DATSUN 510 1968 Service Owner's Guide

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 31 of 252

26

CHAPTER

FOUR

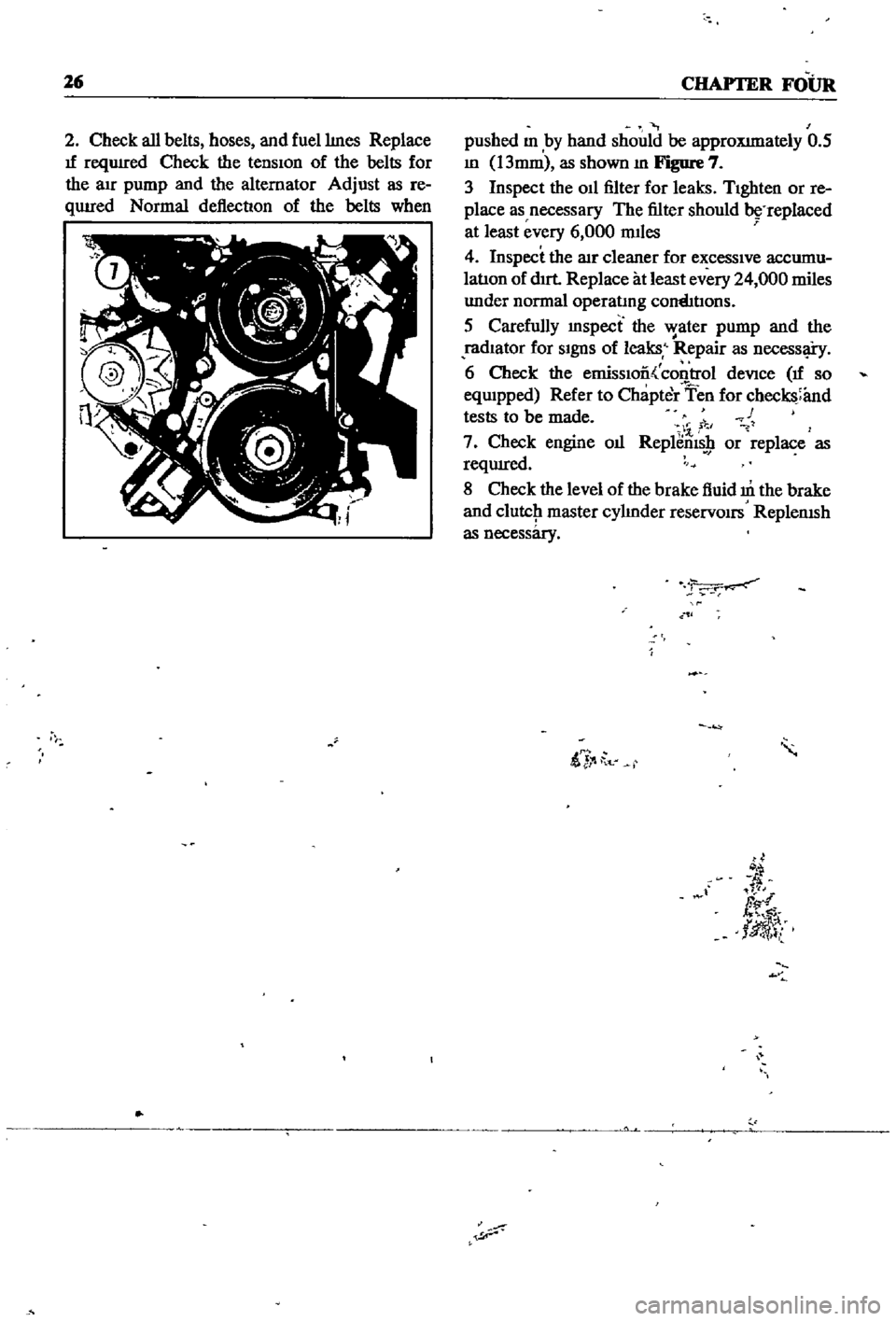

2

Check

all

belts

hoses

and

fuellmes

Replace

If

reqUIred

Check

the

tensIon

of

the

belts

for

the

au

pump

and

the

alternator

Adjust

as

re

qUIred

Normal

deflection

of

the

belts

when

pushed

m

by

hand

should

be

approXImately

0

5

m

13mm

as

shown

m

Figure

7

3

Inspect

the

011

filter

for

leaks

TIghten

or

re

place

as

necessary

The

filter

should

replaced

at

least

every

6

000

mIles

4

Inspect

the

lIlr

cleaner

for

excessIve

accumu

latIon

of

dIrt

Replace

at

least

every

24

000

miles

under

normal

operatmg

cornhtIons

5

Carefully

mspect

the

water

pump

and

the

radIator

for

SIgnS

of

leaks

Repair

as

necessl

i

y

6

Check

the

emissIoo

control

deVice

If

so

eqwpped

Refer

to

Chapter

Ten

for

checks

and

tests

to

be

made

c

1

7

Check

engine

oIl

Replems

9

or

replace

as

reqUIred

8

Check

the

level

of

the

brake

fluid

m

the

brake

and

clutcJ1

master

cylmder

reservOirs

ReplenISh

as

necessary

ii

t

d

fl

tlJ

l

Page 32 of 252

f

CH

APTER

FIVE

I

f

I

t

p

ENGINE

LUBRICATION

SYSTEM

i

k

i

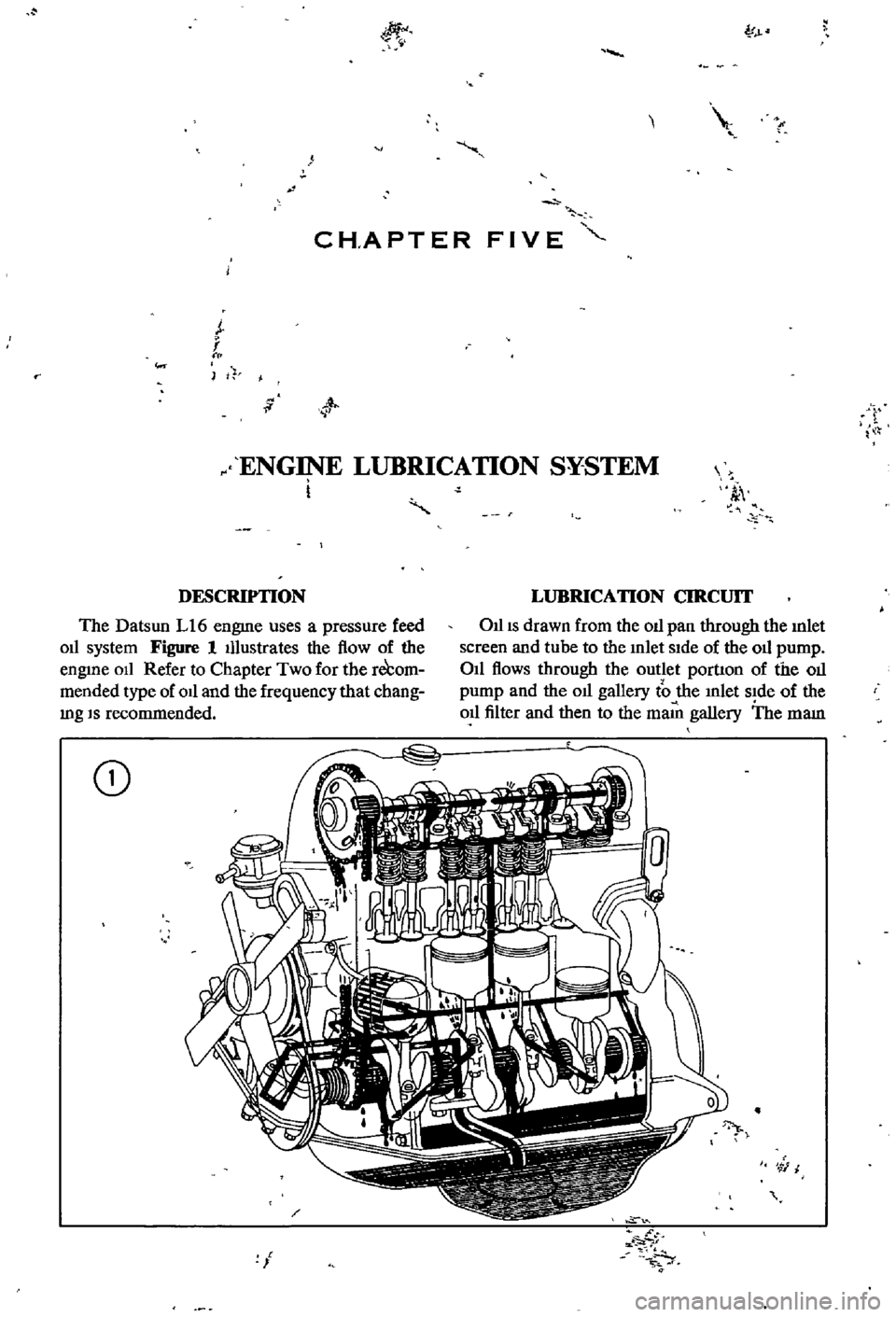

DESCRIPTION

The

Datsun

L16

engme

uses

a

pressure

feed

011

system

Figure

1

Illustrates

the

flow

of

the

engine

011

Refer

to

Chapter

Two

for

the

re

om

mended

type

of

011

and

the

frequency

that

chang

mg

IS

recommended

LUBRICATION

CIRCUIT

