lock DATSUN 510 1968 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 101 of 252

96

CHAFTER

NINE

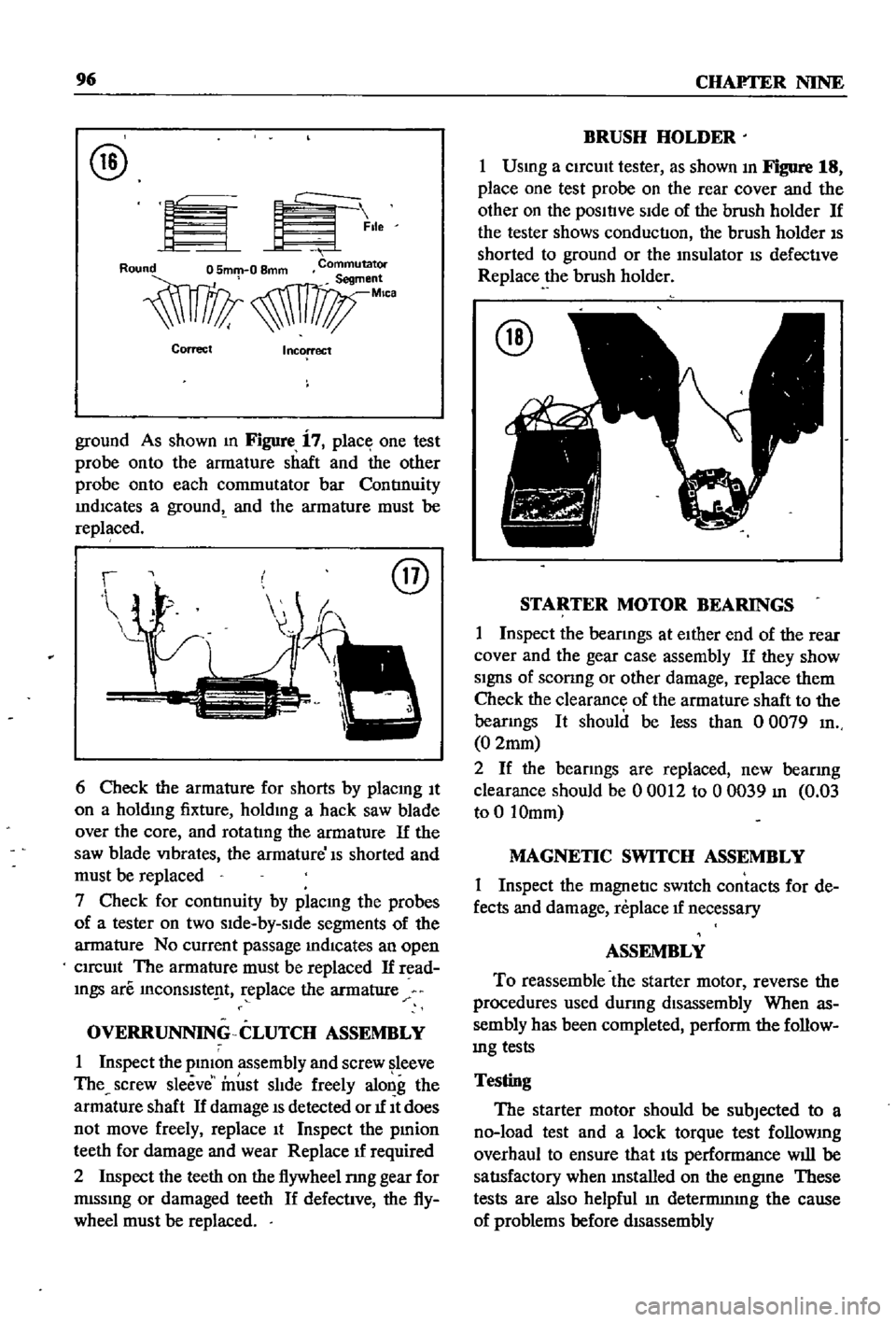

@

EK

lle

Correct

Incorrect

ground

As

shown

m

Figure

i

7

place

one

test

probe

onto

the

armature

shaft

and

the

other

probe

onto

each

commutator

bar

ContInuity

IndICates

a

groundt

and

the

armature

must

be

replaced

@

6

Check

the

armature

for

shorts

by

placmg

It

on

a

holdmg

fixture

holdmg

a

hack

saw

blade

over

the

core

and

rotatIng

the

armature

If

the

saw

blade

VIbrates

the

armature

Is

shorted

and

must

be

replaced

7

Check

for

contInuity

by

placmg

the

probes

of

a

tester

on

two

sIde

by

slde

segments

of

the

armature

No

current

passage

mdlcates

an

open

CIrcUIt

The

armature

must

be

replaced

If

read

mgs

are

InCOnslste

t

replace

the

armature

OVERRUNNING

CLUTCH

ASSEMBLY

1

Inspect

the

plmon

assembly

and

screw

leeve

The

screw

sleeve

must

slIde

freely

along

the

armature

shaft

If

damage

IS

detected

or

1f

It

does

not

move

freely

replace

It

Inspect

the

pmion

teeth

for

damage

and

wear

Replace

1f

required

2

Inspect

the

teeth

on

the

flywheel

nng

gear

for

mlssmg

or

damaged

teeth

If

defective

the

fly

wheel

must

be

replaced

BRUSH

HOLDER

1

Usmg

a

CirCUIt

tester

as

shown

In

Figure

18

place

one

test

probe

on

the

rear

cover

and

the

other

on

the

posltlve

SIde

of

the

brush

holder

If

the

tester

shows

conduction

the

brush

holder

IS

shorted

to

ground

or

the

msulator

IS

defective

Replace

the

brush

holder

@

STARTER

MOTOR

BEARINGS

1

Inspect

the

bearmgs

at

eIther

end

of

the

rear

cover

and

the

gear

case

assembly

If

they

show

SignS

of

sconng

or

other

damage

replace

them

Check

the

clearance

of

the

armature

shaft

to

the

bearmgs

It

should

