lock DATSUN 510 1968 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 71 of 252

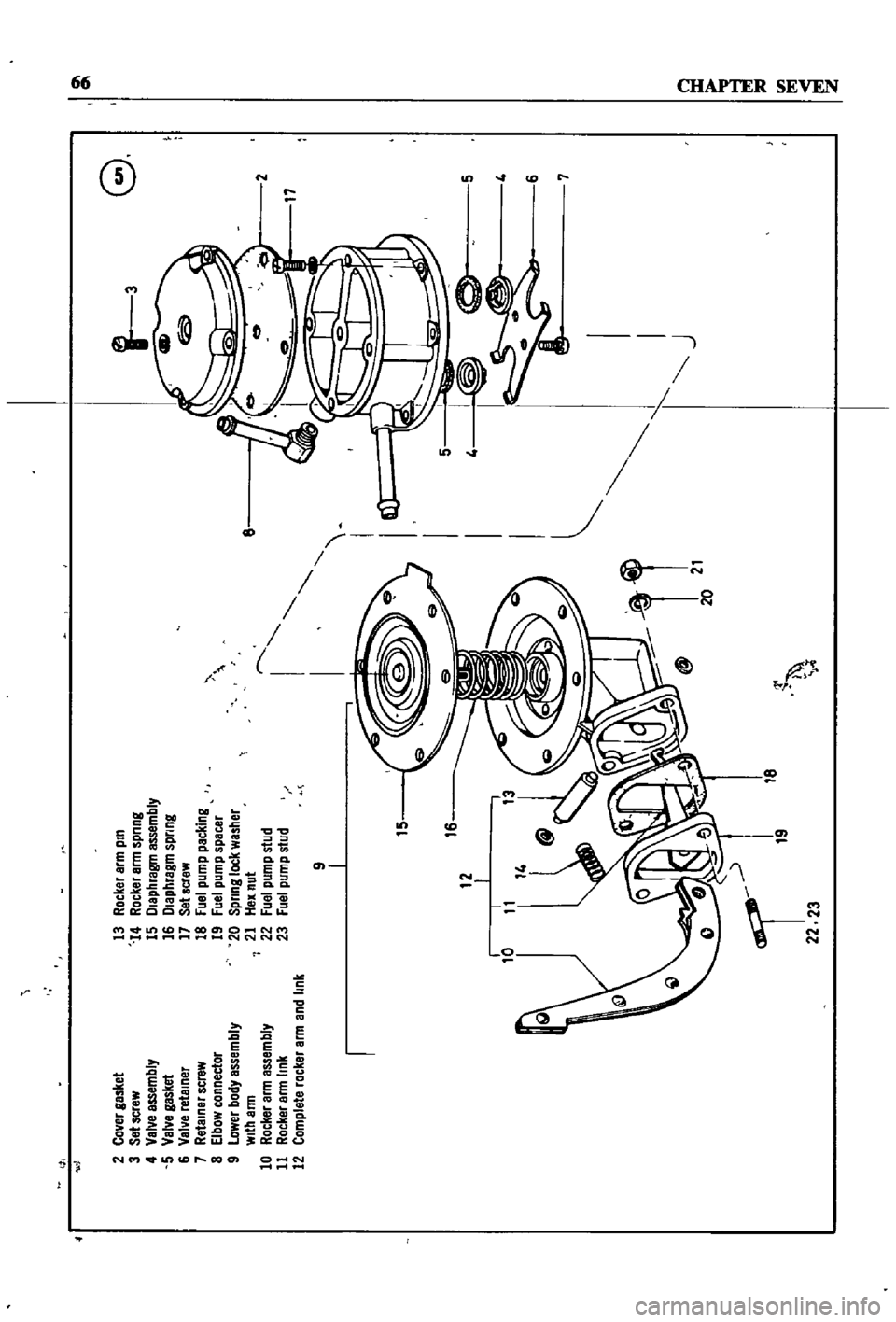

01

01

G

1

3

2

Co

er

gasket

3

Set

screw

4

Val

e

assembly

5

Val

e

gasket

6

Val

e

retelner

7

Retainer

screw

8

Elbow

connector

9

lower

body

assembly

With

arm

10

Rocker

arm

assembly

11

Rocker

arm

link

12

Complete

rocker

arm

and

link

13

Rocker

arm

pin

14

Rocker

arm

spnng

15

Dlephragm

assembly

16

Diaphragm

spring

17

Sehcrew

18

Fuel

pump

pecking

19

Fuel

pump

spacer

20

Spnng

lock

washer

21

Hex

nut

22

Fuel

pump

stud

23

Fuel

pump

stud

2

17

r

I

I

I

I

I

I

I

I

I

J

9

I

I

15

I

0

5

I

16

1i

20

21

g

tI

i

I

lb

18

22

23

r

Page 75 of 252

70

CHAPTER

SEVEN

CD

1

Float

seat

2

Roat

3

Roat

stopper

4

Needle

valve

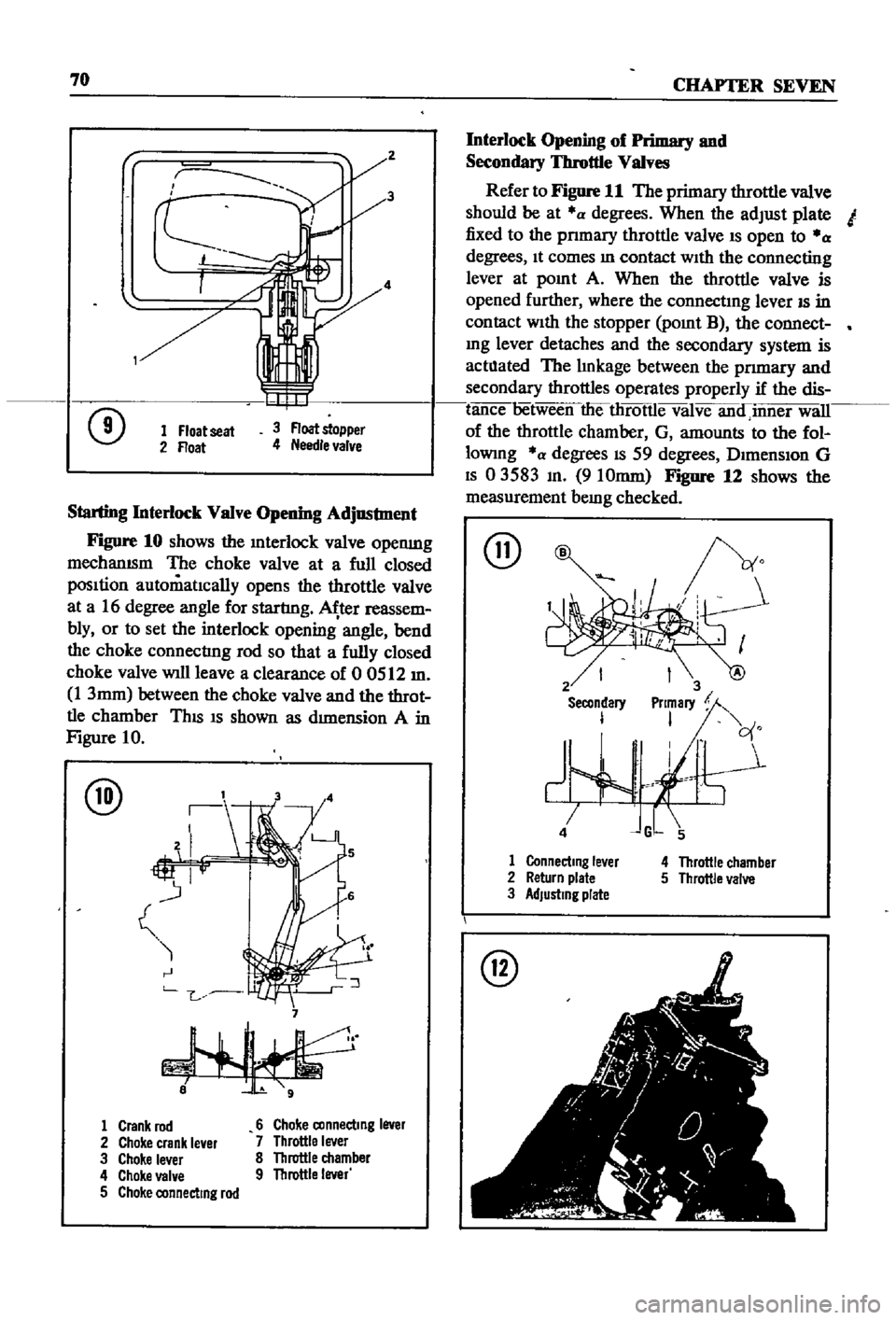

Starting

Interlock

Valve

Opening

Adjustment

Figure

10

shows

the

Interlock

valve

openmg

mechanISm

The

choke

valve

at

a

full

closed

pOSItion

automatIcally

opens

the

throttle

valve

at

a

16

degree

angle

for

startlng

ter

reassem

bly

or

to

set

the

interlock

opening

angle

bend

the

choke

connectlng

rod

so

that

a

fully

closed

choke

valve

will

leave

a

clearance

of

0

0512

m

1

3mm

between

the

choke

valve

and

the

throt

tle

chamber

ThIS

IS

shown

as

dImension

A

in

Figure

10

@

7

1

Crank

rod

6

Choke

connecting

lever

2

Choke

crank

le

er

7

Throttle

lever

3

Choke

lever

8

Throttle

chamber

4

Choke

VBI

e

9

Throttle

lever

5

Choke

connecting

rod

Interlock

Opening

of

Primary

and

Secondary

Throttle

Valves

Refer

to

Figure

11

The

primary

throttle

valve

should

be

at

a

degrees

When

the

adjust

plate

I

fixed

to

the

pnmary

throttle

valve

IS

open

to

a

degrees

It

comes

In

contact

WIth

the

connecting

lever

at

pOInt

A

When

the

throttle

valve

is

opened