OlliS

drawn

from

the

011

pan

through

the

mlet

screen

and

tube

to

the

mlet

side

of

the

011

pump

011

flows

through

the

outlet

portIon

of

the

011

pump

and

the

011

gallery

to

the

mlet

side

of

the

011

filter

and

then

to

the

maID

gallery

The

mam

CD

N

4

r

I

Page 33 of 252

28

CHAPTER

FIVE

011

gallery

supphes

011

to

the

crankshaft

mam

beanngs

Dnlled

passages

m

the

crankshaft

direct

oil

from

the

mam

bearings

to

the

con

nectmg

rod

beanngs

011

mJected

from

jet

holes

in

the

connectIng

rods

IS

directed

to

the

cylmder

walls

and

piston

pins

0U

dlstnbuted

from

the

mam

gallery

enters

the

cham

tensioner

The

pad

IS

held

against

the

cham

by

011

pressure

and

spnng

tension

The

tmung

chain

receives

011

through

the

Jet

located

near

It

LubncatIon

IS

supphed

to

the

cyhnder

head

mam

011

gallery

through

the

crankshaft

center

beanngs

Camshaft

beanngs

on

the

cyhnder

head

are

fed

directly

from

the

cyhnder

head

mam

gallery

The

rocker

arms

and

valves

are

lubncated

intermittently

by

the

camshaft

011

gallery

and

the

small

channel

at

the

base

CIrcle

portIon

of

each

cam

OllIS

supphed

to

the

cam

shaft

011

gallery

through

the

No

2

and

No

3

camshaft

bearings

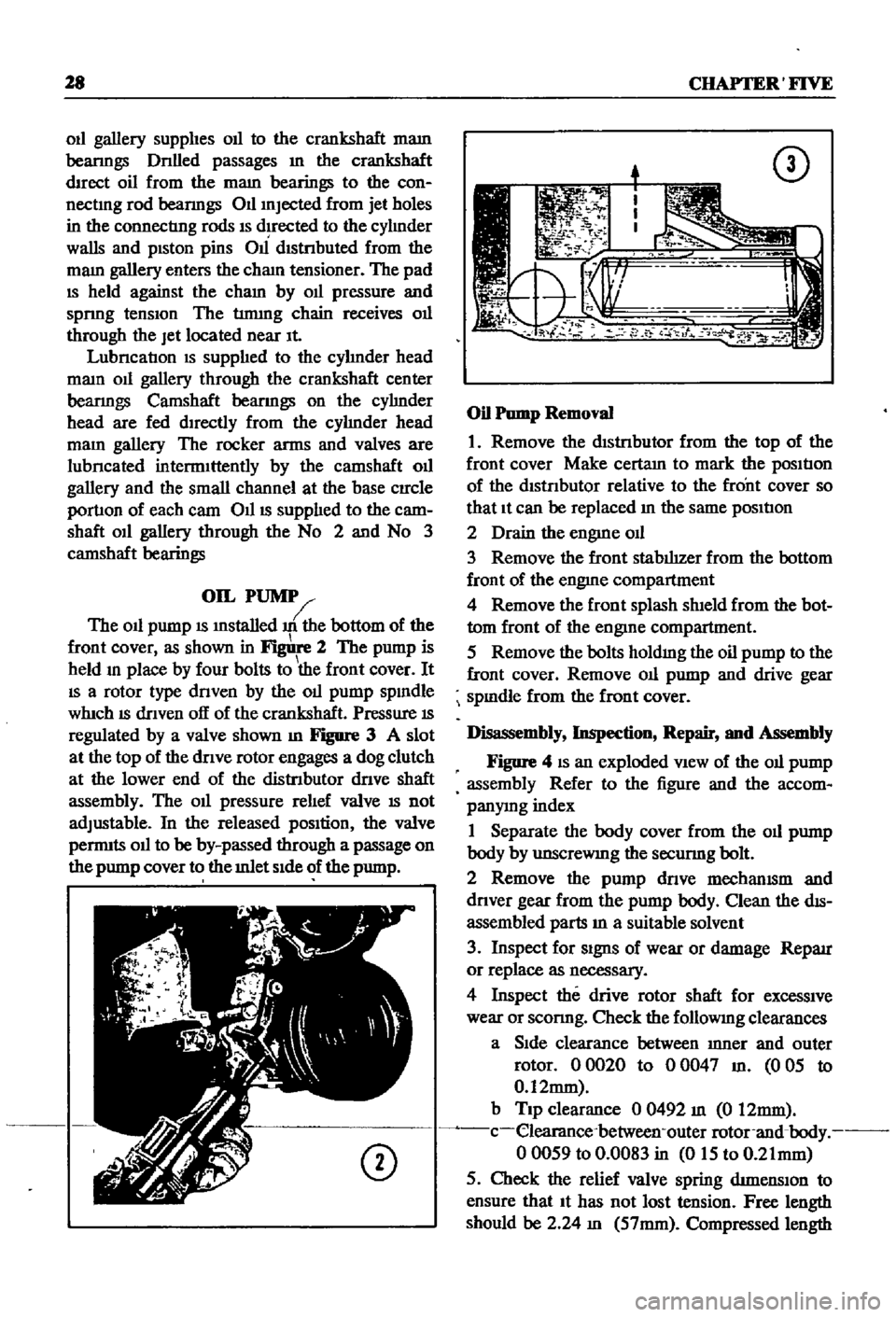

OIL

PUMP

The

011

pump

IS

mstalled

m

the

bottom

of

the

front

cover

as

shown

in

2

The

pump

is

held

m

place

by

four

bolts

to

the

front

cover

It

IS

a

rotor

type

dnven

by

the

011

pump

spmdle

