DATSUN 510 1968 Service Owner's Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 21 of 252

16

CHAPTER

TIlREE

sary

Also

check

all

parts

for

mlSaltgnment

and

uneven

wear

TRANSMISSION

1

Difficult

to

mesh

gears

Make

certam

the

clutch

pressure

plate

and

re

lease

beanng

are

m

good

condItion

The

trouble

can

be

caused

by

worn

gears

shaft

and

or

bear

mgs

DISassemble

and

repaIr

as

requIred

Also

can

be

caused

by

msufficlent

operatmg

stroke

due

to

worn

or

loose

sltdmg

parts

or

a

defective

synchronIZer

DIsassemble

carefully

InSpect

and

replace

as

requIred

2

Gears

slip

out

of

mesh

Generally

thIS

trouble

occurs

when

the

mterlock

plunger

check

ball

and

or

spnng

IS

weakened

or

worn

The

trouble

can

also

be

caused

by

worn

fork

rod

ball

groove

damaged

bearings

or

dam

aged

gears

DIsassemble

carefully

mspect

and

replace

as

required

3

NOIse

If

nOISes

are

heard

wIth

the

engme

idlmg

and

the

clutch

disengaged

the

nOIse

IS

probably

conung

from

the

transmISSIOn

Several

Items

can

cause

nOISes

either

smgly

or

m

combmatIon

Check

the

qualIty

and

quantity

of

lubrIcant

in

the

trans

mISSIon

Replace

or

replenISh

as

necessary

Worn

bearIngs

wIll

usually

produce

a

lugh

humming

at

hIgh

speed

and

a

cycltc

knockIng

sound

at

low

speed

Worn

or

damaged

splInes

and

bushmgs

will

also

cause

nOIse

BRAKES

1

Brake

pedal

goes

to

floor

There

are

numerous

causes

for

thIS

includIng

excessIvely

worn

Itnmgs

aIr

in

the

hydraultc

sys

tem

leaky

brake

lmes

leaky

wheel

cylmders

or

leaky

or

worn

master

cylmder

Check

for

leaks

and

thIn

brake

linmgs

Bleed

and

adjust

the

brakes

If

thIS

doesn

t

cure

the

trouble

rebwld

wheel

cylmders

a

nd

or

master

cylmder

2

Spongy

pedal

Normally

caused

by

aIr

m

the

system

blee

d

and

adjust

the

brakes

3

Brakes

pull

Check

brake

adjustment

Also

check

for

contam

inated

brake

Itmngs

from

leaks

leaky

wheel

cyltnders

loose

caltpers

frozen

or

seIZed

pIstons

and

restrIcted

brake

lmes

or

hoses

In

addItion

check

front

end

alignment

and

suspensIOn

dam

age

such

as

broken

front

or

rear

sprmgs

shocks

etc

Check

condItIon

of

tIres

4

Brakes

squeal

or

chatter

Check

brake

lmmg

thickness

and

brake

drum

roundness

Ensure

that

the

shoes

have

cham

ferred

ends

and

are

not

loose

Inspect

the

condI

tion

of

the

rotors

on

the

front

wheel

dISC

brakes

to

make

certain

they

are

not

scored

or

damaged

Clean

away

all

dIrt

on

shoes

pads

rotors

or

drums

5

Draggmg

brakes

Check

brake

adjustment

includmg

handbrake

Check

for

broken

or

weak

shoe

return

springs

swollen

rubber

parts

due

to

unproper

brake

flUId

or

other

contammatIon

Clean

or

replace

de

fectIve

parts

6

Hard

pedal

Check

brake

linmgs

for

contammation

Also

check

for

restrIcted

brake

lines

and

hoses

7

High

speed

fade

Check

for

dIstorted

or

out

of

round

drums

and

contamInated

brake

lmmgs

Make

certam

the

recommended

brake

flUId

IS

used

Dram

entIre

system

and

refill

If

In

doubt

8

Pulsatmg

pedal

Check

for

dIStorted

or

out

of

round

drums

or

rotors

Check

for

excessIVe

brake

dISC

run

out

STEERING

AND

SUSPENSION

NOTE

Unusual