further

where

the

connectIng

lever

IS

in

contact

With

the

stopper

POInt

B

the

connect

mg

lever

detaches

and

the

secondary

system

is

actllated

The

lInkage

between

the

pnmary

and

secondary

throttles

operates

properly

if

the

dis

tance

6etween

theilirotlle

valve

anainner

will

of

the

throttle

chamber

G

amounts

to

the

fol

lowmg

a

degrees

IS

59

degrees

DImenSIon

G

IS

03583

In

910mm

Figure

12

shows

the

measurement

bemg

checked

@

2

Secondary

I

1

Connecting

le

er

2

Return

plate

3

Adjusting

plate

4

Throttle

chamber

5

Throttle

valve

I

1

I

r

t

i

t

r

1

I

j

I

00

I

r

@

Page 76 of 252

FUEL

SYSTEM

71

Dash

Pot

Adjustment

The

adjustment

of

the

dash

pot

IS

done

by

warmmg

up

the

engme

properly

and

checkIng

If

the

throttle

lever

touches

th

dash

pot

stem

as

the

engine

reaches

1

800

and

2

000

rpm

under

no

load

conditIons

Proper

contact

between

the

throttle

lever

and

the

dash

pot

stem

produces

a

normal

dash

pot

performance

Should

a

normal

mcrease

m

engme

speed

not

occur

adjust

the

dash

pot

as

follows

1

Loosen

the

dash

pot

locknuts

2

Rotate

the

dash

pot

nght

and

then

left

3

Adjust

the

dash

pot

so

that

the

throttle

lever

hIts

the

stem

between

1

800

and

2

000

rpm

4

Fasten

the

lock

nuts

securely

5

The

clearance

between

the

throttle

valve

and

the

throttle

chamber

wall

should

be

0

0709

m

0

8mm

or

10

degrees

In

throttle

valve

angle

MAJOR

CARBURETOR

SERVICE

PROCEDURES

A

carburetor

m

good

operatIng

condition

will

delIver

the

pr

per

gasolme

and

aIr

ratIos

for

all

engme

runnmg

speeds

A

gradual

declme

In

smoothness

response

and

power

Will

occur

as

the

carburetor

slIps

from

adjustment

and

Its

delI

cate

parts

become

dirty

and

worn

Overhaul

should

only

be

attempted

by

an

expenenced

mechanic