be

less

than

0

0079

In

0

2mm

2

If

the

bearings

are

replaced

new

bearing

clearance

should

be

00012

to

00039

In

0

03

to

0

10mm

MAGNETIC

SWITCH

ASSEMBLY

1

Inspect

the

magnetic

sWItch

contacts

for

de

fects

and

damage

replace

1f

necessary

ASSEMBLY

To

reassemble

the

starter

motor

reverse

the

procedures

used

dUring

disassembly

When

as

sembly

has

been

completed

perform

the

follow

mg

tests

Testing

The

starter

motor

should

be

subjected

to

a

no

load

test

and

a

lock

torque

test

follOWIng

overhaul

to

ensure

that

Its

performance

will

be

satIsfactory

when

mstalled

on

the

engme

These

tests

are

also

helpful

In

detennmIng

the

cause

of

problems

before

dIsassembly

Page 102 of 252

ENGINE

ELECI

RlCAL

SYSTEM

97

No

Load

Lock

Torque

Test

1

Connect

the

starter

motor

in

series

with

a

12

volt

battery

and

antmeter

as

shown

in

Figure

19

The

antmeter

should

be

capable

of

mdIcatIng

1

000

amps

@

Switch

Voltmeter

Ammeter

2

Use

torque

testlng

equipment

to

determine

the

torque

the

motor

develops

3

Connect

a

voltmeter

and

a

vanable

resistor

WhICh

IS

used

to

regulate

the

voltage

Into

the

circwt

4

Close

the

sWitch

and

regulate

the

voltage

as

reqUIred

Figure

20

proVIdes

power

voltage

amperage

and

torque

mformatIon

that

1f

fol

lowed

will

mdIcate

the

condItion

of

the

starter

motor

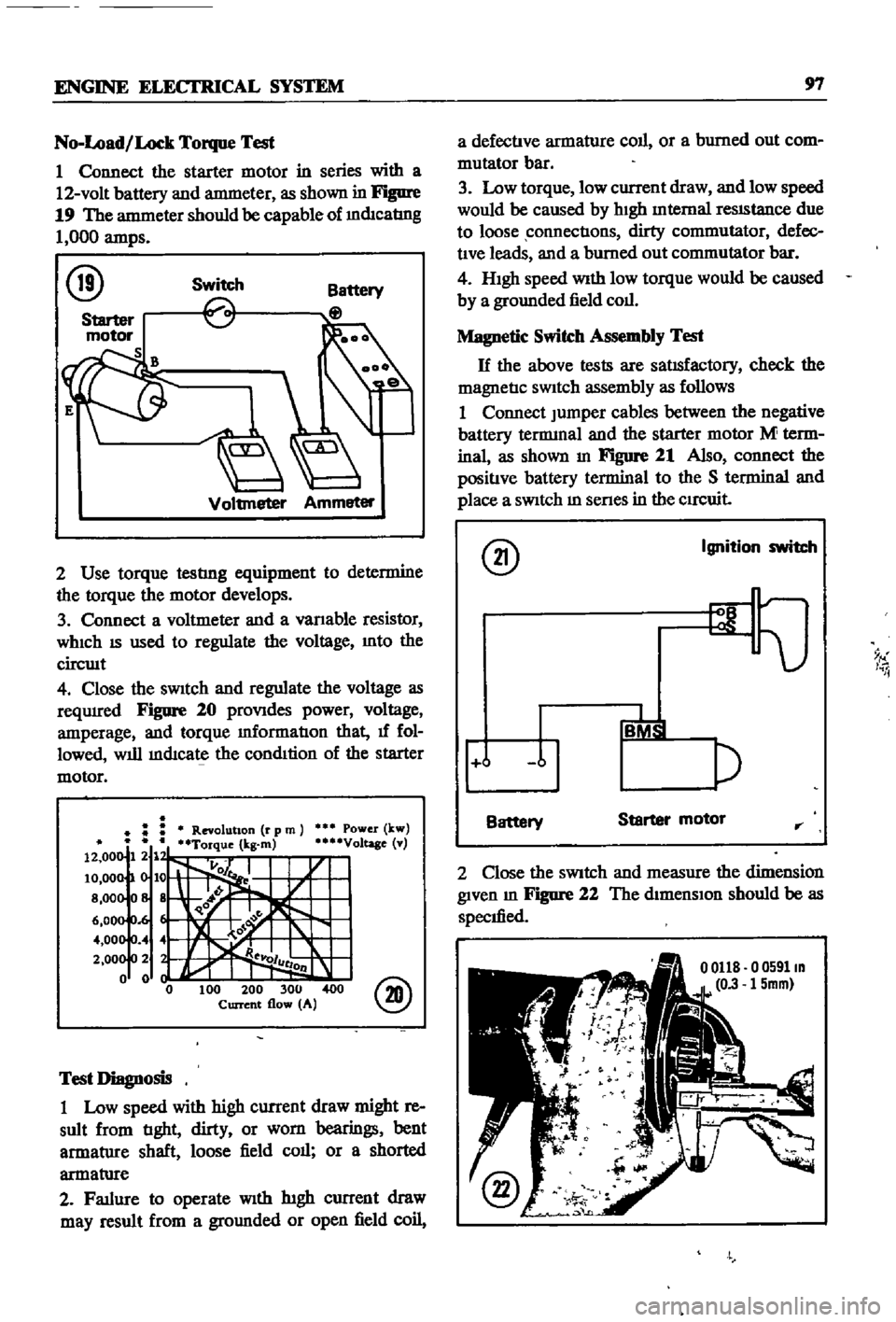

Power

kw

Voltage

v

@

Test

Diagnosis

1

Low

speed

with

high

current

draw

might

re

sult

from

tIght

dirty

or

worn

bearings

bent

armatlIre

shaft

loose

field

call

or

a

shorted

armatlIre

2

Fatlure

to

operate

With

htgh

current

draw

may

result

from

a

gromlded

or

open

field

coil

a

defectIve

armature

coll

or

a

burned

out

com

mutator

bar

3

Low

torque

low

current

draw

and

low