whIch

IS

dnven

off

of

the

crankshaft

Pressure

IS

regulated

by

a

valve

shown

m

Figure

3

A

slot

at

the

top

of

the

dnve

rotor

engages

a

dog

clutch

at

the

lower

end

of

the

distnbutor

dnve

shaft

assembly

The

011

pressure

rehef

valve

IS

not

adjustable

In

the

released

pOSition

the

valve

pernnts

011

to

be

by

passed

through

a

passage

on

the

pump

cover

to

the

mlet

Side

of

the

pump

CD

CD

Oil

Pump

Removal

1

Remove

the

dIStnbutor

from

the

top

of

the

front

cover

Make

certam

to

mark

the

posItIon

of

the

dtstnbutor

relative

to

the

front

cover

so

that

It

can

be

replaced

m

the

same

posItIon

2

Drain

the

engme

od

3

Remove

the

front

stabIhzer

from

the

bottom

front

of

the

engme

compartment

4

Remove

the

front

splash

shIeld

from

the

bot

tom

front

of

the

engine

compartment

5

Remove

the

bolts

holdmg

the

oil

pump

to

the

front

cover

Remove

011

pump

and

drive

gear

spmdle

from

the

front

cover

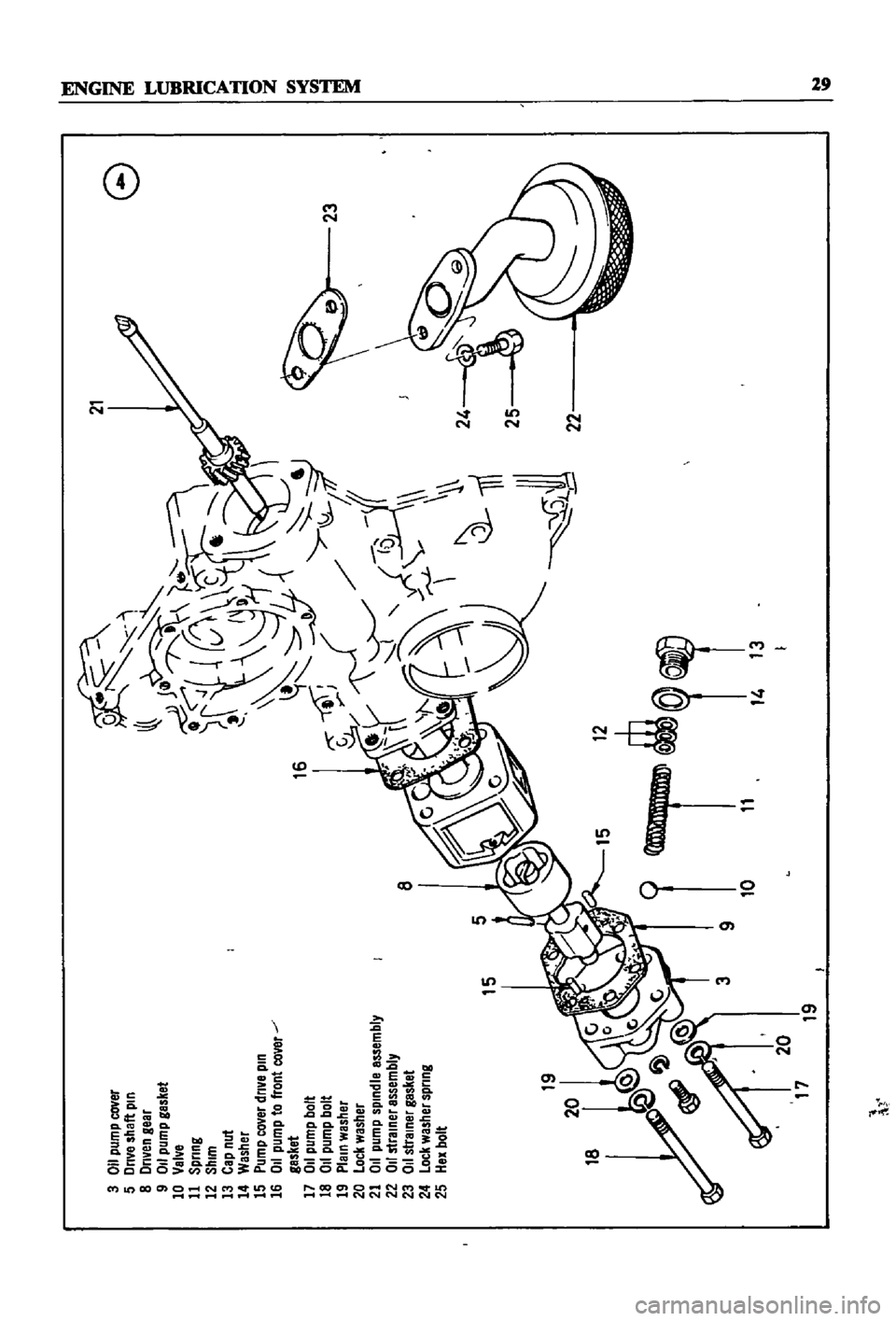

Disassembly

Inspection

Repair

and

Assembly

Figure

4

IS

an

exploded

VIew

of

the

011

pump

assembly

Refer

to

the

figure

and

the

accom

panymg

index

1

Separate

the

body

cover

from

the

011

pump

body

by

unscreWIng

the

secunng

bolt

2

Remove

the

pump

dnve

mechamsm

and

dnver

gear

from

the

pump

body

Clean

the

dIS

assembled

parts

m

a

suitable

solvent

3

Inspect

for

Signs

of

wear

or

damage

Reparr

or

replace

as

necessary

4

Inspect

the

drive

rotor

shaft

for