Accurate

calIbratIon

of

passages

and

dIS

charge

hole

reqUIre

that

extreme

care

be

taken

In

dISassembly

cleanmg

and

reassembly

Use

only

a

hIgh

grade

carburetor

cleaner

and

com

pressed

arr

to

clean

parts

and

passages

Never

use

wire

or

other

pOInted

Instruments

for

clean

ing

CalIbratIon

of

the

carburetor

will

be

af

fected

The

procedures

below

are

generally

true

for

all

models

As

an

aId

Figures

13

and

14

are

typIcal

examples

of

the

carburetors

used

Carburetor

Removal

1

Remove

the

au

cleaner

by

dIsconnectIng

all

hoses

attached

to

It

remoVmg

the

two

bolts

holdmg

the

aIr

cleaner

to

the

support

and

loos

enmg

the

band

bolt

at

the

base

of

the

aIr

cleaner

2

DIsconnect

fuellme

vacuum

Ime

and

choke

wire

u

eqUIpped

from

the

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

holdmg

car

buretor

to

manIfold

5

Lift

carburetor

off

of

manuold

6

Remove

and

dIscard

carburetor

to

manuold

gasket

7

Place

carburetor

on

clean

workbench

Carburetor

Disassembly

1

The

maIn

Jets

slow

Jets

and

needle

valves

on

both

the

pnmary

and

secondary

systenIS

are

accessIble

from

outsIde

the

carburetor

Refer

to

FIgures

13

and

14

for

locatI

n

2

The

choke

chamber

can

be

detached

by

re

mOVIng

the

connectIng

rod

pump

connectIng

rod

return

sprmg

stop

pm

and

the

set

screws

I

that

hold

It

in

place

3

The

pnmary

and

secondary

emulSIon

tubes

can

be

disassembled

by

remOVIng

the

mam

air

bleeds

on

the

respectIve

SIdes

4

To

check

the

accelerator

pump

remove

the

cylInder

cover

Be

careful

not

to

lose

the

return

spnng

and

Inlet

valve

at

the

lower

part

of

the

pIston

durmg

dIsassembly

5

Detach

the

throttle

chamber

from

the

float

chamber

by

remOVIng

the

rod

lInkIng

the

dia

phragm

WIth

the

secondary

throttle

valve

and

the

four

screws

that

hold