speed

would

be

caused

by

hIgh

Internal

reSIStance

due

to

loose

connectIons

dirty

commutator

defec

tIve

leads

and

a

burned

out

commutator

bar

4

HIgh

speed

With

low

torque

would

be

caused

by

a

grounded

field

coll

Magnetic

Switch

Assembly

Test

H

the

above

tests

are

satIsfactory

check

the

magnetIc

SWitch

assembly

as

follows

1

Connect

Jumper

cables

between

the

negative

battery

tennmal

and

the

starter

motor

M

term

inal

as

shown

In

Figure

21

Also

connect

the

positIve

battery

terminal

to

the

S

terminal

and

place

a

SWitch

m

senes

in

the

CIrCuit

@

Ignition

switch

9

I

i

j

Battery

Starter

motor

rr

2

Close

the

SWitch

and

measure

the

dimension

given

m

Figure

22

The

dimensIon

should

be

as

specIfied

o

0591m

15mm

Page 105 of 252

100

CHAPTER

NINE

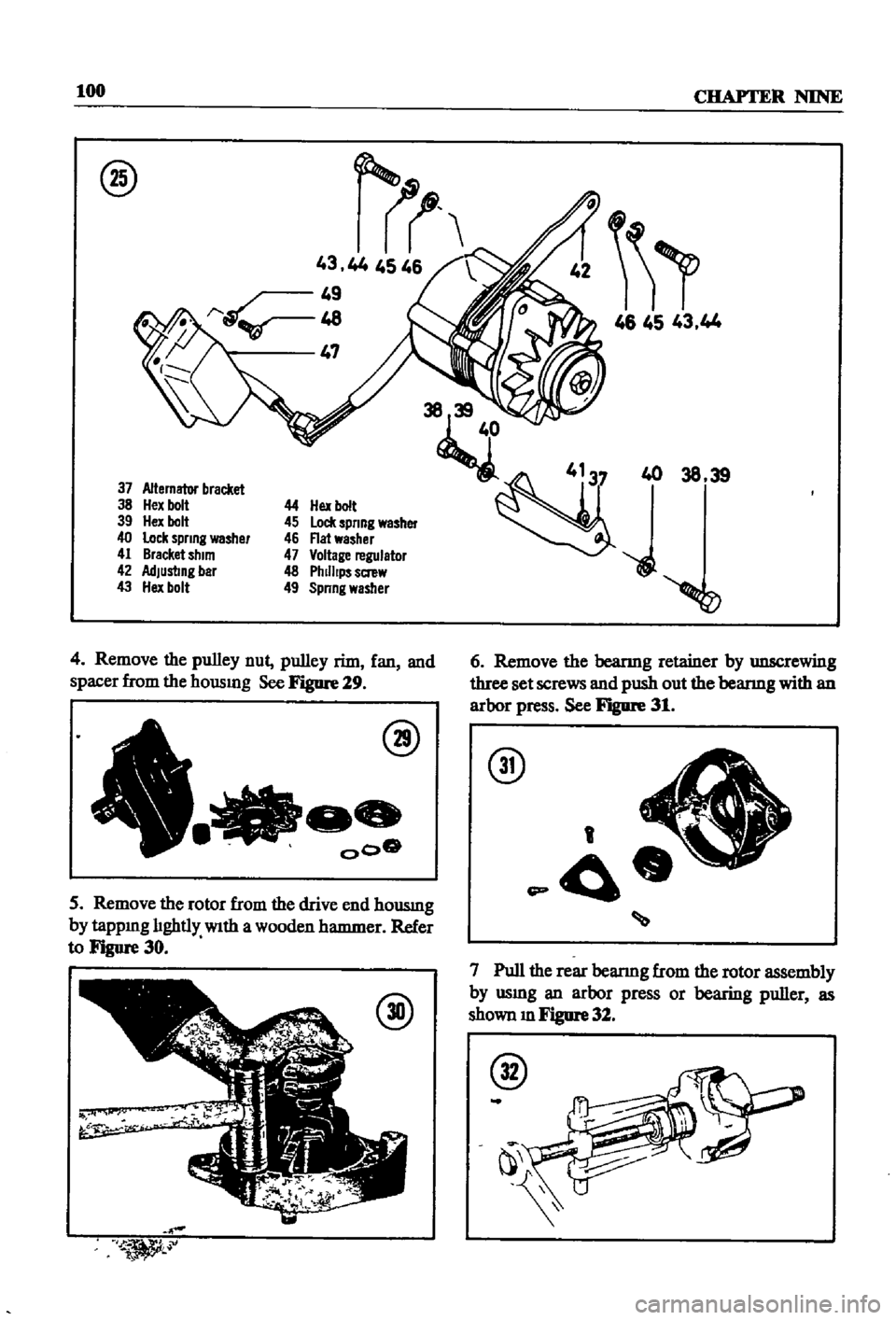

@

1

1

43

44

45

46

49

I

tYV

48

47

37

Alternator

bracket

38

Hex

bolt

39

Hex

bolt

40

lock

spnng

washer

41

8racket

shim

42

AdJusltng

bar

43

Hex

bolt

4

Remove

the

pulley

nut

pulley

rim

fan

and

spacer

from

the

hOUSIng

See

Figure

29

@

000

5

Remove

the

rotor

from

the

drive

end

housmg

by

tappIng

lIghtly

With

a

wooden

hammer

Refer

to

Figure

30

@

1

46

45

43

44

38

39

6

Remove

the

beanng

retainer

by

unscrewing

three

set

screws

and

push

out

the

bearmg

with

an

arbor

press

See

Figure

31

@

A

t

J

r

j

f

1

p

O

7

Pull

the

rear

bearmg

from

the

rotor

assembly

by

usmg

an

arbor

press

or

bearing

puller

as

shown

m

Figure

32

@

Page 109 of 252

104

CHAPTER

NINE

2

When

one

sIde

shows

low

resIstance

and

the

other

shows

high

resIstance

the

dIode

IS

satls

factory

If

both

sIdes

are

low

there

IS

a

short

CIrCUIt

If

both

sIdes

are

hIgh

there

IS

an

open

CIrcUIt

All

diodes

With

open

or

