgly

or

m

combmatIon

Check

the

qualIty

and

quantity

of

lubrIcant

in

the

trans

mISSIon

Replace

or

replenISh

as

necessary

Worn

bearIngs

wIll

usually

produce

a

lugh

humming

at

hIgh

speed

and

a

cycltc

knockIng

sound

at

low

speed

Worn

or

damaged

splInes

and

bushmgs

will

also

cause

nOIse

BRAKES

1

Brake

pedal

goes

to

floor

There

are

numerous

causes

for

thIS

includIng

excessIvely

worn

Itnmgs

aIr

in

the

hydraultc

sys

tem

leaky

brake

lmes

leaky

wheel

cylmders

or

leaky

or

worn

master

cylmder

Check

for

leaks

and

thIn

brake

linmgs

Bleed

and

adjust

the

brakes

If

thIS

doesn

t

cure

the

trouble

rebwld

wheel

cylmders

a

nd

or

master

cylmder

2

Spongy

pedal

Normally

caused

by

aIr

m

the

system

blee

d

and

adjust

the

brakes

3

Brakes

pull

Check

brake

adjustment

Also

check

for

contam

inated

brake

Itmngs

from

leaks

leaky

wheel

cyltnders

loose

caltpers

frozen

or

seIZed

pIstons

and

restrIcted

brake

lmes

or

hoses

In

addItion

check

front

end

alignment

and

suspensIOn

dam

age

such

as

broken

front

or

rear

sprmgs

shocks

etc

Check

condItIon

of

tIres

4

Brakes

squeal

or

chatter

Check

brake

lmmg

thickness

and

brake

drum

roundness

Ensure

that

the

shoes

have

cham

ferred

ends

and

are

not

loose

Inspect

the

condI

tion

of

the

rotors

on

the

front

wheel

dISC

brakes

to

make

certain

they

are

not

scored

or

damaged

Clean

away

all

dIrt

on

shoes

pads

rotors

or

drums

5

Draggmg

brakes

Check

brake

adjustment

includmg

handbrake

Check

for

broken

or

weak

shoe

return

springs

swollen

rubber

parts

due

to

unproper

brake

flUId

or

other

contammatIon

Clean

or

replace

de

fectIve

parts

6

Hard

pedal

Check

brake

linmgs

for

contammation

Also

check

for

restrIcted

brake

lines

and

hoses

7

High

speed

fade

Check

for

dIstorted

or

out

of

round

drums

and

contamInated

brake

lmmgs

Make

certam

the

recommended

brake

flUId

IS

used

Dram

entIre

system

and

refill

If

In

doubt

8

Pulsatmg

pedal

Check

for

dIStorted

or

out

of

round

drums

or

rotors

Check

for

excessIVe

brake

dISC

run

out

STEERING

AND

SUSPENSION