It

However

It

IS

preferable

to

leave

the

throttle

valve

mtact

unless

absolutely

reqUired

If

It

IS

necessary

to

dlS

assemble

the

valve

It

should

be

Installed

so

that

the

secondary

throttle

valve

will

be

gap

free

OtherwIse

stable

Idle

and

good

slow

speed

performance

will

suffer

is

To

check

the

float

the

float

chamber

cover

must

be

removed

I

7

The

dIaphragm

IS

dIsassembled

by

removing

the

set

screws

holdmg

the

dIaphragm

chamber

cover

In

reassemblIng

the

diaphragm

be

careful

not

to

turn

the

edge

of

the

dIaphragm

up

8

In

dlsassemblmg

and

reassembling

the

mter

lockIng

lInks

take

care

so

that

each

lInkage

has

a

smooth

actIon

and

that

parts

are

not

forced

mto

pOSItIon

9

For

vehIcles

equipped

With

an

automatIc

choke

remove

the

brmetal

case

by

releasmg

the

set

screws

The

bimetal

1l

extremely

senSItIve

Page 81 of 252

76

CHAPTER

SEVEN

Carburetor

Assembly

Assembly

is

the

reverse

of

dISassembly

Make

certam

all

gaskets

are

mounted

flat

Be

careful

not

to

use

force

In

assembly

Make

certam

that

all

Interlock

lInks

operate

smoothly

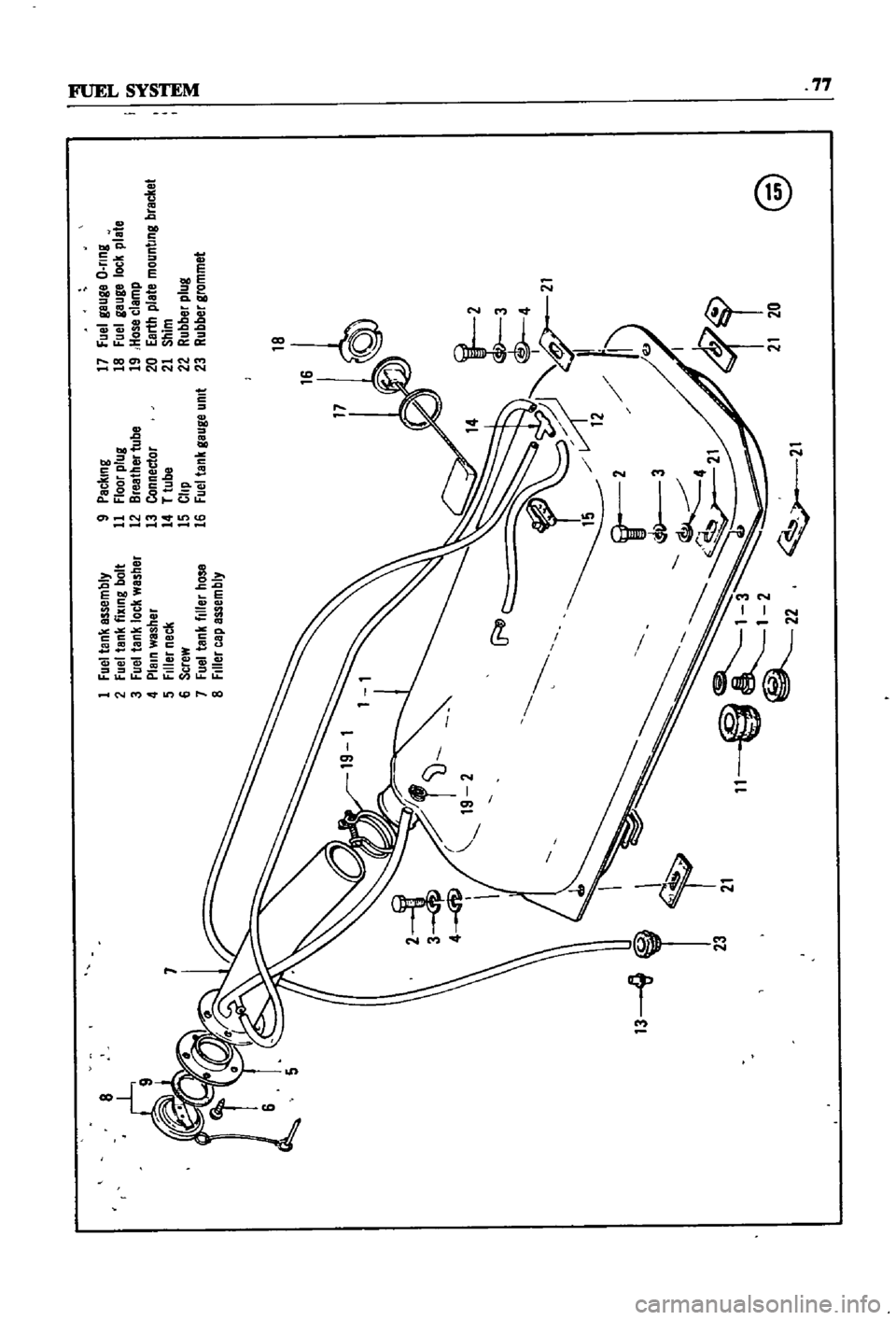

FUEL

TANK

Description

FIgures

15

16

17

and

18

are

exploded

views

of

the

fuel

tanks

used

on

the

sedan

and

wagons

Figure

15

IS

for

sedans

through

model

year

1969

Figure

16

applIes

to

sedans

from

1970

With

evaporative

control

system

F

q

nre

17

shows

the

statIon

wagon

through

1969

Figure

18

applIes

to

the

statIon

wagon

WIth

evaporative

control

system

f

m

1970

The

fuel

tank

for

the

pIck

up

is

shown

m

Figure

19

A

fuel

return

system

from

the

carburetor

to

the

fuel

tank

keeps

fuel

from

becommg

over

heated

m

the

carburetor

float

chamber

When

the

normal

level

m

the

float

chamber

IS

exceeded

a

pressure

valve

opens

and

returns

the

excess