steermg

pullmg

or

wandermg

IS

usually

caused

by

bent

or

otherwise

mIsaligned

suspenszon

parts

Because

of

the

speCialized

equIp

ment

reqUired

to

evaluate

and

correct

these

faults

It

IS

recommended

t

tat

servIce

to

the

steermg

and

suspension

system

be

referred

to

your

Datsun

dealer

oca

quallfied

specrallst

m

thiS

field

1

VibratIOn

felt

m

steermg

wheel

VIbratIon

can

be

caused

by

several

thmgs

includ

ing

lll1proper

aIr

pressure

m

tIres

uneven

wear

Page 22 of 252

TROUBLESHOOTING

17

of

tIre

loose

wheels

unproper

adjustment

or

wear

of

front

wheel

bearIngs

faulty

wheel

align

ment

or

wear

of

transverse

lInk

and

tension

rod

bushings

Inspect

all

parts

carefully

for

wear

or

damage

Replace

or

replUI

parts

as

required

2

Shock

transmltled

through

steering

wheel

This

is

usually

most

noticeable

when

traveling

over

bad

roads

at

relatively

high

speeds

Causes

Include

damage

to

the

idler

ann

insuffiCient

tIghtening

of

steenng

gear

box

wear

of

the

steer

Ing

linkage

and

wear

of

the

suspension

ball

joint

Inspect

all

parts

for

wear

or

damage

Refer

to

Chapter

ThIrteen

for

service

or

repair

you

can

perform

and

for

procedures

which

should

be

referred

to

your

deal

r

3

Shlmmymg

This

is

usually

most

noticeable

when

a

specIfic

speed

IS

attained

and

will

normally

repeat

at

that

speed

Causes

are

generally

unbalanced

wheels

unproper

adjustment

of

steenng

gear

insuffi

cient

backlash

malfunction

of

the

shock

ab

sorbers

or

loose

bolts

for

the

strut

mountIng

Reparr

or

replace

defective

parts

as

required

Refer

to

Chapter

Thirteen

4

Wandermg

of

car

m

one

dlrectlOnl

This

problem

can

be

caused

by

improper

air

pressure

loose

wheel

nuts

difference

in

tire

tread

wear

from

left

to

right

side

Incorrect

adjustment

of

wheel

bearings

defectIve

wheel

beanngs

collapsing

or

twistIng

of

front

spnng

or

Incorrect

wheel

alignment

Also

binding

of

the

brake

shoes

worn

bushings

in

the

transverse

link

or

the

tension

rod

and

deformation

of

s

enng

lInkage

and

suspension

link

can

cause

wander

Carefully

iuspect

all

parts

for

looseness

and

wear

and

re

place

or

repaIr

as

required

In

some

c

ases

a

de

fective

rear

suspension

may

also

cause

the

vehicle

to

wander

5

InstabIlity

Instability

can

be

caused

by

unproper

tIre

pres

sures

worn

bushings

in

the

transverse

link

and

tension

rod

mcorrect

wheel

alignment

worn

steenng

linkage

Incorrect

adjustment

of

steer

ing

gear

and

unbalanced

wheels

Inspect

all

parts

carefully

for

wear

and

damage

Adjust

repair

or

replace

as

required

6

Heavy

feelmg

m

steering

This

can

be

caused

by

improper

tIre

pressures

insuffiCient

or

contamInated

lubncant

in

gear

box

damage

or

insuffiCient

grease

In

suspeuslon

ball

Joint

damaged

or

badly

adjusted

wheel

bearIngs

worn

or

damaged

steermg

gear

dam

age

of

upper

strut

bearing

and

mterference

of

steenng

column

With

turn

signal

SWitch

Inspect

all

parts

carefully

for

wear

and

damage

Adjust

repair

or

replace

as

required

7

ExceSSIve

play

m

steermg

wheel

This

is

usually

caused

by

Incorrect

adjustment

of

the

steenng

gear