excessive

wear

or

sconng

Check

the

followmg

clearances

a

Side

clearance

between

mner

and

outer

rotor

00020

to

00047

m

005

to

0

12mm

b

Tip

clearance

0

0492

m

0

12mm

c

elearance

between

outer

rotor

and

body

00059

to

0

0083

in

015

to

0

21mm

5

Check

the

relief

valve

spring

dtmenslOn

to

ensure

that

It

has

not

lost

tension

Free

length

should

be

2

24

m

57mm

Compressed

length

Page 34 of 252

21

G

3

011

pum

p

cover

5

Drive

shaft

pin

8

Driven

gear

9

011

pump

gasket

10

Valve

11

Spring

12

Shim

13

Cap

nut

14

Washer

15

Pump

cover

drive

pin

16

011

pump

to

front

cover

gasket

17

011

pump

bolt

18

011

pump

bolt

19

Plain

washar

20

Lock

washer

21

011

pump

spindle

assembly

22

011

strainer

assembly

23

011

strainer

gasket

24

Lock

washer

spring

25

Hax

bolt

8

18

12

I

T

10

11

14

13

19

I

t

l

o

z

N

0

Page 35 of 252

30

CHAPTER

FIVE

should

be

1

54

m

39mm

If

the

spnng

tension

is

accurate

the

rehef

valve

should

open

at

54

0

to

59

7

lb

1m

3

8

to

4

2

kg

cm

6

Reassemble

the

oil

pump

Make

certain

all

gaskets

are

mounted

flat

to

avoid

leaks

7

Install

the

dnve

spindle

and

the

oil

pump

to

the

front

cover

8

Install

the

distnbutor

in

the

same

relative

locallon

from

which

it

was

removed

If

the

num

ber

1

cyhnder

was

at

top

dead

center

on

the

compression

stroke

the

punch

mark

on

the

dnve

spindle

should

face

toward

the

front

of

the

engine

9

Install

the

front

splash