fuel

to

the

tank

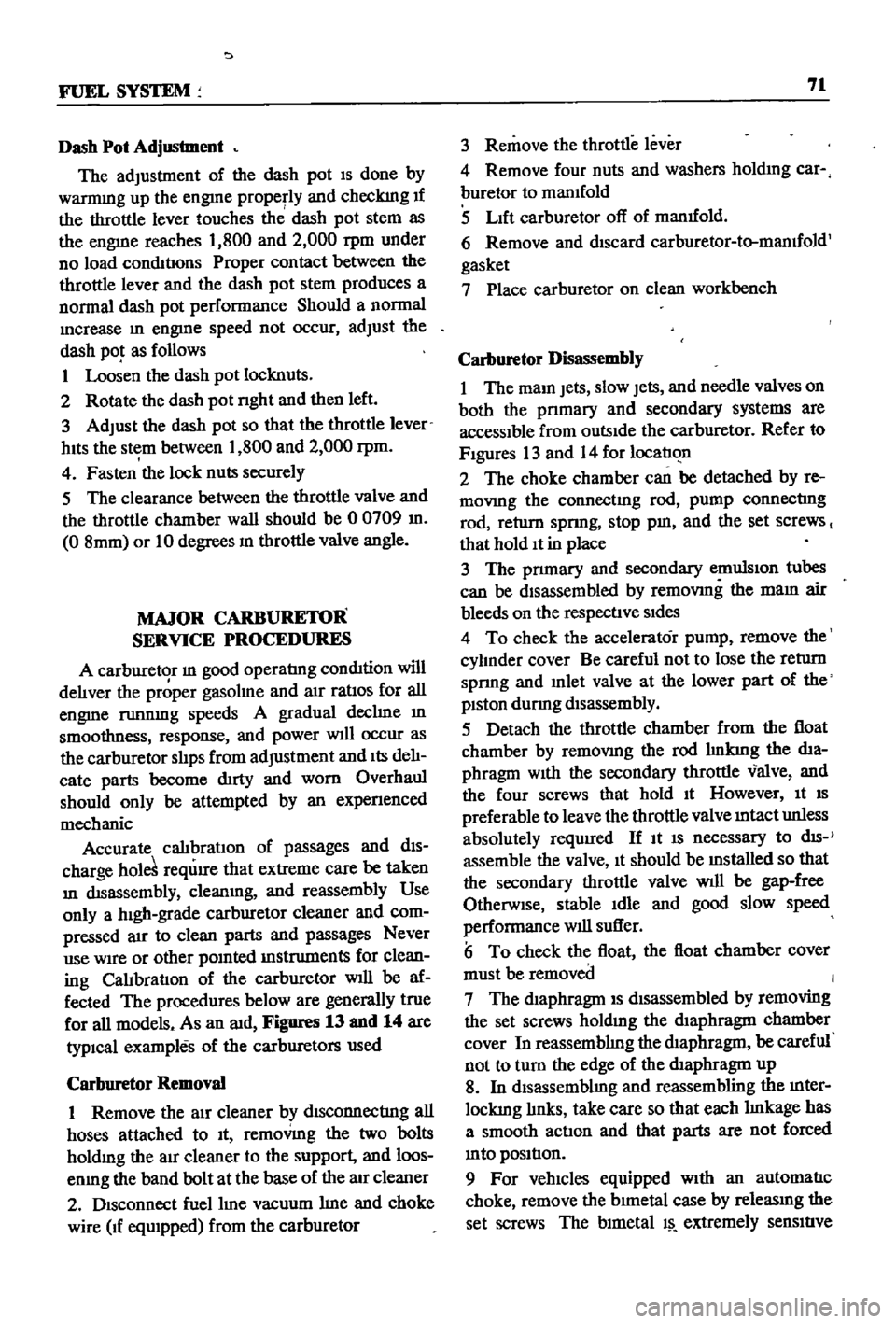

Removal

Sedans

1

Remove

drain

plug

m

bottom

of

fuel

tank

and

drain

the

fuel

into

a

suitable

safe

contamer

2

Detach

rear

seat

and

seat

back

See

Figure

20

3

Open

trunk

lId

and

remove

the

trunk

finISh

mg

board

4

DIsconnect

wire

leadmg

to

fuel

gauge

umt

5

DIsconnect

and

remove

the

fuel

inlet

tube

See

Figure

21

6

DIsconnect

rubber

tubes

of

fuel

outlet

and

fuel

return

lInes

from

the

tank

7

Remove

four

fixmg

bolts

and

lock

washers

from

edge

of

fuel

tank

8

Remove

fuel

tank

from

vehicle

Removal

Wagon

1

Remove

draIn

plug

from

bottom

of

fuel

tank

and

dram

the

fuel

mto

swtable

safe

contatner

2

Disconnect

WIre

leadIng

to

fuel

gauge

unit

3

Disconnect

and

remove

fuel

mlet

tube

4

DISconnect

rubber

tubes

of

fuel

outlet

and

fuel

return

lInes

5

Refer

to

Figure

22

Remove

four

fixing

bolts

holdmg

tank

in

place

6

Remove

fuel

tank

from

veh1c1e

Page 82 of 252

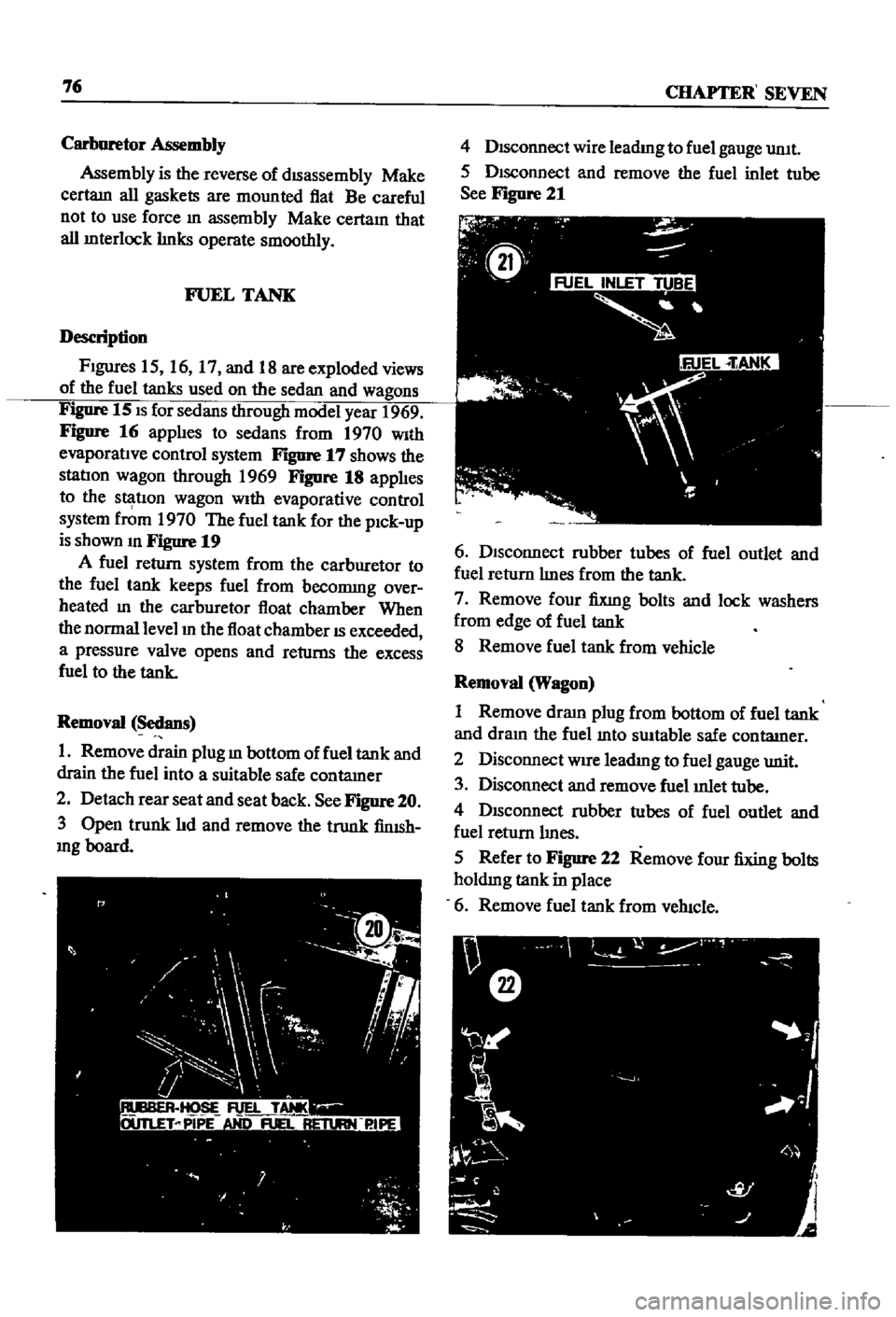

8

1

Fuel

tank

Bssembly

2

Fue

tank

fixing

bolt

3

Fuel

tank

lock

washBr

4

Plain

washer

5

Filler

neck

6

Screw

7

Fuel

tank

filler

hOS8

8

Filler

cap

Bssembly

9

Packing

11

Floor

plug

12

BrBather

tube

13

Connector

14

T

tube

15

Clip

16

Fuel

tank

gauge

umt

17

Fuel

gaUgB

O

nng

18

Fuel

gauge

lock

plate

19

Hose

clamp

20

Earth

plate

mounting

bracket

21

Shim

22

Rubber

plug

23

Rubber

grommB

7

13

Id

@

t

I

l

I

1

Page 88 of 252

23

29

30

i

@

24

t

I

1

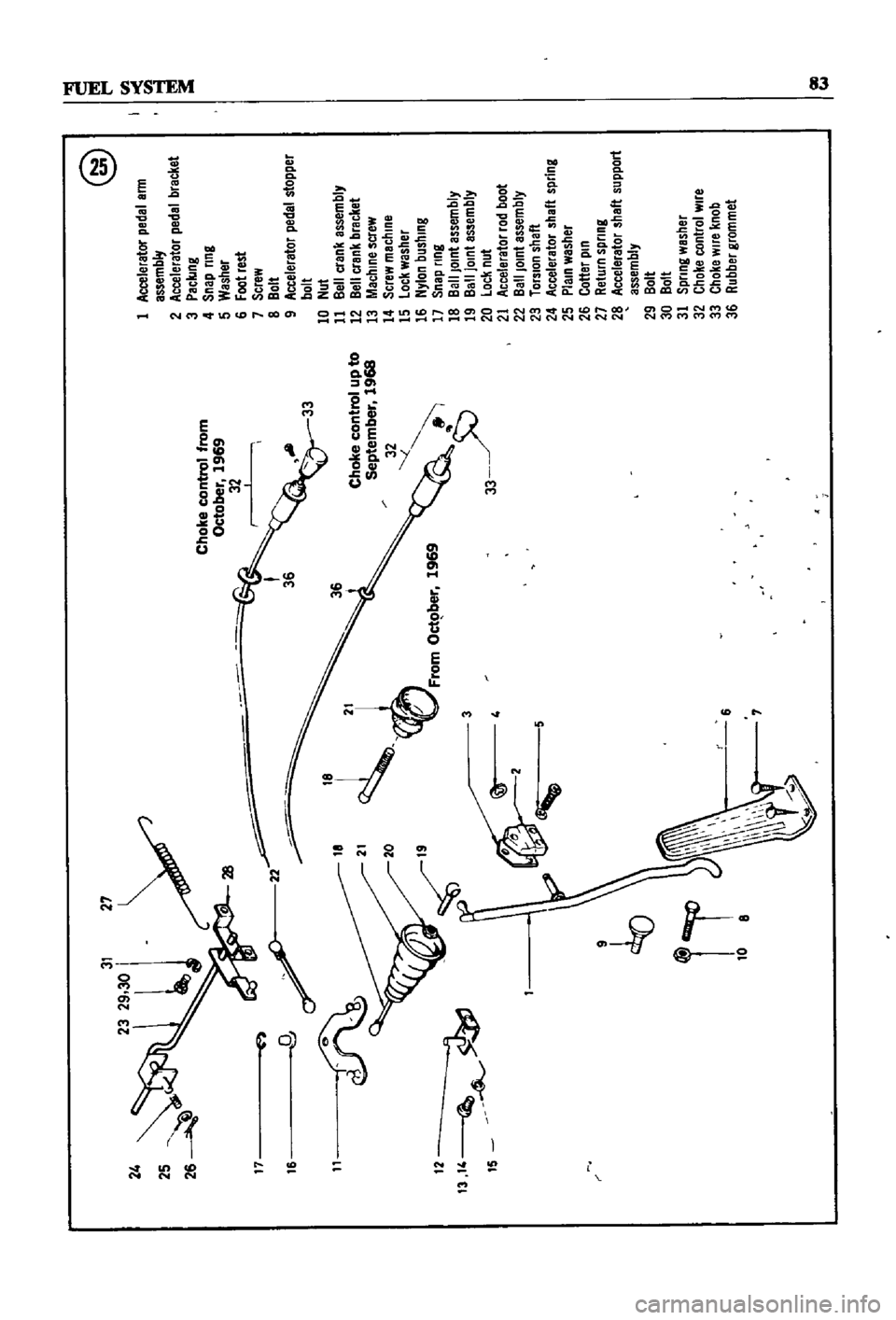

Accelerator

pedal

ann

I

assembly

2

Accelerator

pedal

brecket

3

Packing

4

Snap

ling

5

Washer

17

ll

O

II

C

I

6

foot

rest

7

Screw

8

Bolt

9

Accelerator

pedel

stopper

bolt

10

Nut

11

Bell

crank

assembly

12

Bell

crank

bracket

20

L

13

Machme

screw

14

Screw

mechme