worn

bushings

in

the

steering

linkage

or

Idler

arm

mcorrect

adjustment

of

the

front

wheel

bearings

worn

bushIngs

in

the

trans

verse

lInk

and

tension

rod

Carefully

inspect

all

parts

for

wear

or

damage

Adjust

repair

or

re

place

as

reqUIred

TIRE

WEAR

ANALYSIS

Abnormal

tIre

wear

should

always

be

ana

lyzed

to

deternune

the

cause

The

most

common

are

Incorrect

tIre

pressure

improper

dnving

overloading

and

Incorrect

wheel

ahgDment

Figures

2A

through

2F

identify

wear

patterns

and

mdicate

likely

causes

Of

I

1

l

D

1

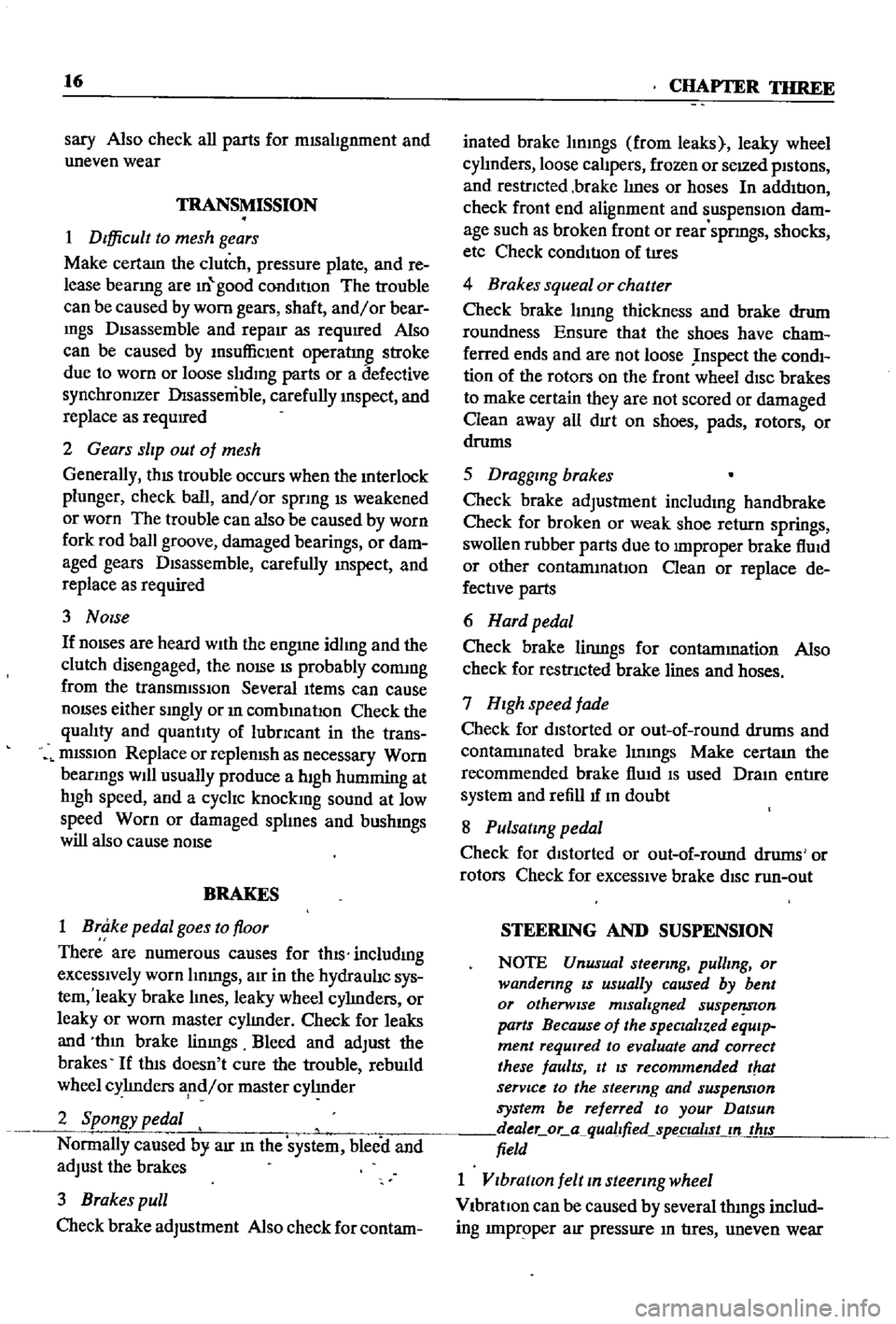

Undennflatlon

Worn

more

on

Sides

than

In

center

Page 23 of 252

18

CHAP1

lER

THlREE

c

c

c

ce

J

1

Ii

j

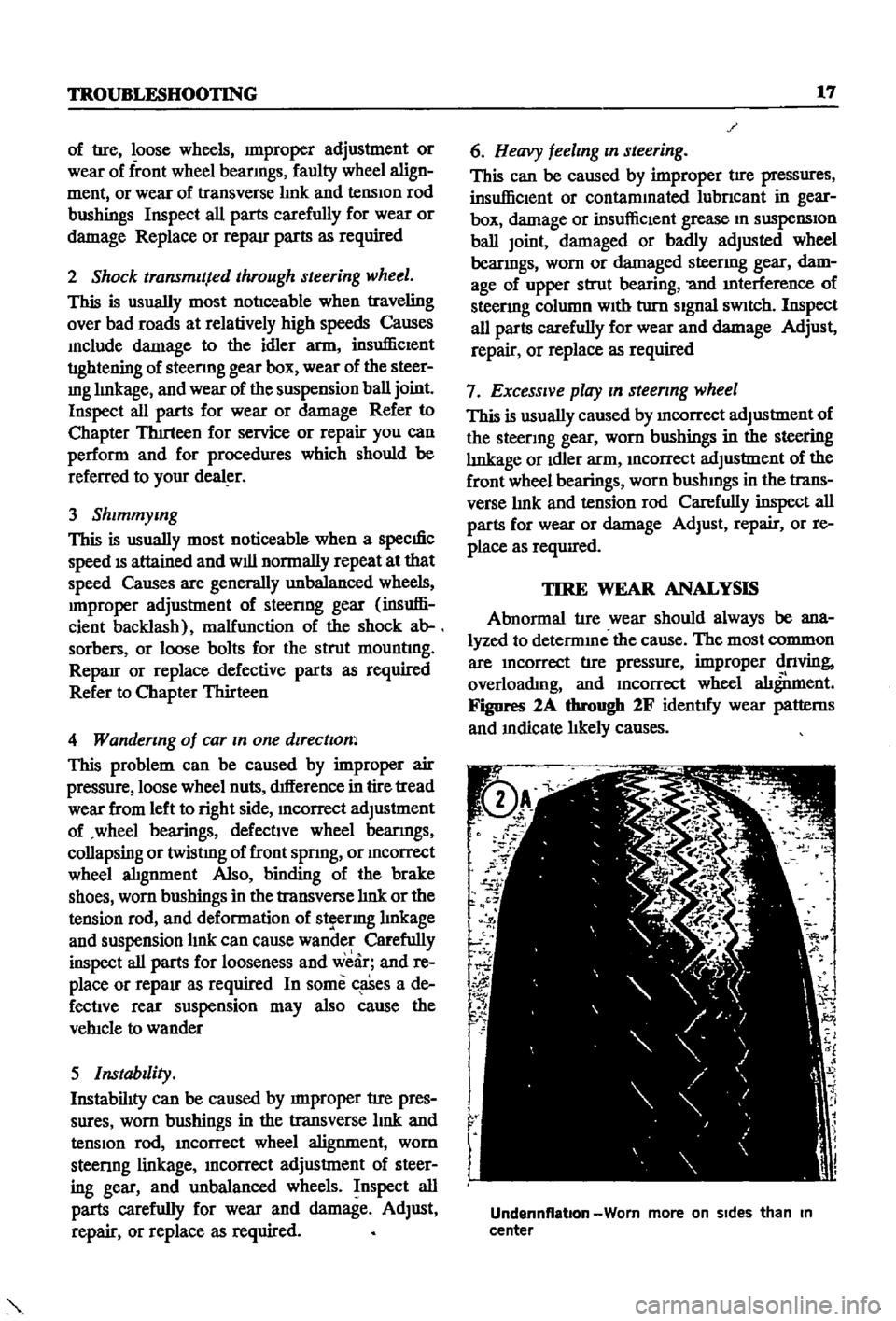

Wheel

Alignment

Worn

more

on

one

sIde

than

the

other

Edges

of

tread

feathered

r

I

0c

l

Road

Abrasion

Rough

wear

on

entire

tire

or

In

patches

t

y

1

OverInflabon

Worn

more

In

center

than

on

sides

Wheel

Balance

Scalloped

edges

indicate

wheel

wobble

or

tramp

due

to

wheel

unbal

ance

f

Q

F

r

r

r

f

i

m

i

O

2

7

iK

J

1

J

i

i

5J

CombInation

Most

tIres

exhibit

a

combination

of

the

above

This

tIre

was

overinflated

center

worn

and

the

toe

In

was

Incorrect

feather

Ing

The

driver

cornered

hard

at

high

speed

feathering

rounded

shoulders

and

braked

rapidly

worn

spots

The

scaly

roughness

In

dlcates

a

rough

road

surface

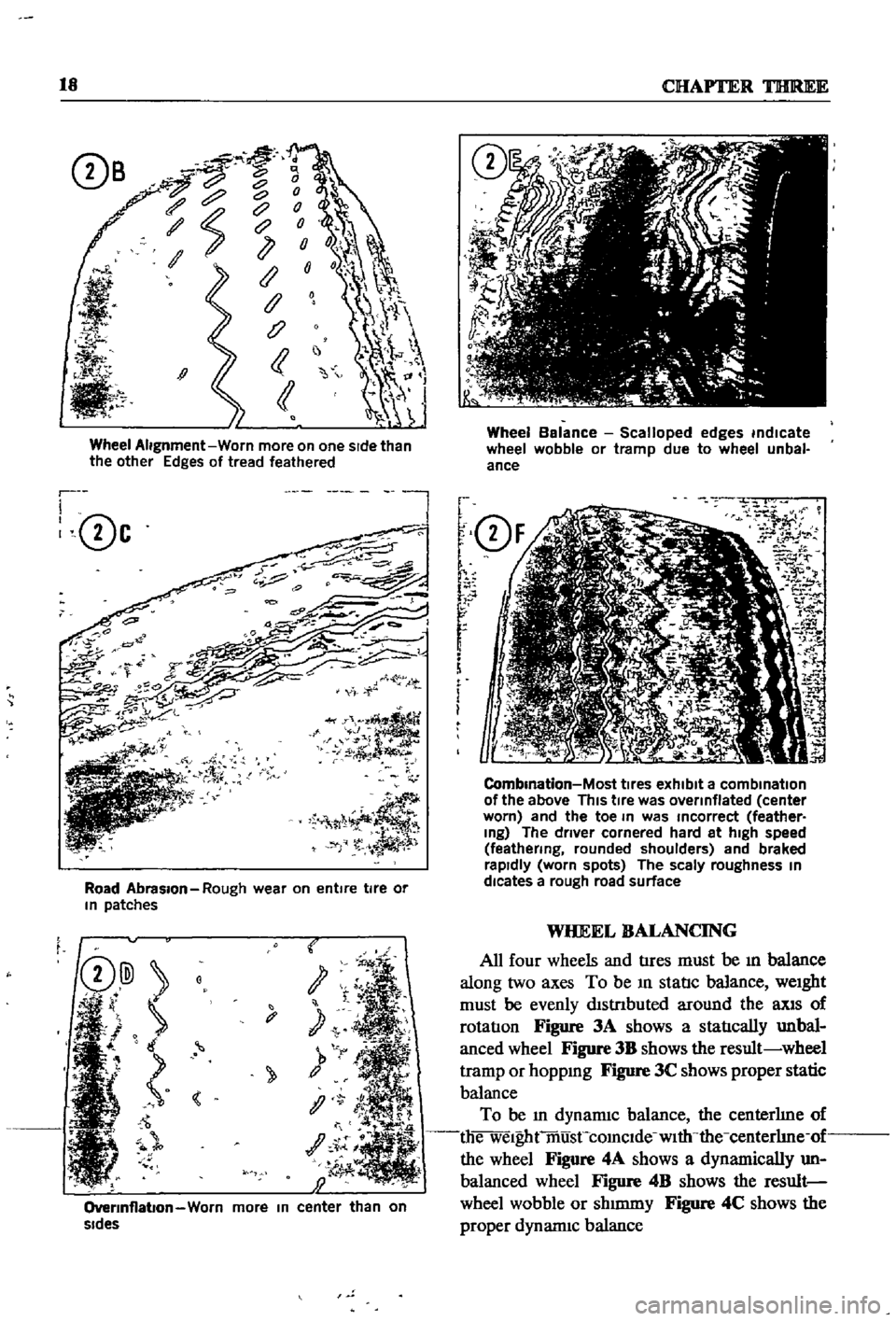

WHEEL

BALANCING

All

four

wheels

and

tIres

must

be

ill

balance

along

two

axes

To

be

ill

statIc

balance

weight

must

be

evenly

dlstnbuted

around

the

llXlS

of

rotatIon

Figure

3A

shows

a

statIcally

unbal

anced

wheel

Figure

3B

shows

the

result

wheel

tramp

or

hoppmg

Figure

3C

shows

proper

static

balance

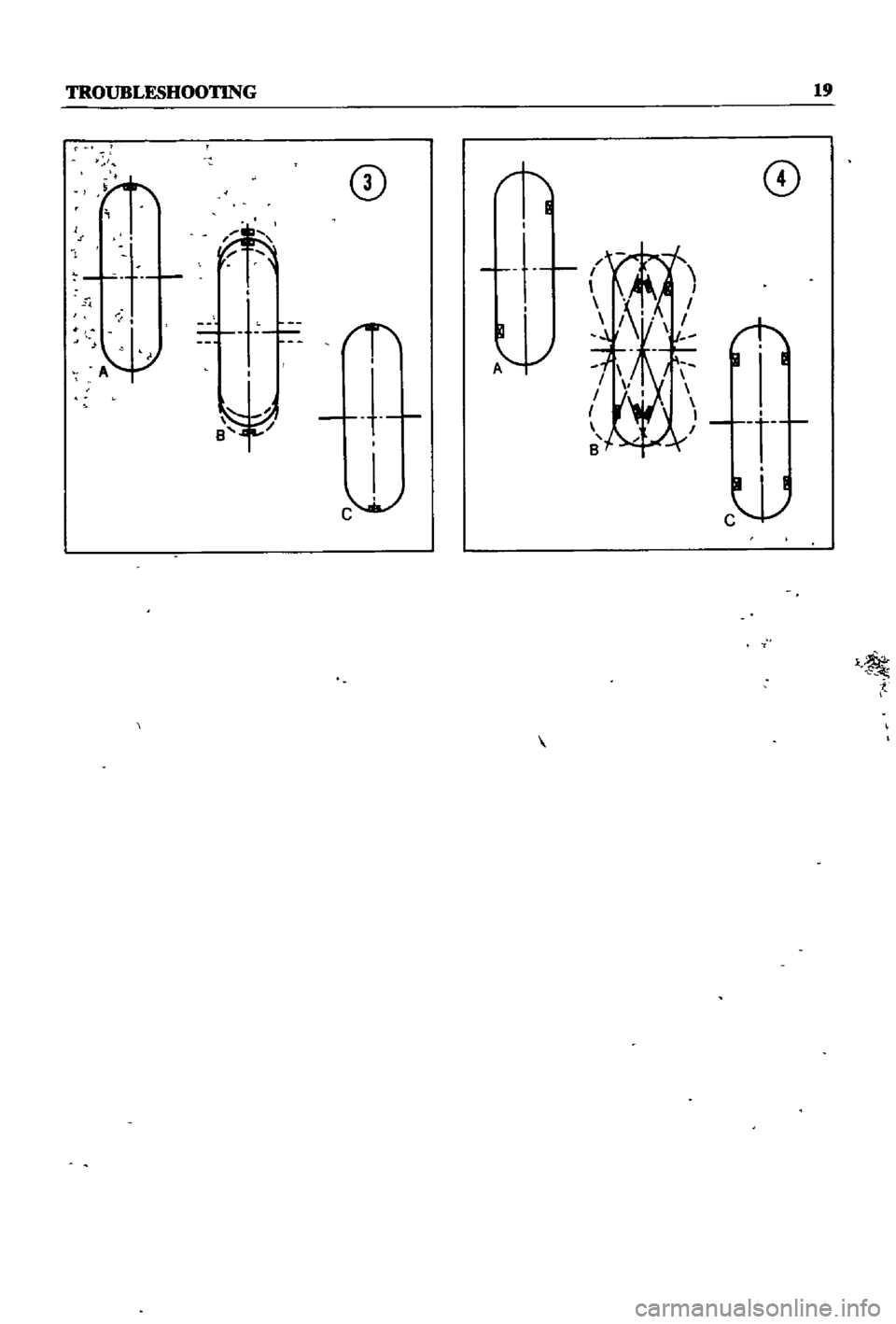

To

be

ill

dynamiC

balance

the

centerhne

of

die

welghtmusCcomclde

with

the

centerhne

of

the

wheel

Figure

4A

shows

a

dynamically

un

balanced

wheel

Figure

4B

shows

the

result

wheel

wobble

or

shmuny

Figure

4C

shows

the

proper

dynannc

balance

Page 24 of 252

rROUBLESIlOOTlNG

CD

CD

t

Page 25 of 252

CHAPTER

FOUR

ENGINE

AND

IGNITION

TUNE

UP

For

best

performance

and

economy

care

must

be

taken

in

perfornnng

tune

ups

While

accuracy

is

required

the

task

IS

not

d1flicult

if

the

steps

m

tlus

chapter

are

followed

carefully

Cars

used

pnmarily

m

CIty

stop

and

go

dnv

ing

WIll

reqwre

attention

more

frequently

than

those

used

on

highways

ThIs

is

because

the

engme

does

not

reach

full

operatIng

temperature

ConsequentlY

valves

tend

to

stick

compression

drops

and

engme

operatIon

becomes

rough

A

tune

up

IS

adVISable

every

6

000

miles

or

sooner

dependmg

on

type

of

driving

Every

12

000

nu1es

the

spark

plugs

and

ignitIon

break

er

pomts

should

be

replaced

not

Just

cleaned

and

adjusted

A

mmor

tune

up

consISts

of

checking

battery

condItIon

cleanmg

gapping

or

replacmg

spark

plugs

and

dIstnbutor

breaker

pomts

adjustIng

dIStnbutor

dwell

angle

adjusting

IgnitIon

tun

mg

and

settIng

the

carburetor

Idle

mixture

and

idle

speed

A

major

wne

up

includes

the

above

items

plus

igllltIon

compressIOn