shield

and

the

front

stablhzer

10

Insert

the

drain

plug

in

the

pan

and

refill

the

engme

11

Oil

pressure

at

idle

should

be

142

to

17

1

lb

lin

1

0

to

1

2

kg

cm

12

Tlghtenmg

torque

values

for

the

oil

pump

mounting

bolts

is

10

8

to

152ft

lb

1

5

to

2

1

kg

m

and

21

69

to

25

31

ft

lb

3

0

to

25

kg

m

for

the

release

valve

cap

nut

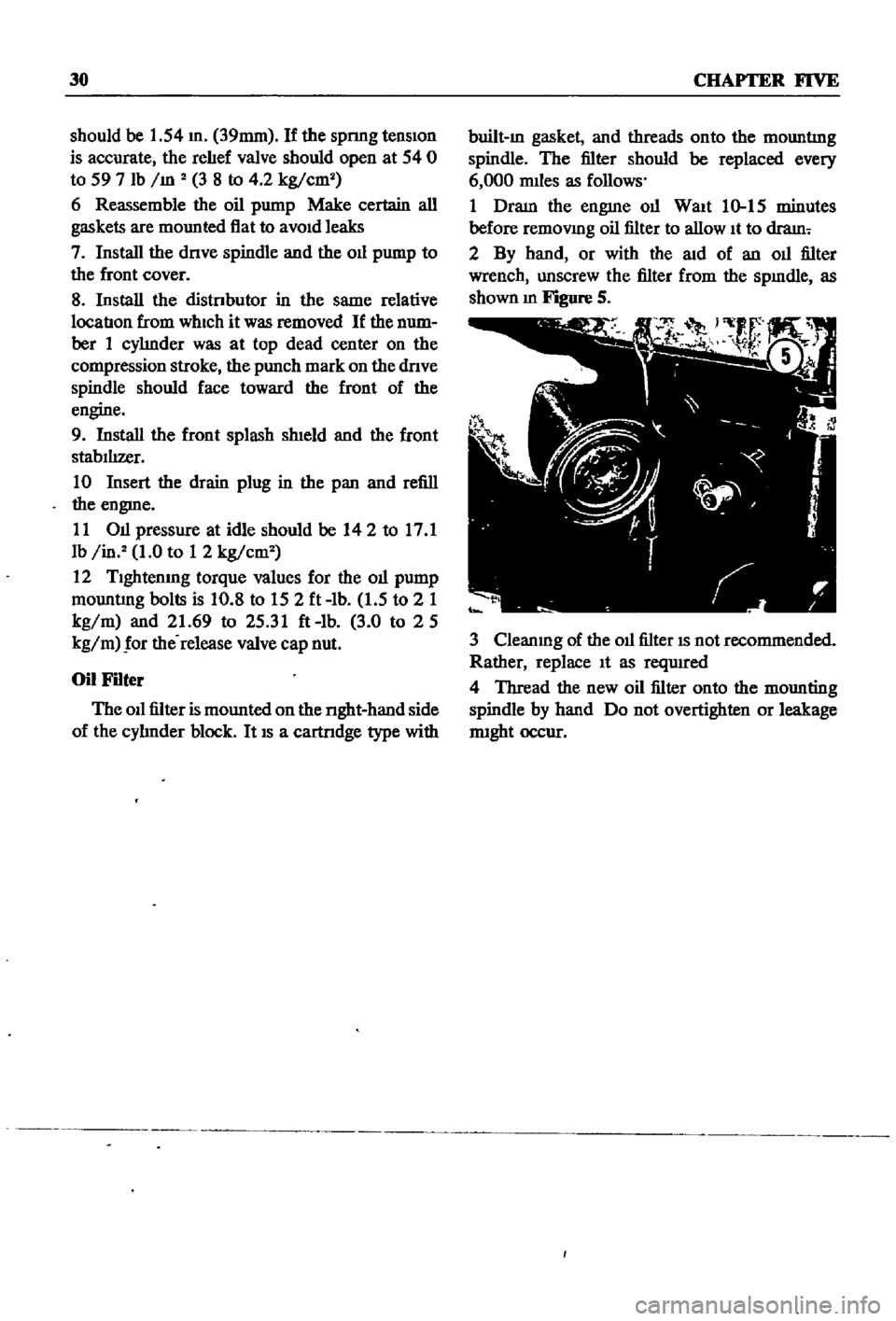

Oil

Filter

The

oil

filter

is

mounted

on

the

nght

hand

side

of

the

cyhnder

block

It

IS

a

cartndge

type

with

built

m

gasket

and

threads

onto

the

mounting

spindle

The

filter

should

be

replaced

every

6

000

miles

as

follows

1

Dram

the

engme

oil

Walt

10

15

minutes

before

removmg

oil

filter

to

allow

It

to

dram

2

By

hand

or

with

the

aid

of

an

oil

filter

wrench

unscrew

the

filter

from

the

spmdle

as

shown

m

Figure

S

3

Cleanmg

of

the

oil

filter

IS

not

recommended

Rather

replace

It

as

reqUIred

4

Thread

the

new

oil

filter

onto

the

mounting

spindle

by

hand

Do

not

overtighten

or

leakage

nught

occur

Page 36 of 252

CHAPTER

SIX

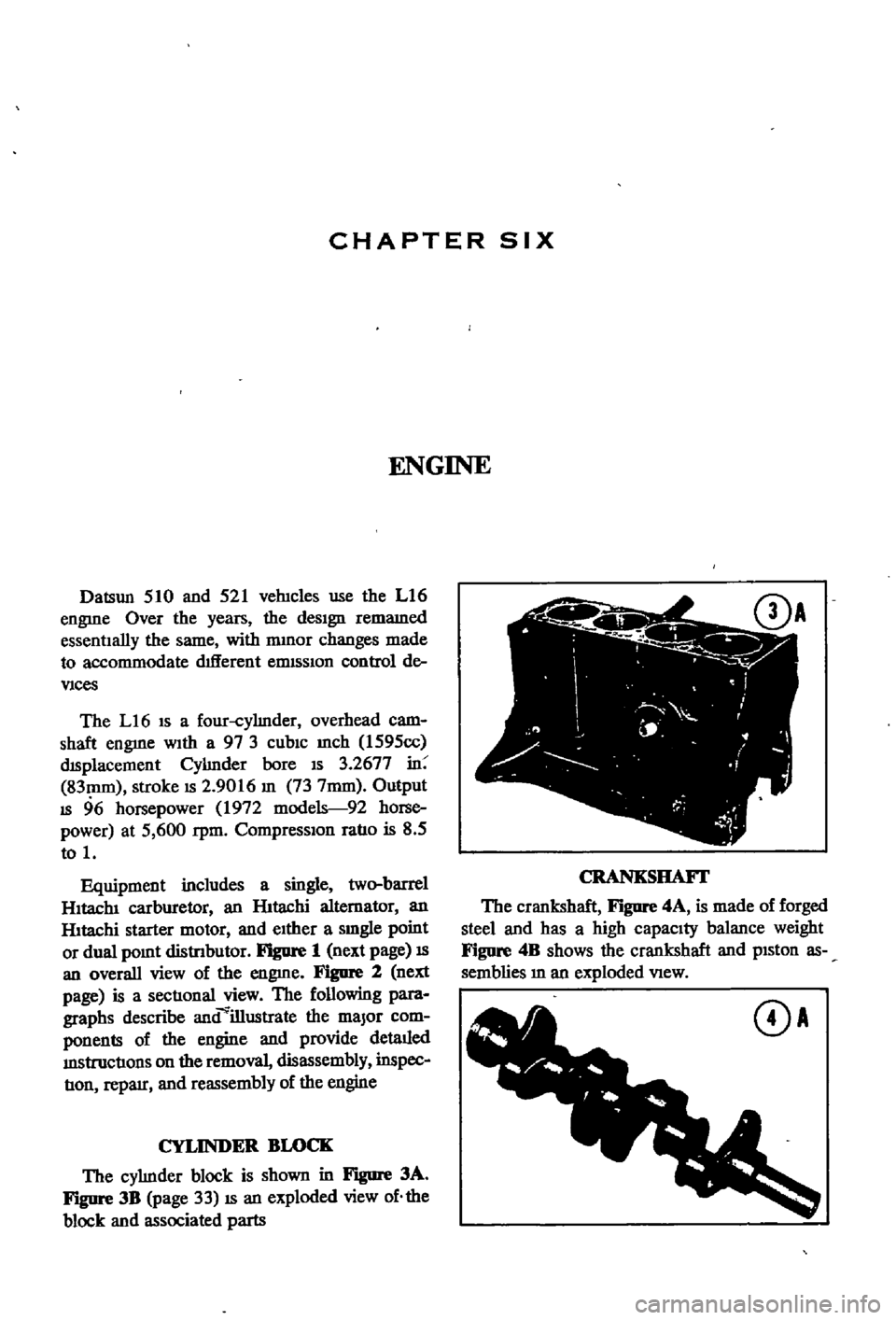

ENGINE

Datsun

510

and

521

veJucles

use

the

L16

engme

Over

the

years

the

deSign

remamed

essentIally

the

same

with

nunor

changes

made

to

accommodate

drlIerent

elIDSSlon

control

de

VIces

The

Ll6

IS

a

four

cylmder

overhead

cam

shaft

engme

With

a

97

3

cubic

mch

1595cc

dISplacement

Cylmder

bore

IS

3

2677

in

83mm

stroke

IS

2

9016

m

73

7mm