15

Lock

washer

12

From

Oct

ber

1969

I

16

Nylon

bushmg

1314

17

Snap

ling

If

3

0

18

Ball

Jomt

assembly

19

Ball

Jomt

assembly

15

20

Lock

nut

21

Accelerator

rod

boot

22

Balllomt

assembly

23

TorSIon

shaft

24

Accelerator

shaft

spring

25

PlaIR

washer

9

26

Colter

pm

do

27

Return

spllng

28

Accelerator

shalt

support

assembly

29

Bolt

II

30

Bolt

31

SPlIng

washer

32

Choke

control

wire

6

33

Choke

wile

knob

10

8

36

Rubber

grommet

7

I

I

er

Page 89 of 252

CHAPTER

EIGHT

COOLING

SYSTEM

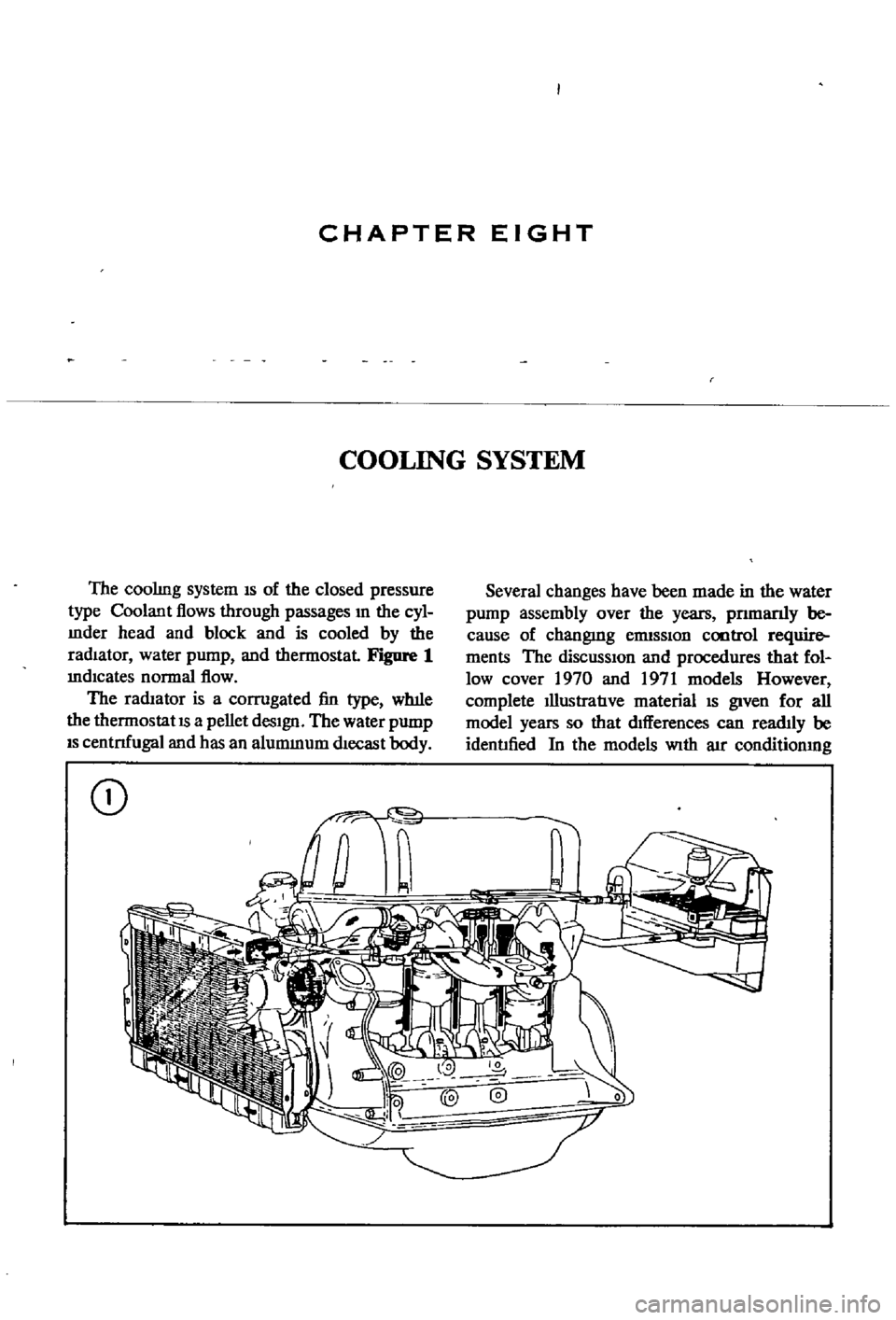

The

coolIng

system

IS

of

the

closed

pressure

type

Coolant

flows

through

passages

In

the

cyl

mder

head

and

block

and

is

cooled

by

the

radIator

water

pump

and

thermostat

Figure

1

mdlcates

normal

flow

The

radIator

is

a

corrugated

fin

type

wh1le

the

thermostat

IS

a

pellet

desIgn

The

water

pump

IS

centnfugal

and

has

an

alummum

dlecast

body

CD

Several

changes

have

been

made

in

the

water

pump

assembly

over

the

years

pnmanly

be

cause

of

changmg

ennSSlon

cootrol

require

ments

The

diSCUSSIOn

and

procedures

that

fol

low

cover

1970

and

1971

models

However

complete

IllustratIve

material

IS

given

for

all

model

years

so

that

dIfferences

can

readIly

be

identIfied

In

the

models

With

aIr

conditionmg

Page 90 of 252

COOLING

SYSTEM

8S

and

In

those

with

exhaust

and

evaporatIve

emIS

sion

control

devIces

a

fan

clutch

IS

combIned

WIth

the

thermostat

to

detect

temperature

m

the

engme

compartlnent

When

the

temperature

nses

the

thermostat

detects

the

change

an

the

fan

clutch

engages

thereby

helpmg

to

cool

the

engme

WATER

PUMP

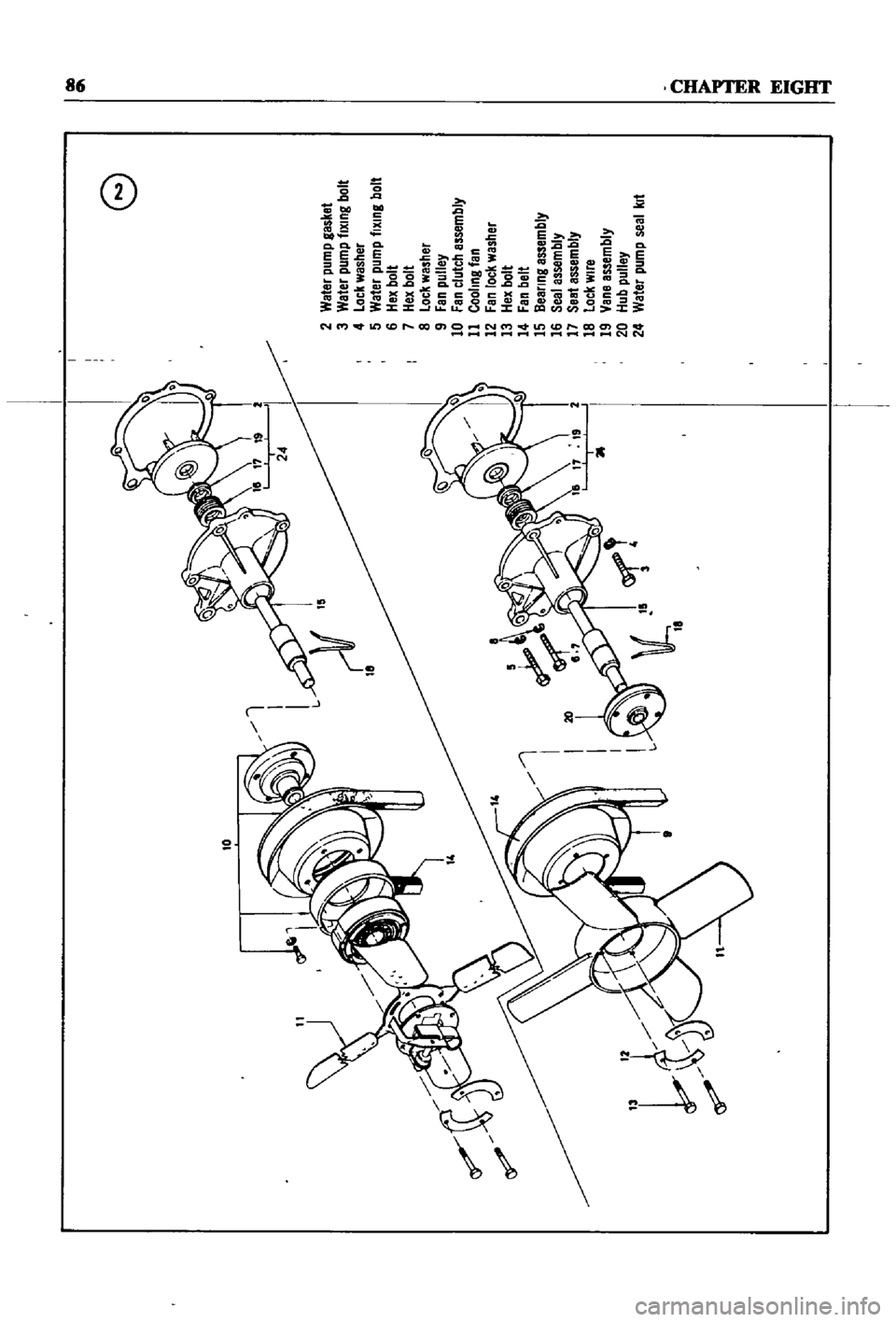

Figure

2

page

86

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1970

to

1971

The

top

half

of

the

IllustratIon

applIes

to

those

models

WIth