valve

clear

ance

carburetor

emISsion

control

deVIce

and

electncal

checks

and

adjustments

Tune

up

Equipment

Required

The

follOWIng

eqUIpment

IS

required

Chap

ter

Two

provides

a

bnef

descnption

of

the

test

eqwpment

I

Voltmeter

ammeter

and

ohmmeter

2

Hydrometer

3

CompressIOn

tester

4

Vacuum

gauge

s

Dwell

meter

6

Tachometer

7

I

StrobOSCOpIC

tmung

lIght

8

Feeler

gauges

9

Torque

wrench

10

Assorted

hand

tools

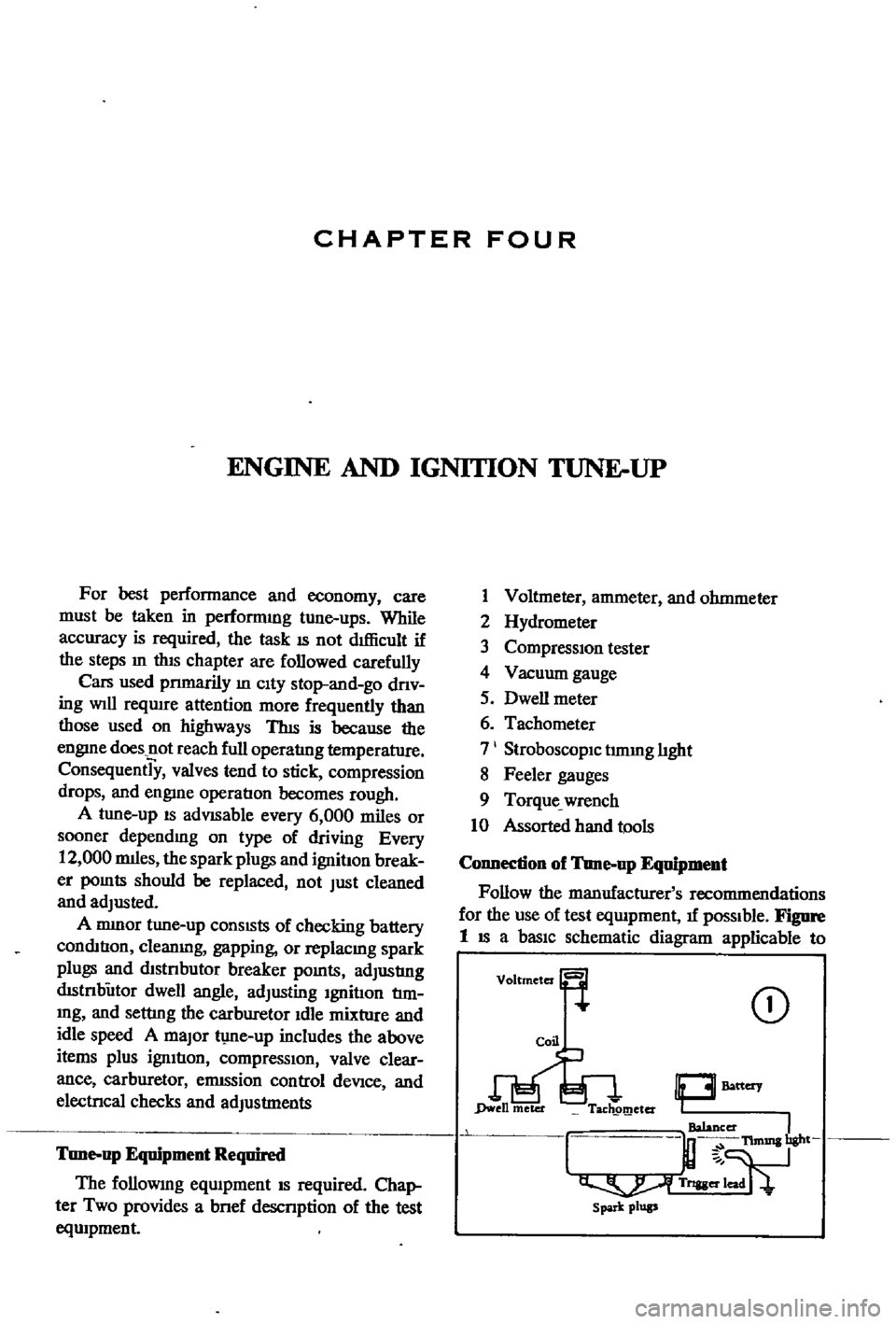

Connection

of

Tune

up

Equipment

Follow

the

manufacturer

s

recommendations

for

the

use

of

test

eqwpment

If

pOSSible

Figme

1

IS

a

basiC

schematic

diagram

applicable

to

CD

10

Battery

I

TIm1Illbght

T

8Ier

spa

k

plup

Page 26 of 252

ENGINE

AND

IGNITION

TUNE

UP

21

many

types

of

test

eqUipment

and

may

be

used

as

a

gUide

If

the

manufacturer

s

mstructioQs

are

not

aVailable

Connections

shown

in

Figure

1

are

as

follows

1

Voltmeter

a

PosItive

lead

to

resistor

side

of

COli

b

Negative

1

ead

to

ground

2

Tlmmg

Light

a

PosItive

lead

to

posItive

battery

termmal

b

Tngger

lead

to

number

1

spark

plug

c

Negative

lead

to

ground

3

Tachometer

a

PosItive

lead

to

dlstnbutor

Side

of

coil

b

Negative

lead

to

ground

4

Dwell

Meter

a

PosItive

lead

to

dlstnbutor

Side

of

COlI

b

Negative

lead

to

ground

BAlTERY

INSPECTION

AND

SERVICE

1

Check

the

level

of

the

electrolyte

m

battery

cells

If

necessary

replemsh

with

distilled

water

Do

not

overfill

2

Measure

the

speCific

gravity

of

the

battery

electrolyte

Refer

to

the

followmg

table

2

Use

the

proper

size

socket

and

wrench

to

remove

spark

plugs

from

the

cyhnder

head

Make

certam

that

the

gaskets

are

removed

from

the

spark

plug

holes

3

Wipe

off

the

msulator

With

a

clean

rag

to

remove

grease

and

dirt

4

Carefully

mspect

the

msulator

and

body

of

each

plug

for

signs

of

cracks

or

chips

Replace

If

faulty

5

Inspect

spark

plug

threads

and

electrodes

for

damage

or

excessive

wear

Replace

as

requrred

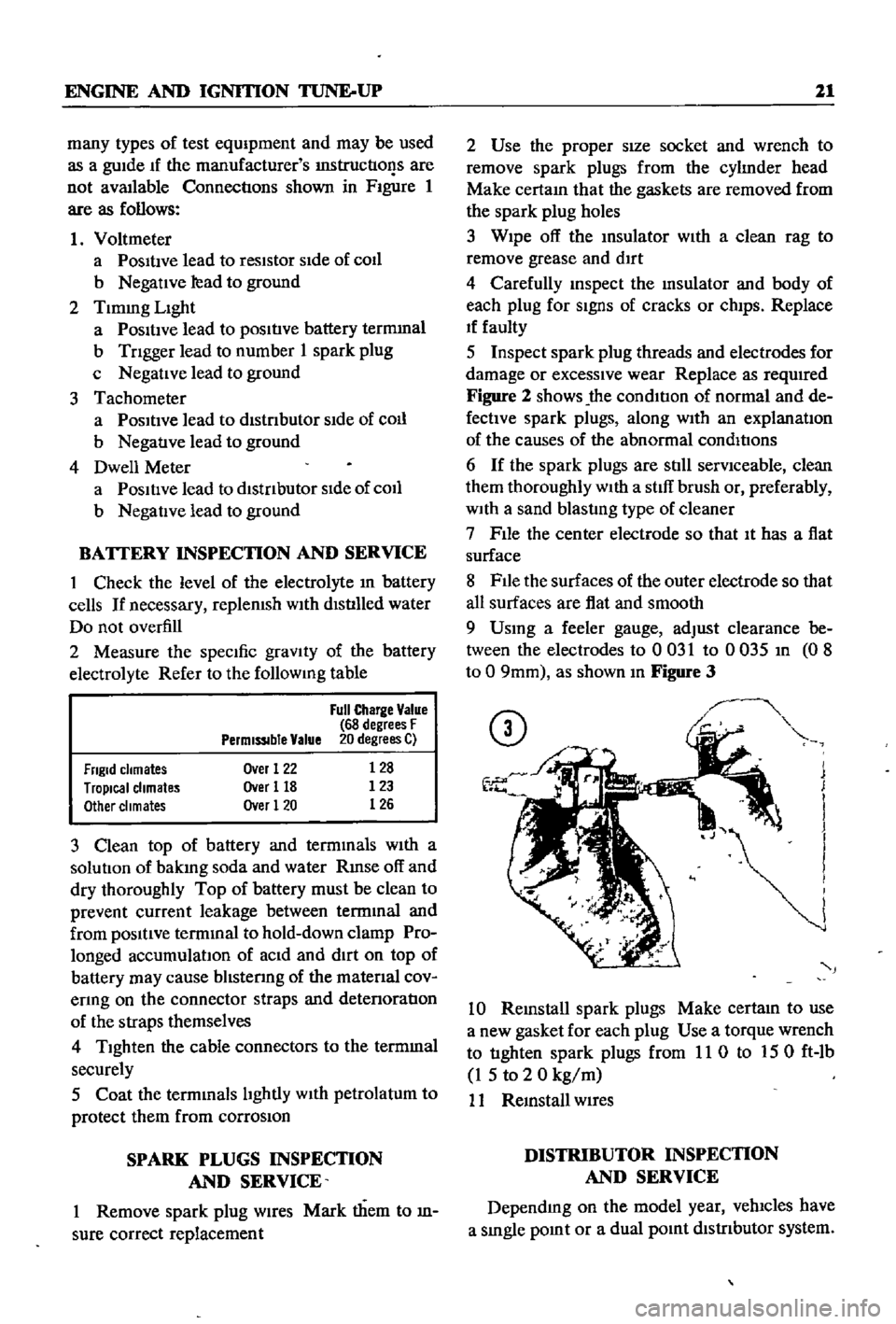

Figure

2

shows

the

cond1t

J

on

of

normal

and

de

fectIVe

spark

plugs

along

with

an

explanation

of

the

causes

of

the

abnormal

conditions

6

If

the

spark

plugs

are

still

serviceable

clean

them

thoroughly

With

a

stiff

brush

or

preferably

With

a

sand

blasting

type

of

cleaner

7

File

the

center

electrode

so

that

It

has

a

fiat

surface

8

File

the

surfaces

of

the

outer

electrode

so

that

all

surfaces

are

fiat

and

smooth

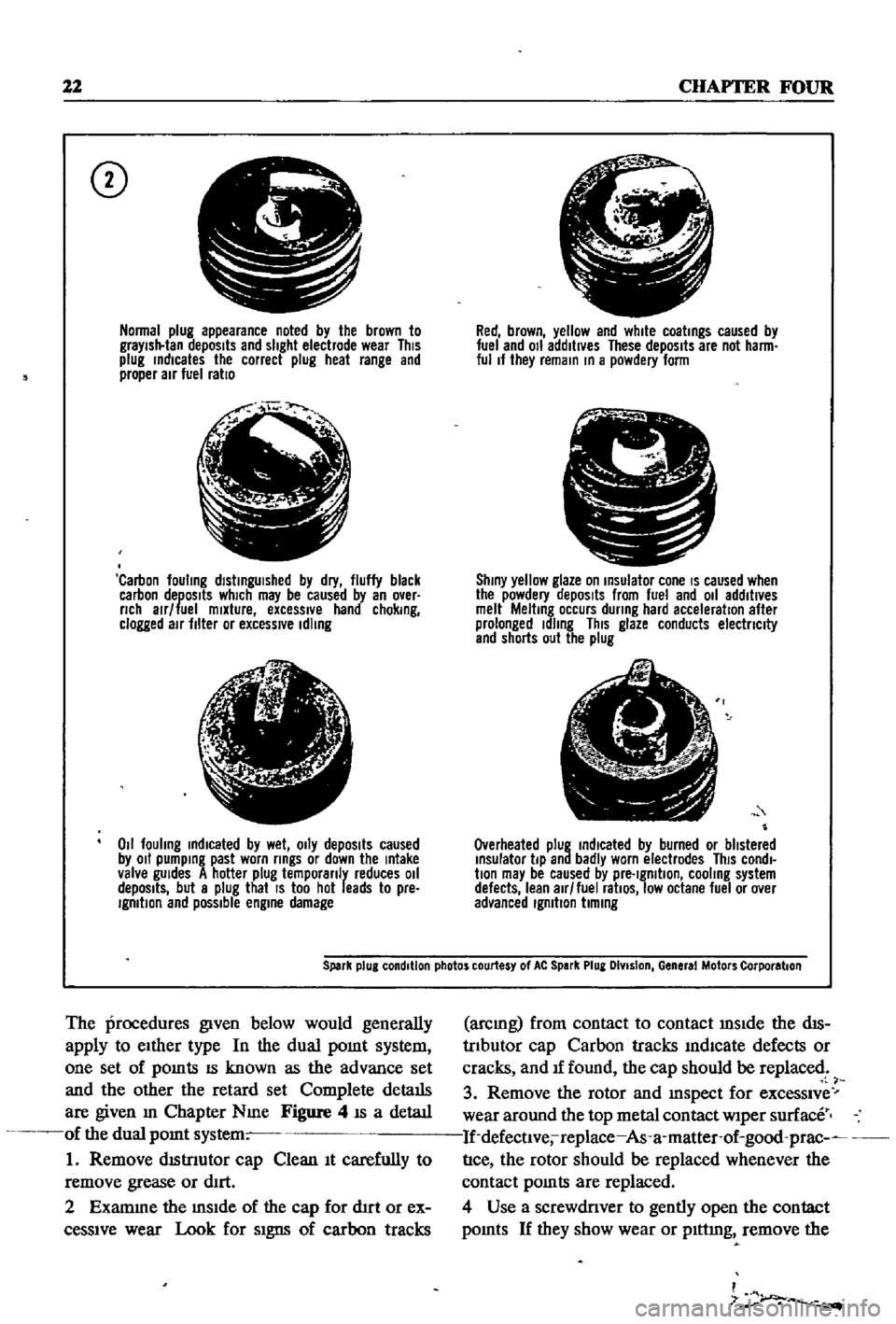

9

Usmg

a

feeler

gauge

adjust

clearance

be

tween

the

electrodes

to

0

031

to

0

035

m

0

8

to

0

9mm

as

shown

m

Figure

3

Full

Charge

Value

CD

68

degrees

F

PermiSSIble

Value

20

degrees

C

3

Frigid

chmates

Tropical

chmates

Other

climates

Over

1

22

Over

118

Over

1

20

128

123

126

3

Clean

top

of

battery

and

termmals

With

a

solutIOn

of

bakmg

soda

and

water

Rmse

off

and

dry

thoroughly

Top

of

battery

must

be

clean

to

prevent

current

leakage

between

termmal

and

from

pOSitive

termmal

to

hold

down

clamp

Pro

longed

accumulatIOn

of

aCid

and

dirt

on

top

of

battery

may

cause

blIstenng

of

the