NOTE

Unusual

steermg

pullmg

or

wandermg

IS

usually

caused

by

bent

or

otherwise

mIsaligned

suspenszon

parts

Because

of

the

speCialized

equIp

ment

reqUired

to

evaluate

and

correct

these

faults

It

IS

recommended

t

tat

servIce

to

the

steermg

and

suspension

system

be

referred

to

your

Datsun

dealer

oca

quallfied

specrallst

m

thiS

field

1

VibratIOn

felt

m

steermg

wheel

VIbratIon

can

be

caused

by

several

thmgs

includ

ing

lll1proper

aIr

pressure

m

tIres

uneven

wear

Page 29 of 252

P

r

OVll

t

ate

I

l

h

l

JlA

ye

I

o

ctg

fI

O

0

I

d

1e

d

c

Ji

uo

JJ

cb

c

s

rlr

I

l

4

c

1

2

24

CHAPTER

FOUR

block

and

should

be

used

as

the

reference

point

m

II

1akmg

adjustments

6

With

a

piece

of

white

chalk

mark

a

hne

down

the

center

of

the

pomter

and

mark

the

timing

groove

on

the

crankshaft

pulley

which

IS

to

be

used

m

tImmg

the

engine

SpecIficatIon

for

tun

ing

reqUIres

trlhmg

at

10

degrees

before

top

dead

center

wluch

would

be

the

fourth

mark

from

the

left

end

of

the

row

of

marks

7

Loosen

the

hold

down

bolt

at

the

base

of

the

dlstnbutor

8

Locate

the

slow

speed

1

Ile

adjustIng

screw

on

the

carburetor

so

that

Ile

speed

can

be

adjusted

whIle

runnmg

Also

locate

throttle

adJustmg

screw

9

Start

engme

and

adjust

speed

With

the

adJust

ing

screws

to

the

readmgs

below

Smgle

pomt

dIStributor

600

rpm

Dual

pomt

trlbutor

700

rpm

10

Alternate

adjustment

of

the

two

screws

untIl

the

smoothest

Idle

at

the

proper

speed

IS

achieved

11

Pomt

the

tlIrung

lIght

at

the

stationary

pomter

When

the

lIght

flashes

the

timmg

mark

n

the

crankshaft

pulley

should

hne

up

With

the

mark

on

the

stationary

pomter

If

It

does

not

exactly

Ime

up

rotate

the

dlstnbutor

gradually

untIl

the

marks

align

mdlcatlng

correct

timmg

12

Shut

off

the

engme

remove

the

tmung

lIght

and

tachometer

tighten

the

hold

down

bolt

on

the

dlStnbutor

and

connect

the

vacuum

advance

hne

to

the

tli

tnbutor

IGNITION

TIMING

IDLE

SPEED

IDLE

MIXTURE

DUAL

POINT

DISTRIBUTOR

ONLY

The

followmg

applies

to