Output

IS

96

horsepower

1972

mode1s

92

horse

power

at

5

600

rpm

Compression

ratIo

is

8

5

to

1

Equipment

includes

a

single

two

barrel

Hltaclu

carburetor

an

HItachi

alternator

an

HItachi

starter

motor

and

either

a

smgle

point

or

dual

pomt

distnbutor

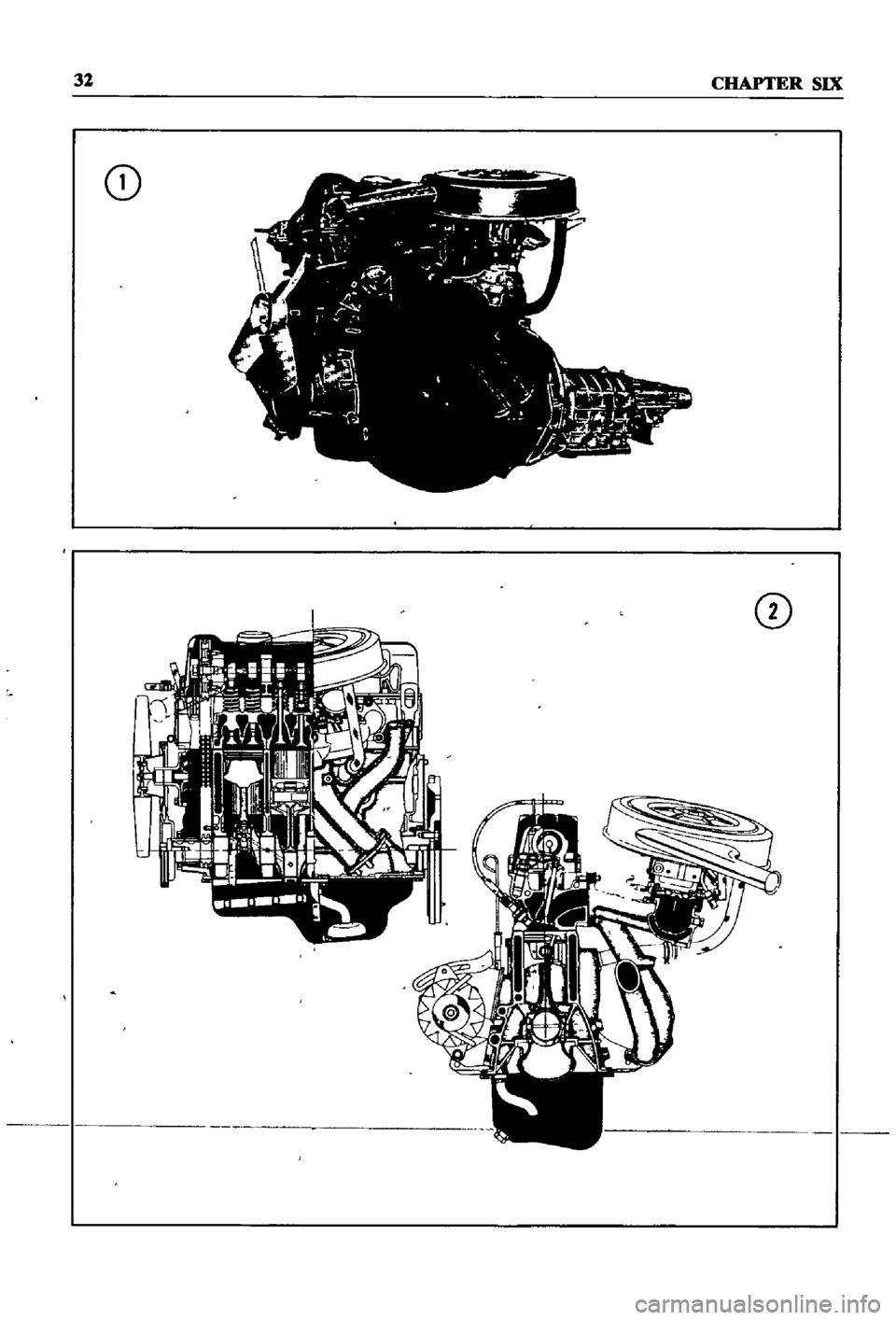

Figure

1

next

page

IS

an

overall

view

of

the

engme

Figure

2

next

page

is

a

sectIonal

view

The

following

para

graphs

describe

and

illustrate

the

major

com

ponents

of

the

engine

and

provide

detaIled

InStructIons

on

the

removal

disassembly

inspec

tIon

reparr

and

reassembly

of

the

engine

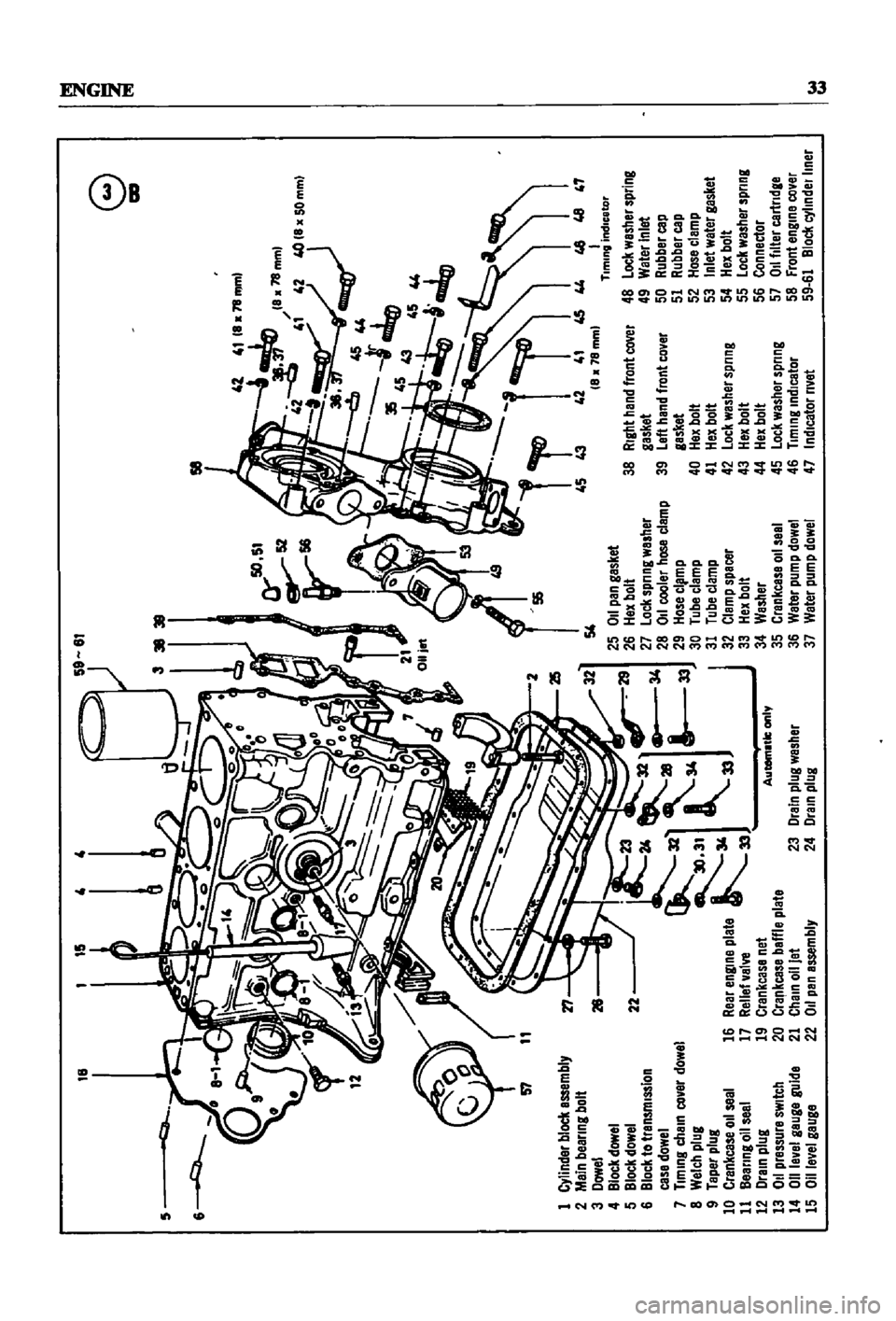

CYLINDER

BLOCK

The

cylmder

block

is

shown

in

Figure

3A

Figure

3B

page

33

IS

an

exploded

view

of

the

block

and

associated

parts

CRANKSHAFI

The

crankshaft

F

JgUre

4A

is

made

of

forged

steel

and

has

a

high

capacity

balance

weight

Figure

4B

shows

the

crankshaft

and

pISton

as

semblies

m

an

exploded

VIew

DA

Page 37 of 252

32

CHAPTER

SIX

CD

CD

Page 38 of 252

4l

4111a

78

mml

la78mml

42

4

42

4OIla50mml

t

4544

i

35

45

lIq

D

1

43

45

44

6

1i

45

43

42

41

45

44

46

46

47

8

78mml

I

Tlmmg

Indicator

48

lock

washer

spring

49

Water

Inlet

50

Rubber

cap

51

Rubber

cap

52

Hosa

clamp

53

Inlet

watar

gasket

54

Hex

bolt

55

lock

washer

spring

56

Connector

57

011

filter

cartndge

58

front

engme

cover

59

61

Bloel

cyllndelllner

18

15

58

57

1

Cylinder

block

assembly

2

Main

beanng

bolt