short

ClrC

ts

must

be

replaced

BRUSH

INSPECTION

1

VIsually

check

the

brushes

for

SIgnS

of

wear

or

damage

If

wear

IS

greater

than

the

wear

lIrmt

shown

in

Figure

47

replace

the

brush

2

ChecJ

the

movement

of

the

brush

for

smooth

ness

If

unsmooth

check

and

clean

the

brush

holder

3

To

check

spnng

pressure

place

a

SUItable

block

on

a

platform

scale

and

press

down

the

brush

holder

WIth

the

brush

and

spnng

on

the

block

untIl

the

brush

smks

In

the

holder

to

00394

m

lmm

heIght

from

the

holder

Sub

tract

the

block

weight

from

the

reading

to

derive

the

spnng

pressure

It

should

be

0

77

Ibs

035

kg

If

the

readmg

IS

under

0

44

Ibs

0

2

kg

replace

the

spring

Figure

48

shows

thIS

test

being

performed

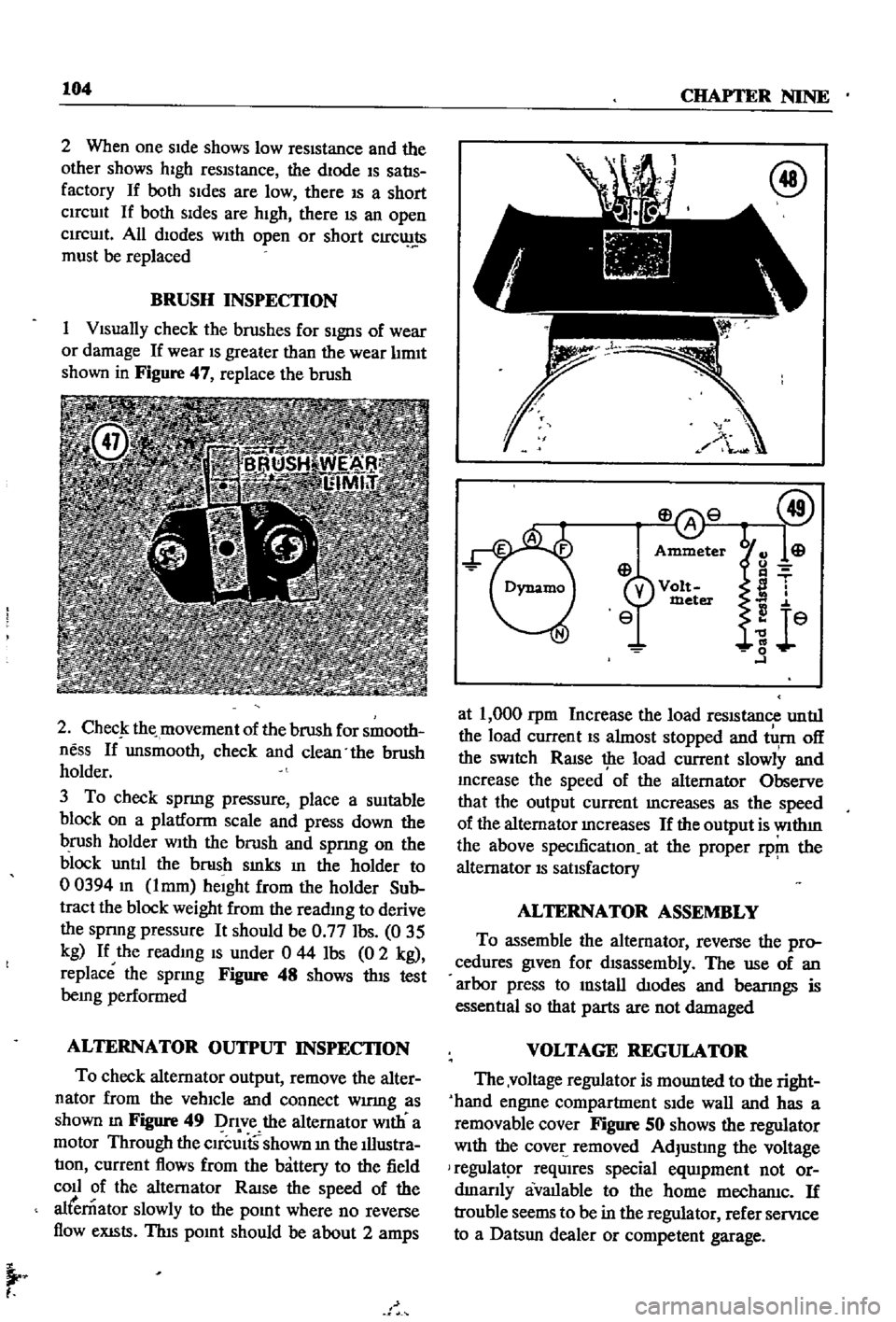

ALTERNATOR

OUTPUT

INSPECTION

To

check

alternator

output

remove

the

alter

nator

from

the

vehIcle

and

connect

wumg

as

shown

m

Figure

49

Dq

ve

the

alternator

WIth

a

motor

Through

the

CIrcUItS

shown

m

the

Illustra

tIon

current

flows

from

the

battery

to

the

field

coll

of

the

alternator

RaISe

the

speed

of

the

alternator

slowly

to

the

pOInt

where

no

reverse

flow

eXISts

ThIs

pOInt

should

be

about

2

amps

I

at

1

000

rpm

Increase

the

load

reSIStance

untIl

the

load

current

IS

almost

stopped

and

tlI

rn

off

the

SWItch

RaIse

the

load

current

slowly

and

mcrease

the

speed

of

the

alternator

Observe

that

the

output

current

mcreases

as

the

speed

of

the

alternator

mcreases

If

the

output

is

wlthm

the

above

specmcatIon

at

the

proper

rp

ll

the

alternator

IS

satIsfactory

ALTERNATOR

ASSEMBLY

To

assemble

the

alternator

reverse

the

pro

cedures

given

for

dIsassembly

The

use

of

an

arbor

press

to

mstall

dIodes

and

bearmgs

is

essentIal

so