matenal

cov

enng

on

the

connector

straps

and

detenoration

of

the

straps

themselves

4

Tighten

the

cable

connectors

to

the

termmal

securely

5

Coat

the

termmals

lIghtly

With

petrolatum

to

protect

them

from

corrosion

SPARK

PLUGS

INSPECTION

AND

SERVICE

1

Remove

spark

plug

WIres

Mark

them

to

fi

sure

correct

replacement

J

J

I

I

j

j

10

Remstall

spark

plugs

Make

certam

to

use

a

new

gasket

for

each

plug

Use

a

torque

wrench

to

tighten

spark

plugs

from

11

0

to

150

ft

lb

1

5

to

2

0

kg

m

11

Remstall

WIres

DISTRIBUTOR

INSPECTION

AND

SERVICE

Dependmg

on

the

model

year

velucles

have

a

smgle

pomt

or

a

dual

pomt

dlstnbutor

system

Page 27 of 252

22

CHAPTER

FOUR

CD

Normal

plug

appearance

noted

by

the

brown

to

graYish

tan

deposits

and

slight

electrode

wear

This

plug

rndlcates

the

correct

plug

heat

range

and

proper

air

fuel

ratio

f

j

l

Carbon

fouling

dlstrngUlshed

by

dry

fluffy

black

carbon

deposits

which

may

be

caused

by

an

over

nch

alr

fuel

mixture

excessIVe

hand

chokrng

clogged

air

filter

or

excessive

Idling

lJ

6

1

4i

Z

011

fouling

rndlcated

by

wet

OIly

depOSits

caused

by

011

pumprng

past

worn

rrngs

or

down

the

rntake

valve

gUides

A

hotter

plug

temporanly

reduces

011

depOSits

but

a

plug

that

IS

too

hot

leads

to

pre

IgmtlOn

and

possible

engrne

damage

Red

brown

yellow

and

white

coatrngs

caused

by

fuel

and

011

additives

These

depOSits

are

not

harm

ful

If

they

remarn

rn

a

powdery

form

C

I

Shrny

yellow

glaze

on

rnsulator

cone

IS

caused

when

the

powdery

depOSits

from

fuel

and

011

additives

melt

Meltrng

occurs

dunng

hard

acceleration

after

prolonged

Idling

This

glaze

conducts

electnclty

and

shorts

out

the

plug

Overheated

plug

rndlcated

by

burned

or

blistered

rnsulator

tip

and

badly

worn

electrodes

This

condl

bon

may

be

caused

by

pre

Igmtlon

cooling

system

defects

lean

air

fuel

ratiOS

low

octane

fuel

or

over

advanced

Igmbon

bmrng

Spark

plug

condition

photos

courtesy

of

At

Spark

Plug

DIvision

General

Motors

Corporation

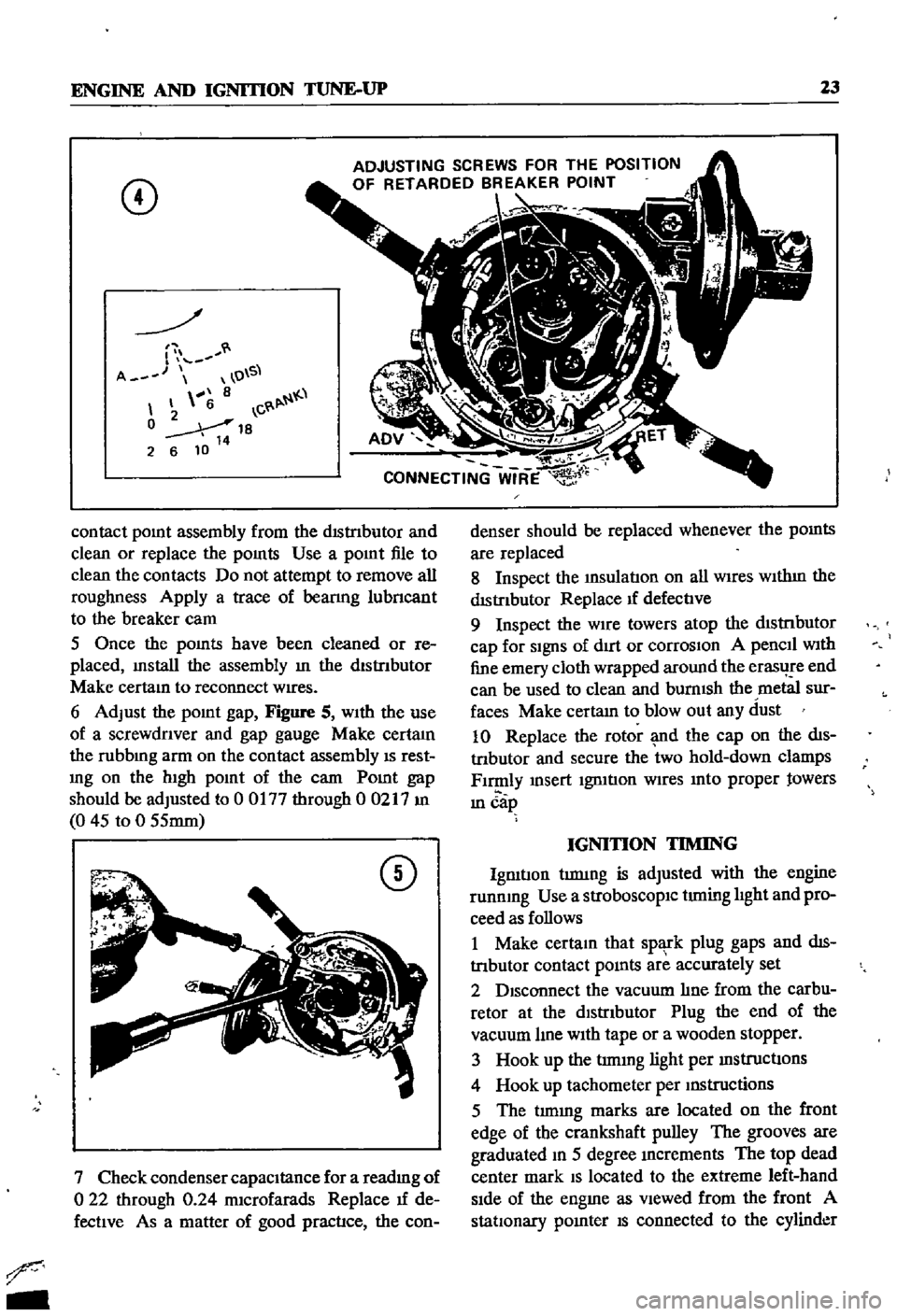

The

procedures

given

below

would

generally

apply

to

eIther

type

In

the

dual

pomt

system

one

set

of

pomts

IS

known

as

the

advance

set

and

the

other

the

retard

set

Complete

details

are

given

m

Chapter

Nme

Figure

4

IS

a

detaIl

of

the

dual

pomt

system

1

Remove

dIStnutor

cap

Clean

It

carefully

to

remove

grease

or

dIrt

2

Examme

the

mSIde

of

the

cap

for

d1rt

or

ex

ceSSIve

wear

Look

for

SIgns

of

carbon

tracks

arcmg

from

contact

to

contact

mSIde

the

dIS

trIbutor

cap

Carbon

tracks

mdlcate

defects

or

cracks

and

If

found

the

cap

should

be

replaced

3

Remove

the

rotor

and

mspect

for

exceSSIve

wear

around

the

top

metal

contact

wiper

surface

If

defectlve

replace

As

a

matter

of

good

prac

nce

the

rotor

should

be

replaced

whenever

the

contact

pomts

are

replaced

4

Use

a

screwdriver

to

gently

open

the

contact

pomts

If

they

show

wear

or

plttmg

remove

the

I

7

r

Page 28 of 252

ENGINE

AND

IGNITION

TUNE

UP

23

CD

ADJUSTING

SCREWS

FOR

THE

POSITION

OF

RETARDED

BREAKER

POINT

r

A

O