3

Dowel

4

Block

dowel

5

Block

dowel

6

Block

to

transmIssIon

case

dowel

7

Tlmmg

chaIn

covar

dowel

8

Welch

plug

9

Taper

plug

10

Crankcase

011

seal

11

Bearing

011

seal

12

Drain

plug

13

011

pressure

sWitch

14

011

level

gauge

guide

15

Oll

evel

gauga

r1

26

54

25

011

pan

gasket

26

Hax

bolt

27

lock

Sprl

ng

washer

28

011

cooler

hose

clamp

29

Hose

cl

mp

30

Tube

clamp

31

Tube

clamp

32

Clamp

spacer

33

Hex

bolt

34

Washer

35

Crankcase

011

seel

36

Waler

pump

dowel

37

Water

pump

dowel

38

RIght

hand

front

caver

gasket

39

left

hand

front

cover

gasket

40

Hex

bolt

41

Hex

bolt

42

lock

washer

spnng

43

Hex

bolt

44

Hex

bolt

45

Lock

washer

spring

46

Tlmmg

Indicator

47

IndIcator

rivet

22

16

23

Drain

plug

washer

24

Dram

plug

e

l

lIlI

1M

1M

Page 39 of 252

34

CHAPTER

SIX

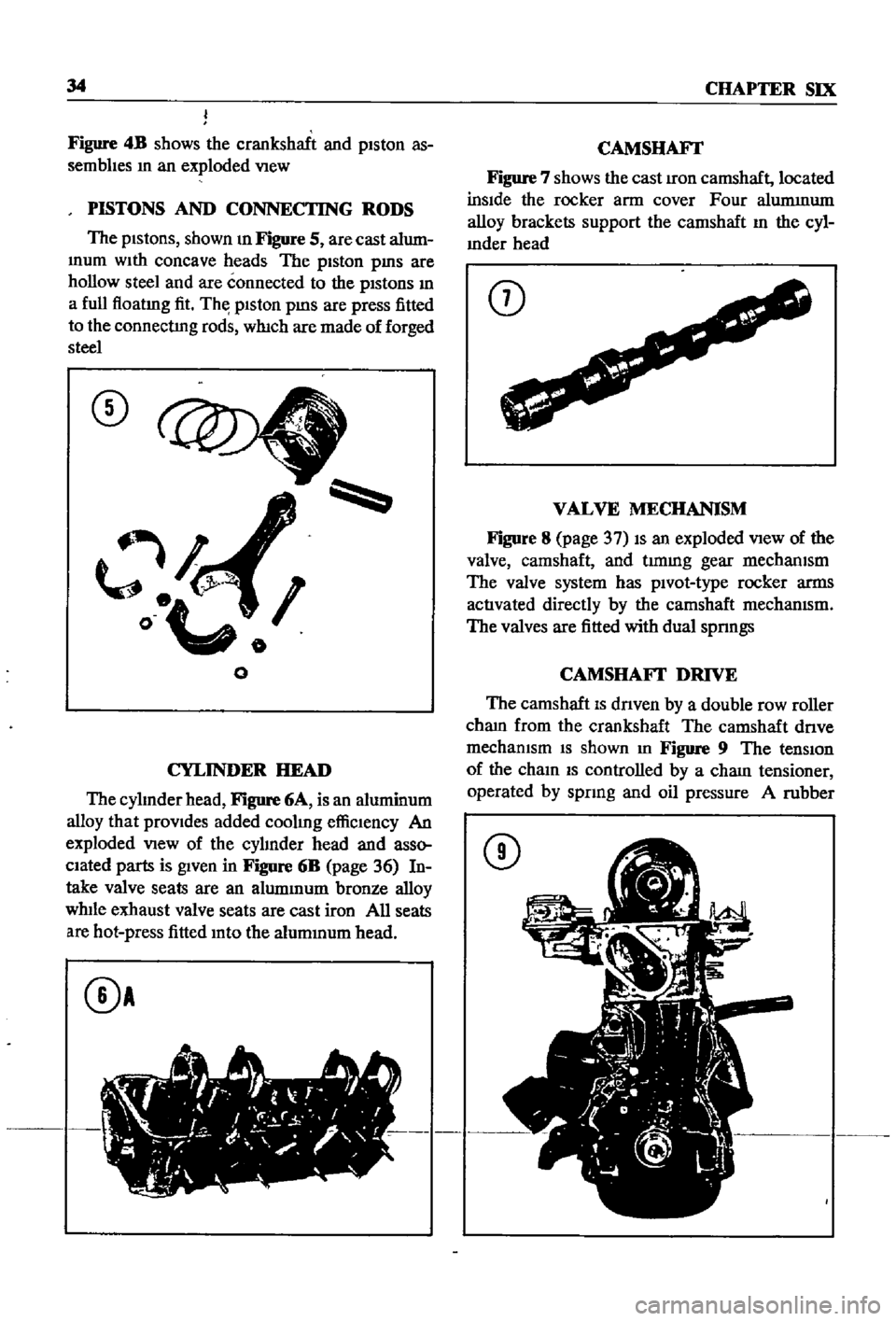

Figure

4B

shows

the

crankshaft

and

piston

as

semblIes

m

an

exploded

VIew

PISTONS

AND

CONNECTING

RODS

The

pistons

shown

m

Figure

5

are

cast

alum

mum

With

concave

heads

The

piston

pms

are

hollow

steel

and

are

connected

to

the

pistons

m

a

full

floatmg

fit

Th

piston

pms

are

press

fitted

to

the

connectIng

rods

which

are

made

of

forged

steel

CD

l

o

o

o

CYLINDER

HEAD

The

cylInder

head

Figure

6A

is

an

aluminum

alloy

that

provides

added

coolmg

effiCiency

An

exploded

VIew

of

the

cylInder

head

and

asso

ciated

parts

is

given

in

Figure

6B

page

36

In

take

valve

seats