that

parts

are

not

damaged

VOLTAGE

REGULATOR

The

voltage

regulator

is

mounted

to

the

right

hand

engme

compartment

SIde

wall

and

has

a

removable

cover

Figure

SO

shows

the

regulator

With

the

cover

removed

AdjustIng

the

voltage

regulatpr

reqUIres

special

eqUIpment

not

or

dmanly

avallable

to

the

home

mechanlc

If

trouble

seems

to

be

in

the

regulator

refer

servIce

to

a

Datsun

dealer

or

competent

garage

Page 121 of 252

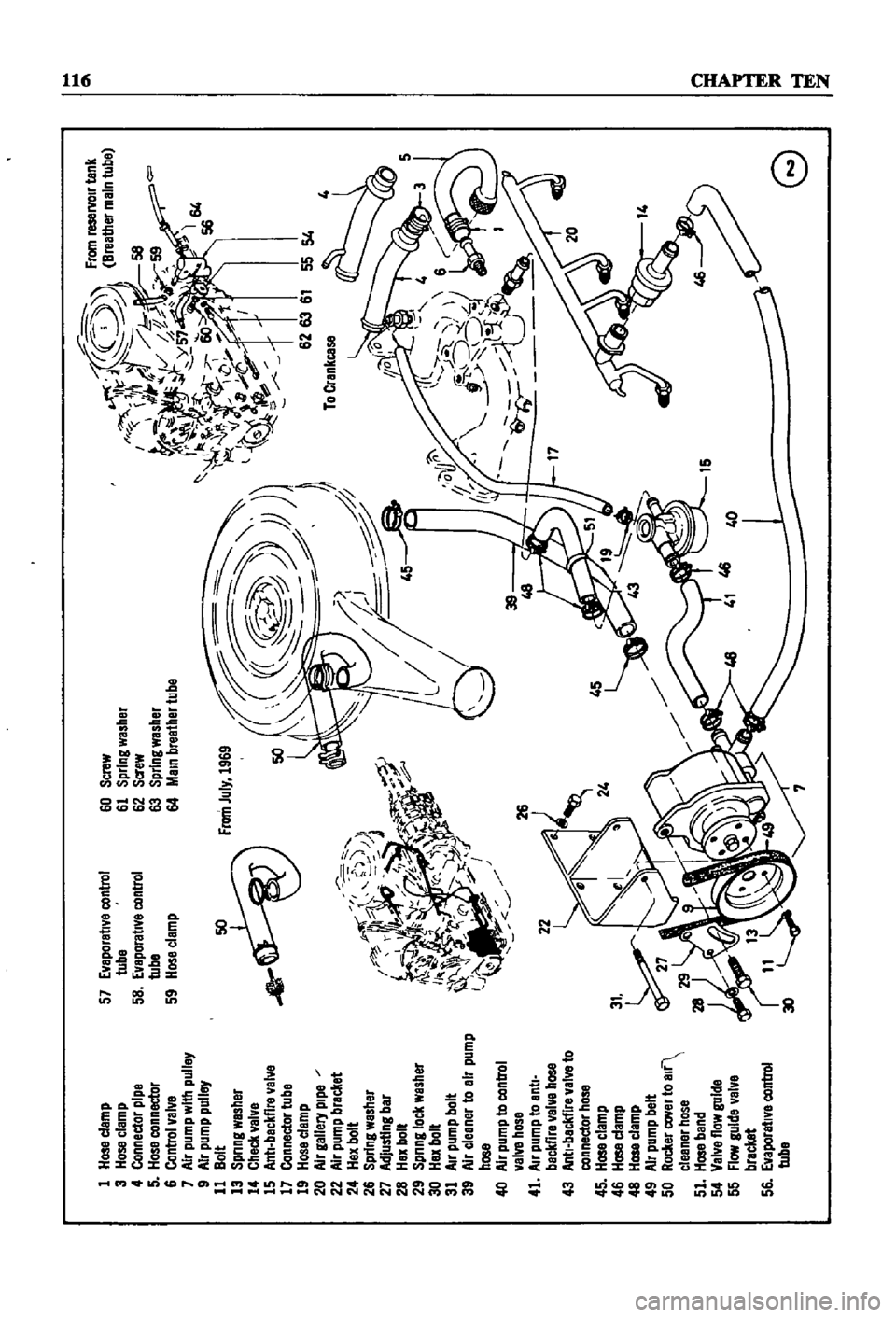

1

Hose

clemp

3

Hose

clamp

4

Connector

pipe

5

Hose

connector

6

Control

valve

7

Air

pump

with

pulley

9

Air

pump

pulley

11

Bolt

13

Spnng

washer

14

Check

valve

15

Antl

beckllre

elve

17

Connector

tube

19

Hose

c1emp

20

Air

gellery

pipe

22

Air

pum

p

bracket

24

Hex

bolt

26

Spring

washer

27

Adjusting

bar

28

Hex

bolt

29

Spnng

lock

washer

30

Hex

bolt

31

Air

pump

bolt

39

Air

c1eener

to

air

pump

hose

40

Air

pump

to

control

alve

hose

41

Air

pump

to

anti

beckllre

velve

hose

43

Antl

backllre

valve

to

connector

hose

45

Hose

clemp

46

Hose

clemp

48

Hose

c1emp

49

Air

pump

belt

50

Rocker

cover

to

alf

clBllner

hosa

51

Hose

band

54

Velve

1I0w

guide

55

Flow

gulda

valve

brackBt

56

Eveporatlve

control

tube

57

Evaporative

control

tube

58

Eveporatlve

control

tube

59

Hose

clamp

60

Screw

61

Spring

washer

62

Screw

63

Spring

washer

64

Main

breather

tube

50

15

i

Page 129 of 252

2

@

24

11

3

10

9

r

7

8

JI

4

J

c

U

12

24

22

19

18

@

20

ta

21

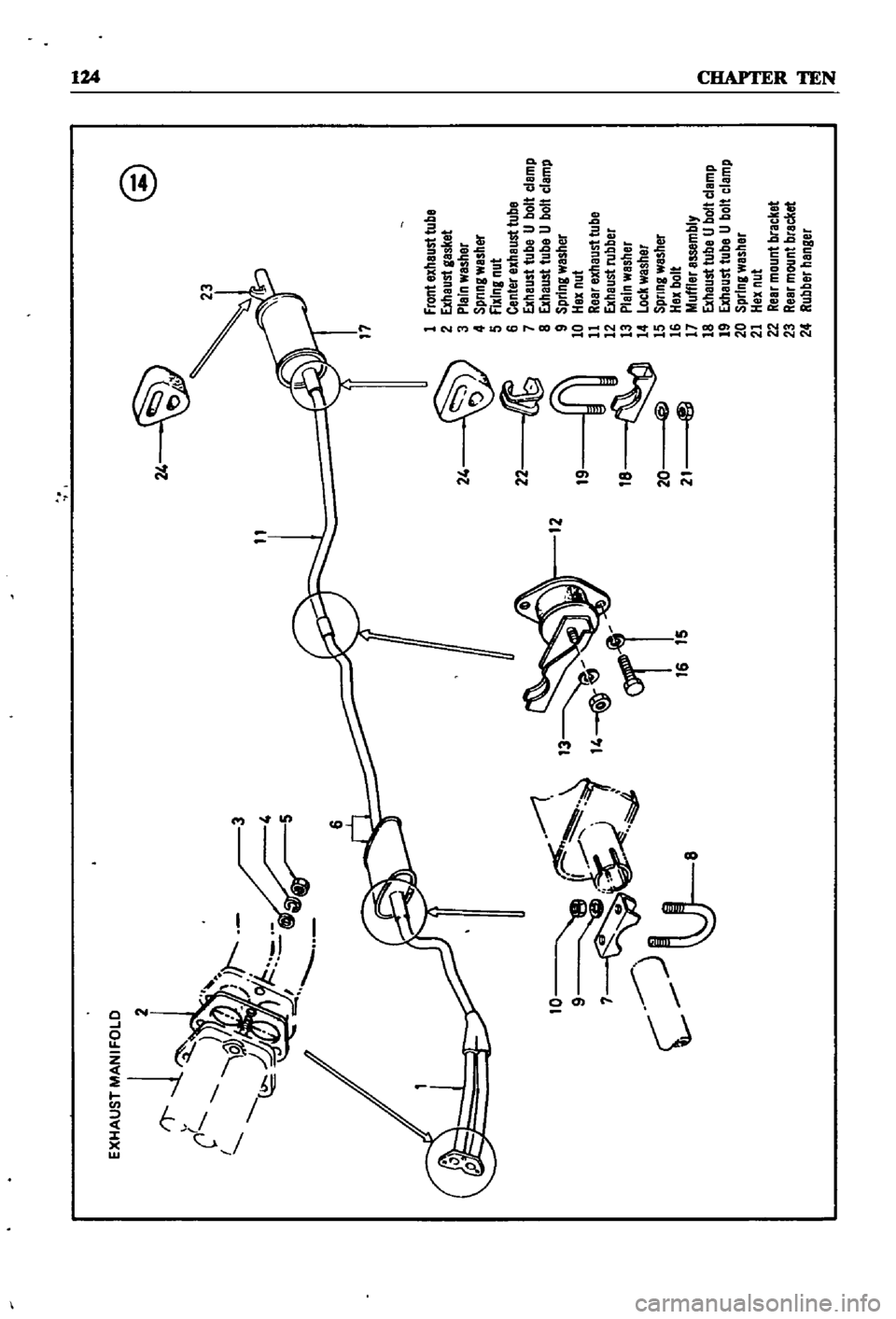

1

frontBxhaust

tube

2

Exheust

gasket

3

Plein

wesher

4

Spnng

wesher

5

fixing

nut

6

Center

exhaust

tube

7

Exhaust

tube

U

bolt

clamp

8

Exhaust

tube

U

bolt

clamp

9

Spring

wesher

10

Hex

nut

11

Reer

exheusttube

12

Exhaust

rubber

13

Plain