S

8

6

C

0

18

2

6

10

14

contact

pomt

assembly

from

the

dIStnbutor

and

clean

or

replace

the

pomts

Use

a

pomt

file

to

clean

the

contacts

Do

not

attempt

to

remove

all

roughness

Apply

a

trace

of

beanng

lubncant

to

the

breaker

cam

5

Once

the

pomts

have

been

cleaned

or

re

placed

mstall

the

assembly

m

the

dlstnbutor

Make

certam

to

reconnect

wires

6

Adjust

the

pomt

gap

Figure

S

With

the

use

of

a

screwdnver

and

gap

gauge

Make

certaIn

the

rubbmg

arm

on

the

contact

assembly

IS

rest

mg

on

the

hIgh

pomt

of

the

carn

Pomt

gap

should

be

adjusted

to

0

0177

through

00217

m

0

45

to

0

55mm

CD

7

Check

condenser

capacItance

for

a

readmg

of

o

22

through

0

24

mIcrofarads

Replace

If

de

fectIve

As

a

matter

of

good

practIce

the

con

r

denser

should

be

replaced

whenever

the

pomts

are

replaced

8

Inspect

the

InSulatIon

on

all

WIres

WIthIn

the

dIStributor

Replace

If

defectIve

9

Inspect

the

WIre

towers

atop

the

dIStnbutor

cap

for

SignS

of

dIrt

or

corrosIOn

A

pencIl

wIth

fine

emery

cloth

wrapped

around

the

erasl

e

end

can

be

used

to

clean

and

burnISh

the

metal

sur

faces

Make

certam

to

blowout

any

dust

10

Replace

the

rotor

md

the

cap

on

the

dIs

tnbutor

and

secure

the

two

hold

down

clamps

FI

ly

msert

IgrntIon

WIres

mto

proper

towers

ill

cap

IGNITION

TIMING

IgmtIon

tIDlIDg

is

adjusted

with

the

engine

runnmg

Use

a

strobOSCOpIC

timing

hght

and

pro

ceed

as

follows

1

Make

certam

that

spl

l

k

plug

gaps

and

dIs

tnbutor

contact

pomts

are

accurately

set

2

DISconnect

the

vacuum

hne

from

the

carbu

retor

at

the

dIstrIbutor

Plug

the

end

of

the

vacuum

hne

wIth

tape

or

a

wooden

stopper

3

Hook

up

the

trmmg

light

per

mstructIons

4

Hook

up

tachometer

per

mstructions

5

The

tImmg

marles

are

located

on

the

front

edge

of

the

crankshaft

pulley

The

grooves

are

graduated

m

5

degree

mcrements

The

top

dead

center

mark

S

located

to

the

extreme

left

hand

sIde

of

the

engme

as

vIewed

from

the

front

A

statIOnary

pomter

S

connected

to

the

cylinder

Page 29 of 252

P

r

OVll

t

ate

I

l

h

l

JlA

ye

I

o

ctg

fI

O

0

I

d

1e

d

c

Ji

uo

JJ

cb

c

s

rlr

I

l

4

c

1

2

24

CHAPTER

FOUR

block

and

should

be

used

as

the

reference

point

m

II

1akmg

adjustments

6

With

a

piece

of

white

chalk

mark

a

hne

down

the

center

of

the

pomter

and

mark

the

timing

groove

on

the

crankshaft

pulley

which

IS

to

be

used

m

tImmg

the

engine

SpecIficatIon

for

tun

ing

reqUIres

trlhmg

at

10

degrees

before

top

dead

center

wluch

would

be

the

fourth

mark

from

the

left

end

of

the

row

of

marks

7

Loosen

the

hold

down

bolt

at

the

base

of

the

dlstnbutor

8

Locate

the

slow

speed

1

Ile

adjustIng

screw

on

the

carburetor

so

that

Ile

speed

can

be

adjusted

whIle

runnmg

Also

locate

throttle

adJustmg

screw

9

Start

engme

and

adjust

speed

With

the

adJust

ing

screws

to

the

readmgs

below

Smgle

pomt

dIStributor

600

rpm

Dual

pomt

trlbutor

700

rpm

10

Alternate

adjustment

of

the

two

screws

untIl

the

smoothest

Idle

at

the

proper

speed

IS

achieved

11

Pomt

the

tlIrung

lIght

at