velucles

With

dual

pomt

distributor

and

an

exhaust

emission

con

trol

deVice

If

these

procedures

are

followed

ha

ul

exhaust

emisSion

should

be

below

the

maximum

allowable

level

1

Locate

the

Idle

and

throttle

adJustmg

screws

on

the

carburetor

2

Warm

up

the

engine

thoroughly

3

Connect

tachometer

and

tmung

light

4

Set

the

Id

le

speed

at

700

rpm

With

the

Idle

adjust

screw

5

Adjust

IgnltJ

on

tuning

at

10

degrees

before

top

dead

center

6

Increase

the

speed

of

the

engme

to

2

000

rpm

With

the

accelerator

or

throttle

hnkage

and

hold

for

about

15

seconds

7

Return

to

Idle

for

one

mmute

8

Set

the

engme

to

best

Idle

at

750

rpm

770

rpm

for

automatJ

c

transIDlsslOn

With

the

Idle

and

throttle

adJustmg

screws

9

Re

uce

engme

speed

at

700

rpm

720

rpm

for

automatic

transmission

by

turnmg

the

Idle

adJustmg

screw

clockWise

for

a

leaner

IlliXture

10

Connect

a

wife

lead

between

the

advance

ami

retard

Side

tenrunals

See

Figure

4

Speed

should

drop

from

100

to

150

rpm

11

Check

IgIl1tIon

tmung

With

tImmg

light

It

should

now

be

at

top

d

ad

center

12

If

the

tlmmg

IS

nSJt

correct

stop

the

engme

and

adjust

the

retarded

breaker

pomt

13

Start

the

engme

and

reclieck

ili

tmung

If

l

incorrect

reset

the

retarded

breaker

pomt

until

it

IS

correct

Repeat

s

nece

s

14

Disconnect

the

wife

bet

reen

the

advance

and

retard

termmals

15

Recheck

tmung

It

should

be

10

degrees

before

top

dead

center

16

If

mcorrect

repeat

the

above

procedures

un

tIl

satIsfactory

17

T

he

Idle

speed

of

automatic

transnllsslOn

vehicles

should

be

about

575

rpm

With

the

gear

j

selector

m

the

dhve

poSltlon

c

t

DWELL

ANGLE

SETIING

1

Connect

the

dwell

angle

meter

2

PLoJust

dwell

angle

to

49

to

55

degrees

OMPRESSION

TEST

I

A

compressIOn

test

IS

performed

to

check

for

worn

piston

nngs

or

to

detect

the

cause

of

a

low

speed

miss

Before

undertaking

the

test

el

llmate

the

pOSSibility

of

sticky

valves

by

usmg

one

of

the

oil

additives

deSigned

for

the

purpose

With

valves

free

test