washer

14

Lock

washer

15

Spnng

washer

16

Hex

bolt

17

Muffler

essembly

18

Exhaust

tube

U

bolt

clamp

19

Exhaust

tube

U

bolt

clamp

20

spring

wesher

21

Hex

nut

22

Rear

mount

bracket

23

Rear

mount

brecket

24

Rubber

henger

i

Page 130 of 252

22

rnL

T

II

19

2

16

rr

I

II

l

r

@

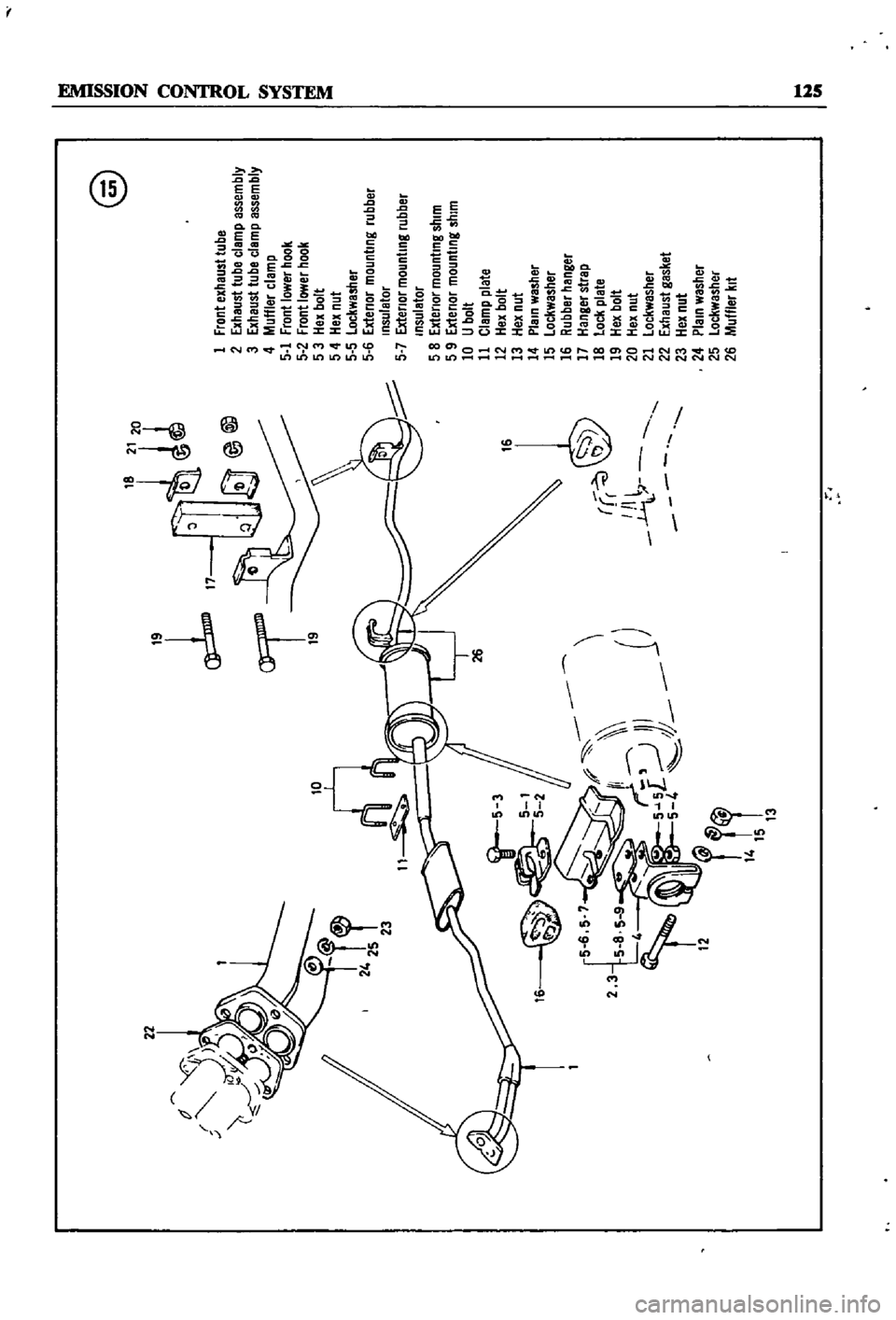

1

Front

exhaust

tube

2

Exhaust

tube

clamp

assembly

3

Exhaust

tube

clemp

assembly

4

Muffler

clamp

5

1

Front

lower

hook

5

2

Front

lower

hook

5

3

Hex

bolt

5

4

Hex

nut

5

5

Lockwasher

5

6

Extenor

mounting

rubber

Insulator

5

7

Extenor

mounting

rubber

Insulator

5

8

Extenor

mounting

shim

5

9

Extenor

mounting

shim

10

U

bolt

11

Clamp

plate

12

Hex

bolt

13

Hex

nut

14

Plain

washer

15

lockwasher

16

Rubber

hanger

17

Hanger

strap

18

lock

plate

19

Hex

bolt

20

Hex

nut

21

lockwasher

22

Exhaust

gasket

23

Hex

nut

24

Plain

washer

25

lockwasher

26

Muffler

kit

l

o

o

t

I

N

III

Page 133 of 252

128

CHAPTER

ELEVEN

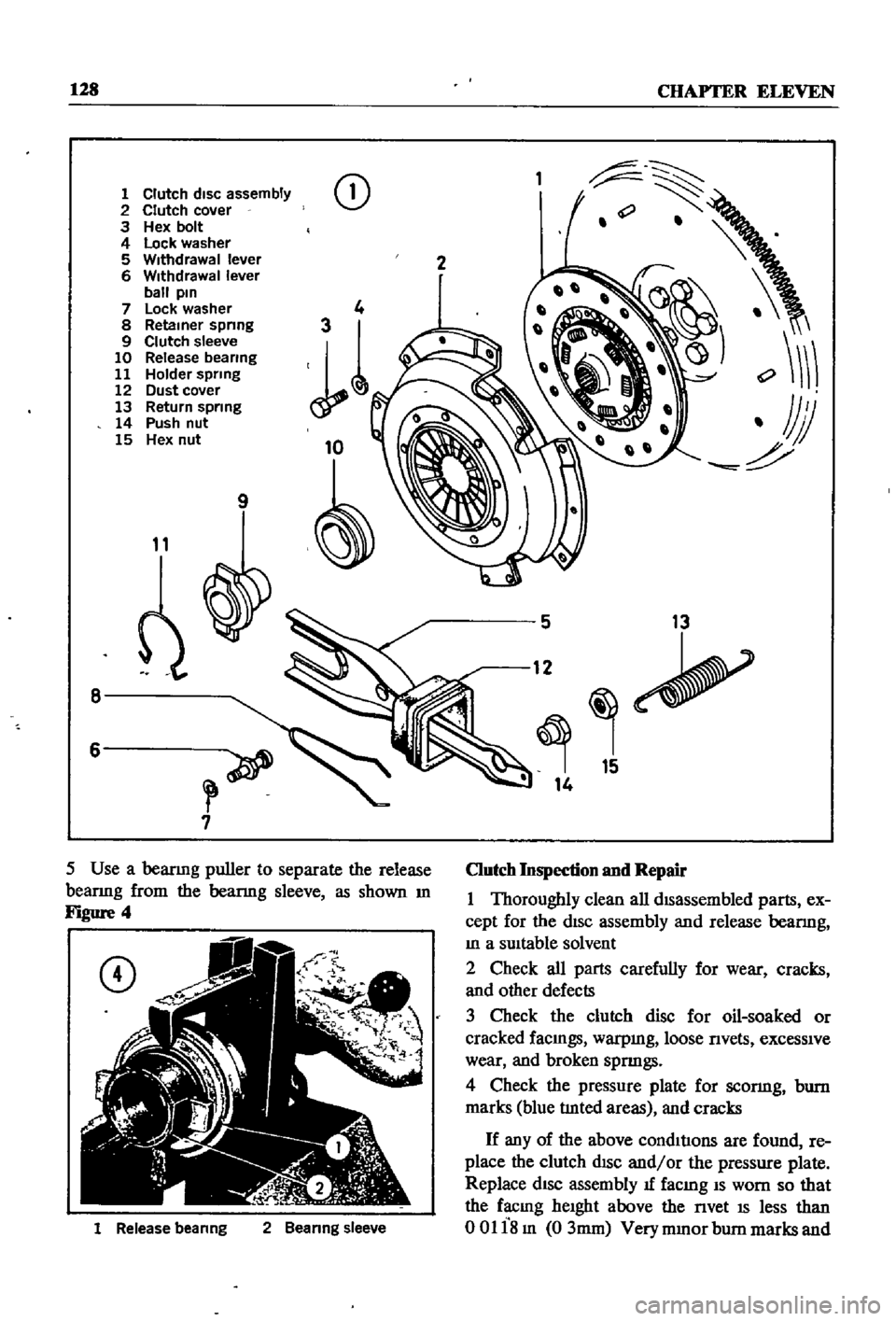

1

Clutch

disc

assembly

2

Clutch

cover

3

Hex

bolt

4

Lock

washer

5

Withdrawal

lever

6

Withdrawal

lever

ball

pin

7

Lock

washer

8

Retainer

spnng

9

Clutch

sleeve

10

Release

bearing

11

Holder

spring

12

Dust

cover

13

Return

spring

14

Push

nut

15

Hex

nut

CD

9

11

8

6

7

1

Release

beanng

2

Beanng

sleeve

2

5

13

12

15

14

Clutch

Inspection

and

Repair

1

Thoroughly

clean

all

dISassembled

parts

ex

cept

for

the

dISc

assembly

and

release

bearmg

In

a

SUItable

solvent

2

Check

all

parts

carefully

for

wear

cracks

and

other

defects

3

Check

the

clutch

disc

for

oil

soaked

or

cracked

faCIngs

warpmg

loose

nvets

exceSSIve

wear

and

broken

spnngs

4

Check

the

pressure

plate

for

sconng

bum

marks

blue

tlnted

areas

and