the

stationary

pomter

When

the

lIght

flashes

the

timmg

mark

n

the

crankshaft

pulley

should

hne

up

With

the

mark

on

the

stationary

pomter

If

It

does

not

exactly

Ime

up

rotate

the

dlstnbutor

gradually

untIl

the

marks

align

mdlcatlng

correct

timmg

12

Shut

off

the

engme

remove

the

tmung

lIght

and

tachometer

tighten

the

hold

down

bolt

on

the

dlStnbutor

and

connect

the

vacuum

advance

hne

to

the

tli

tnbutor

IGNITION

TIMING

IDLE

SPEED

IDLE

MIXTURE

DUAL

POINT

DISTRIBUTOR

ONLY

The

followmg

applies

to

velucles

With

dual

pomt

distributor

and

an

exhaust

emission

con

trol

deVice

If

these

procedures

are

followed

ha

ul

exhaust

emisSion

should

be

below

the

maximum

allowable

level

1

Locate

the

Idle

and

throttle

adJustmg

screws

on

the

carburetor

2

Warm

up

the

engine

thoroughly

3

Connect

tachometer

and

tmung

light

4

Set

the

Id

le

speed

at

700

rpm

With

the

Idle

adjust

screw

5

Adjust

IgnltJ

on

tuning

at

10

degrees

before

top

dead

center

6

Increase

the

speed

of

the

engme

to

2

000

rpm

With

the

accelerator

or

throttle

hnkage

and

hold

for

about

15

seconds

7

Return

to

Idle

for

one

mmute

8

Set

the

engme

to

best

Idle

at

750

rpm

770

rpm

for

automatJ

c

transIDlsslOn

With

the

Idle

and

throttle

adJustmg

screws

9

Re

uce

engme

speed

at

700

rpm

720

rpm

for

automatic

transmission

by

turnmg

the

Idle

adJustmg

screw

clockWise

for

a

leaner

IlliXture

10

Connect

a

wife

lead

between

the

advance

ami

retard

Side

tenrunals

See

Figure

4

Speed

should

drop

from

100

to

150

rpm

11

Check

IgIl1tIon

tmung

With

tImmg

light

It

should

now

be

at

top

d

ad

center

12

If

the

tlmmg

IS

nSJt

correct

stop

the

engme

and

adjust

the

retarded

breaker

pomt

13

Start

the

engme

and

reclieck

ili

tmung

If

l

incorrect

reset

the

retarded

breaker

pomt

until

it

IS

correct

Repeat

s

nece

s

14

Disconnect

the

wife

bet

reen

the

advance

and

retard

termmals

15

Recheck

tmung

It

should

be

10

degrees

before

top

dead

center

16

If

mcorrect

repeat

the

above

procedures

un

tIl

satIsfactory

17

T

he

Idle

speed

of

automatic

transnllsslOn

vehicles

should

be

about

575

rpm

With

the

gear

j

selector

m

the

dhve

poSltlon

c

t

DWELL

ANGLE

SETIING

1

Connect

the

dwell

angle

meter

2

PLoJust

dwell

angle

to

49

to

55

degrees

OMPRESSION

TEST

I

A

compressIOn

test

IS

performed

to

check

for

worn

piston

nngs

or

to

detect

the

cause

of

a

low

speed

miss

Before

undertaking

the

test

el

llmate

the

pOSSibility

of

sticky

valves

by

usmg

one

of

the

oil

additives

deSigned

for

the

purpose

With

valves

free

test

compressIOn

as

follows

1

Run

the

engme

for

15

to

20

mmutes

untIl

normal

operating

temperatures

are

obtained

2

Shut

off

engme

remove

arr

cleaner

and

Page 30 of 252

ENGINE

AND

IGNITION

TUNE

UP

4

25

block

the

throttle

and

choke

m

the

WIde

open

position

3

Remove

all

four

spark

plugs

4

Sequentially

press

a

compressIOn

test

gauge

mto

each

of

the

spark

plug

holes

and

crank

the

engme

for

at

least

four

strokes

Record

the

com

pressIOn

readmg

for

each

cylmder

Standard

compressIOn

readmg

IS

171

Ibs

m

12