compressIOn

as

follows

1

Run

the

engme

for

15

to

20

mmutes

untIl

normal

operating

temperatures

are

obtained

2

Shut

off

engme

remove

arr

cleaner

and

Page 30 of 252

ENGINE

AND

IGNITION

TUNE

UP

4

25

block

the

throttle

and

choke

m

the

WIde

open

position

3

Remove

all

four

spark

plugs

4

Sequentially

press

a

compressIOn

test

gauge

mto

each

of

the

spark

plug

holes

and

crank

the

engme

for

at

least

four

strokes

Record

the

com

pressIOn

readmg

for

each

cylmder

Standard

compressIOn

readmg

IS

171

Ibs

m

12

0

kg

cm

Mmlmum

acceptable

readmg

IS

159

lbs

m

2

11

5

kg

cm

5

No

readmg

should

be

less

than

80

of

the

highest

cylmder

reading

ExceSSive

vanatiC

ns

between

cylmders

accompanied

by

low

speed

mlssmg

of

the

cyhnder

or

cylmders

that

read

low

usually

mdlcates

a

valve

not

properly

seat

mg

or

a

broken

piston

ring

Low

pressures

even

though

uniform

may

mdicate

worn

nngs

ThIS

IS

especlall

true

1f

ex

cessive

011

cQIlsumptlon

has

been

noticed

If

one

or

more

cylmders

read

low

or

uneven

inject

about

a

tablespoon

of

engine

ail

on

top

of

the

piston

of

that

cylinder

and

crank

the

engine

several

tlmes

noting

the

compressIOn

reading

If

compressIOn

has

nsen

the

piston

nngs

or

cylmders

are

worn

and

should

befserviced

If

compressIOn

has

not

unproved

after

addmg

oil

the

valves

are

Stlcking

or

are

not

seating

prop

erly

If

two

adjacent

cylmders

have

low

compres

sion

and

mjectmg

01

9es

not

increas

the

read

mg

the

head

gasket

between

the

cylmders

IS

probably

leaking

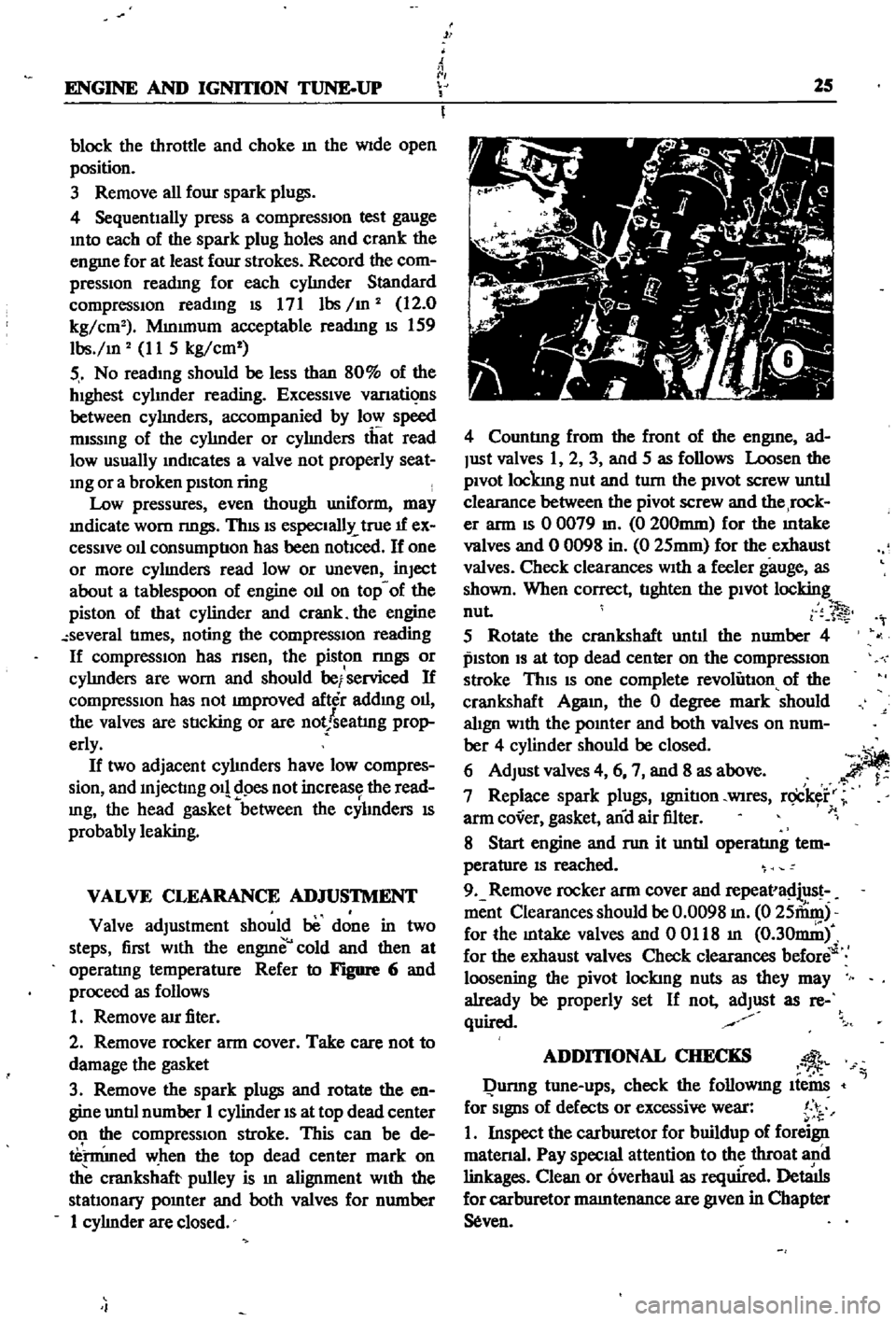

VALVE

CLEARANCE

ADJUSTMENT

Valve

adjustment

should

be

done

in

two

steps

first

With

the

engme

cold

and

then

at

operatmg

temperature

Refer

to

Figure

6

and

proceed

as

follows

1

Remove

arr

liter

2

Remove

rocker

arm

cover

Take

care

not

to

damage

the

gasket

3

Remove

the

spark

plugs

and

rotate

the

en

gine

unt1l

number

1

cylinder

IS

at

top

dead

center

o

l

the

compressIOn

stroke

This

can

be

de

tepnmed

w

hen

the

top

dead

center

mark

on

the

crankshaft

pulley

is