cracks

If

any

of

the

above

condItIons

are

found

re

place

the

clutch

dISC

and

or

the

pressure

plate

Replace

dISC

assembly

1f

facmg

IS

worn

so

that

the

facmg

heIght

above

the

nvet

IS

less

than

00118m

03mm

Very

mmor

bum

marks

and

Page 138 of 252

CLUTCH

TRANSMISSION

AND

DRlVESIIAFI

133

C

8

Q@J

@

C

Operating

Cylinder

Reassembly

1

Soak

pISton

cup

m

brake

flUid

and

Install

It

In

the

same

pOSitIOn

as

before

removal

2

Apply

brake

flUid

to

the

cylInder

and

pIston

before

mstalImg

piston

3

Replace

all

parts

m

the

reverse

order

of

removal

Operating

Cylinder

Installation

1

RemstallatIon

IS

the

reverse

of

removal

2

Bleed

aIr

from

the

hydraulIc

system

3

Adjust

the

pushrod

so

that

withdrawal

lever

end

play

IS

0

0787

to

0

1181

In

2

0

to

3

Omm

Procedures

for

the

adjustment

are

given

below

WITHDRAWAL

LEVER

AD

JUSTMENT

Correct

adjustment

of

the

clutch

withdrawal

lever

IS

essentIal

InsufficIent

free

travel

between

the

release

bearmg

and

dIaphragm

fingers

can

cause

the

clutch

to

slIp

ExceSSIve

free

travel

can

prevent

full

dISengagement

of

the

clutch

Refer

to

Figure

11

1

Loosen

lock

nut

2

SCrew

In

the

pushrod

fully

with

the

adjustmg

nut

3

Unscrew

adJustmg

nut

1

turns

TIghten

lock

nut

J

4

Check

the

end

play

of

the

wIthdrawal

lever

End

play

should

be

0

0787

to

0

0906

in

2

0

to

2

3mm

The

correct

end

play

will

give

a

clear

ance

of

0

0512

m

1

3mm

between

the

release

bearmg

and

diaphragm

fingers

@

1

Lock

nut

2

AdJustmg

nut

3

Wrthdrawal

ever

4

Release

beer

ng

5

Diaphragm

spnng

20

to

30

0

079

to

0

11

B

Unit

mm

m

5

If

the

above

adjustment

does

not

result

in

satIsfactory

clutch

operatIon

the

clutch

dISC

is

probably

worn

excessIvely

and

will

reqUire

re