exhaust

and

evaporatIve

emiSSIOn

control

systems

The

bottom

half

covers

models

WIth

a

crankcase

emiSSIon

control

deVIce

only

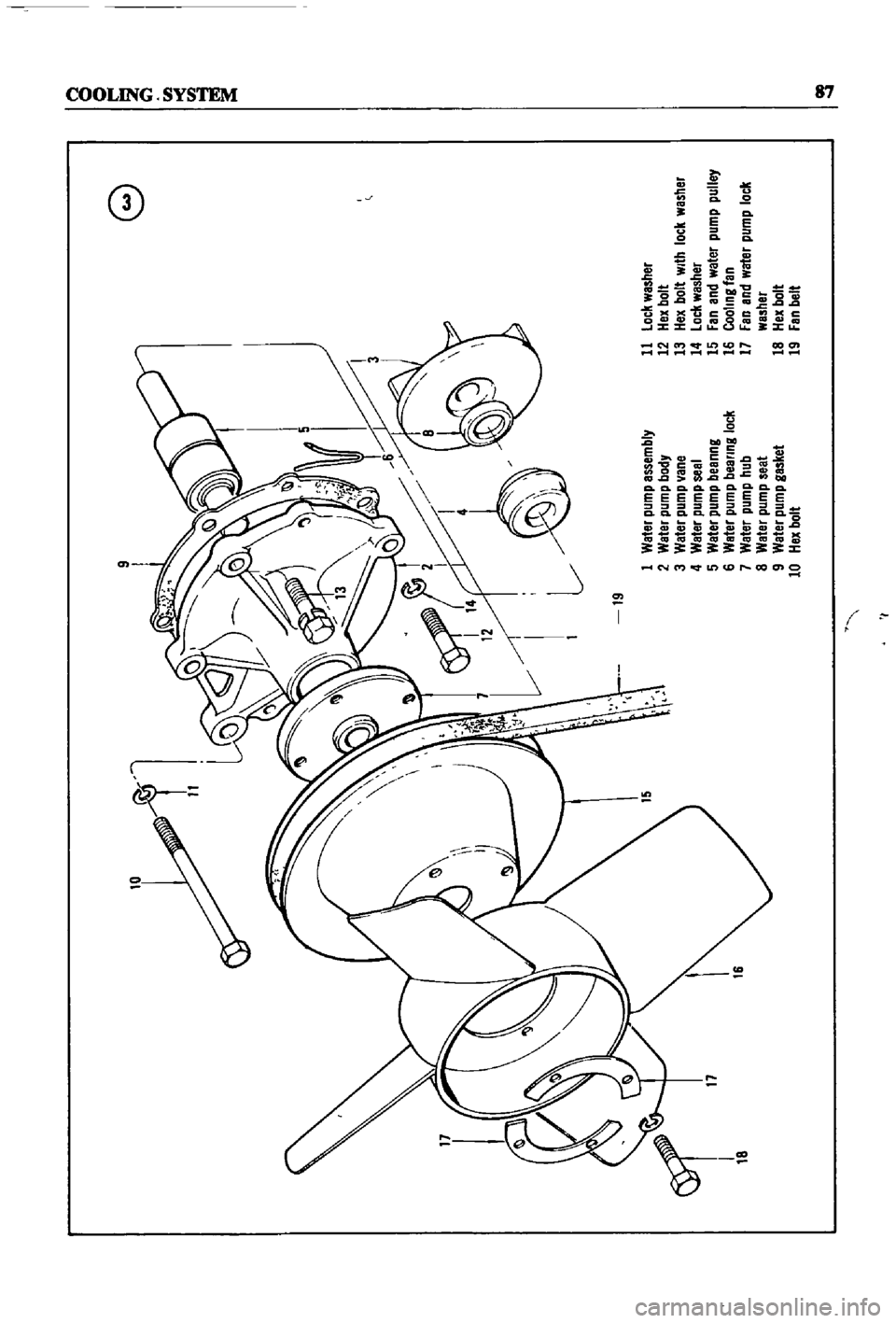

Figure

3

page

87

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1968

models

Without

exhaust

or

evaporatIve

controls

Figure

4

page

88

shows

the

1968

model

With

emISSIon

control

deVIce

As

can

be

seen

from

the

illustratIons

most

dIfferences

eXISt

withIn

the

fan

clutch

assembly

Water

Pump

Removal

1

Remove

upper

and

lower

radIator

hoses

from

the

thermostat

housmg

and

cylmder

block

re

spectIvely

Dram

coolant

from

rad1ator

and

cylInder

block

2

Loosen

the

alternator

mountlng

bolt

and

the

adjustIng

bolt

on

the

alternator

mountIng

bracket

3

Move

the

alternator

toward

the

cylinder

block

untIl

slack

IS

eVIdent

10

the

fan

belt

Re

move

fa

belt

fro

alternator

water

pump

and

crankshaft

pulley

4

It

IS

difficult

to

remove

the

water

pump

from

the

front

housmg

With

the

radiator

and

top

shroud

10

place

so

remove

them

5

Remove

the

bolts

holdmg

the

fan

assembly

to

the

water

pump

and

remove

the

fan

assembly

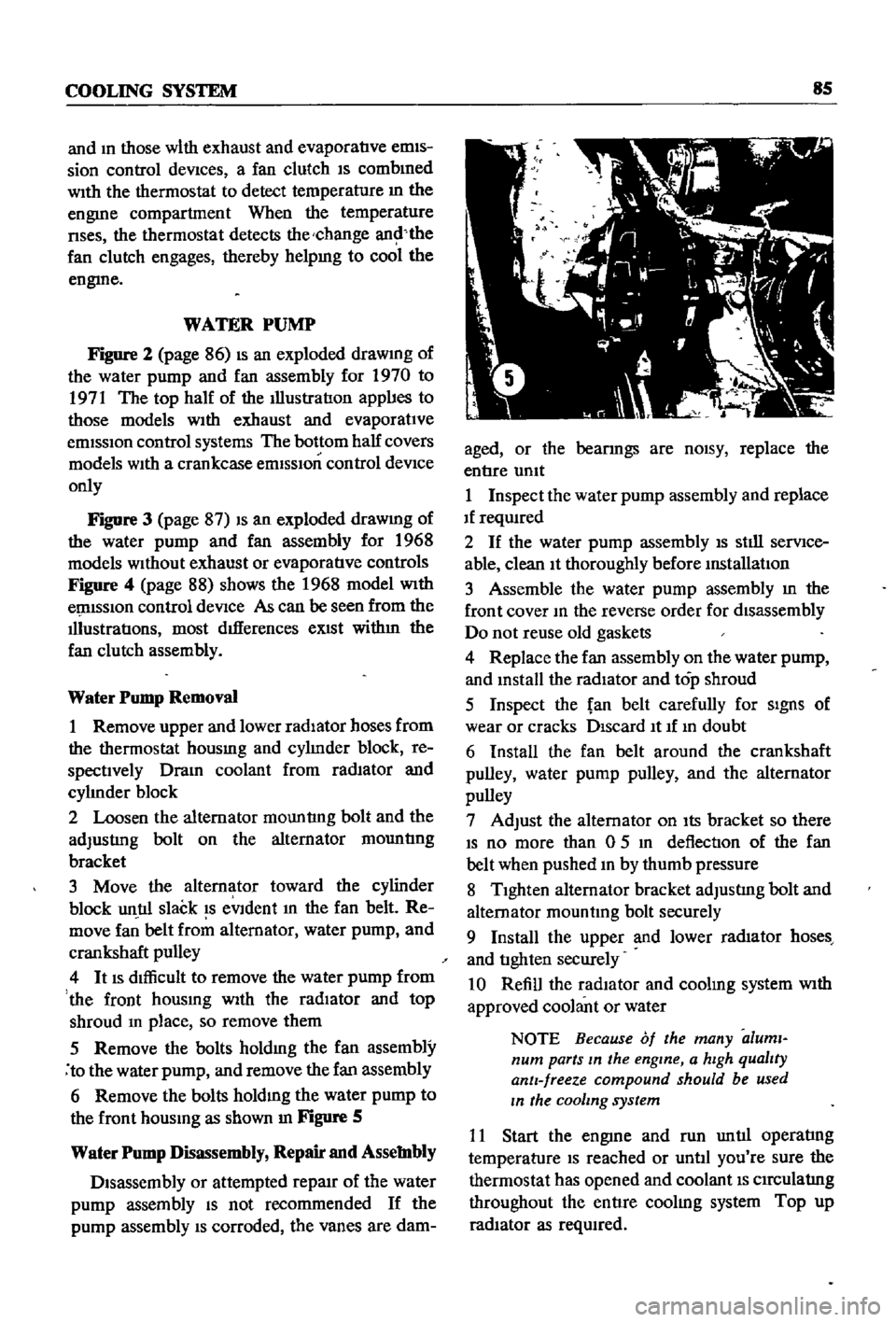

6

Remove

the

bolts

holdmg

the

water

pump

to

the

front

housmg

as

shown

In

Figure

S

Water

Pump

Disassembly

Repair

and

Assembly

Disassembly

or

attempted

repaIr

of

the

water

pump

assembly

IS

not

recommended

If

the

pump

assembly

IS

corroded

the

vanes

are

dam

aged

or

the

bearmgs

are

nOISY

replace

the

entIre

umt

1

Inspect

the

water

pump

assembly

and

replace

If

reqUIred

2

If

the

water

pump

assembly

IS

stIll

serVIce

able

clean

It

thoroughly

before

mstallatIon

3

Assemble

the

water

pump

assembly

m

the

front

cover

10

the

reverse

order

for

disassembly

Do

not

reuse

old

gaskets

4

Replace

the

fan

assembly

on

the

water