0

kg

cm

Mmlmum

acceptable

readmg

IS

159

lbs

m

2

11

5

kg

cm

5

No

readmg

should

be

less

than

80

of

the

highest

cylmder

reading

ExceSSive

vanatiC

ns

between

cylmders

accompanied

by

low

speed

mlssmg

of

the

cyhnder

or

cylmders

that

read

low

usually

mdlcates

a

valve

not

properly

seat

mg

or

a

broken

piston

ring

Low

pressures

even

though

uniform

may

mdicate

worn

nngs

ThIS

IS

especlall

true

1f

ex

cessive

011

cQIlsumptlon

has

been

noticed

If

one

or

more

cylmders

read

low

or

uneven

inject

about

a

tablespoon

of

engine

ail

on

top

of

the

piston

of

that

cylinder

and

crank

the

engine

several

tlmes

noting

the

compressIOn

reading

If

compressIOn

has

nsen

the

piston

nngs

or

cylmders

are

worn

and

should

befserviced

If

compressIOn

has

not

unproved

after

addmg

oil

the

valves

are

Stlcking

or

are

not

seating

prop

erly

If

two

adjacent

cylmders

have

low

compres

sion

and

mjectmg

01

9es

not

increas

the

read

mg

the

head

gasket

between

the

cylmders

IS

probably

leaking

VALVE

CLEARANCE

ADJUSTMENT

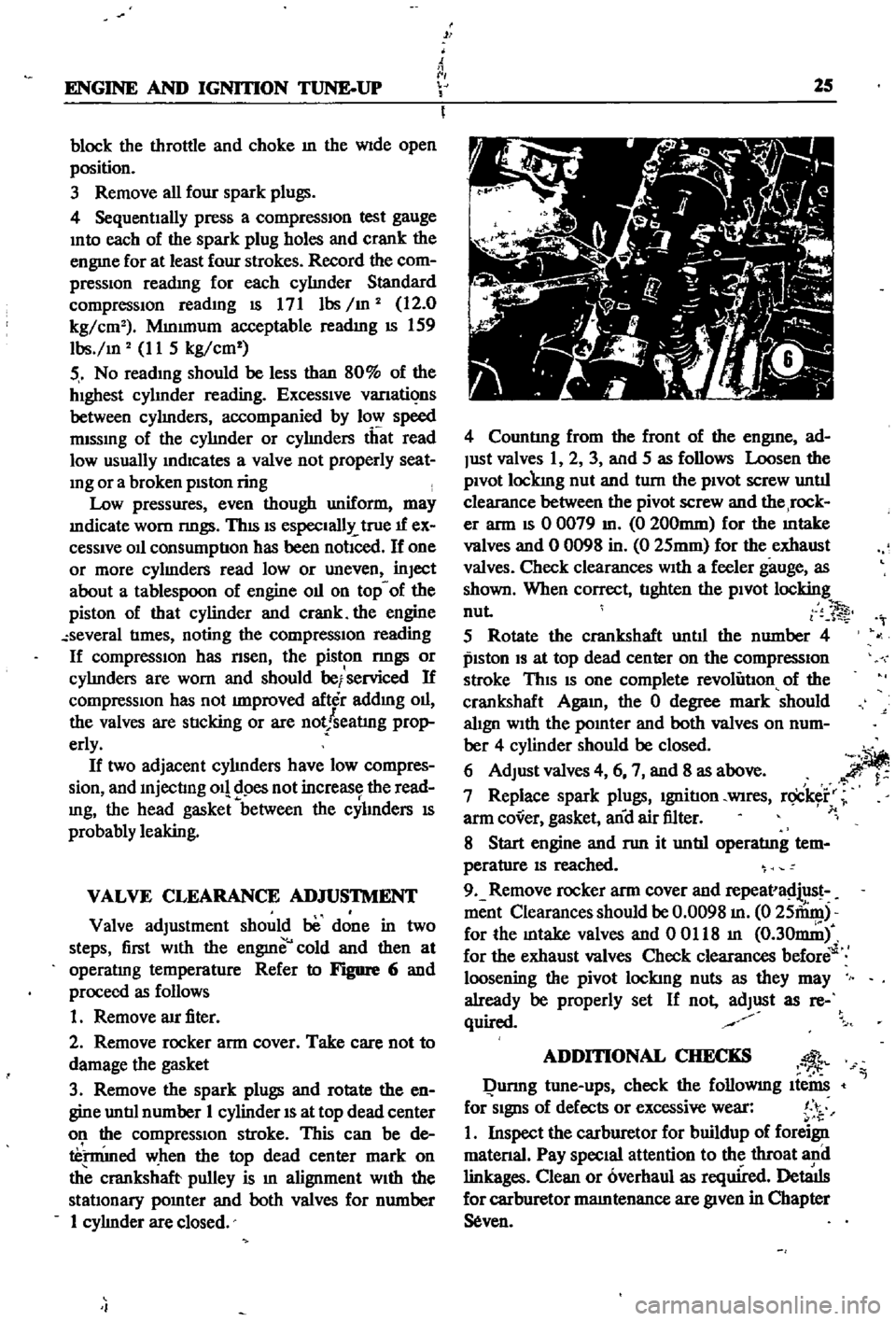

Valve

adjustment

should

be

done

in

two

steps

first

With

the

engme

cold

and

then

at

operatmg

temperature

Refer

to

Figure

6

and

proceed

as

follows

1

Remove

arr

liter

2

Remove

rocker

arm

cover

Take

care

not

to

damage

the

gasket

3

Remove

the

spark

plugs

and

rotate

the

en

gine

unt1l

number

1

cylinder

IS

at

top

dead

center

o

l

the

compressIOn

stroke

This

can

be

de

tepnmed

w

hen

the

top

dead

center

mark

on

the

crankshaft

pulley

is

m

alignment

With

the

statIOnary

pomter

and

both

valves

for

number

1

cylmder

are

closed

I

4

Counting

from

the

front

of

the

engme

ad

Just

valves

1

2

3

and

5

as

follows

Loosen

the

pivot

lockmg

nut

and

turn

the

pivot

screw

unt1l

clearance

between

the

pivot

screw

and

the

rock

er

ann

IS

0

0079

m

0

200mm

for

the

mtake

valves

and

0

0098

in

0

25mm

for

the

exhaust

valves

Check

clearances

With

a

feeler

gauge

as

shawn

When

correct

tlghten

the

pivot

locking

nut

l

1

5

Rotate

the

crankshaft

unt1l

the

number

4

pISton

IS

at

top

dead

center

an

the

compressIOn

stroke

This

IS

one

complete

revolution

of

the

crankshaft

Agam

the

0

degree

mark

should

align

With

the

pomter

and

both

valves

on

num

ber

4

cylinder

should

be

closed

6

Adjust

valves

4

6

7

and

8

as

above

i

I

7

Replace

spark

plugs

Ignition

WIres

r

ick

r

1

arm

cover

gasket

and

air

filter

8

Start

engine

and

run

it

unt1l

operating

tem

perature

IS

reached

9

Remove

rocker

ann

cover

and

repeava

iius

ment

Clearances

should

be

0

0098

m

0

25fumj

for

the

mtake

valves

and

00Il8

m

0

30mi

for

the

exhaust

valves

Check

clearances

before

loosening

the

pivot

lockmg

nuts

as

they

may

already

be

properly

set

If

not

adjust

as

re

quir

l

ADDmONAL

CHECKS

l

Qunng

tune

ups

check

the

followmg

Ite

far

SignS

of

defects

or

excessive

wear

I

i

1

Inspect

the

carburetor

for

buildup

of

foreign

matenal

Pay

Special

attention

to

the

throat

and

linkages

Clean

or

overhaul

as

required

Det8

1ls

for

carburetor

mamtenance

are

given

in

Chapter

seven