placement

as

preVIously

dIScussed

BLEEDING

CLUTCH

SYSTEM

AIr

In

the

clutch

hydraulIc

system

makes

shIft

Ing

gears

extremely

difficult

1f

not

impOSSIble

To

bleed

the

system

proceed

as

follows

1

Remove

the

bleed

screw

dust

cap

from

the

operating

cylInder

2

Attach

a

bleeder

hose

to

the

bleed

screw

Immerse

the

other

end

of

the

hose

m

a

container

f

hydraulIc

brake

fluid

3

Check

to

see

that

clutch

master

cylInder

reservoir

IS

full

of

brake

flUid

ReplenISh

if

necessary

4

Open

the

bleeder

screw

three

quarters

of

a

tlIrn

and

have

an

assistant

pump

the

clutch

pedal

slowly

Pump

the

clutch

until

the

flUid

entenng

the

contatner

is

clean

and

free

from

bubbles

5

TIghten

bleed

screw

Replace

dust

cap

Refill

the

flUid

reservoir

Page 142 of 252

M

I

CL

SMISSION

AND

DRIVESIIAF1

137

i@

v

l

ll

r

1

Neutral

gear

swrtch

2

TransmISSIon

swllch

thud

geu

3

Reverse

gear

SWitch

@1

Control

arm

14

Return

spnng

2

StnkBr

bushmg

15

Re

erse

check

ball

3

O

nng

cep

16

Check

spnng

4

O

nng

17

Retalmng

pm

5

Control

O

nng

18

Slnlung

rod

6

First

and

second

fork

rod

19

Slnlung

pm

7

First

and

second

shill

fork

20

O

nng

8

Thud

and

fourth

lork

rod

22

Control

arm

pm

9

Third

and

fourth

shill

fork

23

Control

washer

10

Reverse

fork

rod

24

Control

arm

bushmg

11

Reverse

shill

fork

25

Control

spnng

12

Rolled

pm

26

Thrust

wesher

13

Reverse

fork

pm

27

Retammg

pm

9

0

11

f

Ir

foUr

1

i

1

k

jl

n

1

1

l

28

Control

lever

35

Lower

washer

29

Control

lever

knob

36

Self

lockmg

nut

31

Washer

37

Rubber

boot

32

Controlle

er

rubber

41

Tnmsmlsslon

hole

cover

33

Washer

42

Tappmg

screw

34

Upper

washer

29

c

28

37

16

t

f

f

1

I

13

1

12

5

T

2V

T

19

25

26

20

31

e

32

@

35

@

36