pump

and

mstall

the

radiator

and

top

shroud

5

Inspect

the

fan

belt

carefully

for

SIgnS

of

wear

or

cracks

DIscard

It

If

10

doubt

6

Install

the

fan

belt

around

the

crankshaft

pulley

water

pump

pulley

and

the

alternator

pulley

7

Adjust

the

alternator

on

Its

bracket

so

there

IS

no

more

than

0

5

10

deflection

of

the

fan

belt

when

pushed

10

by

thumb

pressure

8

TIghten

alternator

bracket

adjustIng

bolt

and

alternator

mountmg

bolt

securely

9

Install

the

upper

and

lower

rad1ator

hoses

and

tIghten

securely

10

Refill

the

radIator

and

coolmg

system

With

approved

coolant

or

water

NOTE

Because

of

the

many

aluml

num

parts

In

the

engine

a

hIgh

qualIty

antI

freeze

compound

should

be

used

In

the

cooling

system

11

Start

the

engme

and

run

untIl

operatIng

temperature

IS

reached

or

untIl

you

re

sure

the

thermostat

has

opened

and

coolant

IS

CIrCulatIng

throughout

the

entIre

coolIng

system

Top

up

radIator

as

reqUIred

Page 91 of 252

10

f

e

2

Weter

pump

gasket

3

Water

pump

tlXlng

bolt

4

Lock

washer

5

Water

pump

tlXlng

bolt

6

Hex

bolt

7

Hex

bolt

8

Lock

washer

9

Fan

pulley

10

Fan

clutch

assembly

11

Cooling

tan

12

Fan

lock

washer

13

Hex

bolt

14

Fan

belt

15

Dealing

assembly

16

Seal

assembly

17

Seatassembly

18

Lock

wire

19

Vane

assembly

20

Hub

pulley

24

Water

pump

seal

kit

Illl

t

l

Page 92 of 252

10

9

8

n

o

o

19

1

Water

pump

assembly

11

lock

washer

2

Water

pump

body

12

Hex

bolt

3

Water

pump

ane

13

Hex

bolt

With

lock

washer

4

Water

pump

seal

14

loc

l

washer

17

6

5

Water

pump

beanng

15

Fan

and

water

pump

pulley

6

Water

pump

bee

ring

lock

16

Cooling

tan

7

Water

pump

hub

17

Fan

and

water

pump

lock

8

Water

pump

seat

washer

9

Water

pump

gasket

18

Hex

bolt

10

Hex

bolt

19

Fen

belt

I

I