m

alignment

With

the

statIOnary

pomter

and

both

valves

for

number

1

cylmder

are

closed

I

4

Counting

from

the

front

of

the

engme

ad

Just

valves

1

2

3

and

5

as

follows

Loosen

the

pivot

lockmg

nut

and

turn

the

pivot

screw

unt1l

clearance

between

the

pivot

screw

and

the

rock

er

ann

IS

0

0079

m

0

200mm

for

the

mtake

valves

and

0

0098

in

0

25mm

for

the

exhaust

valves

Check

clearances

With

a

feeler

gauge

as

shawn

When

correct

tlghten

the

pivot

locking

nut

l

1

5

Rotate

the

crankshaft

unt1l

the

number

4

pISton

IS

at

top

dead

center

an

the

compressIOn

stroke

This

IS

one

complete

revolution

of

the

crankshaft

Agam

the

0

degree

mark

should

align

With

the

pomter

and

both

valves

on

num

ber

4

cylinder

should

be

closed

6

Adjust

valves

4

6

7

and

8

as

above

i

I

7

Replace

spark

plugs

Ignition

WIres

r

ick

r

1

arm

cover

gasket

and

air

filter

8

Start

engine

and

run

it

unt1l

operating

tem

perature

IS

reached

9

Remove

rocker

ann

cover

and

repeava

iius

ment

Clearances

should

be

0

0098

m

0

25fumj

for

the

mtake

valves

and

00Il8

m

0

30mi

for

the

exhaust

valves

Check

clearances

before

loosening

the

pivot

lockmg

nuts

as

they

may

already

be

properly

set

If

not

adjust

as

re

quir

l

ADDmONAL

CHECKS

l

Qunng

tune

ups

check

the

followmg

Ite

far

SignS

of

defects

or

excessive

wear

I

i

1

Inspect

the

carburetor

for

buildup

of

foreign

matenal

Pay

Special

attention

to

the

throat

and

linkages

Clean

or

overhaul

as

required

Det8

1ls

for

carburetor

mamtenance

are

given

in

Chapter

seven

Page 34 of 252

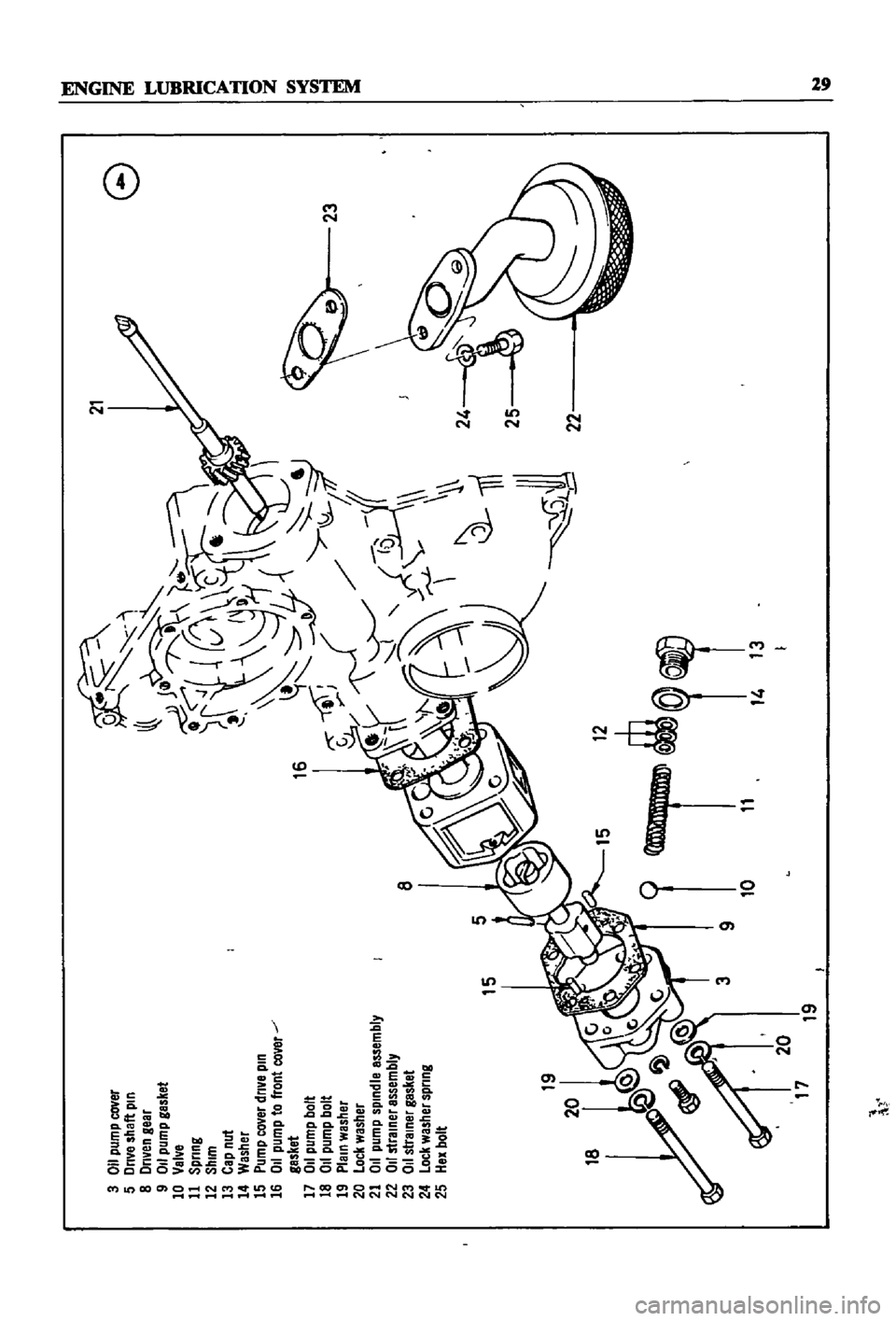

21

G

3

011

pum

p

cover

5

Drive

shaft

pin

8

Driven

gear

9

011

pump

gasket

10

Valve

11

Spring

12

Shim

13

Cap

nut

14

Washer

15

Pump

cover

drive

pin

16

011

pump

to

front

cover

gasket

17

011

pump

bolt

18

011

pump

bolt

19

Plain

washar

20

Lock

washer

21

011

pump

spindle

assembly

22

011

strainer

assembly

23

011

strainer

gasket

24

Lock

washer

spring

25

Hax

bolt

8

18

12

I

T

10

11

14

13

19

I

t

l

o

z

N

0