are

an

alummum

bronze

alloy

while

exhaust

valve

seats

are

cast

iron

All

seats

are

hot

press

fitted

mto

the

alummum

head

0A

CAMSHAFr

Figure

7

shows

the

cast

Iron

camshaft

located

inSide

the

rocker

arm

cover

Four

alummum

alloy

brackets

support

the

camshaft

m

the

cyl

mder

head

CD

VALVE

MECHANISM

Figure

8

page

37

IS

an

exploded

VIew

of

the

valve

camshaft

and

t1mmg

gear

mechanism

The

valve

system

has

pivot

type

rocker

arms

activated

directly

by

the

camshaft

mechanIsm

The

valves

are

fitted

with

dual

spnngs

CAMSHAFI

DRIVE

The

camshaft

IS

dnven

by

a

double

row

roller

cham

from

the

crankshaft

The

camshaft

dnve

mechanIsm

IS

shown

m

Figure

9

The

tensIOn

of

the

cham

IS

controlled

by

a

cham

tensioner

operated

by

spnng

and

oil

pressure

A

rubber

CD

Page 40 of 252

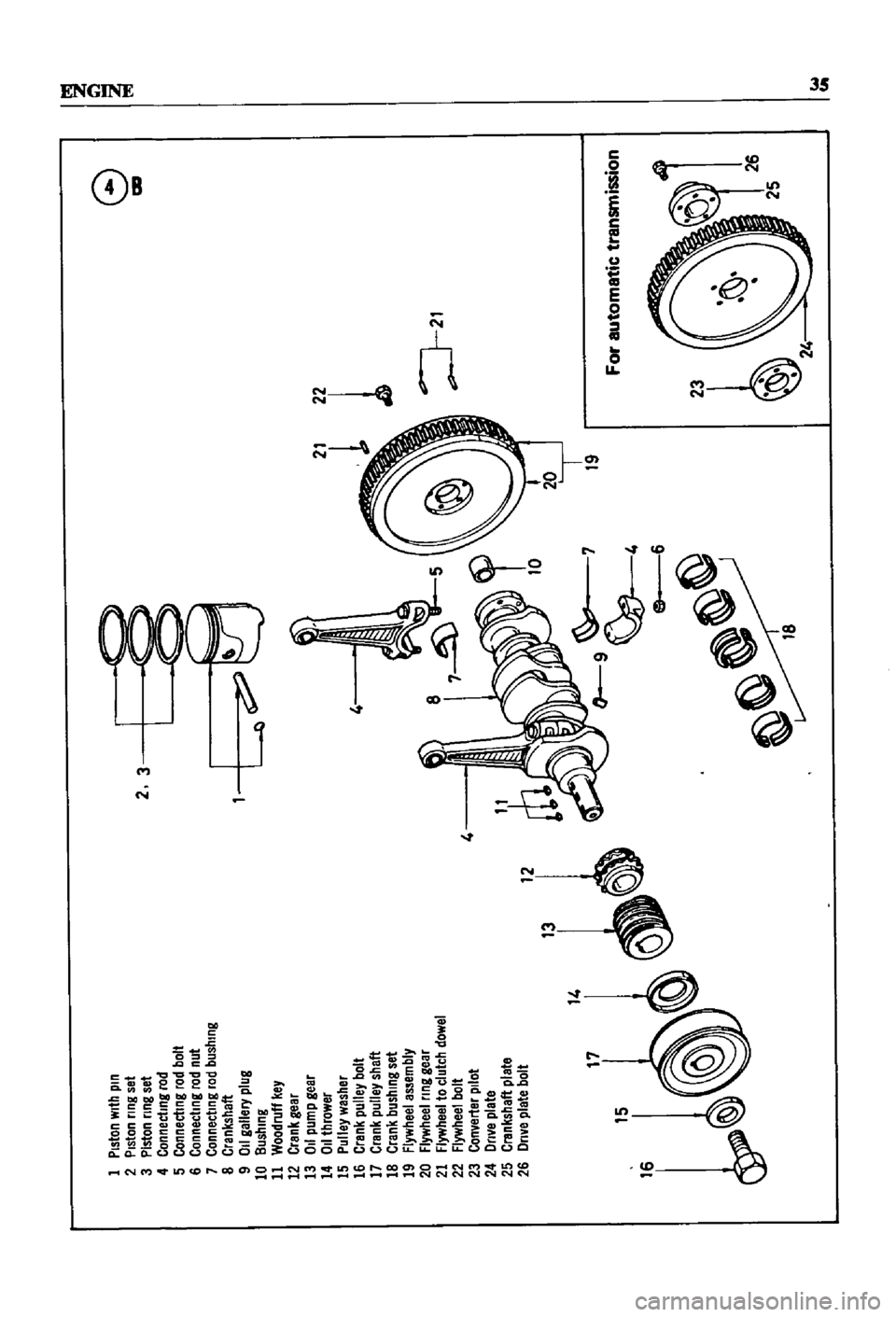

I

Piston

with

pin

2

Piston

nng

set

3

Piston

nng

set

4

Connecting

rod

5

Connecting

rod

bolt

6

Connecting

rod

nut

7

Connecting

rod

bushing

8

Crankshaft

9

011

gallery

plug

10

Bushing

11

Woodruff

key

12

Crank

gear

13

011

pump

gear

14

OJlthrower

15

Pulley

washer

16

Crank

pulley

bolt

17

Crank

pulley

shaft

18

Crank

bushing

set

19

Flywheel

assembly

20

Flywheel

nng

gear

21

Flywheel

to

clutch

dowel

22

Flywheel

bolt

4

23

Converter

pilot

24

Dnve

plate

25

Crankshaft

plate

26

Dnve

plate

bolt

13

I

14

17

15

2

3

l

L

4

8

9

6

19

1

J

21

2

24

8

ICD

I

For

automatic

transmission

W

lit